Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Reduce tower height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

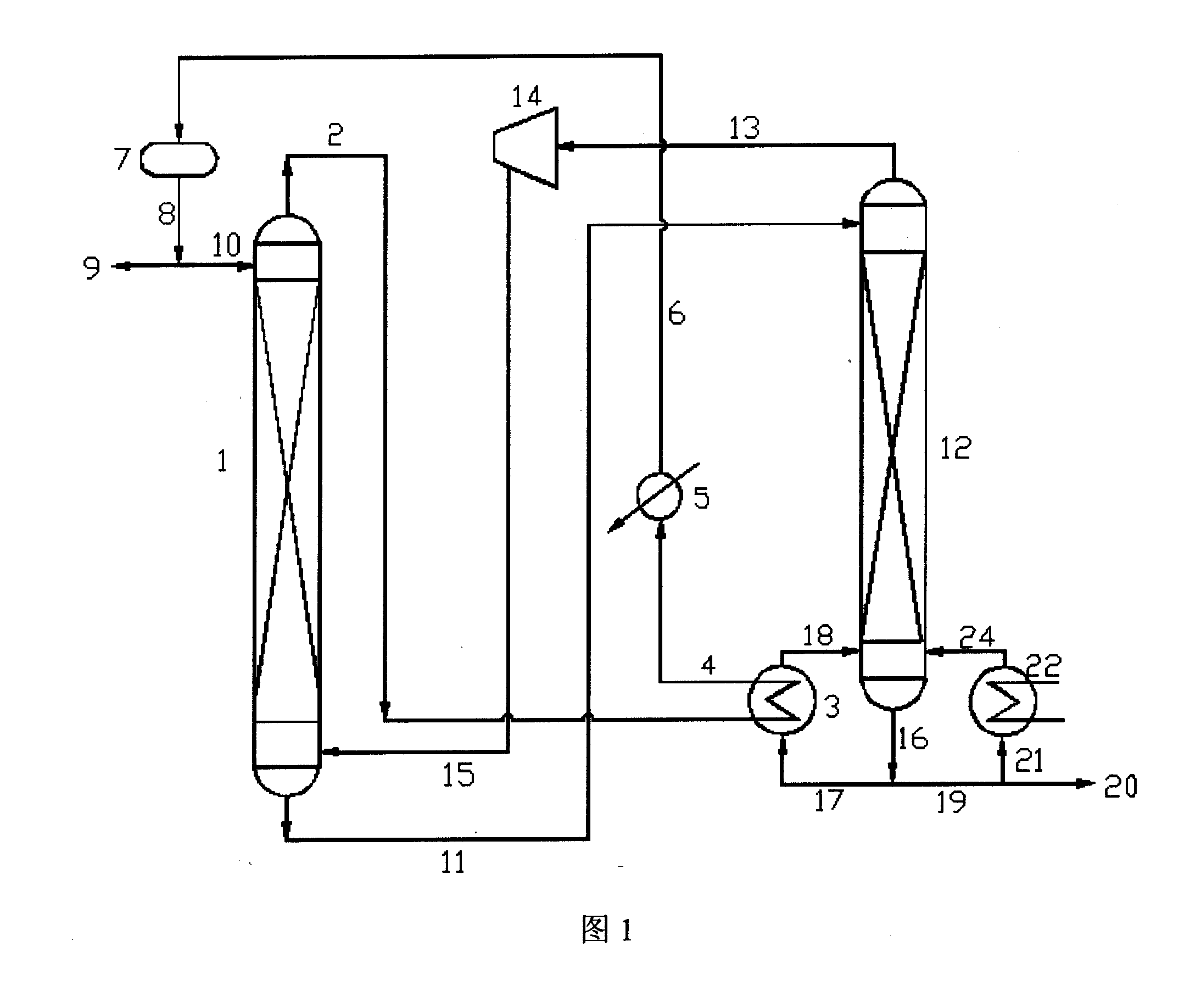

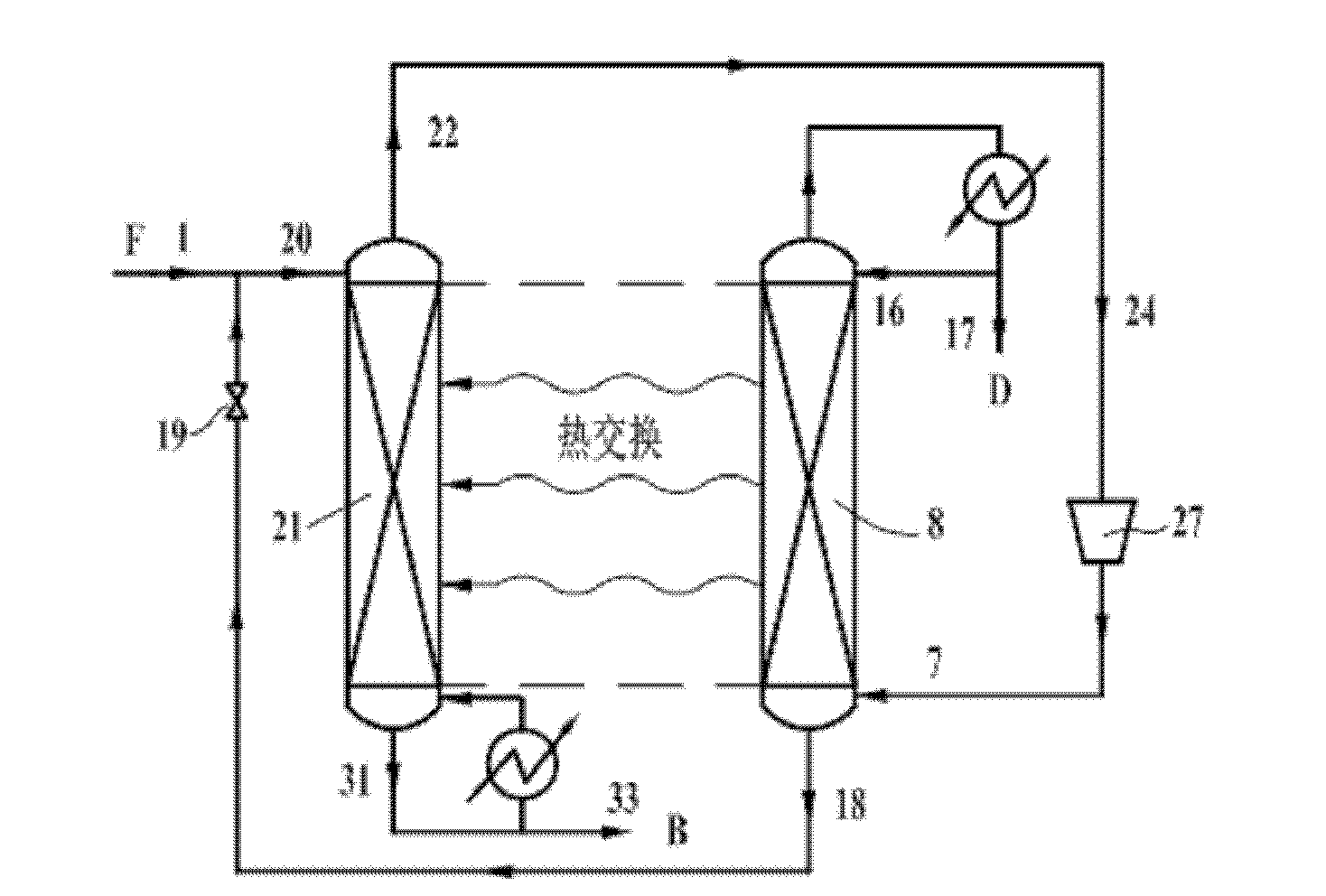

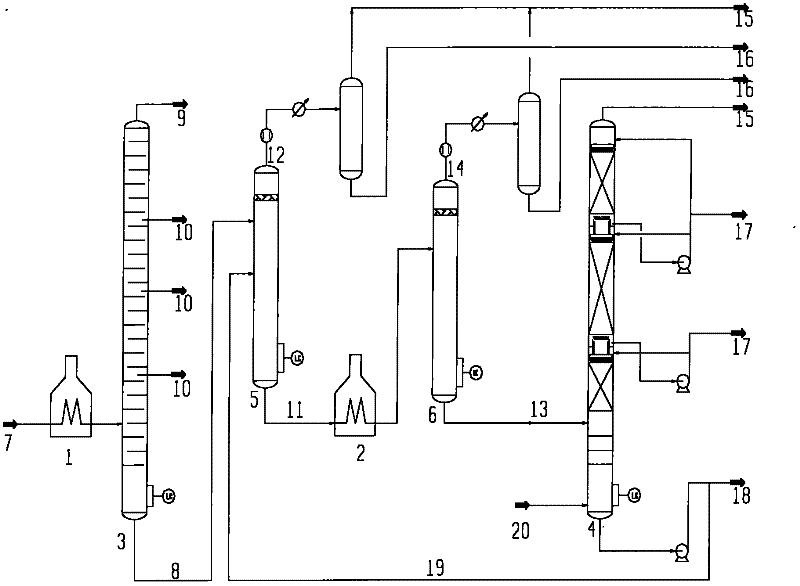

Differential pressure low-energy-consumption distillation method and equipment

ActiveCN101239247AAchieve rectificationMeet reboil requirementsFractional distillationRefluxDifferential pressure

The present invention provides a rectifying method having differential pressure and lower energy consumption, and an apparatus, including a general knockout tower section, a underpressure knockout tower section, a main reboiler, a reflux accumulator and a compressor, wherein , a compressor is set between the underpressure knockout tower section and the general knockout tower section, the gas material tube on the top of the underpressure knockout tower section is connected to the inlet of the compressor, the outlet of the compressor is connected to the gas inlet ont the bottom of the general knockout tower section; gas material outlet of the general knockout tower section is connected to the heat medium inlet of the main reboiler, heating medium outlet is connected to the reflux accumulator of the general knockout tower section; the liquid outlet on the bottom of the general knockout tower section is connected to the liquid inlet of the underpressure knockout tower section; the liquid material outlet tube on the bottom of the underpressure knockout tower section is connected to the cooling medium inlet of the main reboiler, outlet of the cooling medium is connected to the inlet of the reboiler of the underpressure knockout tower section. The invention realises thermally coupled distillation, matching heat exchange. The minimum heat consumption is realised by differential pressure temperature reduction means, even the cool-heat load are fully matched, the consumption is zero. Ways to achieve the aim only is adding a compressor in the equipment, the dynamic consumption is lower than the original consumption.

Owner:TIANJIN UNIV

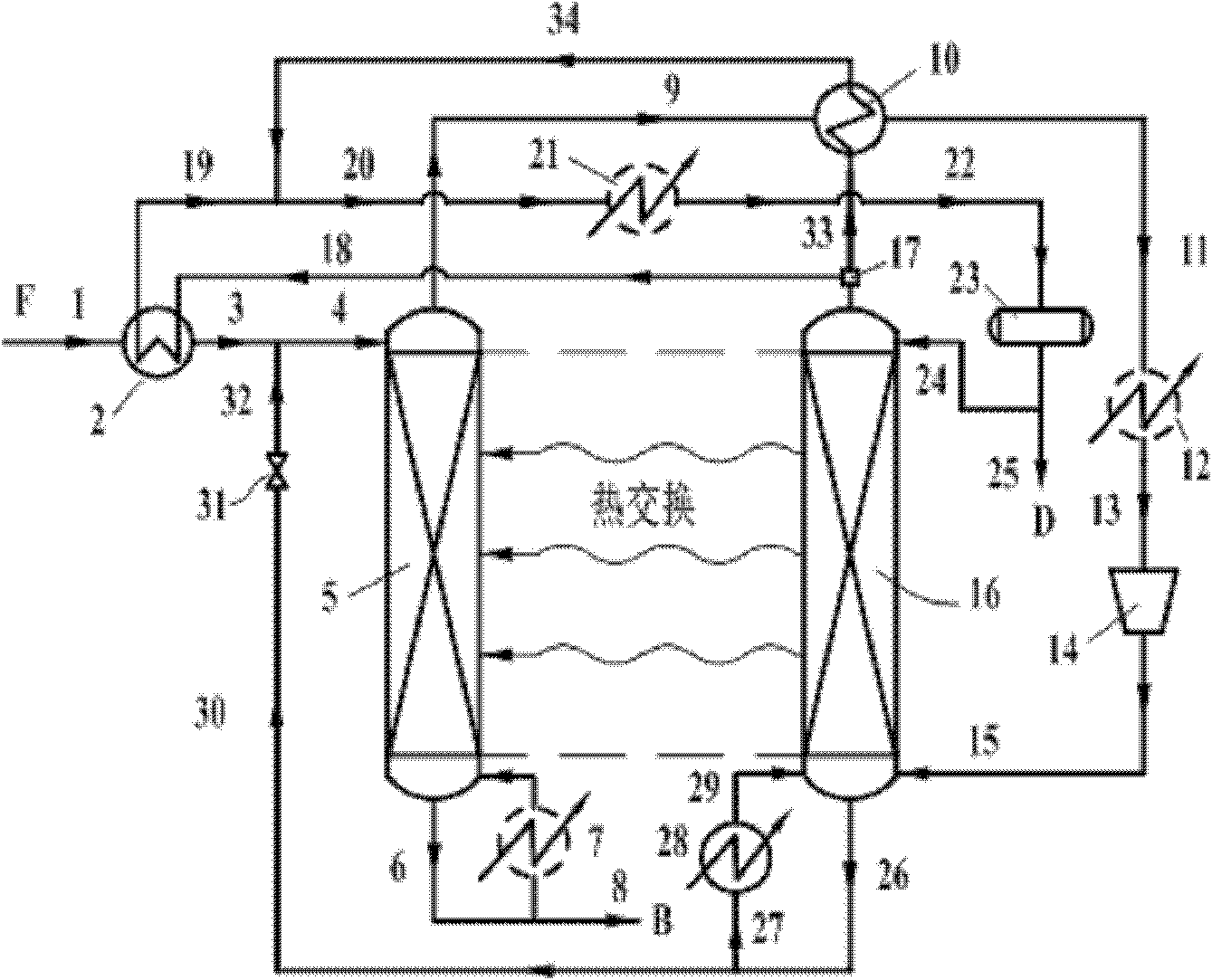

Rectifying section tower bottom reboiling internal heat-integrated energy-saving rectifying apparatus and method

InactiveCN101874935AReduce gas volumeReduced Compression Power ConsumptionDistillation regulation/controlFractional distillationReboilerEconomic benefits

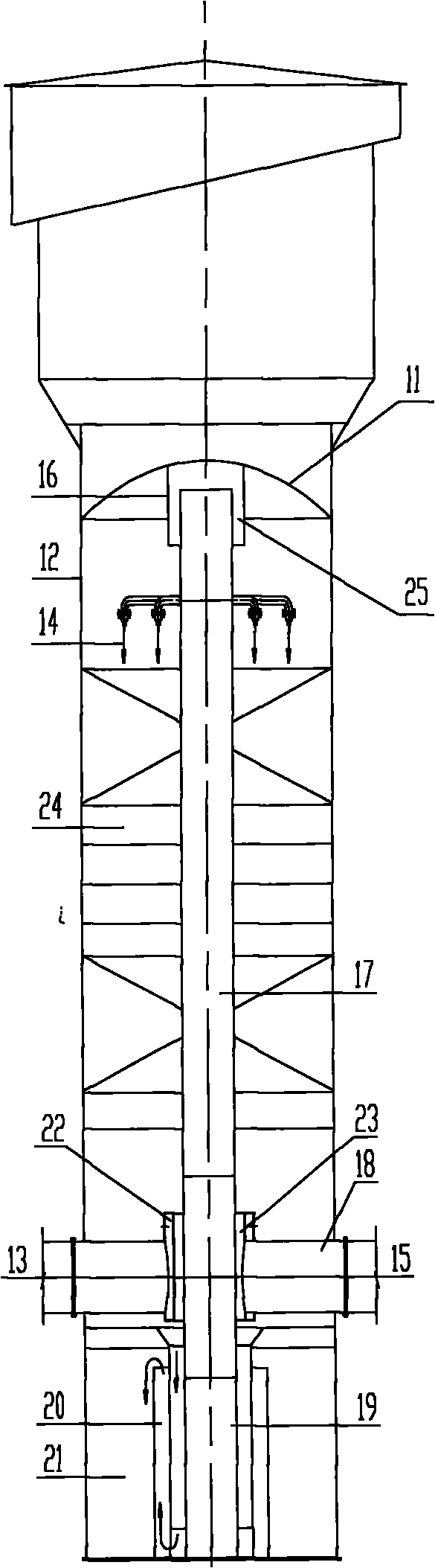

The invention relates to a rectifying section tower bottom reboiling internal heat-integrated energy-saving rectifying apparatus and a method. A main reboiler (28) is positioned at the tower bottom of a rectifying section (16); the tower bottom of a stripping section (5) is provided with an auxiliary reboiler (7); an auxiliary condenser (21) is arranged between a tower top gas outlet pipe and a tower top liquor condensate return pipe of the rectifying section; a feed preheater (2) is arranged at a feed position; and a gas overheater (10) and an auxiliary gas overheater (12) are arranged between a tower top steam outlet pipe of the stripping section and an inlet of a compressor (14). Compared with the traditional rectification separating method, the apparatus and the method can greatly reduce the total energy consumption of a whole rectifying tower system, the operation cost can be saved, and the purposes of energy saving and efficiency improvement can be achieved. Therefore, the rectifying section tower bottom reboiling internal heat-integrated energy-saving rectifying apparatus and the method can create great economic benefit and have a broad prospect in industrial application.

Owner:TIANJIN UNIV

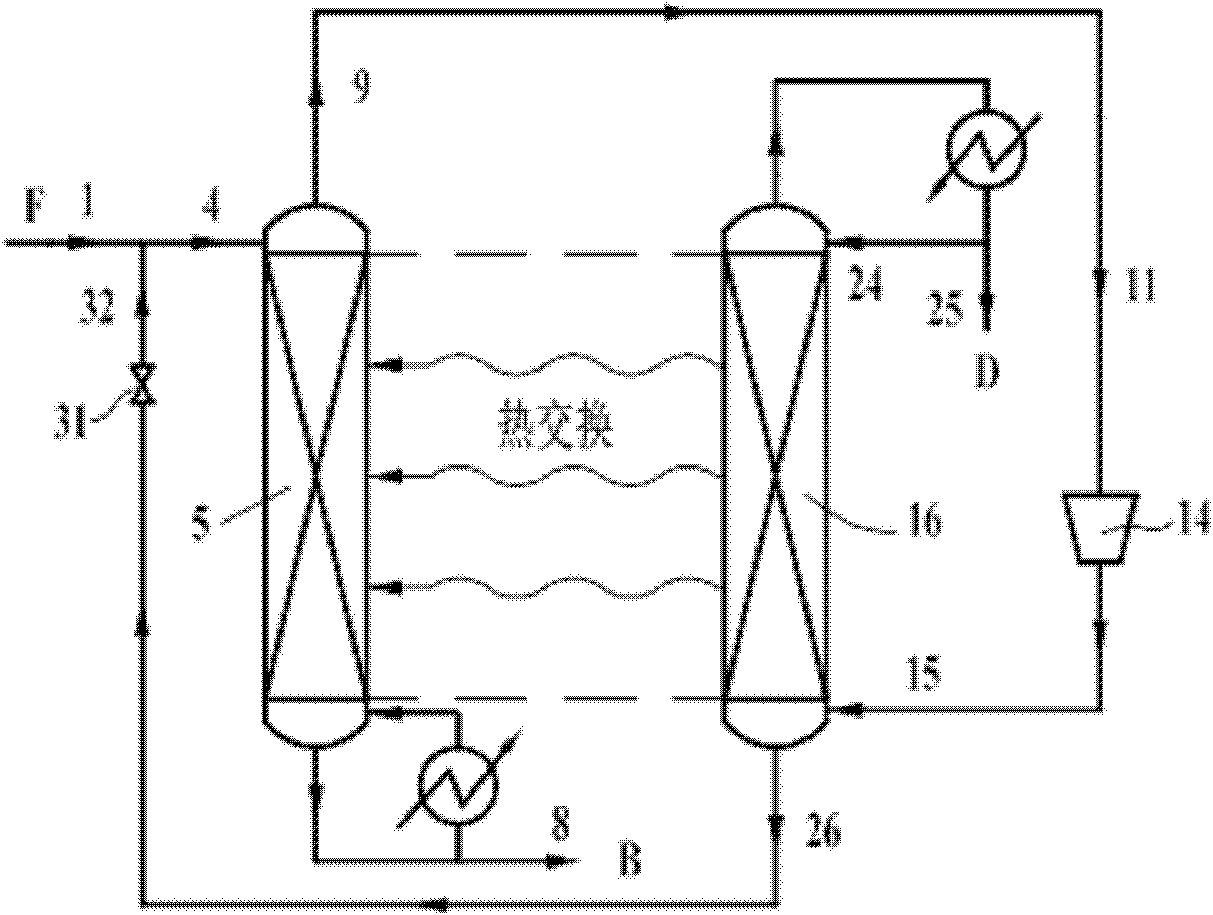

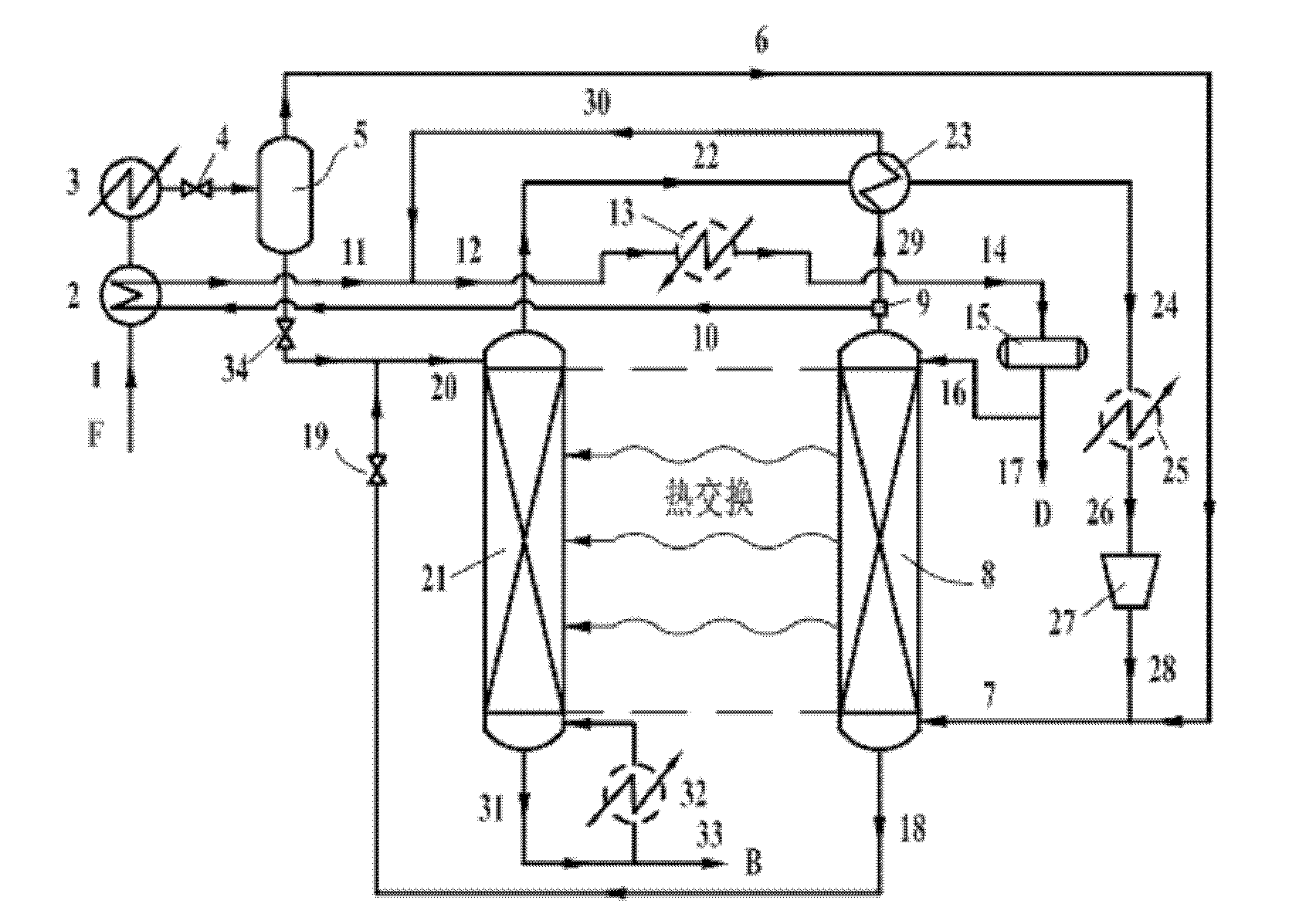

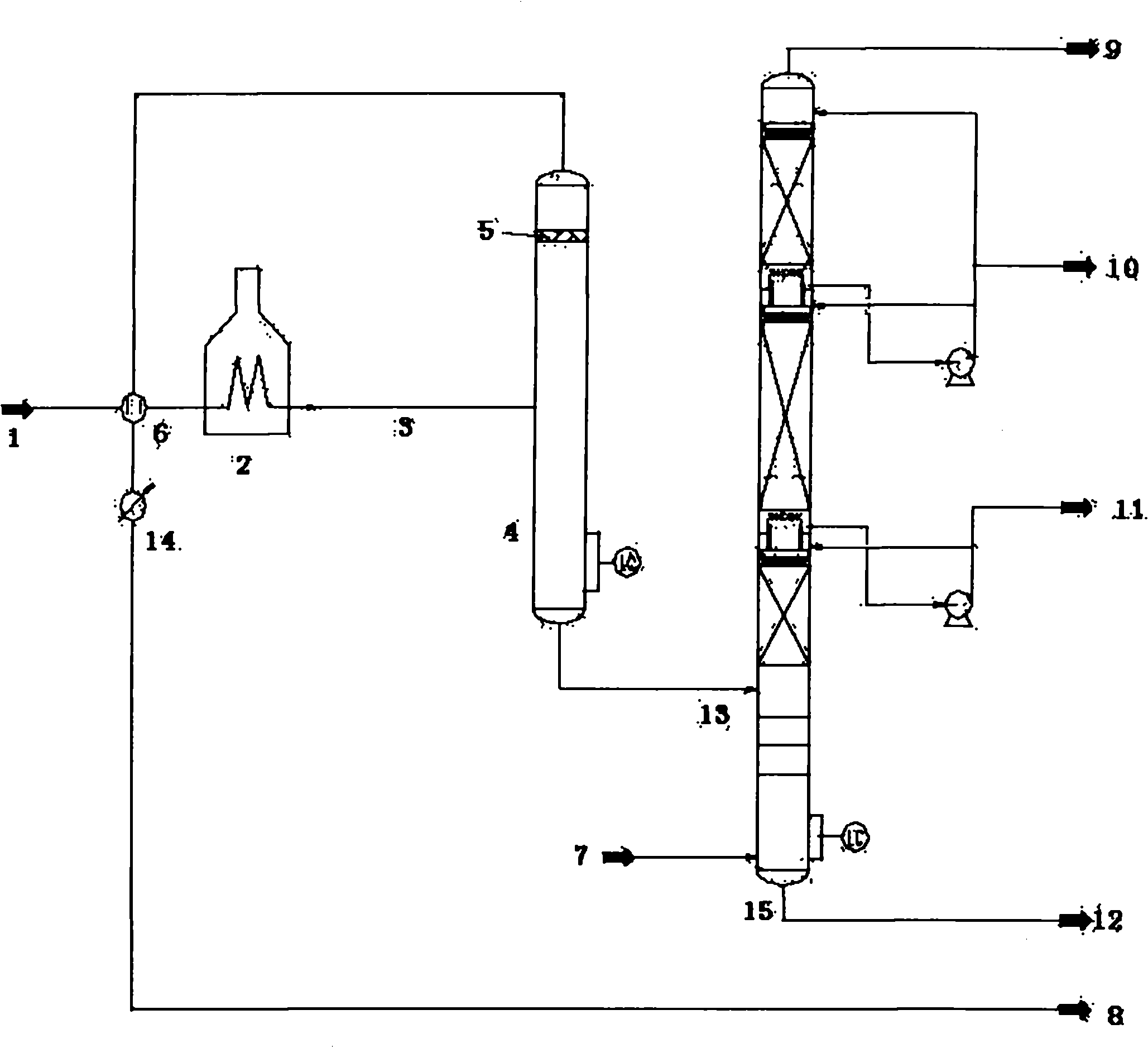

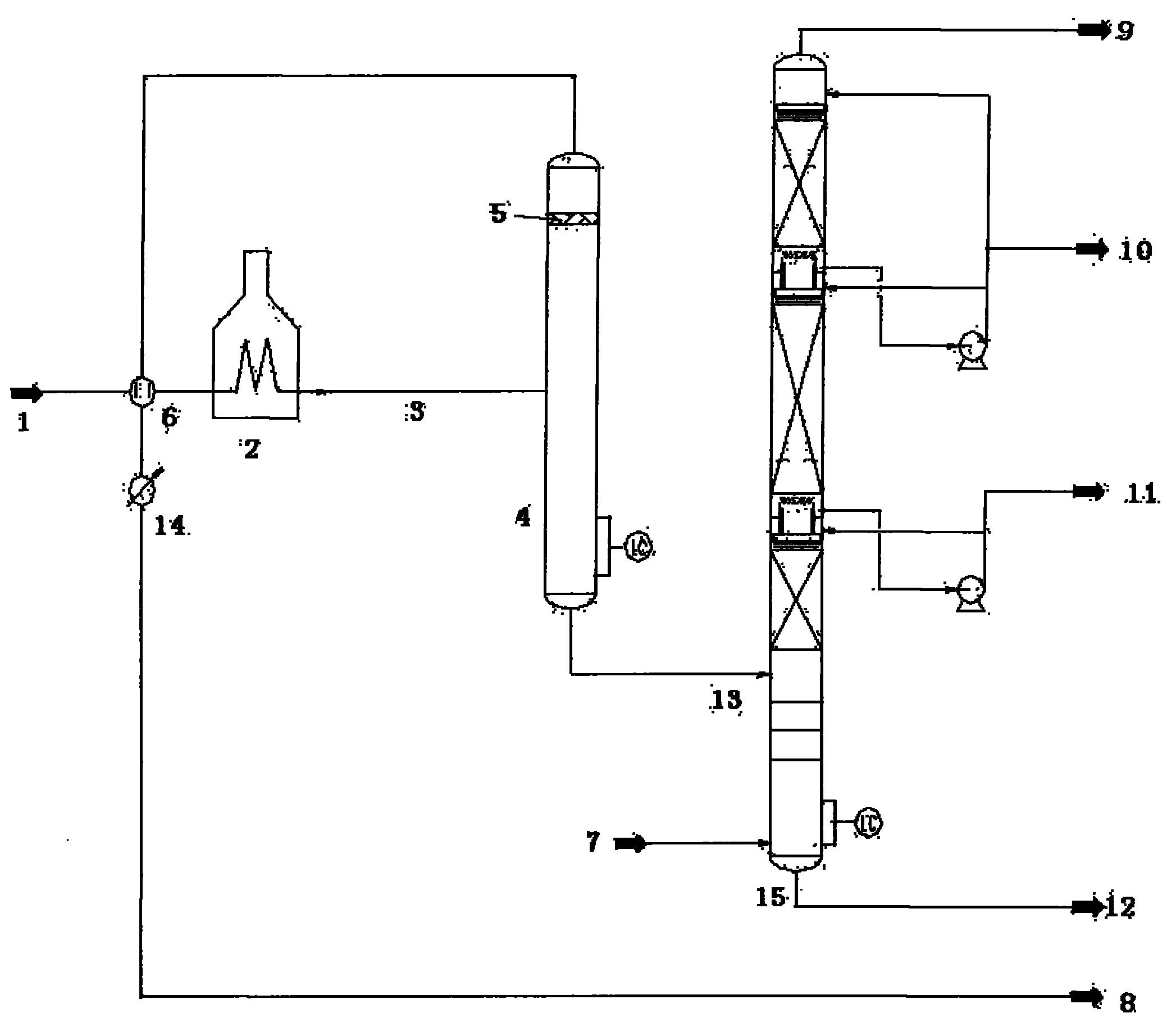

Flash evaporation feed type internal heat integration energy-saving rectifying device and method

