Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134 results about "Annular fin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In thermal engineering, an annular fin is a specific type of fin used in heat transfer that varies, radially, in cross-sectional area. Adding an annular fin to an object increases the amount of surface area in contact with the surrounding fluid, which increases the convective heat transfer between the object and surrounding fluid. Because surface area increases as length from the object increases, an annular fin transfers more heat than a similar pin fin at any given length. Annular fins are often used to increase the heat exchange in liquid–gas heat exchanger systems.

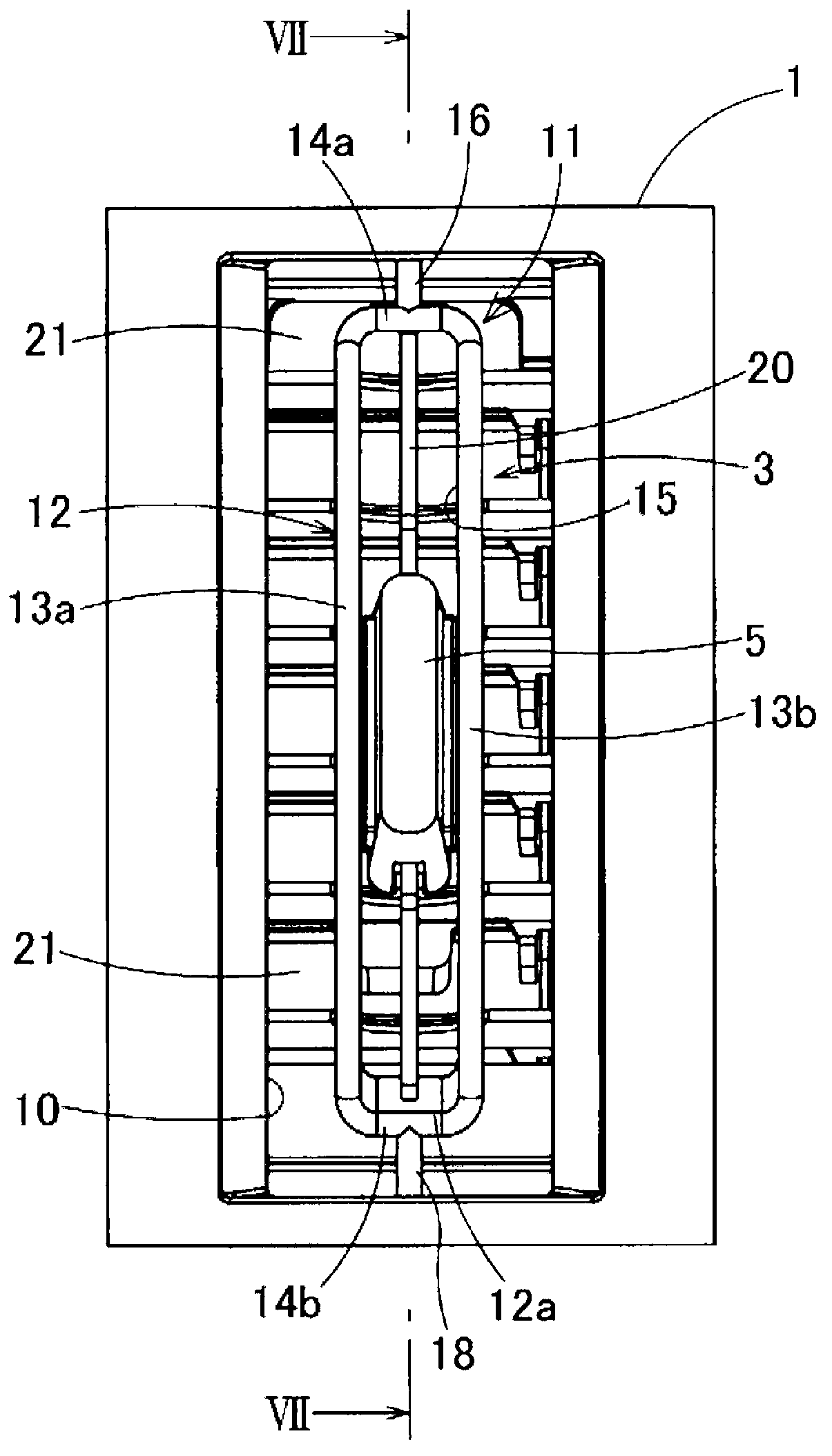

Temperature sensing device for metering fluids

InactiveUS20050038172A1Improve thermal conductivityImproves rate of temperature transferThermometer detailsThermometers using electric/magnetic elementsThermowellAnnular fin

