Molding powder bonding device

A technology of plastic powder and driving device, applied in the field of plastic powder manufacturing device, can solve the problems of insufficient, resin powder matrix melted and bonded into agglomerates, resin powder matrix is not firm enough, etc., to ensure safe production and prevent material agglomeration , to ensure the effect of heating requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

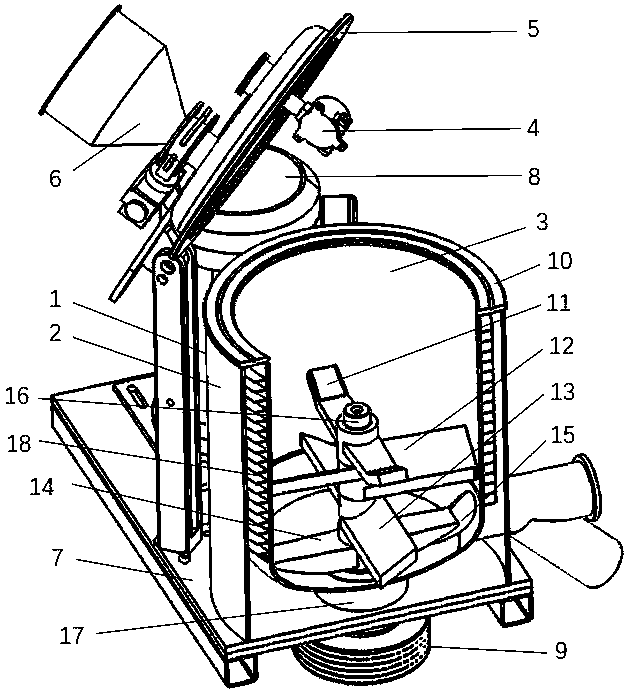

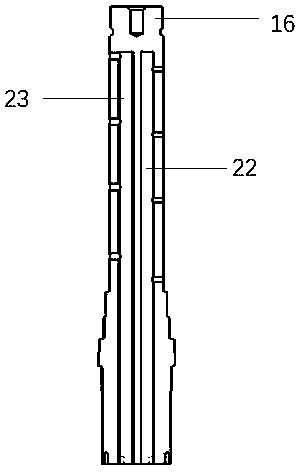

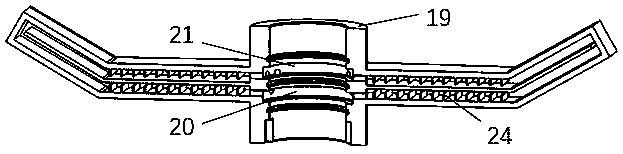

[0024] The invention provides a plastic powder bonding device, which includes a reaction tank 1, a base 7 and a driving device. The reaction tank 1 includes a tank body, a tank cover 5 and a stirring mechanism arranged in the tank body. The tank body is cylindrical The upper opening container, the tank body is provided with an inner cylinder 3 and an outer cylinder 2, and there is a gap between the inner cylinder 3 and the outer cylinder 2. The inner cylinder 3 is composed of a cylindrical side wall, a hemispherical bottom surface and a transition arc surface. The wall and the hemispherical bottom surface are smoothly connected by a transition arc surface, and multi-layer annular cooling fins 18 are arranged on the outer surface of the side wall of the inner cylinder 3 of the tank. The inner cylinder 3 and the outer cylinder 2 are connected through the annular cover plate 10 at the upper opening end, the lower end of the inner cylinder 3 is connected to the upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com