InactiveCN101874934AReduce gas volumeReduced Compression Power ConsumptionDistillation regulation/controlFractional distillationVapor–liquid separatorReboiler

The invention relates to a flash evaporation feed type internal heat integration energy-saving rectifying device and a method, and the device comprises a system heat recovery heat exchanger, a feed preheater, a gas-liquid separator, a rectifying section, an auxiliary condenser, a stripping section, a compressor, an auxiliary reboiler and the like. The device is mainly characterized in that the gas-liquid separator is arranged on a feed pipeline; raw material liquid passes through the system heat recovery heat exchanger for heating and the feed preheater for further pre-heating and then enters into the gas-liquid separator; gas separated by the gas-liquid separator directly enters into tower bottom at the rectifying section, and liquid passes through a pressure reducing valve for reducing pressure and then enters into the top part of the stripping section; in addition, one part of saturated steam at tower top at the rectifying section is used for pre-heating fed materials, and the other part of the saturated steam is used for heating a gas overheater at the tower top at the stripping section. Compared with an ordinary internal heat integration rectifying tower, the adoption of the method and the device can greatly reduce the total energy consumption during the rectifying process, save operation cost and further achieve the purposes of energy conservation and synergy.

Owner:TIANJIN UNIV

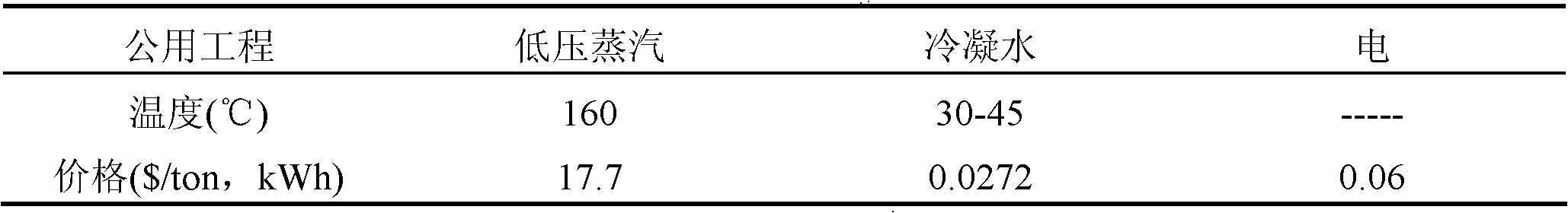

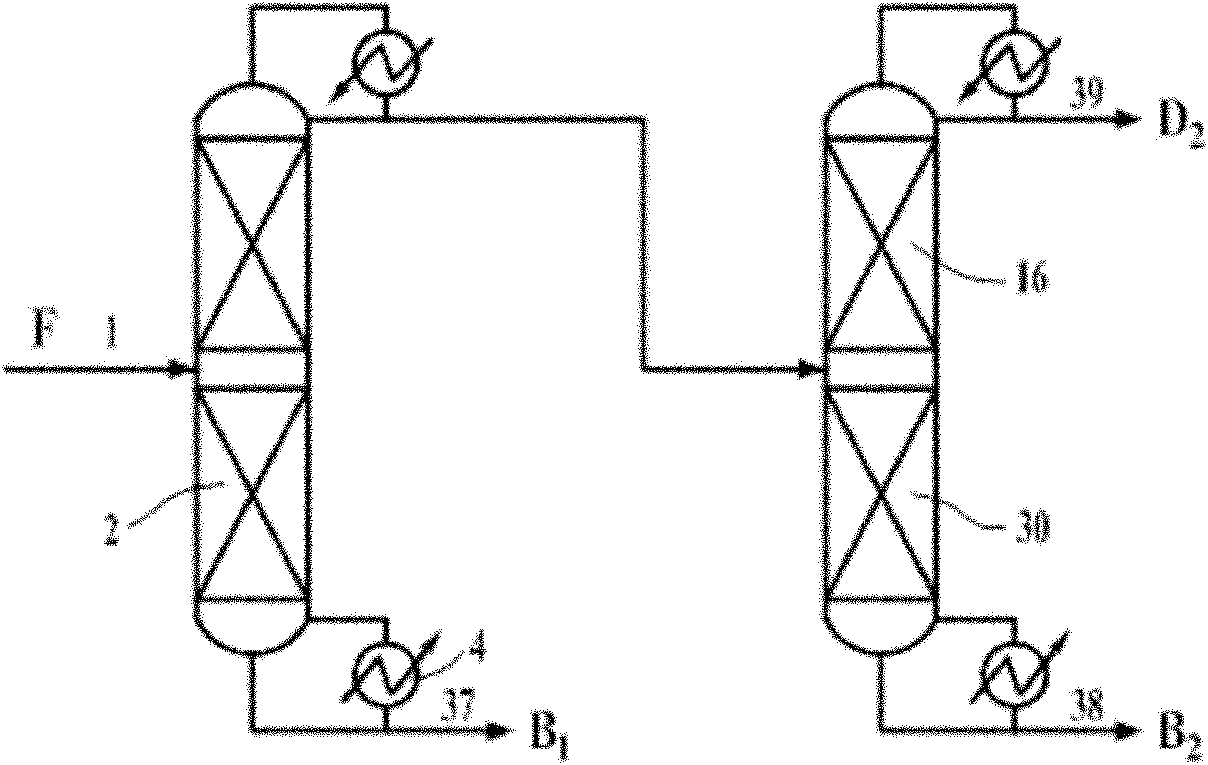

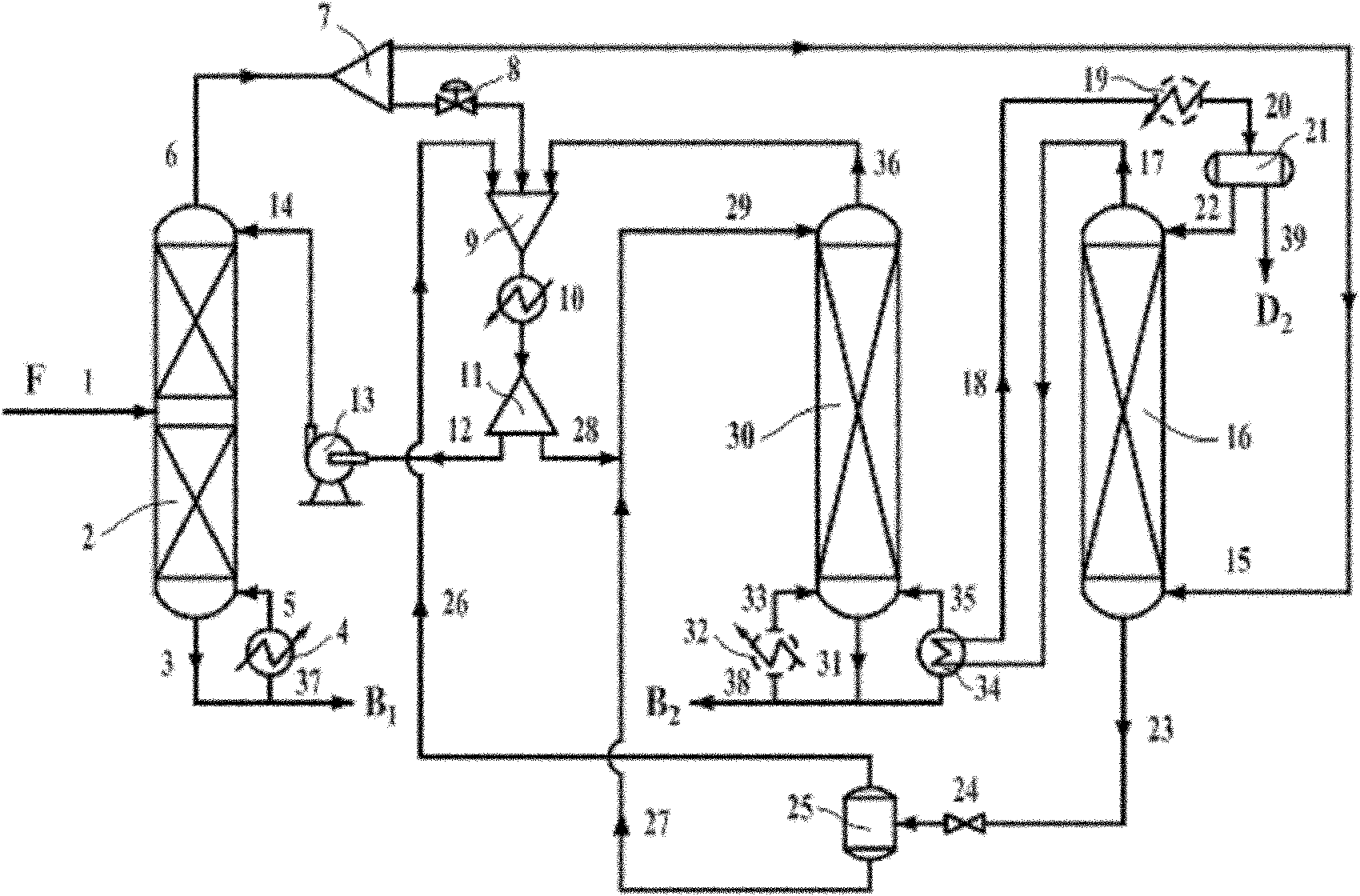

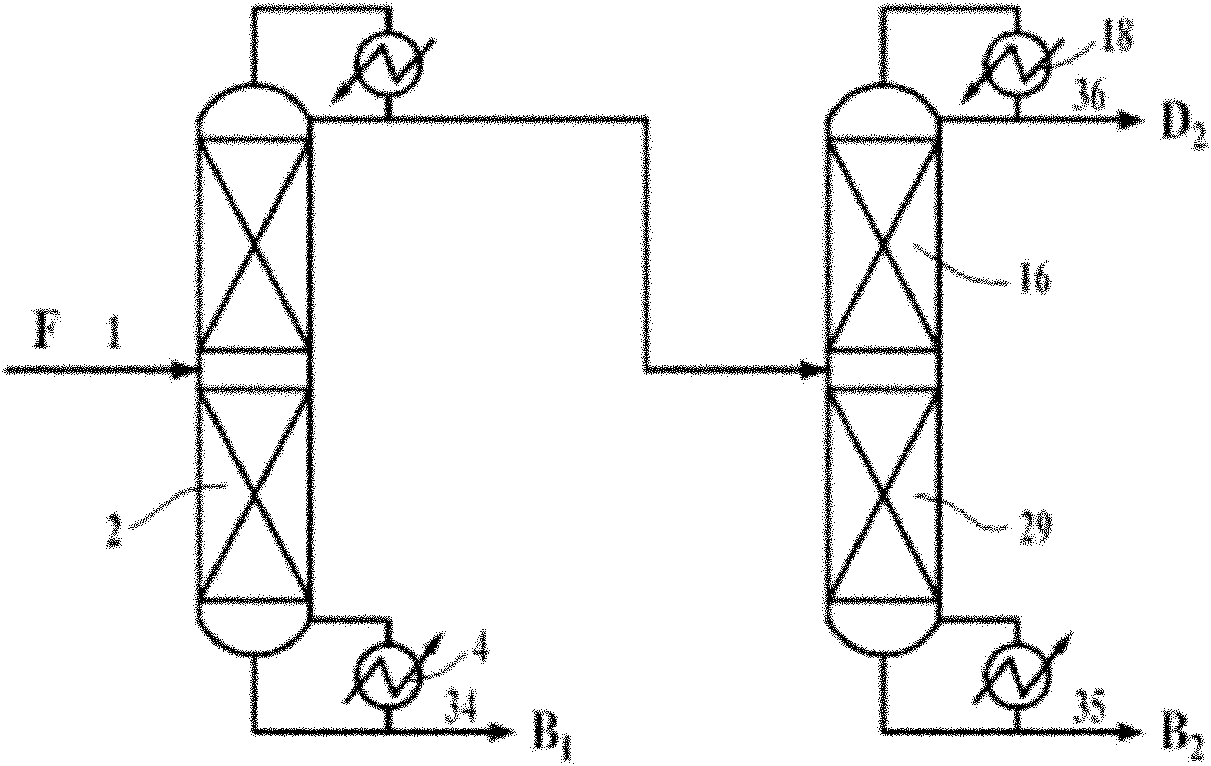

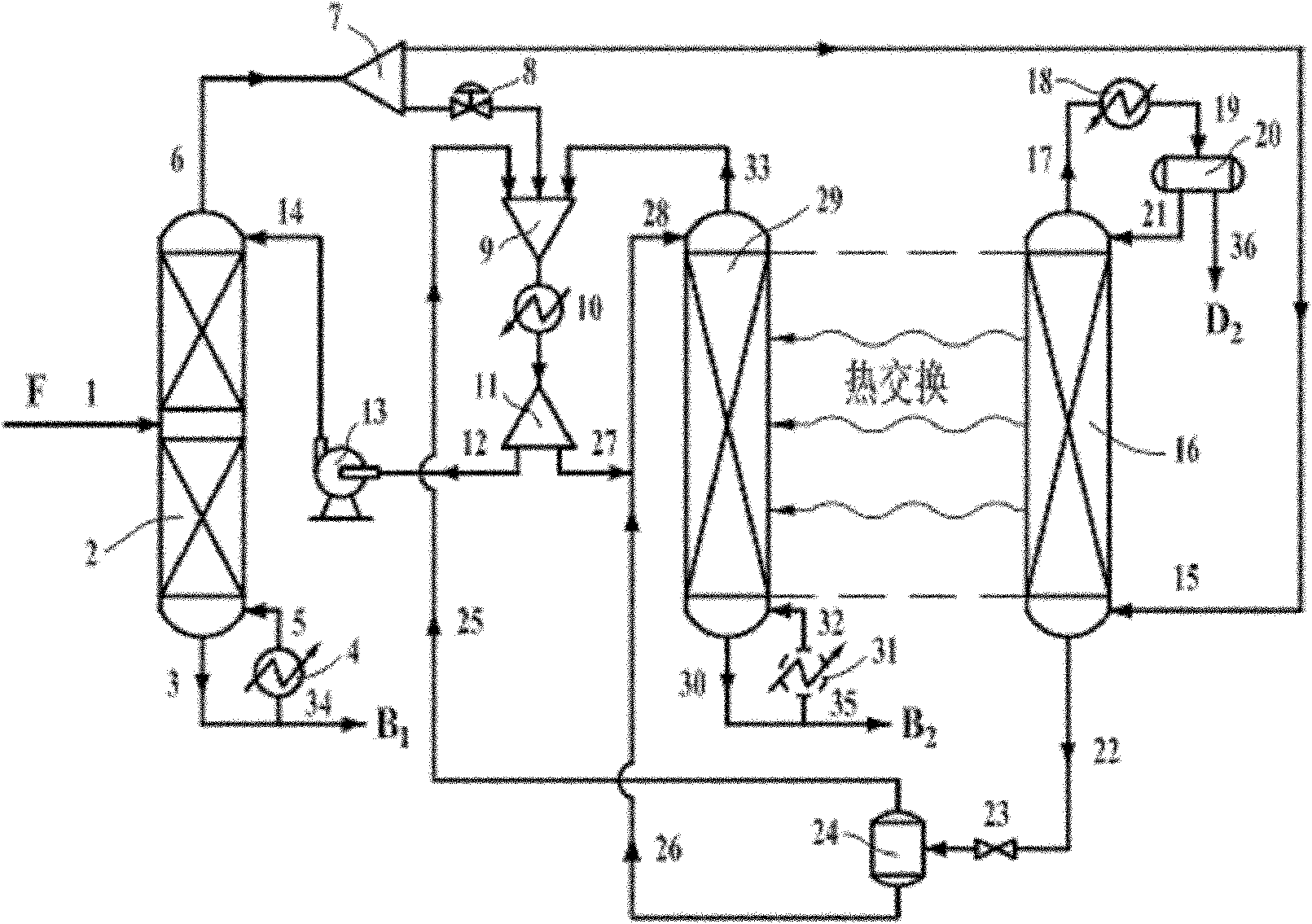

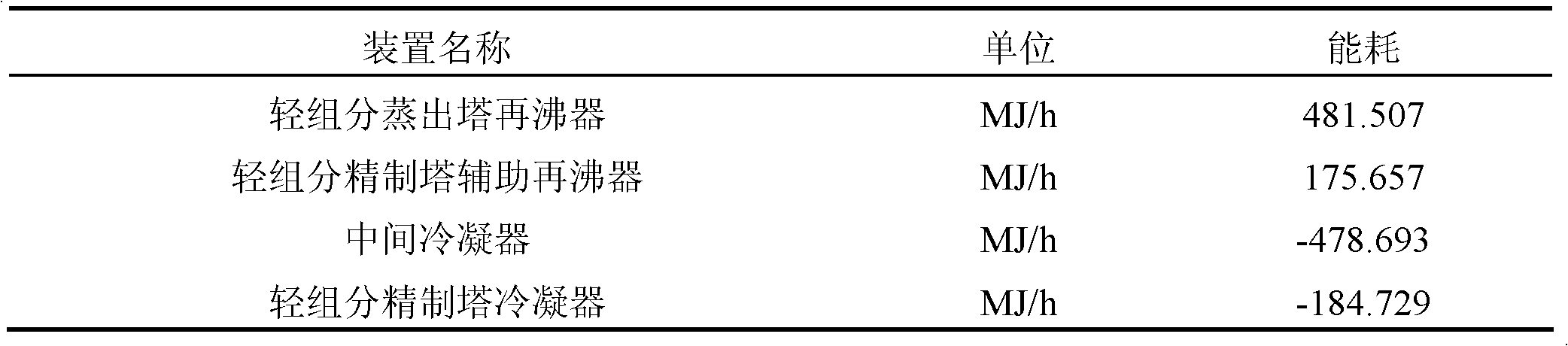

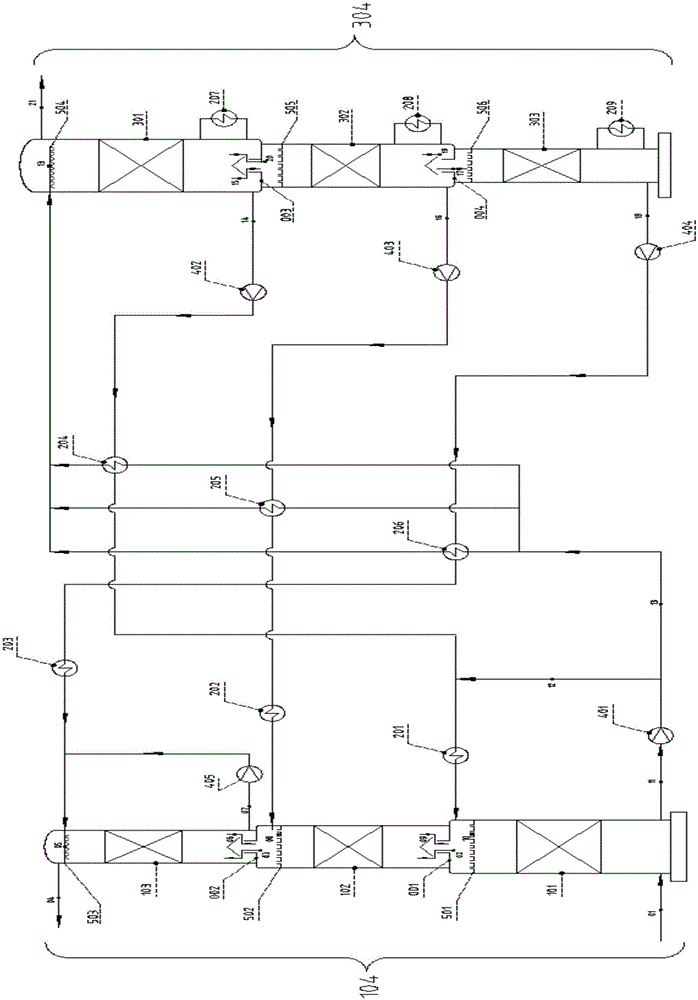

Energy-saving distillation method and device through differential pressure column section heat integration in rectification column sequences

InactiveCN101966398AMeeting Reboiling NeedsReduce usageDistillation regulation/controlSteam distillationDifferential pressureReboiler

The invention relates to an energy-saving rectification device and method through differential pressure column section heat integration in rectification column sequences. The device comprises a light component boil-up column, a light component refining column rectification column section, an auxiliary condenser, a return tank, a flash tank, a light component refining column stripper section, an auxiliary reboiler and a main reboiler, wherein the light component boil-up column is used for pressurizing the light component refining column rectification column section; a top saturated vapor outlet pipe of the light component refining column rectification column section is connected to the heat media inlet of the main reboiler; the heat media outlet of the main reboiler is connected to the inlet of the auxiliary condenser; a bottom liquid outlet pipe is connected to the inlet of the return tank; a bottom liquid outlet pipe of the light component refining column stripper section is connected to the cold media inlet of the auxiliary reboiler and the cold media inlet of the main reboiler respectively; and the cold media outlets of the auxiliary reboiler and the main reboiler are respectively connected to a reboiled vapor inlet pipe of the light component refining column stripper section. The invention realizes single-column heat integration and matched heat exchange in the rectification column sequences. The invention realizes minimum heat consumption of the single column through differential pressure column section heat integration, even ensures the cold and heat load to be perfectly matched and ensures zero consumption, thus greatly reducing energy consumption of the system and achieving the aims of energy saving and synergy.