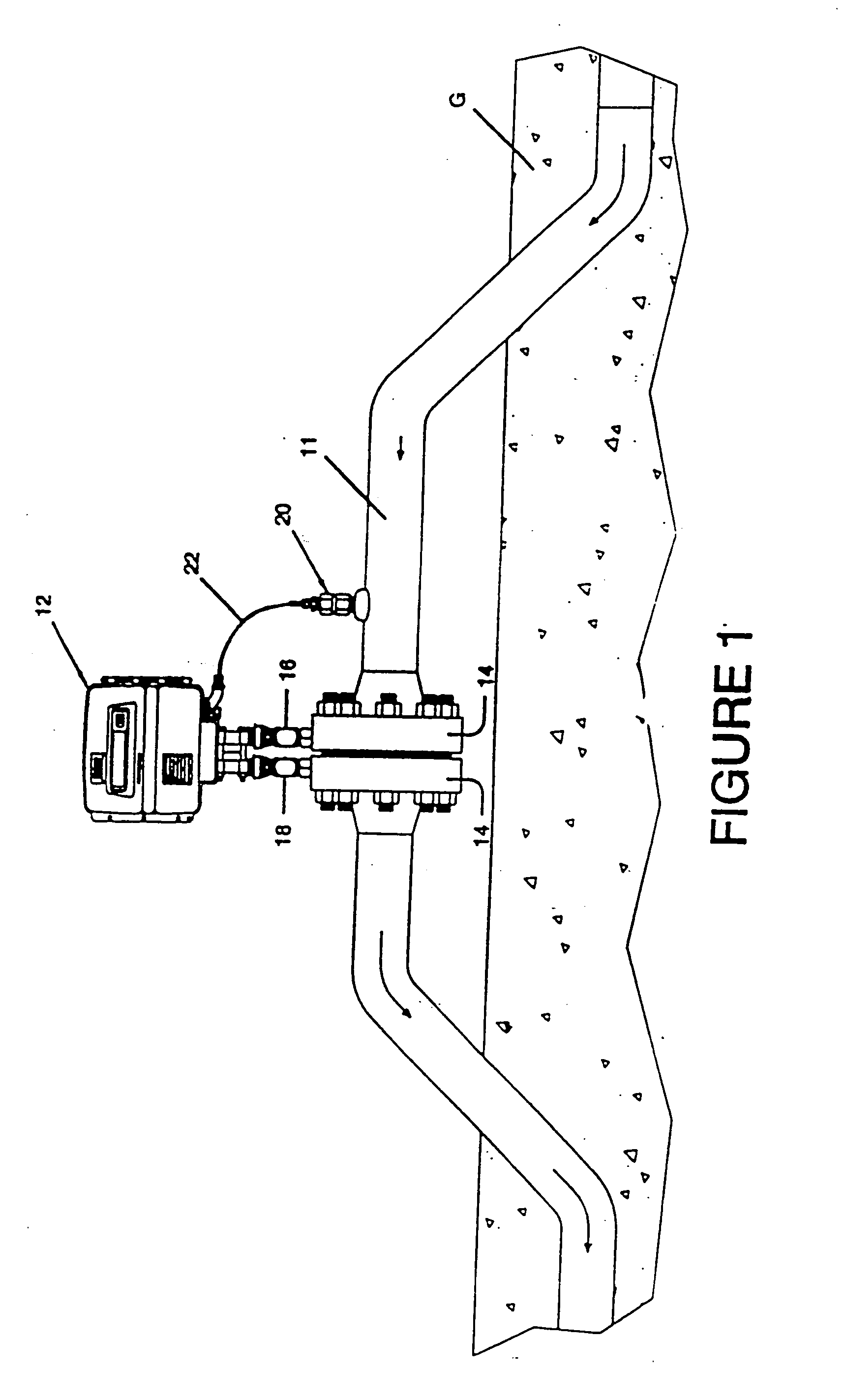

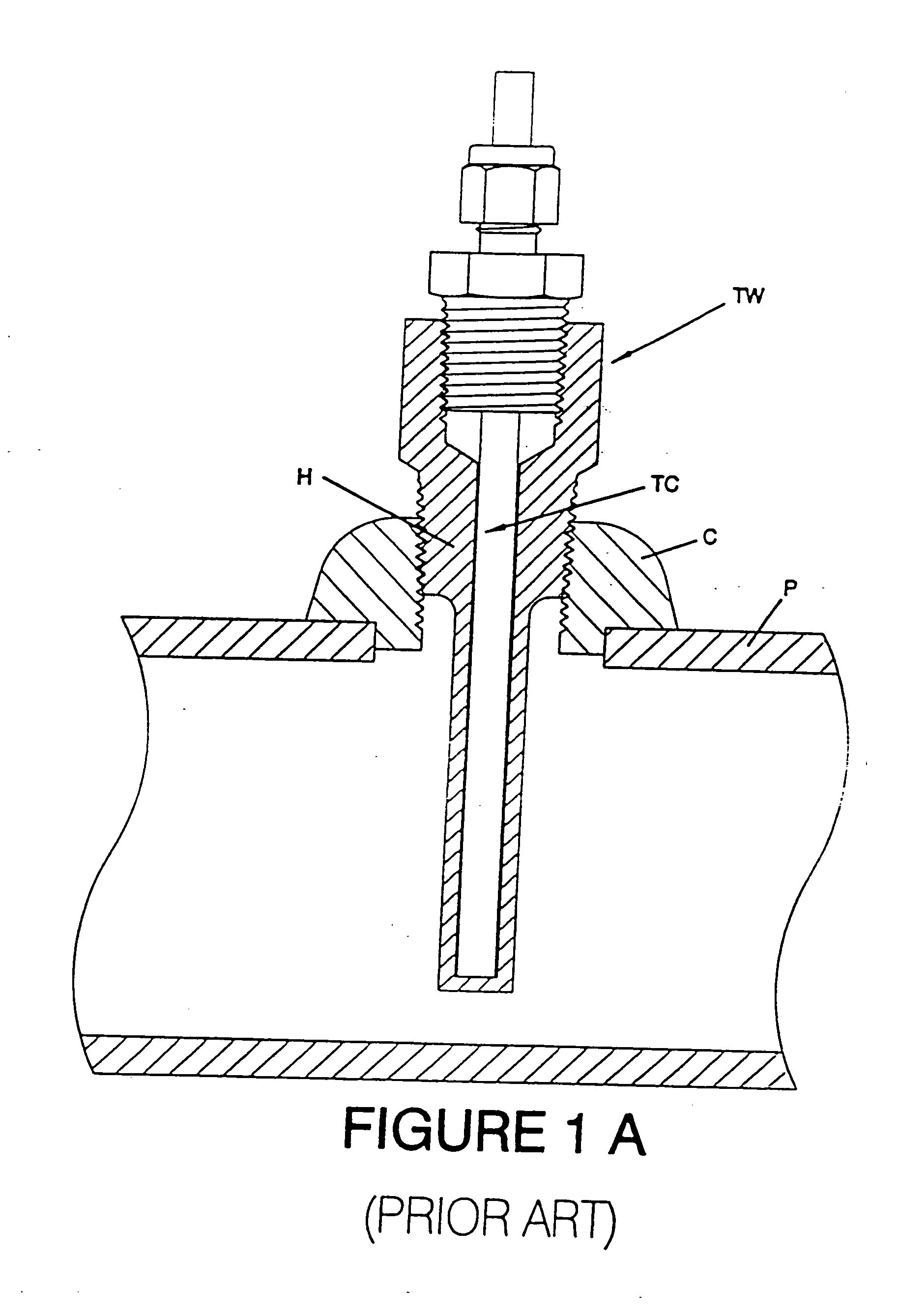

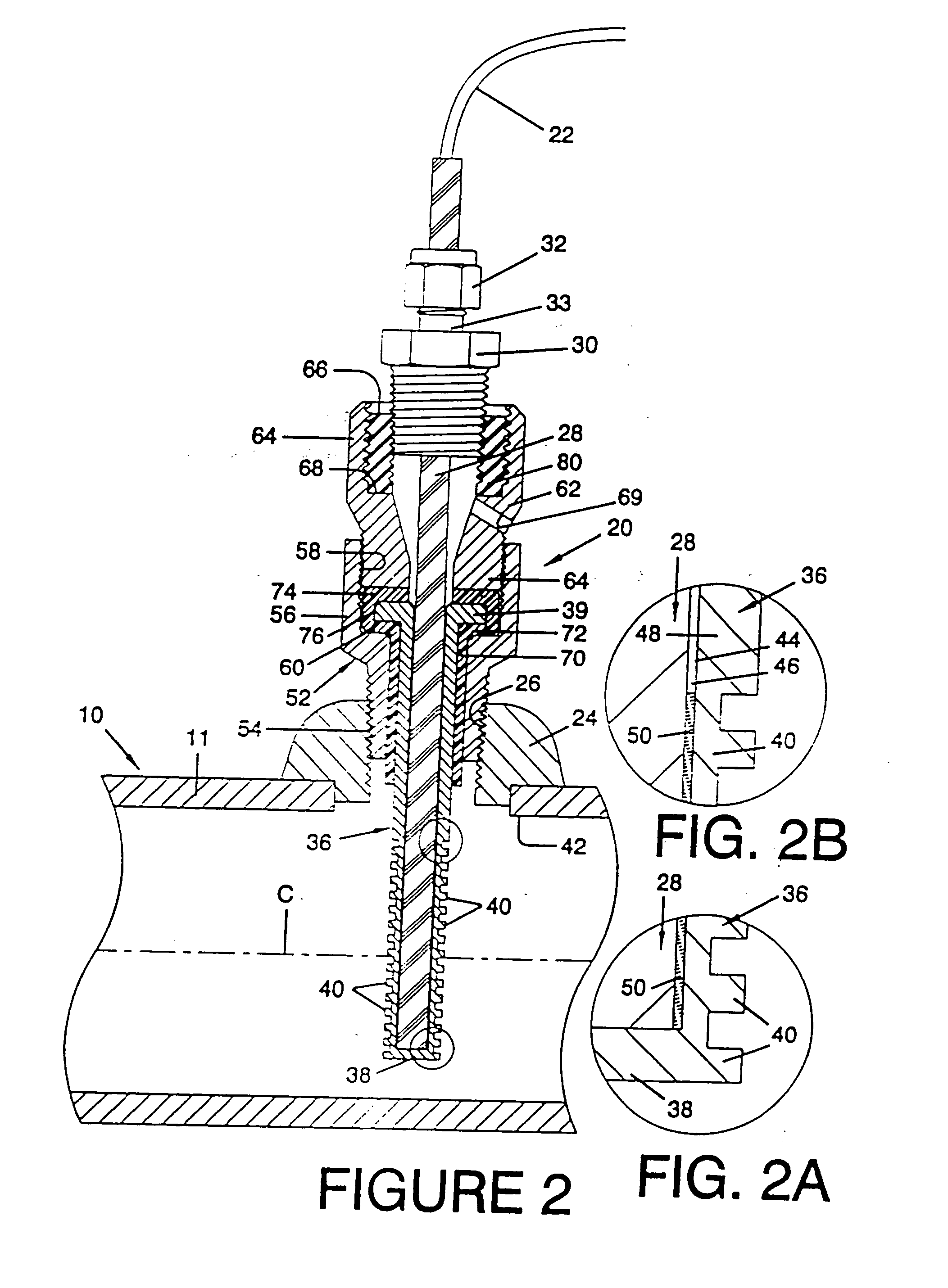

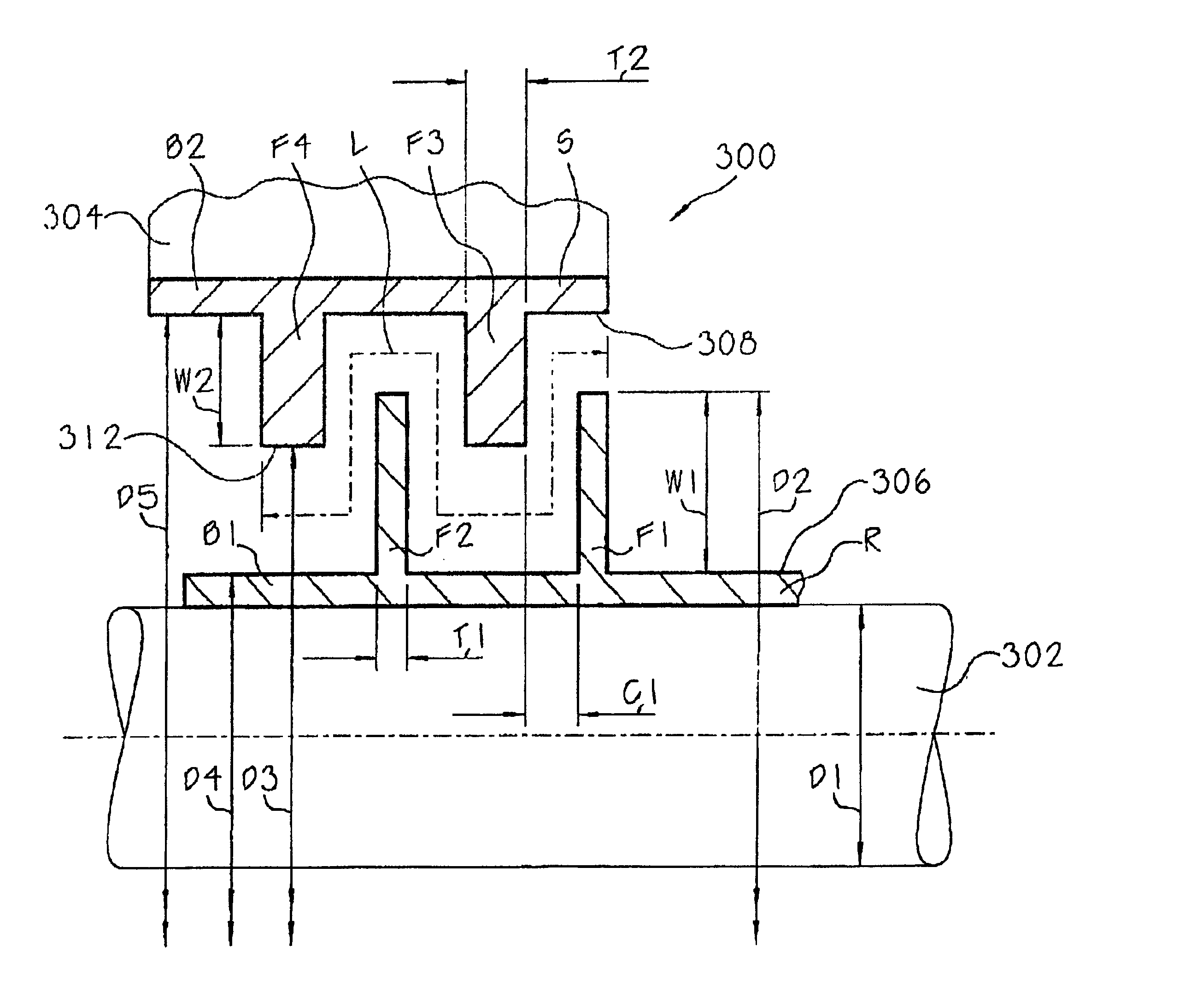

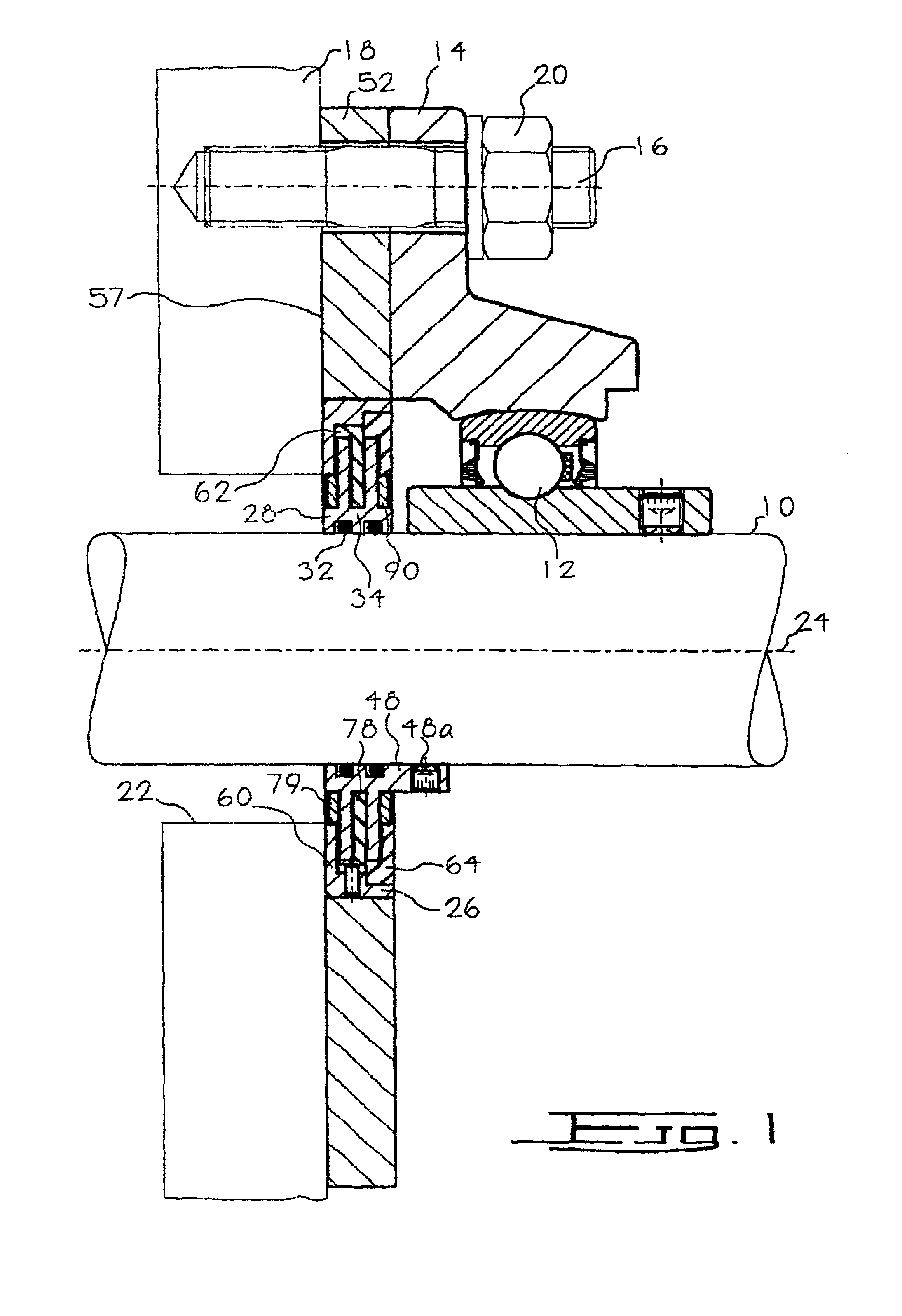

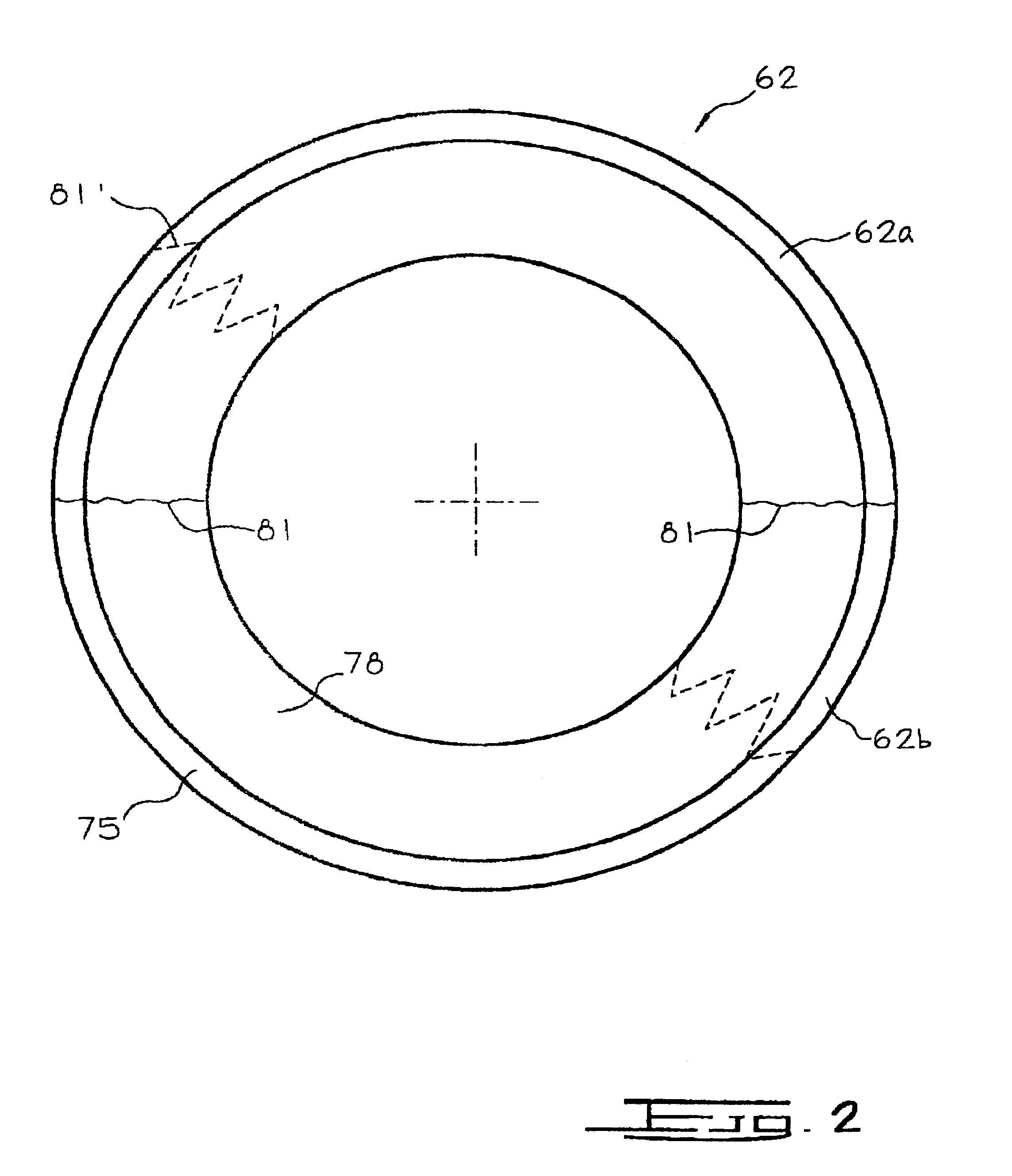

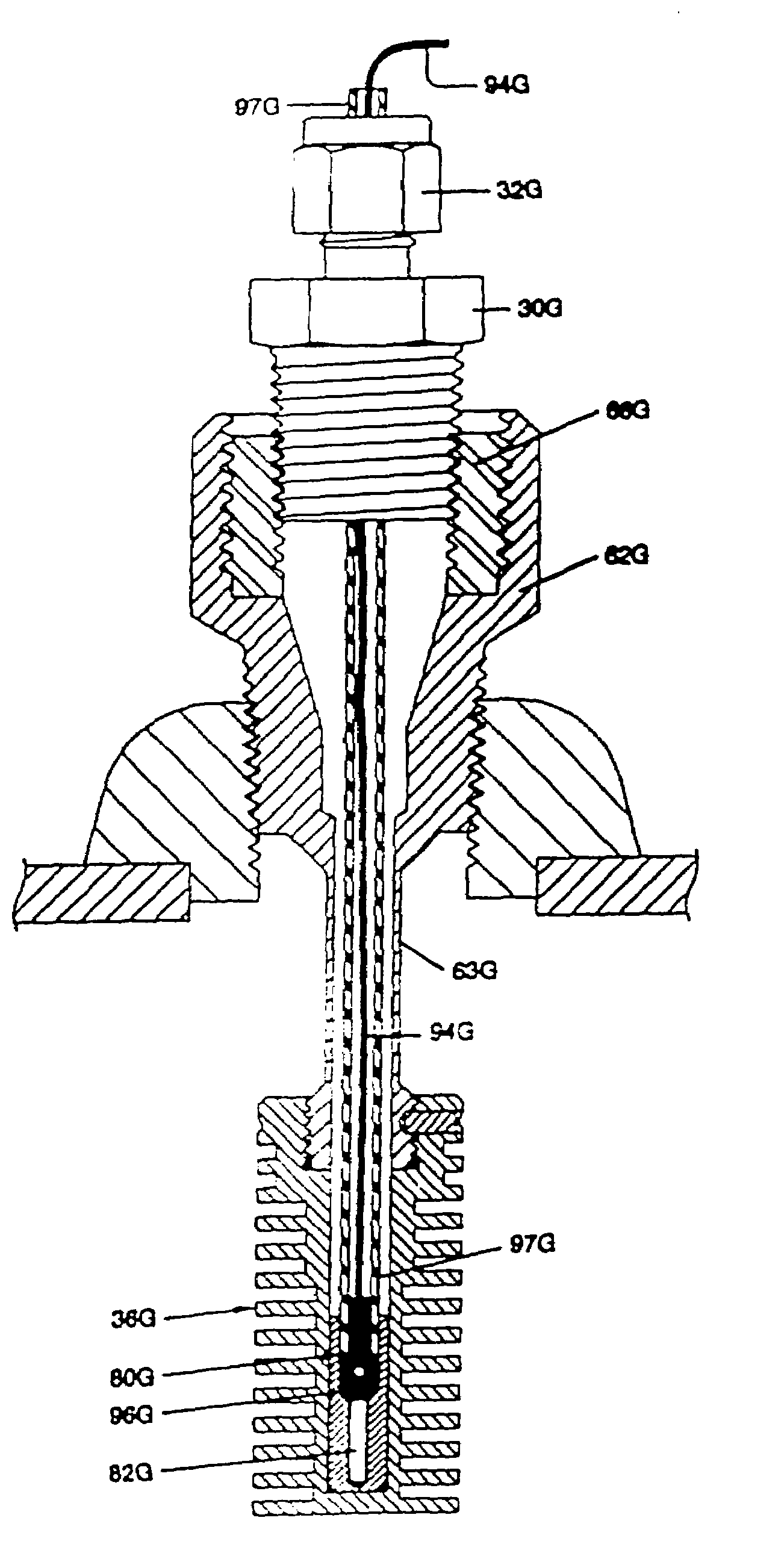

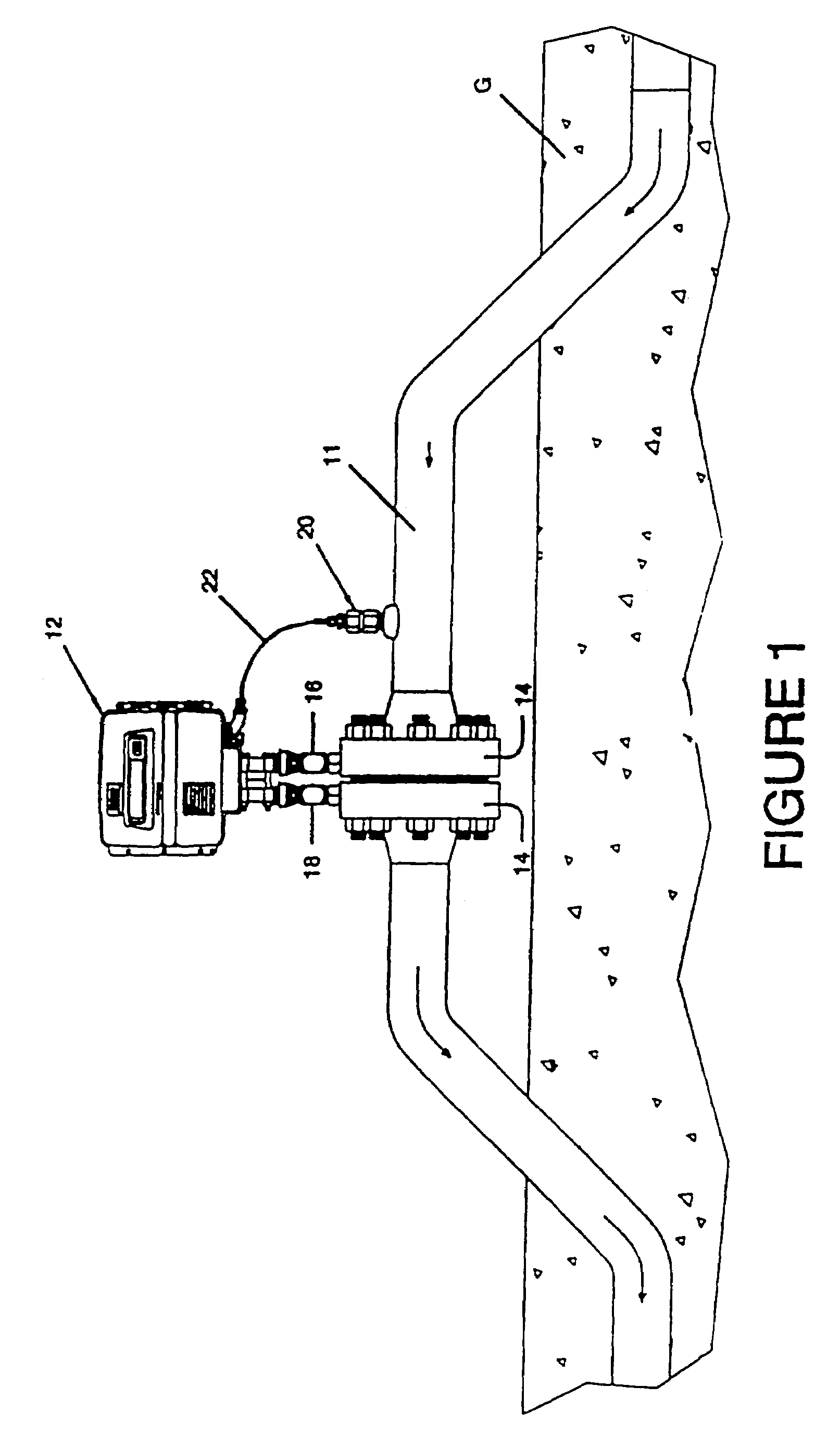

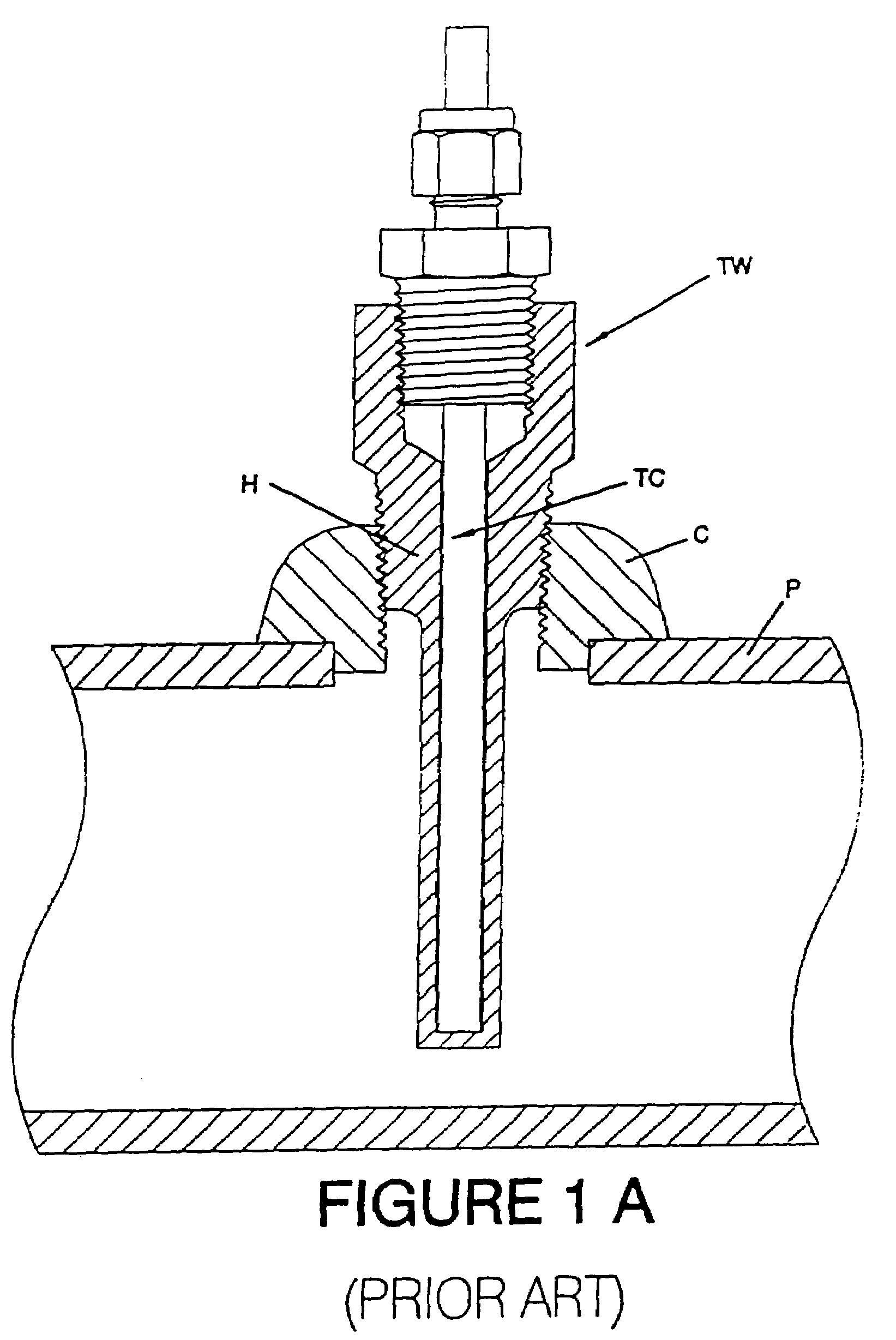

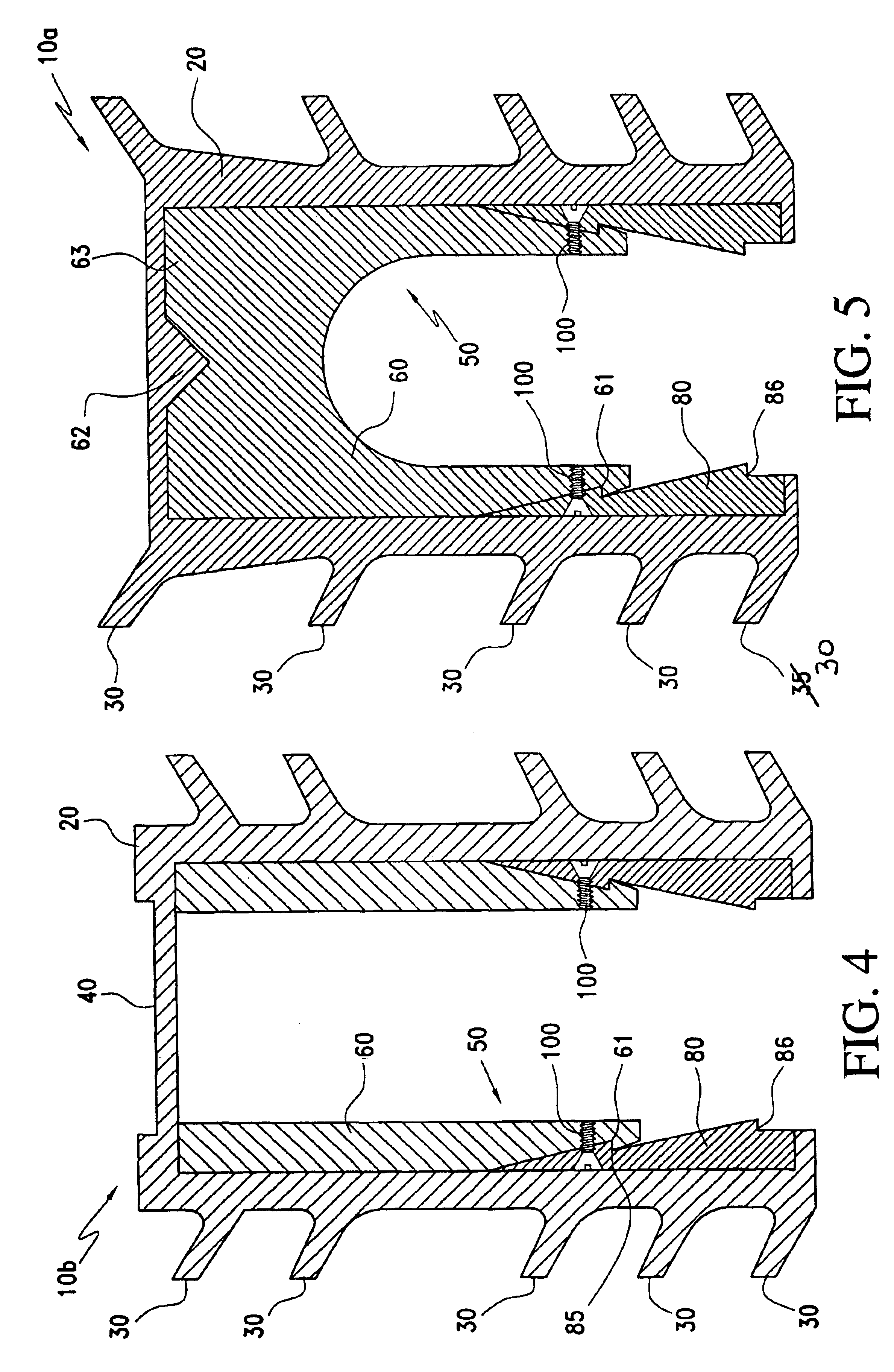

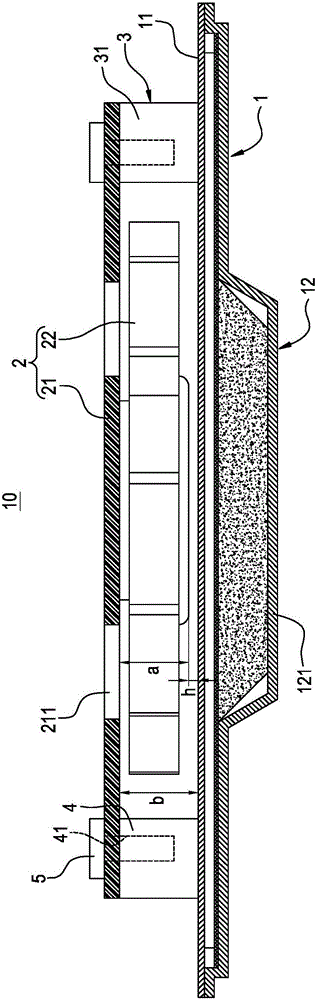

A thermowell assembly (20) shown in FIG. 2 is positioned in a pipeline (10) for sensing the temperature of the fluid medium in the pipeline (10) for transmitting the sensed temperature to a meter (12). A temperature sensing probe is received within a temperature conducting tube (36) forming a thermowell and having a plurality of annular fins (40) extending thereabout. In the embodiments of FIGS. 1-7, a liquid (50) is provided in an annular space between the thermocouple (28) and the temperature conducting tube (36). Non-metallic members (70, 74, 80) are positioned between the pipeline (10) and the temperature transmitting tube (36) to isolate thermocouple (28) from ambient changes in the temperature of metal pipeline (10) which may result in an error in the temperature of the flow medium sensed by the thermowell assembly (20). High temperature embodiments shown in FIGS. 4 and 5 do not contain any non-metal components and provide a minimal metal to metal contact between the metallic temperature conducting tube (36B) of the thermowell (20B) and the adjacent metal mounting structure (52B, 62B). The embodiments shown in FIGS. 8-12 illustrate a temperature sensing probe comprising a temperature sensing assembly (80F, 80G) mounted within the internal bore (37F, 37G) of the finned tube (36F, 36G). The temperature sensing assembly (80F, 80G) includes a carrier (82F, 81G) with epoxy (96F, 96G) mounting a temperature sensing element (93F, 93G) within the carrier (82F, 81G).

Owner:PARKER INTANGIBLES LLC

Shaft seals for sealing pulverulent solids

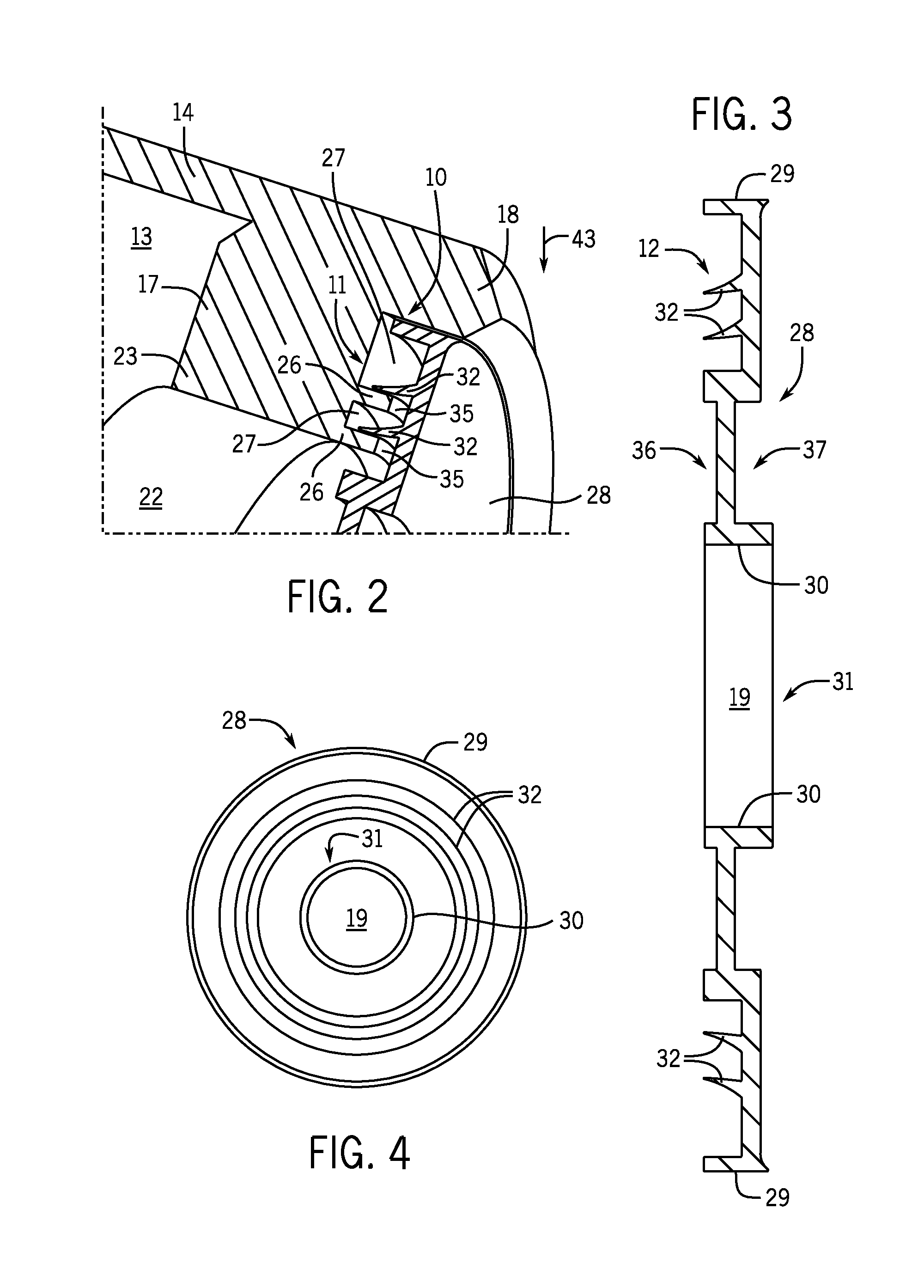

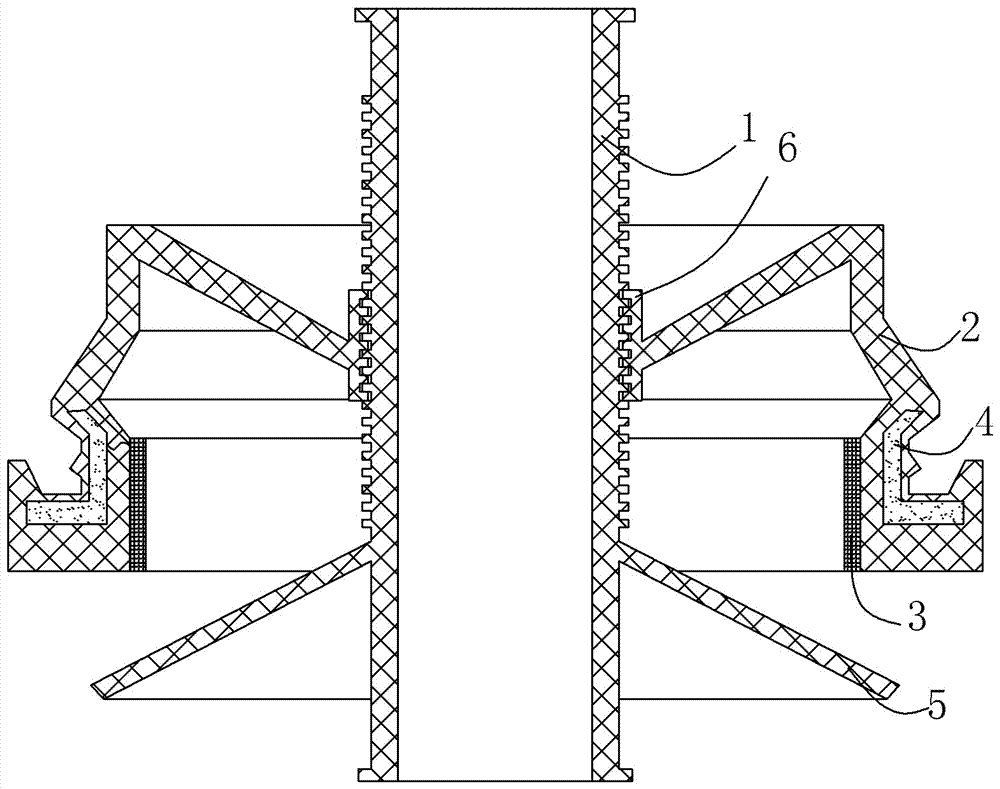

An apparatus and method for providing a seal between first and second relatively rotatable parts of machines which operate in an environment comprising dust, grit or other finely divided solid material entrained in air, water or other fluid. The seal includes a rotor and a stator between which there is an annular passage with substantial clearance between the interfacing surfaces defining the passage. The solid material entrained in the fluid which enters the annular passage is deposited in layers on the interfacing surfaces when the mechanism is in use. The layers substantially reduced the cross sectional size of the annular passage and restrict flow of the fluid there through. The annular passage may be rendered tortuous by providing the rotor with annular fins which in use project into annular recesses in the stator, and vice versa.

Owner:BAYNE CHRISTOPHER FREDERICK

Temperature sensing device for metering fluids

InactiveUS7165883B2Improve thermal conductivityImproves rate of temperature transferThermometer detailsThermometers using electric/magnetic elementsEpoxyEngineering

A thermowell assembly (20) shown in FIG. 2 is positioned in a pipeline (10) for sensing the temperature of the fluid medium in the pipeline (10) for transmitting the sensed temperature to a meter (12). A temperature sensing probe is received within a temperature conducting tube (36) forming a thermowell and having a plurality of annular fins (40) extending thereabout. In the embodiments of FIGS. 1–7, a liquid (50) is provided in an annular space between the thermocouple (28) and the temperature conducting tube (36). Non-metallic members (70, 74, 80) are positioned between the pipeline (10) and the temperature transmitting tube (36) to isolate thermocouple (28) from ambient changes in the temperature of metal pipeline (10) which may result in an error in the temperature of the flow medium sensed by the thermowell assembly (20). High temperature embodiments shown in FIGS. 4 and 5 do not contain any non-metal components and provide a minimal metal to metal contact between the metallic temperature conducting tube (36B) of the thermowell (20B) and the adjacent metal mounting structure (52B, 62B). The embodiments shown in FIGS. 8–12 illustrate a temperature sensing probe comprising a temperature sensing assembly (80F, 80G) mounted within the internal bore (37F, 37G) of the finned tube (36F, 36G). The temperature sensing assembly (80F, 80G) includes a carrier (82F, 81G) with epoxy (96F, 96G) mounting a temperature sensing element (93F, 82G) within the carrier (82F, 81G).

