Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Increase investment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

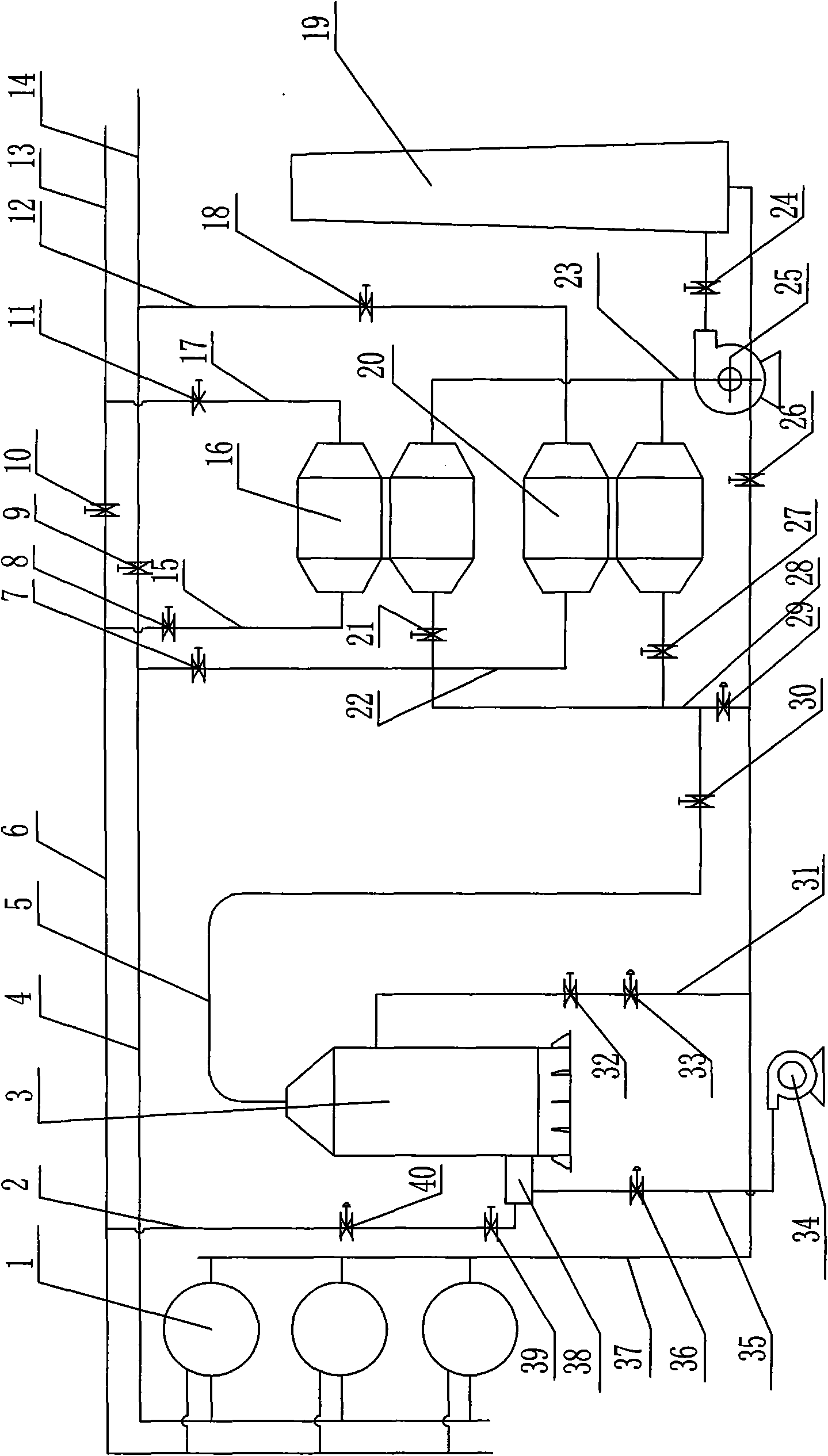

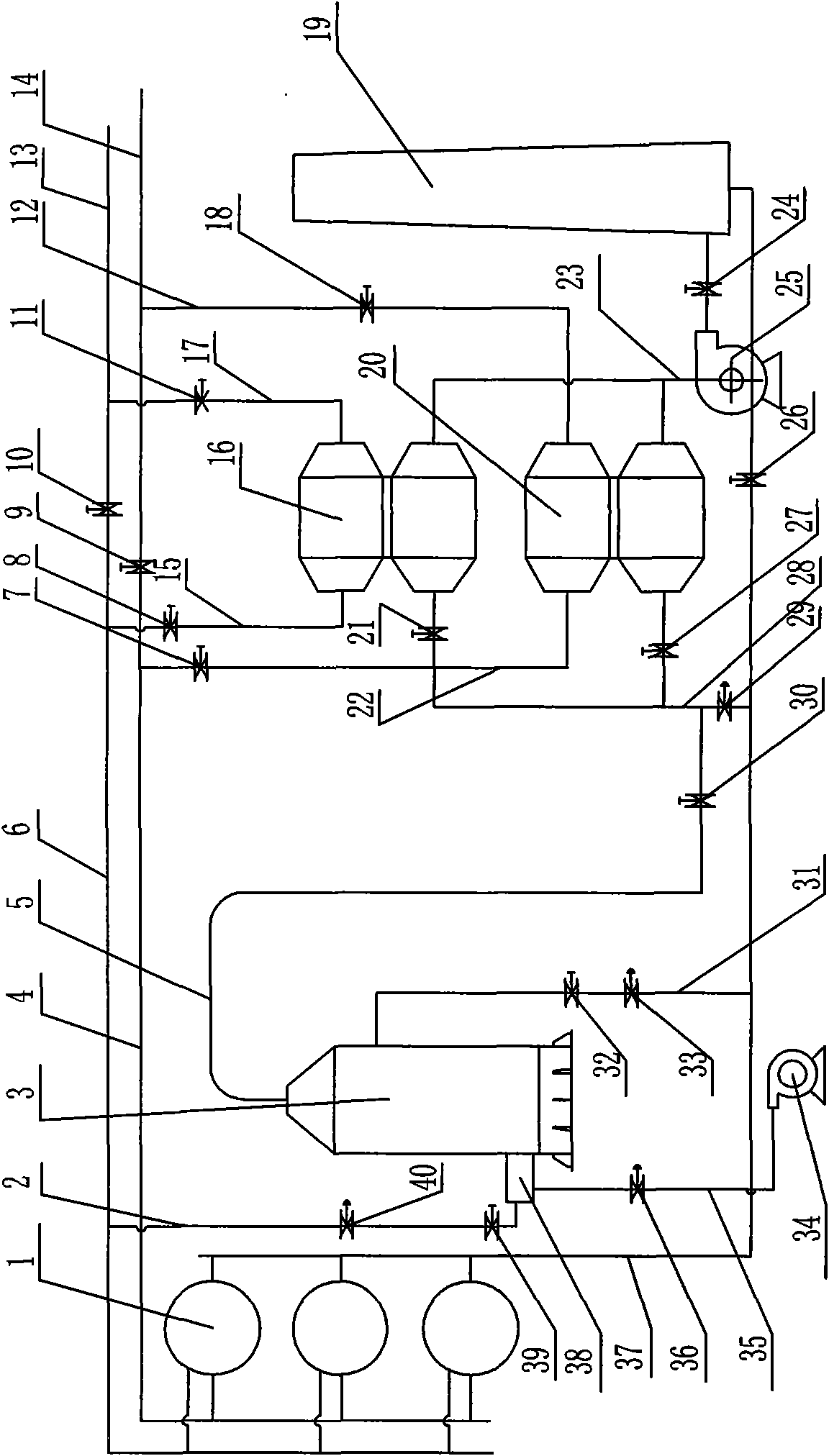

Simultaneous sintering and desulphurization and denitration system, and desulphurization and denitration method

ActiveCN102936651AEmission reductionLess investmentDispersed particle separationAir quality improvementElectrostatic precipitatorFlue gas

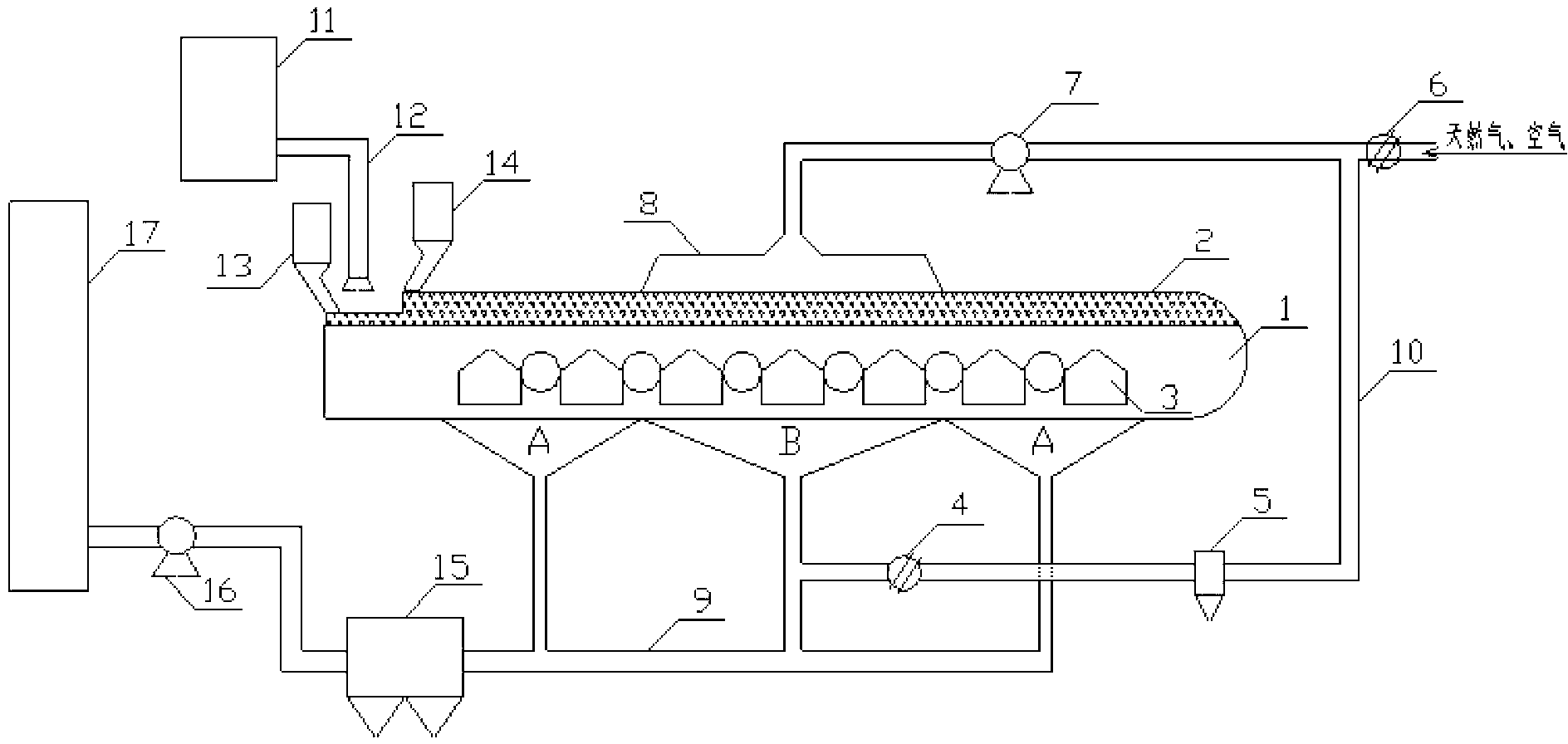

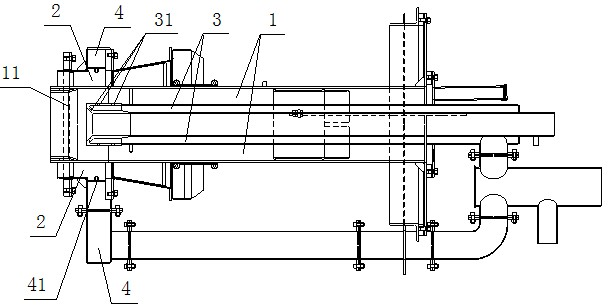

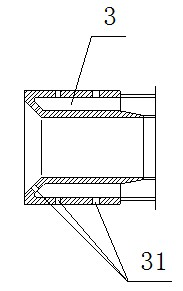

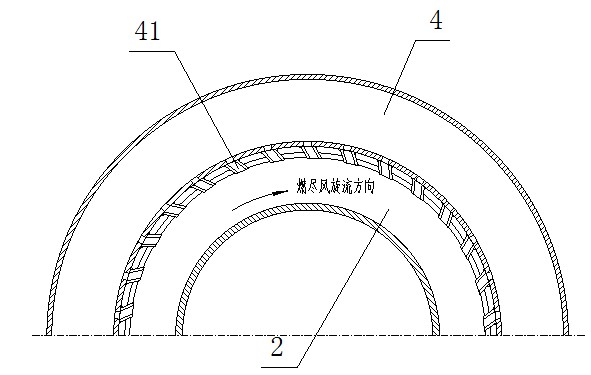

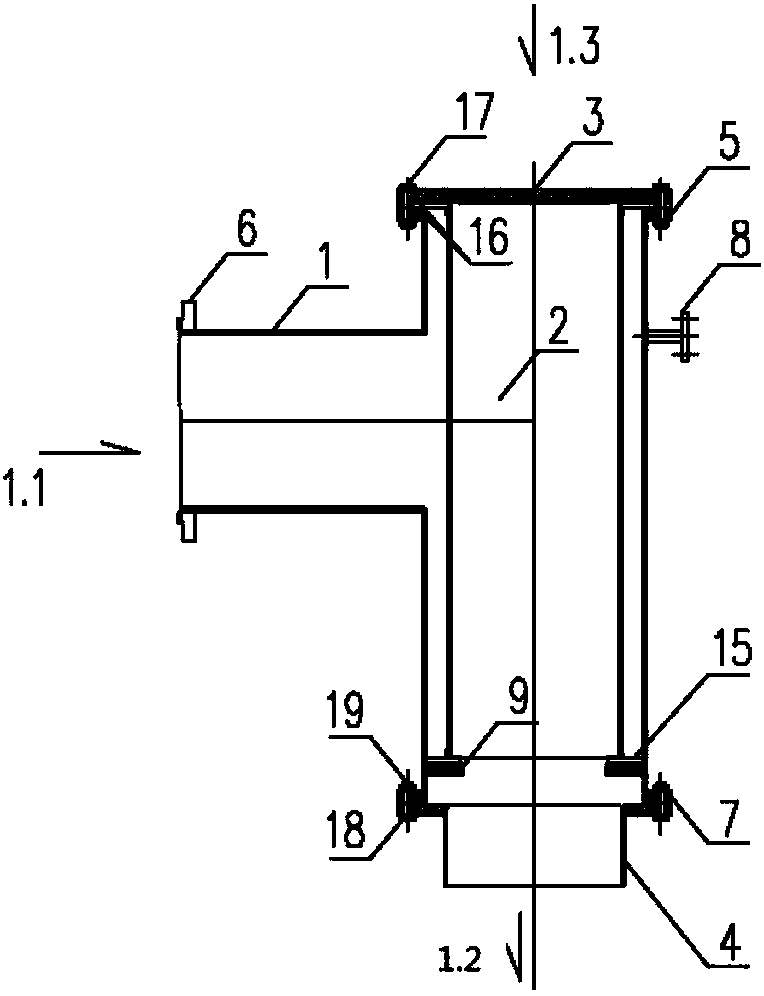

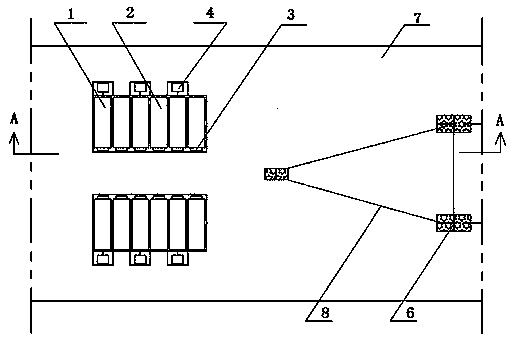

The invention discloses a simultaneous sintering and desulphurization and denitration system. The system comprises a sintering machine, a bellows, an electrostatic precipitator, a main exhaust fan and a chimney which are connected through a flue gas main pipeline. A branched pipeline is led out from an SO2 and NOx high-concentration-region bellows outlet pipeline, and is adopted as a sintering flue gas circulation pipeline. With the sintering flue gas circulation pipeline, a circulation flue gas flapper valve, a precipitator, a natural gas inlet valve connected to an outer gas inlet pipe, a circulation fan, and circulation flue gas mask are sequentially connected. The flue gas mask is covered on a sintering material layer right above the SO2 and NOx high-concentration-region bellows. A sprayer is arranged between a sintering grate-layer material system and a sintering material feeding system of the sintering machine. A residual ammonia water solution tank is connected with the sprayer. The cost of the system and the method are low. With the method and the system, discharge concentration of SO2 and NOx in sintering flue gas can be effectively reduced, and desulphurization and denitration can be simultaneously carried out during the sintering process. Therefore, environment pollution caused by sintering flue gas can be reduced.

