Device and method for preparing high-toughness cast aluminum-based composite material

An aluminum-based composite material and a composite material technology are applied in the field of high-strength and toughness casting aluminum-based composite materials preparation devices, which can solve the problems of precipitation of volatile elements, difficulty in exerting their effects, serious material inhalation, etc., and achieve low investment costs and reduced costs. cost, the effect of reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

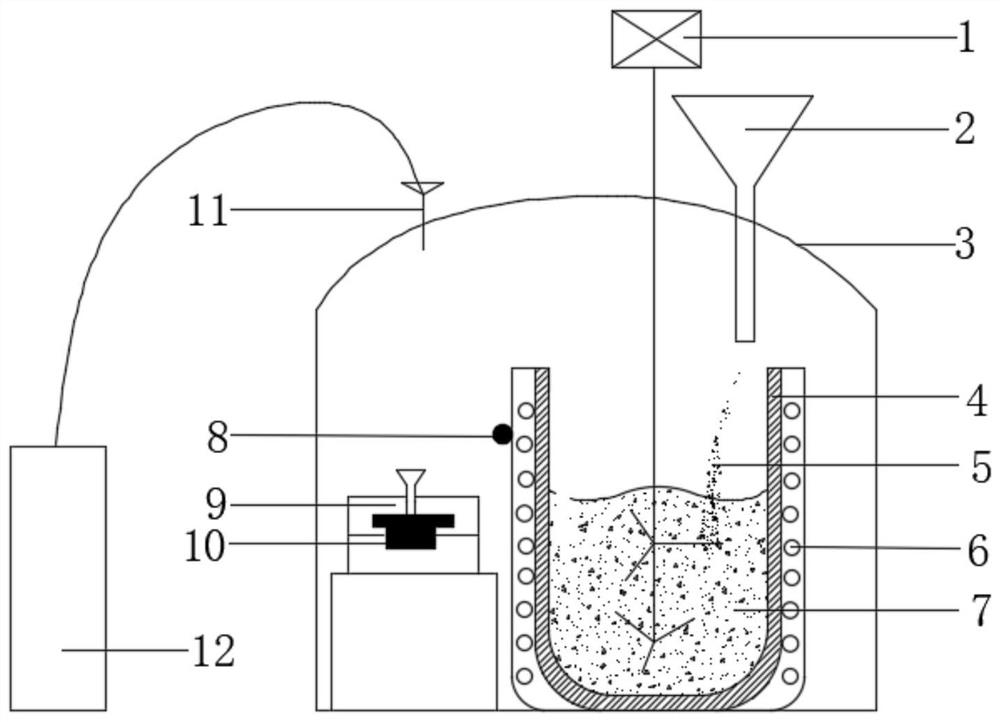

[0033] The method of preparing high-strength and tough aluminum matrix composite materials using the above-mentioned preparation device, the method mainly comprises the following steps and processes:

[0034] (1) Material design

[0035]The design principle is to separate the volatile elements from the non-volatile elements, the volatile elements include magnesium, zinc and lithium, and the non-volatile elements include aluminum, copper, silicon, manganese, nickel and iron. The elements that are not easy to volatilize are first smelted, the reinforced phase is added, the aluminum matrix composite material is prepared by strong shear stirring, and then the volatile element alloy is added to the aluminum matrix composite material, and the short-term stirring is carried out to promote the homogenization of the composition, and finally the high strength and toughness aluminum matrix composite material is obtained.

[0036] (2) Melting, melt treatment

[0037] The non-volatile alloyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com