Owner:PARKER INTANGIBLES LLC

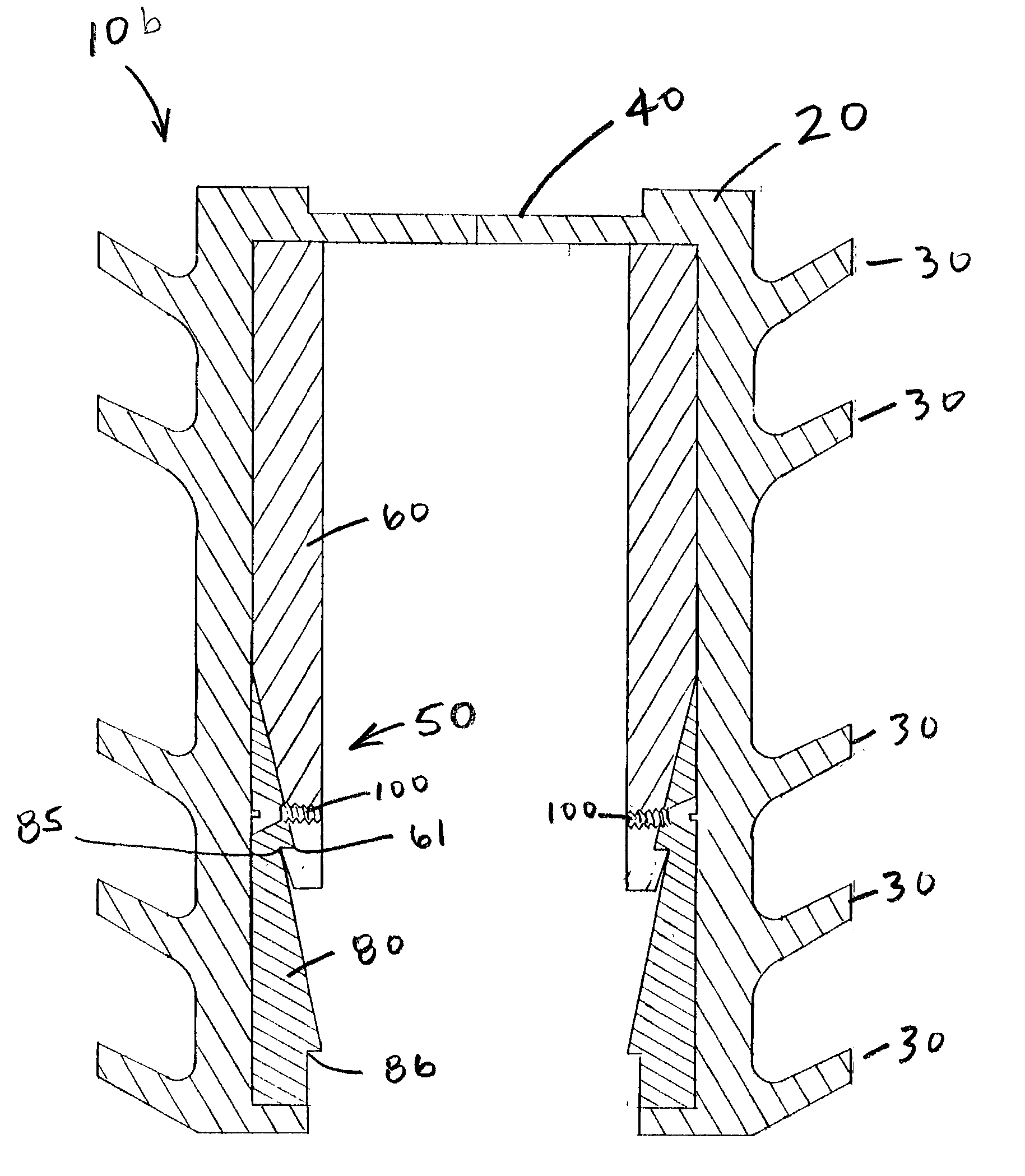

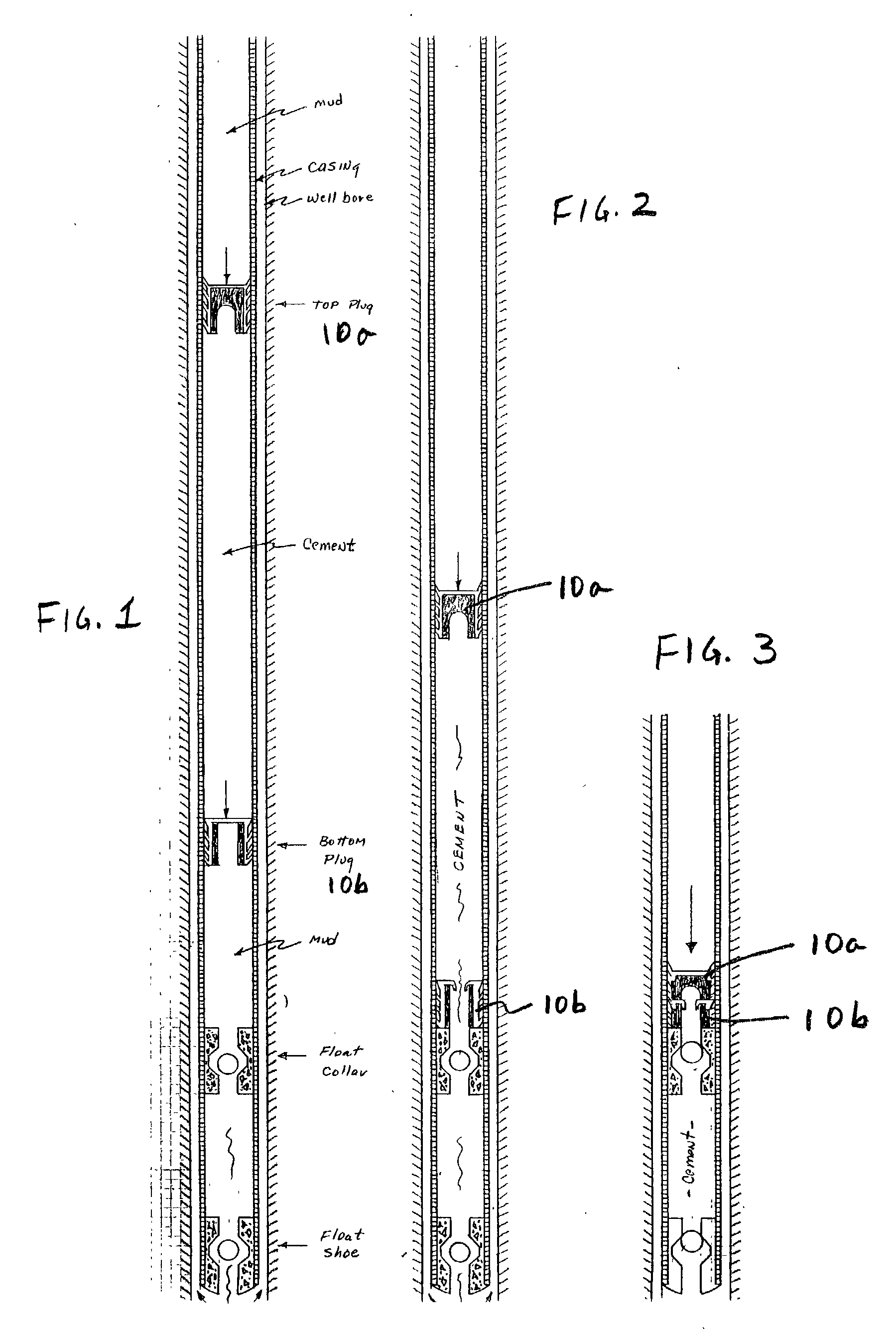

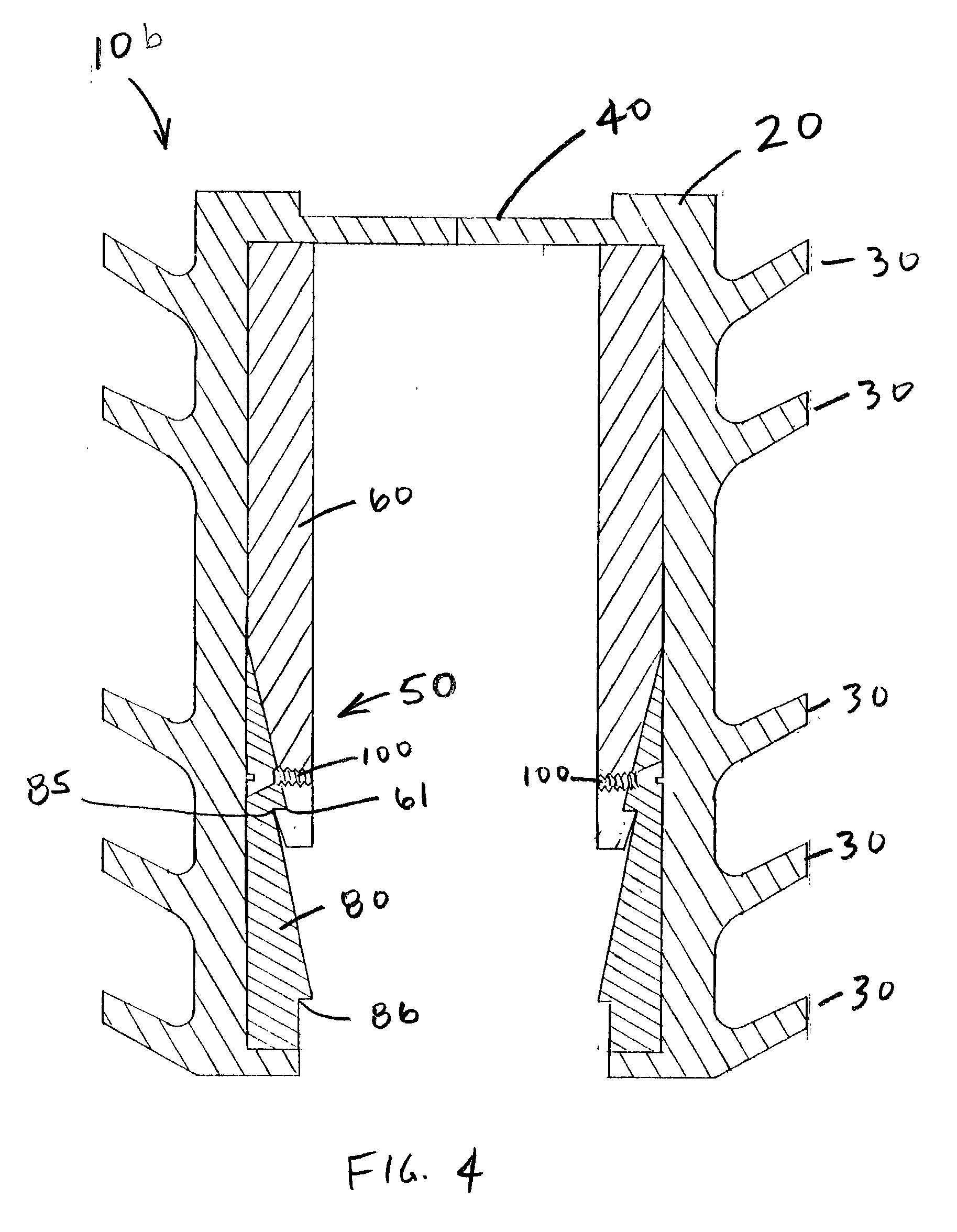

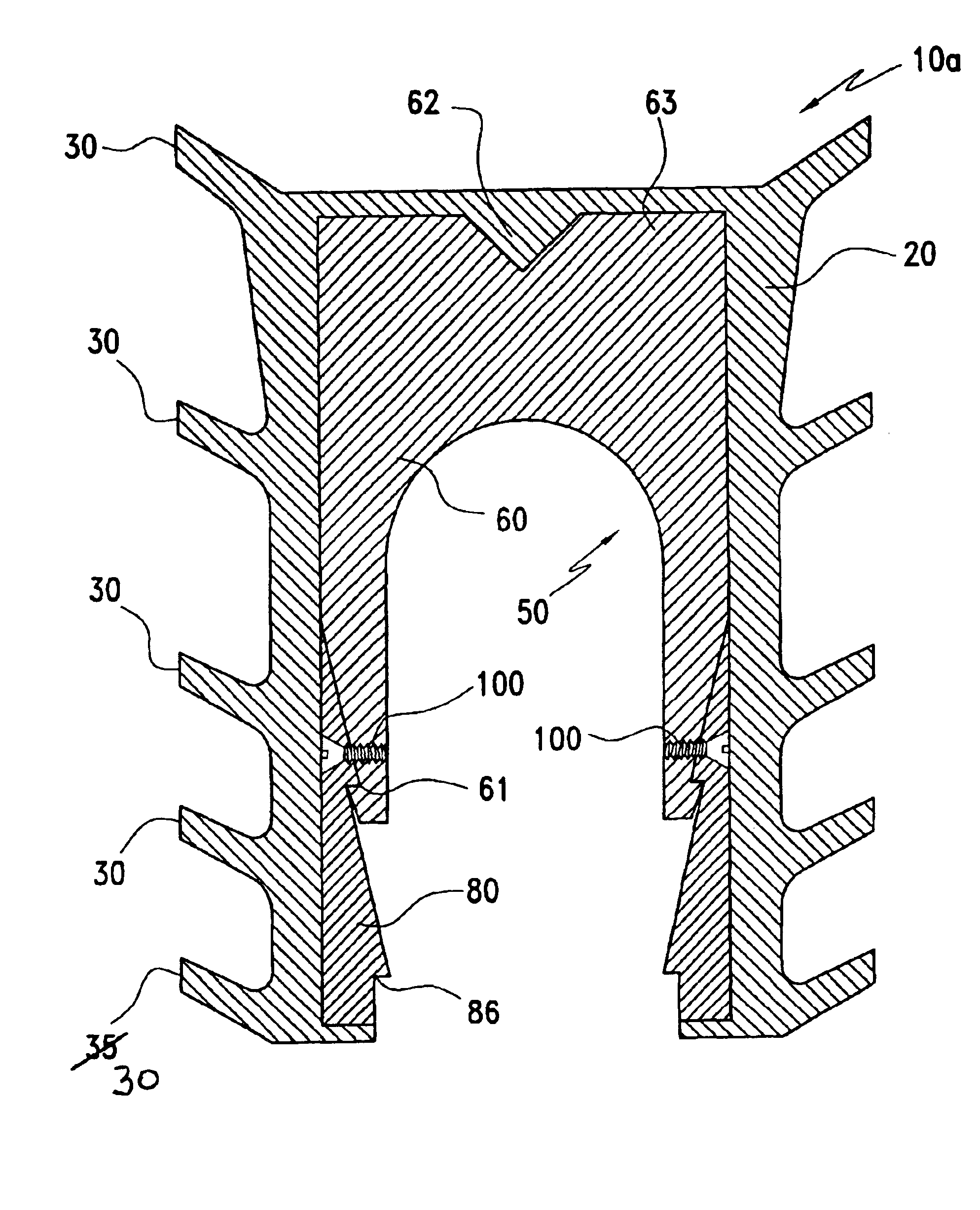

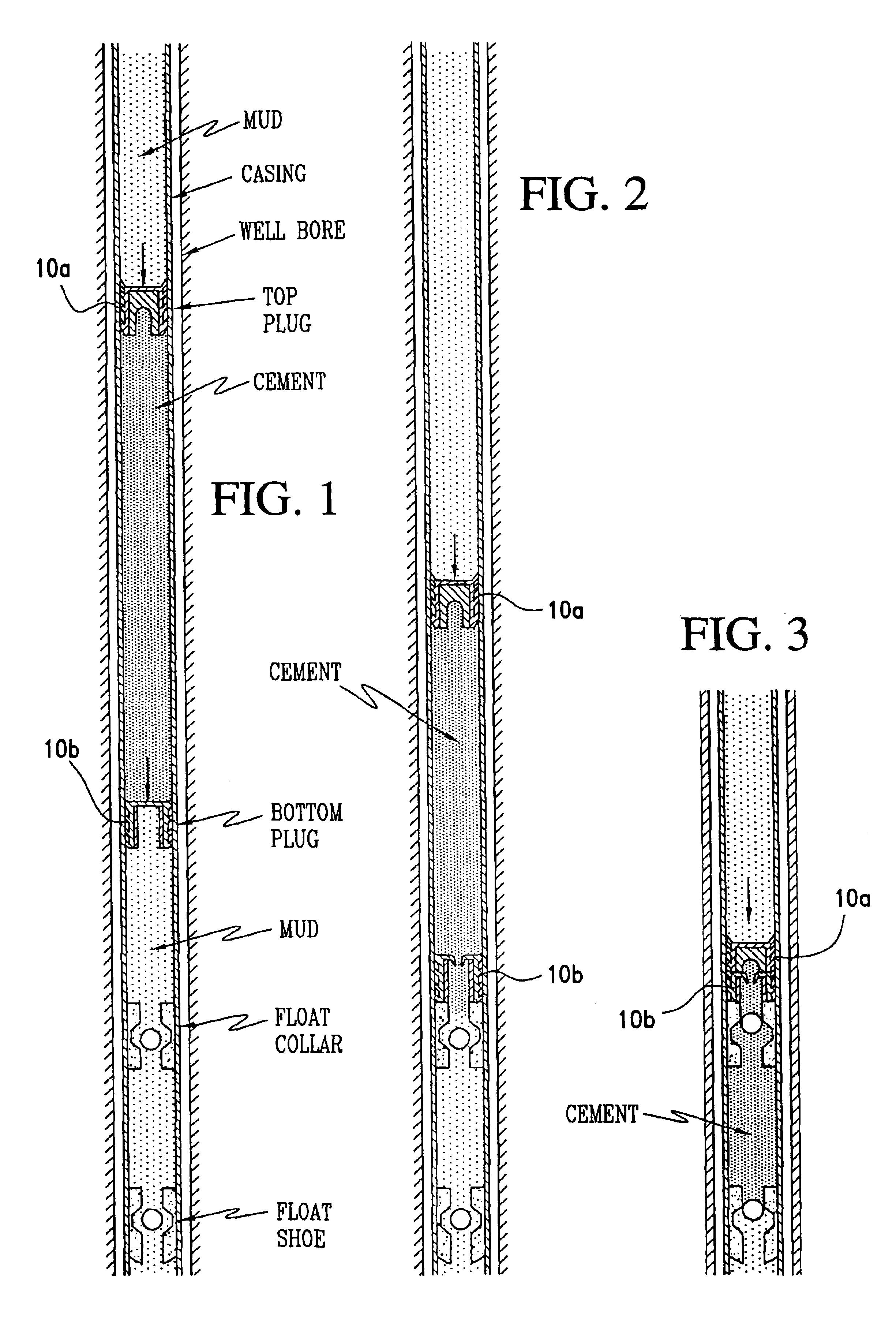

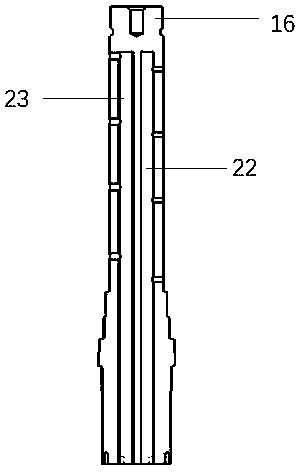

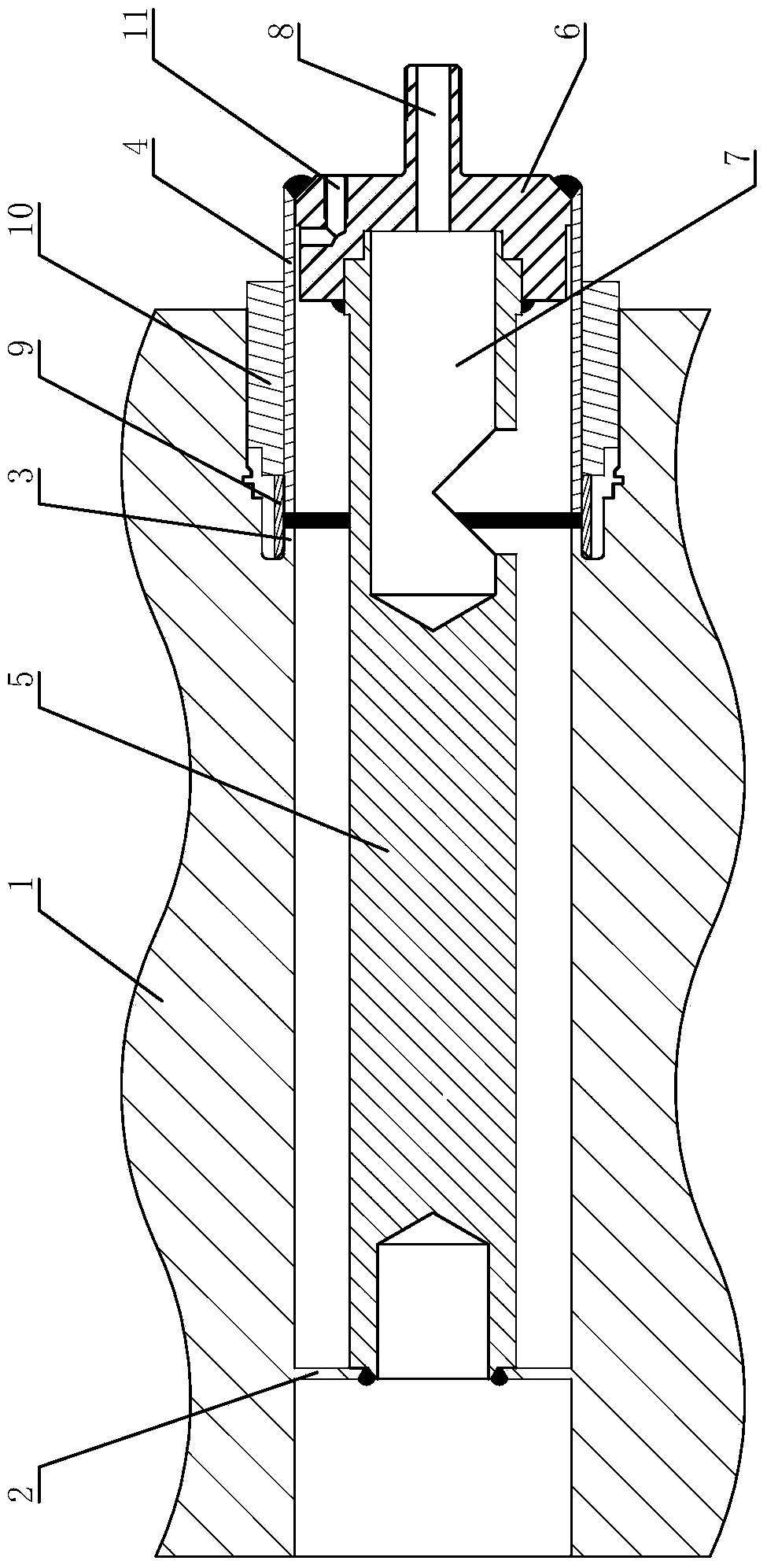

Non-rotating cement wiper plugs

A non-rotating cement wiper plug has an insert, with inner and outer telescoping sleeves, within a resilient outer body. The outer body has annular fins which bear against a casing wall. The inner sleeve has a tapering nose within a tapered cavity in the outer sleeve. Slots in the outer sleeve form a plurality of segments. The inner and outer sleeves are preferably of a frangible material. When the plug is pumped down and lodges against downhole float equipment, pump pressure compresses the plug, forces the inner sleeve down within the outer sleeve, forces the segments radially outward, and fractures or separates the outer sleeve segments. The outer body is forced against the casing wall so tightly that it cannot rotate in response to the forces from a rotary drill bit. Lock surfaces on the inner and outer sleeves lock them together and maintain the outer body in its forced-outwardly position.

Owner:MIKOLAJCZYK RAYMOND F

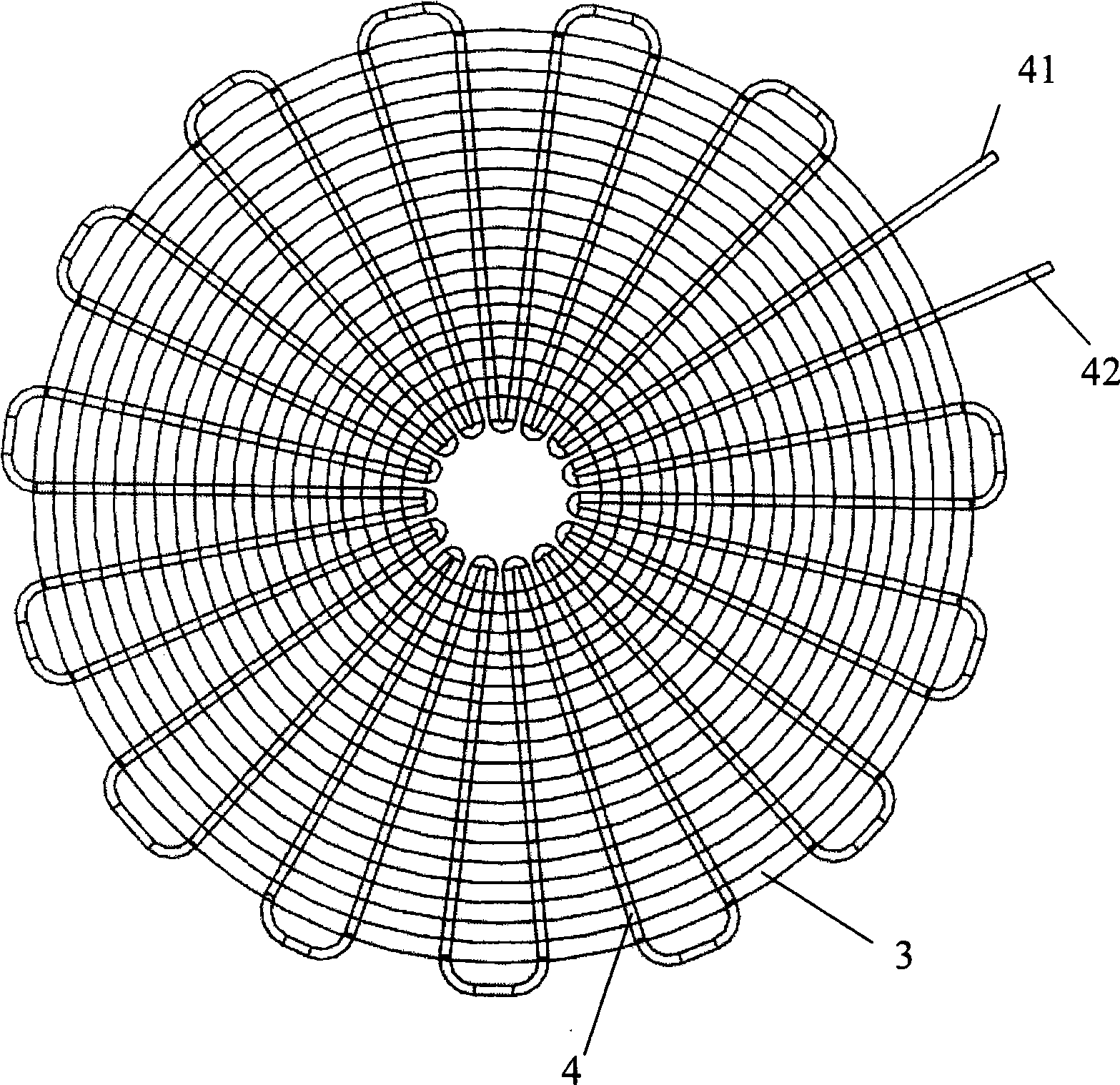

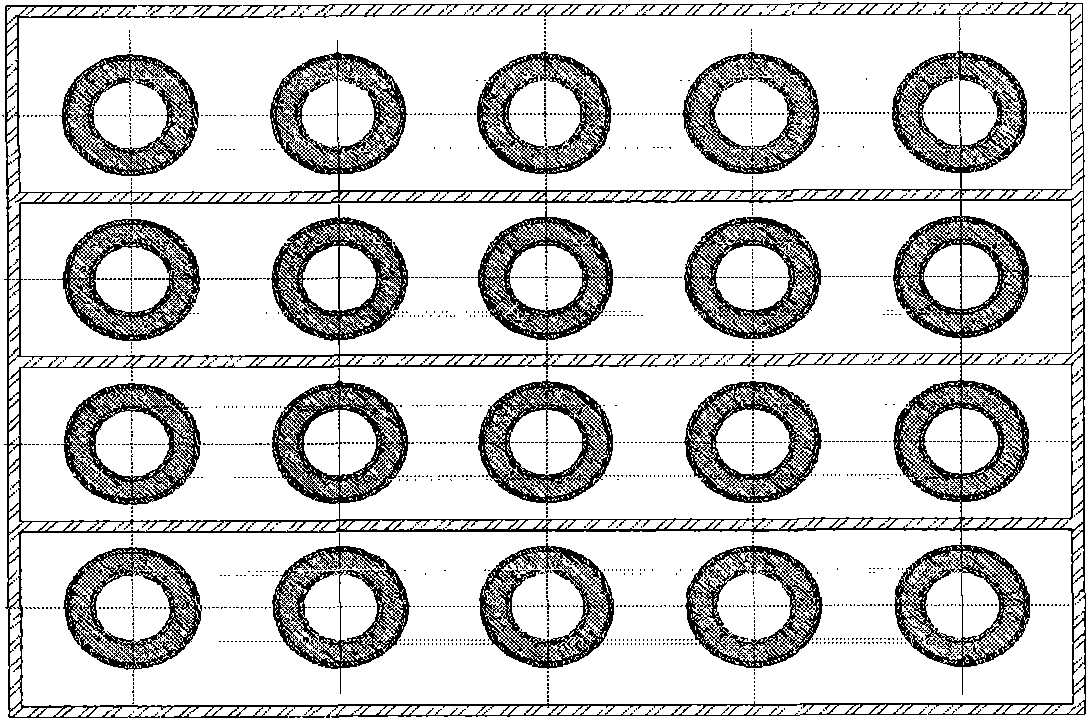

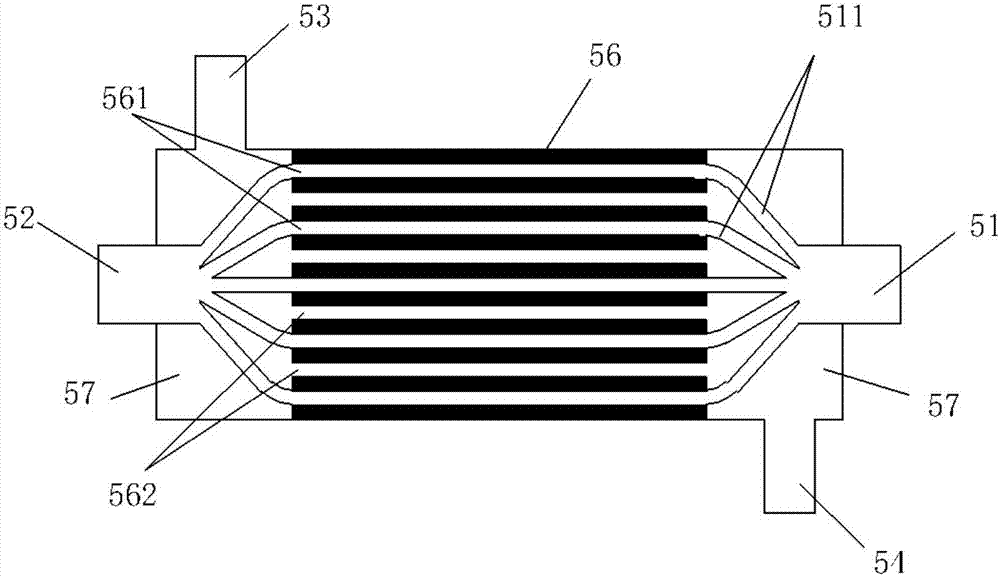

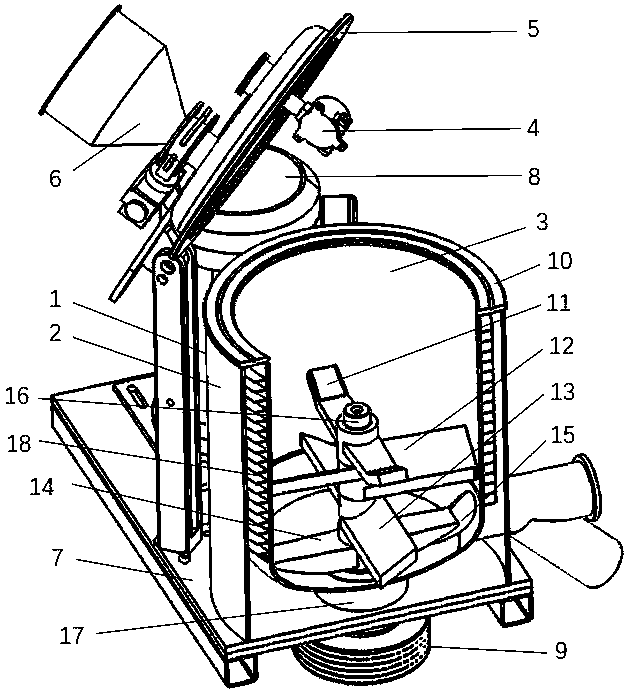

Heat exchanger structure of air conditioner

InactiveCN101504228AImprove working environmentImprove energy efficiency ratioEvaporators/condensersBusiness efficiencyEngineering

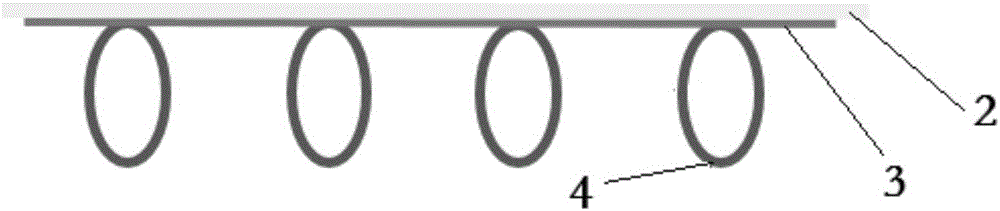

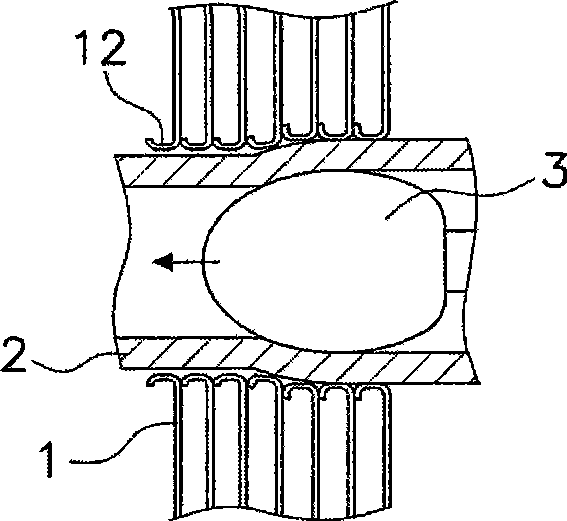

The invention provides a heat exchanger structure of an air conditioner, which comprises a plurality of fins paralelly arranged at intervals and heat exchange tubes inserted in the fins; the heat exchanger structure has improvements that the fins are annular bodies, and the plurality of annular fins are arranged concentrically, racially, parallelly and at intervals; and the heat exchange tubes are arranged and inserted into the annular fins radially, end parts of the heat exchange tubes are connected by U-shaped elbows to form a plate-shaped heat exchanger, each heat exchange tube is provided with one or more inlets and outlets, and the fins are matched with the direction of the air flow generated by the fan so as to effectively reduce air flow resistance, increase air flow rate, reduce noises and improve energy efficiency ratio of the air conditioner.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Non-rotating cement wiper plugs

A non-rotating cement wiper plug has an insert, with inner and outer telescoping sleeves, within a resilient outer body. The outer body has annular fins which bear against a casing wall. The inner sleeve has a tapering nose within a tapered cavity in the outer sleeve. Slots in the outer sleeve form a plurality of segments. The inner and outer sleeves are preferably of a frangible material. When the plug is pumped down and lodges against downhole float equipment, pump pressure compresses the plug, forces the inner sleeve down within the outer sleeve, forces the segments radially outward, and fractures or separates the outer sleeve segments. The outer body is forced against the casing wall so tightly that it cannot rotate in response to the forces from a rotary drill bit. Lock surfaces on the inner and outer sleeves lock them together and maintain the outer body in its forced-outwardly position.

Owner:MIKOLAJCZYK RAYMOND F

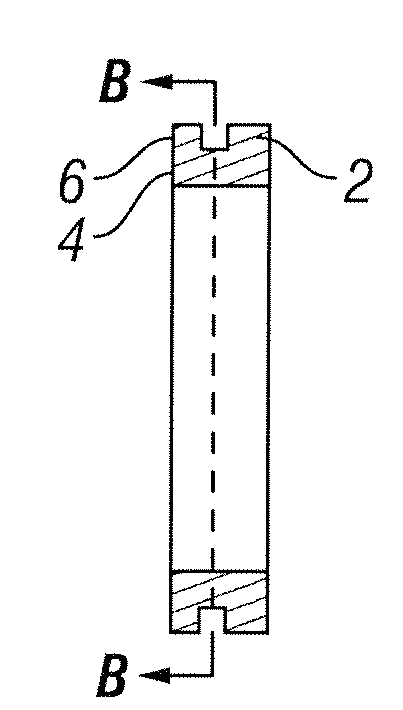

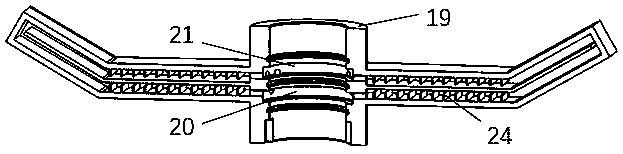

Unidirectional labyrinth seal

ActiveUS9133940B1Easy maintenancePromote repairEngine sealsRollersMechanical engineeringLabyrinth seal

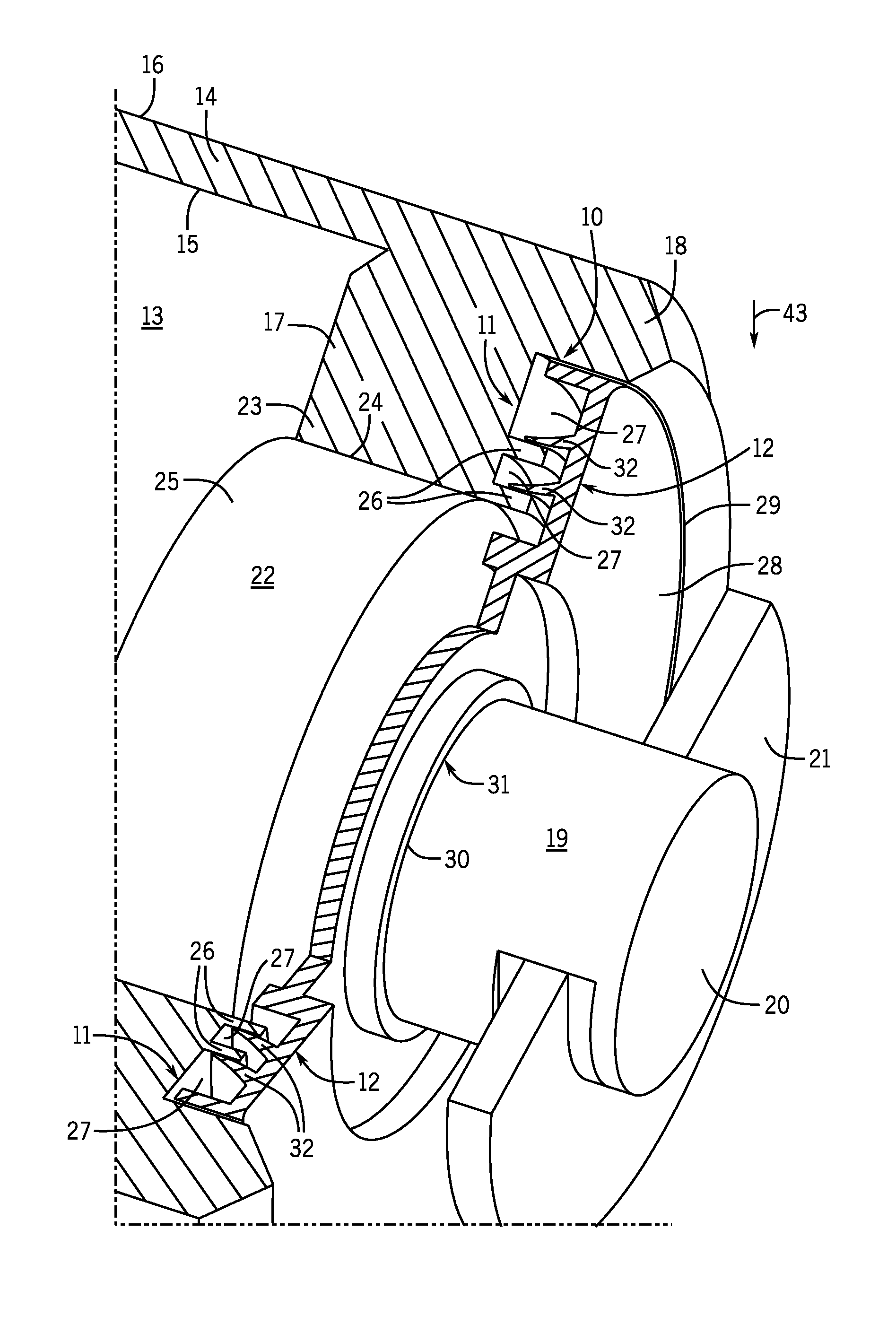

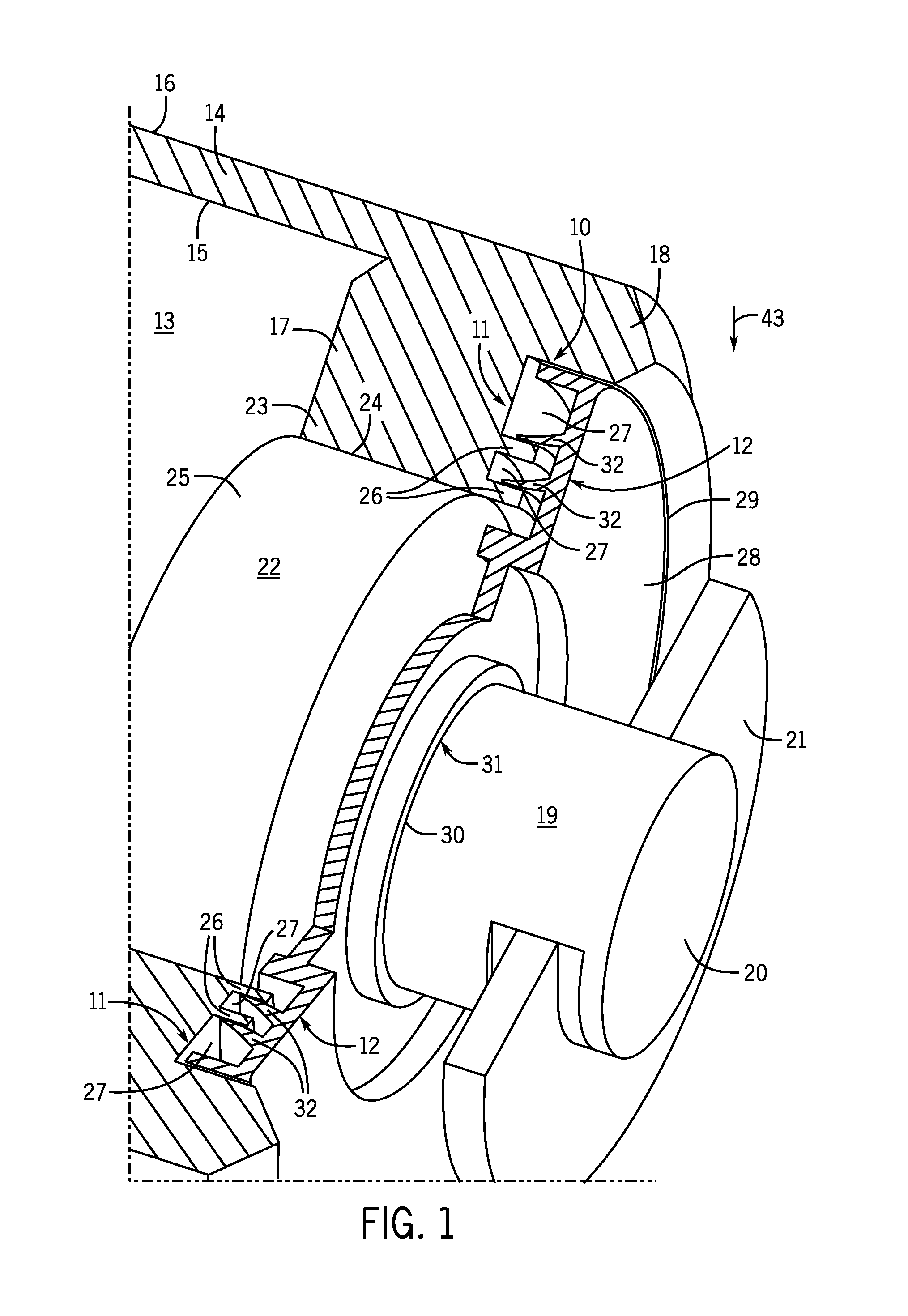

A unidirectional annular labyrinth seal having flexible annular fins positioned on a circular plate near an outer edge of the circular plate wherein the fins are biased towards a center of the circular plate. Annular ribs are positioned on an end of an idler roller. The fins project into recesses formed by the annular ribs, thereby forming the unidirectional annular labyrinth seal. The annular fins engage the annular ribs when the temperature of air within an interior of the roller is similar to the temperature of air exterior to the roller, thereby closing the labyrinth seal. The flexible annular fins bend away from the annular ribs when the temperature of air within the interior of the roller is higher than that of air exterior to the roller, thereby opening the labyrinth seal and allowing heated air within the interior of the roller to escape through the labyrinth seal.