Owner:ANGANG STEEL CO LTD

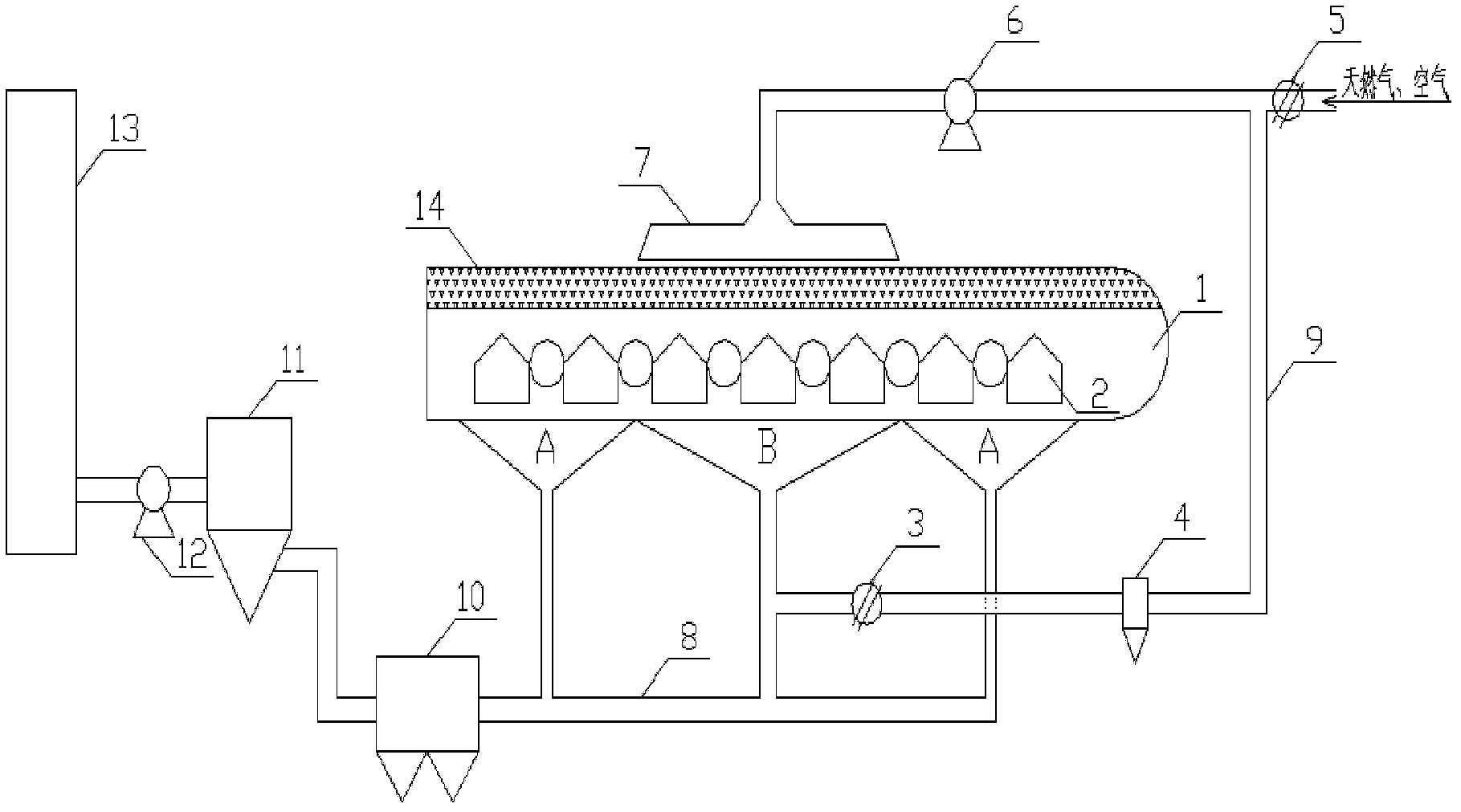

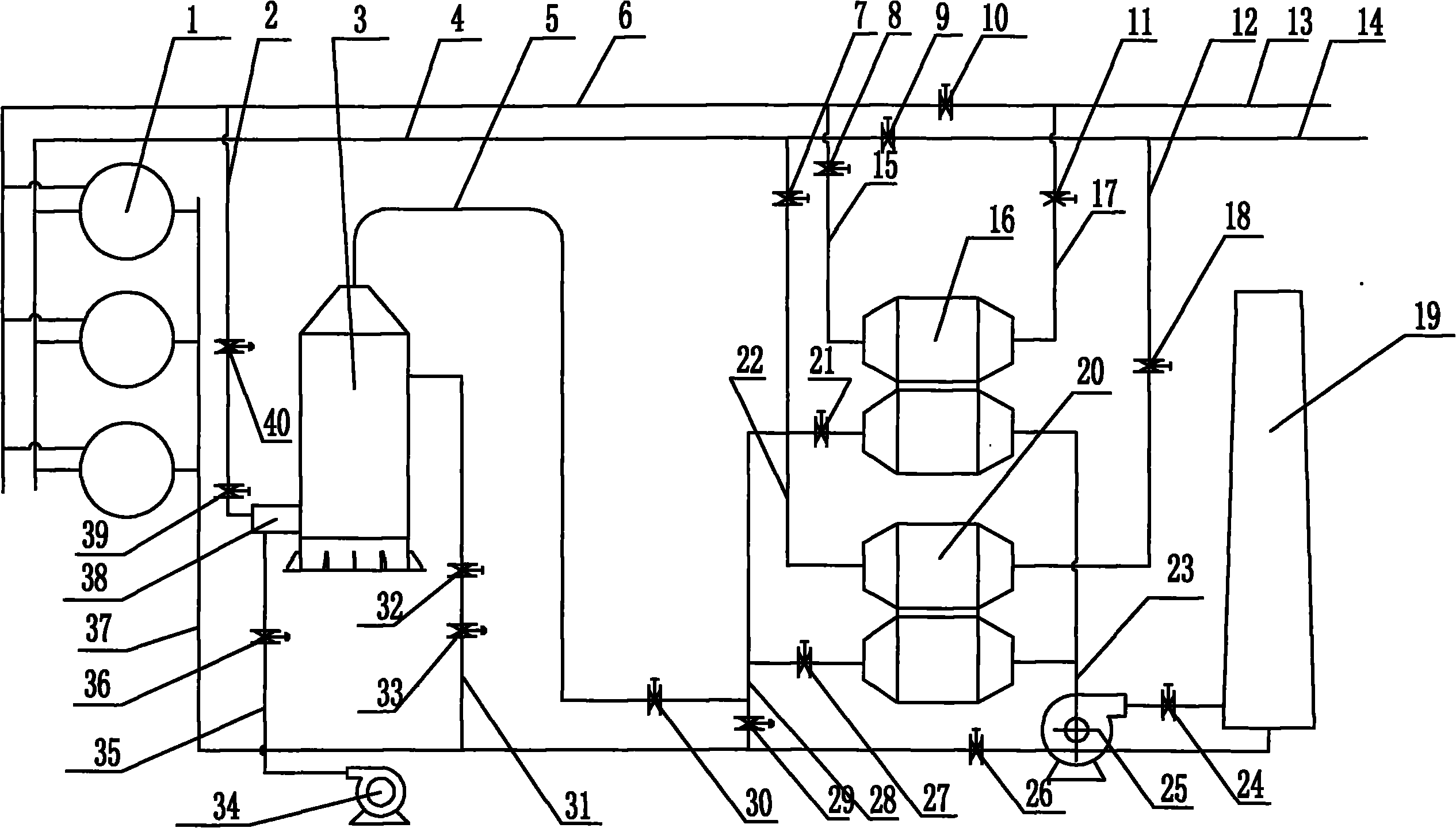

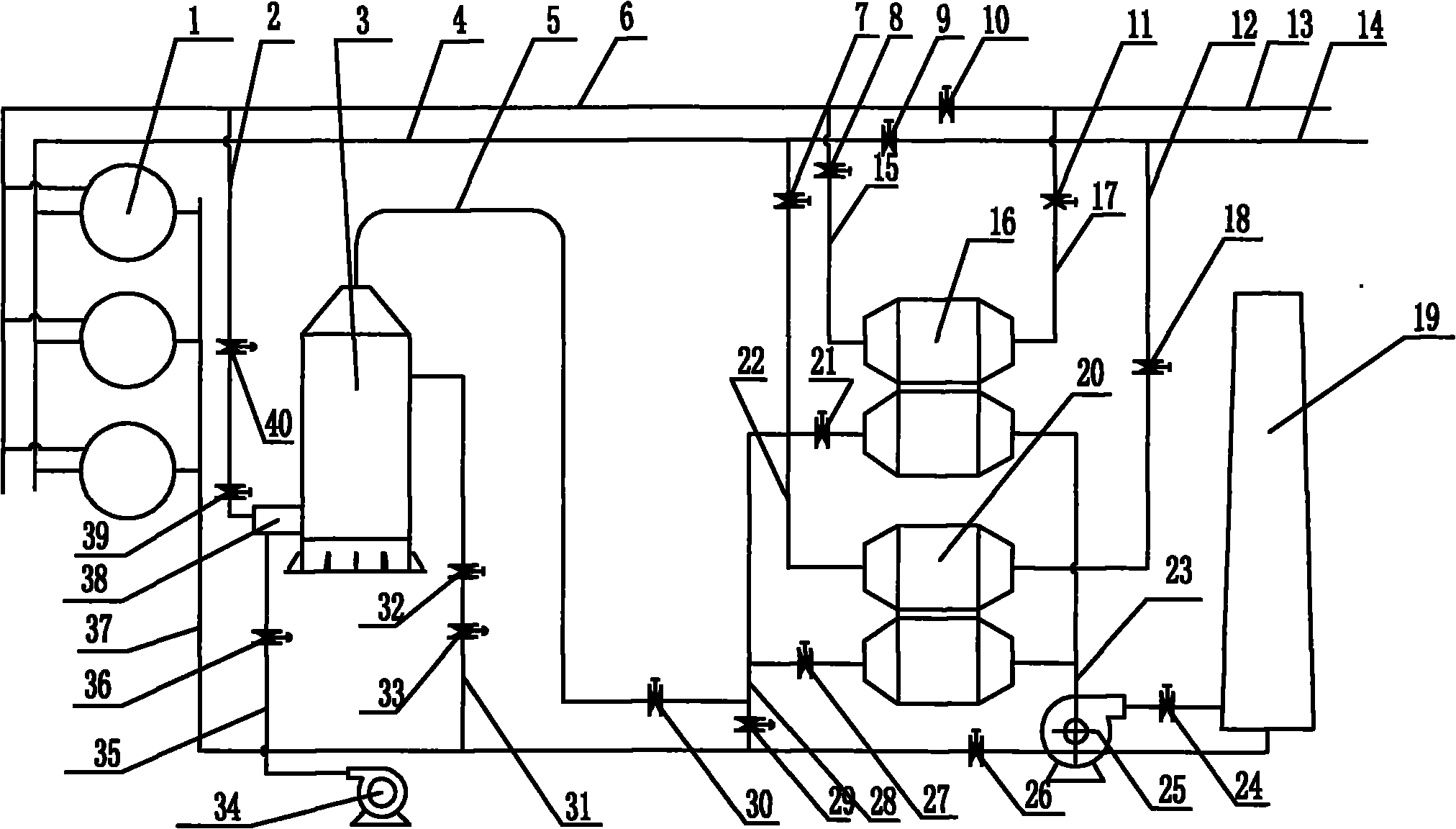

Sintering denitrification system and nitrogen oxide removal method thereof

ActiveCN103157356AEmission reductionDoes not affect sintering productionDispersed particle separationHigh concentrationNitrogen oxides

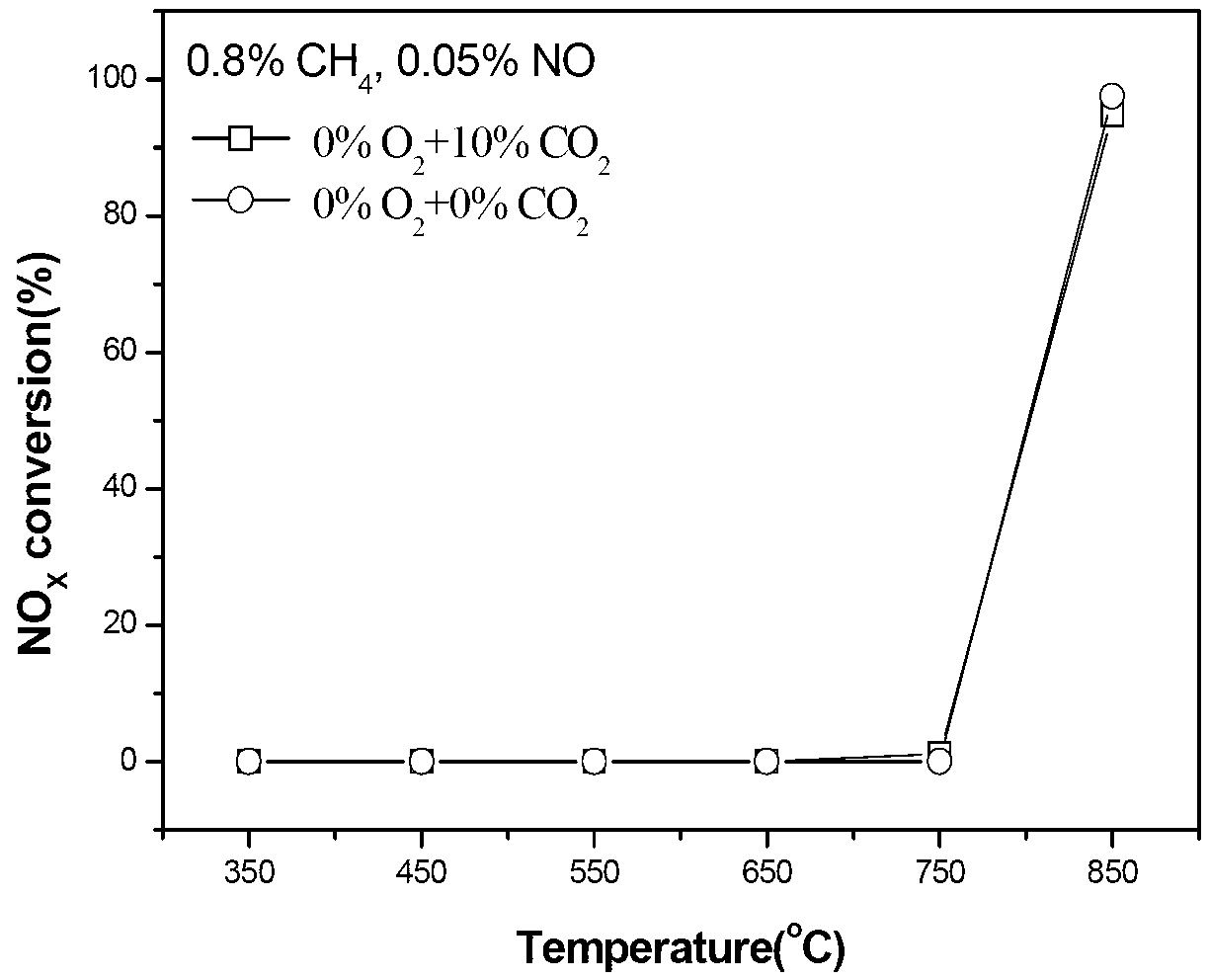

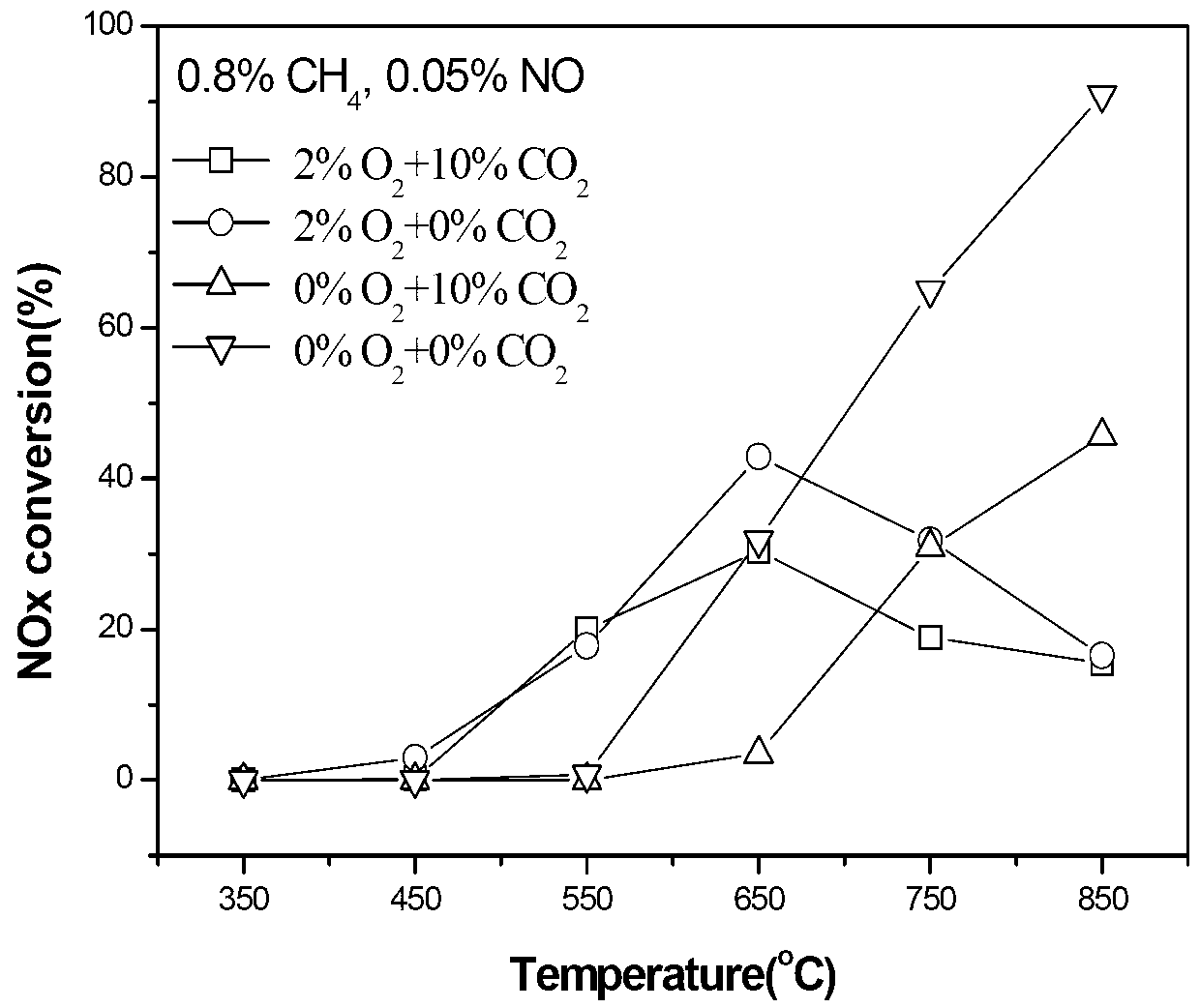

A sintering denitrification system and a nitrogen oxide removal method thereof. The invention discloses a sintering denitrification system, comprising a sintering machine, air boxes, an electricprecipitator, a desulfurization device, a main exhaust fan and a chimney, which are connected by a sintering flue gas main pipeline. The system is characterized in that a branch pipe is led out from an outlet pipe of the air boxes in a nitrogen oxide high concentration zone as a sintering flue gas circulating pipeline; the sintering flue gas circulating pipe is successively connected with a circulating flue gas baffle valve, a dust remover, a natural gas entrance valve connected with an outer intake pipe, a circulating fan and a circulating flue gas cover, which is covered on a sinter layer right above the air boxes in nitrogen oxide high concentration zone. The sintering flue gas enters into air boxes in the high concentration zone, and introduces part of the flue gas into the flue gas circulating pipe to become circulating sintering flue gas; the volume of the circulating sintering flue gas is controlled by the circulating flue gas baffle valve; the circulating sintering flue gas is dedusted by the electricprecipitator and then mixed with natural gas and air entering from the natural gas entrance valve; the mixed gas is introduced into the circulating flue gas covert through the circulating fan; and the circulating sintering flue gas reacts with sintering flue gas with high NOx concentration for partial denitration.