Owner:TIANJIN UNIV

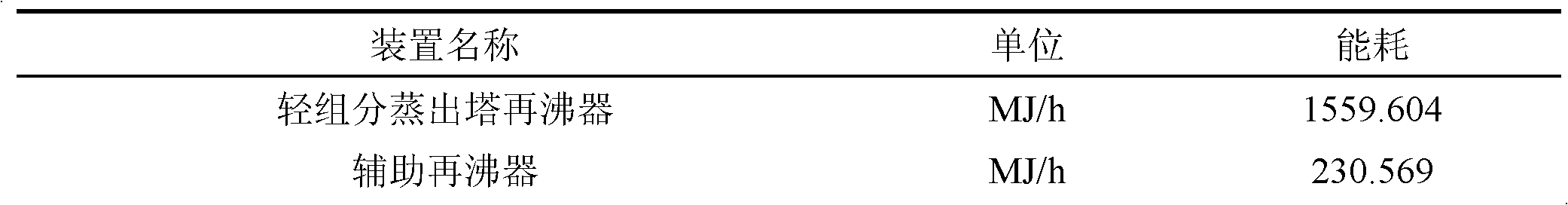

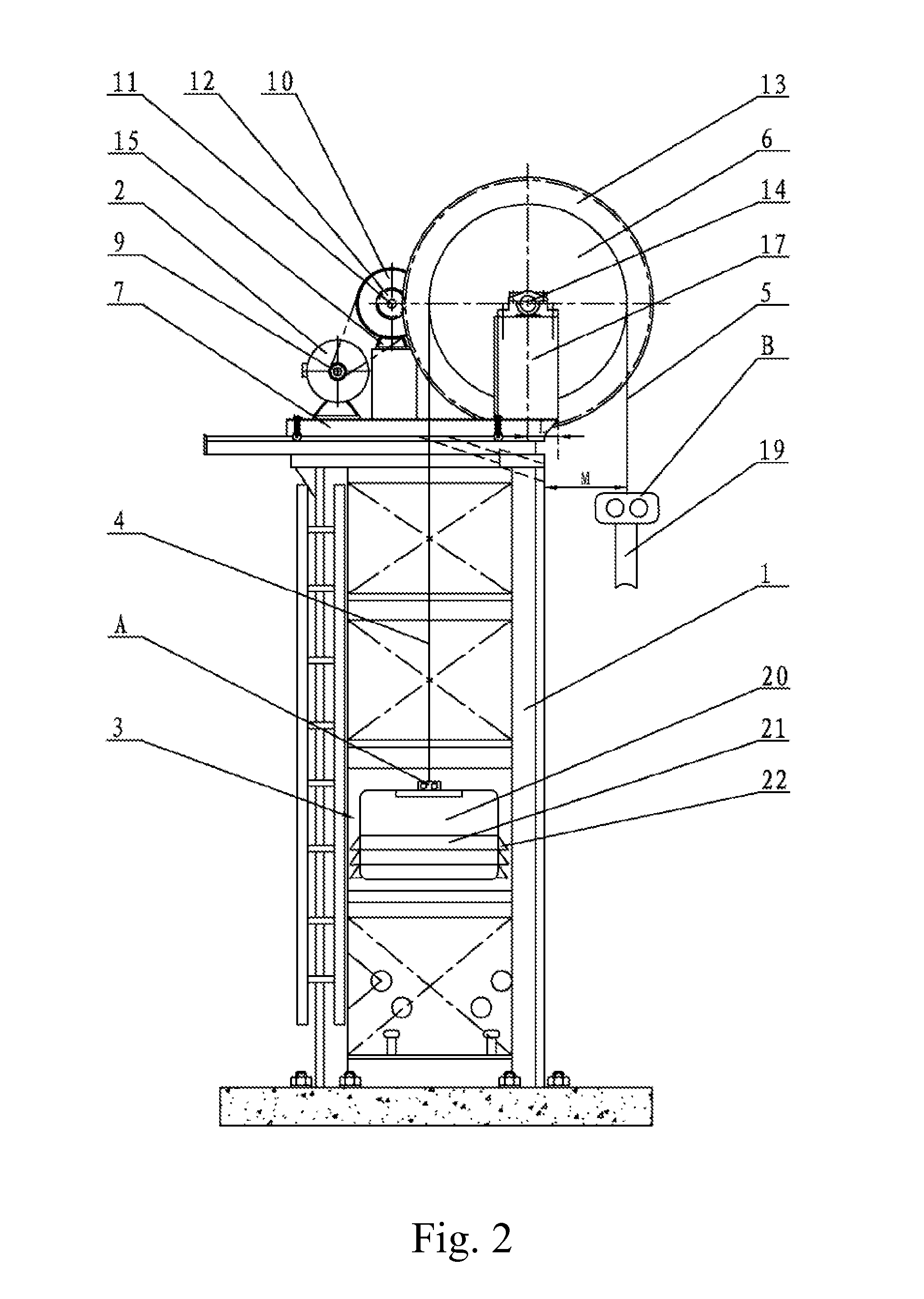

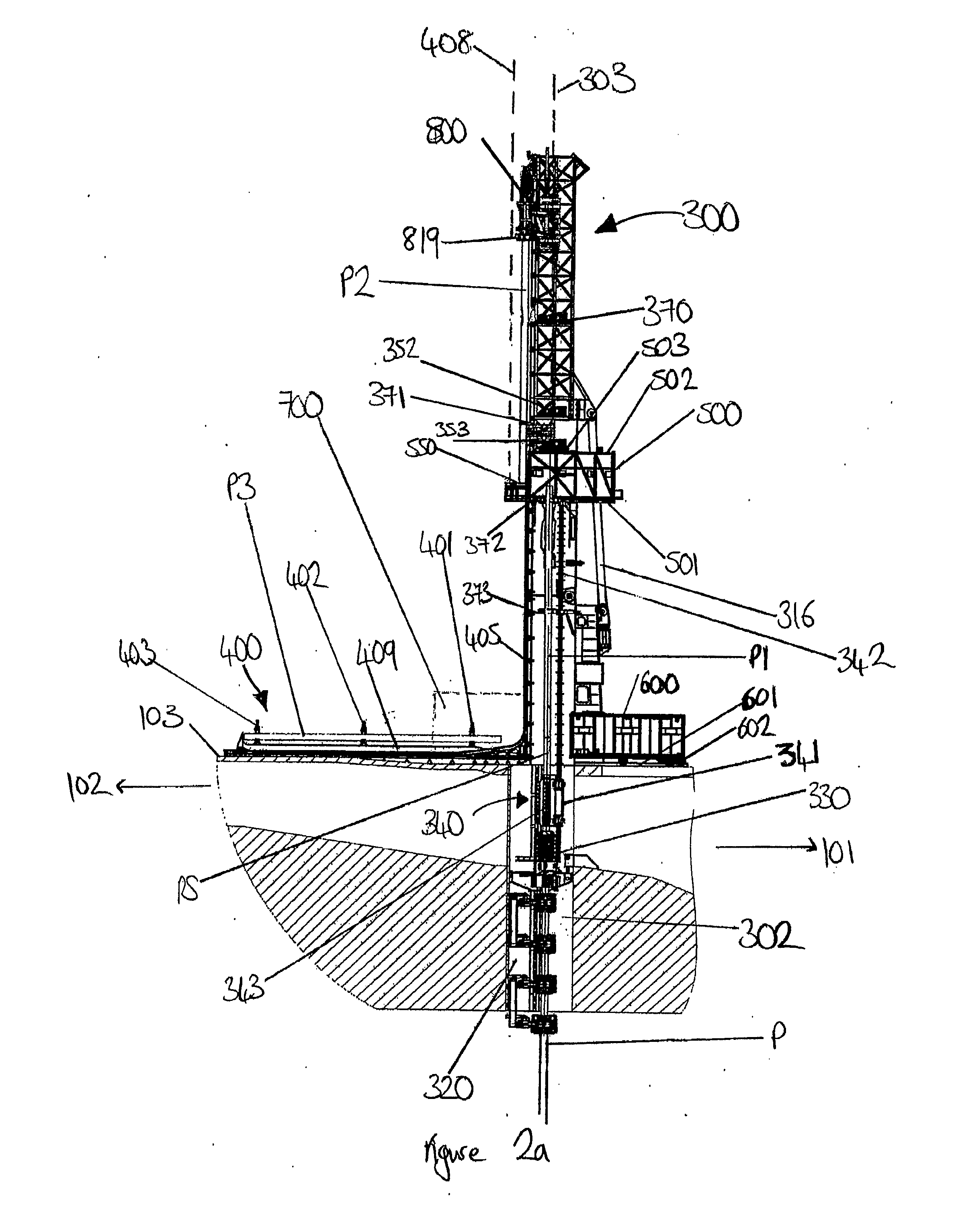

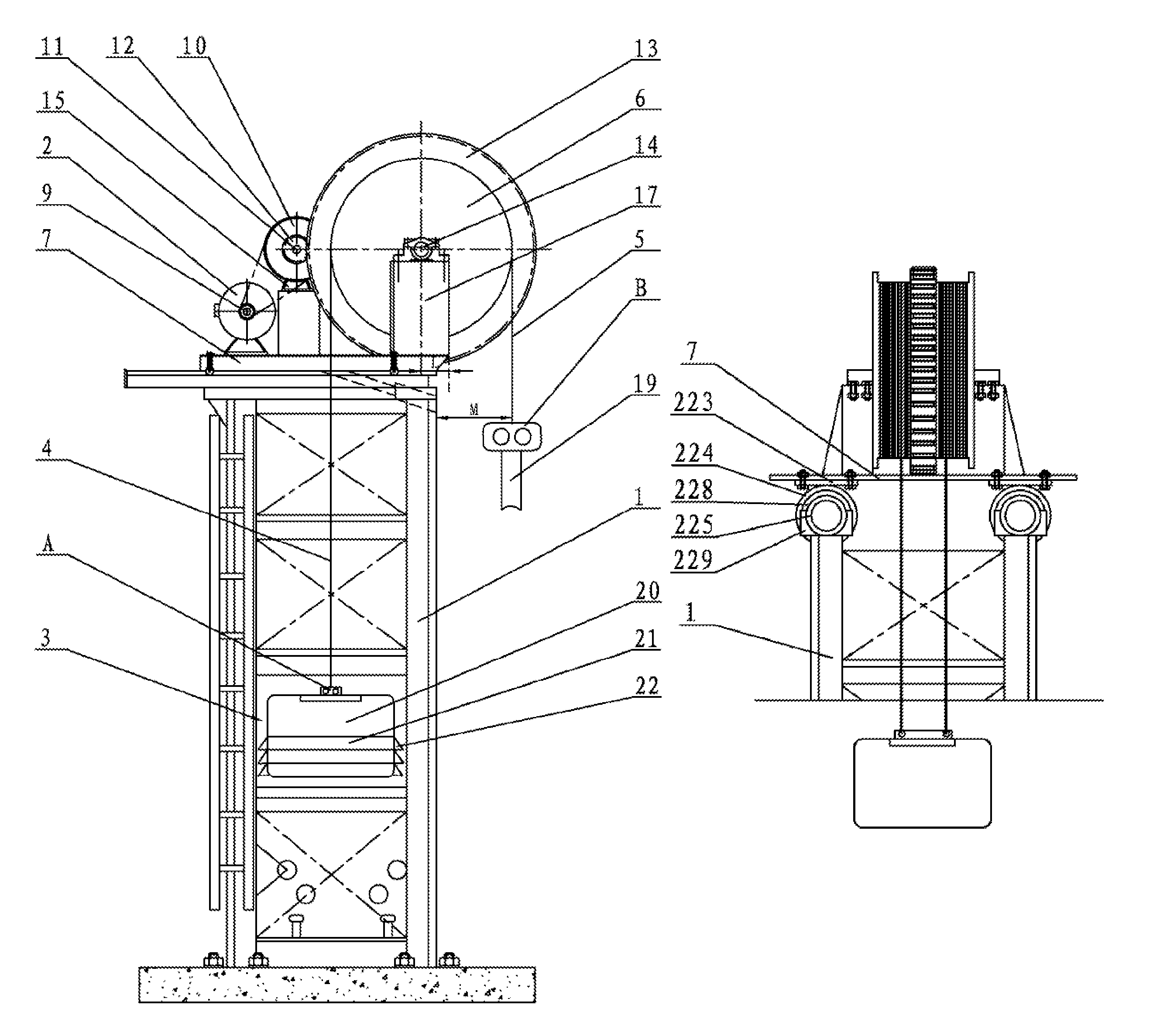

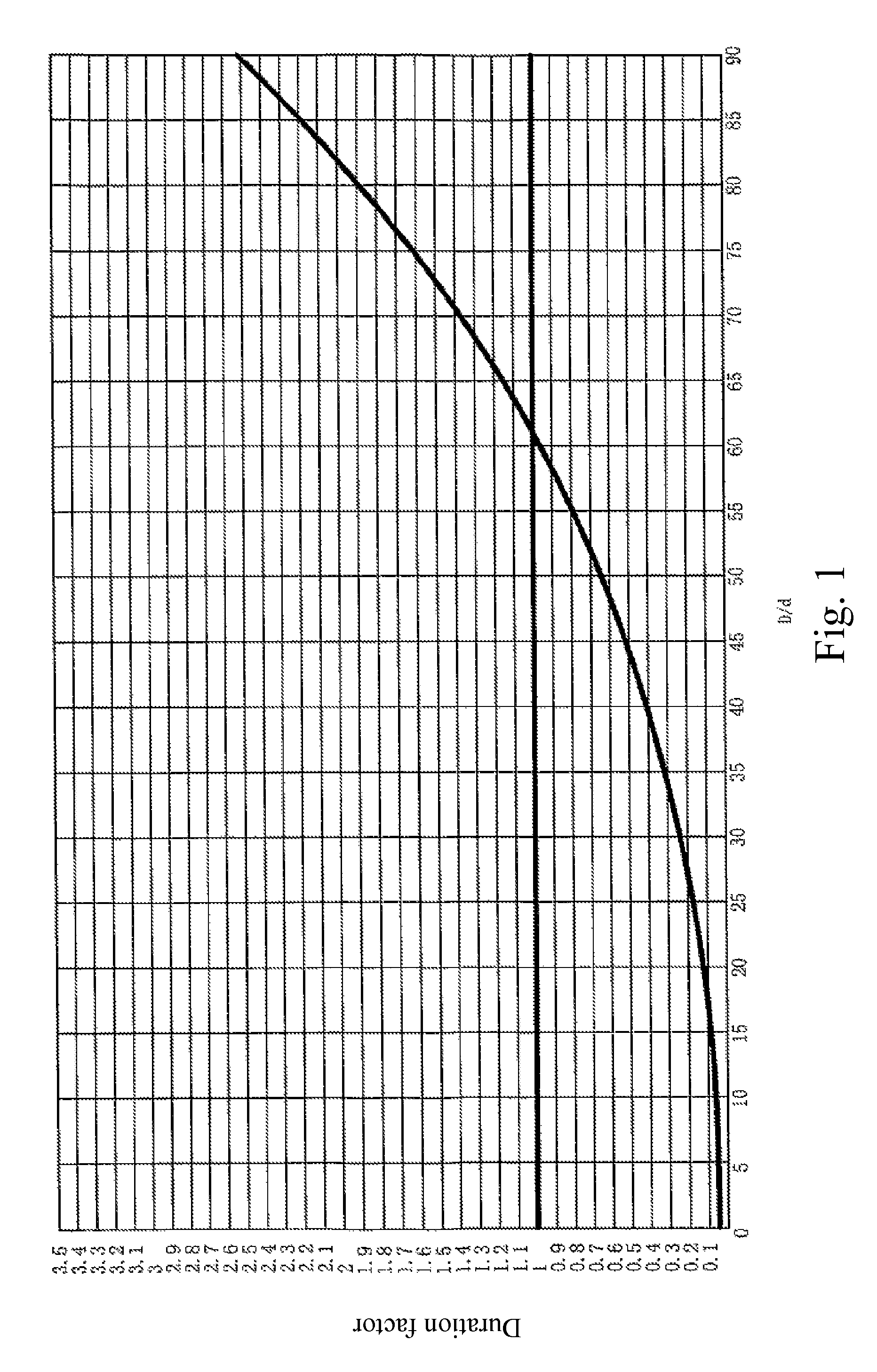

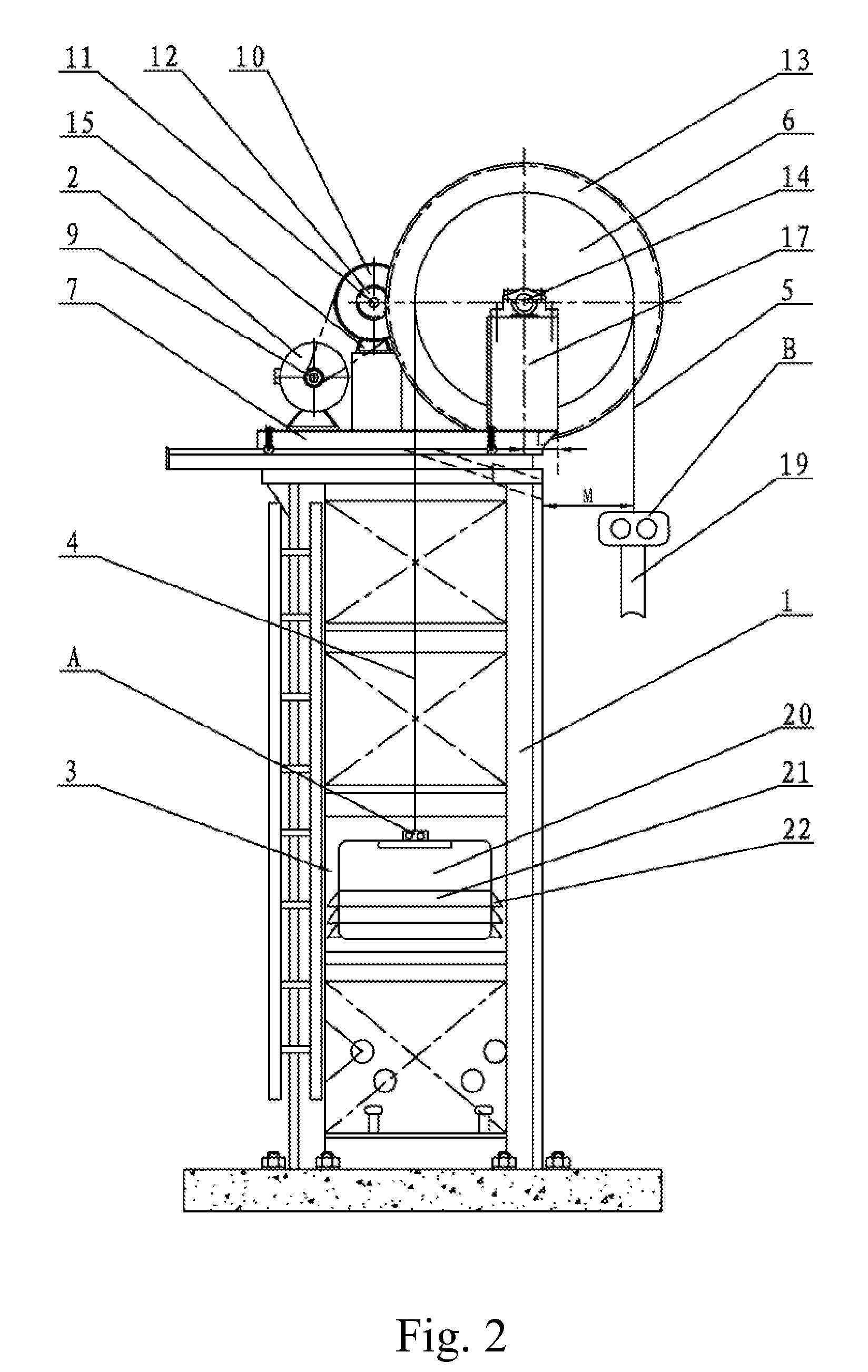

Tower frame combined transmitting pumping unit without guiding wheels

ActiveUS20130058803A1Long durationThe method is simple and safePositive displacement pump componentsDerricks/mastsControl systemEngineering

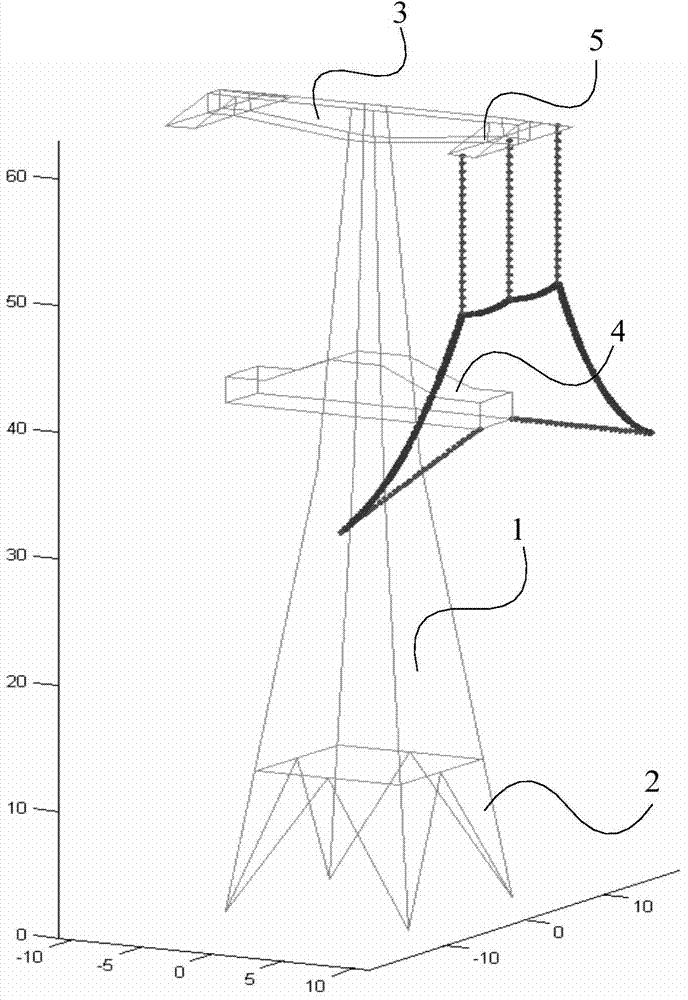

A tower frame combined transmitting pumping unit without guiding wheels includes a tower frame, a powering system, a transmitting system, a controlling system, a balancing weight box, a weight hauling cable, a rope wheel, a driving rope and rope hangers. The rope wheel is fixed on a side of an operation platform through a rope wheel supporting device. A central axis line of the rope wheel is located within the operation platform. A wheel rim of the rope wheel extends beyond the operation platform and a minimum distance between a most external rim thereof. The weight hauling cable and the driving rope twine around the rope wheel reversely. A free end of the weight hauling cable is connected to the balancing weight box through a rope hanger A. A platform moving device is installed between the operation platform and a top of the tower frame.

Owner:SICHUAN MODERN CENTURY MECHANICAL & ELECTRICAL COMPANY

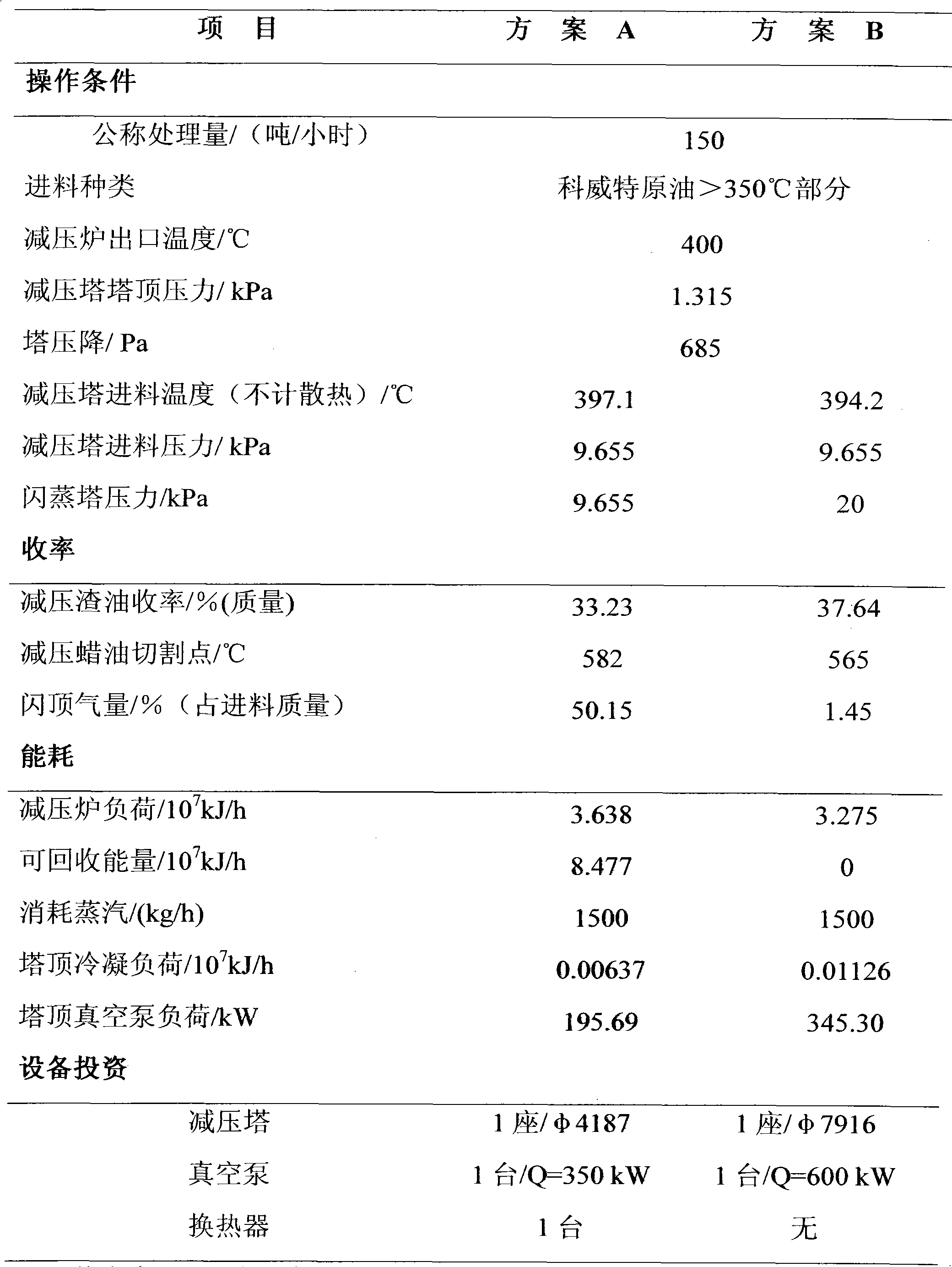

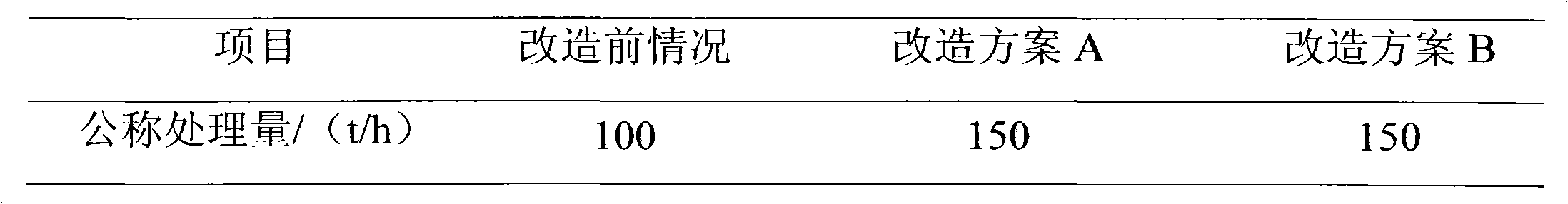

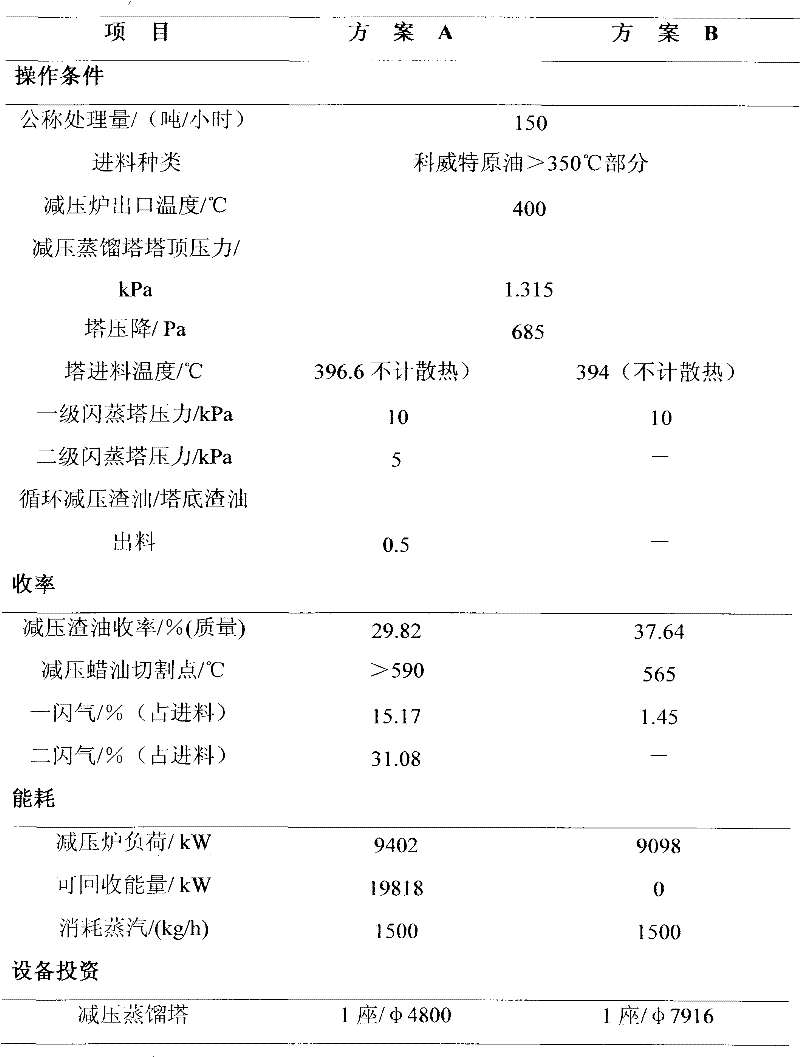

Distillate yield improving vacuum distillation method and device

ActiveCN102311772AAvoid lateral thermal displacementEasy to separateVacuum distillationHydrocarbon oils treatmentLow speedVaporization

The invention discloses a distillate yield improving vacuum distillation method and device. A flash vaporization vessel is arranged on an oil transfer line between a vacuum furnace and a vacuum distillation tower. Vacuum distillation raw materials enter the oil transfer line and the flash vaporization vessel after being heated by the vacuum furnace. Gas liquid separation is carried out in the flash vaporization vessel: liquid discharged from the bottom of the flash vaporization vessel, namely flash bottom oil, is introduced into the vacuum distillation tower; and gas discharged from the top of the flash vaporization vessel, namely flash top gas, is led out of the device after being condensed into liquid. According to the vacuum distillation method and device with the flash vaporization vessel arranged behind the vacuum furnace, on one hand, the yield of vacuum distillate is increased, on the other hand, a conventional decompression oil transfer line low-speed section is omitted, the operation load of the vacuum tower is reduced, and the diameter of the vacuum tower can be appropriately reduced, so equipment investment is saved, and the operating cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Energy-saving rectifying device for integrating energy in rectifying tower sequence and method

InactiveCN101966397AReduce energy consumptionLow operating costFractional distillationVaporizationEngineering

The invention relates to an energy-saving rectifying device for integrating energy in a rectifying tower sequence and a method, wherein the device comprises a light component evaporating tower, a steam flow distributor, a steam mixer, a central condenser, a liquid flow distributor, a rectifying tower section of a light component refining tower, a stripping tower section of the light component refining tower, a reducing valve, and a flash vaporization vessel, wherein the light component evaporating tower does not have a ceiling condenser and is used for supplying high pressure steam to the rectifying tower section of the light component refining tower; the reducing valve and the flash vaporization vessel are arranged between the rectifying tower section of the light component refining tower and the stripping tower section of the light component refining tower; the internal heat exchange between the two tower sections not only can reduce the hot load consumption at the bottom of the stripping tower section of the light component refining tower, but also can reduce the condensing load consumption at the top of the rectifying tower section of the light component refining tower. Compared with the conventional multi-component rectifying and separating system, the device in the invention can greatly reduce the total energy consumption of the entire rectifying tower system, save the operation cost, and reach the purpose of saving energy and increasing efficiency.