Owner:TAYLOR JOHN +1

Cooling device with ringed fins

InactiveUS20080210404A1Heat transferring effect can be promotedGood effectSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

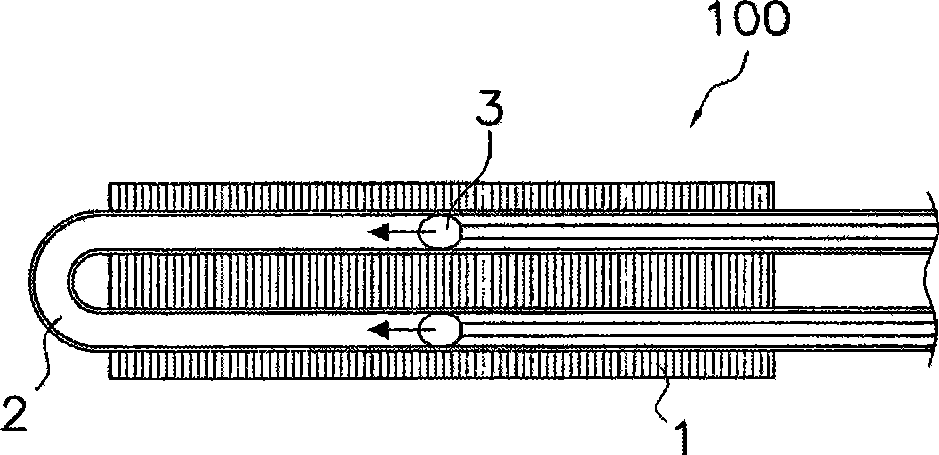

A cooling device includes a heat-conducting base, two fin sets, and a heat pipe. The two fin sets are respectively constructed by a metallic stripe that is periodically folded and is arranged as a ring type. The heat pipe has a heated section that is thermally connected to the heat-conducting base, and a condensing section that is extended from the heat-conducting base is further formed as a flat shape, on which two oppositely flat faces are formed. The two flat faces of the condensing section of the heat pipe are respectively contacted closely with the two fin sets by being sandwiched therein. In such case, the contact area between the condensing section of heat pipe and the fin sets is enhanced, thus that the heat-conducting effect is promoted significantly.

Owner:COOLER MASTER CO LTD

Process equipment for integral ring-shaped finned tube and technique thereof

The invention discloses a manufacturing equipment and technological method of entire ring-shaped fin tube, which comprises the following parts: multiple-station mutual-control fin pipe rolling device, operational device, synchronous feeding device, high-frequency heating device, cooling heat disposal device and electric control device, wherein the blank is supplied by starting feeding motor through declaration mechanism, bevel gear pair to anchor feeding head, whose surface is heat by high-frequency heater, the pipe-shaped blank is transmitted in the multiple-station mutual-control fin pipe rolling device, which is set in the non-lifting rolling mould to mould the blank, the cooling device reduces temperature for entire fin pipe, which proceeds heat disposal through heating disposal device.

Owner:余金盘

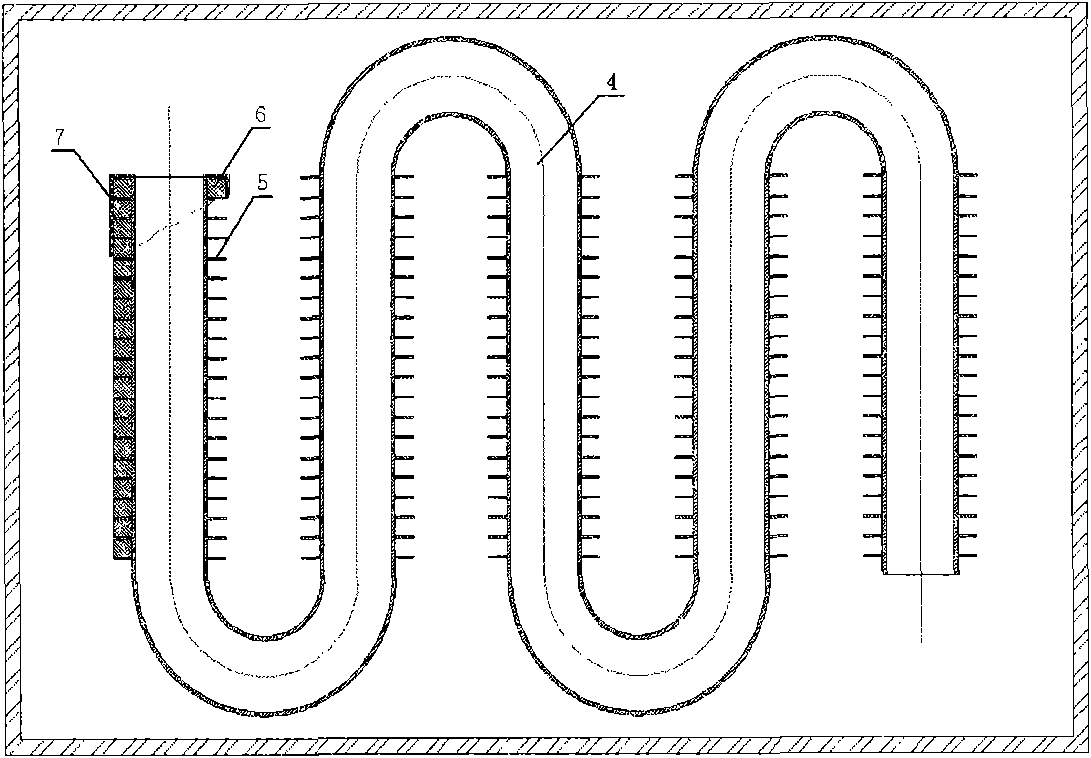

High-temperature phase change heat accumulation pipe and heat accumulator

InactiveCN101598513ASmall volumeHigh heat storage densityHeat storage plantsHeat-exchange elementsMolten saltEngineering

The invention provides a high-temperature phase change heat accumulation pipe and a heat accumulator. The heat accumulator comprises a casing and a high-temperature phase change heat accumulation pipe arranged in the casing. The high-temperature phase change heat accumulation pipe is characterized in that the high-temperature phase change heat accumulation pipe comprises an S-shaped working medium conduit, the outer side of the S-shaped working medium conduit is provided with annular fins, a fan ring heat accumulation unit is installed between the annular fins, a phase change material is filled in the fan ring heat accumulation unit, and a working medium is installed in the S-shaped working medium conduit and is mixed molten salt. The invention utilizes the solid-liquid phase change process of the phase change material to complete the storage and release of energy, has the advantages of small volume, large heat accumulation density and constant-temperature heat release and has a certain development prospect.

Owner:HARBIN ENG UNIV

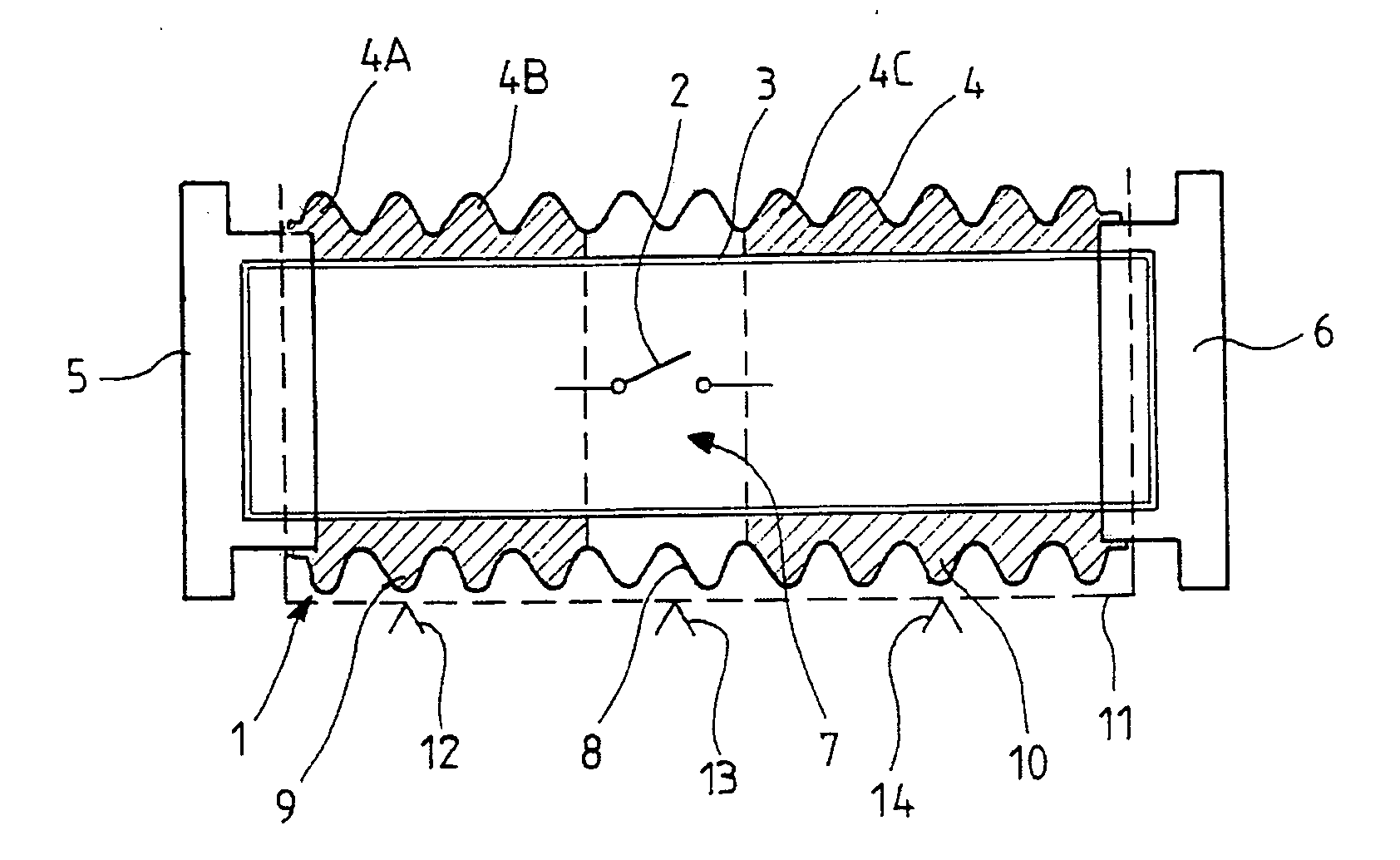

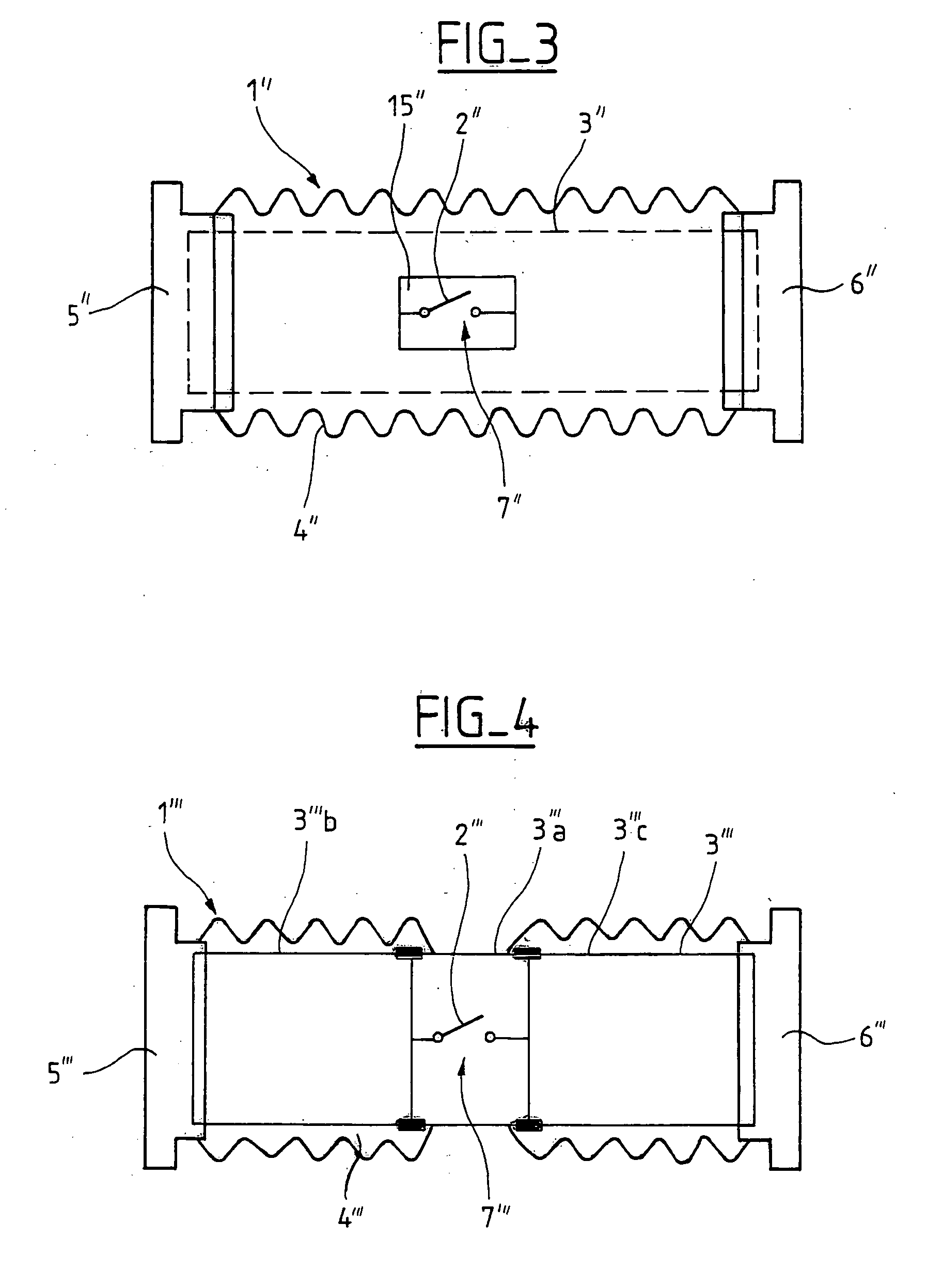

Electrical Device Containing Insulating Gas Under Pressure and Including a Composite Insulator Provided With a Window for Observing Contacts

InactiveUS20070295694A1Improve abilitiesContact mechanismsHigh-tension/heavy-dress switchesElastomerComposite insulators

The gas-tight, high or medium voltage electric switch device (1), containing an insulating gas under pressure, comprises switch contacts (2) capable of occupying an open position and a closed position and disposed inside a composite insulator formed by a rigid tube (3) surrounded by an elastomer casing (4) whose outside surface defines a succession of annular fins. The rigid tube and the elastomer casing are arranged so as to define an observation window (7) that is at least translucent, and through which the open or closed position of the switch contacts is visible.

Owner:ALSTOM TECH LTD

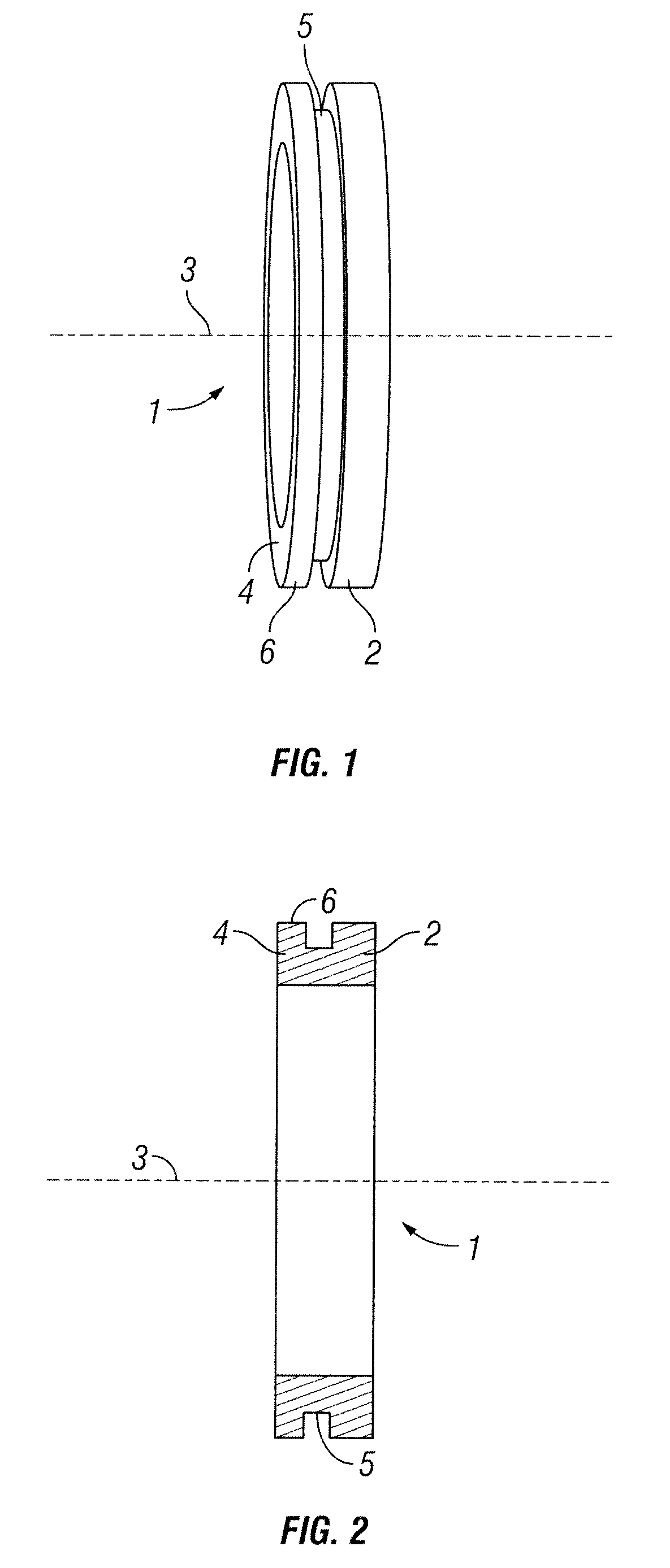

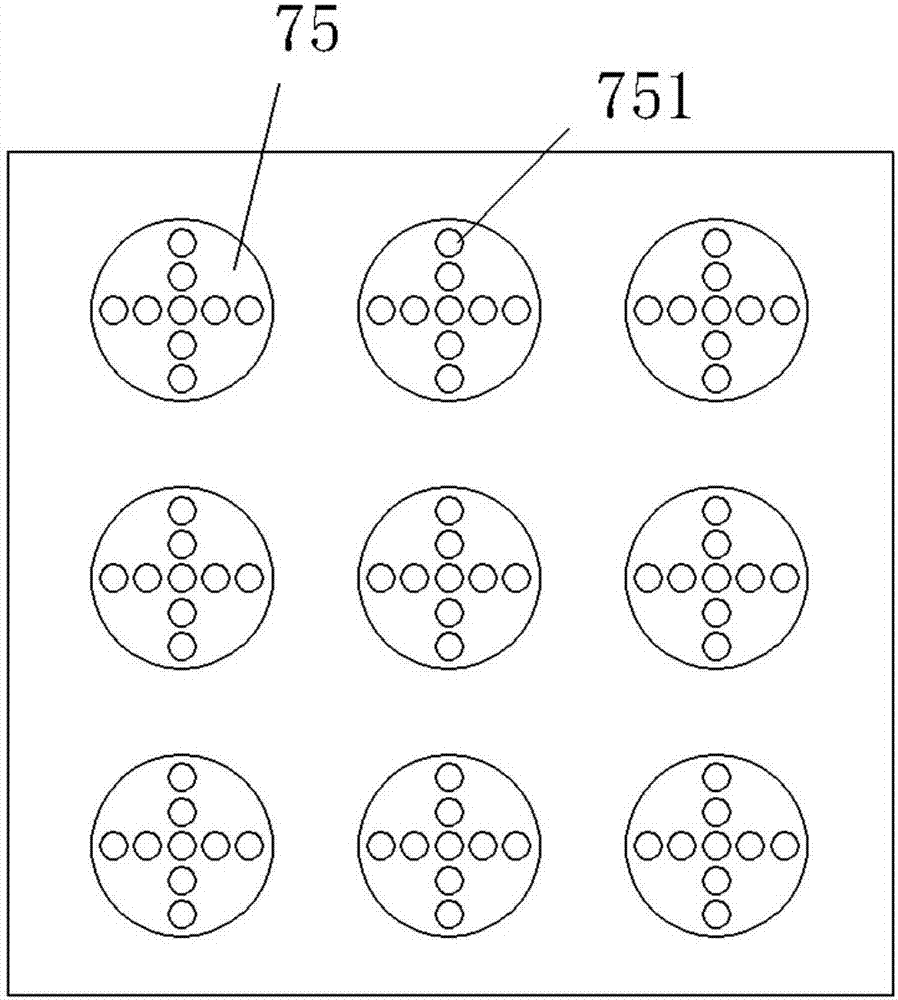

Mechanical Seal with Superior Thermal Performance

InactiveUS20080237995A1Improve thermal performanceEasy to transformEngine sealsEngineeringMechanical engineering

A stationary mating ring for a mechanical seal is provided, comprising an annular body having a central axis and a sealing face; a first circumferential groove formed into the body behind the sealing face; and a first annular fin extending radially from the central axis. The mating ring further may include a second circumferential groove formed in the body adjacent to the first circumferential groove, wherein the second circumferential groove defines a second annular fin extending radially from the central axis. Optionally, the first or second annular fins each include a plurality of subdivided fins extending radially from the central axis, and such fins are symmetrically spaced around the central axis. Also provided is a complete mechanical seal, comprising a rotating ring having a sliding interface against a mating ring constructed in accordance with the aforementioned features.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

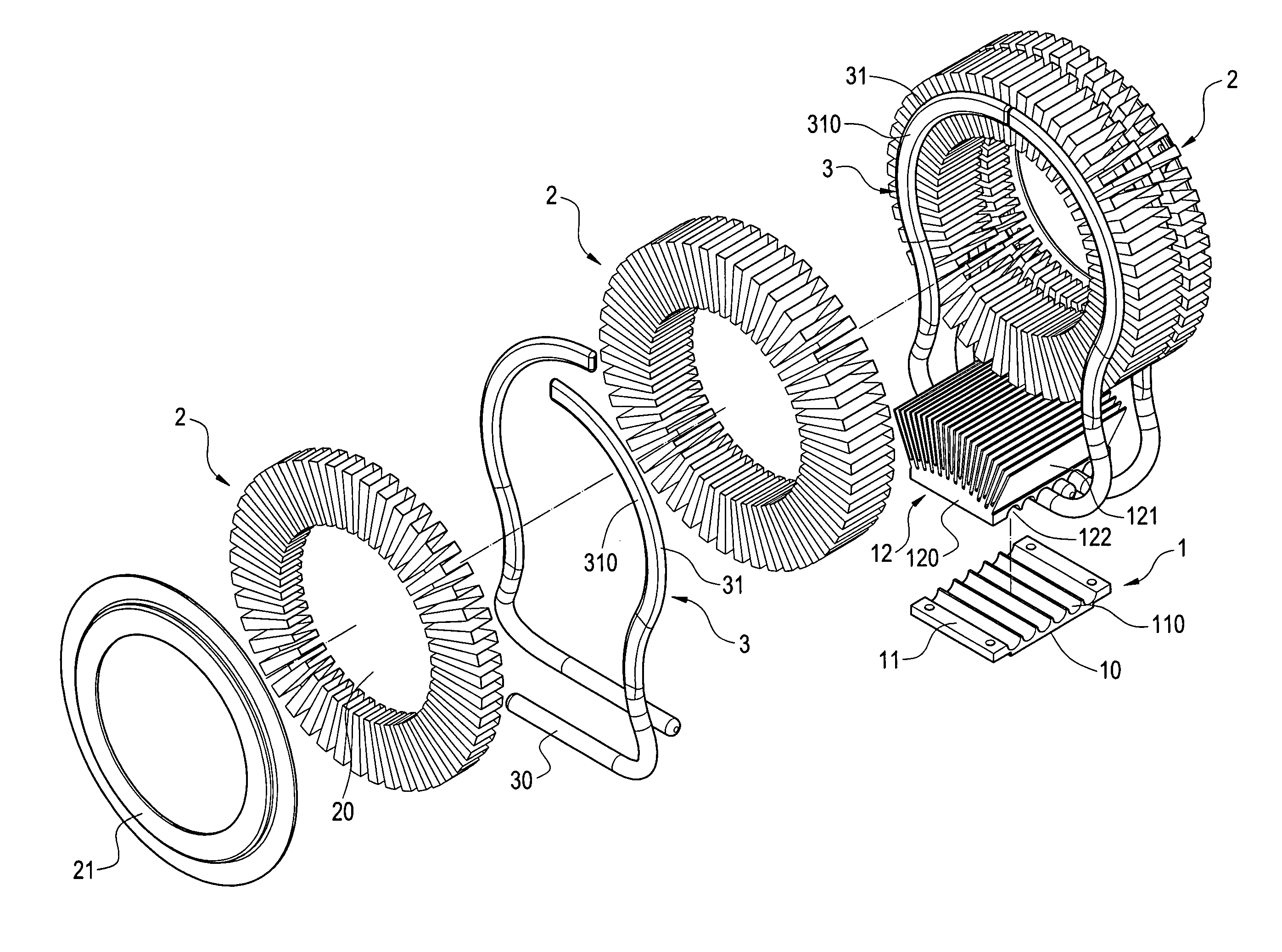

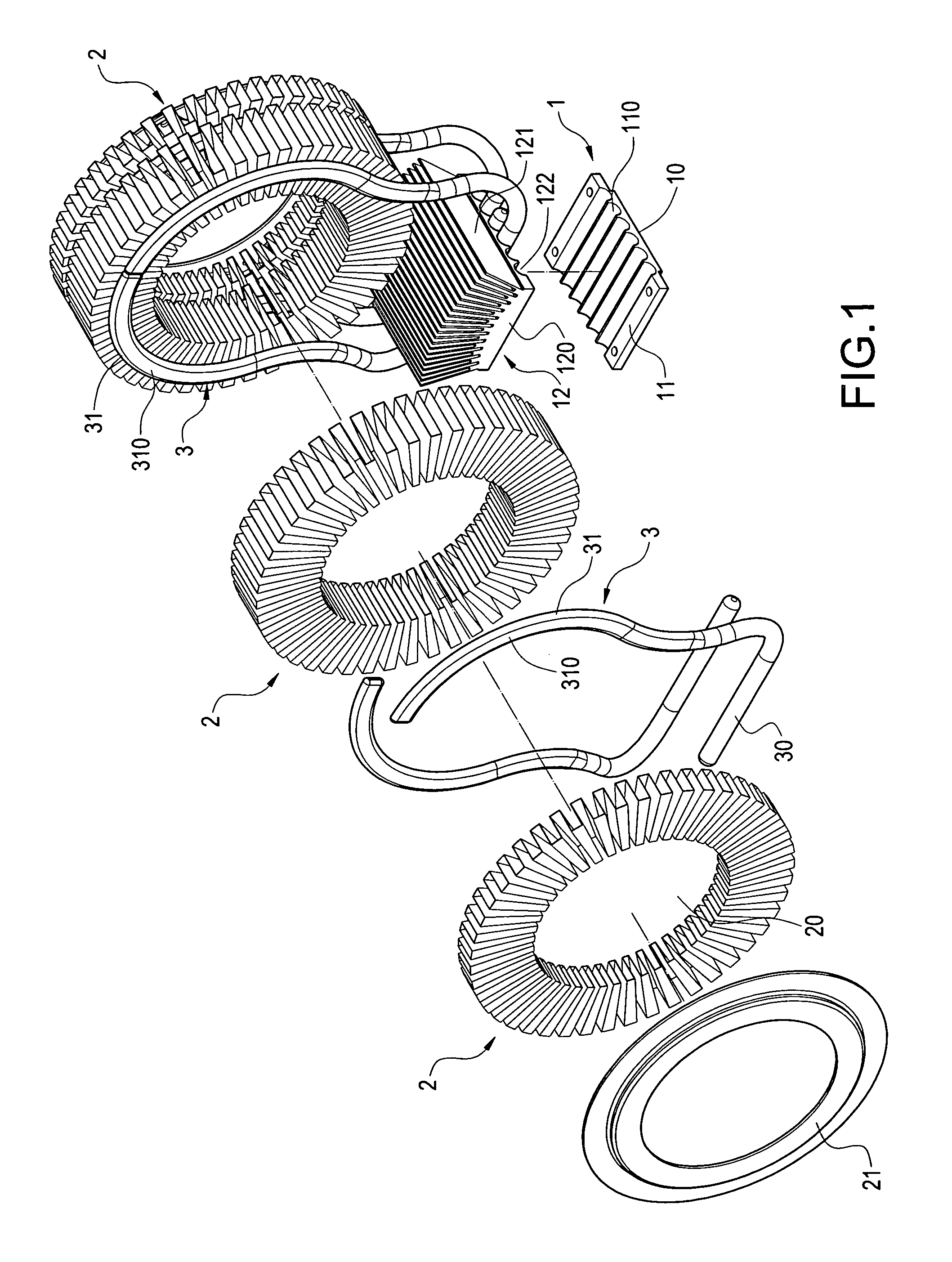

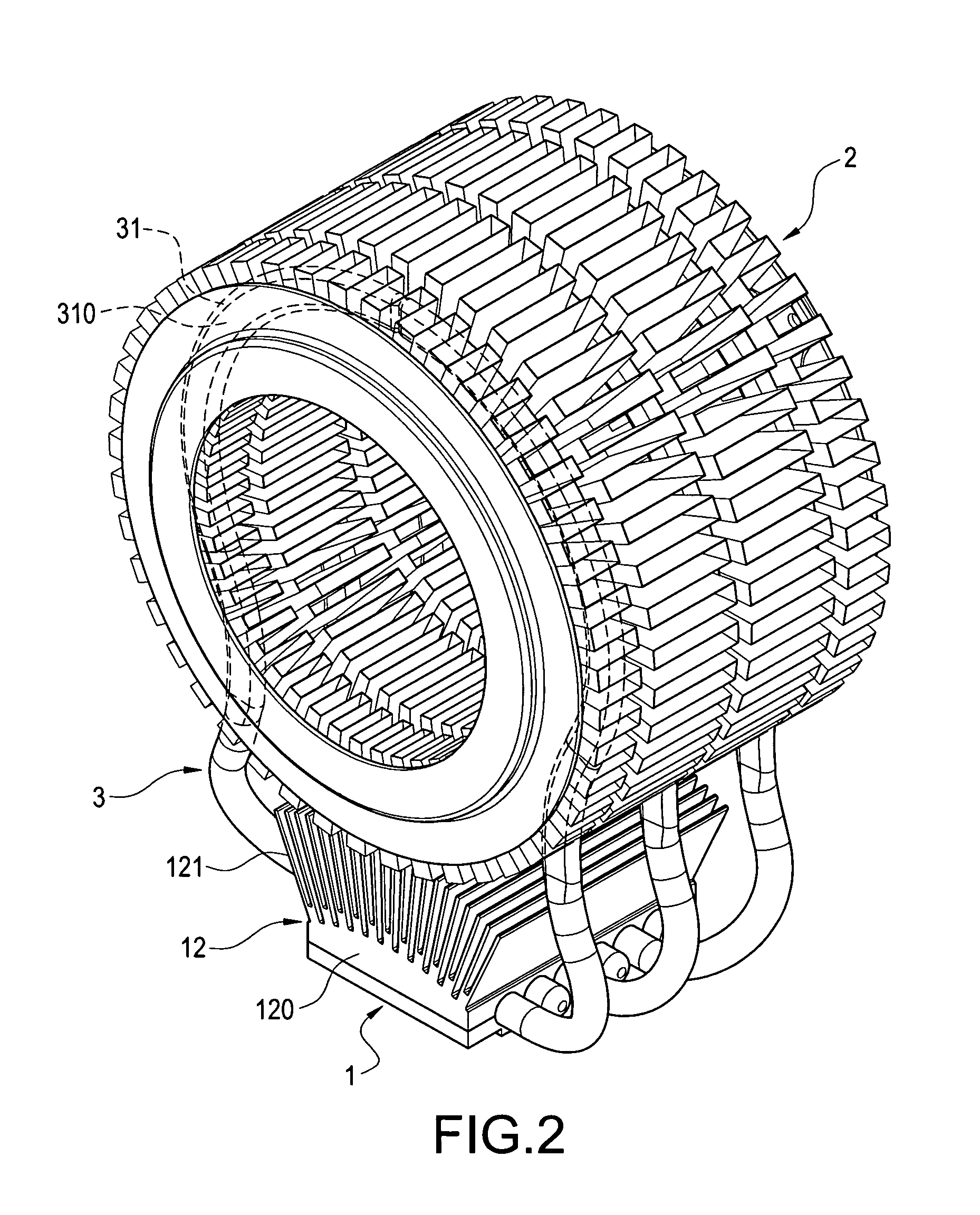

Solar thermoelectric generation device based on Fresnel lens and heat pipe principle

InactiveCN103560706AAvoid contaminationReduce noiseCondensersGenerators/motorsFresnel lensGlass cover

The invention provides a solar thermoelectric generation device based on a Fresnel lens and a heat pipe principle, and belongs to the field of solar thermal power generation engineering. The device mainly comprises the point focusing type Fresnel lens, a transparent glass cover plate, a cylindrical cavity type heat absorber inner wall, a cylindrical cavity type heat absorber outer wall, annular thermoelectric generation modules, flat plate type thermoelectric generation modules, annular fins and uniform-section straight fins. Compared with other solar thermoelectric generation devices, the solar thermoelectric generation device based on the Fresnel lens and the heat pipe principle can achieve uniform heating of walls of heating ends of the thermoelectric generation modules, has the advantages of being compact in structure, few in operation parts, low in noise, reliable to operate, low in maintenance cost, convenient to adjust and good in performance, and can be used as a distribution type energy source.

