Divided plate column for separating four-component mixture with controllable vapor phase distribution ratio

A technology of partition column and distribution ratio, applied in distillation separation, separation method, distillation purification/separation, etc., can solve the problems of high energy consumption, difficult control and high equipment cost for separating four-component mixture, and achieve remarkable separation effect. , Improve product quality and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

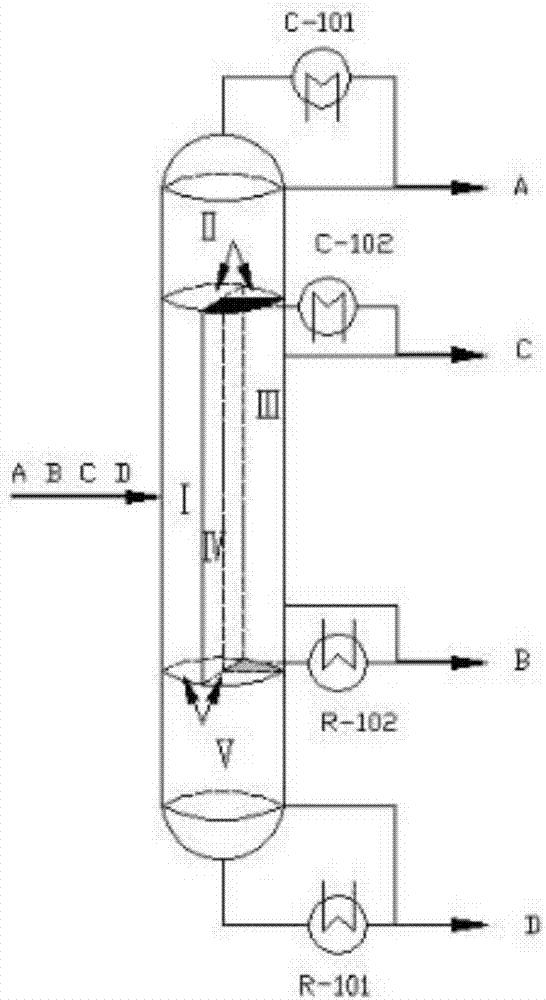

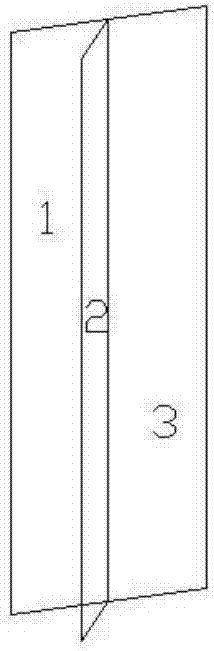

[0028]The divider column for separating the four-component mixture with controllable vapor phase distribution ratio in this embodiment includes a public rectification section II and a public stripping section V, wherein the public rectification section II is located at the top of the tower, and the top of the tower is connected to the first condenser C -101, the public stripping section V is located at the bottom of the tower, and the bottom of the tower is connected to the first reboiler R-101; it is characterized in that there are three partitions along the direction of the tower diameter between the public rectifying section II and the public stripping section V Divided into three areas, including pre-fractionation section I, main column section I III and main column section II IV, the pre-fractionation section I is surrounded by the first partition 1, the third partition 3 and the outer wall of the partition column , with a feed inlet; the main tower section Ⅲ is surrounded...

Embodiment 2

[0042] The structure of the partition tower in this embodiment is the same as in Embodiment 1, and the four-component mixture to be separated is still a mixture of pentane, hexane, heptane and octane. The difference is that the angle α between the first partition 1 and the third partition 3 of the partition tower in this embodiment is 180°, the angle β between the first partition 1 and the second partition 2 is 50°, The angle γ between the second partition 2 and the third partition 3 is 130°.

[0043] The feed rate of the four-component mixture of pentane, hexane, heptane and octane to be separated is 50 kmol / h, and the molar ratio of pentane, hexane, heptane and octane is 1:2:1:1. The output of hexane is 20 kmol / h, and the output of heptane and octane is 10 kmol / h; the top reflux ratio is 7.2, the liquid phase distribution ratio is 0.381, and the vapor phase distribution ratio is 0.8; The condensed water (28 degree of condensed water of 7bar) consumption of condenser is 3250...

Embodiment 3

[0051] The structure of the partition tower in this embodiment is the same as in Embodiment 1, and the four-component mixture to be separated is still a mixture of pentane, hexane, heptane and octane. The difference is that the angle α between the first partition 1 and the third partition 3 of the partition tower in this embodiment is 190°, the angle β between the first partition 1 and the second partition 2 is 50°, The included angle γ between the second partition 2 and the third partition 3 is 120°.

[0052] The feed rate of the four-component mixture of pentane, hexane, heptane and octane to be separated is 60 kmol / h, and the molar ratio of pentane, hexane, heptane and octane is 1:2:2:1. The output of hexane and heptane is 20 kmol / h, and the output of octane is 10 kmol / h; the top reflux ratio is 7.2, the liquid phase distribution ratio is 0.43, and the vapor phase distribution ratio is 0.78; The condensed water (28 degree condensed water of 7bar) consumption of condenser i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com