Owner:TIANJIN UNIV

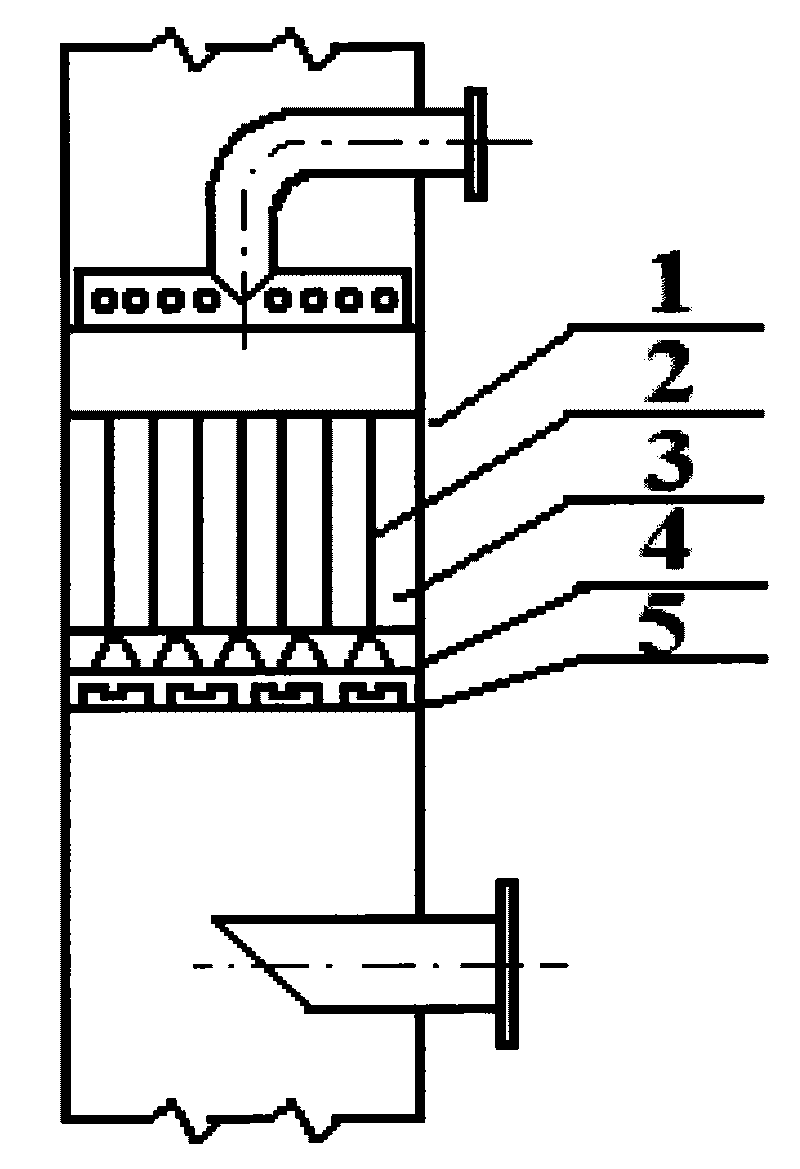

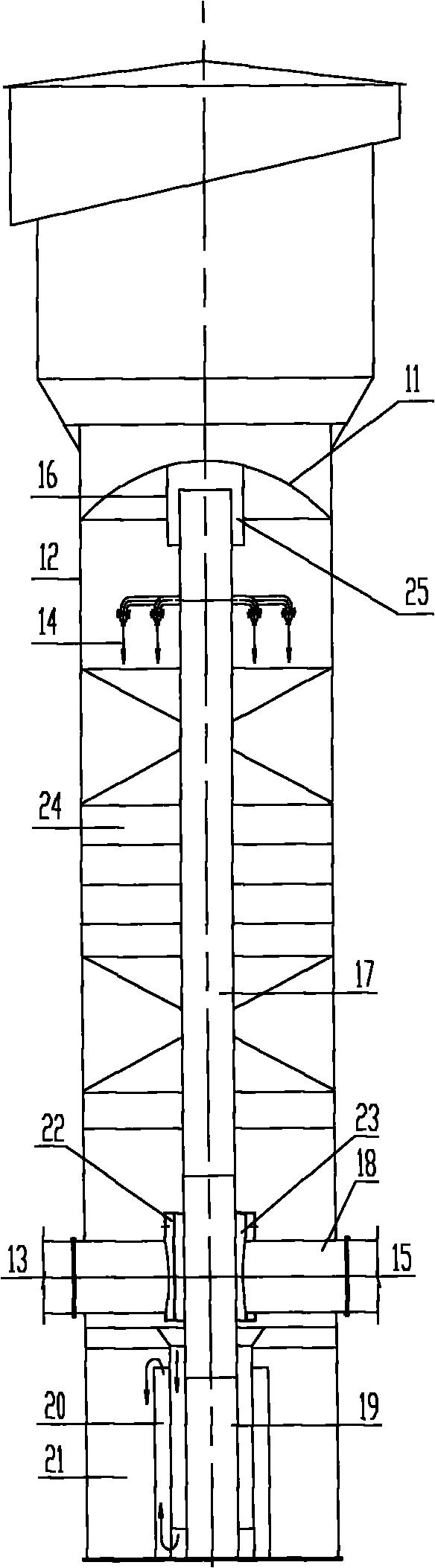

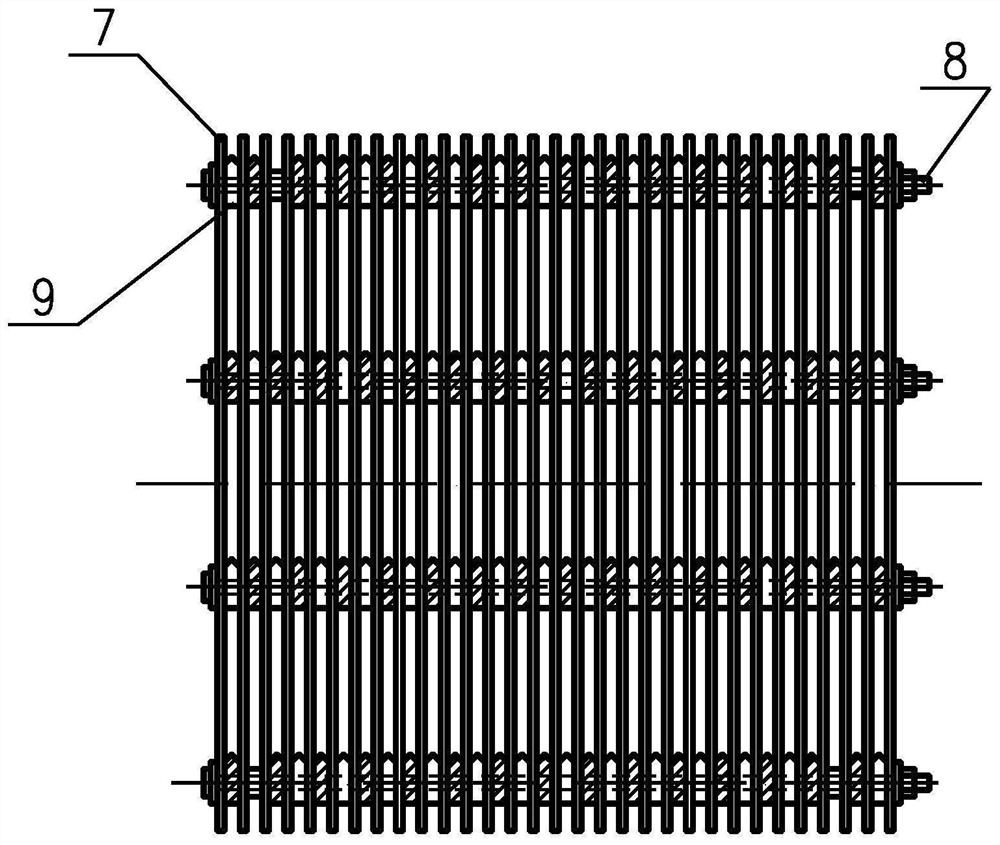

Filler assembly capable of eliminating amplification effect

ActiveCN101708452AEvenly distributedEfficient and stable mass transfer effectChemical/physical/physico-chemical processesFractional distillationEngineeringTower

The invention discloses a filler assembly capable of eliminating amplification effect, which comprises a filler section, a filler clapboard, filler units, a filler support plate and a liquid redistribution board, wherein the filler clapboard partitions the filler section into a plurality of filler units, the liquid redistribution board is provided with open pores matched with the filler units, a weir is arranged around the open pores, the weir is provided with tooth gaps, and the open pores have the shapes similar to those of the filler units, and have small area. The assembly changes a filler tower into the plurality of filler units connected in parallel, and the vapor and liquid of the filler section are uniformly distributed and the wall flow effect is eliminated by matching the corresponding liquid redistribution board so as to ensure efficient and stable mass transfer effect and eliminate the amplification effect; the adverse initial distribution of a liquid distributor is corrected; by adopting a plug-in structure, the treatment capacity of the tower is only related to the number of the filler units, so the design of the tower is not limited by the scale; and the liquid distributor is replaced by a distribution board so as to reduce the requirements on tower height and mounting level and reduce the investment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

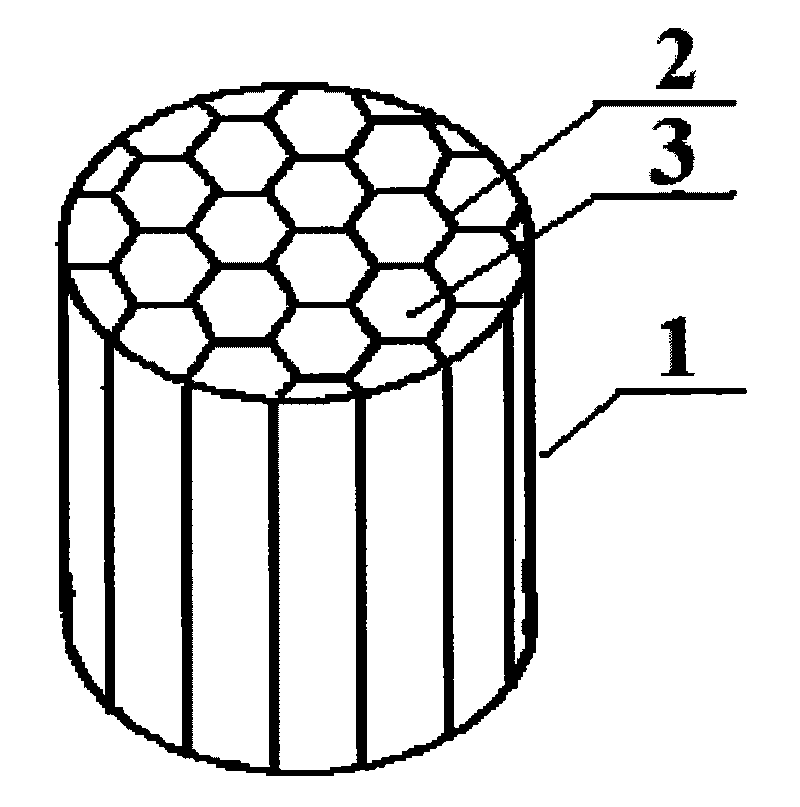

Mixed butyraldehyde separation device and application of packed towers

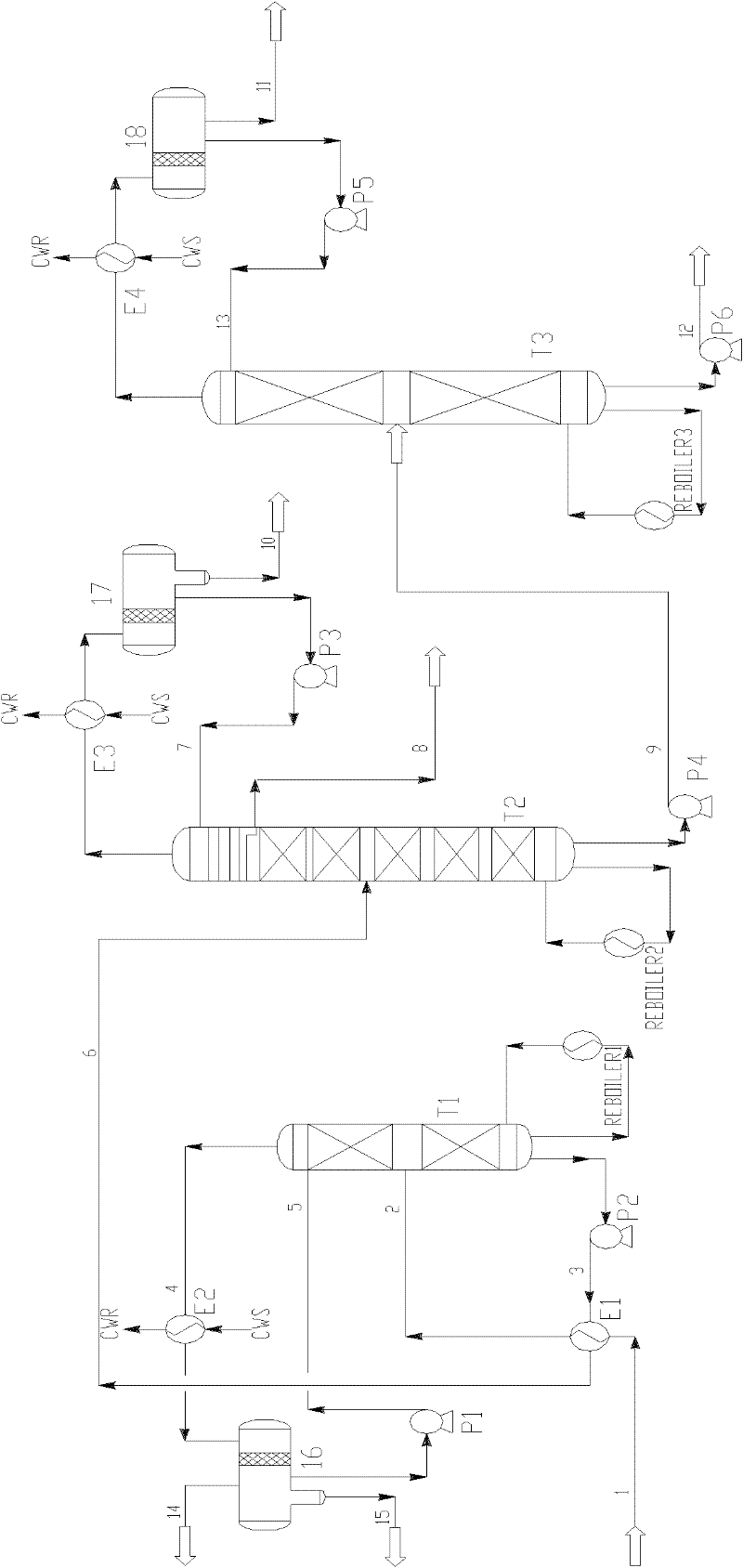

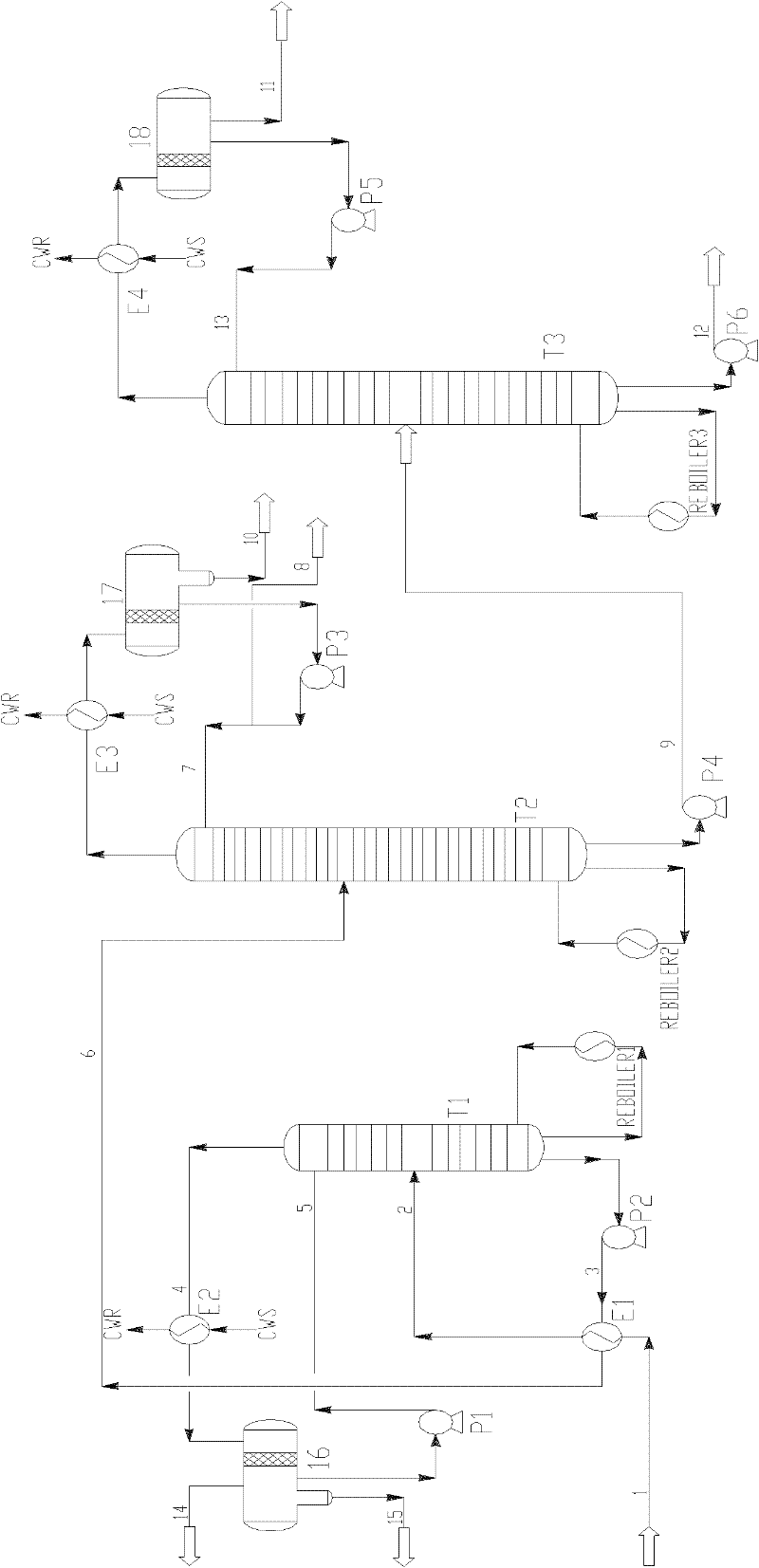

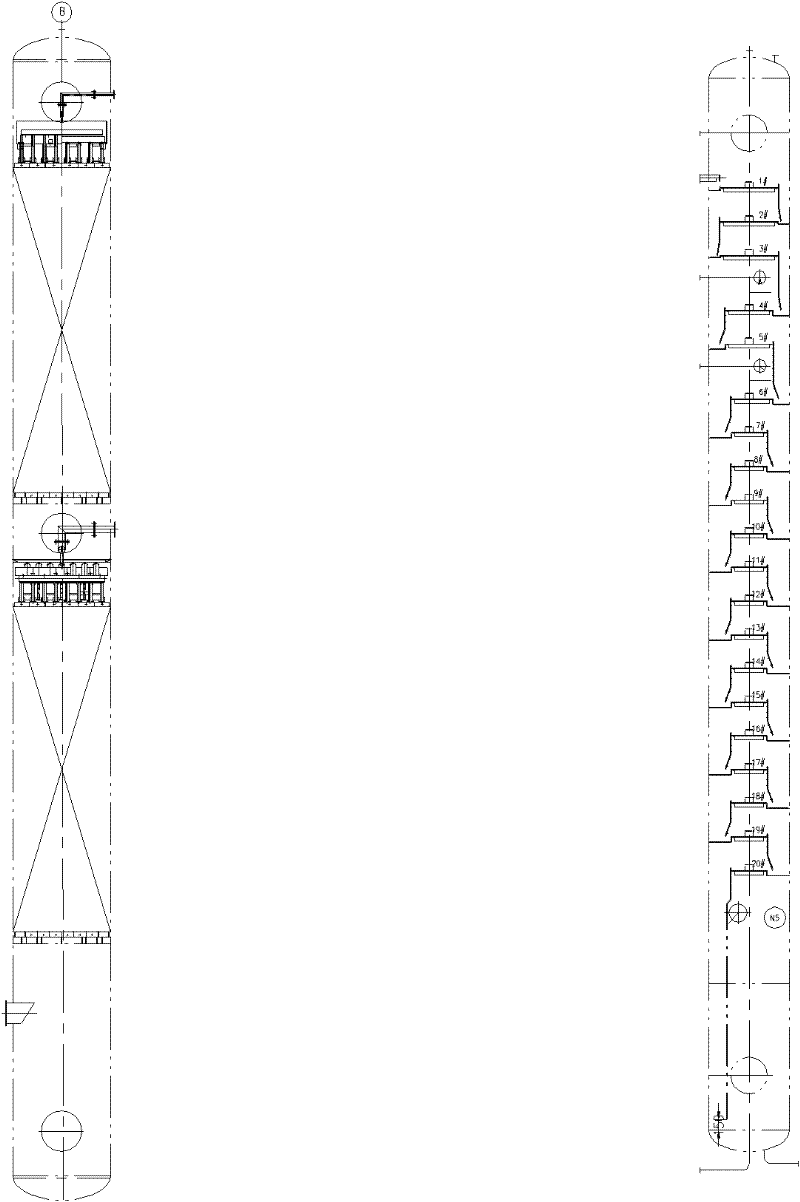

InactiveCN102580337AReduce energy consumptionReduce tower heightCarbonyl compound separation/purificationFractional distillationMaterial consumptionEngineering

The invention provides a mixed butyraldehyde separation device and the application of packed towers. The packed towers are used as a stabilization tower and an n-butanal tower; a tower tray and packing mixed way is adopted by an isomer tower, the five layers of tower trays are arranged on the top of the isomer tower, and the packing way is adopted at the other parts of the isomer tower; the packing is metal plate corrugated regular packing with the specific surface area of 250-500m<2> / m<3>; the tower trays are float valve tower trays, and each float valve has a form of F1 circular float valve or trapezoid guide float valve; and grid plate type packing pressing rings and grid plate type packing supports are used for limiting and supporting the packing in all packing sections. According to the invention, the energy consumption is greatly reduced, the tower height is effectively reduced and the metal material consumption is saved; and the packing is the metal plate corrugated regular packing, thus having the characteristics of high flux, low pressure reduction and high separation efficiency.