Owner:CHONGQING UNIV

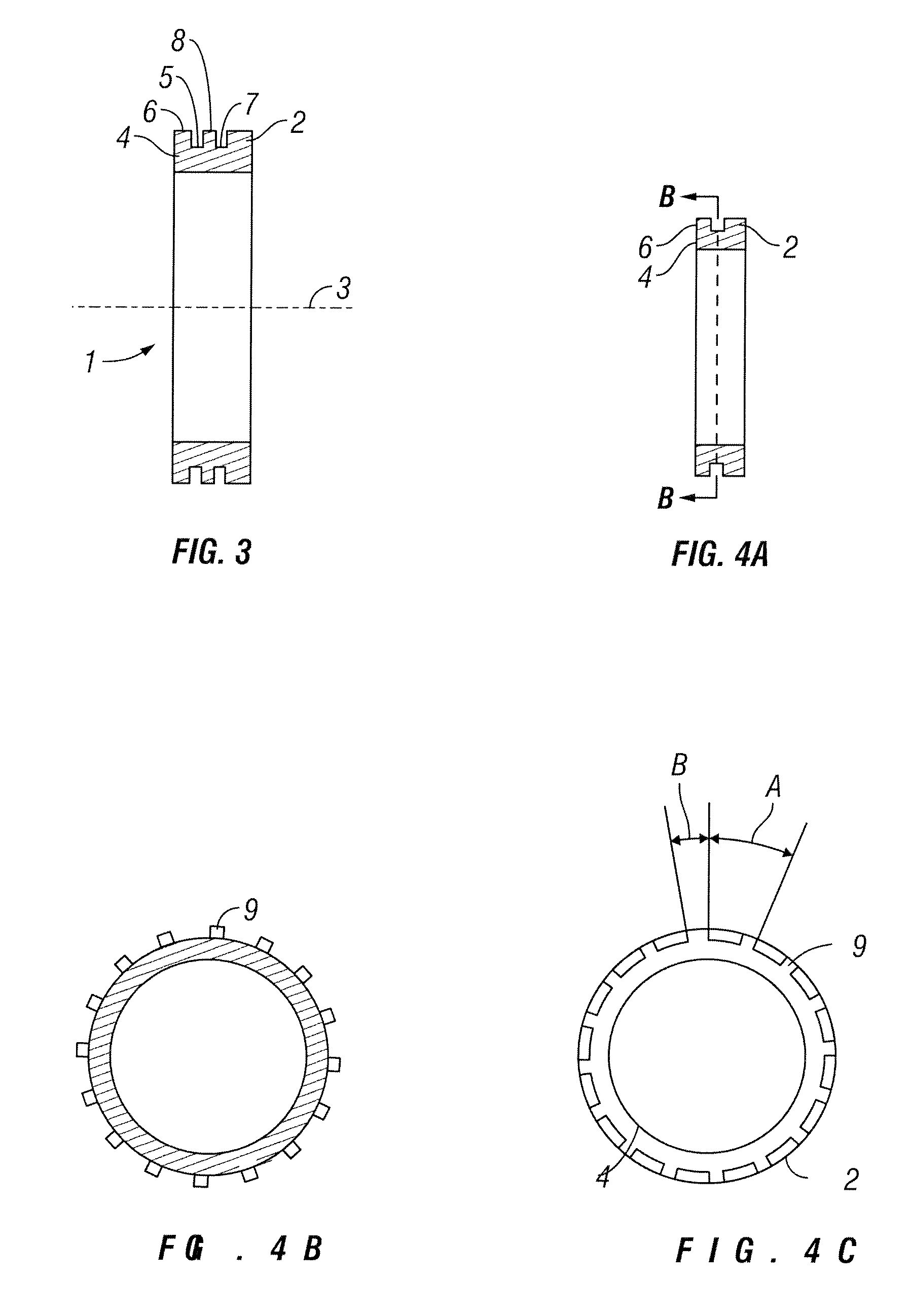

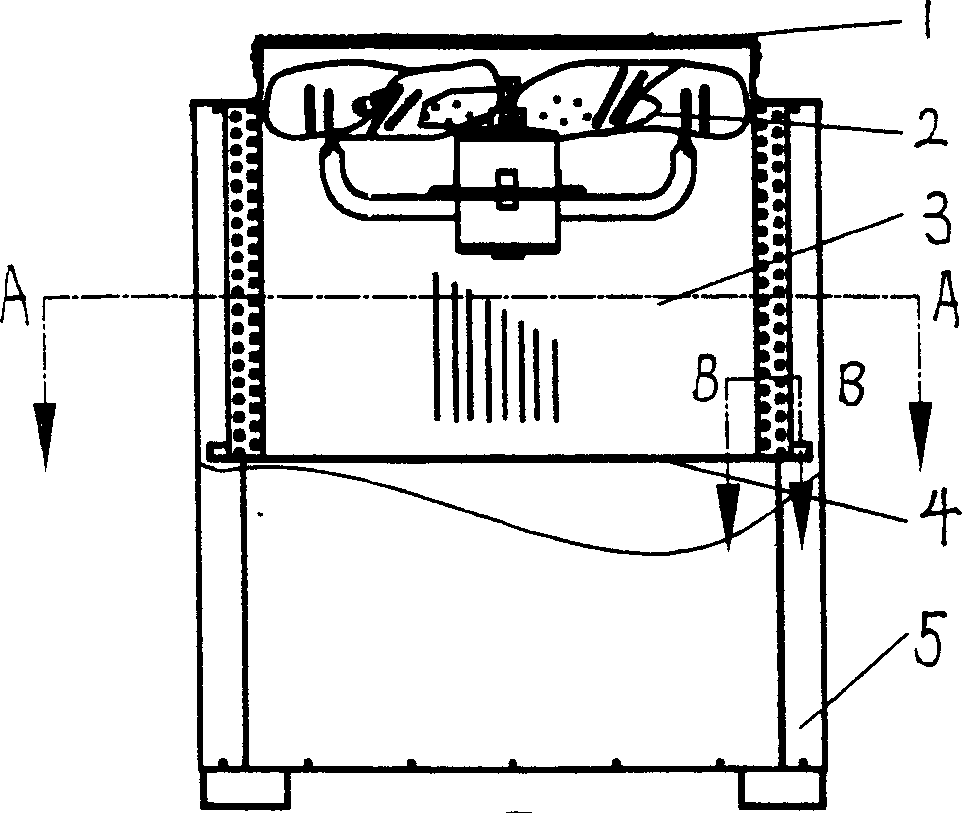

Air conditioner heat exchanger and air conditioner

The invention relates to an air conditioner heat exchanger and an air conditioner. The air conditioner heat exchanger comprises a plurality of heat exchange pipes (4) and a plurality of annular fins (2). The annular fins (2) are arranged at intervals to form a hollow annular cylinder and are each provided with a plurality of first holes (21). The heat exchange pipes (4) penetrate the corresponding first holes (21) in the annular fins (2) respectively. An air inlet is formed in one of the two ends of the annular cylinder. Air outlets (B) are formed in gaps among the annular fins (2). According to the air conditioner heat exchanger, air outflow within a larger-angle range can be achieved so as to improve the comfort feeling of the human body. In addition, the multiple heat exchange pipes of the air conditioner heat exchanger penetrate the fins arranged at intervals, the bending procedure can be avoided, equipment and labor cost can be reduced, and the machining efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

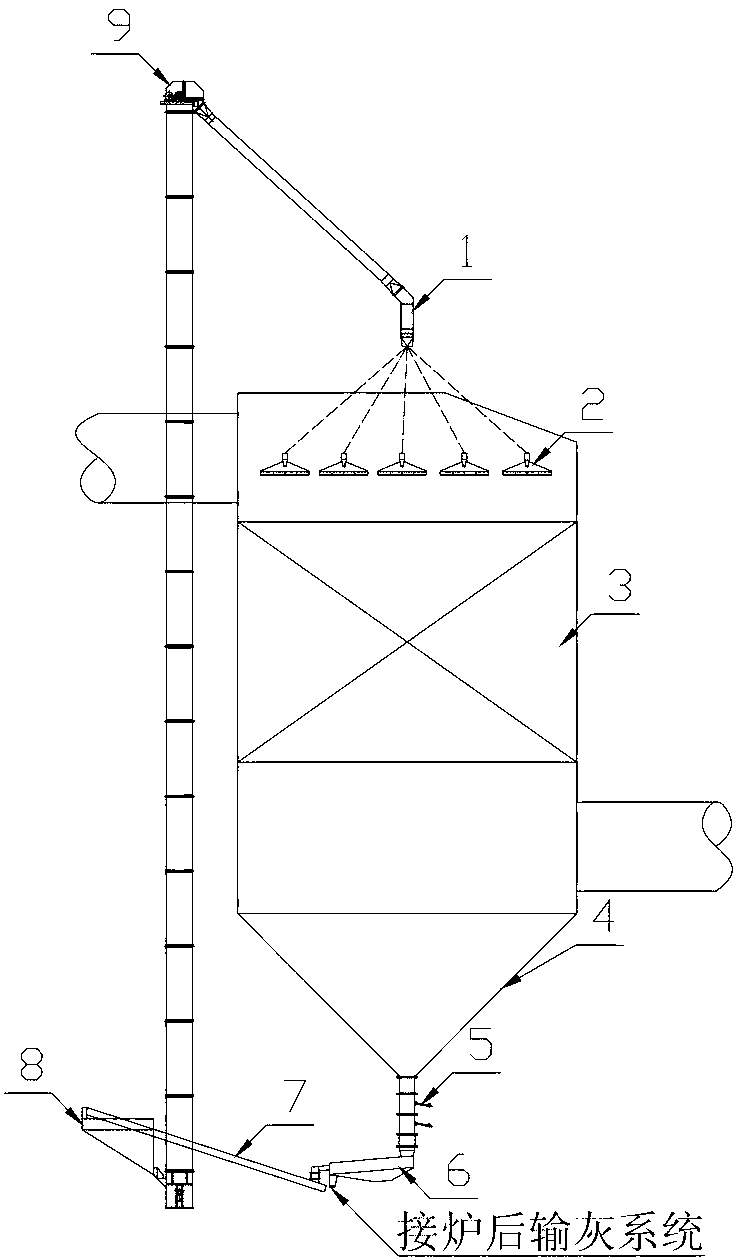

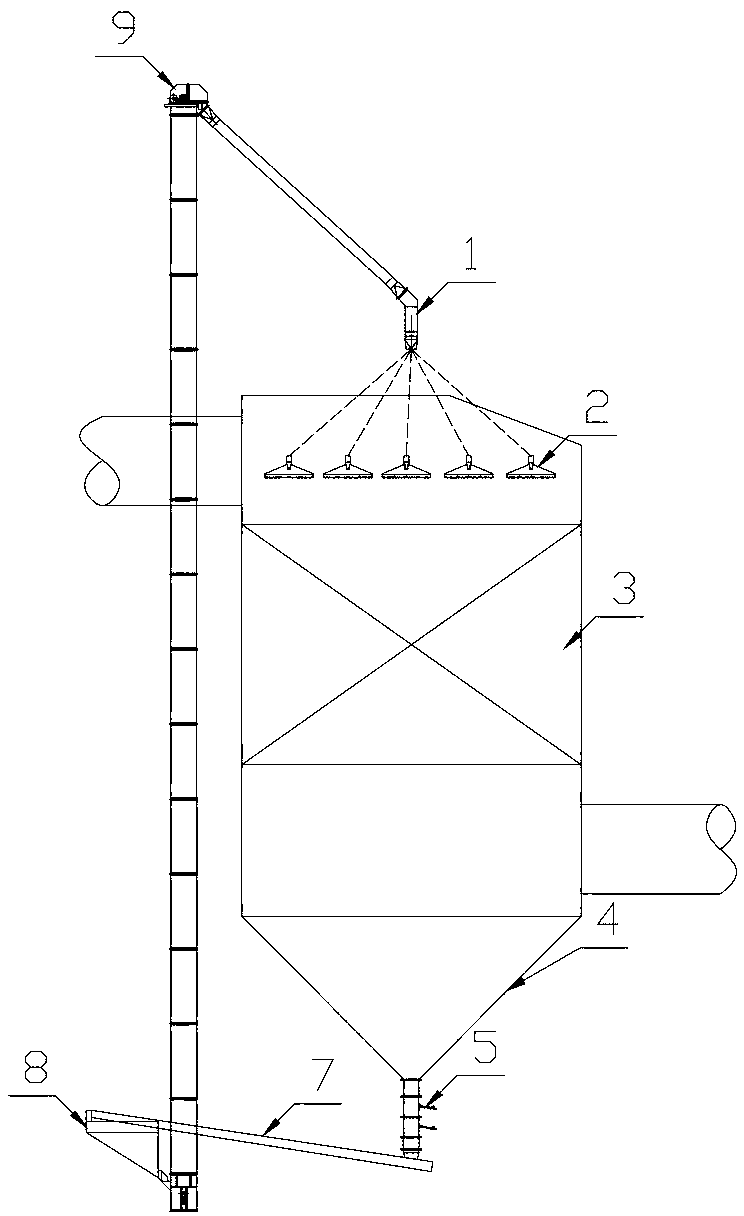

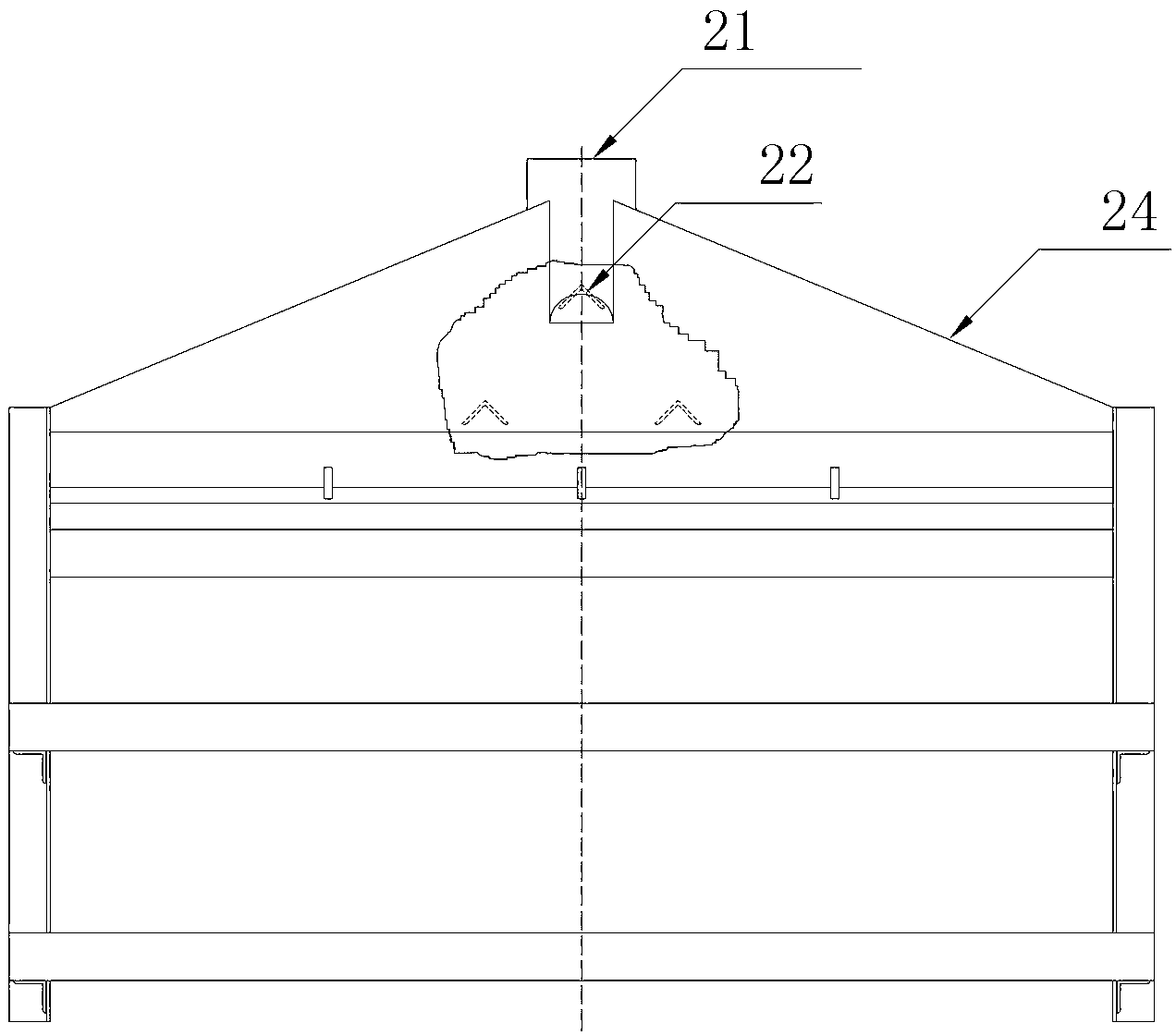

Dust cleaning system applicable to heat recovery boiler with complex heating surface

The invention discloses a dust cleaning system applicable to a heat recovery boiler with a complex heating surface. The dust cleaning system comprises a lifter, a shot separating device, a shot distributer, a sealed flap valve, a separating device, a shot storing bin and a horizontal shot conveying device. The shot distributer is a slot type shot distributor, the slot type shot distributor is good in shot distributing effect, can guarantee full coverage on a first heat exchange tube layer, structurally effectively buffer falling speed of steel shots, and reduce impact of the steel shots to the heat exchange tubes and anti-wear strips; the steel shots in grain size of 2-4mm are utilized, compared with a conventional shot-falling dust cleaning system, the dust cleaning system is more applicable to dust cleaning of the heat recovery boiler utilizing a complex heating surface like a radiator fin / a fin / an annular fin tube to strengthen heat exchange, dispersity and distributing compactness of the shots on the heating surface are easier to guaranteed, and dust cleaning effect is good; and impact to the surfaces of the heat exchange tubes from the small-grain-size steel shots is lower, and service life of equipment is prolonged. The dust cleaning system applicable to the heat recovery boiler with the complex heating surface is capable of immediately effectively cleaning dust on the surface of the heating surfaced, is stable in running, low in investment and maintenance cost, and can maintain high efficient heat exchange of the complex heating surface.

Owner:BEIJING CENTURY BENEFITS

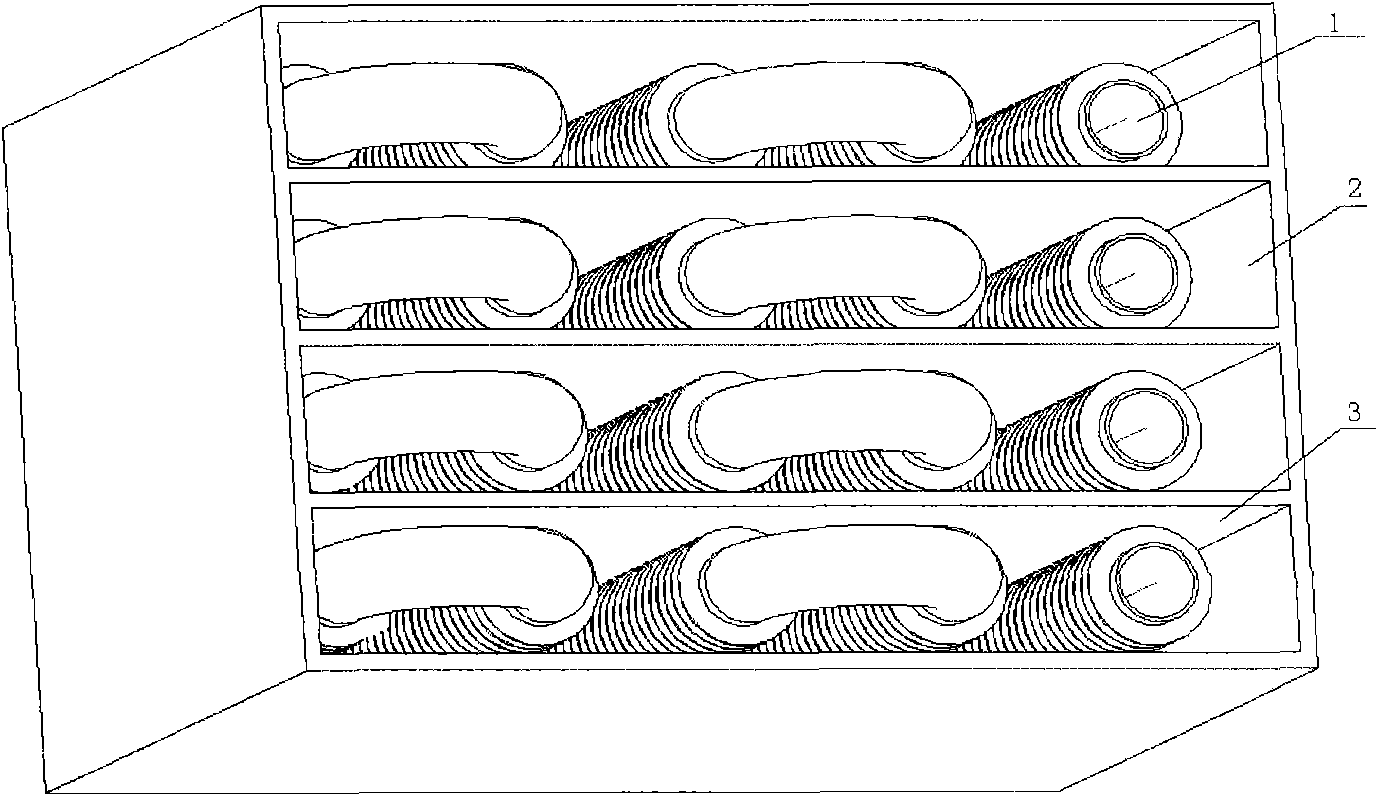

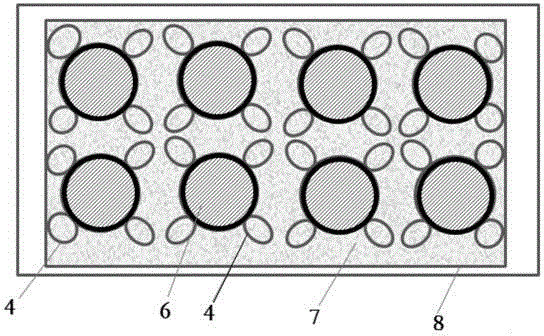

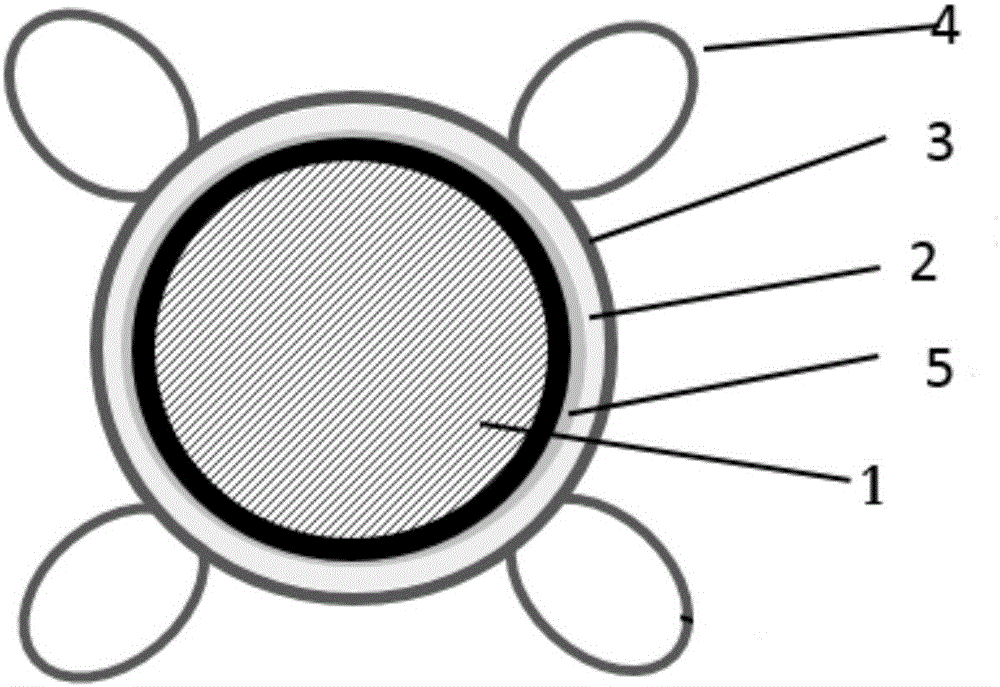

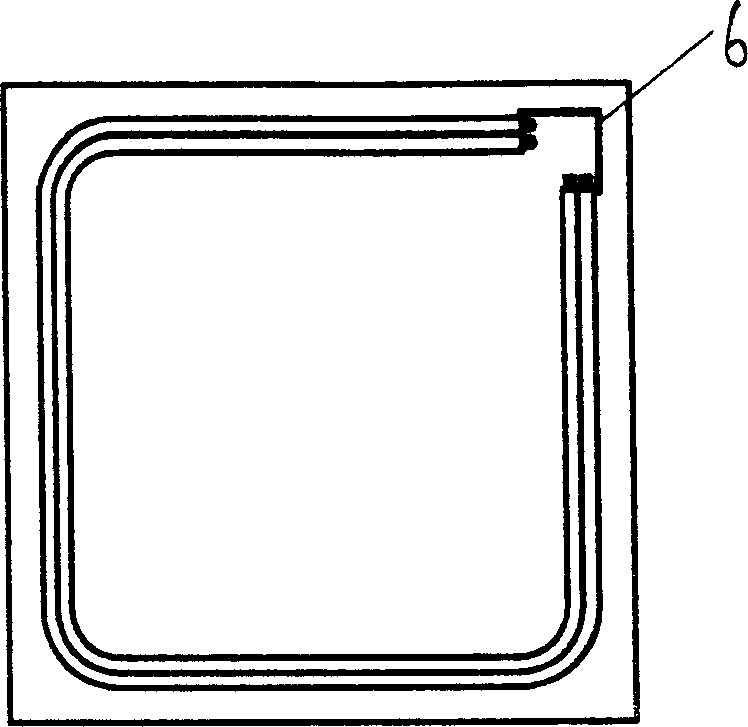

Heat exchange structure with annular fins and heat dissipation device with heat exchange structure

ActiveCN106410314AGood thermal contact with the wallThin structureSecondary cellsEngineeringPhase-change material

The invention relates to a heat exchange structure with annular fins, which is used for improving heat dissipation capability of a heat generation device on an external environment. The heat exchange structure comprises the heat generation device and a heat conduction tape, wherein the heat conduction tape is wound around the heat generation device, and one group or multiple groups of annular fins are arranged at the outer side of the heat conduction tape. The invention also relates to a heat dissipation device having the heat exchange structure with the annular fins. The heat dissipation device comprises a box body and multiple groups of heat exchange structures, the multiple groups of heat exchange structures are arranged in the box body, a heat absorption material is arranged between the box body and the heat exchange structures, and the heat absorption material comprises one of a phase change material, an elastic encapsulating material or insulation heat conduction oil. Compared with the prior art, the heat exchange structure with the annular heat conduction fins has the advantages of excellent heat transfer improvement effect, good impact buffer effect, structure flexibility, light weight, small size and the like, and the composite heat dissipation device is excellent in heat dissipation performance.