Owner:ANGANG STEEL CO LTD

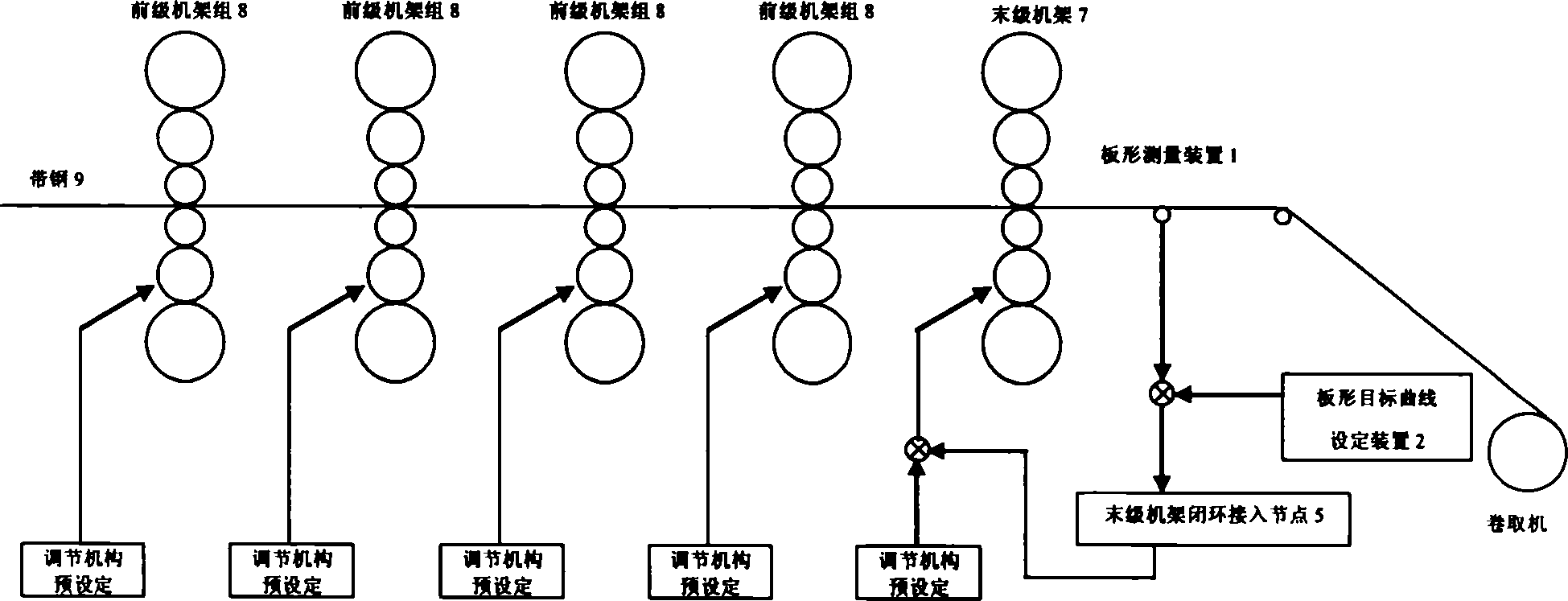

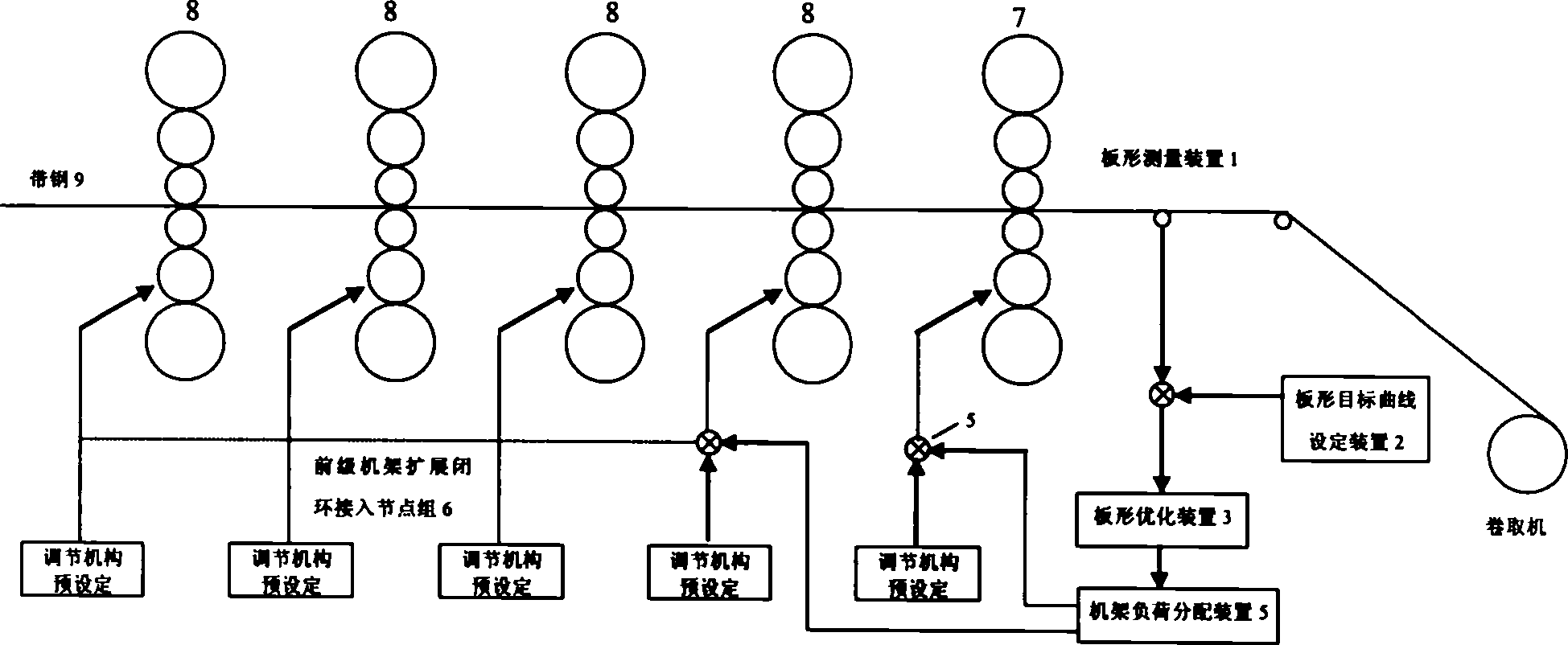

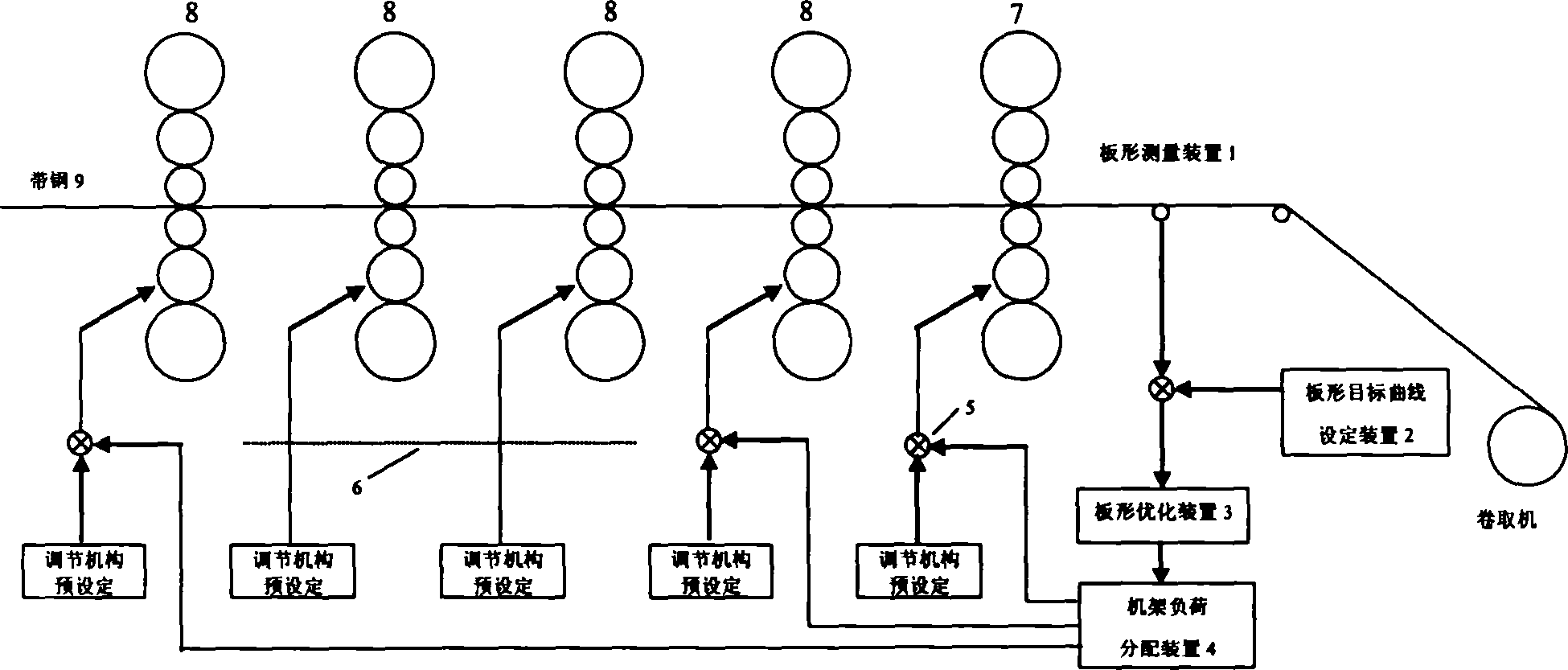

Plate form expansion feeding back closed-loop control system and method for cold continuous rolling machine

InactiveCN1887461AImproving strip shape qualityQuality improvementProfile control deviceMetal rolling arrangementsEngineeringClosed loop

The plate form expansion feeding back closed-loop control system for cold continuous rolling machine includes a frame combination, a last stage frame, a plate form measuring device, a plate form target curve setting deice and a last stage frame closed-loop access node. It features that it has also plate form optimizing device, frame load distributor of the plate form optimizing device and front frame expanding closed-loop access node; that the plate form measuring device, the plate form target curve setting deice, the plate form optimizing device, frame load distributor, the last stage frame closed-loop access node and the last stage frame are connected successively to constitute the plate form feeding back closed control loop; and that in the plate form feeding back closed control loop, the frame load distributor is connected through the front frame expanding closed-loop access node to the front stage frame combination to constitute the plate form expanding feedback closed control loop combination.

Owner:BAOSHAN IRON & STEEL CO LTD

Treatment method for saline wastewater

InactiveCN103408191ASimple processReliable and efficient processMultistage water/sewage treatmentVaporizationTherapeutic effect

The invention discloses a treatment method for saline wastewater. The treatment method comprises the steps as follows: introducing saline wastewater into a regulation tank, and regulating the pH value to 7.5-9.5; adding salt-tolerant compound bacteria to a water body, performing a primary anaerobic biochemical reaction, damaging the structures of organic substances in the saline wastewater, and degrading partial organic substances; continuously introducing the water body into a reaction tank, regulating the pH value to 7-9, adding the salt-tolerant compound bacteria, and performing an aerobic reaction; performing MVR mechanical vaporization subjected to the reaction to the water body, and then leading out the water body from the reaction tank for recovering and standby. The treatment method adopts specific sequential process degradation steps in order, not only has a very good treatment effect, but also is simple in each individual treatment step, is convenient to operate and easy to implement, and does not generate extra hazardous solid waste.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

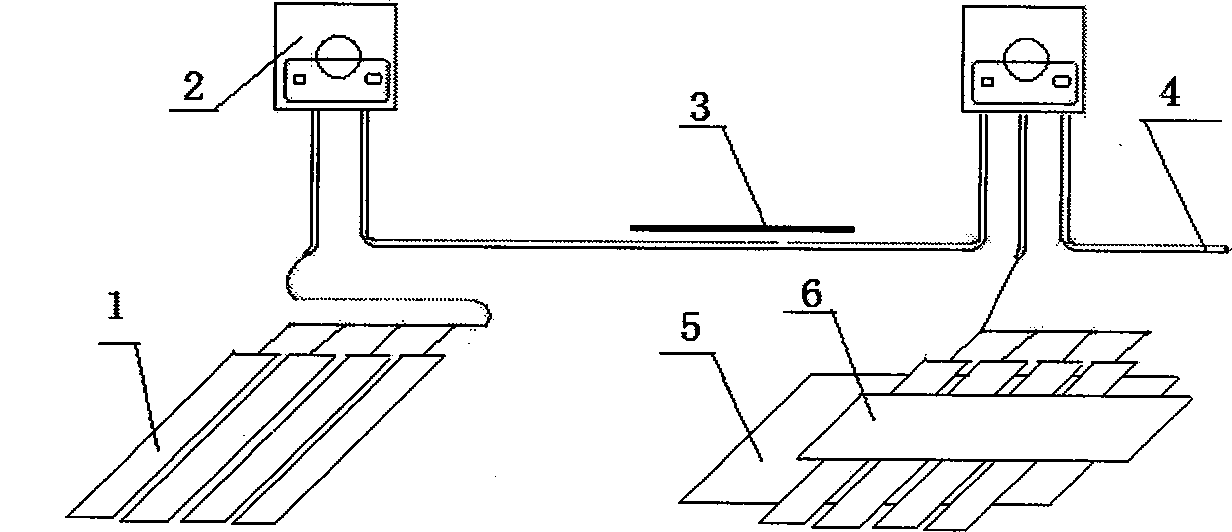

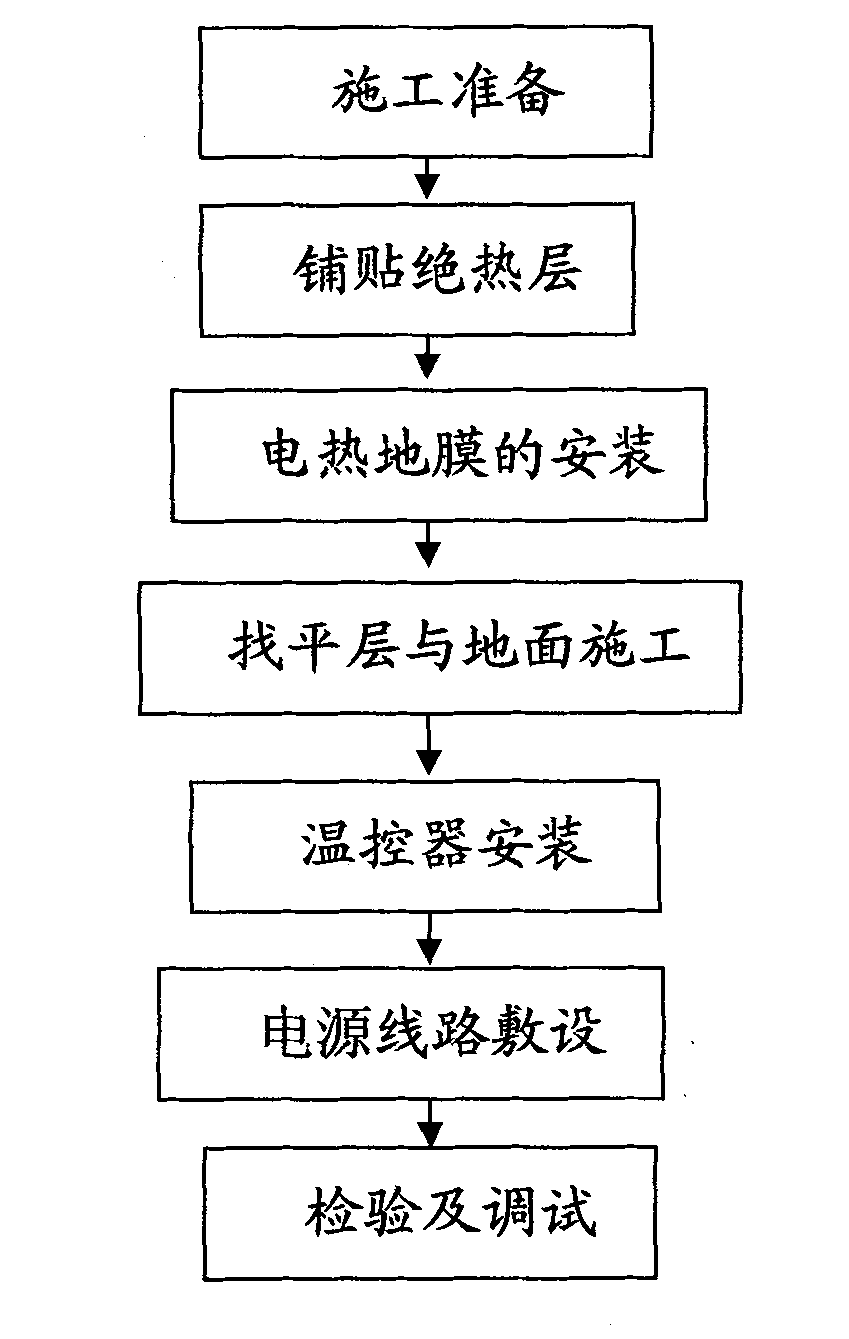

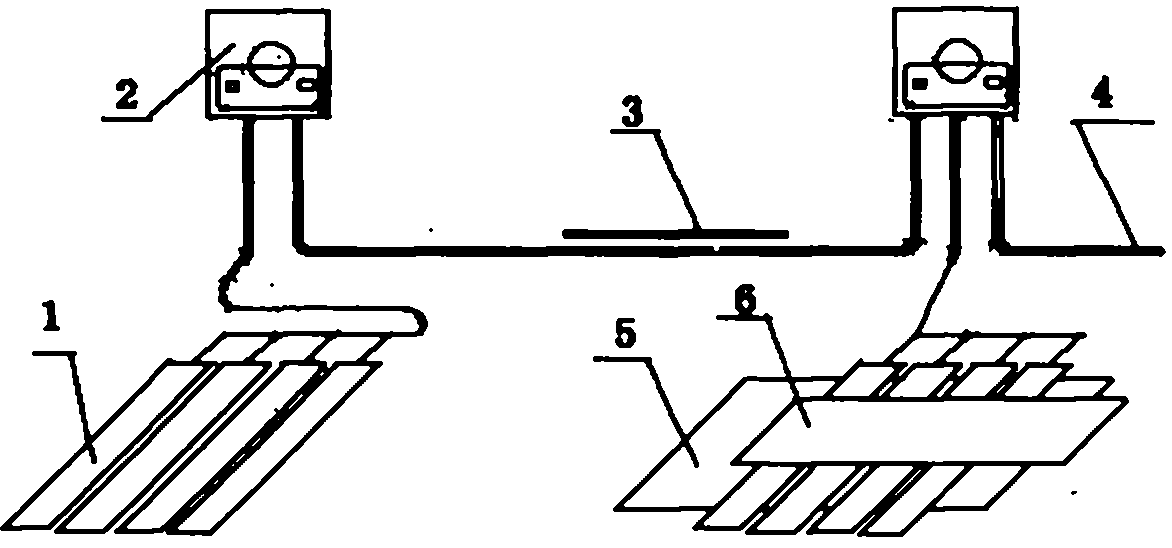

Low-temperature radiation electrothermal film floor heating system

InactiveCN102705893AWon't cause flyingGood effectLighting and heating apparatusElectric heating systemEnvironmental resistanceInfrared