Owner:TIANJIN UNIV

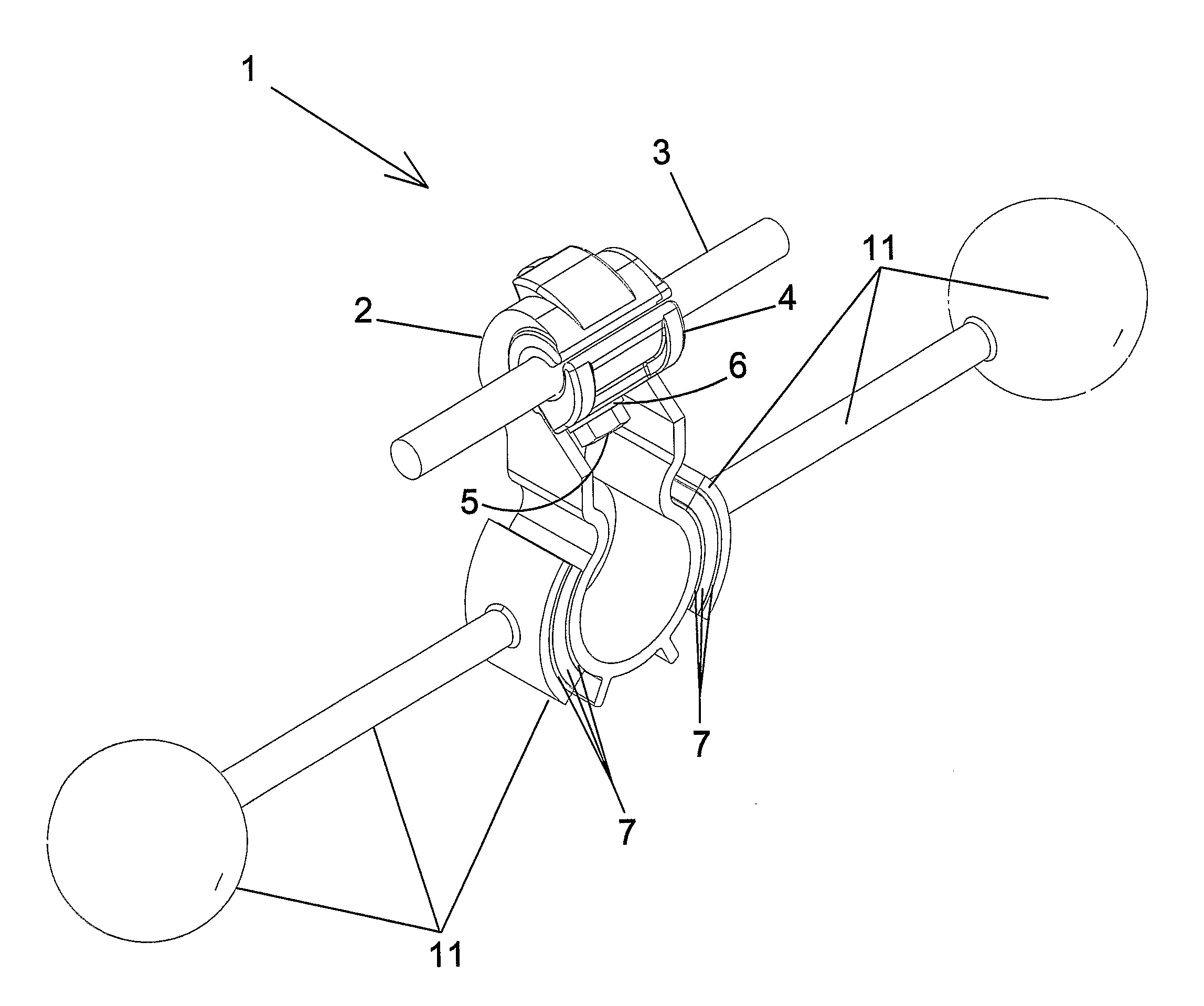

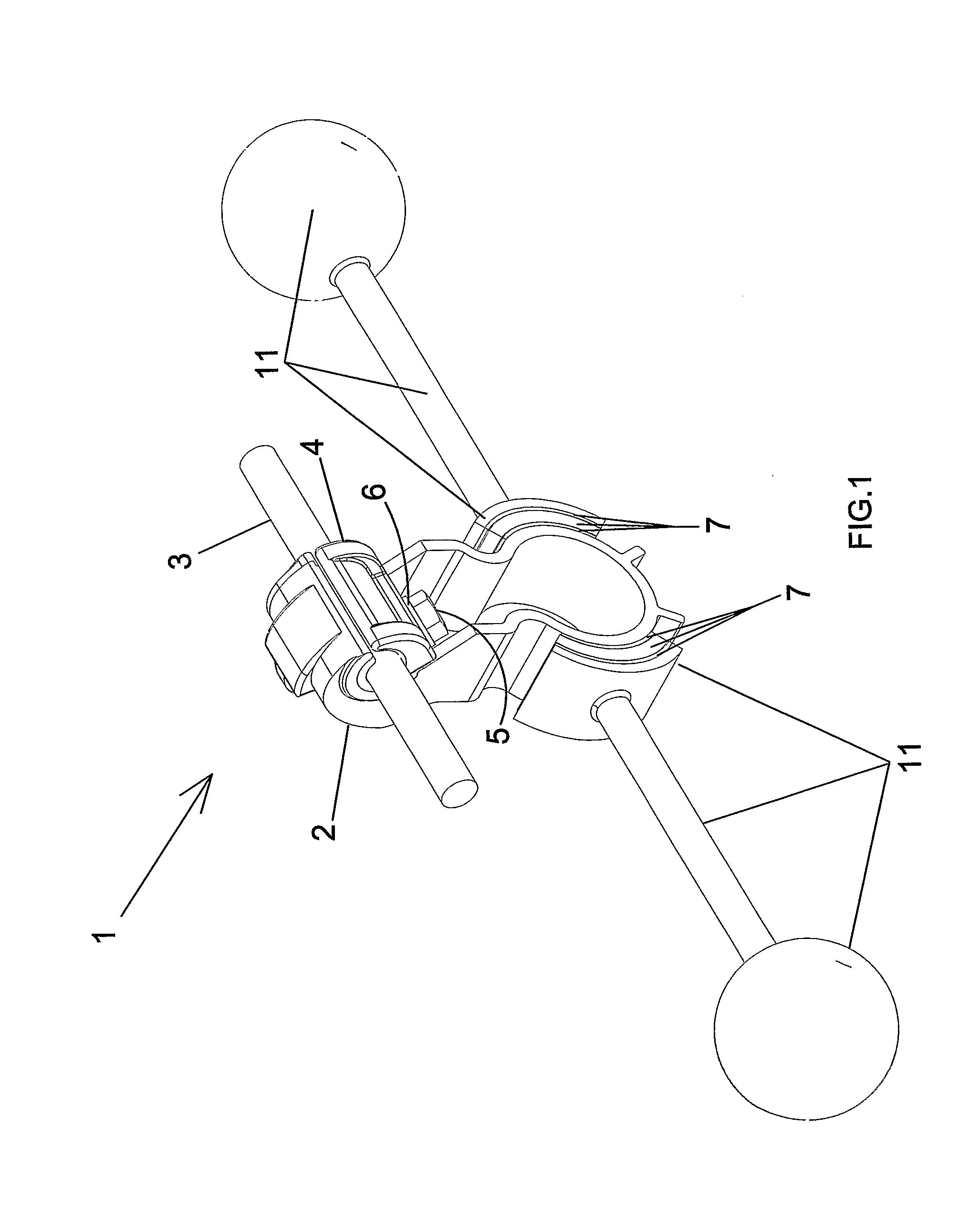

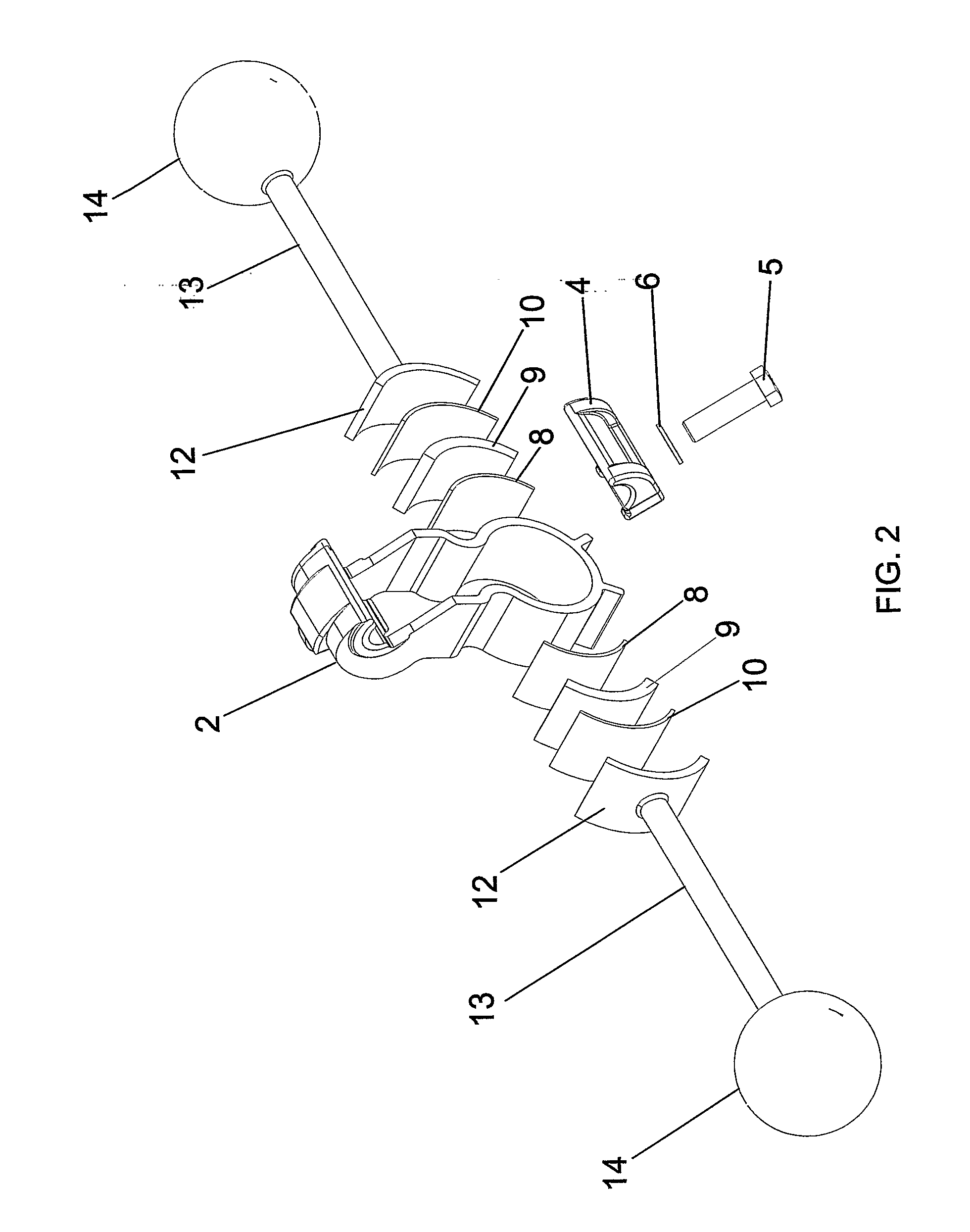

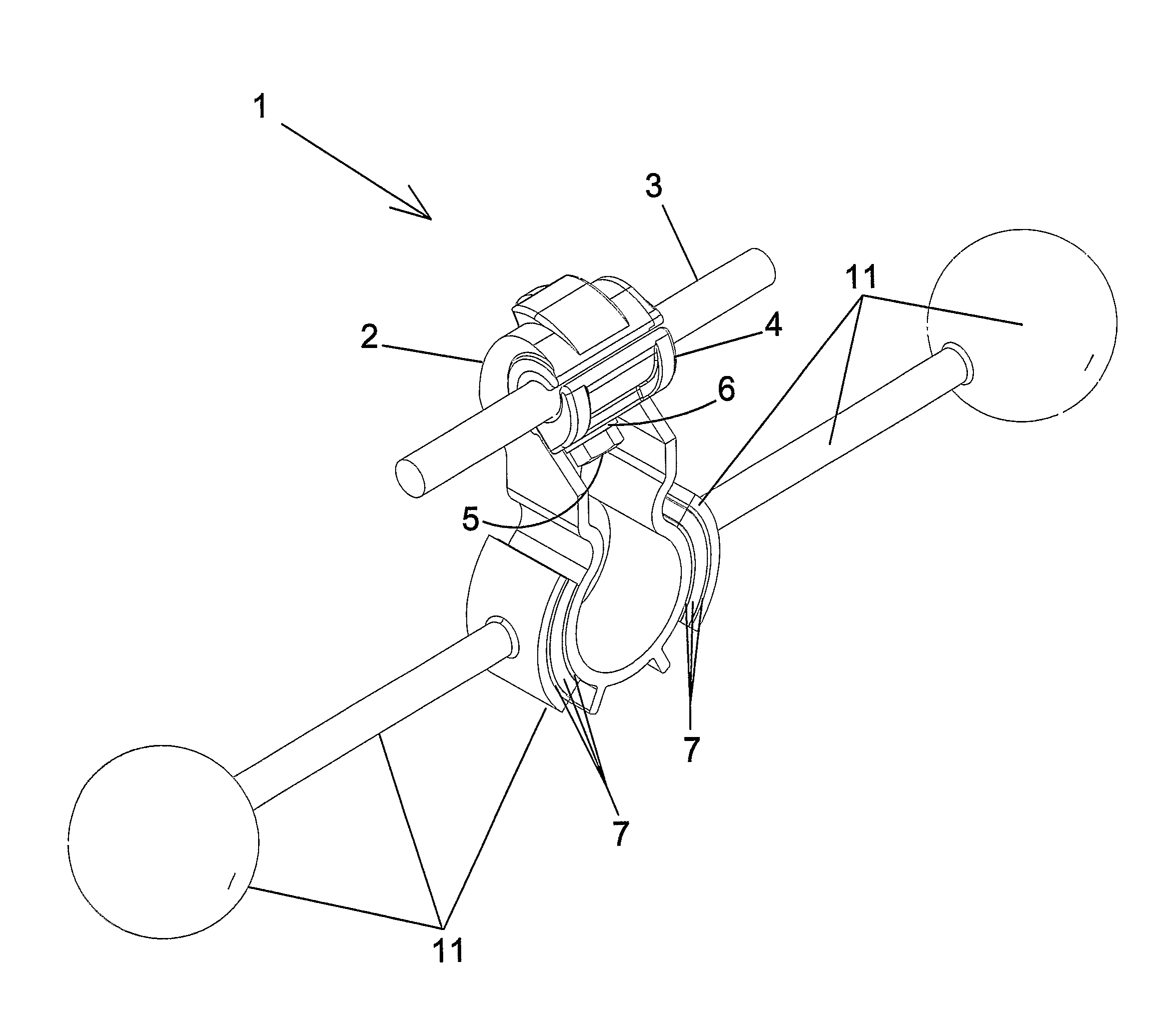

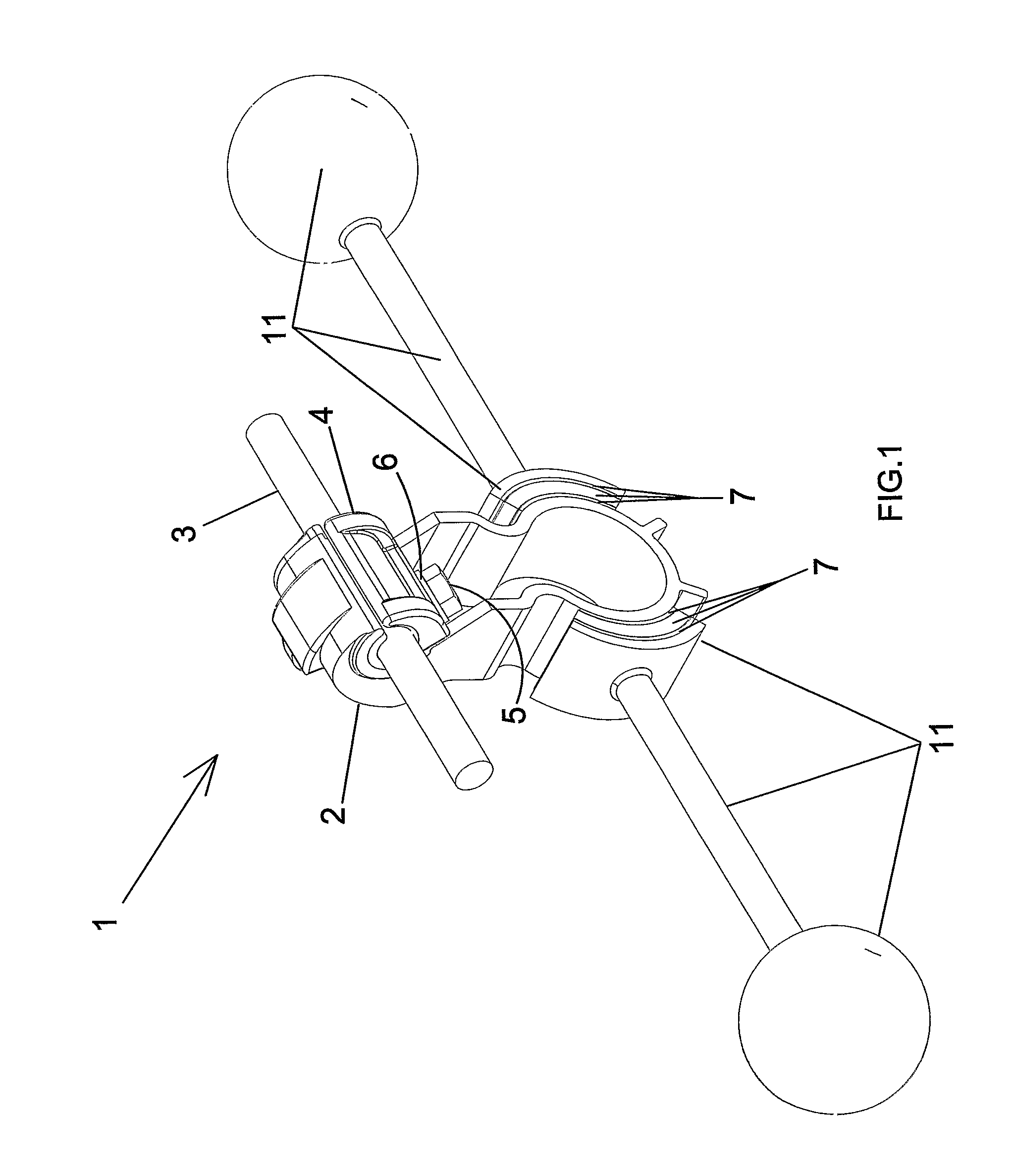

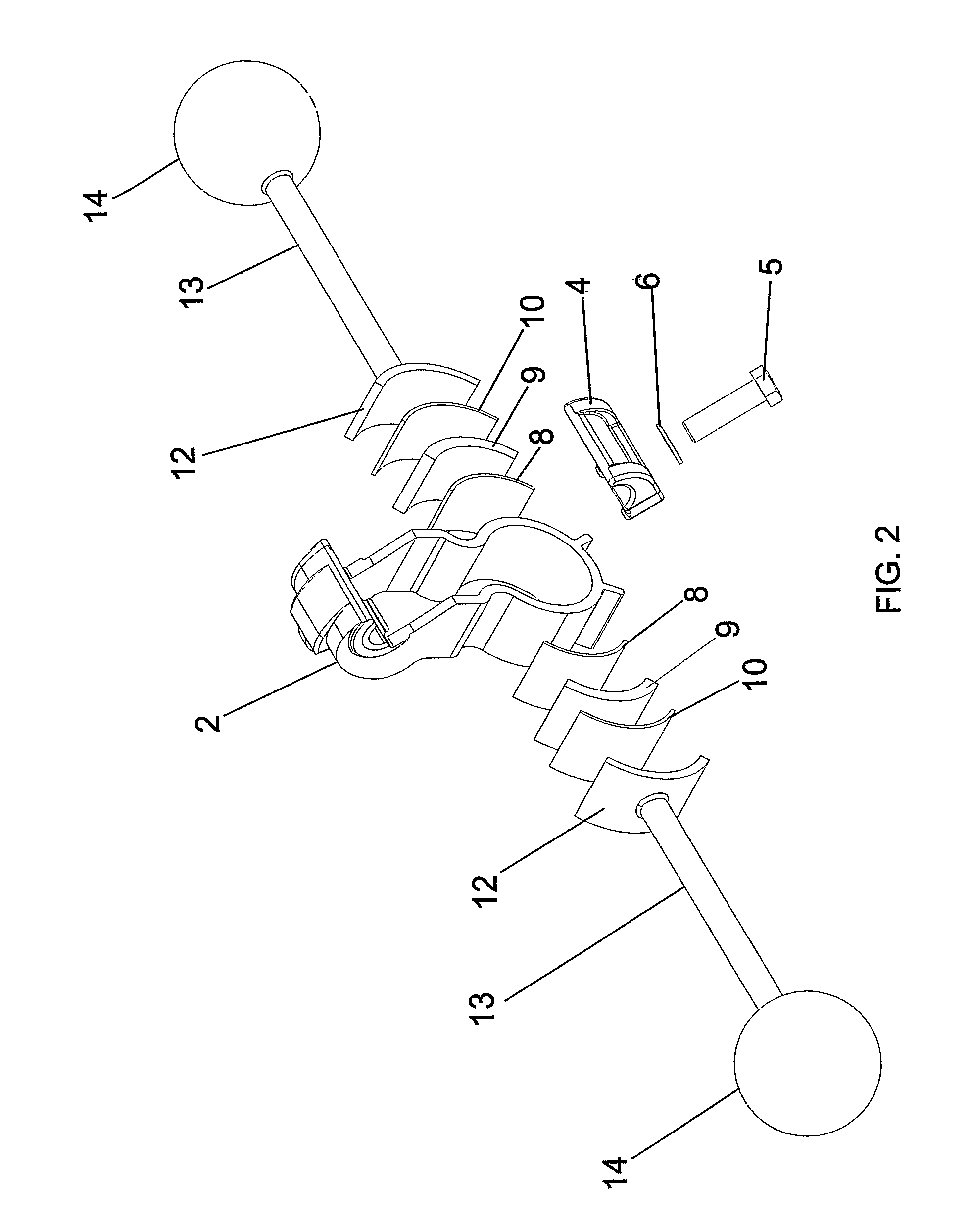

Device for dynamically neutralizing vibrations in single cable overhead power transmission lines

InactiveUS20110024152A1Extensive controlEasy to operateDevices for damping mechanical oscillationsElastic componentEngineering

The present invention refers to a device for dynamically neutralizing vibrations in single cable overhead power transmission lines. The device comprises a main body (2) a screw (5) and washer (6) assembly for mounting the main body onto the cable (3) and inertial components (11) consisting of rods (13) projecting in opposite directions from said main body (2) and balance masses (14) positioned at the distal end of said rods, wherein said main body (2) is integrally manufactured and comprises an upper frontal portion to receive an embracing lid (4) that embraces the cable (3) and side portions for mounting matching viscous-elastic components (7)

Owner:ESPINDOLA JOSE JOAO DE

Crude oil pressure-reduced distillation method and device

InactiveCN102311754AEasy to separateGood stripping effectVacuum distillation separationVacuum distillationHydrogenGas phase

The invention discloses a crude oil pressure-reduced distillation method and a crude oil pressure-reduced distillation device. A flash tower is arranged between a reduced-pressure furnace and a reduced-pressure distillation tower, an oil transfer line is eliminated, a reduced-pressure distillation raw material is heated in the reduced-pressure furnace and directly enter the flash tower, a small amount of stripping gas is introduced into the flash tower, and the liquid phase, namely flash bottom oil, obtained by gas-liquid separation in the flash tower is introduced into the reduced-pressure distillation tower; and a gas phase, namely flash top gas, discharged from the top of the flash tower is condensed into a liquid phase to be led out of the device. A high-temperature hydrogen or inert gas is introduced into the bottom of the flash tower. When the pressure-reduced distillation method and the pressure-reduced distillation device, in which the flash tower for high-temperature hydrogen or inert gas stripping flash tower is arranged behind the reduced-pressure furnace, are used, the yield of a reduced-pressure fraction oil is increased, the conventional reduced-pressure oil transfer line is not used, the operation load of the reduced-pressure furnace is lowered, and the tower diameter of the reduced-pressure tower can be reduced properly; therefore, equipment investment is reduced, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

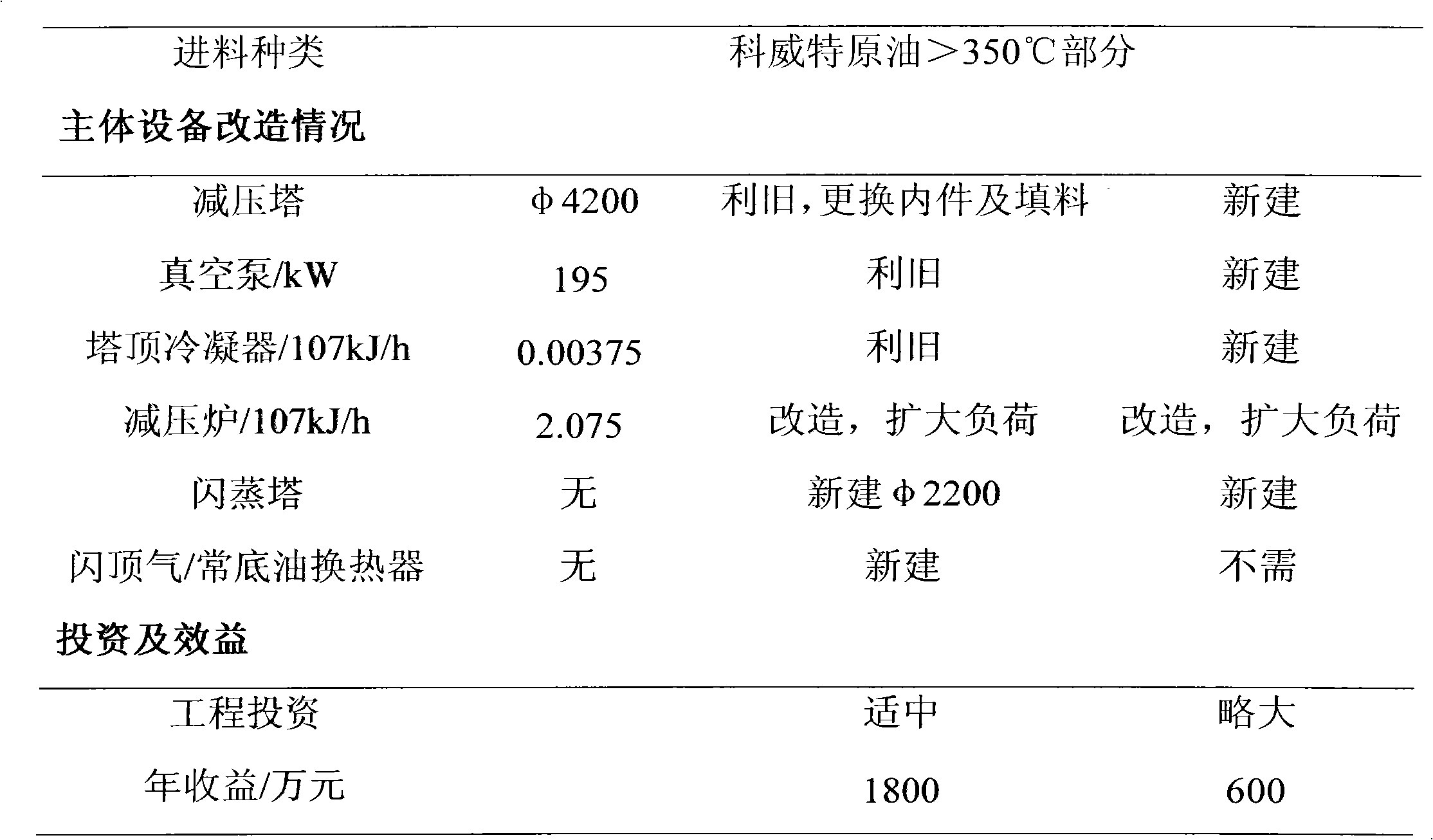

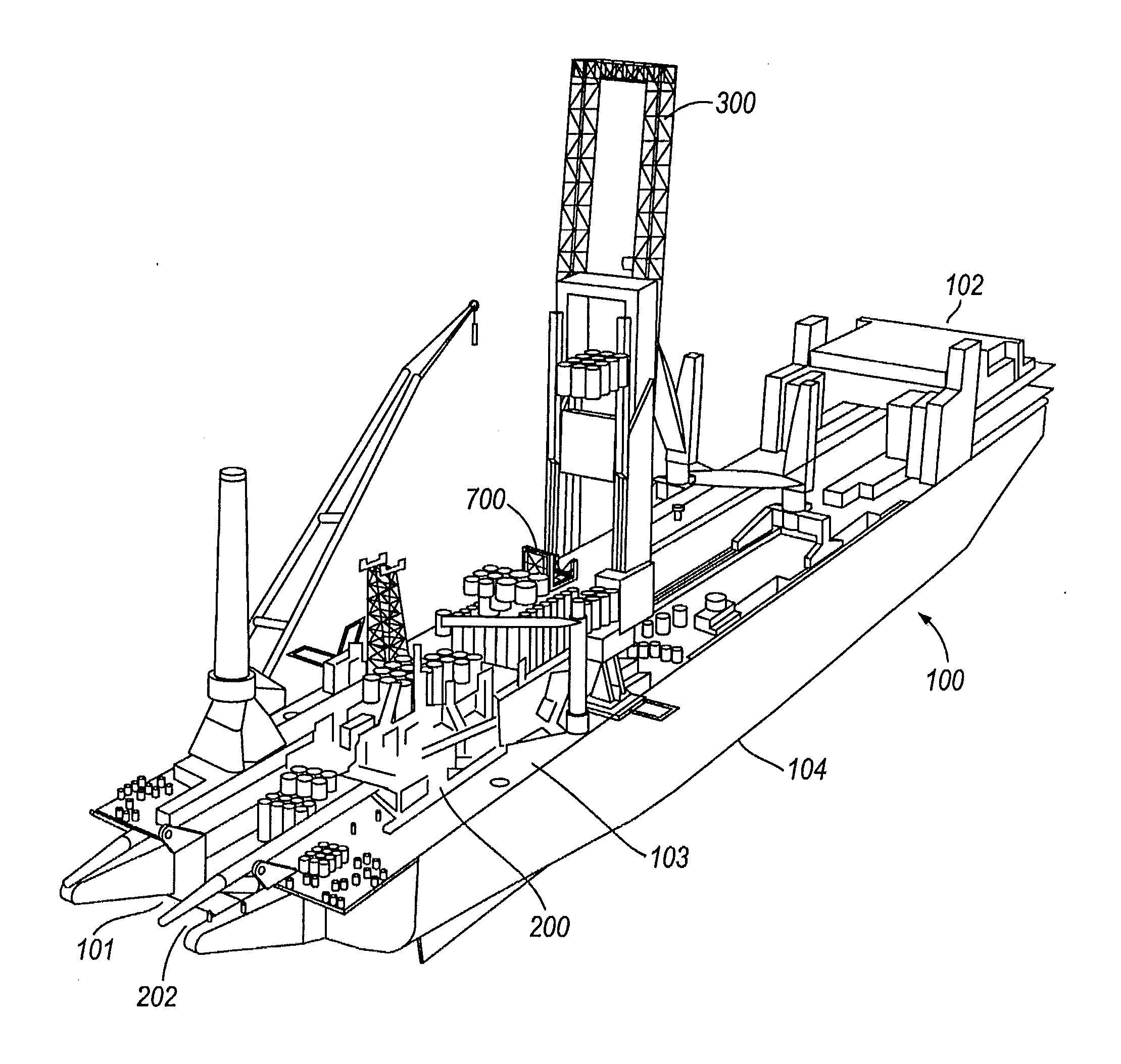

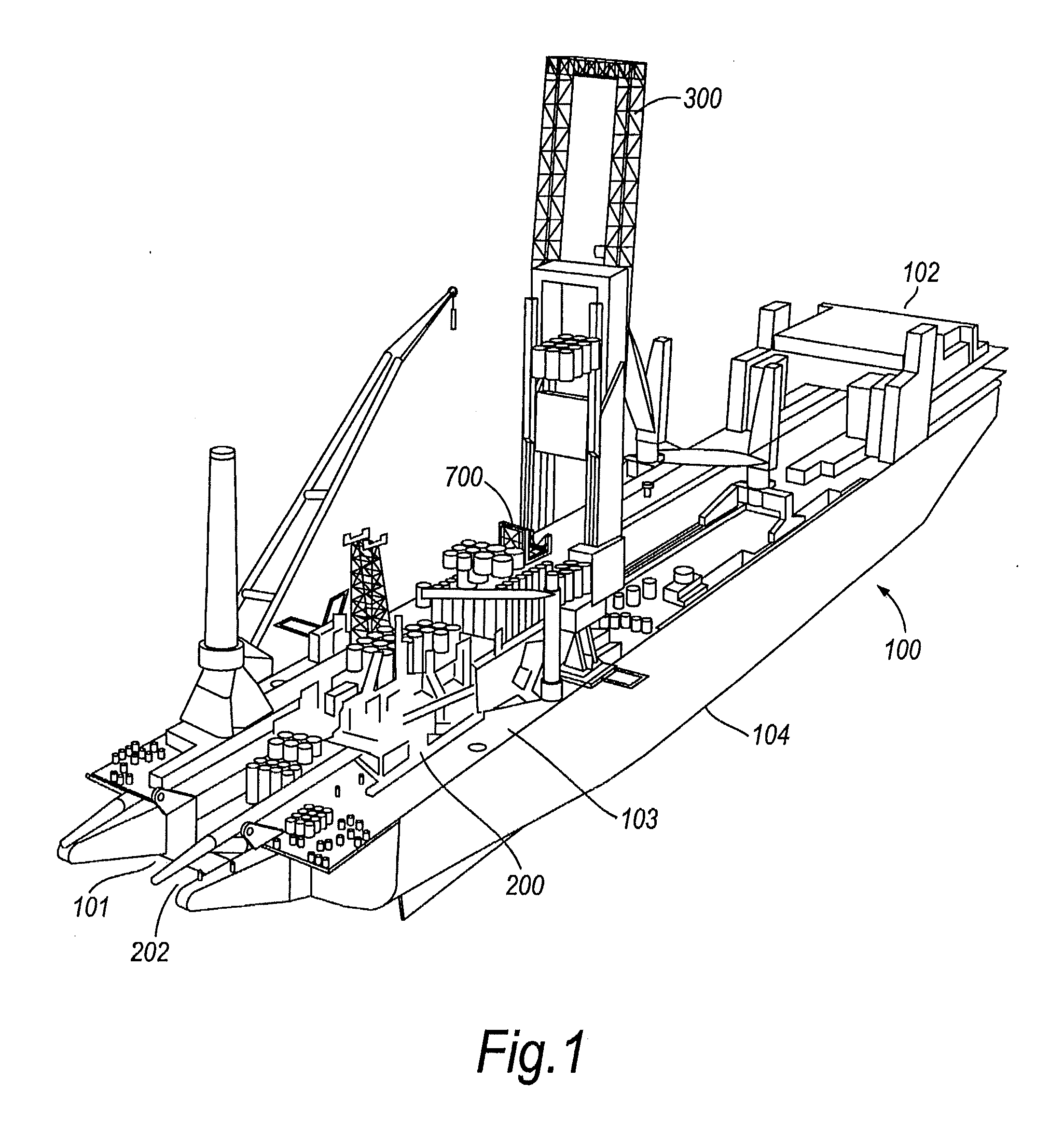

Pipe-laying vessel and method of laying a pipeline

ActiveUS20130294838A1Reduce the overall heightReduces likelihood of fatiguePipe laying and repairPipe-laying vesselsMarine engineeringTower

A pipe-laying vessel including a pipe-laying tower extending upwardly from the vessel, the tower including a first lower section extending upwardly from a proximal end to a distal end above the main deck of the vessel, and a second upper section movably mounted on the first lower section, and the tower having a first pipe-laying configuration for laying pipeline P in which the upper section is positioned above the lower section and pipe is passed from the upper section to the lower section when, in use, it is being laid, and a second stowed configuration in which the second upper section is moved relative to the lower section and the overall height of the tower is reduced.