Owner:SHANGHAI UNIV OF ENG SCI

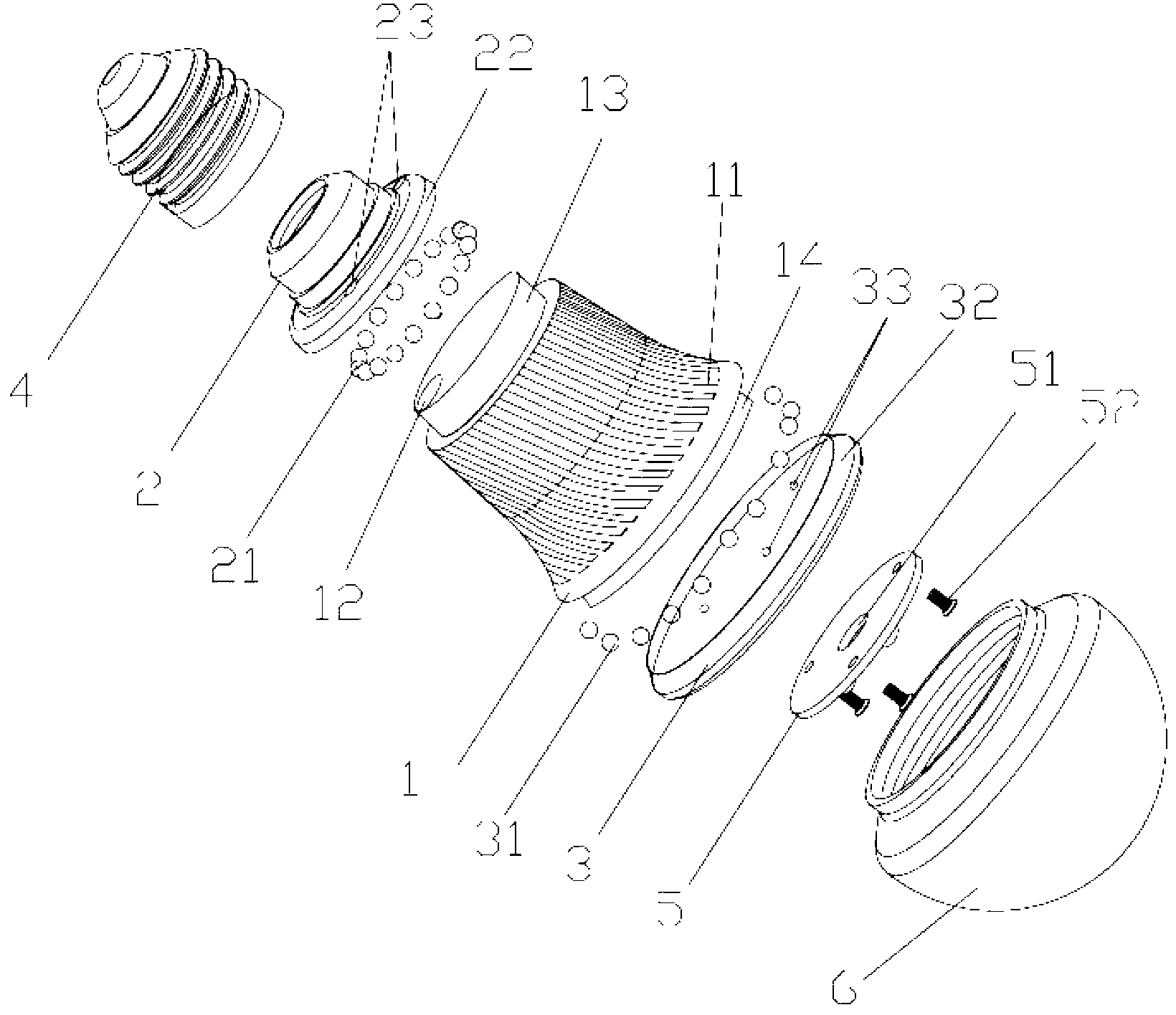

Light-emitting diode (LED) bulb lamp

ActiveCN103234132ASimple structureCompact structurePoint-like light sourceLighting heating/cooling arrangementsEngineeringLight head

The invention discloses a light-emitting diode (LED) bulb lamp. A radiating casing in the LED bulb lamp comprises a hollow annular fin group, a first port and a second port, wherein the hollow annular fin group is formed by at least three fins evenly distributed on a circumference at intervals, and the first port and the second port extend out from two ends of the radiating casing. The first port and the second port are respectively combined with a first annular guide rail in a lamp holder installation base and a second annular guide rail in a lamp shade installation base in a sleeved mode through a first ball and a second ball, so that the radiating casing can rotate along the lamp holder installation base and the lamp shade installation base. During working of the LED bulb lamp, air in the radiating casing is heated by an LED chip, the hot air rises up, a radiating casing group can be pushed to rotate along the first annular guide rail and the second annular guide rail by utilizing the air heat convection theory, air flowing is accelerated, and natural radiating is combined with air cooling forced radiating, so that the radiating effect is enhanced. Gaps are reserved among adjacent fins of the annular fin group, so that the radiating casing is of an opened structure, and the heat can be radiated conveniently.

Owner:中山市亮健照明科技有限公司

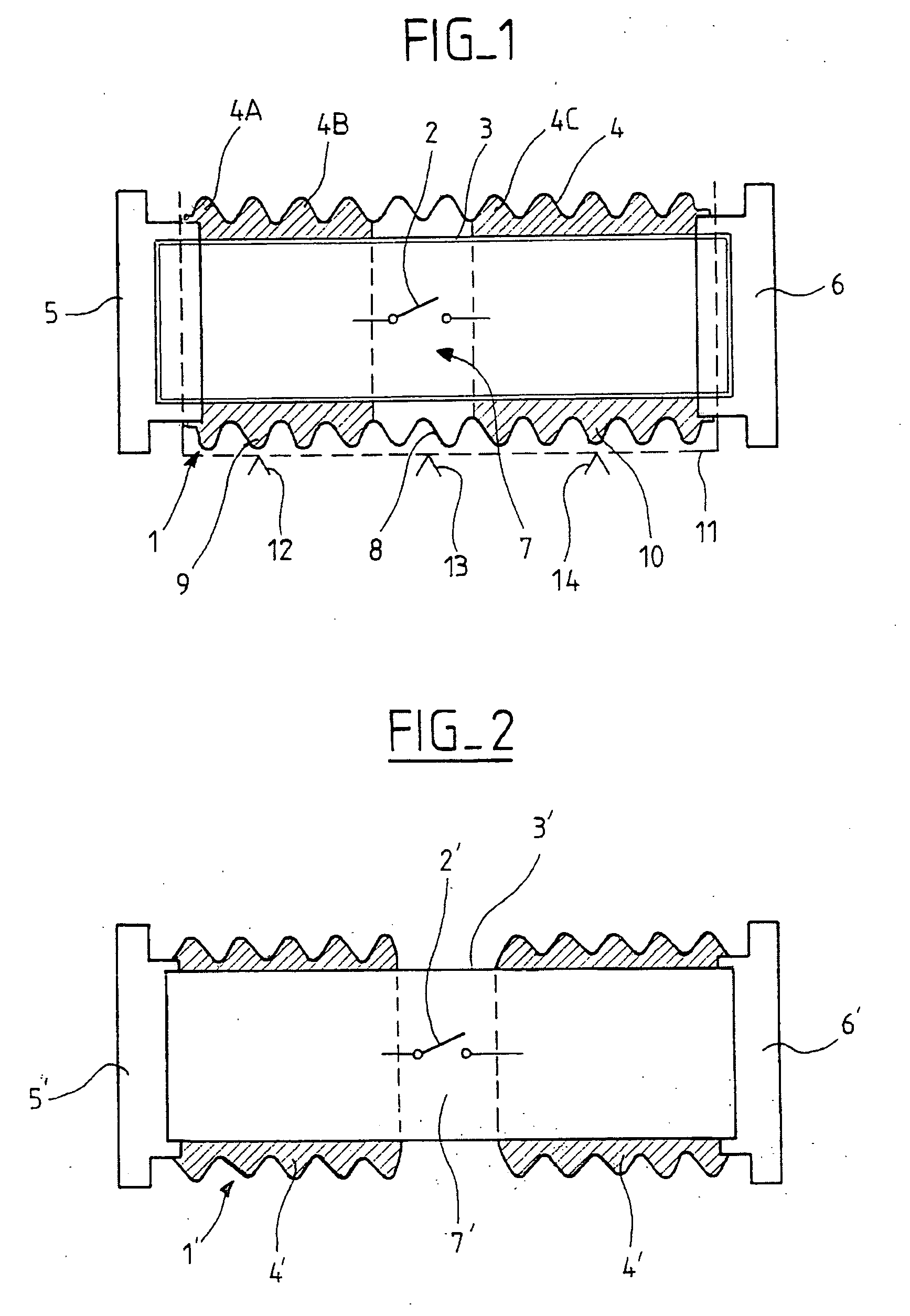

Heat exchanger fin and fin tube type heat exchanger

InactiveCN101509741ASection shape optimizationReduce gapEvaporators/condensersTubular elementsEngineeringHeat transfer efficiency

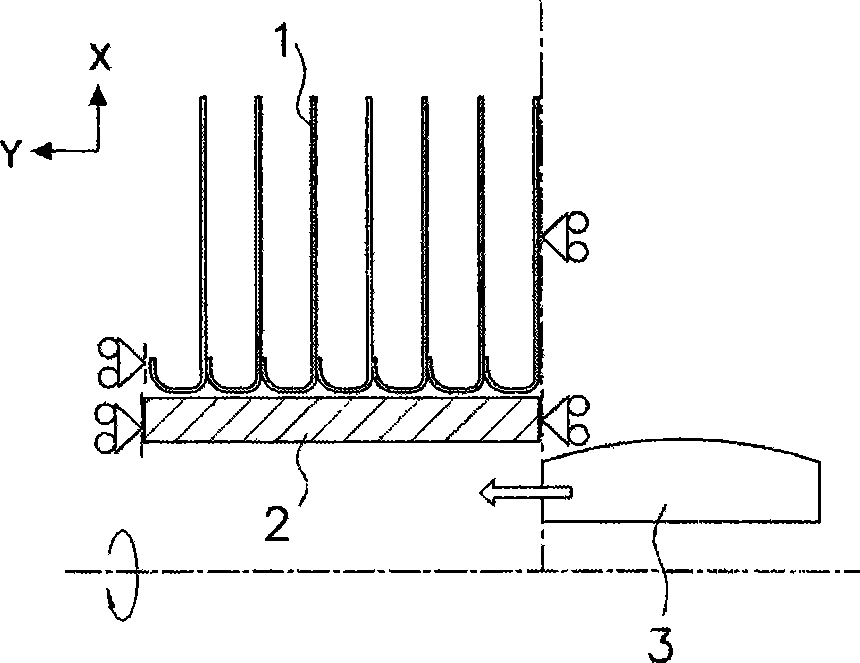

The invention relates to a heat exchanger fin and a fin tubular heat exchanger and belongs to the technical field of heat exchange. The heat exchanger fin comprises: a platy fin main part and an annular fin rolling ring provided with a through hole inside. The fin rolling ring extends towards the direction of the intersection with the fin main part and consists of a rolling ring root, a rolling ring middle part and a rolling ring bent end part. The rolling ring root is connected with the fin main part. The section of the fin rolling ring is shaped as a spline curve, a control point of the spline curve is an intermediate point of the rolling ring middle part, and the spline curve passes through the intermediate point of the rolling ring middle part, a first end point of the rolling ring middle part, a second end point of the rolling ring middle part, a specified point of the rolling ring bent end part and a specified point of the rolling ring root. As the section of the fin rolling ring is shaped as the spline curve, the clearance between the fin rolling ring and the outer surface of a heat transfer pipe can be the minimum, thus improving the heat transfer efficiency between the fin rolling ring and the outer surface of the heat transfer pipe.

Owner:SHANGHAI JIAO TONG UNIV +1

Energy-saving and environment-friendly PVC coating heating furnace

ActiveCN107166960ACatalytic combustion ensuresIncrease temperatureFurnace componentsFurnace typesCombustion chamberFlue gas

The invention discloses an energy-saving and environment-friendly PVC coating heating furnace. The heating furnace comprises a combustion chamber, a heating chamber, heating flues and a discharge flue, and is characterized in that a flue gas heat exchanger is arranged on the upper portion of the discharge flue; a cold medium outlet of the flue gas heat exchanger communicates with an inlet of a catalytic combustor through a waste gas pipeline, and a middle section of the waste gas pipeline is arranged in an inner cavity of the combustor; irradiation arc plates and semicircular annular fins are arranged on the side walls, facing the heating flues, of the heating chamber; and a heat accumulating type heat exchanging body is arranged in the flue gas heat exchanger. Compared with the prior art, the energy-saving and environment-friendly PVC coating heating furnace has the following advantages that an organic waste gas treating device is designed, the three processes of air suction, preheating and catalytic combustion are conducted and completed at the same time, waste gas is subjected to double-stage preheating, it is guaranteed that the organic waste gas has an initiation temperature required by catalytic combustion, energy is saved, and environment friendliness is achieved; and the irradiation arc plates of special structures are adopted for the side walls of the heating flues, the combustion chamber and a feedback regulating device are designed, a temperature in the furnace is uniform and stable, it is guaranteed that a mould is uniformly heated, and the yield of products is greatly increased.

Owner:佛山市方普防护技术有限公司

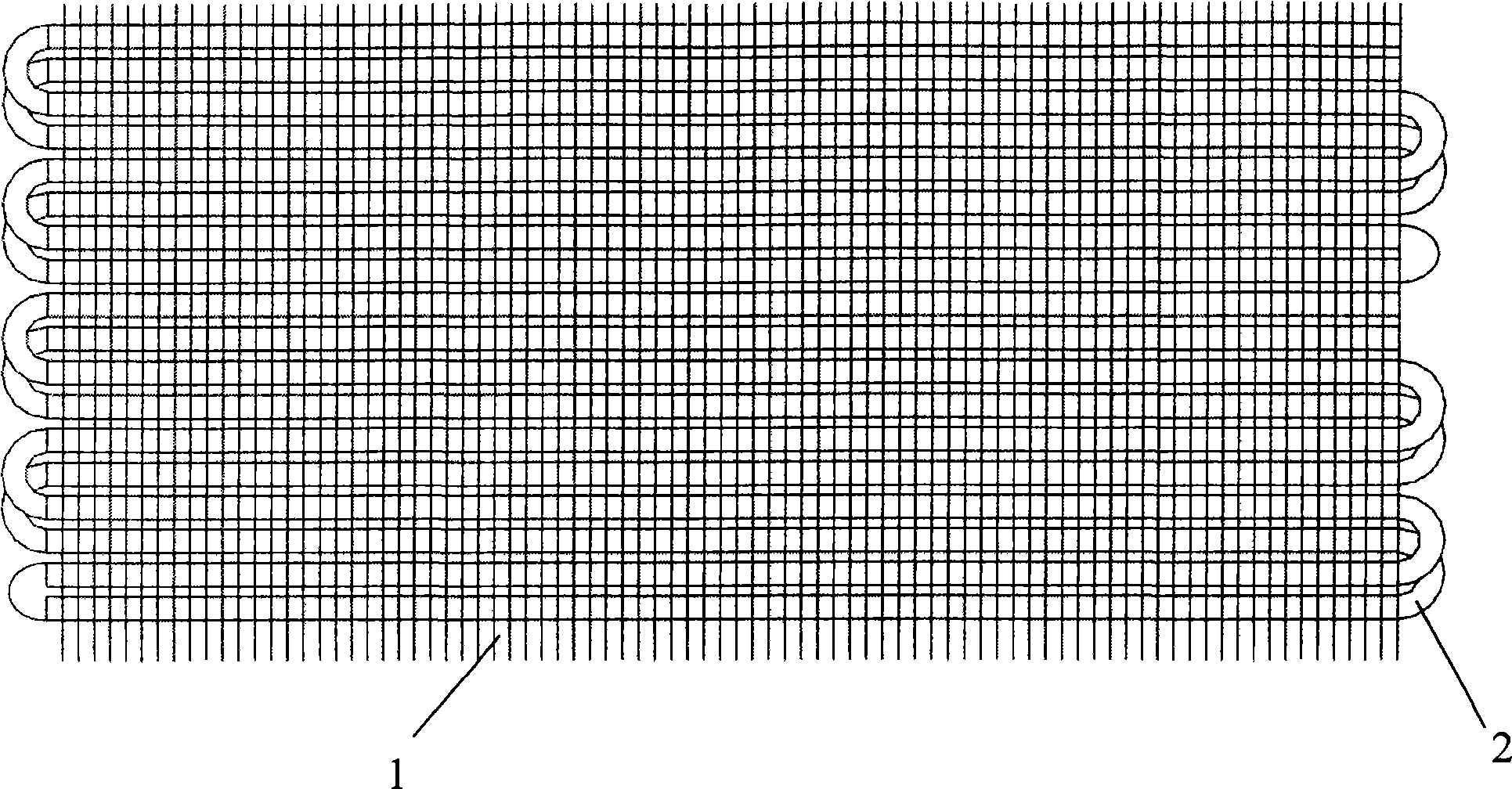

Composite tube type heat exchanger built from close annular fins

An integrated and closed heat exchanger of ring finned tube type is formed by connecting a set of G form and at least two sets of L form or some other forms of heat exchanger with connection plate. The formed heat exchanger is connected with sealed base plate to let generated air stream only pass through gap between fin plated for making prepared unit utilize peripheral ventilation space sufficiently under minimum volume in order to realize high efficiency of refrigerating and heating on unit volume.

Owner:劳特斯空调(江苏)有限公司

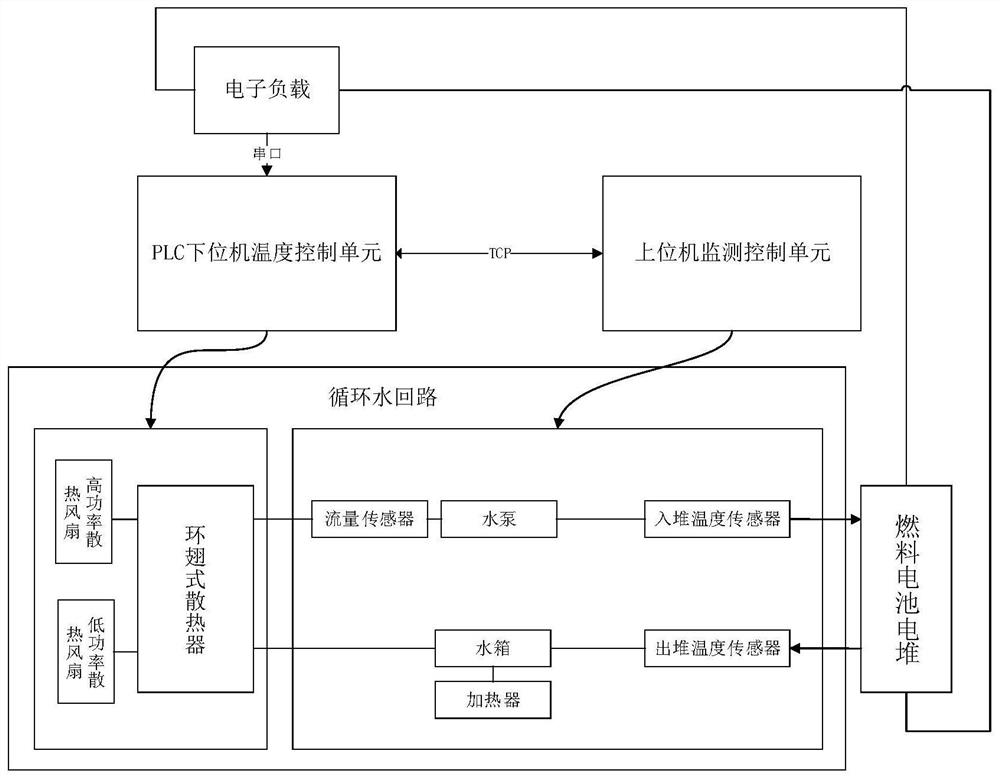

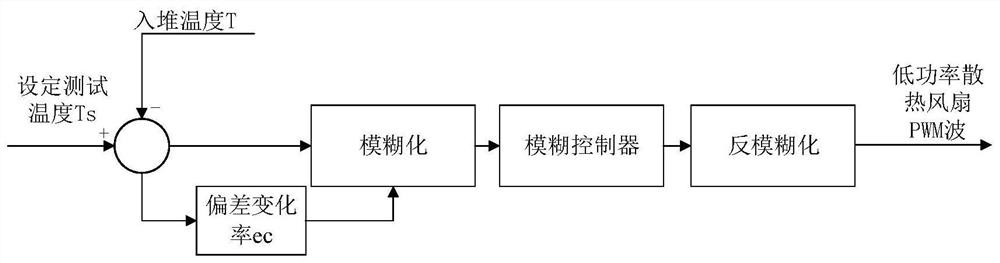

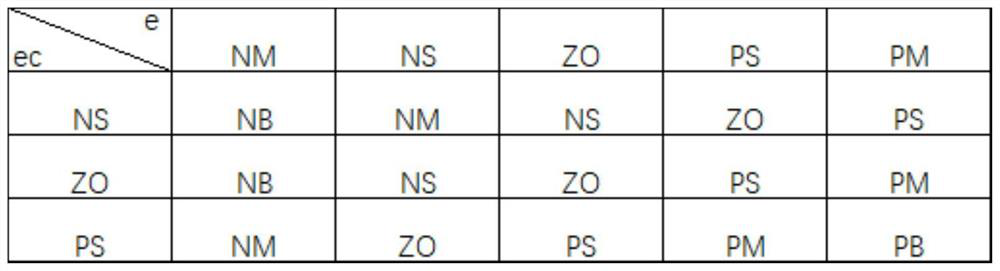

Fuel cell temperature control system compatible with different power stacks

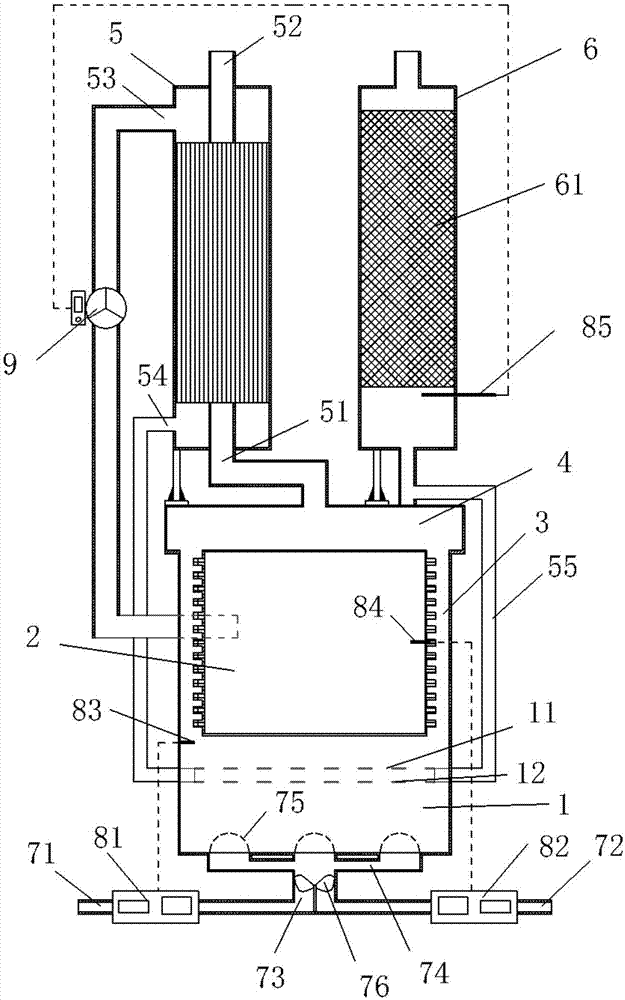

ActiveCN113078334ASmall temperature fluctuationsFast cooling responseFuel cell heat exchangeTemperature controlElectronic load

The invention provides a fuel cell temperature control system compatible with different power stacks. The fuel cell temperature control system comprises a PLC lower computer temperature control unit, an upper computer monitoring control unit, a circulating water loop and an electronic load, the circulating water loop comprises circulating water, an in-pile temperature sensor, an out-pile temperature sensor, a water tank, a water pump, a flow sensor, a heater, an annular fin type radiator, a high-power cooling fan and a low-power cooling fan; the PLC lower computer temperature control unit calculates the heat dissipation power required by the fuel cell stack according to the electronic load power so as to judge the working mode of the fuel cell temperature control system, and controls the working states of the heater, the high-power heat dissipation fan and the low-power heat dissipation fan by comparing the in-stack temperature with the set test temperature in different working modes, the temperature of the fuel cell is controlled, and the device has the advantages of being high in heat dissipation response speed, small in temperature fluctuation range of the fuel cell and wide in test target power range.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Molding powder bonding device

The invention discloses a molding powder bonding device which comprises a reaction tank, a pedestal and a driving device, wherein the reaction tank comprises an agitating mechanism in a tank body; thetank body is a cylindrical container with an opening in the top; multiple layers of annular heat dissipation sheets are arranged in an inner barrel of the tank body; a material feeding opening is formed in a tank cover; an oxygen detector is arranged on the inner side of the tank cover; the agitating mechanism consists of a rotating shaft, and a first blade group, a second blade group, a third blade group and a fourth blade group which are connected to the rotating shaft in a sleeving manner from top to bottom; water cooling loops are arranged in agitating blades; a nitrogen passageway is formed in the reaction tank; and the driving device is a motor driving the rotating shaft to rotate through a belt transmission mechanism. The molding powder bonding device can guarantee a heating requirement during molding powder bonding, so that molding powder and pigment can be quickly bonded; the molding powder bonding device also can bring away residual heat to prevent a material from being blocked; and a nitrogen loop can guarantee safe production.

Owner:河南朗星工业自动控制技术有限公司 +1

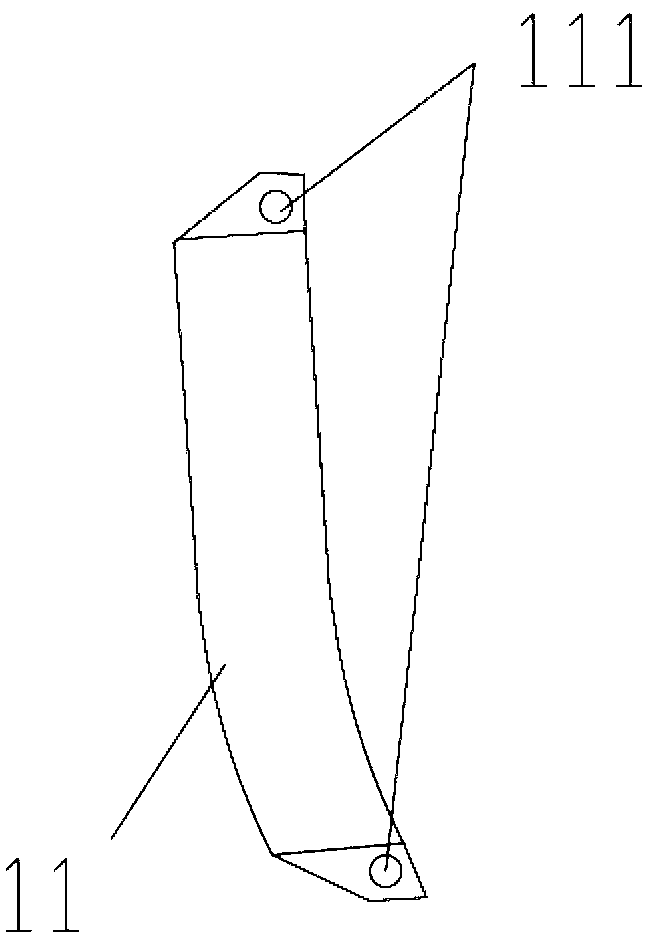

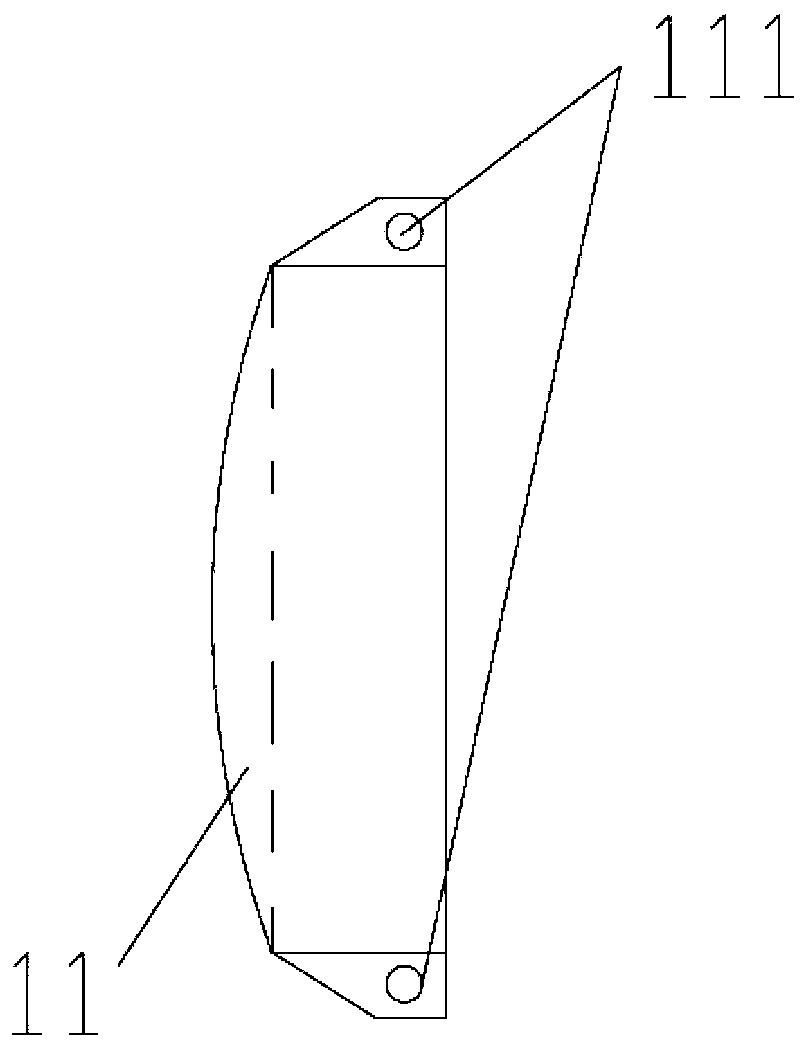

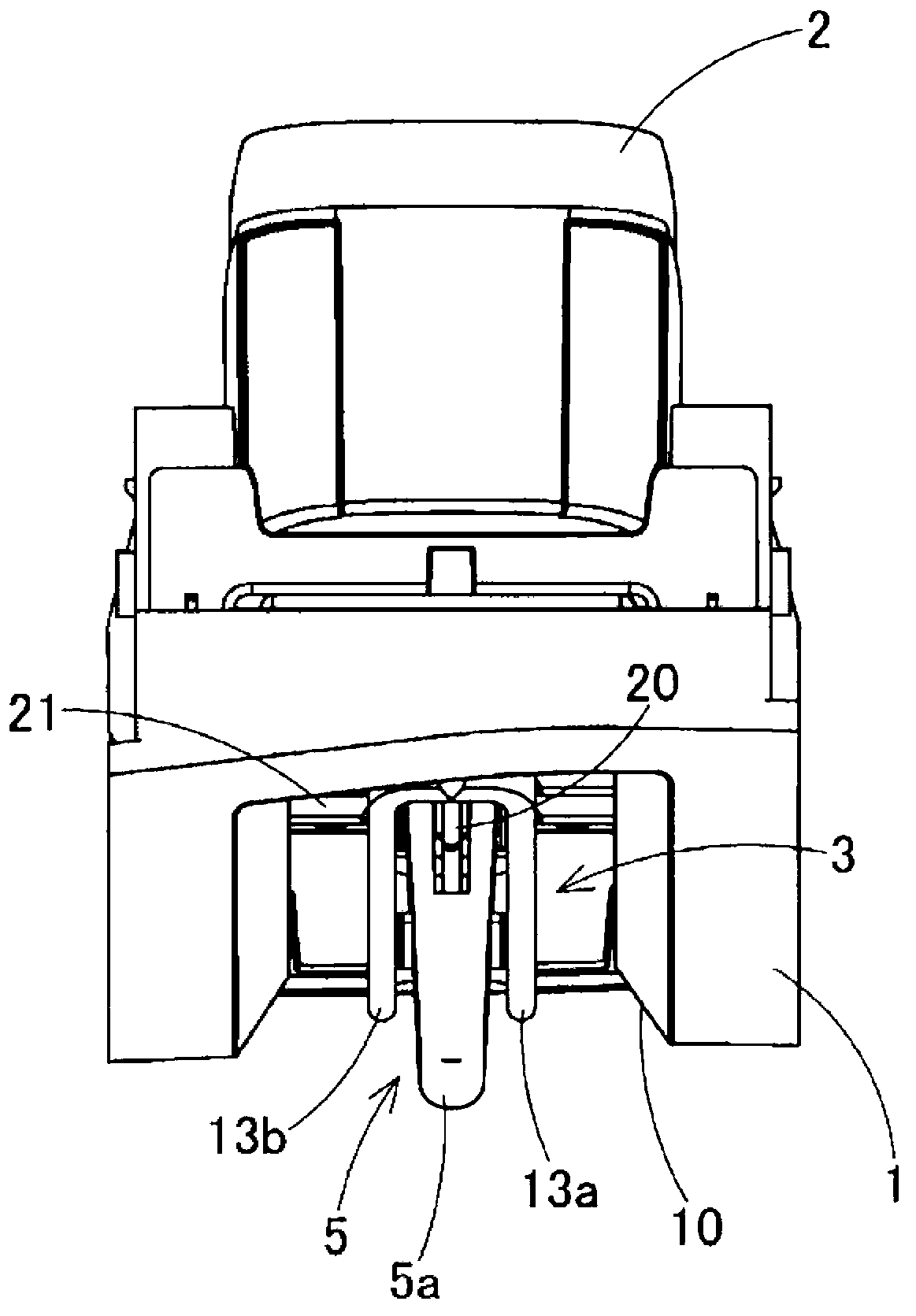

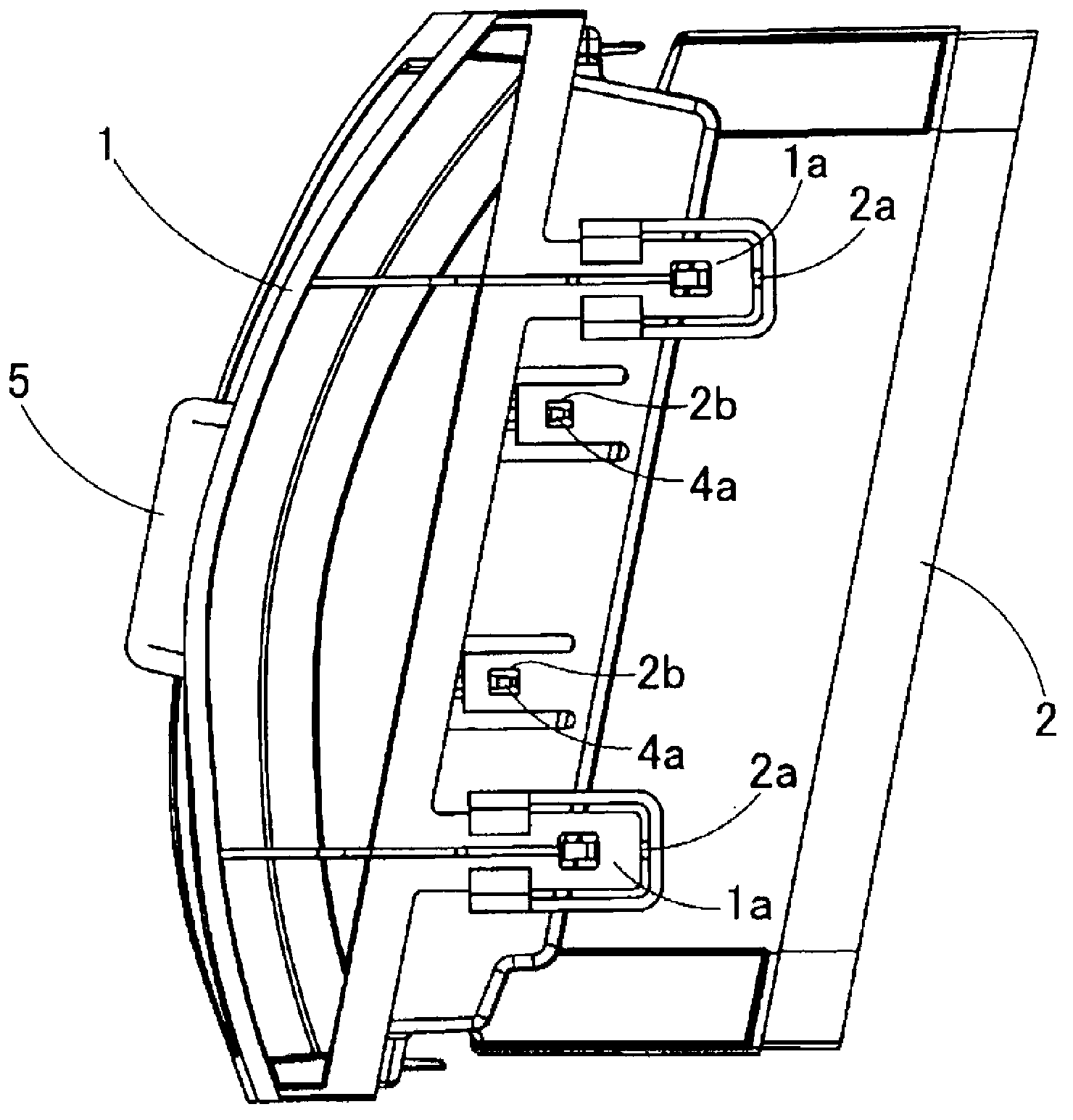

Register

ActiveCN102741075AChange directionChange directivityAir-treating devicesVehicle heating/cooling devicesEngineeringBlow out