The invention relates to a low-temperature radiation electrothermal film floor heating system. An insulating layer (5) is arranged below an electrothermal floor film (1); a finishing layer (6) is arranged above the electrothermal floor film (1); and a temperature controller (2) and a power supply (4) are connected with the electrothermal floor film (1). The low-temperature radiation electrothermal film floor heating system comprises the power supply, the temperature controller, the insulating layer, the electrothermal floor film and the finishing layer. Due to the adoption of the low-temperature radiation electrothermal film floor heating system, the human body feels warm and comfortable. The comprehensive effect of the low-temperature radiation electrothermal film floor heating system is superior to that of the traditional heating system adopting the convectional heating mode. The low-temperature radiation electrothermal film floor heating system solves the problems on the radiation difficulty of the public heating system and the heating of the areas with sufficient power, has strong controllability, can regulate the room temperature randomly and can be started randomly to meet the personalized requirement of people. Because the low-temperature radiation electrothermal film floor heating system heats directly by using the infrared rays of the electromagnetic infrared waves, the air circulation is omitted, and no dust is caused. The low-temperature radiation electrothermal film floor heating system has low investment cost and long service life, is environmental friendly, healthy and free from maintenance, consumes less energy, can ensure that the human body feels comfortable and is suitable for the heating of the new building and the old building. The floor structure can be prefabricated, partially prefabricated or assembled and laid on the site and is easy to construct and convenient to maintain.

Owner:YONGSHENG CONSTR GRP

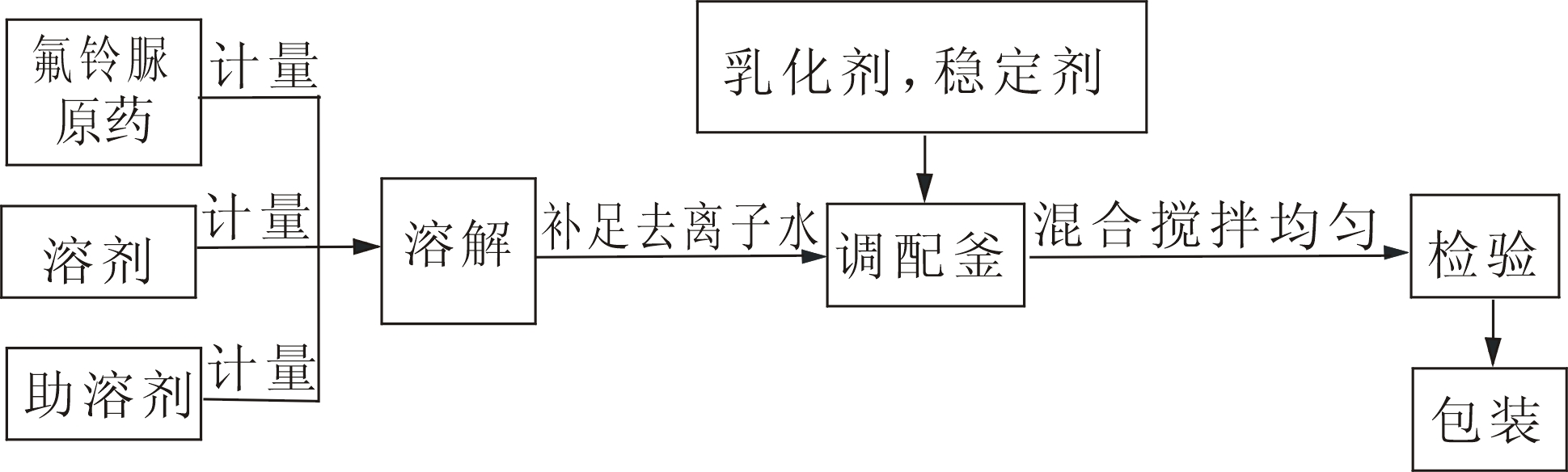

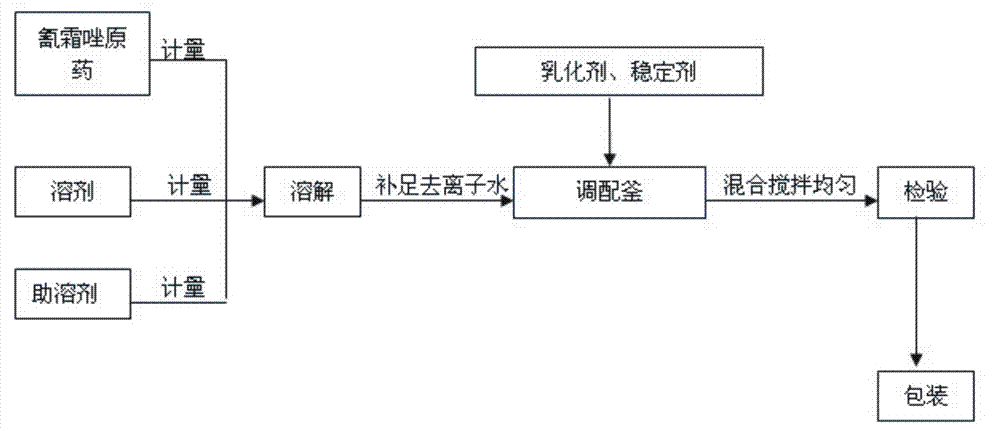

Hexaflumuron microemulsion and preparation method thereof

The invention discloses a hexaflumuron microemulsion and a preparation method thereof. The hexaflumuron microemulsion comprises the following components in percentage by weight: 1-10% of hexaflumuron, 5-60% of a solvent and a cosolvent, 5-20% of an emulsifier, 1-5% of a stabilizer and the balance of deionized water. The preparation method comprises the following steps: fully dissolving bulk hexaflumuron with the solvent and the cosolvent; adding the dissolved bulk hexaflumuron to a blending kettle; and then adding the emulsifier, the stabilizer and the deionized water in a certain proportion, and fully and evenly mixing to obtain the hexaflumuron microemulsion. The hexaflumuron microemulsion is efficient, low-toxic, environmentally-friendly and safe for people and livestock.

Owner:GUANGDONG ZHONGXUN AGRI TECH

Pre-dedusting, desulfuration and denitration integrated processing device and method

PendingCN107596798AHigh catalytic efficiencyExtended service lifeDispersed particle separationIntegrated processingAir pollution

The invention belongs to the technical field of air pollution control, particularly relates to a processing device and method with pre-dedusting as well as desulfuration and denitration. The device comprises a pre-dedusting region, a desulfuration region, a buffer region and a denitration region which are connected in turn from bottom to top, wherein an air inlet connected with a flue is formed under the pre-dedusting region; an air outlet connected with a chimney is formed above the denitration region; the pre-dedusting region comprises a flue-dust retainer and a guide plate located above theflue-dust retainer; a flue-dust collecting region formed by the flue-dust retainer and the guide plate penetrates through the middle of the desulfuration region; the desulfuration region and the denitration region are connected with an ammonia gas conveying pipe and a storage silo for placing active coke; the buffer region includes a mixed ammonia cylinder wall; and the upper part, the middle part and the lower part of the mixed ammonia cylinder wall are respectively equipped with an air deflector, an ammonia spraying tube and a flow equalizing plate. This processing system is low in investment and building cost and operation cost, can switch among a desulfuration and denitration integrated mode, a desulfuration mode and a denitration mode according to components of flue, rapidly improvesflue processing amount through a parallel connection manner of reactors, so as to solve the problem that flue amount of enterprises is too large.

Owner:CISDI RES & DEV CO LTD

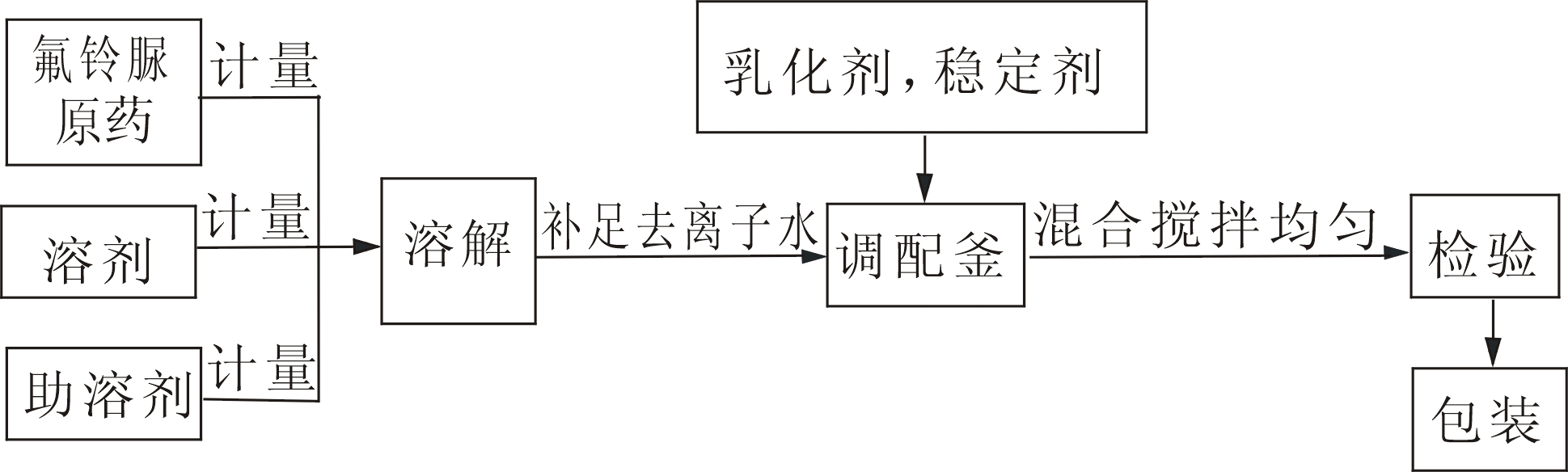

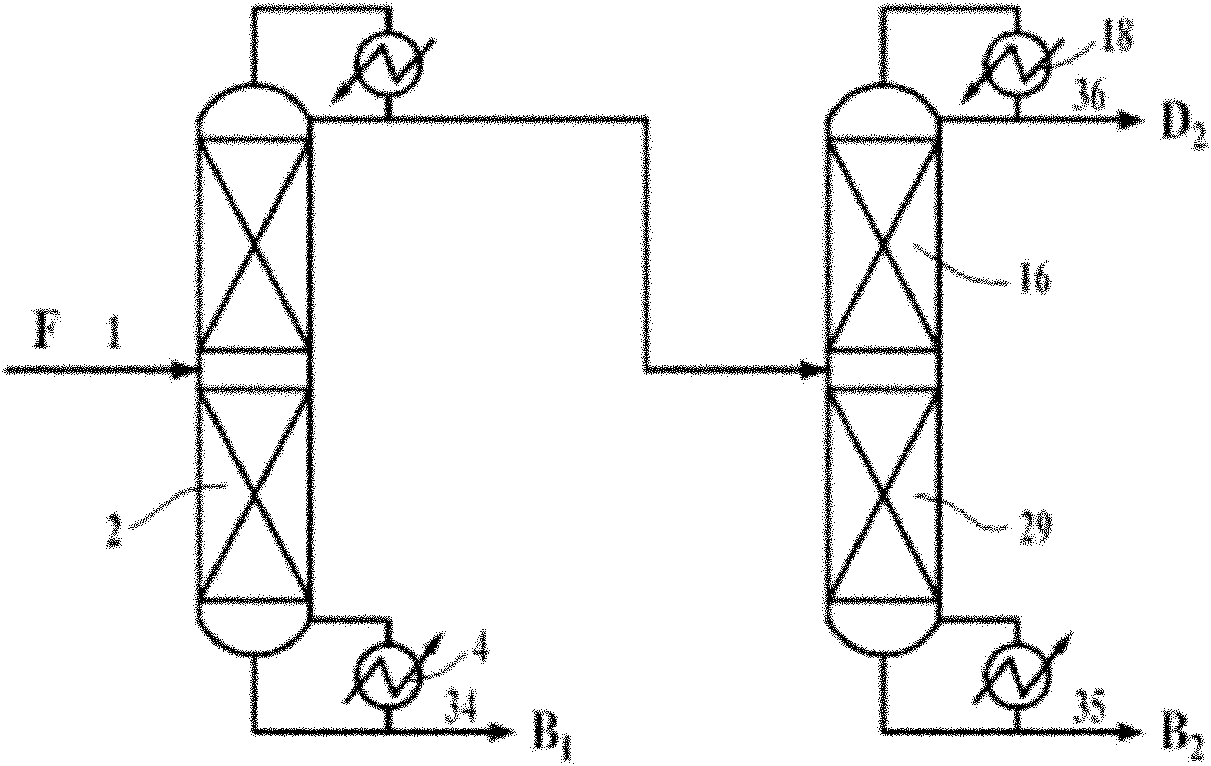

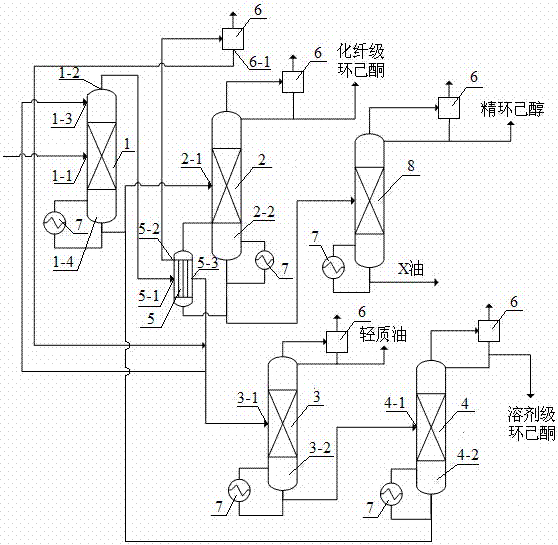

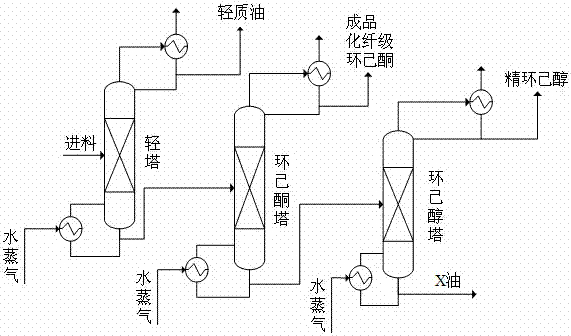

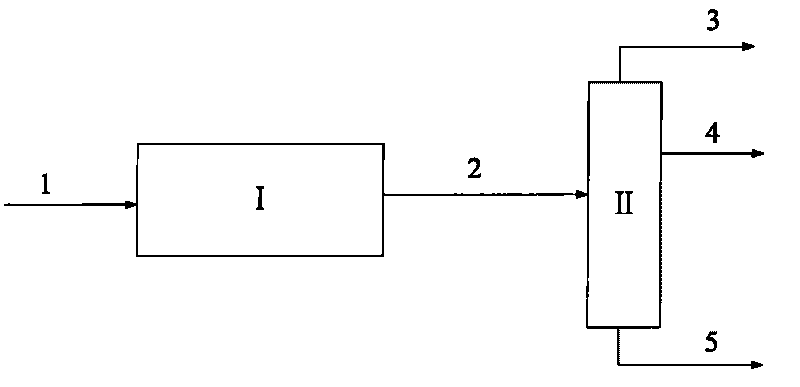

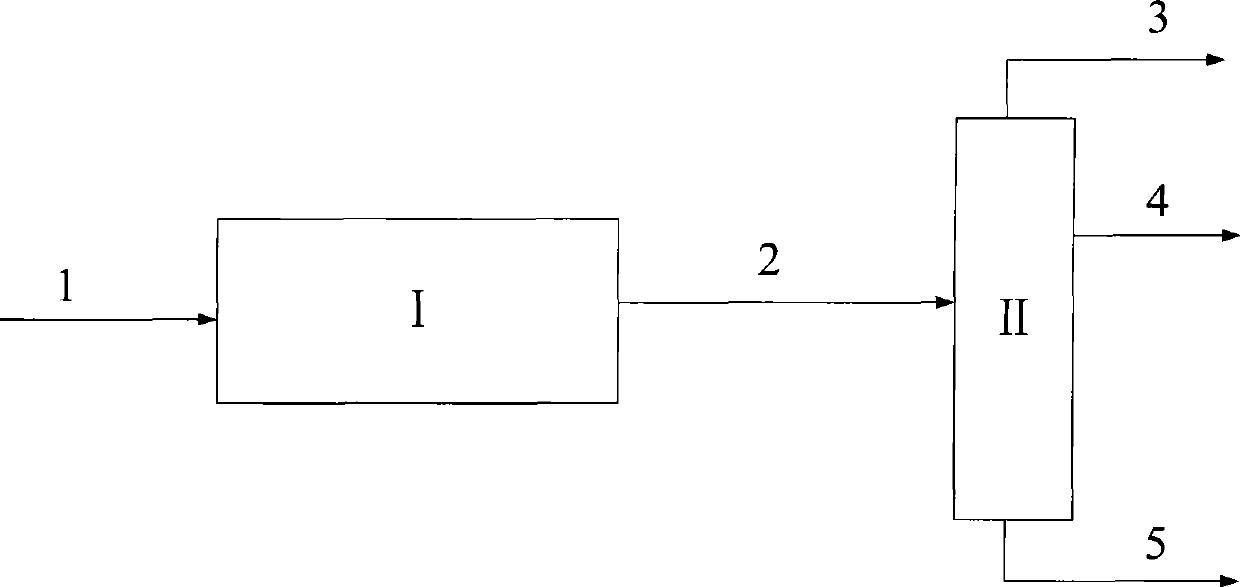

Energy-saving rectifying device for integrating energy in rectifying tower sequence and method

InactiveCN101966397AReduce energy consumptionLow operating costFractional distillationVaporizationEngineering

The invention relates to an energy-saving rectifying device for integrating energy in a rectifying tower sequence and a method, wherein the device comprises a light component evaporating tower, a steam flow distributor, a steam mixer, a central condenser, a liquid flow distributor, a rectifying tower section of a light component refining tower, a stripping tower section of the light component refining tower, a reducing valve, and a flash vaporization vessel, wherein the light component evaporating tower does not have a ceiling condenser and is used for supplying high pressure steam to the rectifying tower section of the light component refining tower; the reducing valve and the flash vaporization vessel are arranged between the rectifying tower section of the light component refining tower and the stripping tower section of the light component refining tower; the internal heat exchange between the two tower sections not only can reduce the hot load consumption at the bottom of the stripping tower section of the light component refining tower, but also can reduce the condensing load consumption at the top of the rectifying tower section of the light component refining tower. Compared with the conventional multi-component rectifying and separating system, the device in the invention can greatly reduce the total energy consumption of the entire rectifying tower system, save the operation cost, and reach the purpose of saving energy and increasing efficiency.