Owner:SAIPEM SPA

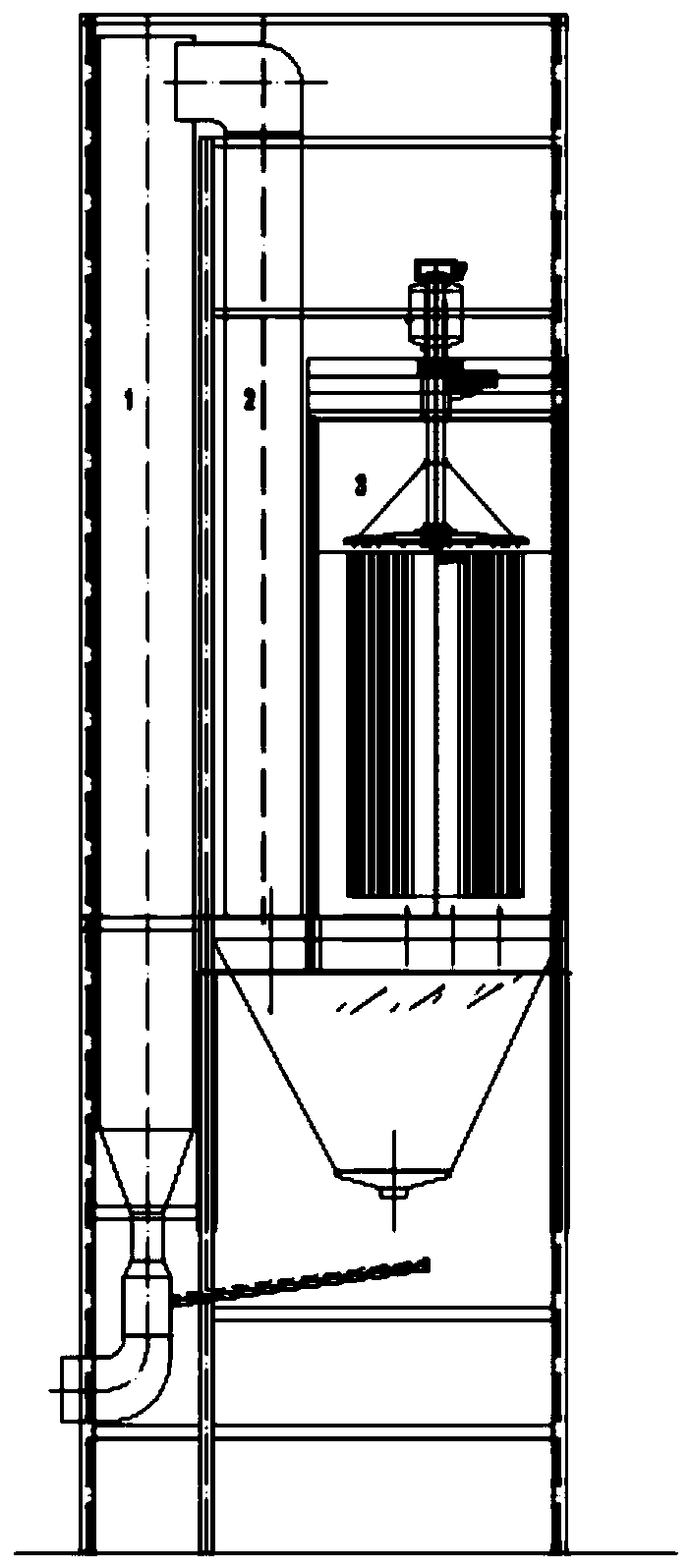

Granulating system and method thereof

ActiveCN105233756AEfficient use ofSufficient heat exchangeGranulation by liquid drop formationFertilizer mixturesPulp and paper industryTower

The invention discloses a granulating system and a method thereof, and belongs to the field of chemical fertilizer production. The granulating system comprises a tower body, a feeding device and a material receiving device, wherein the cross section of the tower body is polygonal; at least two spray heads are arranged at the periphery of the top of the tower body; the feed opening of each nozzle is communicated with a discharge opening of the feeding device; first exhaust pipes arranged at the top of the tower body wind extend out of the tower body across the top of the tower body, and are communicated with a temperature and humidity lowering device outside the tower body; the air outlet of the temperature and humidity lowering device is communicated with the air inlet of an induced draft fan; the induced draft fan is positioned at the position close to the bottom of the tower body outside the tower body; the induced draft fan is communicated with the inner cavity of the tower body; a dust remover is additionally arranged on a second exhaust pipe; a powder outlet of the dust remover is communicated with the feeding device. According to the granulating system disclosed by the invention, the height of the tower body is lowered by 20-50%; the maximum radius of the tower body is smaller than 8m; granulation is not influenced by seasons or weather; various problems which are confronted with when chemical fertilizers are produced through tower granulation can be solved, and safe and stable production of composite fertilizers is realized.

Owner:TIANJI COAL CHEM IND GROUP

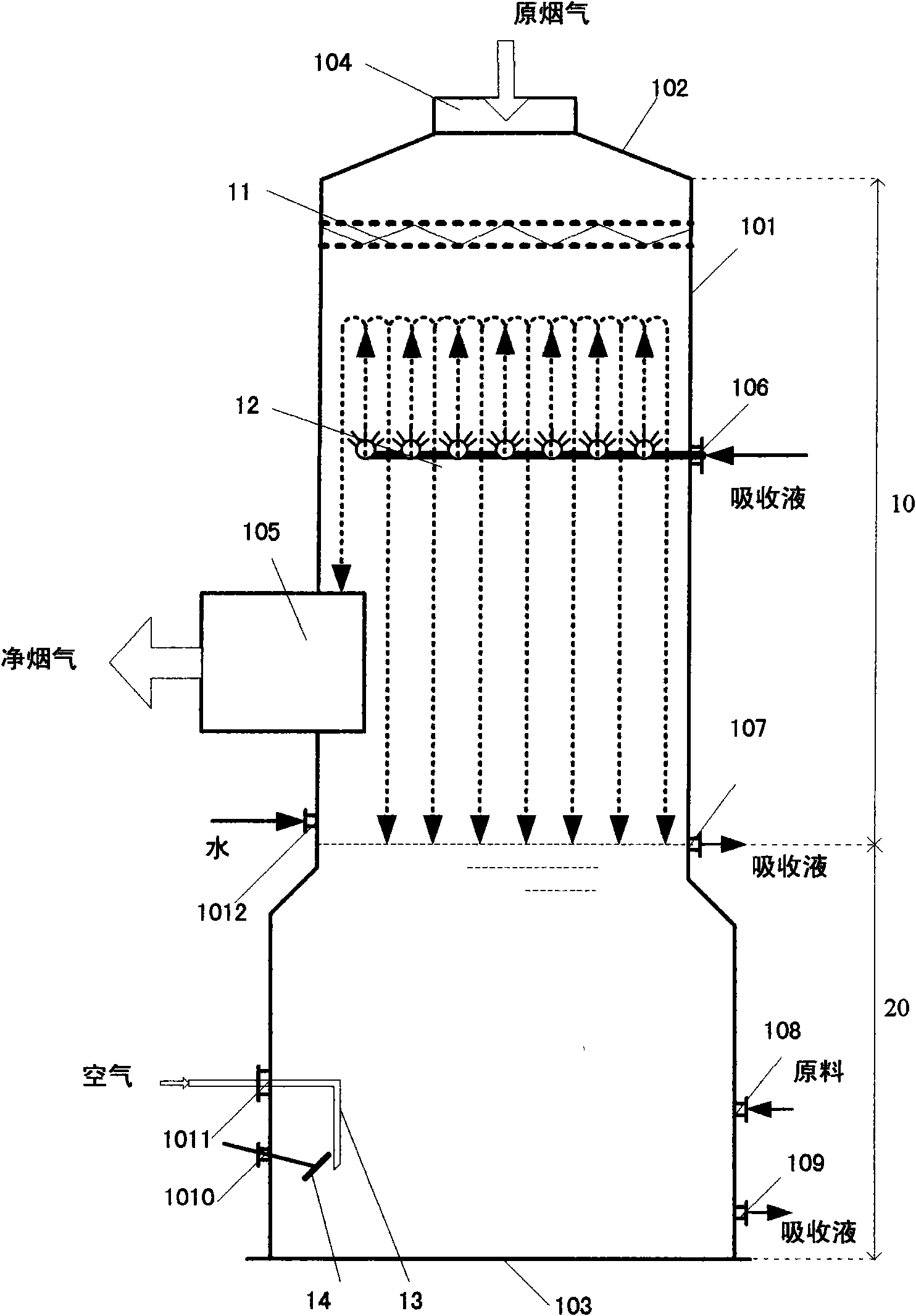

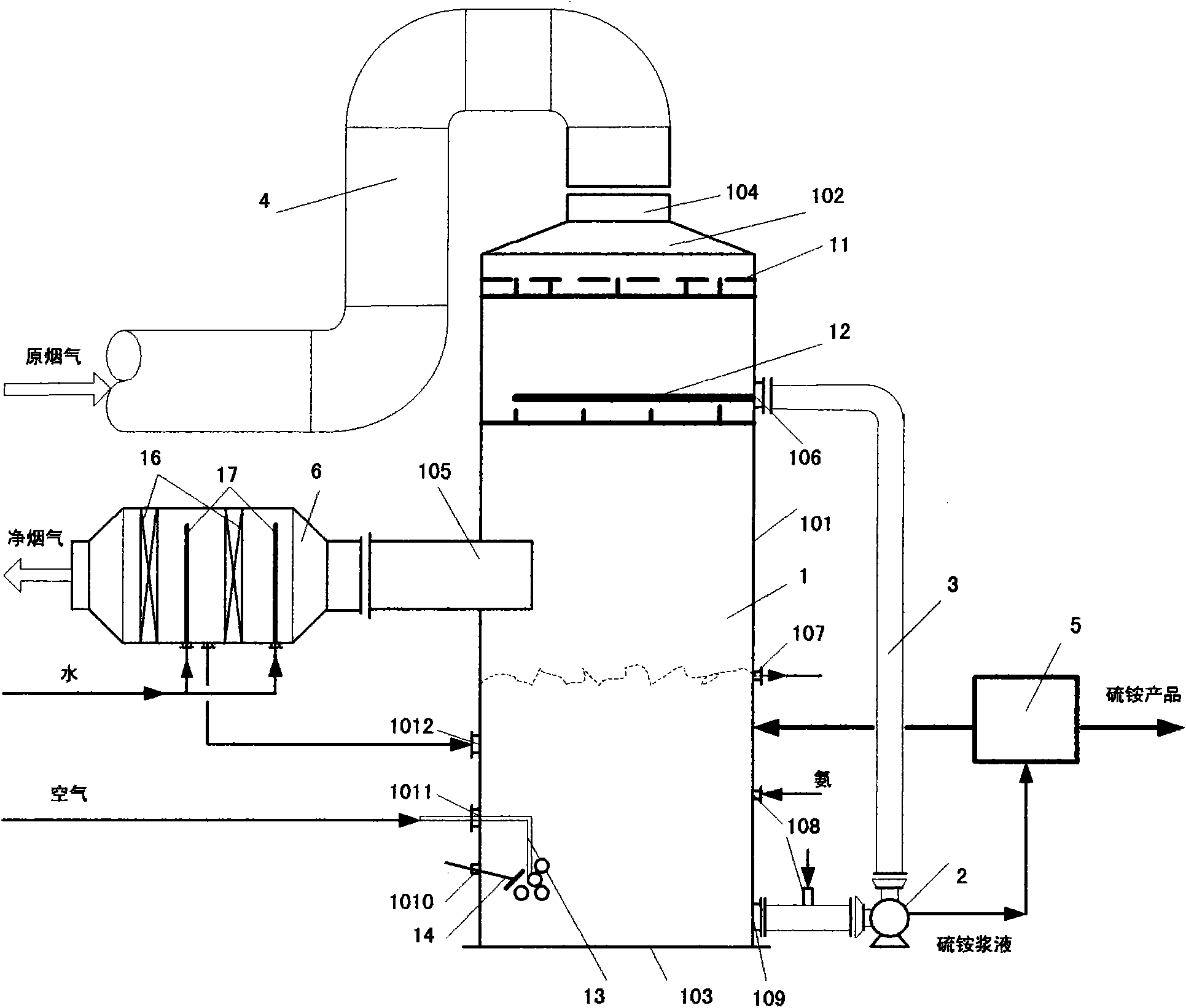

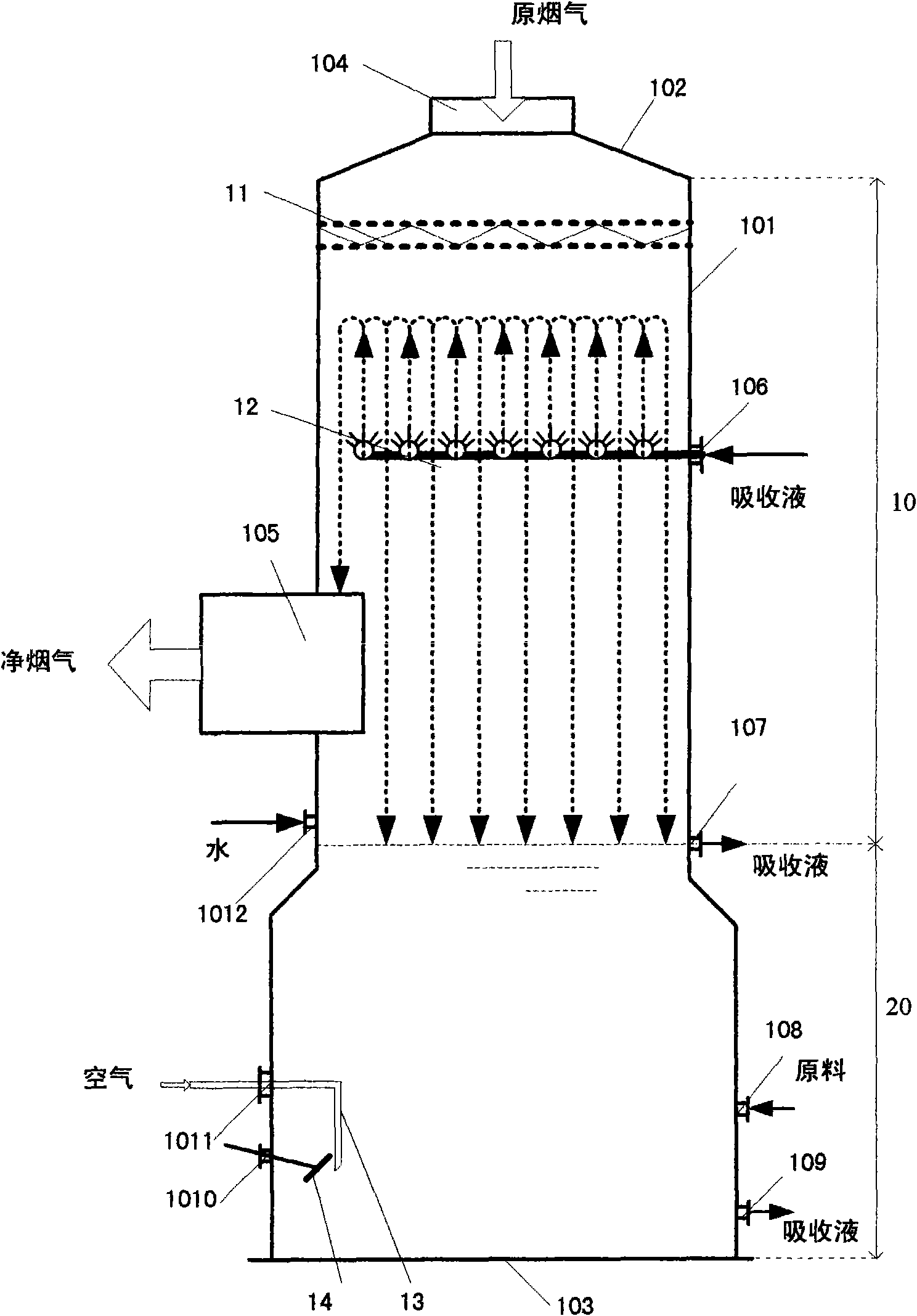

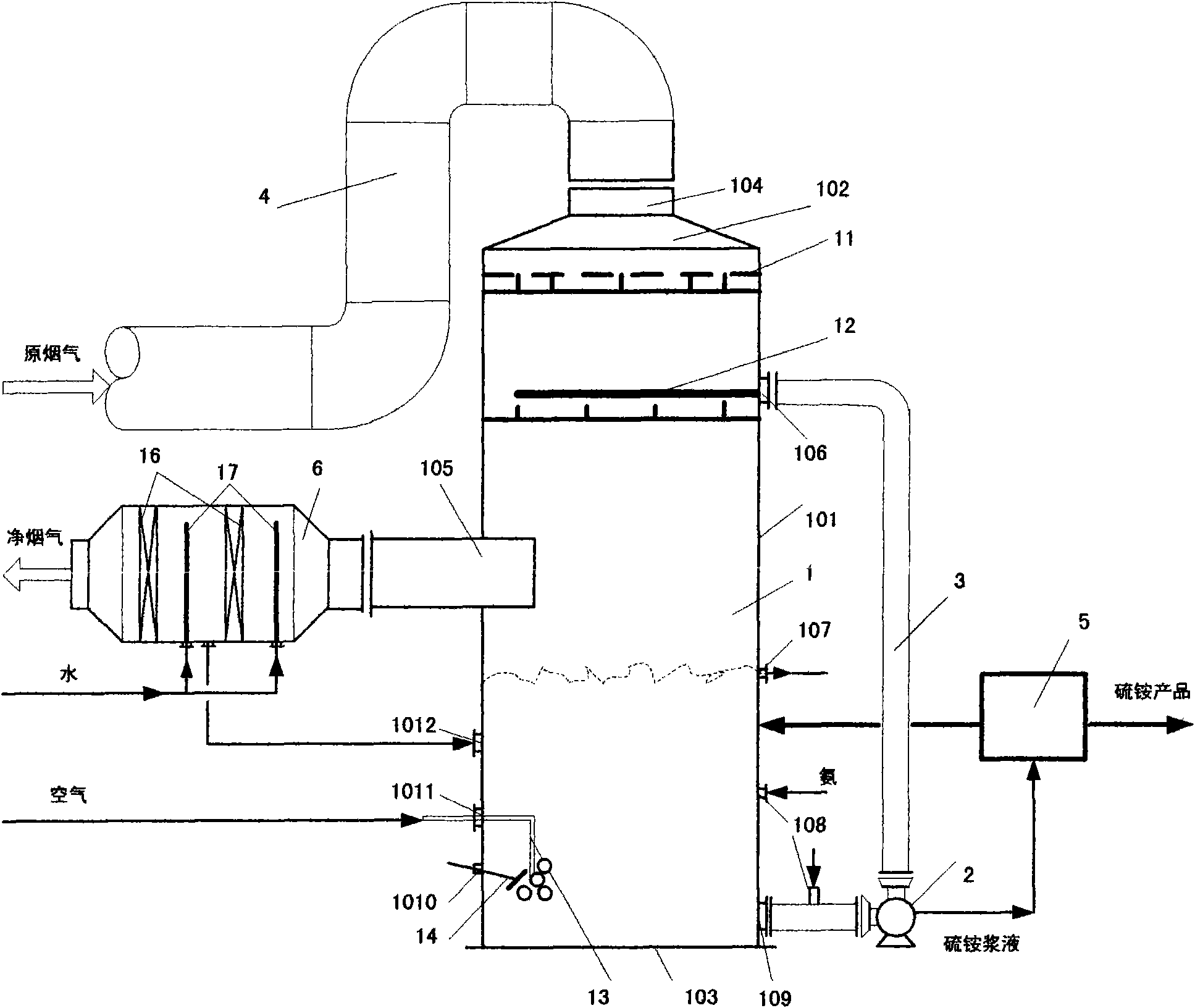

Jacking flue gas processing device and method

InactiveCN101549254ASuperior Escape Control EffectImprove mass transfer efficiencyDispersed particle separationFlue gasProcess engineering

The invention discloses a new jacking flue gas processing device and a method thereof. Flue gas enters from the top of the device, and ammoniated alkali absorption liquid absorbs acid gas of the flue gas, thereby realizing multifunctional integration process of oxidation and crystallization. The invention is characterized in that a provided flue gas uniform distribution machine and an upwardly mounted atomizing nozzle enable gas-liquid two-phase to have impact jet contact, in particular simultaneous contact of back flow and parallel flow of the flue gas with the absorption liquid is formed above an absorption liquid spray thrower, thereby finishing main processing task and canceling a cold shocking water spray member installed in other technologies; the flue gas is contacted with the absorption liquid in parallel flow, thereby further improving the processing efficiency, and simultaneously efficiently controlling the escape loss of ammonia; a parallel flow demister with high efficiency and compact device is used, so wide application is expected in the filed of flue gas purification.

Owner:娄爱娟

Crude oil distillation method

The invention discloses a crude oil distillation method. A primary flash distillation tower is arranged between a normal pressure distillation tower and a pressure reduction furnace, a pressure reduction oil line from an outlet of the pressure reduction furnace to a pressure reduction distillation tower is omitted, a secondary flash distillation tower is arranged between the pressure reduction furnace and the pressure reduction distillation tower, tower bottom heavy oil of the normal pressure distillation tower, i.e. normal bottom oil enters the primary flash distillation tower after being mixed with cyclic pressure reduction slag oil, the tower top gas phase of the primary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, bottom oil of the primary flash distillation tower enters the secondary flash distillation tower through being heated by the pressure reduction furnace, the tower top gas phase of the secondary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, and bottom oil of the secondary flash distillation tower is introduced into a flash distillation section of the pressure reduction distillation tower for pressure reduction distillation. Compared with the prior art, the method has the advantages that on one hand, the yield of the pressure reduction slag oil is reduced, and the economic benefits of devices are improved; and on the other hand, the load of the pressure reduction furnace and the pressure reduction distillation tower is reduced, the device investment is saved, and the energy consumption of the devices is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