Disclosed is a register which comprises an elongate air blow-out port (10) which is long in the long direction and short in the short direction, and which has louvres (3) that can move forward arranged in the long direction on the inner side of the air blow-out port (10). The louvres (3) which can move forward are formed by one longitudinal fin (11) having an annular fin part (12) in the centre. The annular fin part (12) has an opening (15) which is substantially rectangular when seen from the front and opens in the air-blowing direction, and comprises flat plate parts (13a, 13b) at both ends thereof. An upper shaft part (17) is provided at one end of the annular fin part (12) with an upper fin part (16) interposed, and a lower shaft part (19) is provided at the other end with a lower fin part (18) interposed. The upper shaft part (17) and the lower shaft part (19) are pivotably supported by a bearing part on a fixed wall

Owner:HOWA PLASTICS CO LTD +1

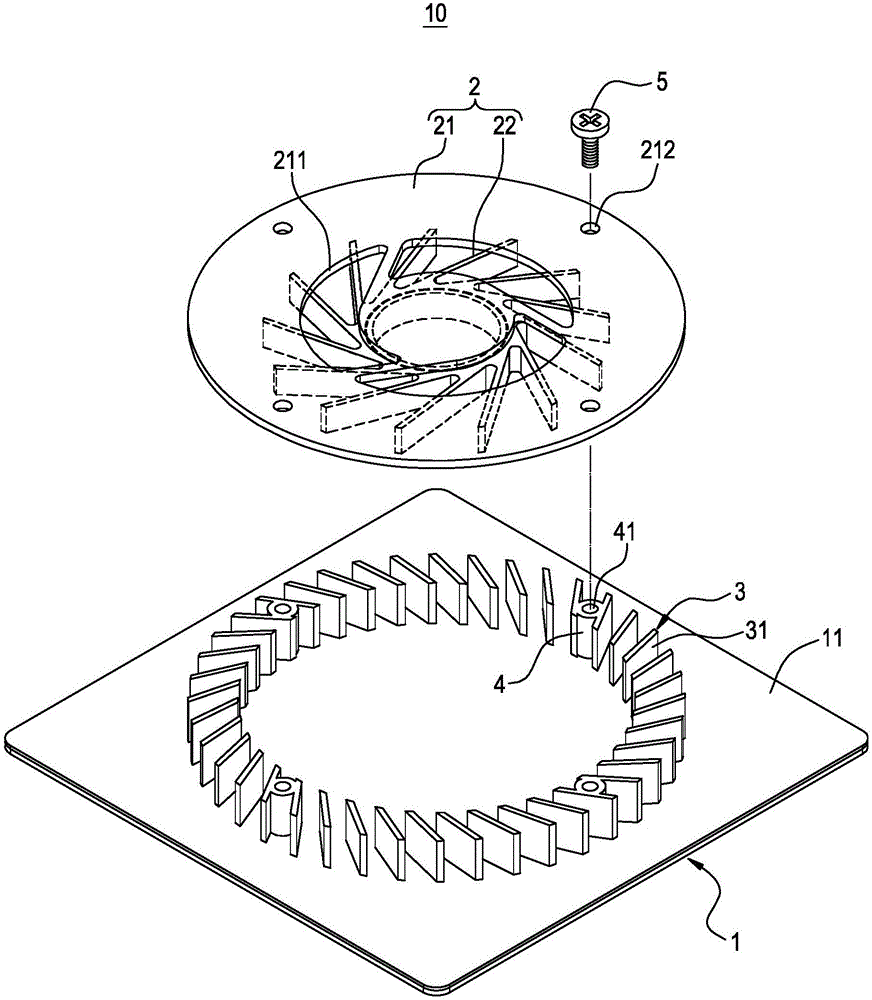

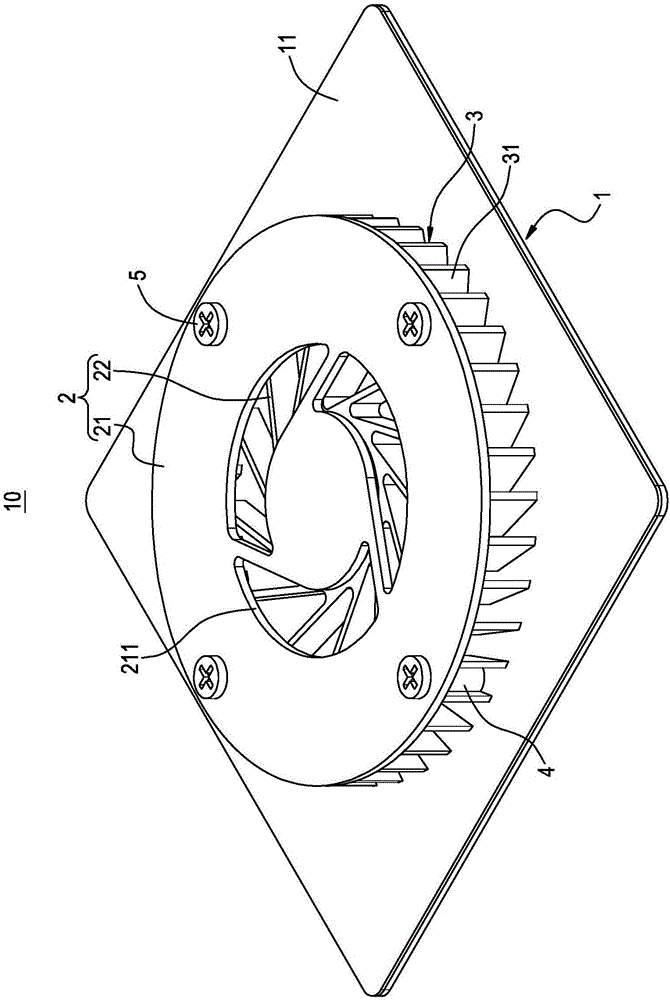

Thin heat dissipating device

InactiveCN106332517AHeat dissipation fastImprove cooling efficiencyDigital data processing detailsCooling/ventilation/heating modificationsEngineeringAnnular fin

The invention discloses a thin heat dissipating device comprising a uniform-temperature plate, a fan module and an annular fin group. The uniform-temperature plate has a condensing surface. The fan module and the uniform-temperature plate are fixedly connected with each other. The fan module includes a cover plate and a fan mounted under the cover plate, and the cover plate is provided with an air vent corresponding to the fan. The annular fin group is clamped between the cover plate and the condensing surface, and the annular fin group annularly surrounds the outer periphery of the fan. Thus, the fan is accommodated in a space formed by the cover plate, the condensing surface and the annular fin group and can blow air directly to the uniform-temperature plate and the annular fin group, and therefore, the heat dissipating efficiency of the thin heat dissipating device is improved.

Owner:CHAUN CHOUNG TECH

Stator cooling channel tolerant to localized blockage

ActiveUS9306432B2Magnetic circuit stationary partsCooling/ventillation arrangementEngineeringMechanical engineering

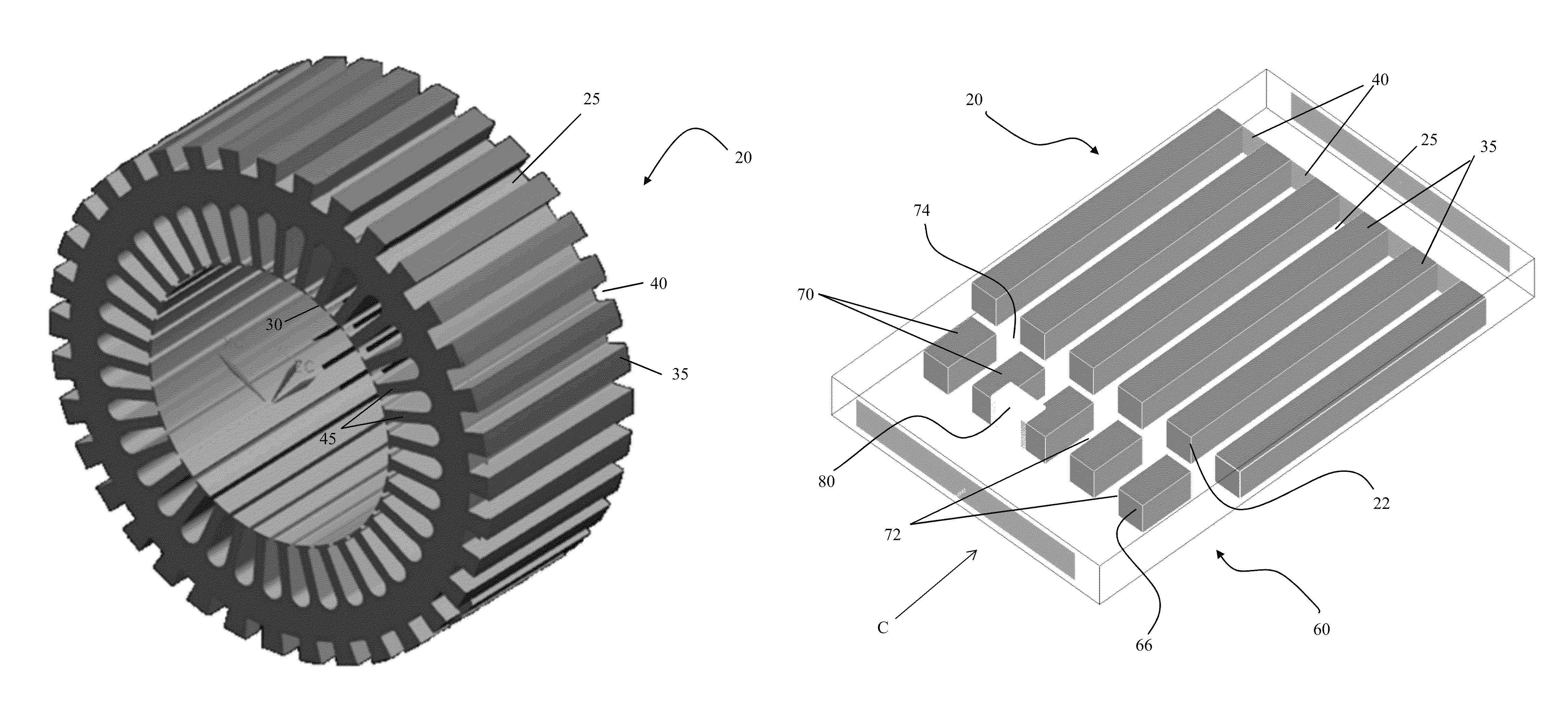

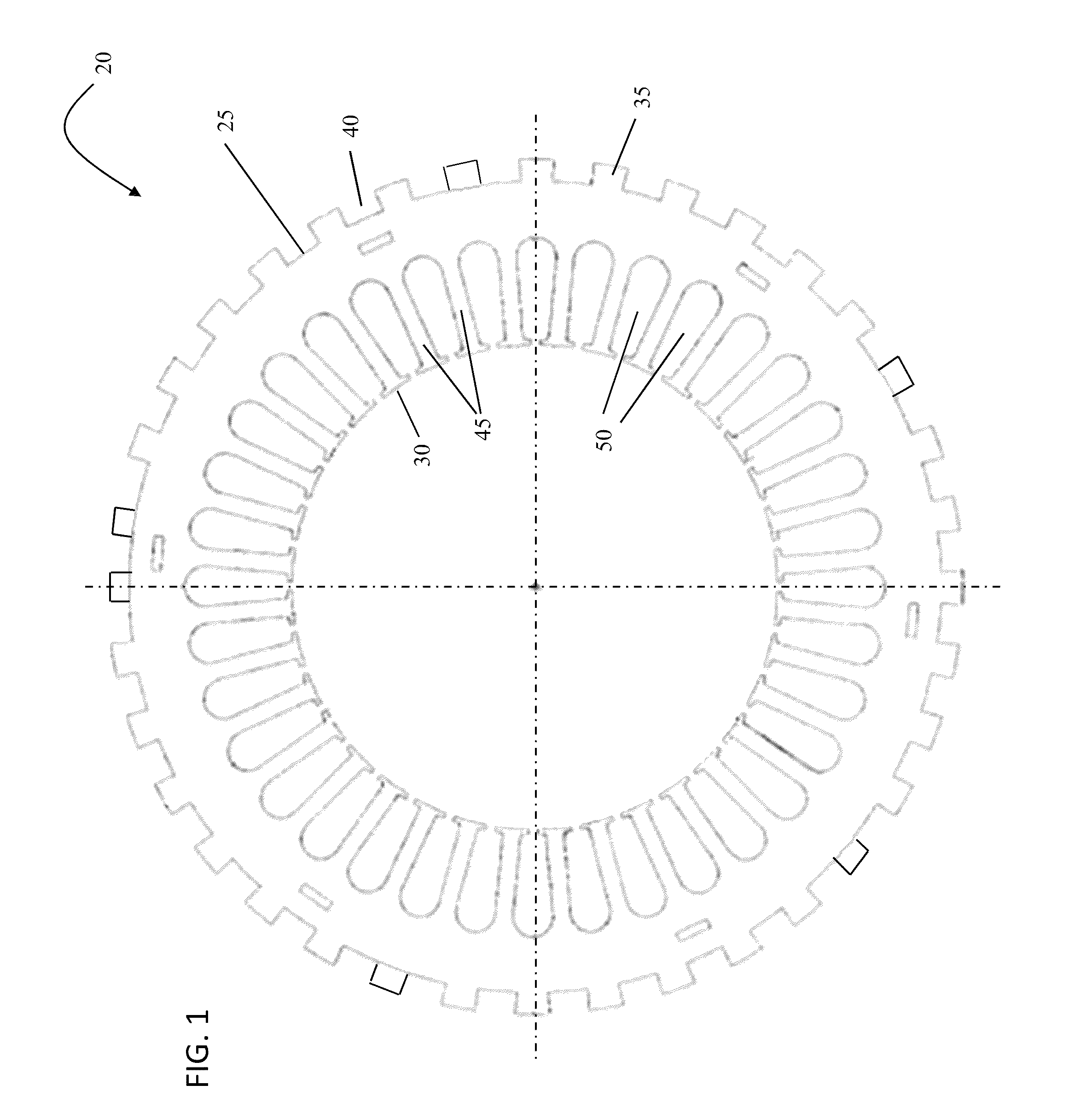

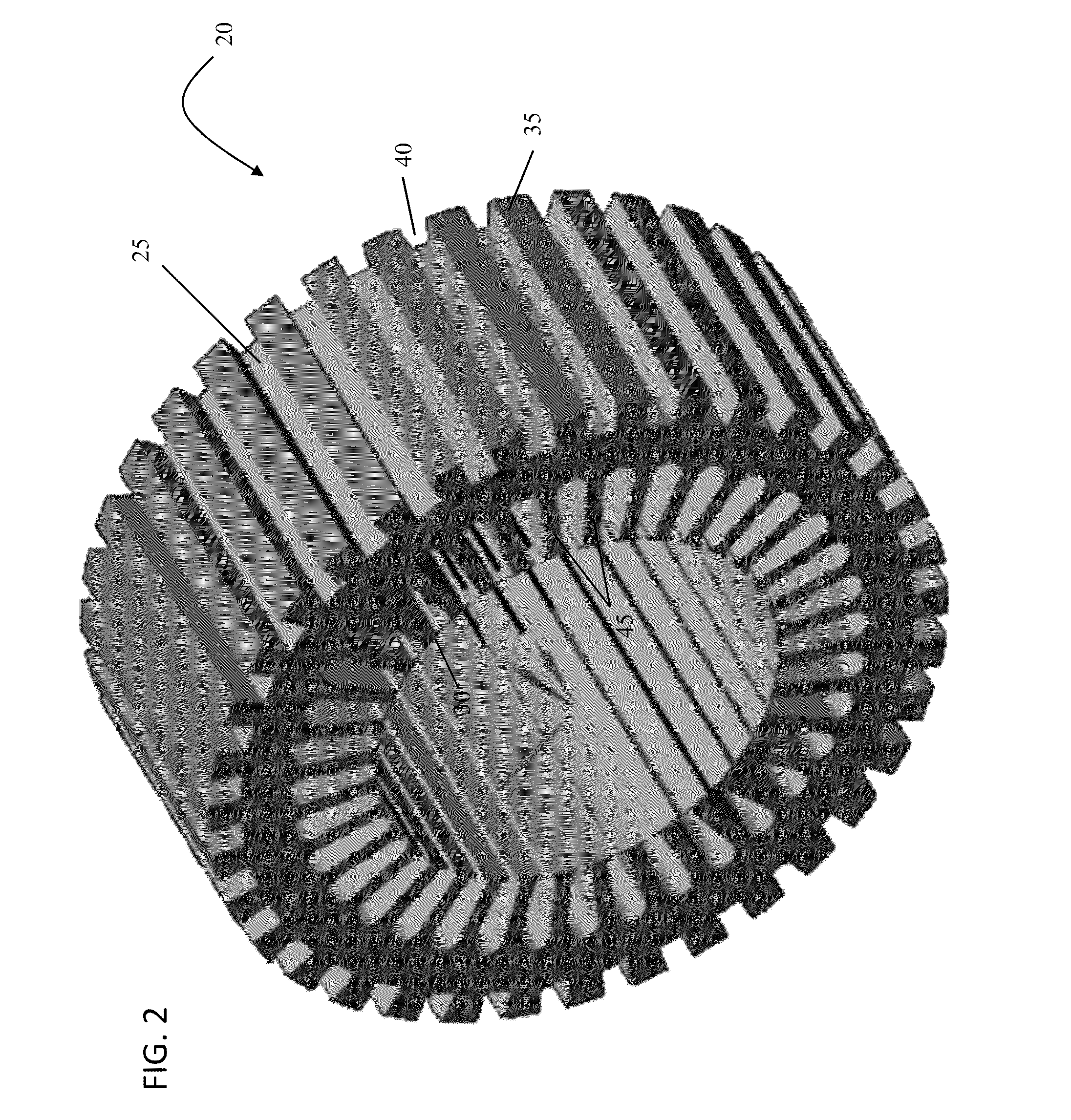

A motor is provided including a stator core having a plurality of stator fins projecting outwardly from the stator core. A plurality of stator cooling channels is defined between adjacent stator fins. A flow mixer ring is axially aligned with the stator core and separated therefrom by an axial gap. The flow mixer ring includes a plurality of ring fins projecting inwardly from an interior surface and a plurality of ring cooling channels defined between the plurality of ring fins. The plurality of ring fins extends from a first surface over at least a portion of an axial length of the flow mixer ring.

Owner:HAMILTON SUNDSTRAND CORP

Automobile wire harness sheath

ActiveCN107069602ASolve the problem that it is easy to pull out from the sheet metal holePrevent prolapsePiezoelectric/electrostriction/magnetostriction machinesEngineeringHardness

The invention relates to an automobile wire harness sheath. A piezoelectric crystal is fixed by adhering to an annular inner wall of a protective annular sleeve; an annular clamping groove is formed on an outer circumferential surface of the protection annular sleeve; an U-shaped annular chamber which is fitted and nested with the annular clamping groove is preset in the protection annular sheath; an electrorheological fluid which is conductively connected to the piezoelectric crystal through an electrode fills the U-shaped annular cavity; an annular fin which is positioned in the rear of the annular cavity is arranged on the outer wall of the rear end of a center sheath; the hardness of the annular fin is lower than that of the protection annular sheath and the periphery of the annular fin is expanded to the outer rim of the annular cavity; after the harness is pulled, the center sheath moves forward relative to the protection annular sheath, which makes the annular fin go into the U-shaped annular cavity to press the piezoelectric crystal; and the piezoelectric crystal is triggered to generate a power supply which exerts on the electrorheological liquid to make the electrorheological liquid electrified. The automobile wire harness sheath improves rigidity so as to prevent the protection annular sheath from coming off from a sheet metal hole.

Owner:ZHEJIANG DAIDE LONGTREE AUTOMOBILE CO LTD

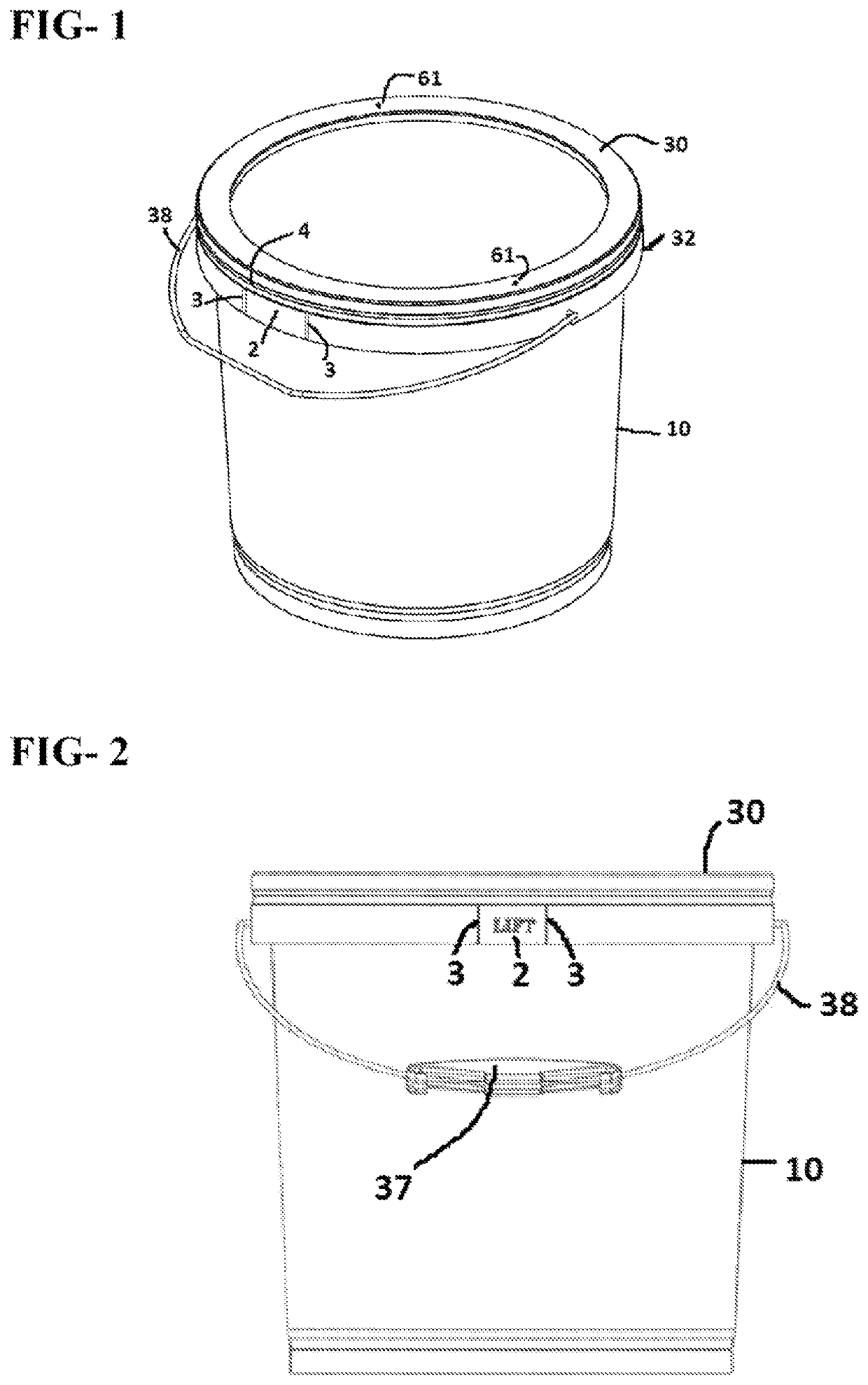

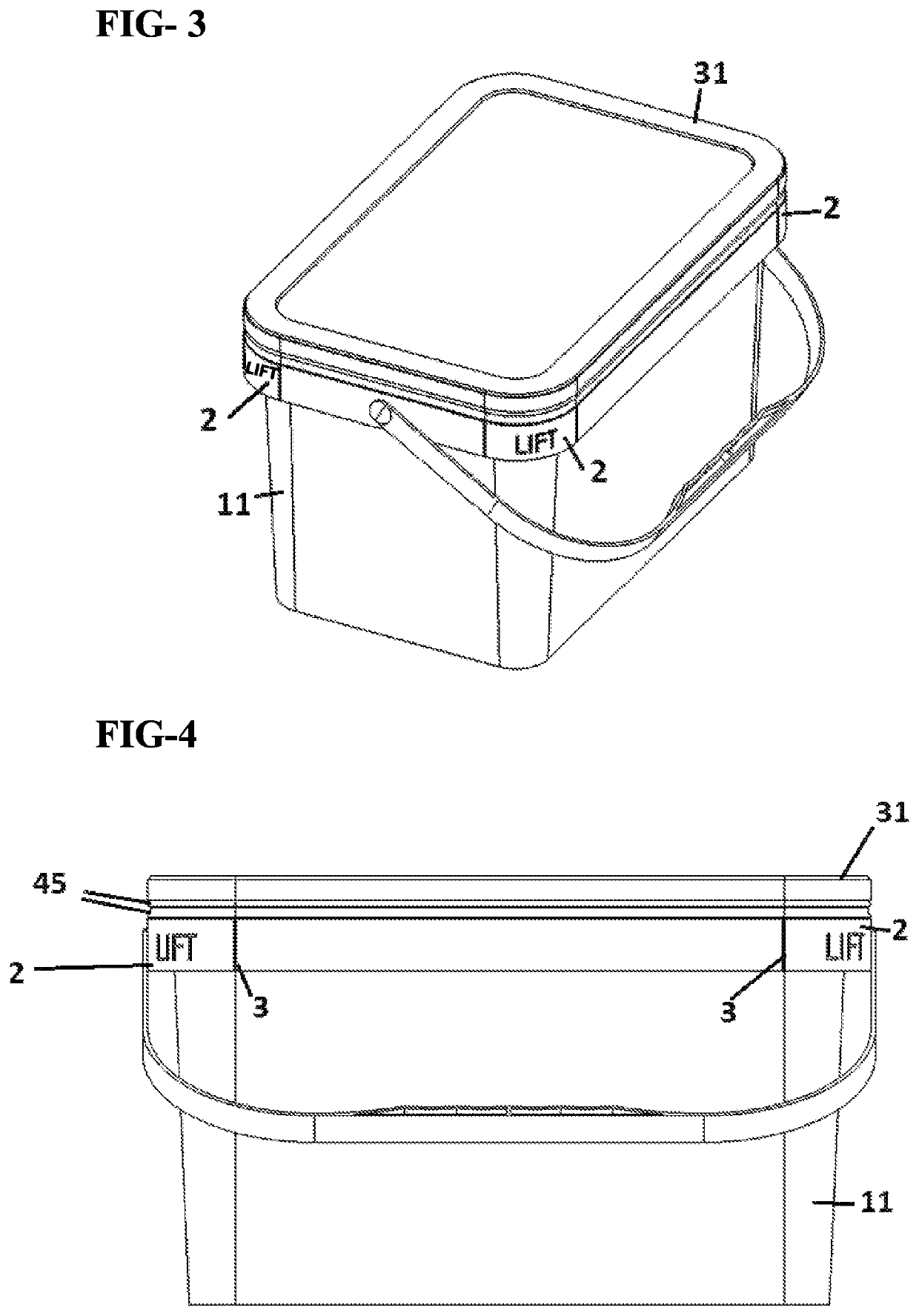

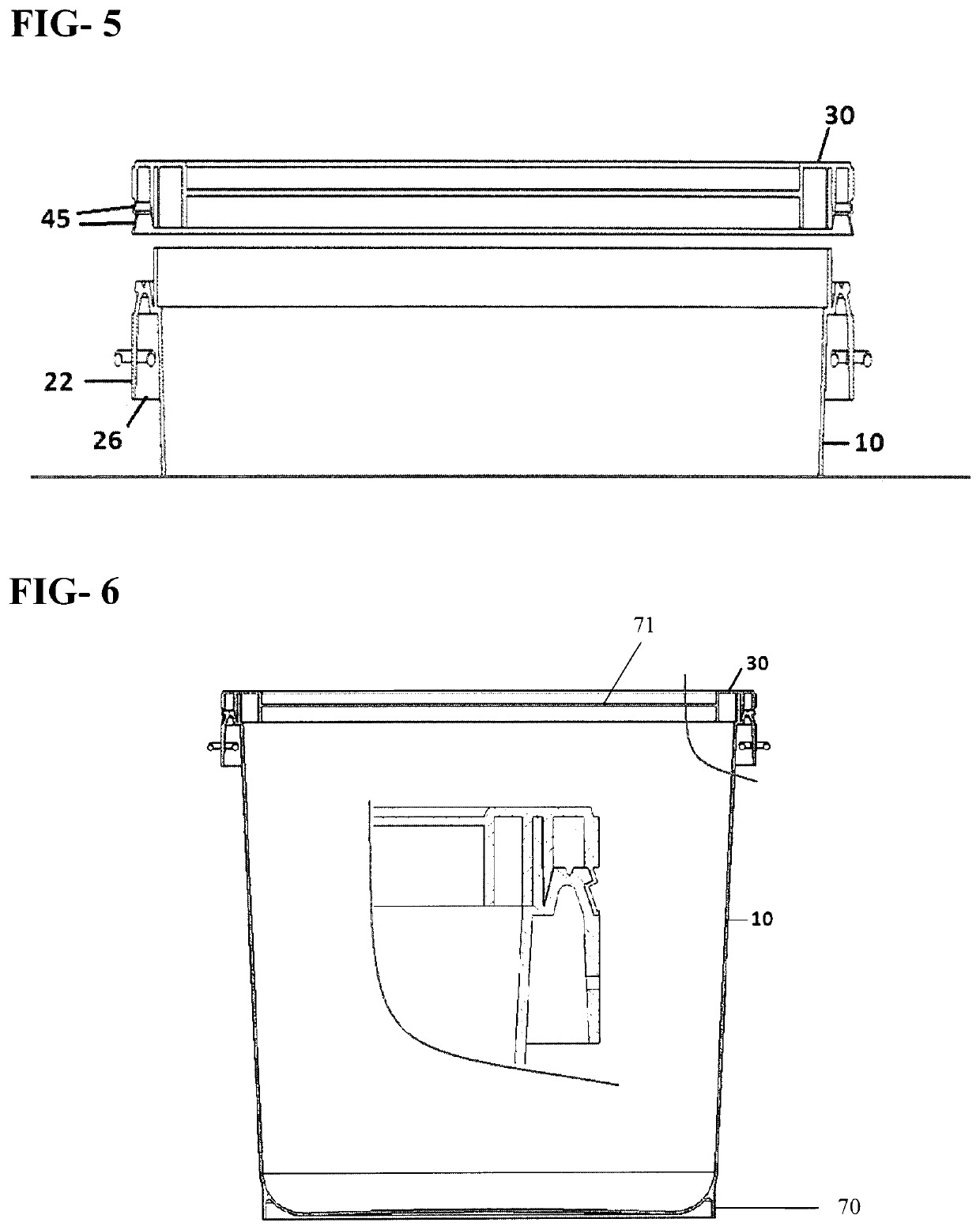

Plastic container body and container closure and carry handle grip / container leverage opening tool assembly

ActiveUS11014716B2Strong forceReduce manufacturing costRemovable lids/coversLidsWide mouthEngineering

A plastic injection moulded wide mouth container body and container cover locking and sealing mechanism which includes an annular flange and an annular angular notch groove respectively in a pre-determined configuration so as to provide a tight leak-proof seal when the container lid is fitted over, around and within the container body hoop annular fin and upon locking engagement. The present invention incorporates a multi-use plastic handle grip which may also be used as a closure opening levering tool to disengage the container lid from the container body in a safe and ergonomic manner. More significantly the invention, and when in use and upon first usage opening, does not require the removal of any portion of the container lid to comply with tamper evident requirements, nor needs other tools such as knives and metal levers to completely remove the container closure from the container body. Still furthermore the invention includes a plurality of venting channels and adjacent ports which allows the evacuation of increased internal air pressure within the closed container head space with no leakage of the packaged fluid product. The invention may be adapted to plastic containers of any size and shape being round, oval, square or rectangular tapered or straight wall containers.

