Composite tube type heat exchanger built from close annular fins

A finned tube heat exchanger technology, applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of large space occupied by the system, waste of steel, large volume of the whole machine, etc., and achieve small occupied space , convenient installation and transportation, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

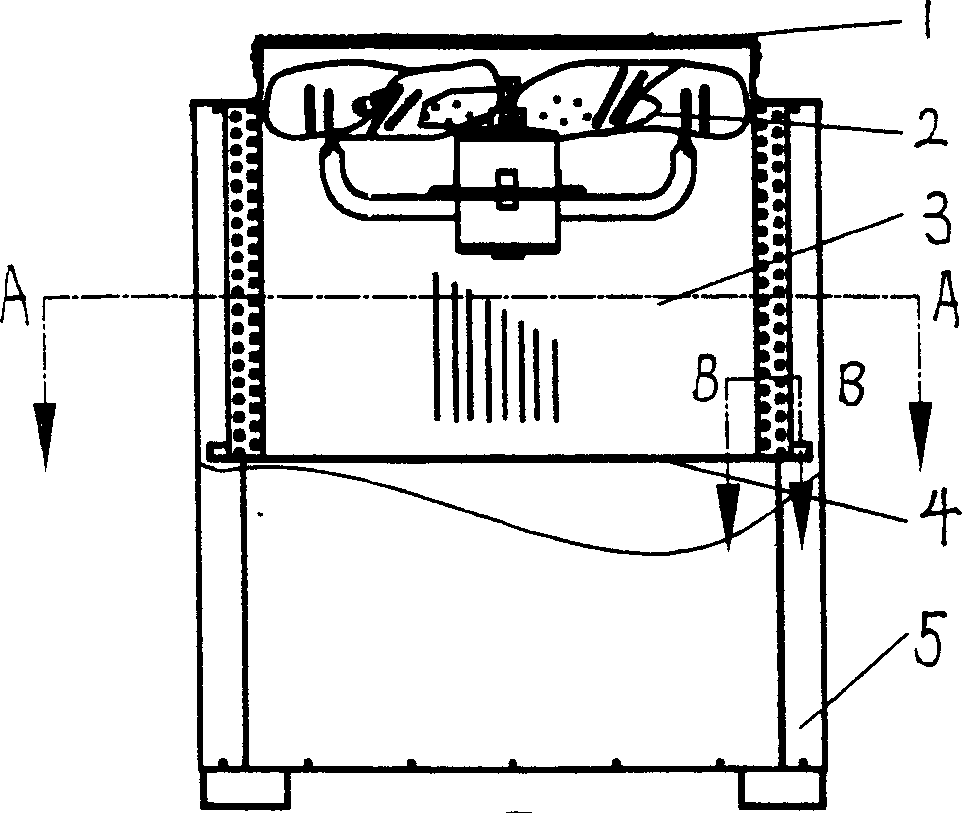

[0015] Such as figure 1 As shown, the sealing baffle 4 is installed in the middle of the column 5, the annular heat exchanger 3 is installed on the upper end surface of the sealing support plate 4, and the fan 2 and the net cover 1 are installed on the top of the column 5.