Owner:TIANJIN UNIV

Fosthiazate aqueous emulsion and preparation method thereof

The invention discloses a fosthiazate aqueous emulsion and a preparation method thereof. The fosthiazate aqueous emulsion comprises the following components by weight percent: 1-30% of fosthiazate, 2-40% of solvent and cosolvent, 2-8% of emulsifying agent, 1-5% of wetting agent, 0.5-2% of dispersant, 1-5% of stabilizing agent, 0-5% of antifreezing agent, and the balance of deionized water. The method comprises the following steps of: dissolving fosthiazate into the solvent, and adding the emulsifying agent, the wetting agent, the stabilizing agent and the dispersant to obtain an oil phase; and mixing the antifreezing agent and water to obtain a water phase, and gradually adding the oil phase into the water phase or gradually adding the water phase into the oil phase under a high shear condition, thus obtaining the fosthiazate aqueous emulsion. The fosthiazate aqueous emulsion disclosed by the invention has the characteristics of high efficiency, low toxicity, environmental friendliness, safety to human and livestock, and easiness for degradation.

Owner:GUANGDONG ZHONGXUN AGRI TECH

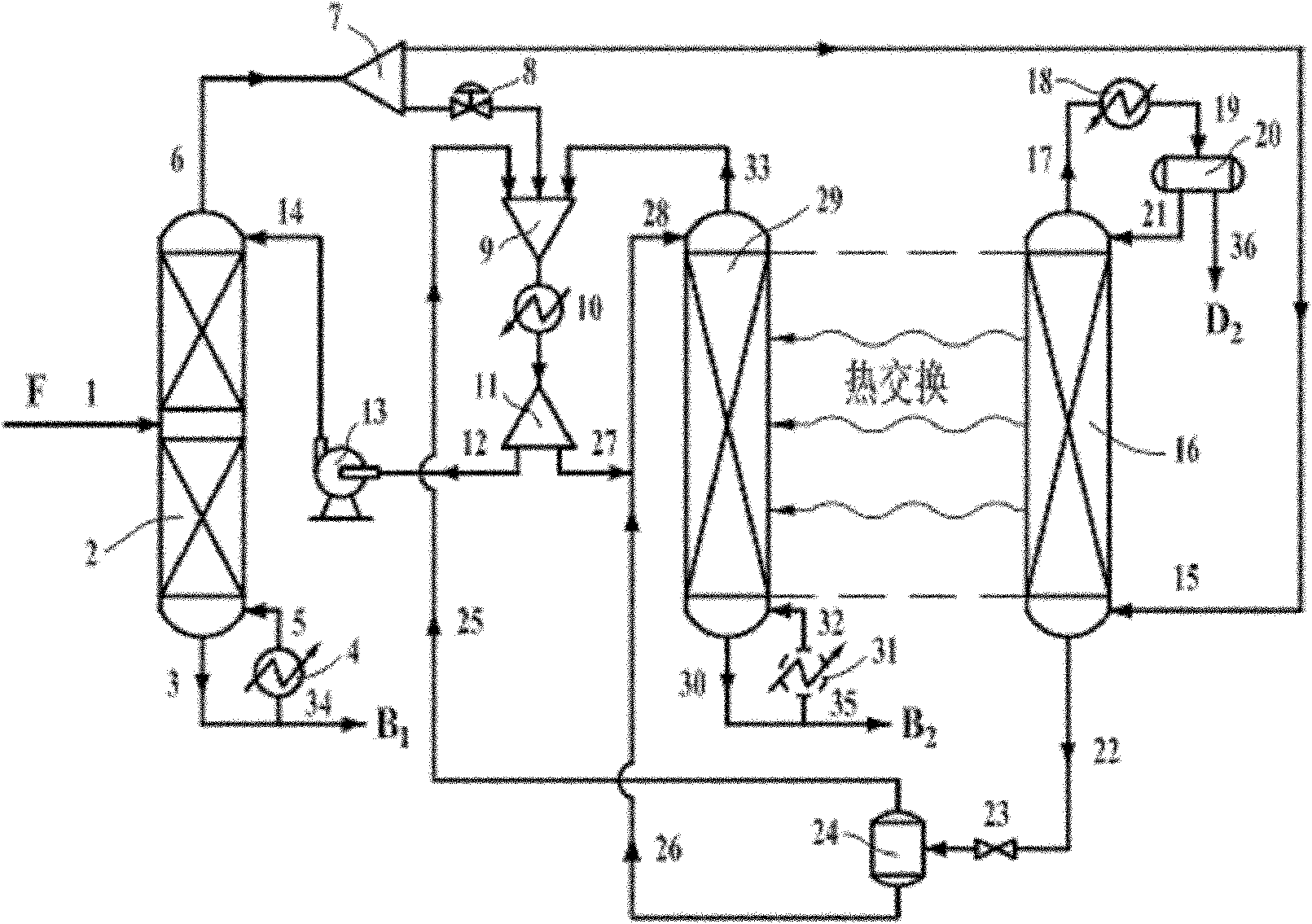

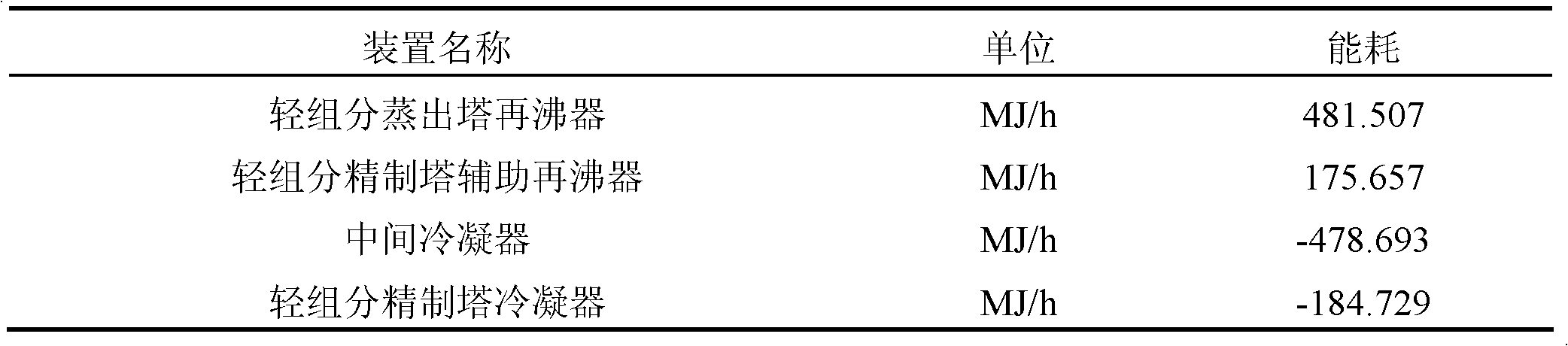

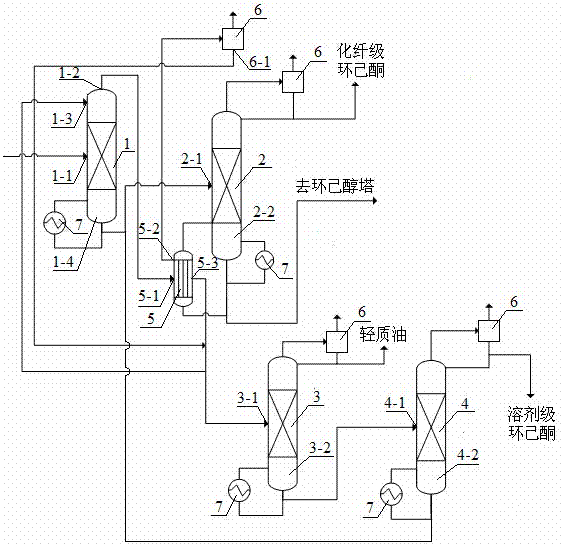

Device and method for cyclohexanone rectification

ActiveCN106943764AImprove qualityHigh purityCarbonyl compound separation/purificationFractional distillationCyclohexanoneFiber

The invention discloses a device and a method for cyclohexanone rectification. The device comprises a first light component column, a first cyclohexanone column, a second light component column, and a second cyclohexanone column, wherein an afterheat reboiler is arranged at the column bottom of the first cyclohexanone column. The method comprises the following steps: introducing cyclohexanone / cyclohexanol impurity-containing mixture into a first light component column, introducing the column top outflow of the first light component column into the afterheat reboiler, carrying out heat exchange on the column bottom material of the first cyclohexanone column, mixing the outflow and the condensate of the non-condensed gas, introducing into the reflux inlet of the first light component column and the feed inlet of the second light component column respectively, collecting lightweight oil from the column top of the second light component column, introducing the column bottom outflow of the second light component column into the feed inlet of the second cyclohexanone column, collecting solvent-grade cyclohexanone from the column top of the second cyclohexanone column, introducing the column bottom outflow of the first light component column and he second cyclohexanone column into the feed inlet of the first cyclohexanone column, and collecting chemical fiber-grade cyclohexanone from the column top of the first cyclohexanone column. The device disclosed by the invention is low in energy consumption, and the obtained cyclohexanone product has high quality. The method disclosed by the invention has simple process and good stability.

Owner:长沙兴和新材料有限公司

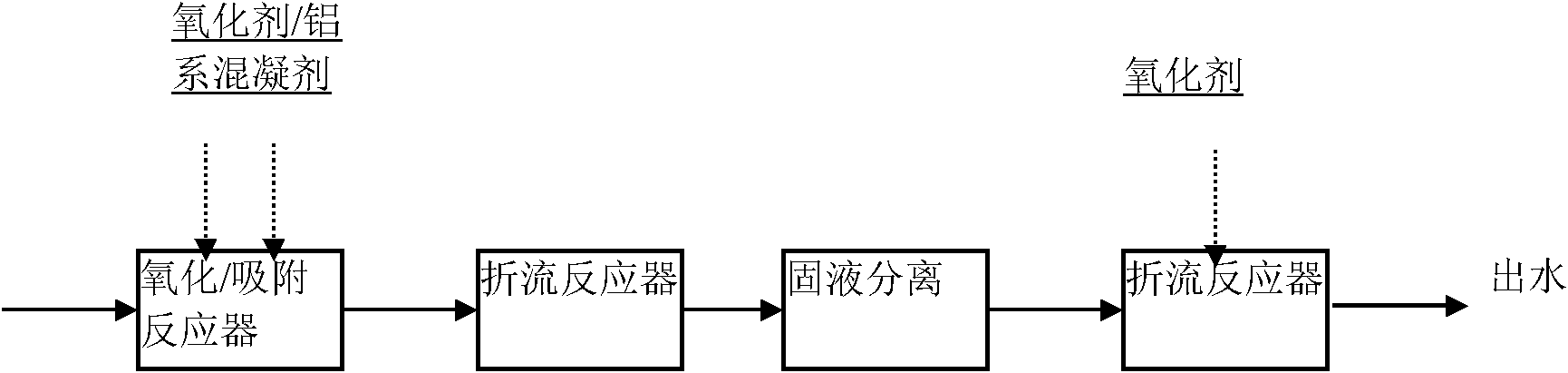

Processing method for leatherworking waste water

InactiveCN102718337AReduce the impactIncrease investment costsMultistage water/sewage treatmentWater/sewage treatment by oxidationSewageFluorine containing

The invention discloses a processing method for leatherworking waste water, comprising the following main steps: 1) adding 3-10 mg / l oxidizing agent in the leatherworking waste water, simultaneously or sequentially adding 5-25 ml / g Al-system coagulant to conduct oxidation adsorption baffling reaction; 2) carrying out solid-liquid separation on the effluent obtained by the step 1); and 3) adding fluorine-containing oxidizing agent in the effluent obtained by the step 2) with the additional amount of available chlorine being 5-50 mg / l to conduct oxidation reaction, and then discharging. The method disclosed herein can reduce the influence of pollution discharge on environment without obvious increase of investment and operation cost. The CODcr of the waste water processed by the method of the invention is less than 50mg / L.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