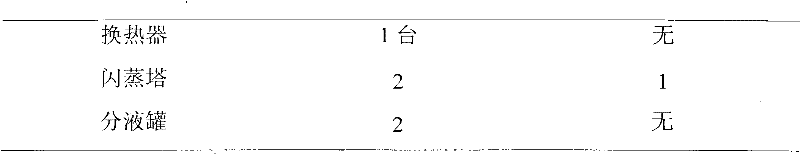

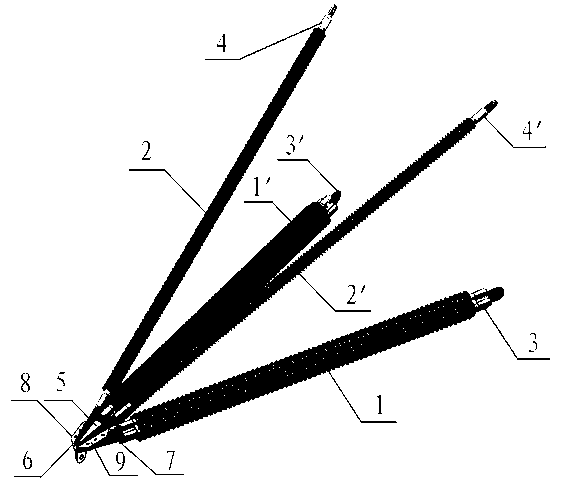

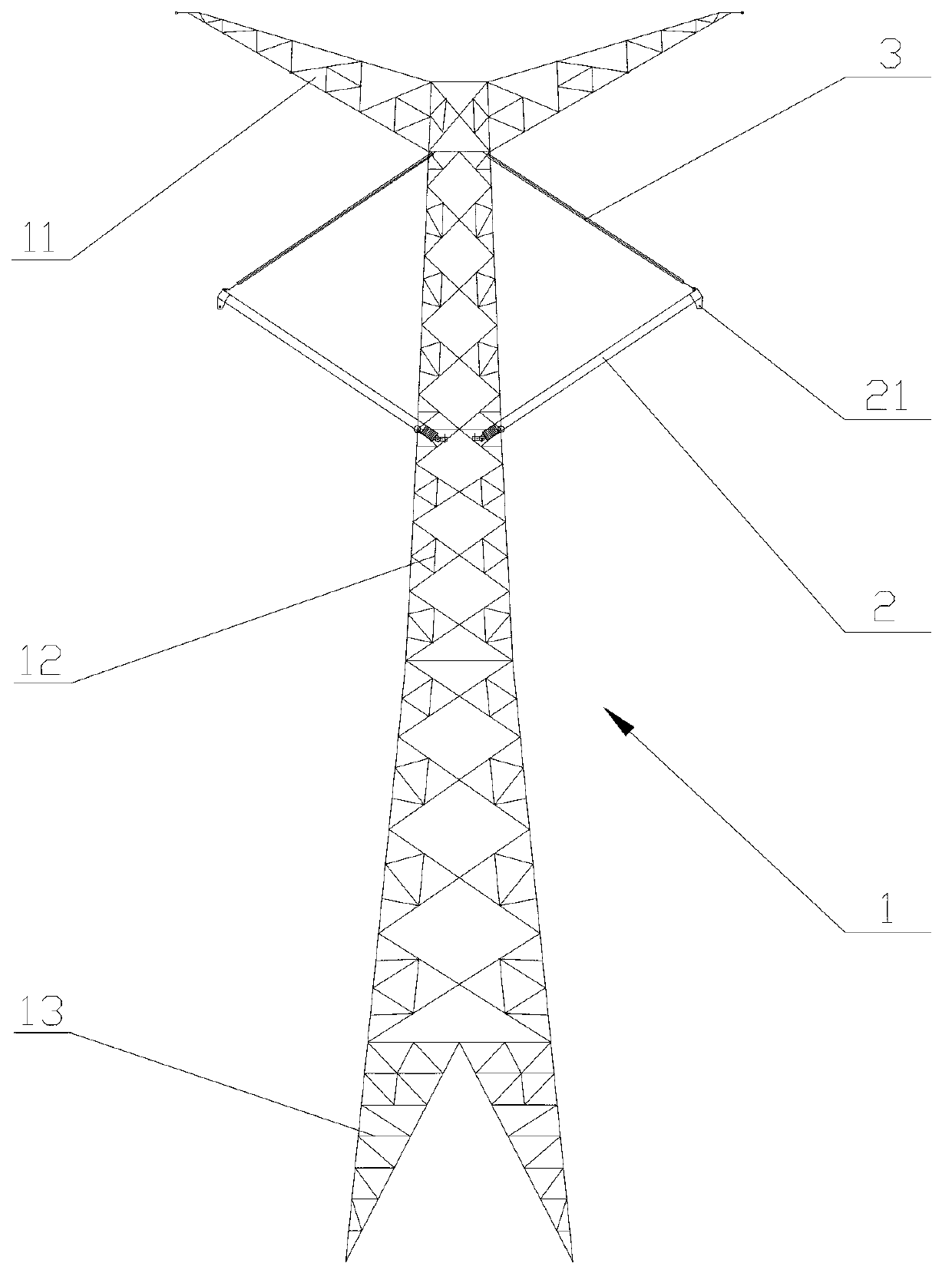

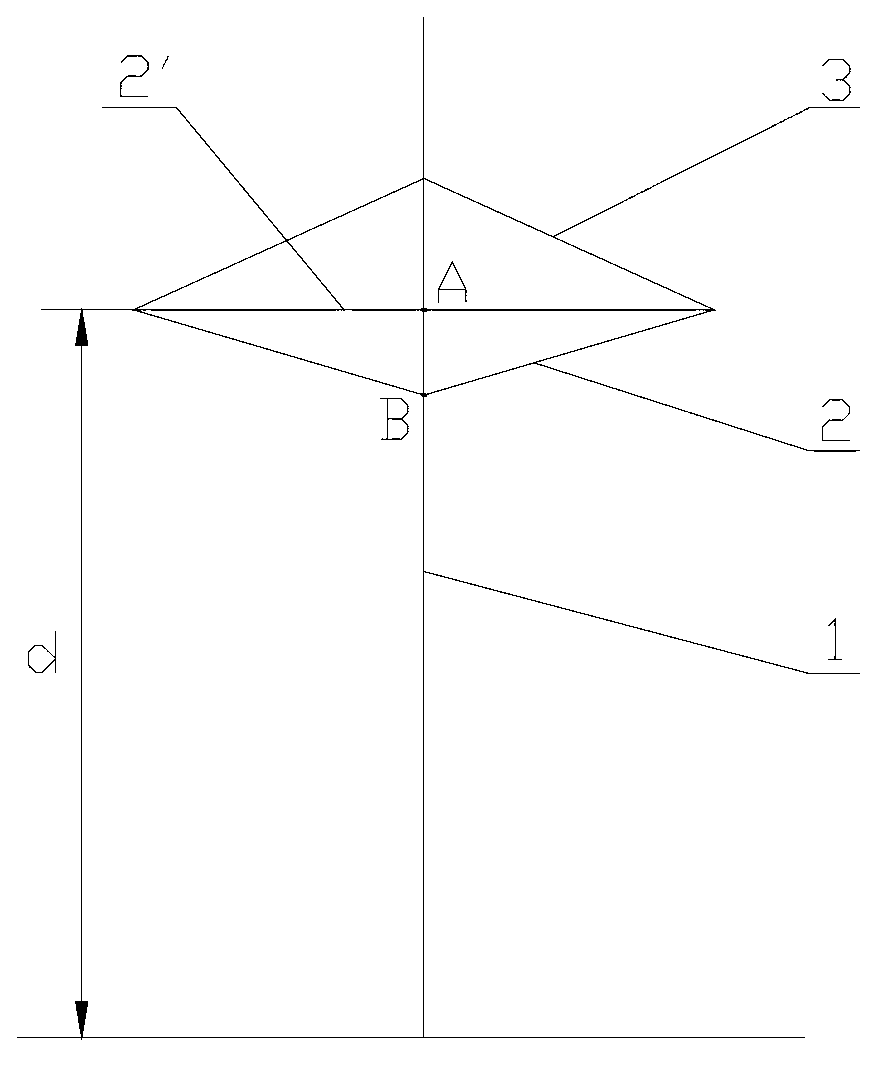

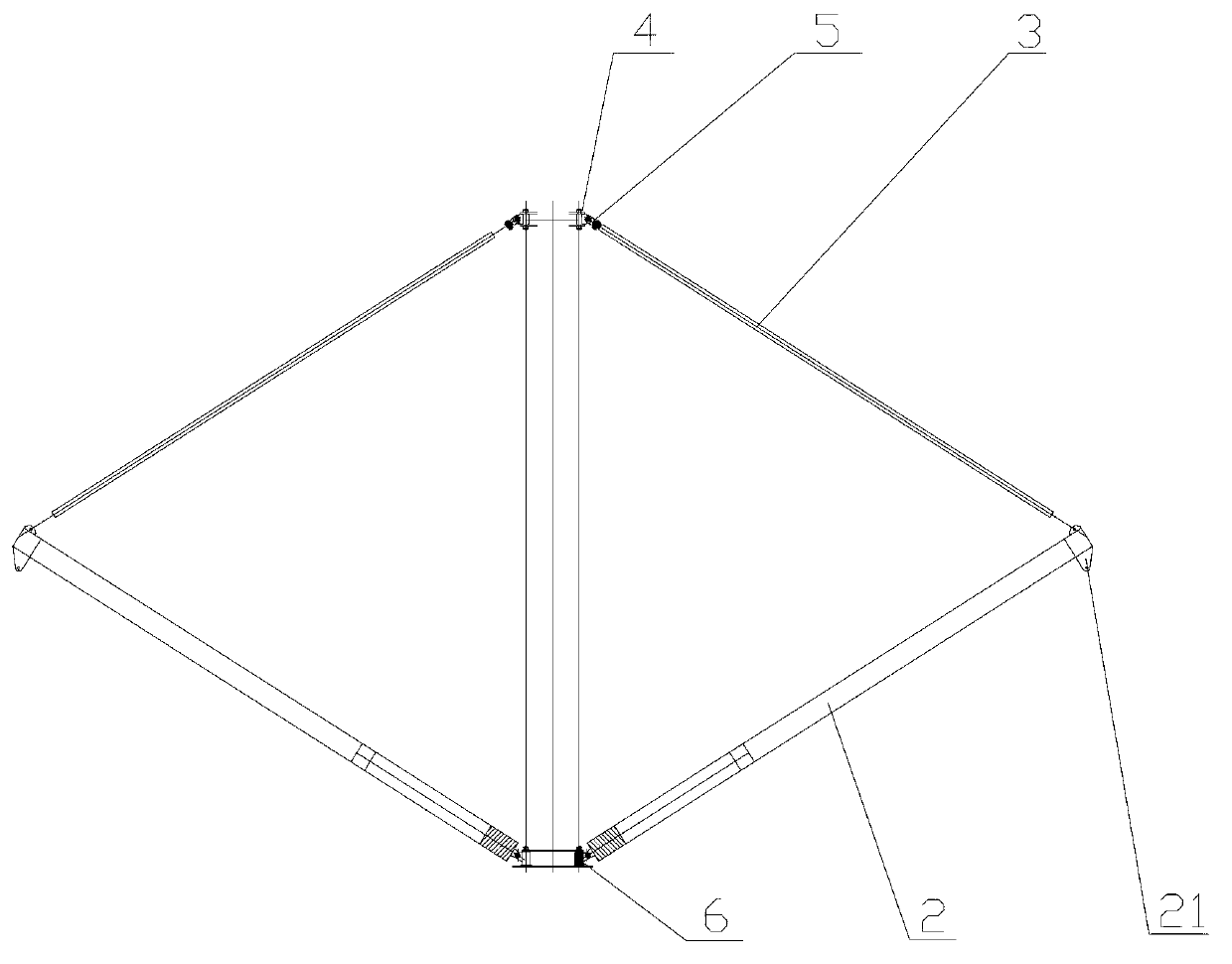

Composite material combined type cross arm for high-tension transmission line tower pole

The invention discloses a composite material combined type cross arm for a high-tension transmission line tower pole. The composite material combined type cross arm comprises two anti-bending composite insulating parts and two tensile composite insulating parts. Four end part armor clamps and four root part armor clamps are respectively arranged at the end parts and the root parts of the anti-bending composite insulating parts and the tensile composite insulating parts, wherein the end part armor clamps and the root part armor clamps, which are respectively arranged at the two ends of the anti-bending composite insulating parts are spliced; the end part armor clamps and the root part armor clamps, which are respectively arranged at the two ends of the tensile composite insulating parts are pressed; and an end part clamp connecting plate is used for fixedly connecting the four end part clamps through bolts to form the composite material combined type cross arm. The structure of the composite insulating parts is improved so that the self gravity of the composite cross arm is effectively reduced, the diameter of an electric gap circle between a wire and an iron tower is reduced, and the width of a passage and the tower height are reduced. The composite material combined type cross arm is simple in structure and fast to assemble and can be arrayed into tower shapes including a drum shape, an umbrella shape and the like, so that the occupied land is saved and the composite material combined type cross arm is good for popularization and application.

Owner:北玻电力复合材料有限公司

Reduced pressure distillation method with low energy consumption and deep total distillation rate

ActiveCN103242896AIncrease gasification rateReduce pressure drop lossTreatment with plural serial refining stagesThermodynamicsEconomic benefits

The invention discloses a reduced pressure distillation method with low energy consumption and deep total distillation rate. By arranging a reduced pressure flashing tower behind a reduced pressure heating furnace, light fractions vaporized by heat are separated out, load of a reduced pressure distillation tower is reduced and energy consumption of an apparatus is reduced; by arranging a reduced pressure flashing tank behind the reduced pressure distillation tower, relatively light fractions in reduced pressure residues can be further flashed under a vacuum degree higher than that of the bottom of a reduced pressure distillation tower, yield of reduced pressure distillate oil is increased, and thus a reduced pressure distillation operation with low energy consumption and deep total drawing rate can be realized. With the reduced pressure distillation method, the content of fractions with a temperature lower than 500 DEG C in the reduced pressure residues can be reduced to the minimum, so that the distillation rate of the reduced pressure distillation is increased and economic benefits of the apparatus can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

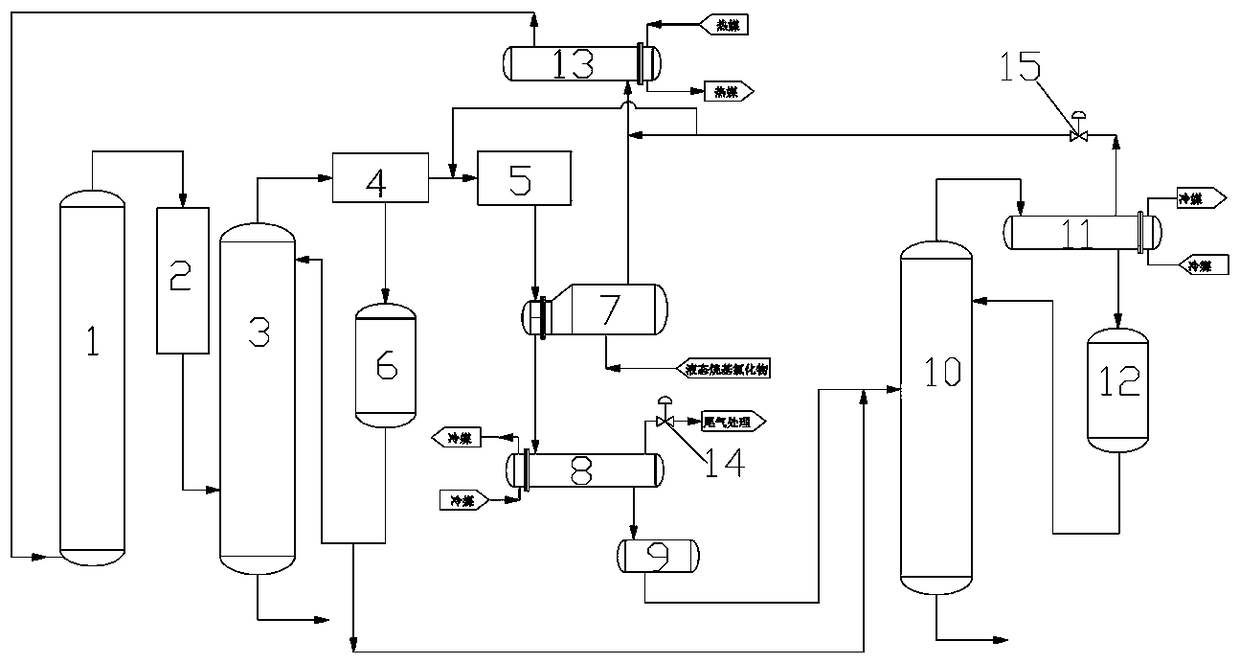

Methane chloride recycling and feeding process and device

ActiveCN108530260AEliminate damageEliminate quality issuesHalogenated hydrocarbon separation/purificationGas phaseBoiling point

The invention provides a methane chloride recycling and feeding process and device. The process comprises the following specific steps: removing the vast majority of dust from a methane-chloride-containing gas mixture from the top of a reactor via a dust removal system, and then washing the gas mixture via a dust removal tower to remove high-boiling-point substances and fine powder; after condensing a material on the top of the dust removal tower via a cooling system, taking part of the material as a cleaning solution, and feeding the other part of the material to a refining tower; feeding noncondensable gas in the cooling system to a compressing system; carrying out heat exchange on compressed gas and liquid methane chloride via a vaporizer, vaporizing the liquid methane chloride, coolingand condensing the compressed gas, and then feeding the compressed gas into a condenser for further condensing, carrying out tail gas removal treatment on noncondensable gas in the condenser, and feeding condensate to a buffering tank; enabling the methane chloride of the buffering tank and the methane chloride of a storage tank to enter the refining tower together; and enabling a gas phase on the top of the refining tower to enter a partial condenser for partial condensing, and feeding the condensate into a refluxing tank and totally refluxing the condensate into the refining tower. The methane chloride can be recycled effectively, the main content is higher than 99.5%, moreover, the process is simple, the investment of equipment is low, and energy conservation and consumption reductionare implemented.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

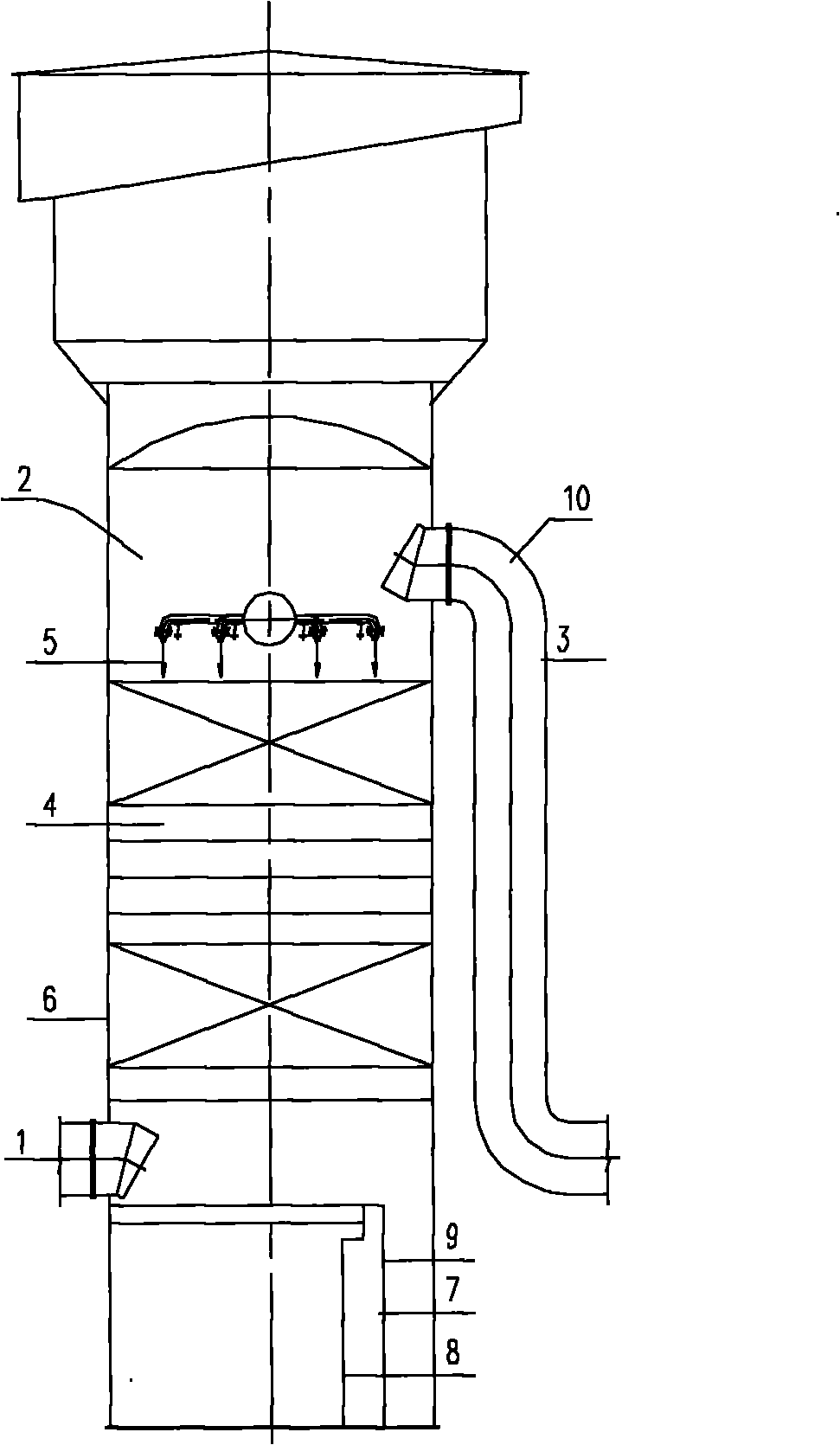

Desulfurizing tower for gas desulfuration by using liquid phase catalytic oxidation

ActiveCN101987976ASimple structureImprove stabilityDispersed particle separationGas purification by liquid washingCatalytic oxidationProduct gas

The invention discloses a desulfurizing tower for gas desulfuration by liquid phase catalytic oxidation. The lower part of the washing segment of a desulfurizing tower is provided with an inlet for gas to be desulfurized, and the upper part of the washing segment of the desulfurizing tower is provided with a doctor solution spraying part. The desulfurizing tower is characterized in that a descending pipeline causing desulfurized gas to pass is arranged along the axis of the washing segment of the desulfurizing tower, and the top of the washing segment of the desulfurizing tower is provided with an entrainment capturing device and is communicated with a horizontal pipeline which can lead the desulfurized gas out of the lower part of the washing segment of the desulfurizing tower. The desulfurizing tower of the invention has simple structure and good stability and is easy to manufacture and install. The structure that sulfurous gas enters or leaves the desulfurizing tower is more reasonable, which is favourable for the even distribution of desulfurized gas which enters or leaves the desulfurizing tower; the entrainment capturing device arranged on the top reduces entrainment, is favourable for lowering tower height and is favourable for reducing the equivalent diameter of the washing segment of the desulfurizing tower so as to bring convenience for reducing amplification effect and improve desulfurizing efficiency; a vertical heavy-calibre gas pipeline which is connected out of the upper part of the washing section is cancelled, namely eccentric load, wind load and the like which are unfavorable for the desulfurizing tower are cancelled.

Owner:鞍钢集团工程技术有限公司

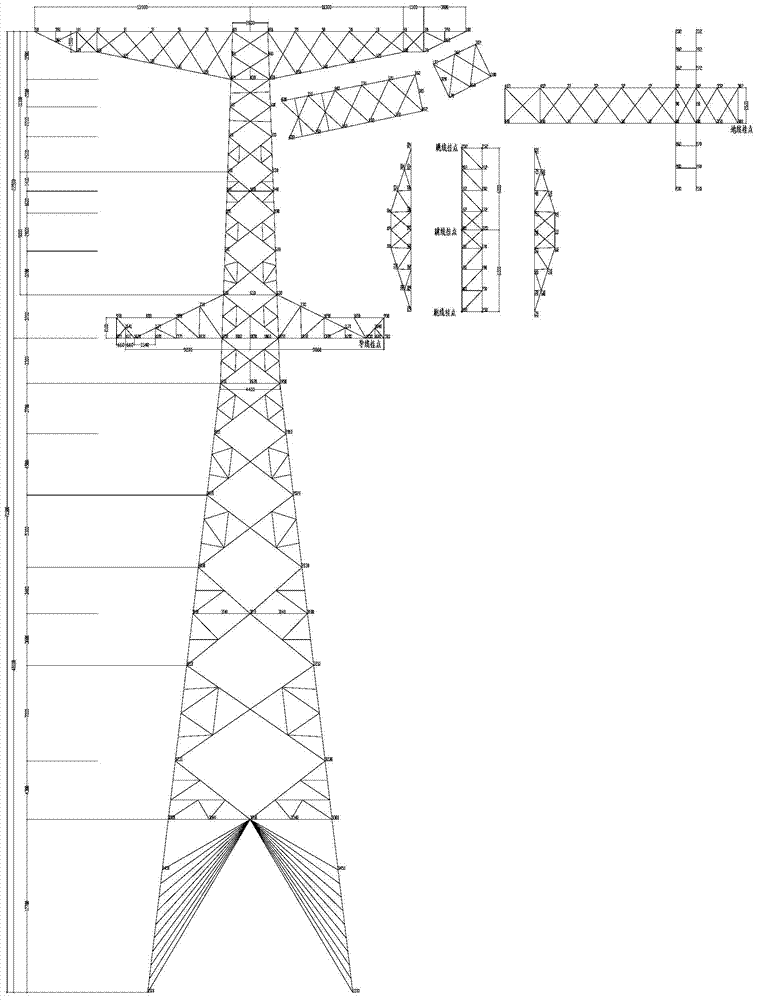

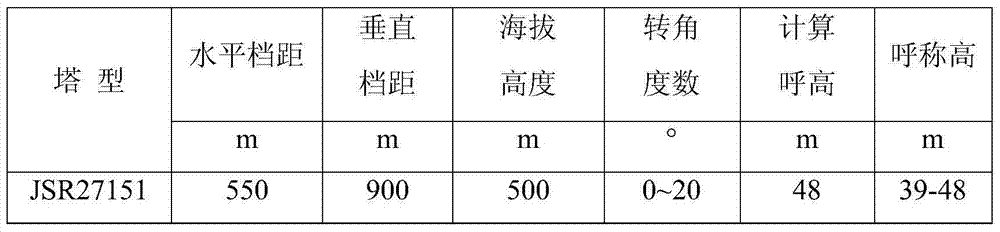

Upward-winding tension-resistant tower on extra-high-voltage direct-current transmission line

The embodiment of the invention provides an upward-winding tension-resistant tower on an extra-high-voltage direct-current transmission line. The upward-winding tension-resistant tower comprises a tower body, tower legs, a ground wire support and a guide wire cross arm, wherein an upward-winding wire jumper support is arranged on the outer side of the ground wire support, and the lower plane of the upward-winding wire jumper support is perpendicular to the central axis of the ground wire support; above the guide wire cross arm, an upward-winding wire jumper guides the current to an advancing side strain clamp from a retreating side strain clamp. According to the upward-winding tension-resistant tower on the extra-high-voltage direct-current transmission line, it is avoided that because the distance from the wire jumper to the ground is not enough, the rooting problem is caused or because the distance between trees on a high slope is not enough, the trees should be cut. Besides, for the tension-resistant tower located on a steep slope, the edge phase wire jumper is wound upwards to be arranged, on the one hand, influences on the environment are reduced, on the other hand, the perpendicular distance from a cross arm on the lowermost layer of the tower to the ground is effectively reduced, the consumption of tower material of the iron tower is reduced, and finally the purposes that comprehensive investment of the line is saved, the tower is convenient to construct and running reliability of the line is improved are achieved.

Owner:STATE GRID CORP OF CHINA +8

Mixed-flow discharge gas treatment method and treatment method

InactiveCN101549253ASimple structureSuperior ammonia slip control effectDispersed particle separationMixed flowSpray nozzle

The invention discloses a new mixed-flow discharge gas treatment device and a method. The discharge gas enters the device from the top of the device so as to realize the integrated function of absorption of acidic gas in the discharge gas by ammonia-containing alkaline absorption liquid, oxidisation and crystallisation. The technical proposal of the invention aims to provide a discharge gas distributor and an absorption liquid spray thrower with a spraying nozzle mounted upwards such that five different gas-liquid contact areas, including a gas uniform flow area, a gas mixed flow area, a gas forward flow area, a gas-liquid separation area and an absorption liquid storage tank, are arranged in the discharge gas treatment device. The beneficial effects of the invention are that the treatment efficiency is 98-99%, the pollutant content in the purified discharge gas is 50-250mg / Nm3, the ammonia escape control effect is excellent, the escaped ammonia content in the purified discharge gas is 5-25mg / Nm2, the treatment device has a simple structure, optimises the water utilisation, and has obvious application prospect in the field of discharge gas purification.

Owner:王建敏

Device for dynamically neutralizing vibrations in single cable overhead power transmission lines

InactiveUS8309846B2Improve actionReduce in quantityMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsElastic componentEngineering

Owner:ESPINDOLA JOSE JOAO DE

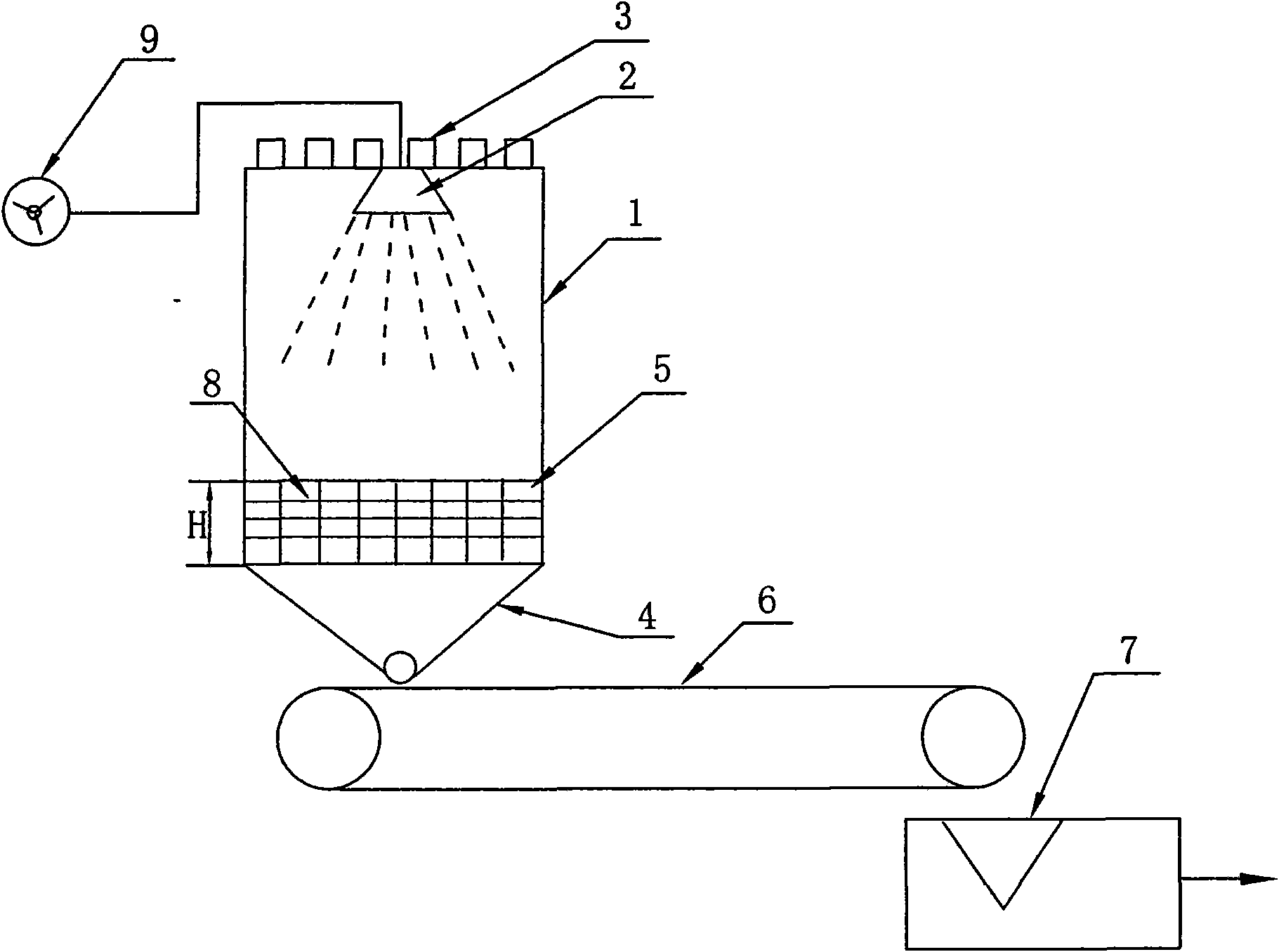

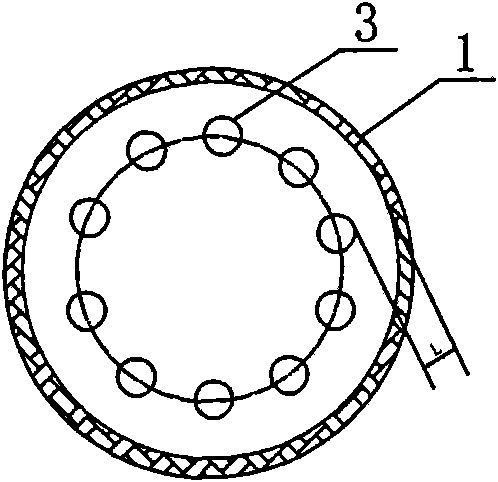

Novel tower-type air-cooled prilling device for full-melting compound fertilizers

ActiveCN101555181AIncrease the speed of descentEasy to packFertiliser formsFertilizer mixturesTO-18Engineering

The invention provides the air-cooled crystallization prilling device for full-melting compound fertilizers, which comprises a prilling tower (1) and a rotary prilling head (2), wherein, the height of the prilling tower (1) is 15m to 70m, and the diameter thereof is 6m to 18m; the rotary prilling head (2) is mounted in the center of the top part on the inner side of the prilling tower (1); a cone-shaped collector (4) is connected to the lower part of the prilling tower (1); the invention is characterized in that a circle of exhaust fans (3) are at least mounted at the top of the prilling tower (1); the air inlets of the exhaust fans (3) are communicated with the inner cavity of the prilling tower (1); the distance L between the edge of the outermost exhaust fan (3) and the inner wall of the prilling tower (1) is 0.9m to 2.5m; a circle of air-inlet windows (5) with the height H thereof being 1.2m to 3m are formed at the bottom of the prilling tower (1) and the upper part of the cone-shaped collector (4); a conveying device (6) is mounted below the discharge hole of the cone-shaped collector (4); and a drum cooler (7) is mounted at the discharging end of the conveying device (6). The invention has the advantages of good prilling effect and convenient manufacture and installation.