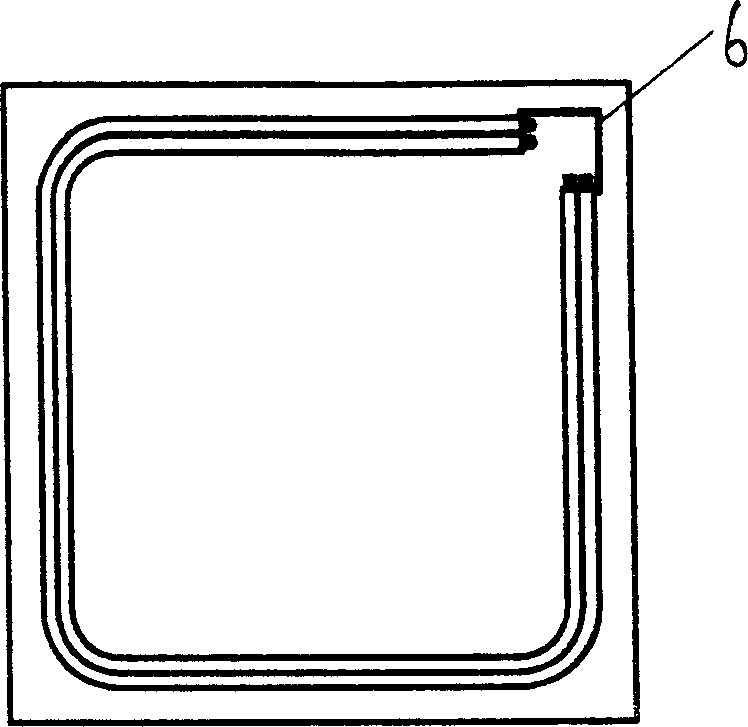

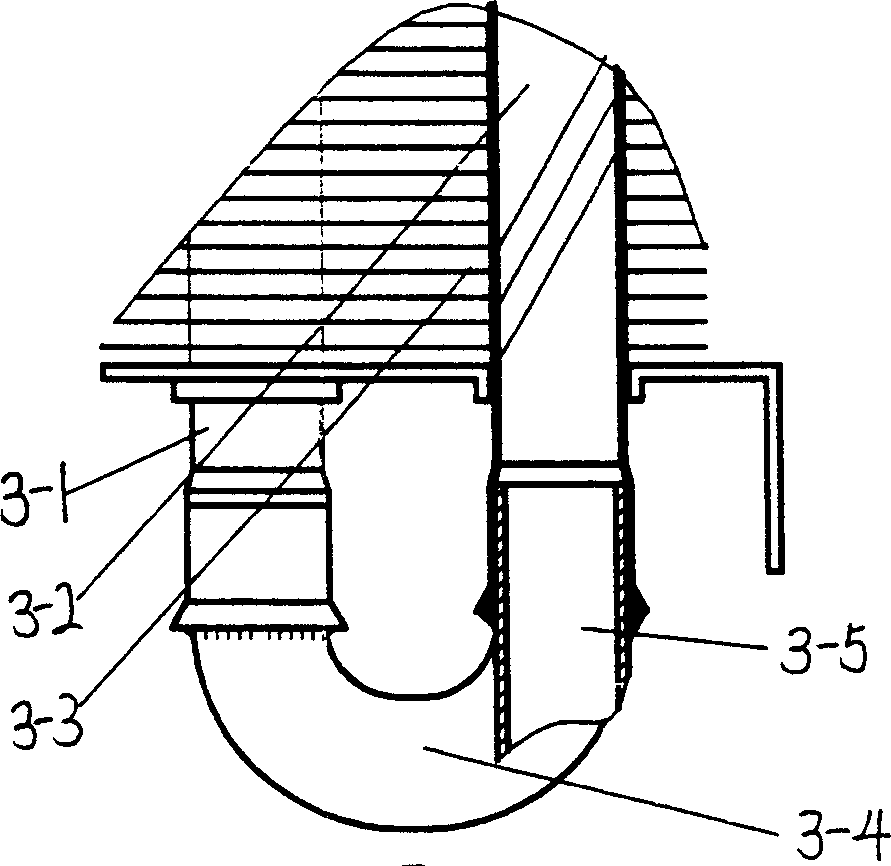

[0016] Such as figure 1 , figure 2 , image 3 As shown, the heat exchanger 3 is composed of a group of G-shaped or two or more groups of L-shaped or U-shaped or other structural heat exchangers and connecting plates 6, 7, 8 combined. Closed annular finned tube heat exchanger, the lower part is sealed, and the upper part is equipped with a condensing fan 2 and a net cover 1 for air guidance. The airflow generated only passes through the middle of the gap between the fins 3-3. The system makes full use of the surrounding ventilation space in the smallest peripheral volume state. The airflow flows evenly through the finned tube heat exchanger, maximizing the heat exchange area and realizing the unit Desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com