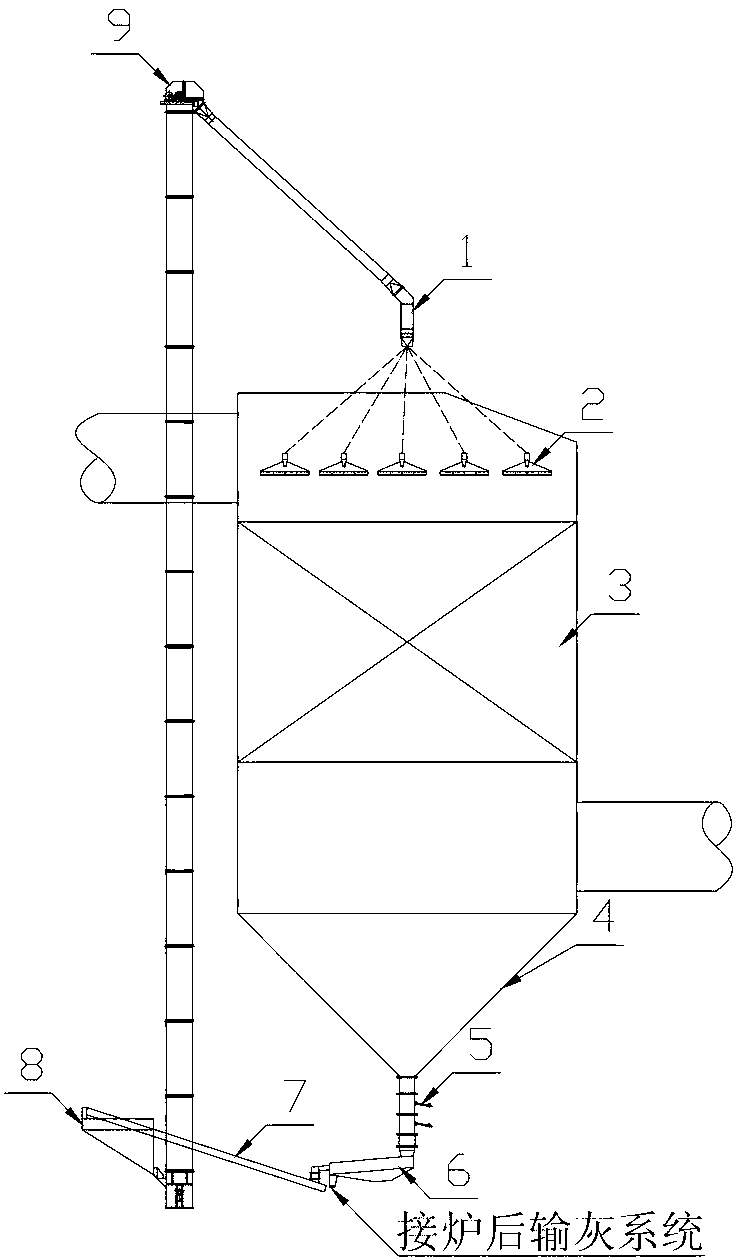

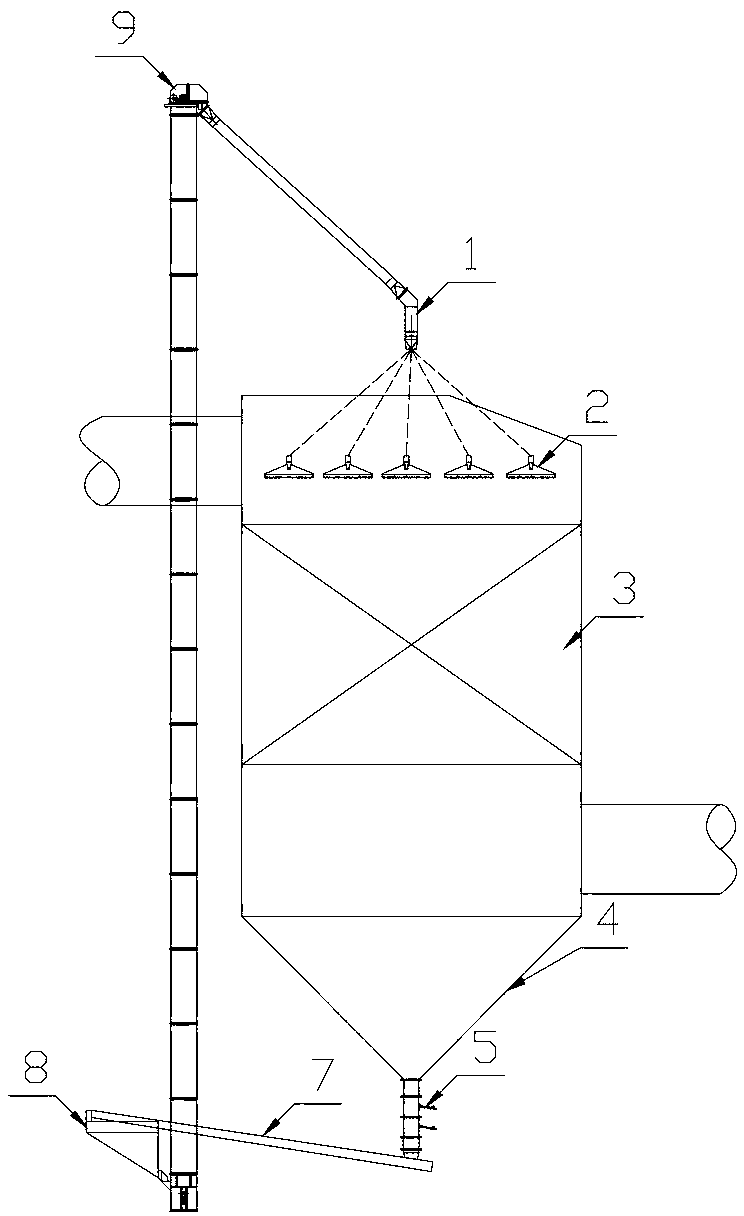

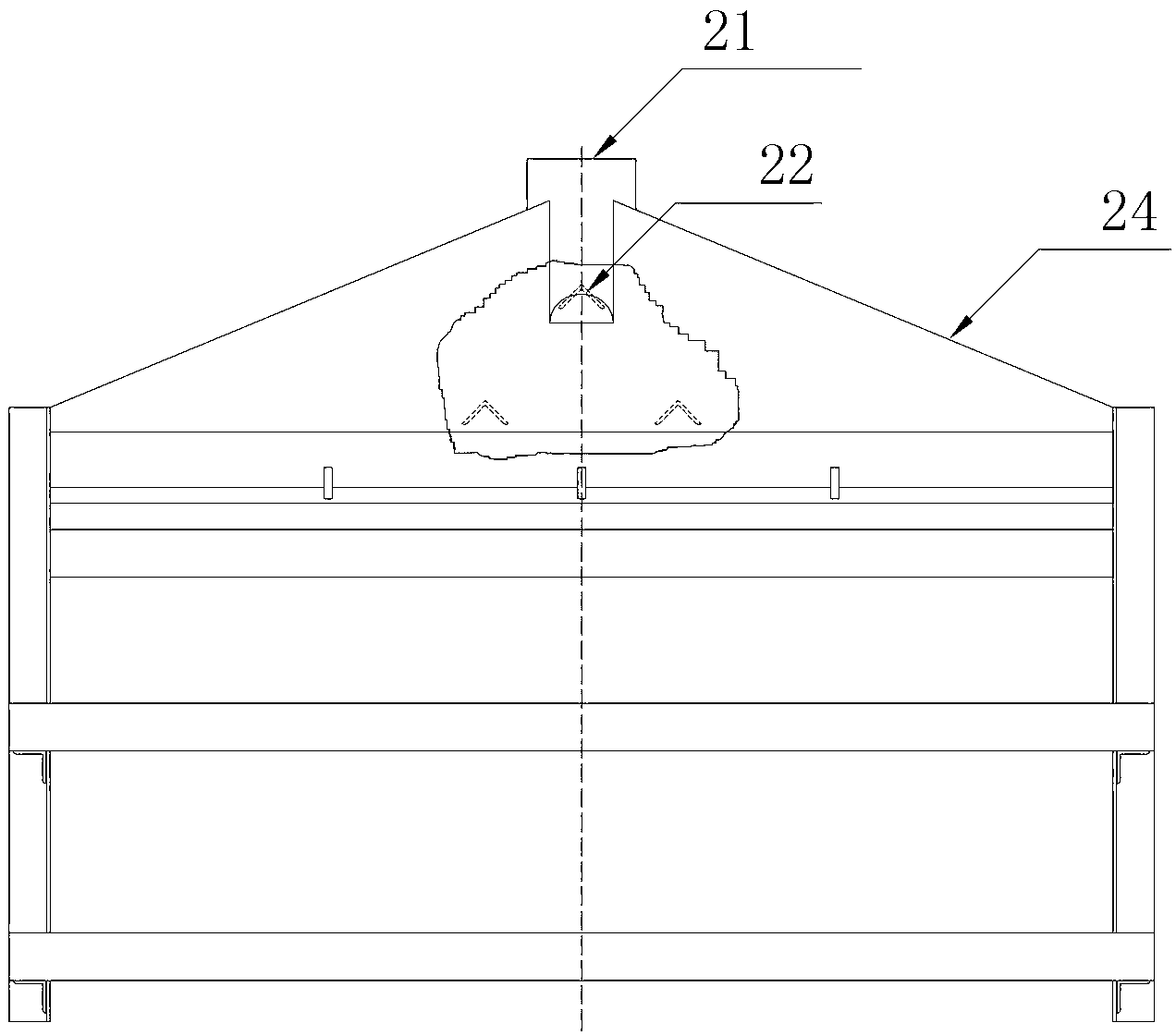

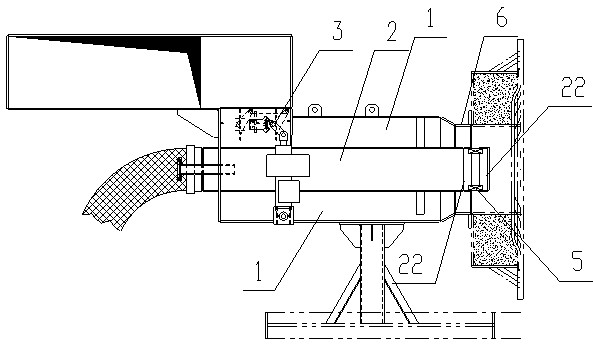

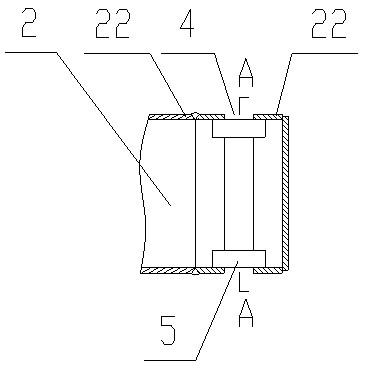

Dust cleaning system applicable to heat recovery boiler with complex heating surface

The invention discloses a dust cleaning system applicable to a heat recovery boiler with a complex heating surface. The dust cleaning system comprises a lifter, a shot separating device, a shot distributer, a sealed flap valve, a separating device, a shot storing bin and a horizontal shot conveying device. The shot distributer is a slot type shot distributor, the slot type shot distributor is good in shot distributing effect, can guarantee full coverage on a first heat exchange tube layer, structurally effectively buffer falling speed of steel shots, and reduce impact of the steel shots to the heat exchange tubes and anti-wear strips; the steel shots in grain size of 2-4mm are utilized, compared with a conventional shot-falling dust cleaning system, the dust cleaning system is more applicable to dust cleaning of the heat recovery boiler utilizing a complex heating surface like a radiator fin / a fin / an annular fin tube to strengthen heat exchange, dispersity and distributing compactness of the shots on the heating surface are easier to guaranteed, and dust cleaning effect is good; and impact to the surfaces of the heat exchange tubes from the small-grain-size steel shots is lower, and service life of equipment is prolonged. The dust cleaning system applicable to the heat recovery boiler with the complex heating surface is capable of immediately effectively cleaning dust on the surface of the heating surfaced, is stable in running, low in investment and maintenance cost, and can maintain high efficient heat exchange of the complex heating surface.

Owner:BEIJING CENTURY BENEFITS

Constant temperature and humidity system for chancery and adjusting method for constant temperature and humidity system

ActiveCN102997350AReduce work intensityReduce loadEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsControl systemHigh energy

The invention discloses a control system for temperature and humidity of an air conditioner of a chancery and an adjusting method for the system, which mainly solve the technical problem of high energy consumption because of simultaneous control of temperature and humidity of the conventional air-conditioning system of the chancery. According to the constant temperature and humidity system for the chancery, a constant temperature and humidity inner unit is arranged in a machine room, a plurality of constant temperature and humidity outer units are connected in parallel outside the machine room, an air outlet of the constant temperature and humidity inner unit is connected with an air supply pipe; the air supply pipe is led to a storeroom of the chancery; the air supply pipe in the storeroom of the chancery is provided with a plurality of air outlets; an air return pipe with a plurality of air inlets is arranged in the storeroom of the chancery and is led to the machine room; and an air outlet of the air return pipe is positioned in the machine room. The system is characterized in that a heat pump pipeline type air conditioning unit inner unit is arranged in the machine room, and is connected with a heat pump pipeline type air conditioning unit outer unit outside the machine room, the heat pump pipeline type air conditioning unit inner unit is connected with the air supply pipe and the air return pipe through pipelines respectively, the air return pipe of the unit is connected to the constant temperature and humidity machine inner unit; and the pipelines are provided with temperature sensors and humidity sensors.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

High wind temperature energy saving and emission reduction combined preheating method for blast furnace

InactiveCN101928796ASimple processSystem operation and control are simpleBlast furnace detailsHeating stovesProcess engineeringSmoke

The invention relates to a high wind temperature energy saving and emission reduction combined preheating method for a blast furnace, and belongs to the technical field of energy saving and emission reduction and steel smelting equipment. The method comprises the steps of: mixing hot smoke from a hot blast furnace and a front combustion furnace; then exchanging the heat of the mixed smoke with that of cold air and cold gas respectively; supplying the hot air and the hot gas formed after the heat exchange to the hot blast furnace; meanwhile, supplying the hot gas and air which is from a blower of a front furnace to a burner. By the preheating method, a secondary air turbolator heat exchanger is not needed, and control valves and connection pipelines which are used in the method are greatly reduced, so that installation is facilitated, cost is reduced, the probability of reducing leakage is facilitated and maintenance is convenient.

Owner:江苏中天能源设备有限公司

High-blast-temperature energy-saving and emission-reducing combined type preheating system for blast furnace

InactiveCN101928797AAchieving blast temperatureSimple processBlast furnace detailsHeating stovesCold airCombustor

The invention relates to a high-blast-temperature energy-saving and emission-reducing combined type preheating system for a blast furnace, which belongs to the technical fields of energy saving, emission reduction and iron and steel smelting equipment. The high-blast-temperature energy-saving and emission-reducing combined type preheating system for the blast furnace comprises a cold coal gas inlet pipeline, a cold air inlet pipeline, a hot air furnace, a combustor, a preposed combustion furnace, a preposed furnace blower, an air preheating combined type heat pipe heat exchanger, a coal gas preheating combined type heat pipe heat exchanger, a draught fan and a chimney. The high-blast-temperature energy-saving and emission-reducing combined type preheating system for the blast furnace has the advantages of economic operation, energy saving and wide application to the iron and steel smelting industry.

Owner:江苏中天能源设备有限公司

Rotational flow and direct current combined gas burner

ActiveCN102537959AReduce the difficulty of blendingAchieve large capacityGaseous fuel burnerInlet channelRotational flow

The invention discloses a rotational flow and direct current combined gas burner, and belongs to the field of gas burners. The gas burner comprises a burnout air channel with burnout air and a gas channel with a gas fuel, wherein the burnout air channel comprises a central direct current air channel and a peripheral rotational flow air channel; the gas channel comprises a central air inlet channel in the direct current air channel, and a gas nozzle at the front end of the gas channel spouts the gas fuel so as to be mixed with the direct current air in the direct current air channel; and the gas burner also comprises a circumferential inlet channel arranged on the periphery of the rotational flow air channel, and the gas nozzle at the front end of the gas burner spouts the gas fuel so as to be mixed with the rotational flow air in the rotational flow air channel. The gas burner provided by the invention can be used for reducing the adulterate burning difficulty of a high-heating-value gas fuel, when the gas fuel is put into operation, the good commixture and combustion of the gas fuel and air are ensured; and when the gas fuel is off stream, the burnout air function is still completely realized, and the burnout of coat dust and low NOx discharge capacity of the boiler are guaranteed.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

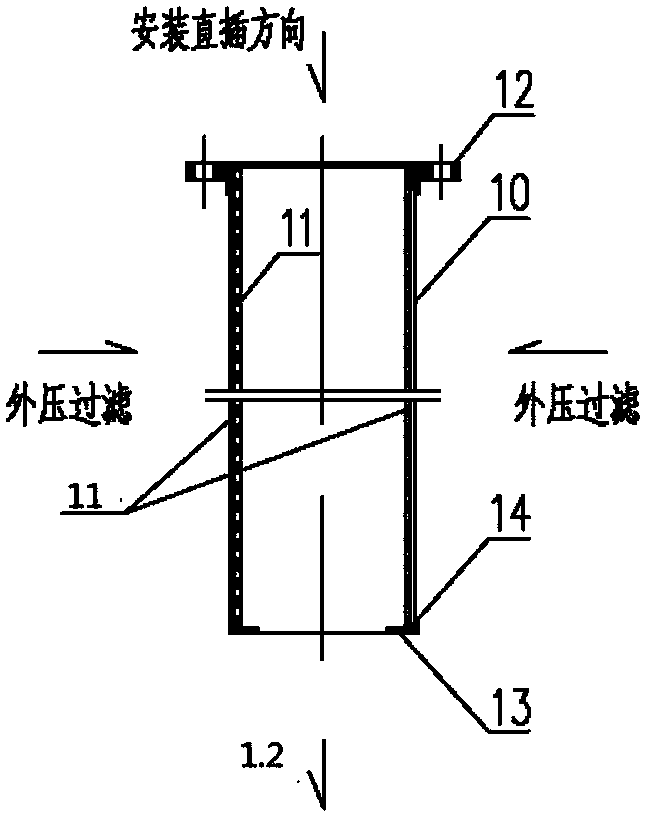

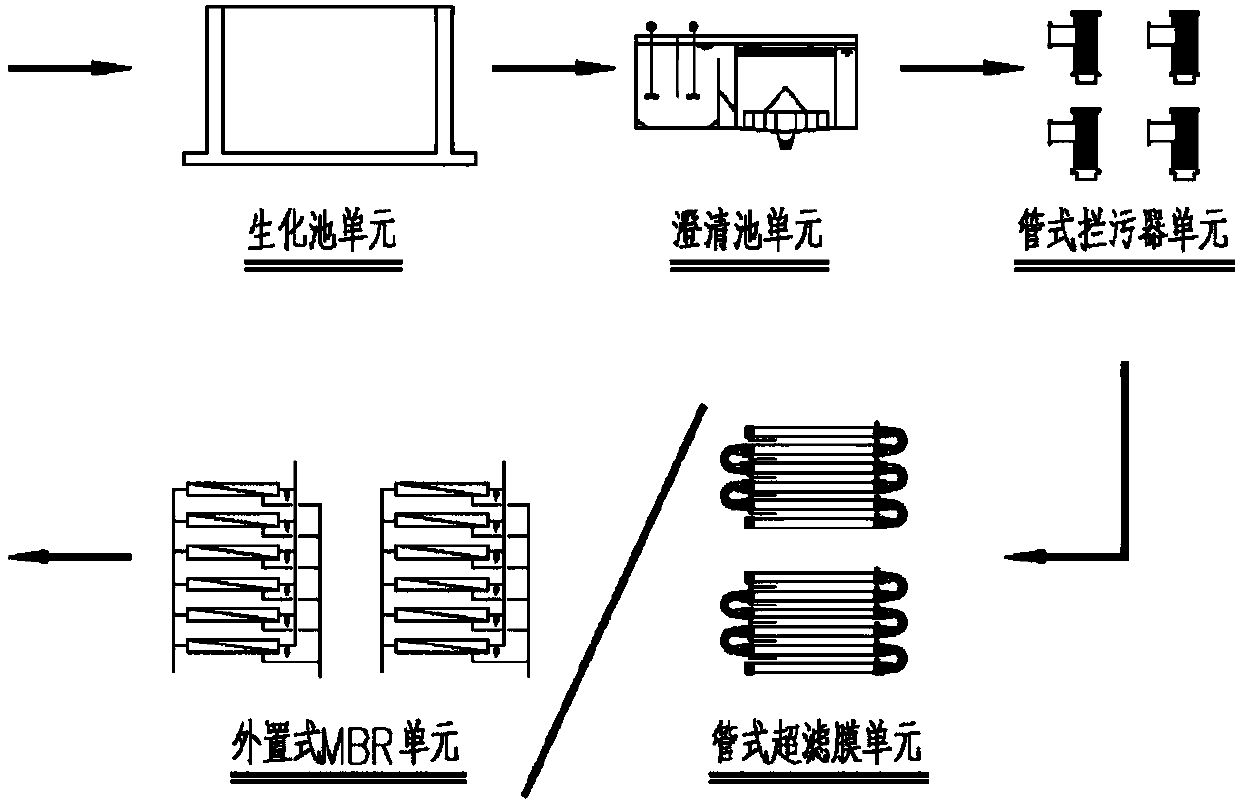

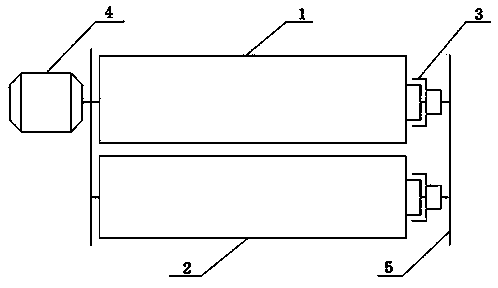

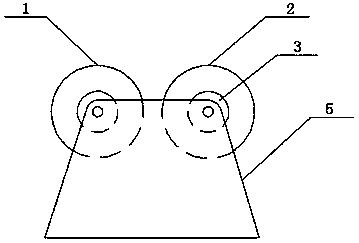

Transverse type pipeline trash blocking device and sewage recycling system

ActiveCN107854880AImprove efficiencyIncreased maintenance difficultyTreatment involving filtrationMultistage water/sewage treatmentSewageSewage treatment

The invention discloses a transverse type pipeline trash blocking device. The transverse type pipeline trash blocking device comprises a main body, a cover plate, an external short pipe and a trash blocking filter element, wherein the trash blocking filter element is used for filtering suspended matters; the main body is provided with a water inlet, a water outlet, a filter element mounting port and a filter element support plate, wherein the filter element support plate is used for supporting and fixing the trash blocking filter element, and the water inlet is arranged on the side wall of themain body, and is provided with a first connecting flange; the water outlet is arranged at one end of the main body, and is provided with a second connecting flange; the filter element mounting portis arranged at the other end of the main body, and is provided with a third connecting flange; the trash blocking filter element and the cover plate are connected by the third connecting flange, and the main body and the external short pipe are connected by the second connecting flange; the trash blocking filter element is provided with a trash blocking screen pipe and an inner support skeleton, and the inner support skeleton is used for supporting the trash blocking screen pipe. The invention further discloses a sewage recycling system using the transverse type pipeline trash blocking device.The transverse type pipeline trash blocking device has the advantages that the transverse type pipeline trash blocking device can be used as the sewage treatment pretreatment unit, and be well used for replacing the traditional filtering device; by adopting the transverse installation type, the overhauling and the replacement of the filter element can be favorably performed.