Owner:福建佳玛驰生态科技有限公司

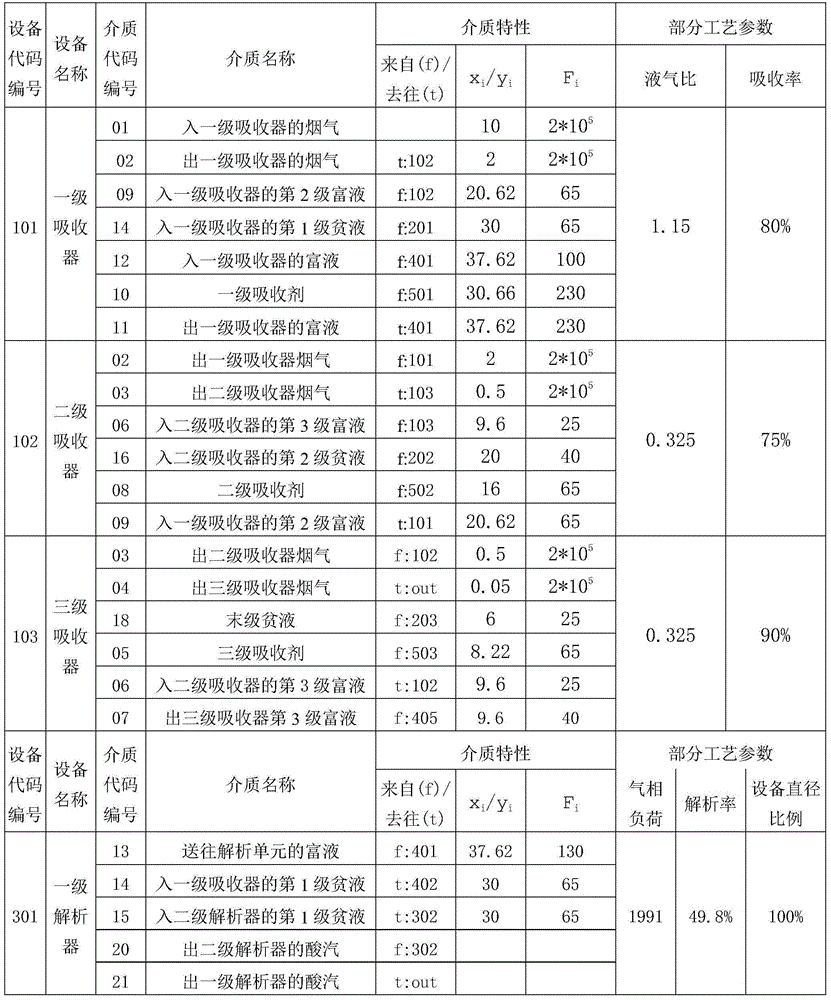

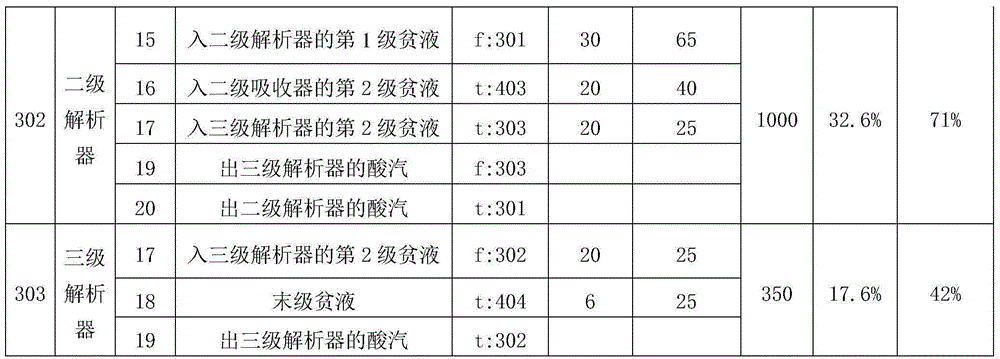

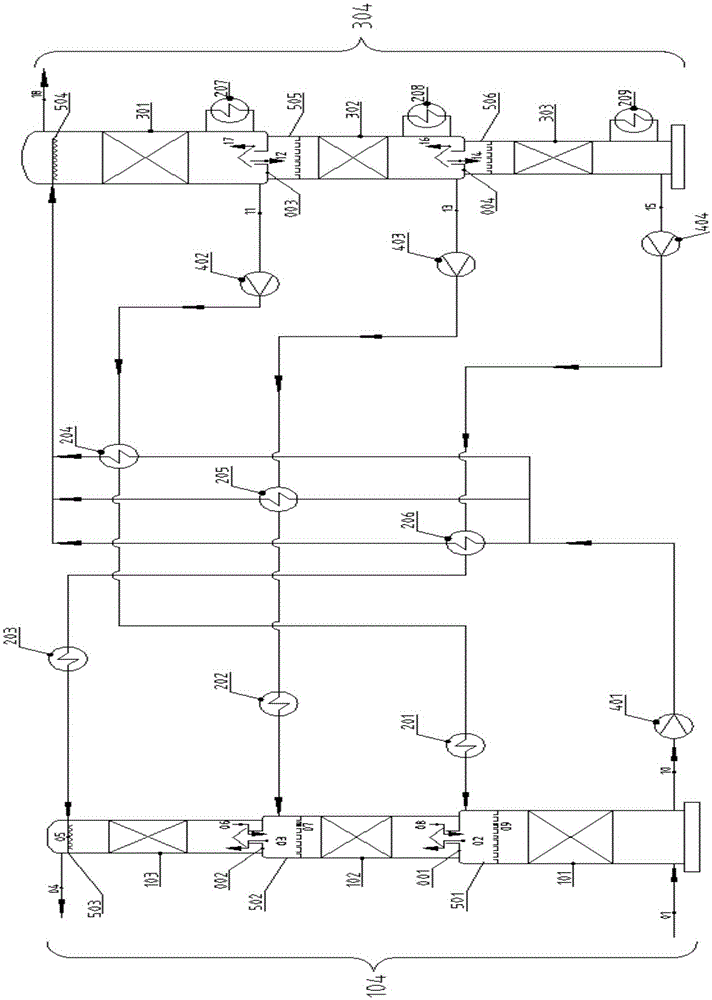

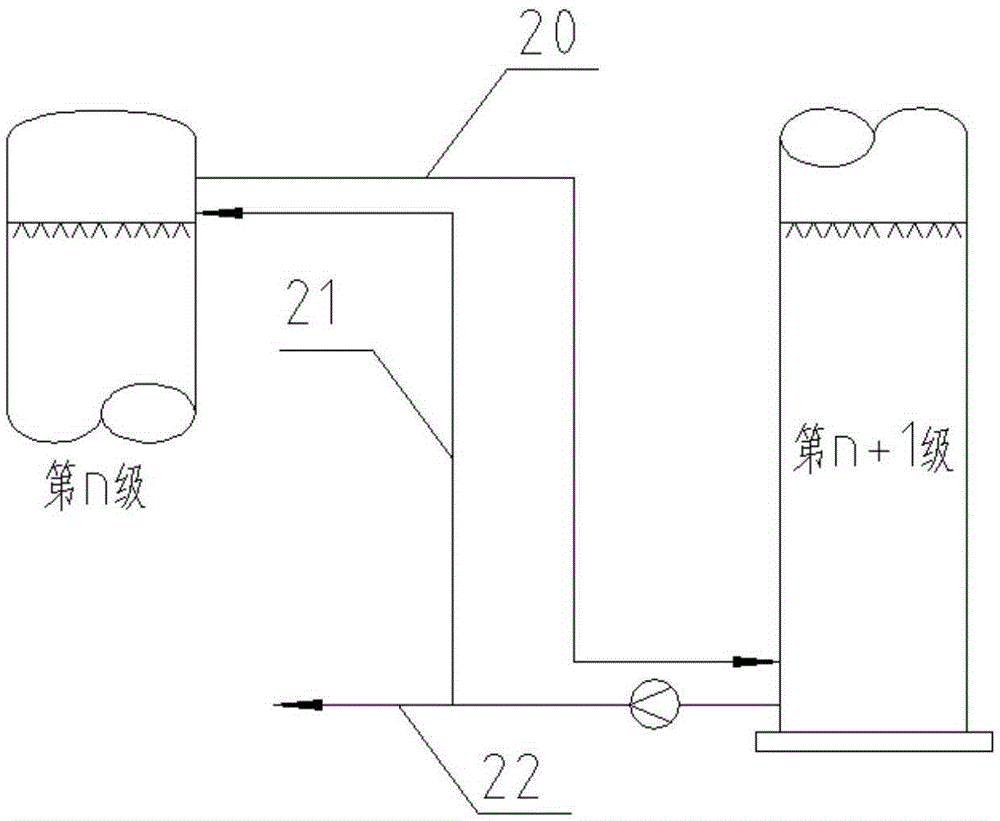

Multi-stage nested absorption-analysis citrate process for purifying SO2 in smoke

The invention provides a multi-stage nested absorption-analysis citrate process for purifying SO2 in smoke. The process includes the steps that multi-stage absorption is conducted; solutions are utilized stepwise among stages of absorption devices; circulation nesting use among stages and multi-stage analysis are conducted on partial absorption liquid. The process has the advantages that the utilization efficiency of absorbent is improved; the process medium procedure is clear; all the stages of devices in the process unit are optimally configured; the absorption devices are small in size; the utilization amount of the total absorbent is small, and electricity consumption in transport is low; the analysis driving force is large; process devices are few; the pressure system is consistent, and the process is convenient to operate.

Owner:马鞍山艺诚机电有限公司

Multistage absorption-desorption citrate process for purifying SO2 in flue gas

ActiveCN105251315AReduce volumeReduce dosageDispersed particle separationPressure systemProcess equipment

The invention provides a multistage absorption-desorption citrate process for purifying SO2 in flue gas. The process comprises the following steps: multistage absorption; gradient utilization of solutions among absorption device stages; and multistage desorption. The multistage absorption-desorption citrate process has the following advantages: the utilization efficiency of an absorbent is improved; process media and flow are clear; configuration of each stage of device in process units is optimized; the sizes of absorption devices are small; the overall usage amount of the absorbent is small and power consumption in conveying is low; desorption impetus is great; the amount of process equipment is small; pressure systems are consistent; operation is convenient; etc.

Owner:马鞍山艺诚机电有限公司

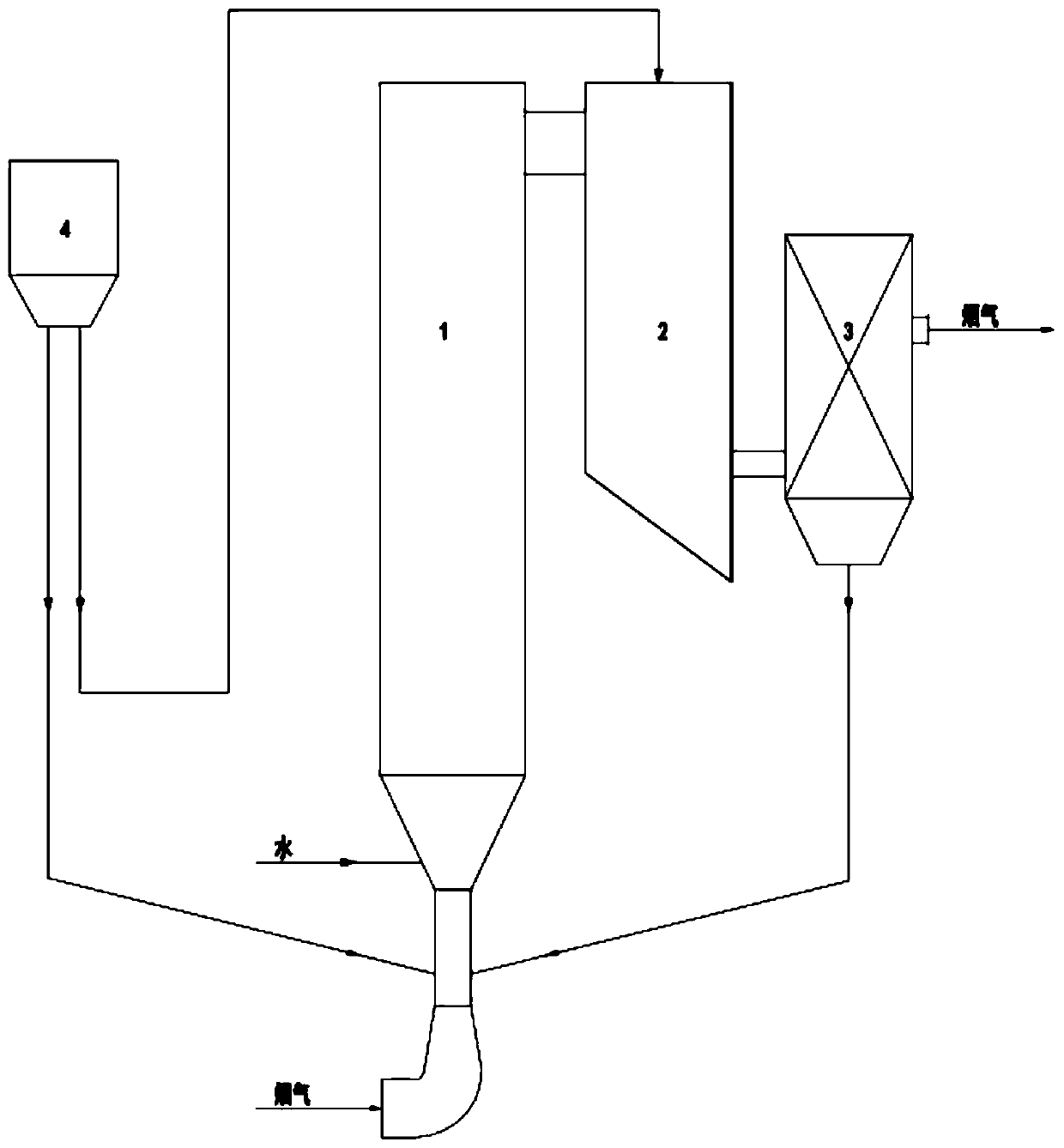

Two-stage circulating fluidized bed desulfurization system and desulfurization process thereof

InactiveCN111249872ALower tower heightLower the overall elevationGas treatmentDispersed particle filtrationSulfur dioxideProcess engineering

The invention belongs to the field of flue gas treatment. The problem that the arrangement elevation of a desulfurization system is increased, a support structure is large and complex, and the operation resistance of the desulfurizing tower is large can be solved. According to the two-stage circulating fluidized bed desulfurization system and the desulfurization process provided by the invention,the advantage of high concentration of materials in an ascending tower and the advantage of high contact probability of fresh materials and sulfur dioxide in a descending tower are utilized, so that the height of the tower is reduced and the overall utilization rate of a desulfurizing agent is increased under the condition of ensuring the same residence time of flue gas. The desulfurization systemcomprises a desulfurization tower and a desulfurizing agent bin, wherein the desulfurizing tower comprises the ascending tower and the descending tower, and the top of the ascending tower is communicated with the top of the descending tower; the desulfurizing agent bin is respectively communicated with a venturi section connected with the bottom of the ascending tower and the top of the descending tower and is used for respectively adding a desulfurizing agent into the desulfurizing tower from the venturi section of the ascending tower and the top of the descending tower.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL

Electric transmission line tower using composite insulators

InactiveCN103276939AReduce longitudinal unbalanced tensionGuaranteed ground distanceTowersComposite insulatorsWire tension

The invention discloses an electric transmission line tower using composite insulators. The electric transmission line tower using the composite insulators comprises tower legs, a tower body and a tower head, and further comprises at least one group of composite insulators which are arranged on the lateral side of the tower and are composed of a suspension insulator and a supporting insulator. One end of the suspension insulator is connected with the tower body, the other end of the suspension insulator is connected with one end of the supporting insulator, the other end of the supporting insulator is connected with the tower body, and the connecting point of the other end of the supporting insulator and the tower body is located below the connecting point of the suspension insulator and the tower body. One end, connected with the suspension insulator, of the supporting insulator is provided with a link fitting. Because the supporting insulator is hinged to the tower body, the bending moment, of the supporting insulator, generated by unbalanced wire tension and the bending moment and the torque, generated by the unbalanced wire tension, of the tower are eliminated, and requirements for the strength of the supporting insulator and the tower are reduced. On the premise that the clearance to ground of a wire is guaranteed, the height of the electric transmission line tower using the composite insulators is reduced, the bending and twisting affect of a conductor load on the tower and the basis load of the tower are reduced.

Owner:STATE GRID CORP OF CHINA

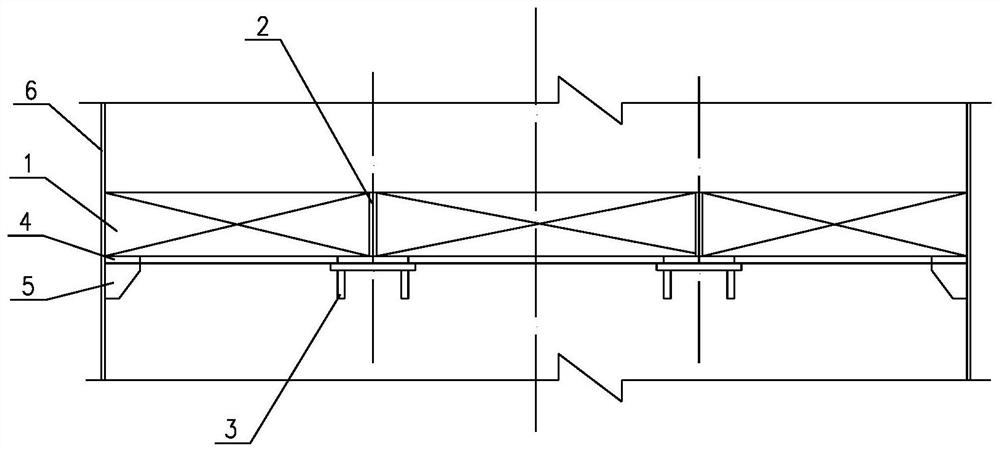

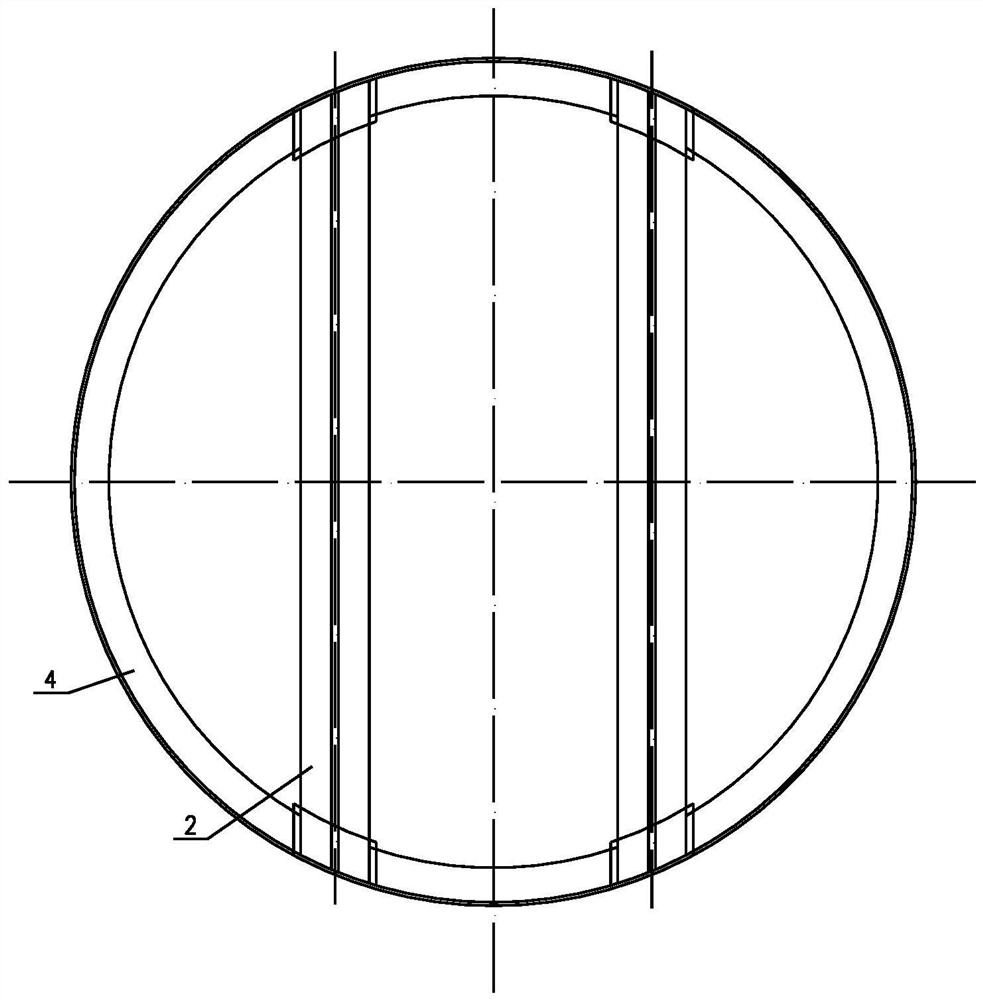

Filler support

PendingCN113117366AReduce tower heightLow costDispersed particle separationLiquid-gas reaction processesShaped beamEngineering

The invention relates to the technical field of packed towers, in particular to a filler support. The filler support comprises a steel plate net filling nest, T-shaped beams, T-shaped beam supports, a supporting ring and a supporting plate, wherein the supporting ring is annular and is fixedly connected to the inner wall of a packed tower, the supporting plate is fixedly connected to the inner wall of the packed tower, and the supporting ring is supported by the supporting plate; one or more T-shaped beams are arranged in the packed tower, vertical beams of the T-shaped beams face upwards, the two ends of cross beams of the T-shaped beams are fixedly connected to the T-shaped beam supports, and the T-shaped beam supports are fixedly connected to the inner wall of the packed tower; and the steel plate net filling nest is placed on a plane formed by the upper surfaces of the cross beams of the T-shaped beams and the upper surface of the supporting ring. According to the invention, regular packing or random packing can be placed, tower height is reduced, and cost is reduced; and gas-liquid distribution is uniform, and mass transfer efficiency is improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Tower frame combined transmitting pumping unit without guiding wheels

ActiveUS9234411B2Simple and safe processLong durationConstructionsDerricks/mastsControl systemEngineering

A tower frame combined transmitting pumping unit without guiding wheels includes a tower frame, a powering system, a transmitting system, a controlling system, a balancing weight box, a weight hauling cable, a rope wheel, a driving rope and rope hangers. The rope wheel is fixed on a side of an operation platform through a rope wheel supporting device. A central axis line of the rope wheel is located within the operation platform. A wheel rim of the rope wheel extends beyond the operation platform and a minimum distance between a most external rim thereof. The weight hauling cable and the driving rope twine around the rope wheel reversely. A free end of the weight hauling cable is connected to the balancing weight box through a rope hanger A. A platform moving device is installed between the operation platform and a top of the tower frame.

Owner:SICHUAN MODERN CENTURY MECHANICAL & ELECTRICAL COMPANY

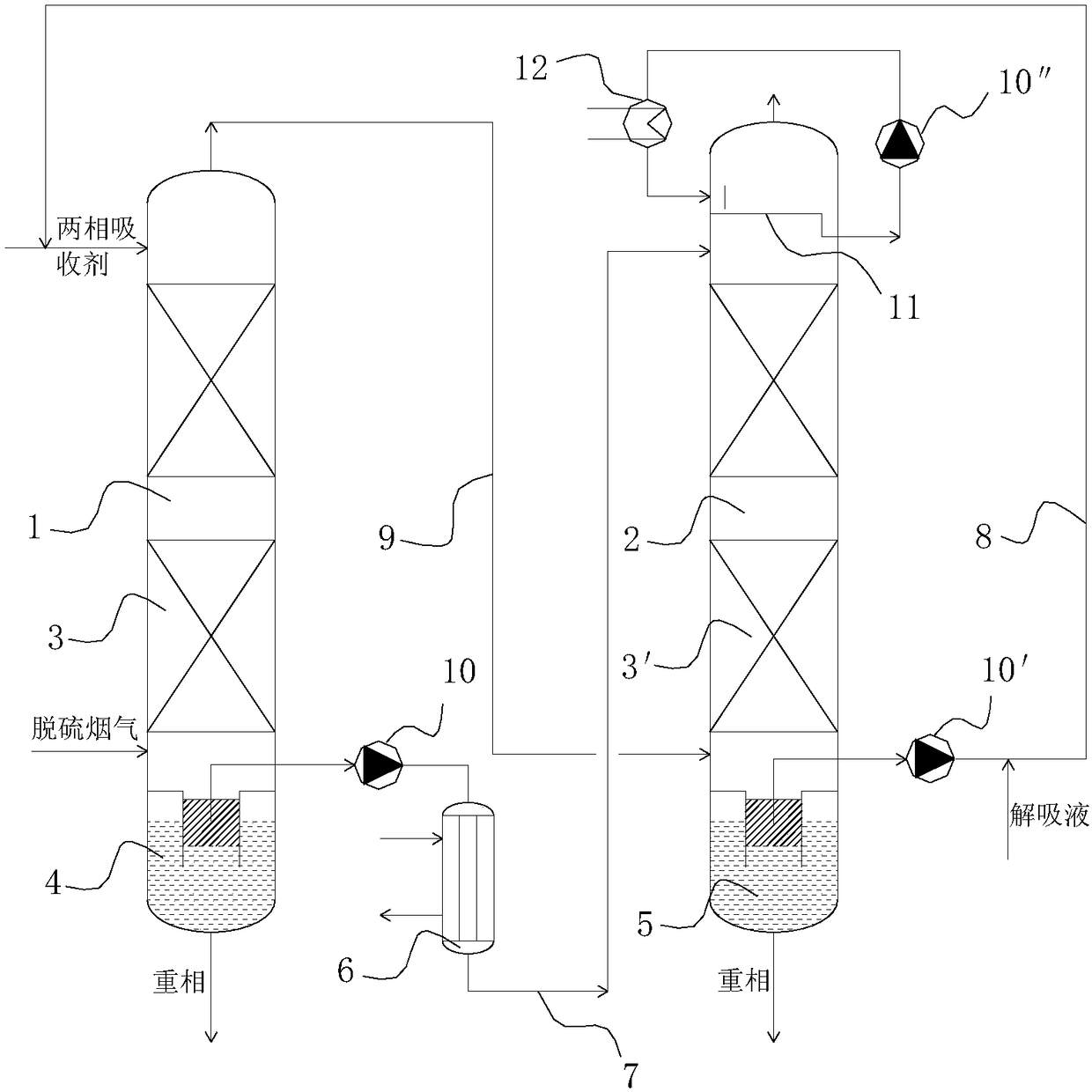

Two-phase absorbent based flue gas carbon dioxide absorbing device

InactiveCN108201785ALow investment costReduce tower heightGas treatmentDispersed particle separationCarbon dioxideFlue gas

The invention relates to a two-phase absorbent based flue gas carbon dioxide absorbing device. The two-phase absorbent based flue gas carbon dioxide absorbing device comprises a high-temperature absorption tower and a low-temperature absorption tower, wherein a flue gas inlet is formed in the lower part of the high-temperature absorption tower, and flue gas is fed to the lower part of the low-temperature absorption tower through a flue gas pipeline from the top; a first phase splitter is arranged on the bottom of the high-temperature absorption tower; light phase in the first phase splitter isfed to the upper part of the low-temperature absorption tower through a first absorbent pipeline; an inter-stage cooler is arranged on the first absorbent pipeline; a second phase splitter is arranged on the bottom of the low-temperature absorption tower; and light phase in the second phase splitter is fed to the upper part of the high-temperature absorption tower through a second absorbent pipeline. The device adopts a two-tower scheme, and reduces tower height, so that investment cost of the absorption tower is reduced.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com