Owner:TYLER GLENN NORMAN +1

Automatic dirt removing type air energy water heater

InactiveCN105258339AImprove heat exchange efficiencySpeed up the flowFluid heatersGlass fiberEngineering

The invention discloses an automatic dirt removing type air energy water heater. The automatic dirt removing type air energy water heater comprises an evaporator, a compressor, a water tank and a heat exchange pipe set. The heat exchange pipe set comprises a plurality of heat exchange pipes which are arranged along the inner wall of the water tank, are the same in diameter and are vertically arranged. Every two adjacent heat exchange pipes are communicated through a connecting pipe. The outer wall of any heat exchange pipe is sleeved with a dirt prevention pipe. The upper ends and the lower ends of the heat exchange pipes are connected with heat exchange pipe bearings respectively. The dirt prevention pipes can rotate relative to the heat exchange pipes. The water tank is arranged outside the heat exchange pipe set in a covering manner. A plurality of annular grooves containing annular fins are formed in the inner wall of the water tank from top to bottom, and the annular grooves and the opposite annular fins are matched in grain and depth. An insulating layer is arranged at the outer portion of the water tank. The insulating layer comprises glass cellucotton, insulating cotton and a foam plate arranged from interior to exterior in sequence. The designed automatic dirt removing type air energy water heater is high in heating speed, the heat exchange area is increased, and the energy consumption is reduced.

Owner:广西广拓新能源科技有限公司

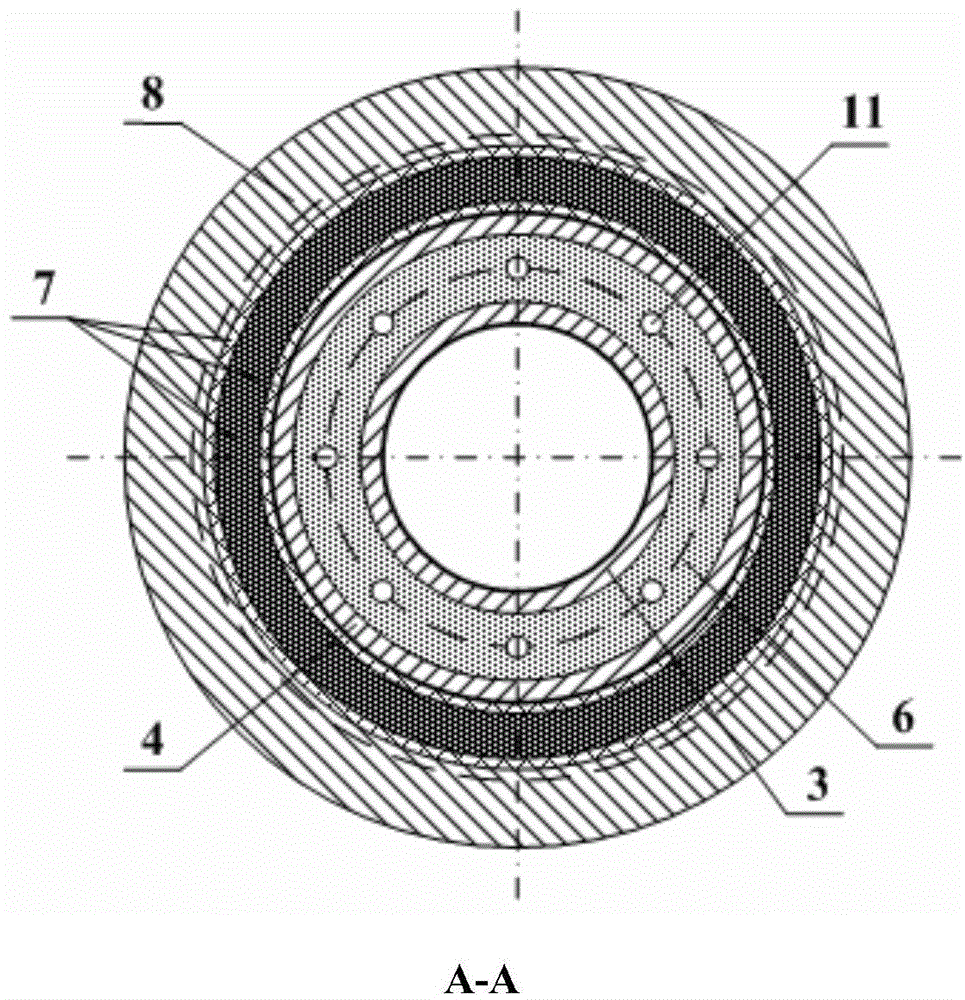

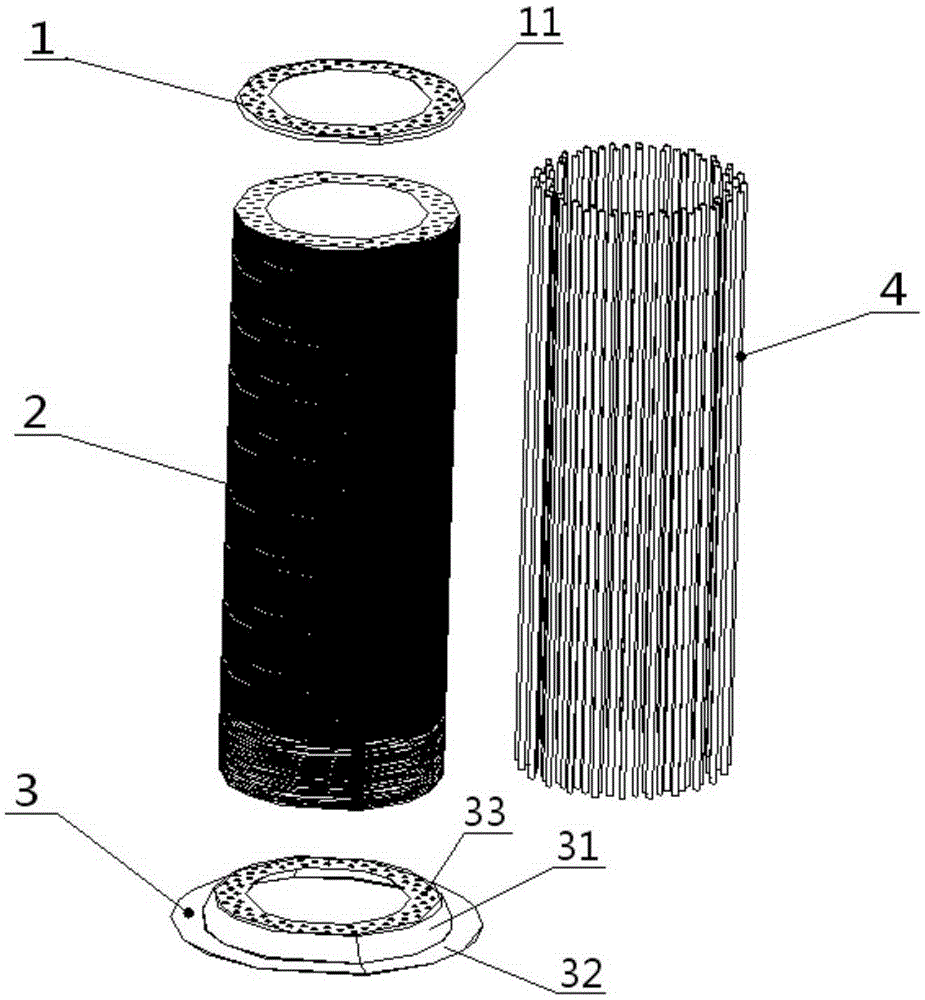

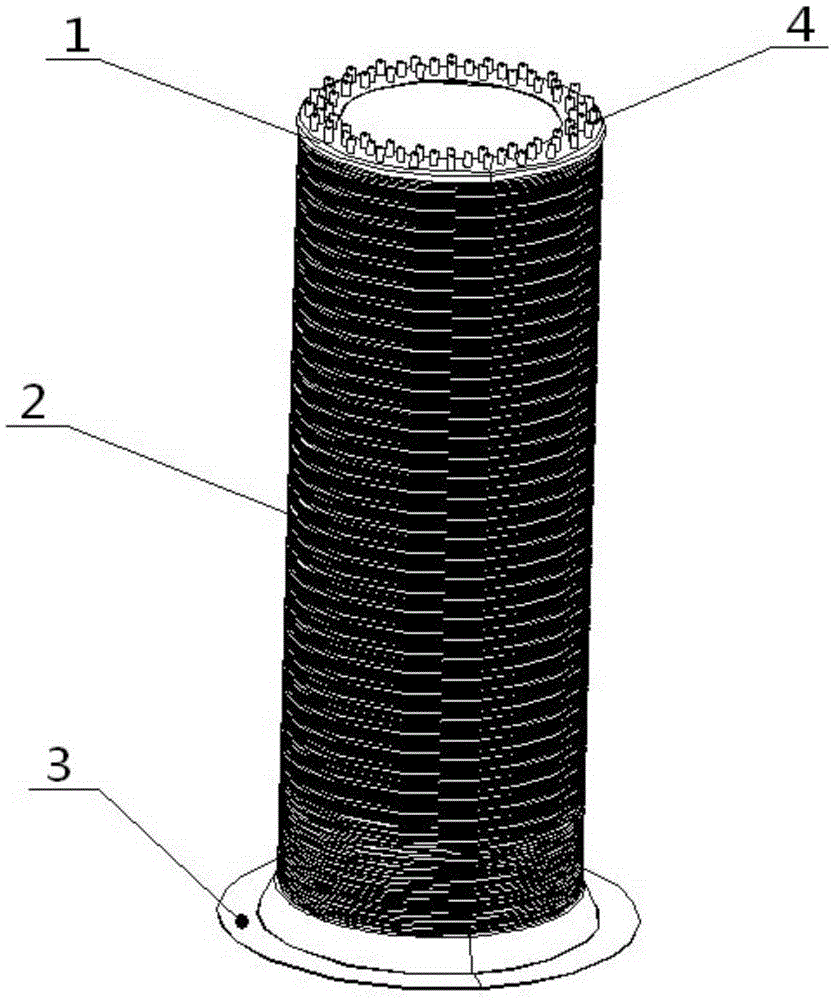

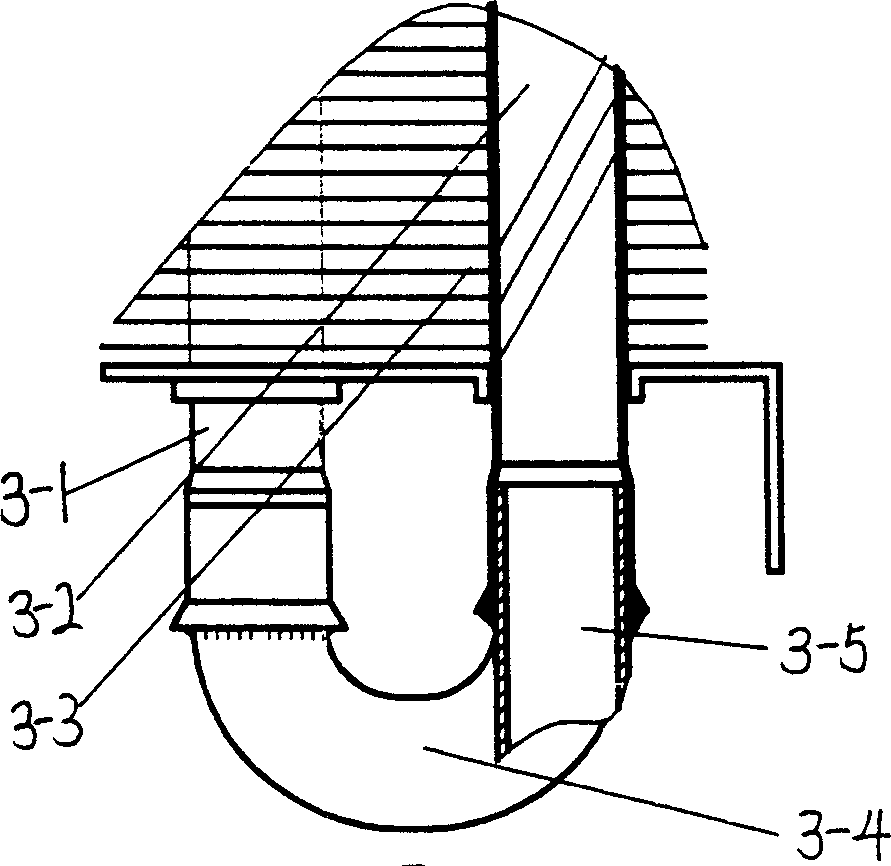

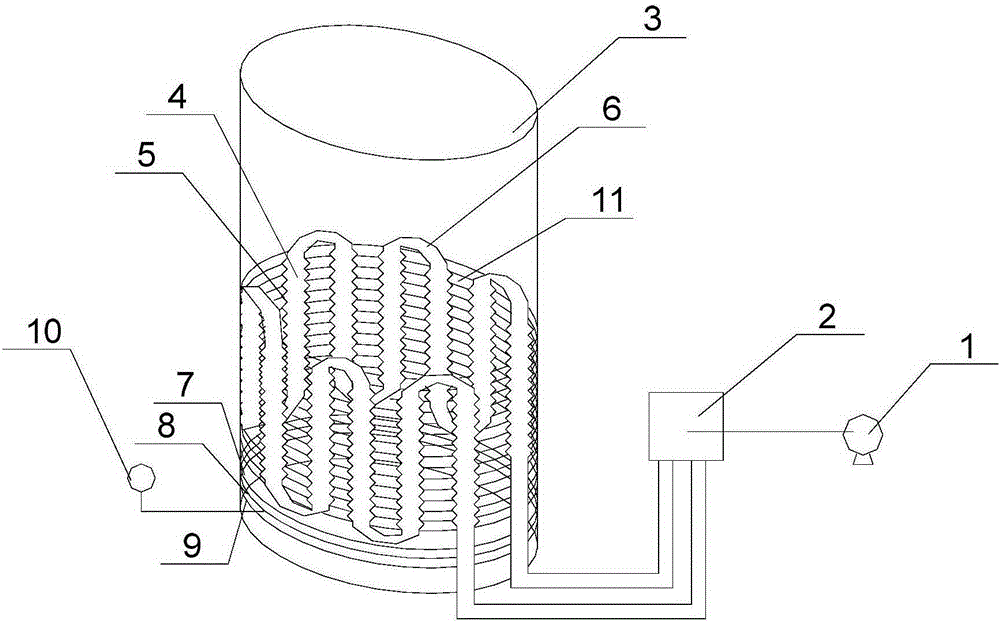

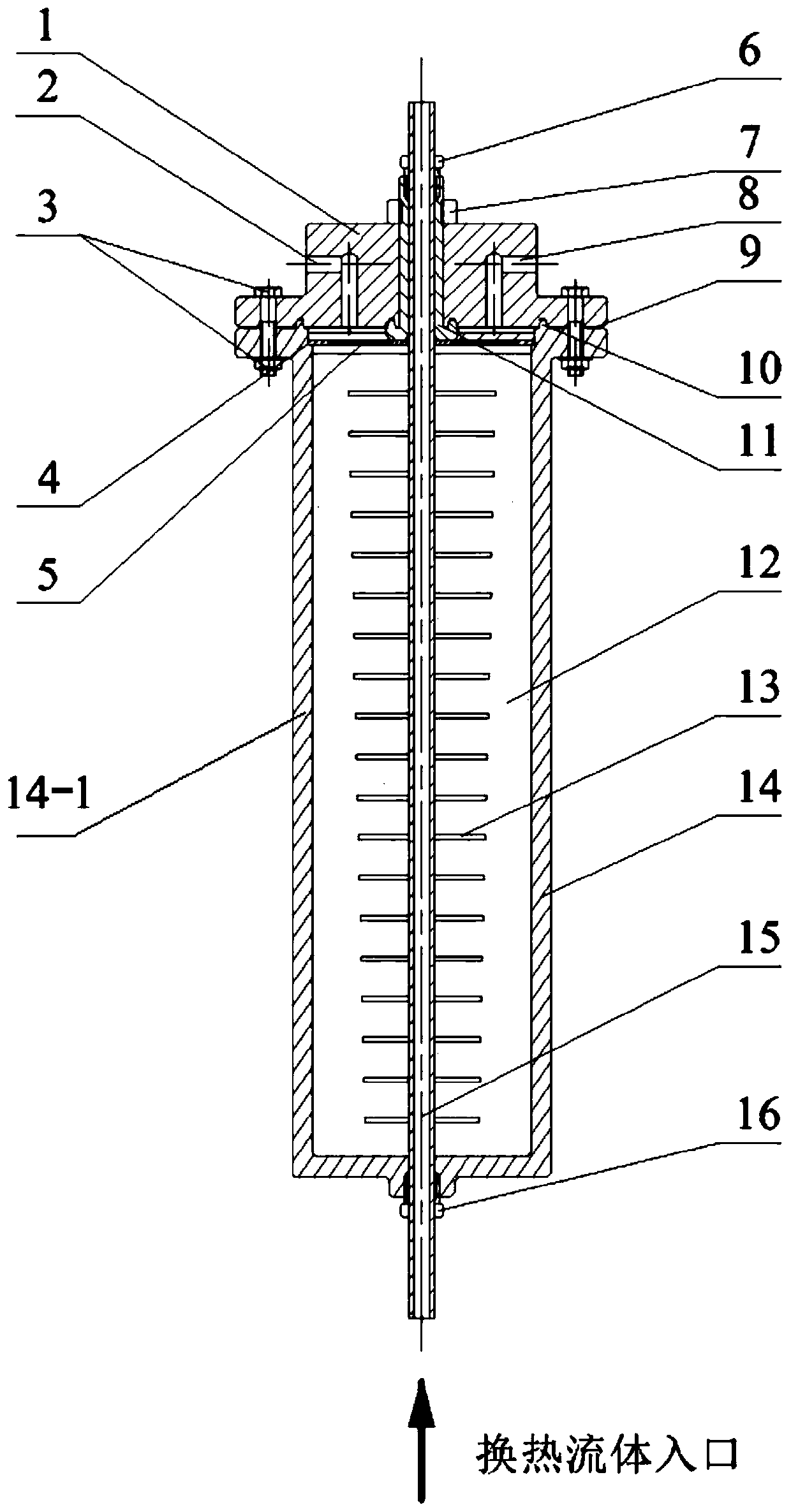

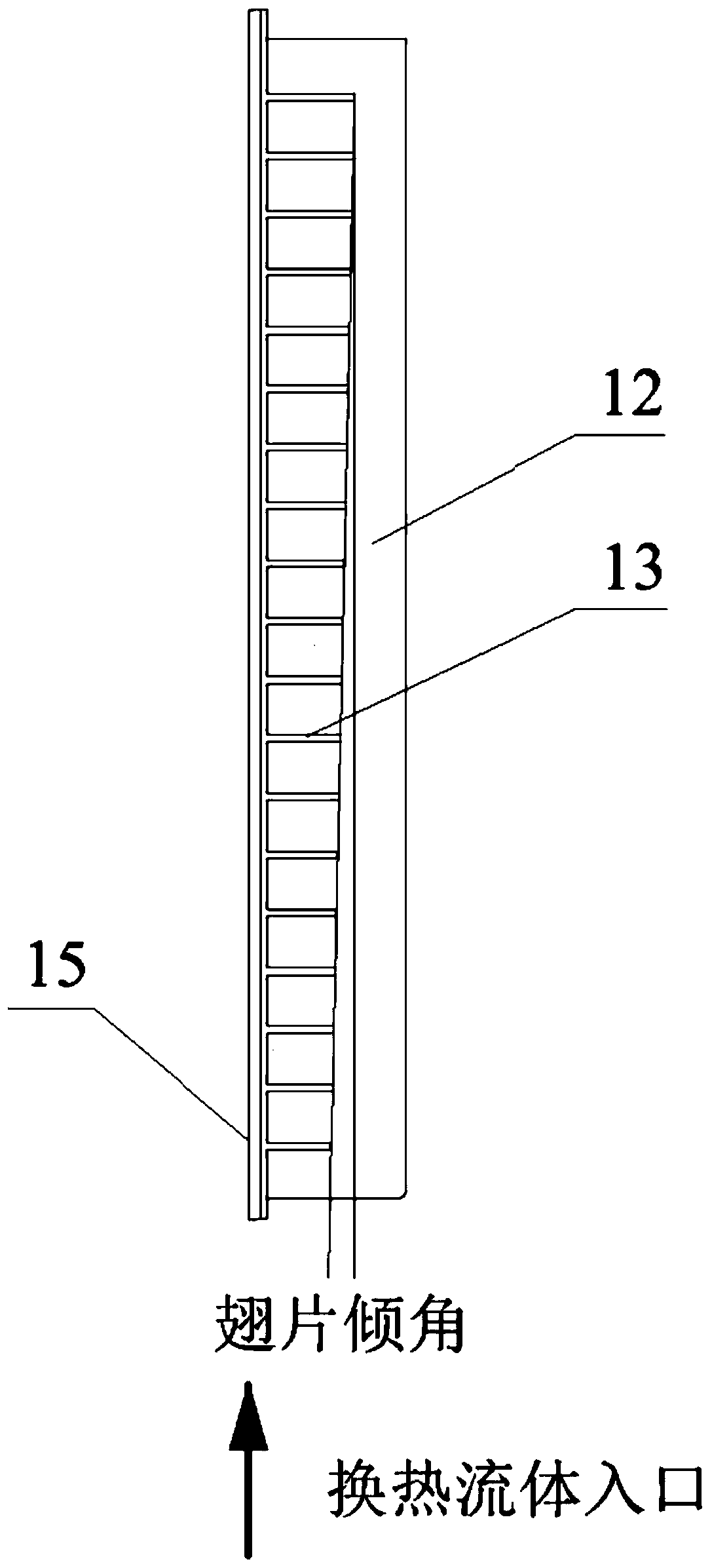

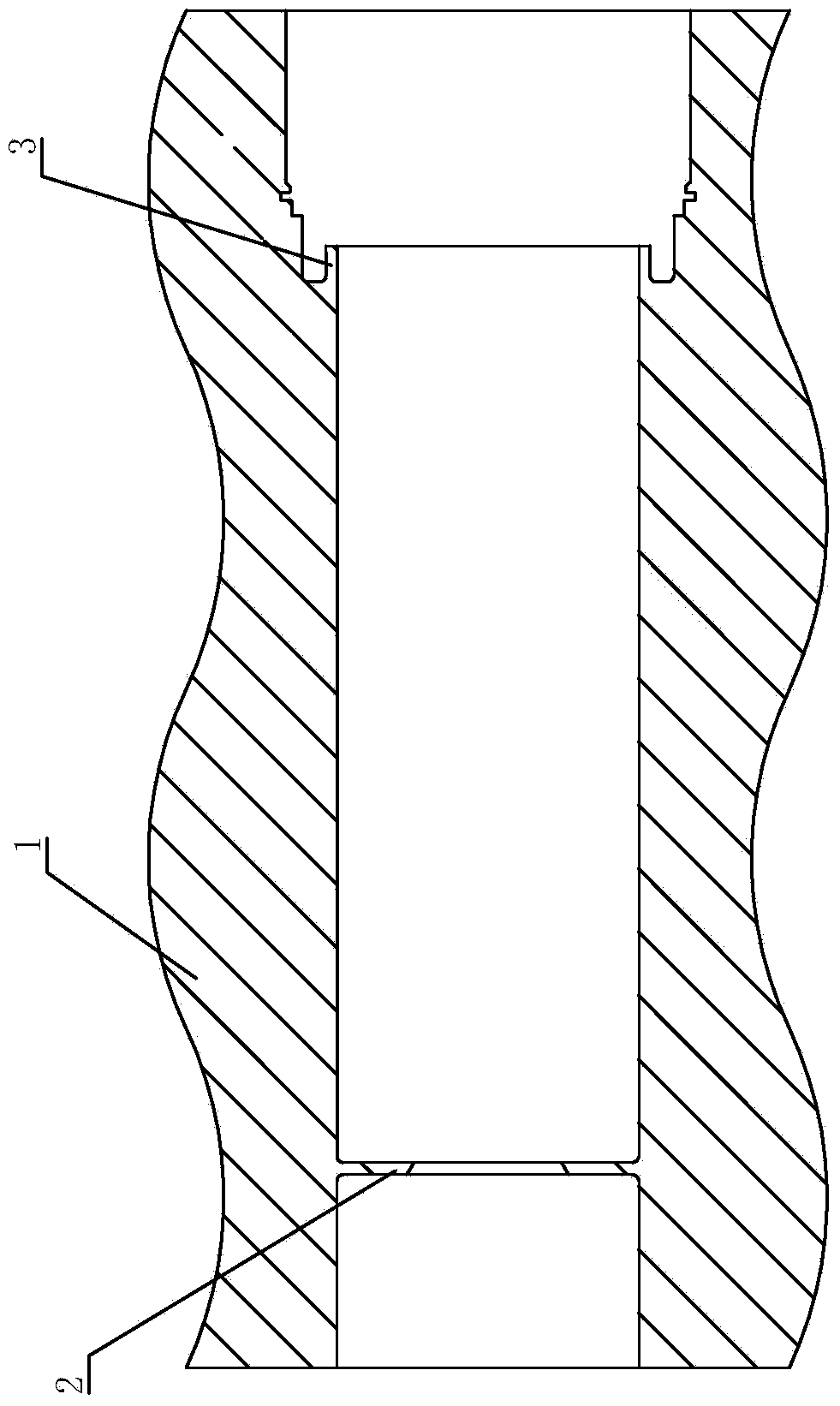

Metal hydride based annular fin type efficient heat storage reactor

PendingCN111076593AIncreased effective heat outputImprove heat transfer performanceHeat storage plantsEnergy storageMetallic hydrogenEngineering

The invention discloses a metal hydride based annular fin type efficient heat storage reactor which comprises a reactor shell and a heat exchanging fluid pipe, wherein a gas hole allowing hydrogen toenter and exit and a safety valve port are formed in the upper end of the reactor shell; the heat exchanging fluid pipe penetrates to the upper end of the reactor shell from the lower end of the reactor shell; the upper end lower ends of the heat exchanging fluid pipe extend into the external part of the reactor shell; a plurality of annular fin structures are mounted on the part, in the reactor shell, of the heat exchanging fluid pipe at intervals in the axial direction; the diameters of the annular fins are sequentially reduced from top to bottom; a metal hydride powder bed is filled in thereactor shell; and the heat exchanging fluid pipe is connected with the reactor shell in a sealing manner. The metal hydride based annular fin type efficient heat storage reactor solves the problems that during the heat releasing process, the traditional shell-and-tube metal hydride heat storage reactor is lower in output temperature and poorer in heat exchanging performance.

Owner:XI AN JIAOTONG UNIV

Hydraulic test sealing structure of pressure container and mounting and use method of hydraulic test sealing structure

ActiveCN103557325AImprove sealingDimensional accuracy meets the requirementsMaterial strength using tensile/compressive forcesPressure vesselsEngineeringHydraulic test

The invention relates to a hydraulic test sealing structure of a pressure container. The hydraulic test sealing structure comprises a container body with a cylindrical cavity, wherein an annular fin is arranged in front of the cylindrical cavity; an annular groove type thin wall is arranged behind the cylindrical cavity; the rear end of the thin wall is hermetically welded with a hydraulic pressure connecting pipe; a sealing core rod penetrates into the cylindrical cavity from back to front and then is hermetically welded with the annular fin; the rear end of the sealing core rod is fixedly connected with a plug; the plug is positioned in the hydraulic pressure connecting pipe and is fixedly connected with the hydraulic pressure sealing pipe; the rear part of the sealing core rod is provided with a drainage cavity which is communicated with the cylindrical cavity; the plug is provided with a water injection hole for communicating the drainage cavity with the exterior. The invention also relates to a mounting and use method of the sealing structure. The invention provides the hydraulic test sealing structure and the mounting and use method aiming at an unconventional pressure container, so that effective sealing of a water outlet of the pressure container is realized, smooth pressure test of the pressure container is guaranteed, and the dimensional accuracy meets the requirements after hydraulic test. The hydraulic test sealing structure can be applied to hydraulic test sealing.

Owner:DONGFANG (GUANGZHOU) HEAVY MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com