Owner:CEEP CO LTD

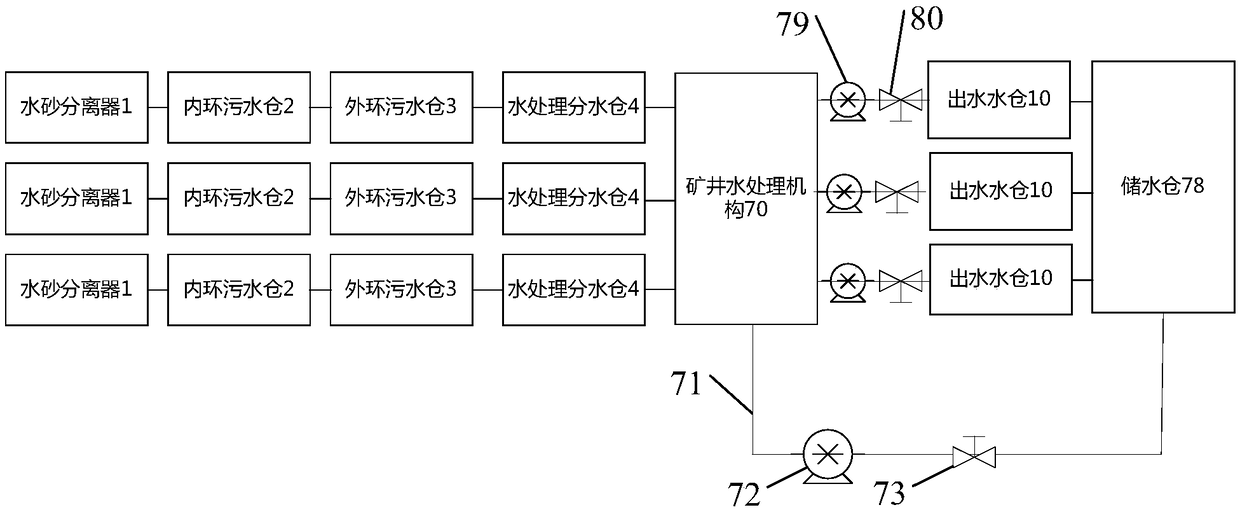

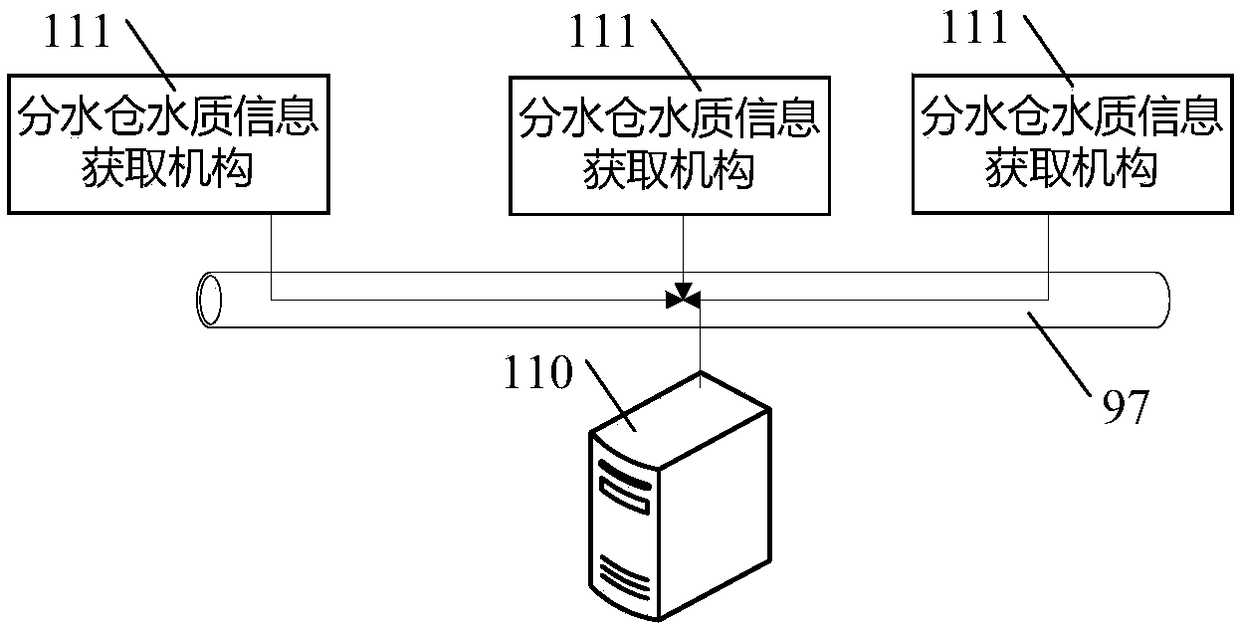

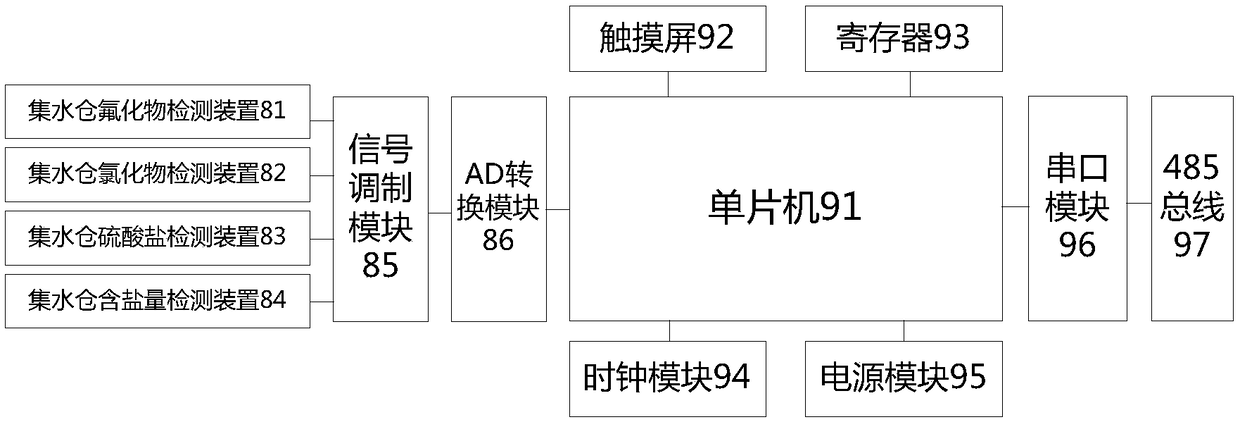

Multiple treating-based mine water quality treating and monitoring system

ActiveCN109384290AProtect normal service lifeAvoid spread outWater/sewage treatment by magnetic/electric fieldsRepeated treatmentWater quality

The invention provides a multiple treating-based mine water quality treating and monitoring system. According to the system, a water quality control host can correspondingly compare a fluoride content, a chloride content, a sulfate content and a salt content in mine water in a certain water-out sump with preset threshold values after a liquid level meter of the water-out sump senses a liquid levelsignal, and control starting of a reflux valve and operating of a reflux pump when a certain content exceeds the corresponding preset threshold value, so as to enable the mine water in the water-outsump to return to a mine water treating mechanism for secondary treatment. When water quality is unqualified, secondary treatment is performed. The system is provided with a plurality of water-out sumps, so that the treated mine water can be separately stored; if the water treatment is unqualified, the treatment process can be suspended to adjust the medicament and ratio, and then the treatment can be carried out to ensure that the water treatment can meet the requirements. The system can avoid the phenomenon that when detection is carried out after treatment of a large quantity of mine water,repeated treatment is required if a large quantity of water is unqualified in quality.

Owner:SHANDONG DONGSHAN WANGLOU COAL MINE

Method for crystallizing and separating para xylene

InactiveCN101735002ASimple structureEasy to operateCrystallisation purification/separationFiltrationSlurry

The invention relates to a method for crystallizing and separating para xylene, and mainly solves the problems of high investment and complicated operation of adsorptive separation and purification of the para xylene. The method adopts a technical scheme that: the method comprises the following steps: delivering mixed xylene containing 60 to 95 percent of para xylene into a crystallizer for cooling crystallization, and crystallizing out slurry containing para xylene crystals; and delivering the slurry into a filtration and purification unit, and separating to obtain mother liquor, scourage and pure para xylene, wherein the filtration and purification unit is a tower washer. The method better solves the problems, and can be applied to industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

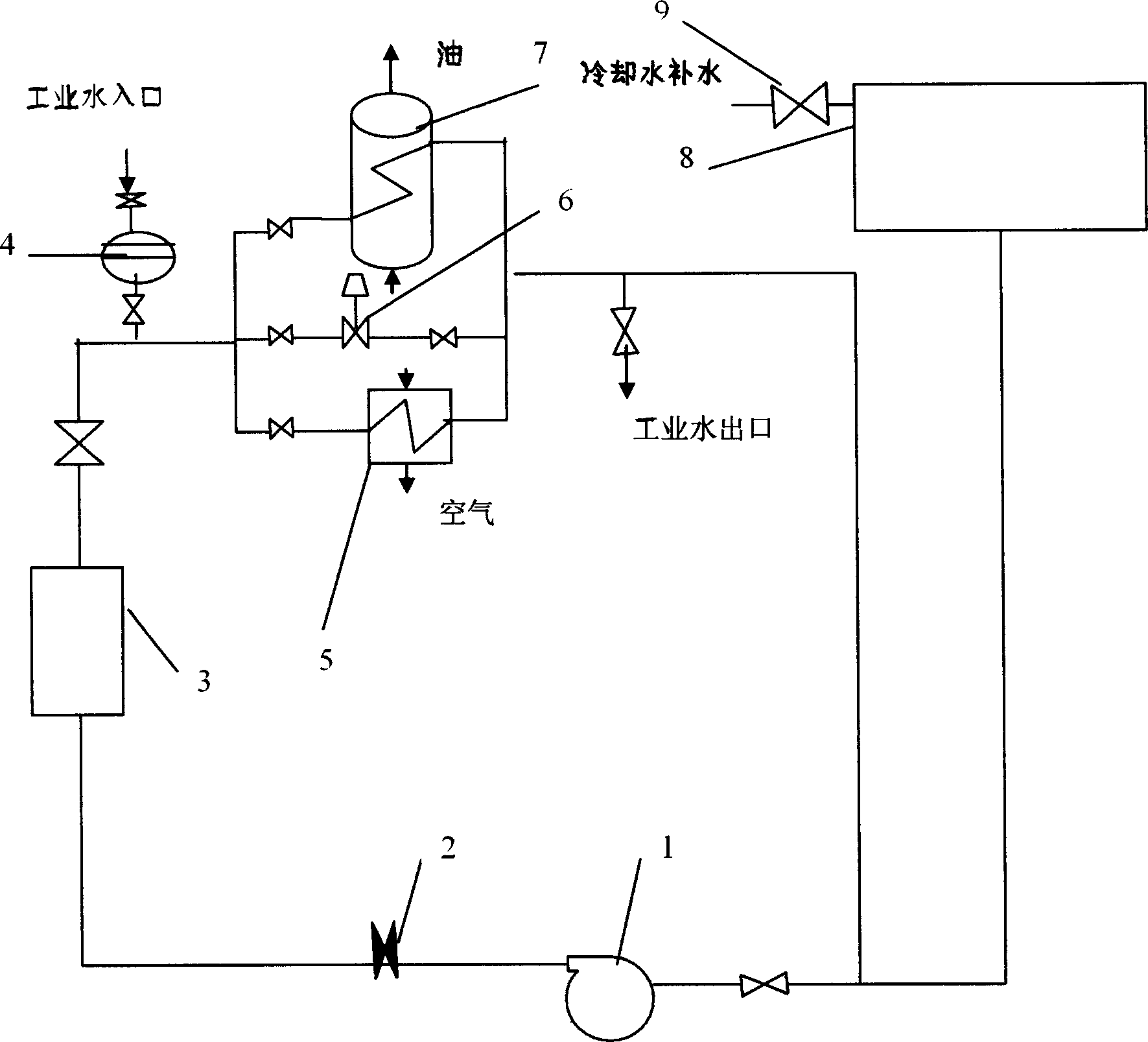

Water saving method applied to turboset

InactiveCN1563689AGuaranteed safe operationReduce cooling effectTurbine/propulsion engine coolingCooling/ventillation arrangementWater savingPower station

A water saving method is applied on the steam turbine set and the oil supply cooling system of the steam turbine and the cooling and entilation system of the engine in the power plant. The closed cooling system is comprised of the air cooler, oil cooler, water cooler group, colling pump, the coolant applies pure water, the coolant takes off the heat from the oil cooler and air cooler and temp raised, being pressurized through the cooling pump, the water enters the water cooling group where the heat is transferred and became temperate wtaer, circulating closely, running through the oil cooler, air cooler to meet the need of the cooling system for the steam turbine.

Owner:烟台众力电力节能有限公司

Method for separating p-xylene crystal

ActiveCN101735001BSimple and fast operationLow priceCrystallisation purification/separationFiltrationSimulated moving bed

Provided is a process for crystallization separating p-xylene, comprising: a) feeding a mixed xylenes stream comprising greater than or equal to 60% by weight, of p-xylene, such as 60% to 98% by weight of p-xylene, to a crystallization unit to perform cooling crystallization, to obtain a slurry comprising p-xylene crystals; and b) feeding the slurry to a filtration and purification unit, to obtain a mother liquor, washings, and p-xylene, wherein the filtration and purification unit uses a simulated moving bed or a combination of multiple moving beds.

Owner:CHINA PETROLEUM & CHEM CORP +1

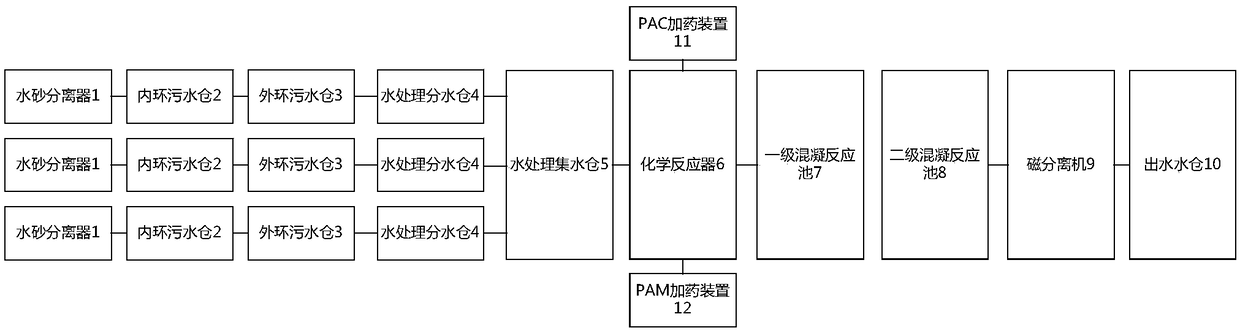

Coal mine underground sewage water quality softening reuse process treatment system

InactiveCN109205918AGuaranteed service lifeAvoid spread outWaste water treatment from quariesWater treatment parameter controlWater qualityCoal

The invention provides a coal mine underground sewage water quality softening reuse process treatment system. A sewage treatment chamber is arranged in a mining region; a water sand separator, an inner ring sewage cabin and an outer ring sewage cabin are arranged in the sewage treatment chamber; mine inflow is discharged to the water sand separator; after being separated by the water sand separator, the water is conveyed to the inner ring sewage cabin; mine water passes through the inner ring sewage cabin and is then conveyed to the outer ring sewage cabin; a water treatment region comprises water treatment water distribution cabins, a water treatment water collection cabin, a chemical reactor, a primary coagulation reaction pool, a secondary coagulation reaction pool, a magnetic separation machine, a water outlet water cabin and a water treatment control device; the quantity of the water treatment water distribution cabins is matched with the mining regions; the mine water of each mining region is gathered and is collected to the water treatment region in a concentrated way for unified treatment. The distributed arrangement of treatment equipment is avoided; the centralized management on sewage treatment cannot be realized; the investment cost is high; the operation cost is high.

