Hydraulic test sealing structure of pressure container and mounting and use method of hydraulic test sealing structure

A hydrostatic test and pressure vessel technology, applied to pressure vessels, using stable tension/pressure to test material strength, fixed-capacity gas storage tanks, etc., can solve the problems of no pressure test channel structure design cases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

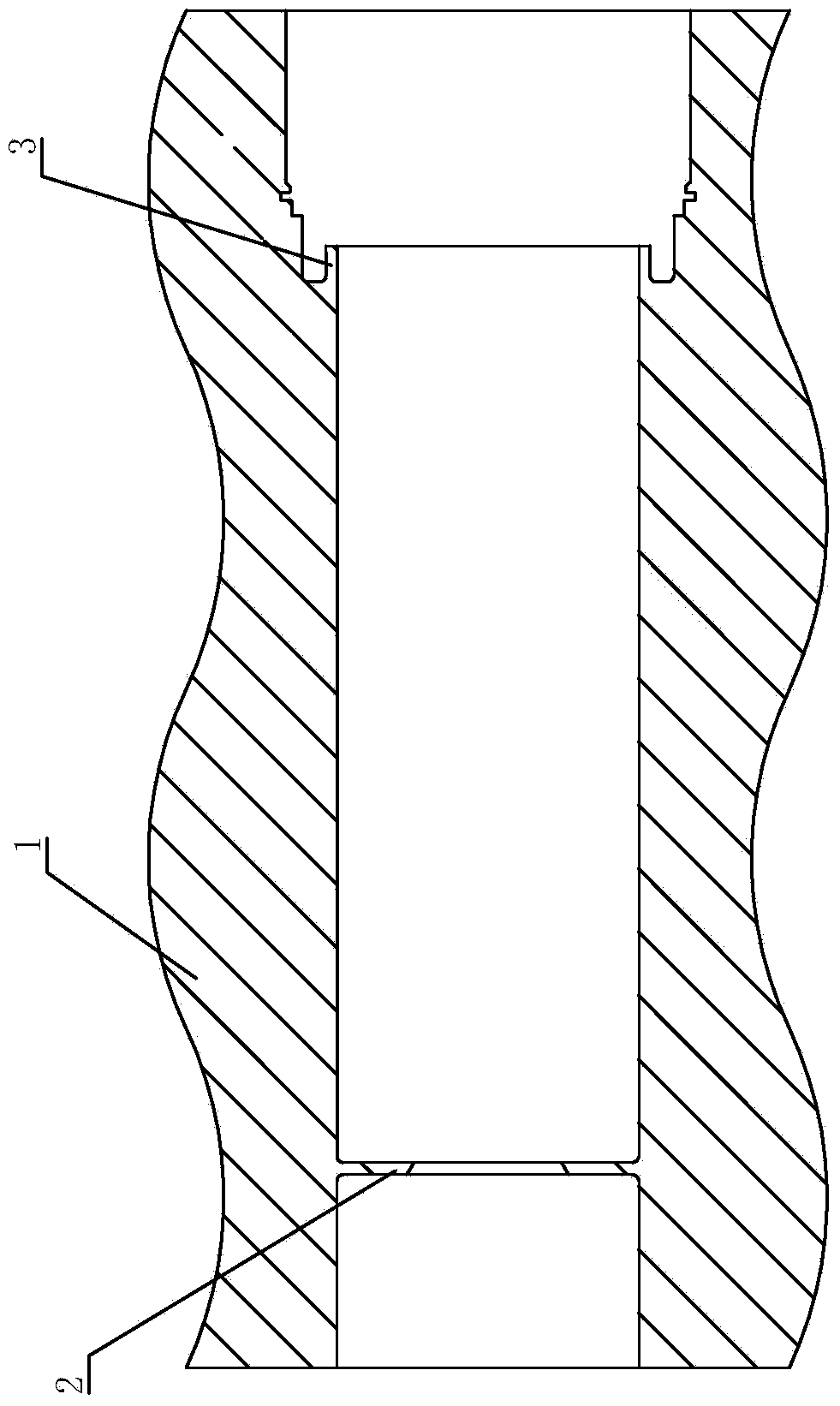

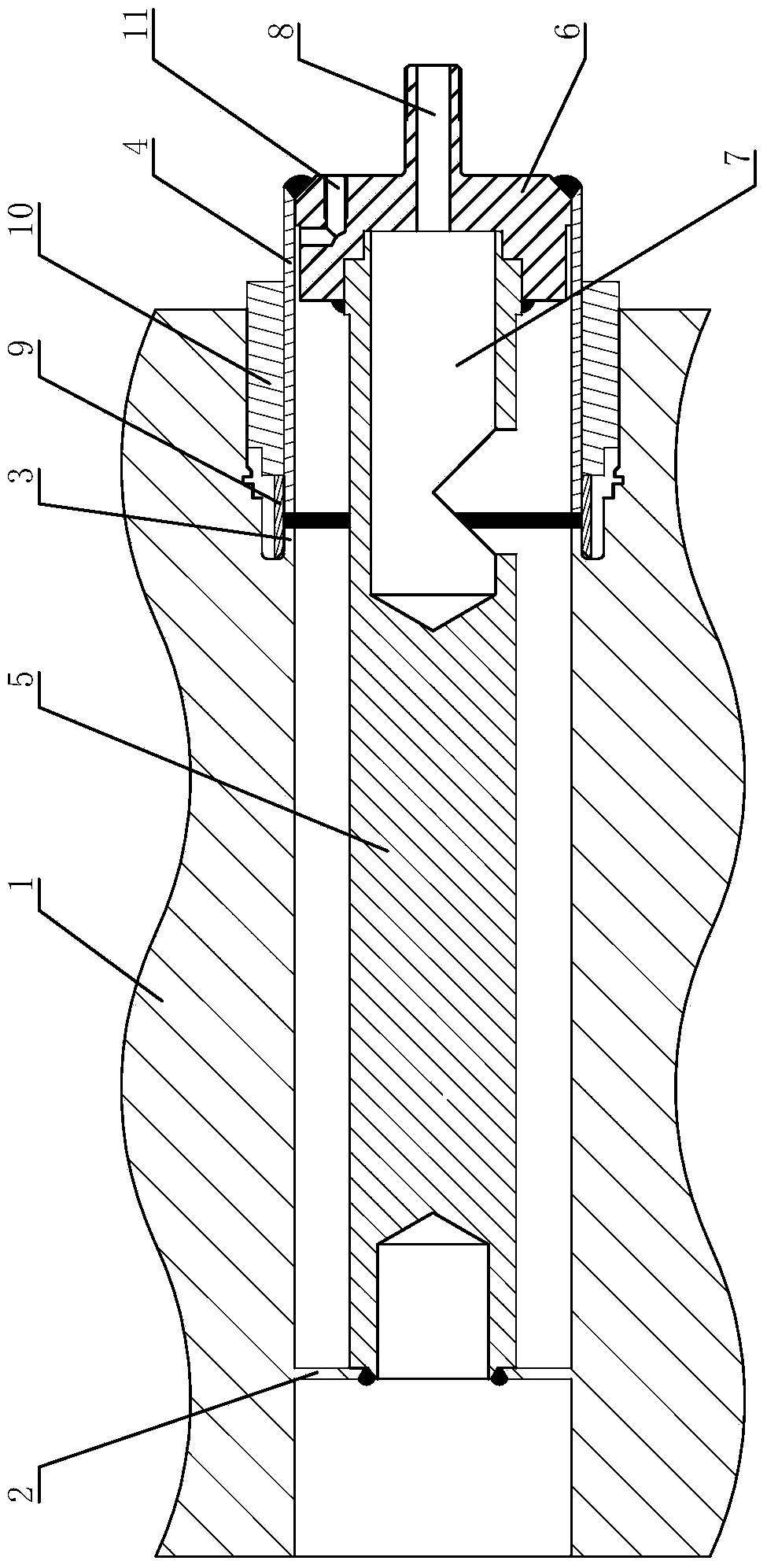

[0030] like figure 2 The hydraulic test sealing structure of the pressure vessel includes a vessel body 1 with a cylindrical inner cavity. A 3.75 mm thick annular groove thin wall 3 is provided on the rear side of the cylindrical inner chamber, and a hydraulic connection pipe 4 is sealed and welded at the rear end of the thin wall 3 . The welding seal between the hydraulic joint 4 and the thin wall 3 is because the hydraulic test seal at the thin wall 3 cannot be realized by mechanical sealing; and the original design function of the thin wall 3 is to connect and weld Water pipes are used. The thin wall 3 has reserved a certain length margin in the previous processing, which is used for the welding water crimping pipe 4 in the hydraulic test. The welding of the hydraulic connection pipe 4 and the thin wall 3 is realized by using an automatic TIG welding machine that can rotate around the axis.

[0031] The front side of the cylindrical inner cavity is provided with a 4mm t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com