Owner:SHANDONG DONGSHAN WANGLOU COAL MINE

Arresting device and runway being provided with arresting device

The scheme of the invention discloses an aerial acceleration type drum-type runway stopper which is a mechanical roller device. The runway stopper comprises multiple groups of roller sets, wherein each roller set comprises a driven roller and a driving roller; the driving roller can independently rotate at high speed; each roller set is provided with a braking device. When an aircraft slides at high speed and is close to the runway stopper, the driving rollers are started and clockwise rotate at high speed, the sliding wheels of the aircraft run onto the driven rollers under the function of inertia, when the sliding wheels of the aircraft are contacted with the driving rollers, as the driving rollers are rotating at high speed in the direction opposite to the sliding wheels, the forward inertia of the sliding wheels is transferred, the sliding wheels are supported above the driven rollers and driving rollers and rotate in the air, and the motion of the aircraft relative to the ground stops. As the aerial accelerated movement of the sliding wheels and the roller sets release inertial energy, the inertia force of the aircraft disappears instantly, and the aircraft is stopped. The aerial acceleration type drum-type runway stopper can stop the aircraft at any position within the sliding distance of the aircraft, and particularly can stop large-scale and heavy aircrafts within a short distance.

Owner:叶元华

Cyazofamid microemulsion and preparation method thereof

ActiveCN102763644AHigh disease activityIncrease investment costsBiocideFungicidesActive componentMicroemulsion

The invention discloses a cyazofamid microemulsion and a preparation method thereof. The cyazofamid microemulsion comprises the following components by weight percent: 1-10 percent of cyazofamid, 5-60 percent of solvent and co-solvent, 5-20 percent of emulsifier, 1-5 percent of stabilizer, and the balance of deionized water. The preparation method comprises the following steps: completely resolving the cyazofamid active component by the solvent and co-solvent, adding the solution to a mixing kettle, then adding a certain proportion of emulsifier, stabilizer and deionized water, and fully mixing to obtain the cyazofamid microemulsion. According to the invention, the purposes of high efficiency, low toxicity, environmental friendliness, security of human and livestock, and high activity to crop diseases are achieved, the production process is simple and processing and production are easy.

Owner:中高(天津)知识产权管理有限公司

Mixed gas combustor

The invention discloses a mixed gas combustor, relating to a gas combustor. The mixed gas combustor comprises two channels which are embedded inside and outside, a combustion air channel is arranged on the periphery and a fuel channel is arranged in the center, a burner nozzle is formed on the front end of the combustion air channel, and the front end of the fuel channel is provided with a spraying orifice for enabling fuel in the fuel channel to be radially outwards spirally spayed. The invention aims at providing the novel gas combustor, which has better stable combustion while combusting low-heat-value gas fuel with large flow, can not cause nozzle burning and coking problems while combusting high-heat-value gas fuel with small flow, and can combust a mixed fuel of a low-heat-value gas fuel and a high-heat-value gas fuel.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Selective catalytic reduction denitration reactor

InactiveCN109173704AExtend your lifeLow investment costGas treatmentDispersed particle separationGas pipelineProcess engineering

The invention discloses a selective catalytic reduction denitration reactor, comprising a reactor body, wherein the top of the reactor body is connected with a gas inlet pipeline and the bottom of thereactor body is connected with a gas outlet pipeline; the reactor body is internally provided with flow equalization grids, blowing drying devices, optical wave heating devices and catalyst layers; the flow equalization grids are located at the upper part in the reactor body; the reactor body is internally provided with a plurality of catalyst layers; an optical wave heating device is arranged above each catalyst layer; the blowing drying devices are arranged above the optical wave heating devices; an online micro differential pressure detection device is arranged at each of the upper part and lower part of each catalyst layer; the blowing drying device communicate with a high-pressure and high-temperature steam pipeline and a gas outlet bypath respectively through a steam pipeline; and the gas outlet bypath communicates with the gas outlet pipeline. The selective catalytic reduction denitration reactor is high in denitration efficiency and the NOx emission concentration can be controlled within an extremely low emission value and is lower than national ultralow emission standards.

Owner:宫子凡

Production technology of dimethyl carbonate

InactiveCN106866417AIncrease productionReduce energy consumptionChemical industryPreparation from organic carbonatesChemistryDimethyl sulfite

Owner:SHANDONG DEPU CHEM IND SCI & TECH

Iron-carbon micro-electrolysis filler for treatment of printing and dyeing wastewater

InactiveCN108117138ALarge amount of waterDeep colorWater/sewage treatment using germicide/oligodynamic-processWaste water treatment from textile industryTreatment effectElectrolysis

The invention discloses an iron-carbon micro-electrolysis filler for treatment of printing and dyeing wastewater. The iron-carbon micro-electrolysis filler is characterized in that dyestuff wastewateris treated by utilizing a micro-electrolysis method, the removal rate of CODcr is about 67%, and the color removal rate is nearly 100%. Results show that acid wastewater contributes to removing the CODcr and removing the color, and acid wastewater with a pH value of 4 is selected; and the prolonged micro-electrolysis reaction time contributes to improving the treatment effect, while investment and operation cost can be increased, and the reaction time needs to be controlled to be 50 minutes.

Owner:哈尔滨市恒源麻纺机械有限公司

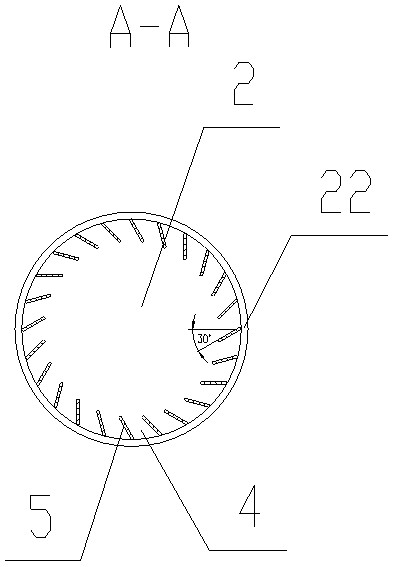

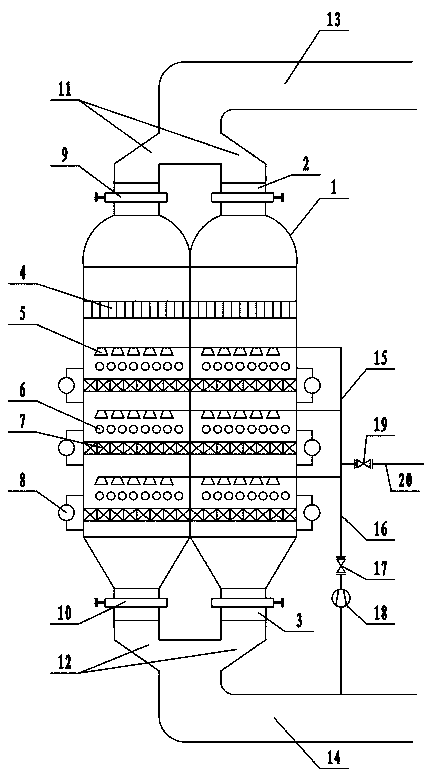

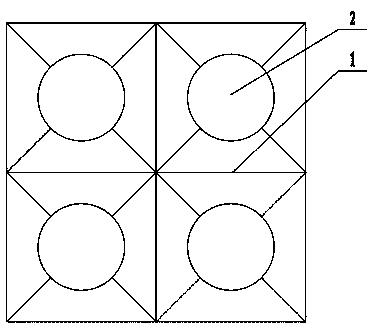

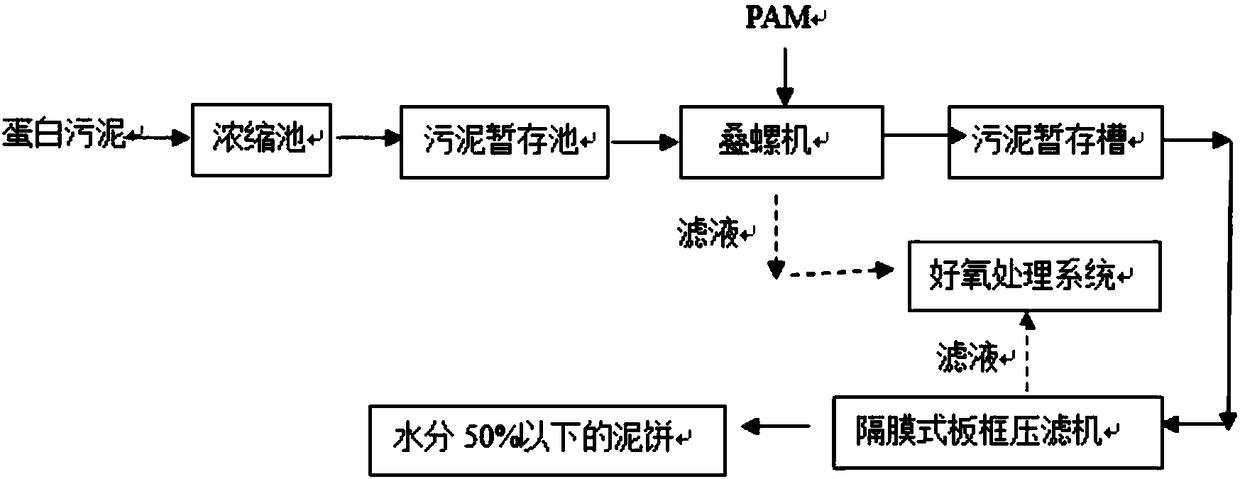

Protein sludge deep dehydration method

ActiveCN108178479AConvenient for subsequent disposalRealize resource reuseSludge treatment by de-watering/drying/thickeningWaste water treatment from food industrySludgeFilter press

A protein sludge deep dehydration method comprises the following steps: (1) protein sludge having a moisture content of 98% or more is transported to a sludge concentration tank, and the moisture content of the protein sludge concentrated by the sludge concentration tank is reduced to 95% or less; (2) the protein sludge concentrated by the sludge concentration tank enters a sludge temporary storage tank, and then is transported from the temporary storage tank to a pipeline mixer, a flocculant is added and mixed uniformly with the protein sludge, then the protein sludge enters a stacking-screwsludge dehydration machine for dehydration, and the moisture content of the protein sludge dehydrated by the stacking-screw sludge dehydration machine is reduced to 85% or less; (3) the protein sludgedehydrated by the stacking-screw sludge dehydration machine is dropped into the sludge temporary storage tank, and transported into a diaphragm type plate and frame filter press to be dehydrated, andthe moisture content of the protein sludge filtered through the diaphragm type plate frame filter press is reduced to 50% or less. The method can realize deep dehydration of the protein sludge.

Owner:LINYI YUWANG VEGETABLE PROTEIN

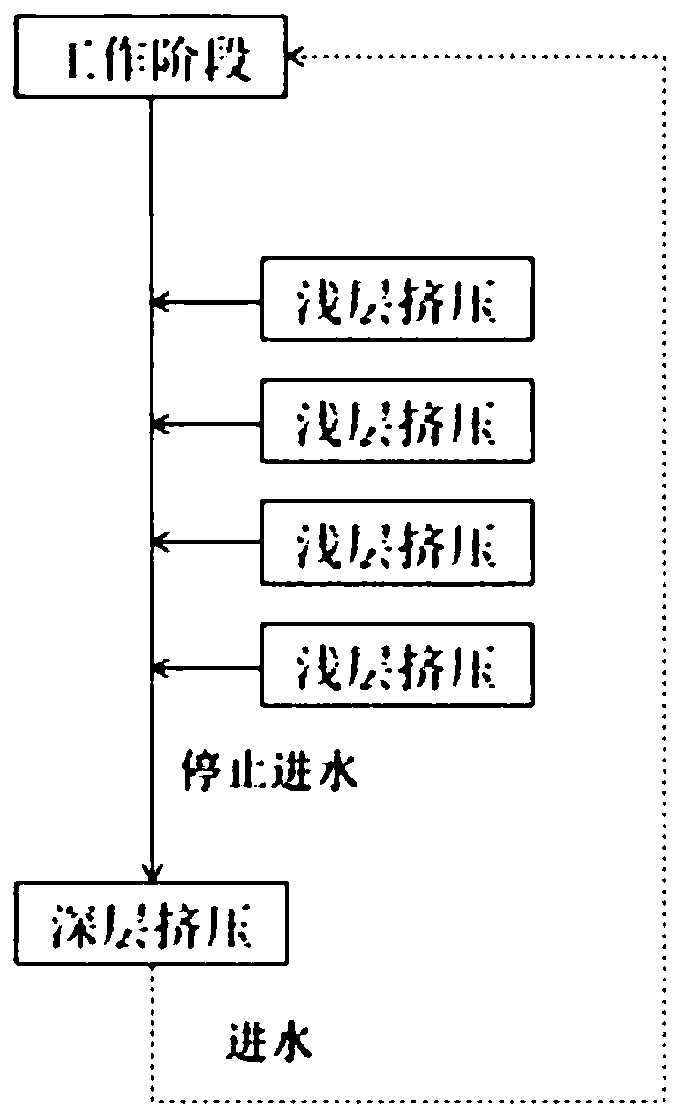

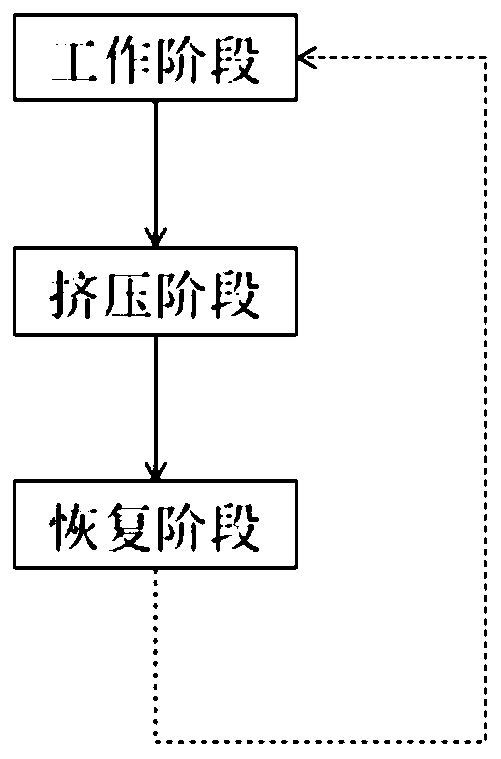

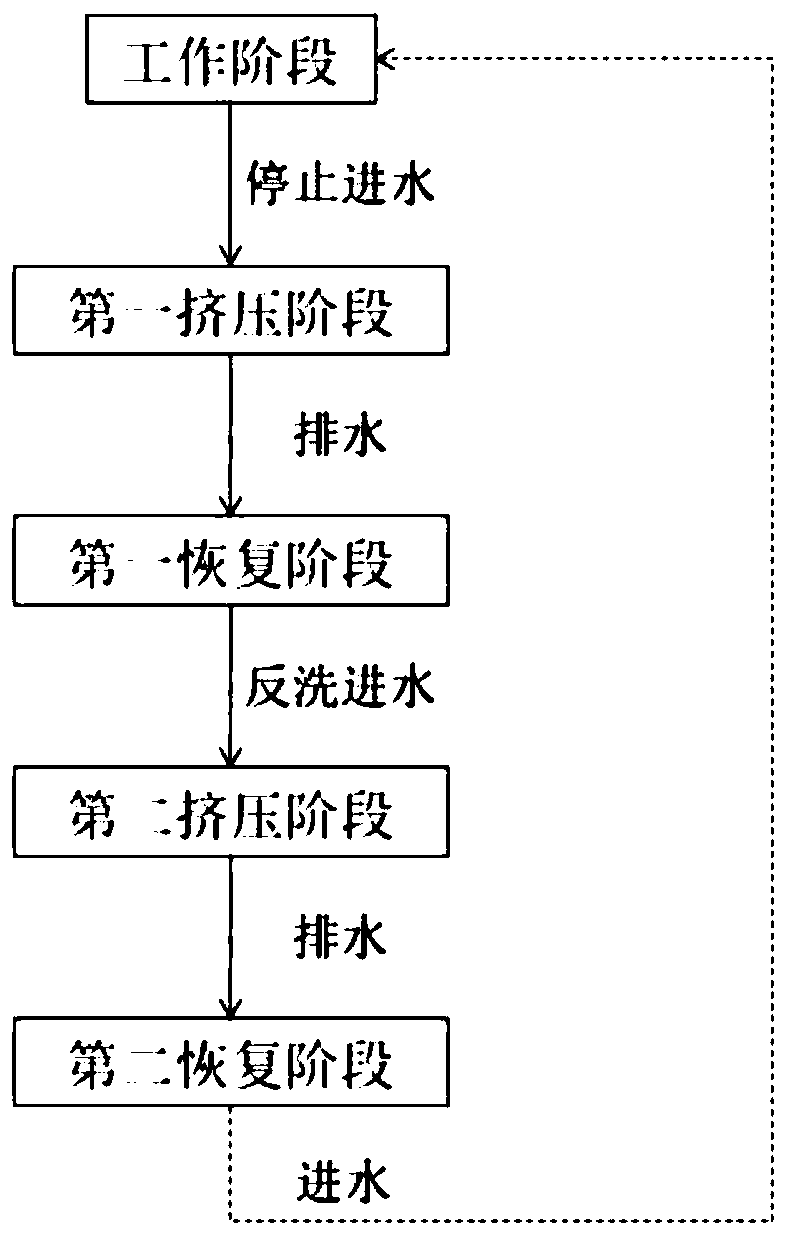

Enhanced nitrification process based on coupled demolding

ActiveCN111362408AAvoid cloggingStable and uniform dissolved oxygen distributionWater contaminantsTreatment with aerobic and anaerobic processesSewageSewage treatment

The invention discloses an enhanced nitrification process based on coupled demolding, and belongs to the technical field of sewage treatment. In the sewage nitrification process, under a condition ofkeeping a certain content of dissolved oxygen in a system, extrusion treatments are carried out on an elastic filler so as to generate different deformation degrees, in each extrusion treatment, deepextrusion and shallow extrusion are coupled; deep extrusion is carried out when the system load decreases, the effluent quality is close to an index value, or the system resistance exceeds a designedinflow water distribution pressure; and shallow extrusion is carried out when the system load is stable. Through the combination of deep extrusion and shallow extrusion, on one hand, demolding and redistribution of a bio-membrane filler can be realized, the mass transfer efficiency is improved, on the other hand, dissolved oxygen inside and outside the bio-membrane filler can be distributed more uniformly, through the synergistic effect of deep extrusion and shallow extrusion, the nitrification reaction is enhanced, the sewage treatment efficiency is improved, and the effluent quality is recovered.

Owner:ANHUI PUSHI ECOLOGICAL ENVIRONMENT ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com