Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Affect operability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

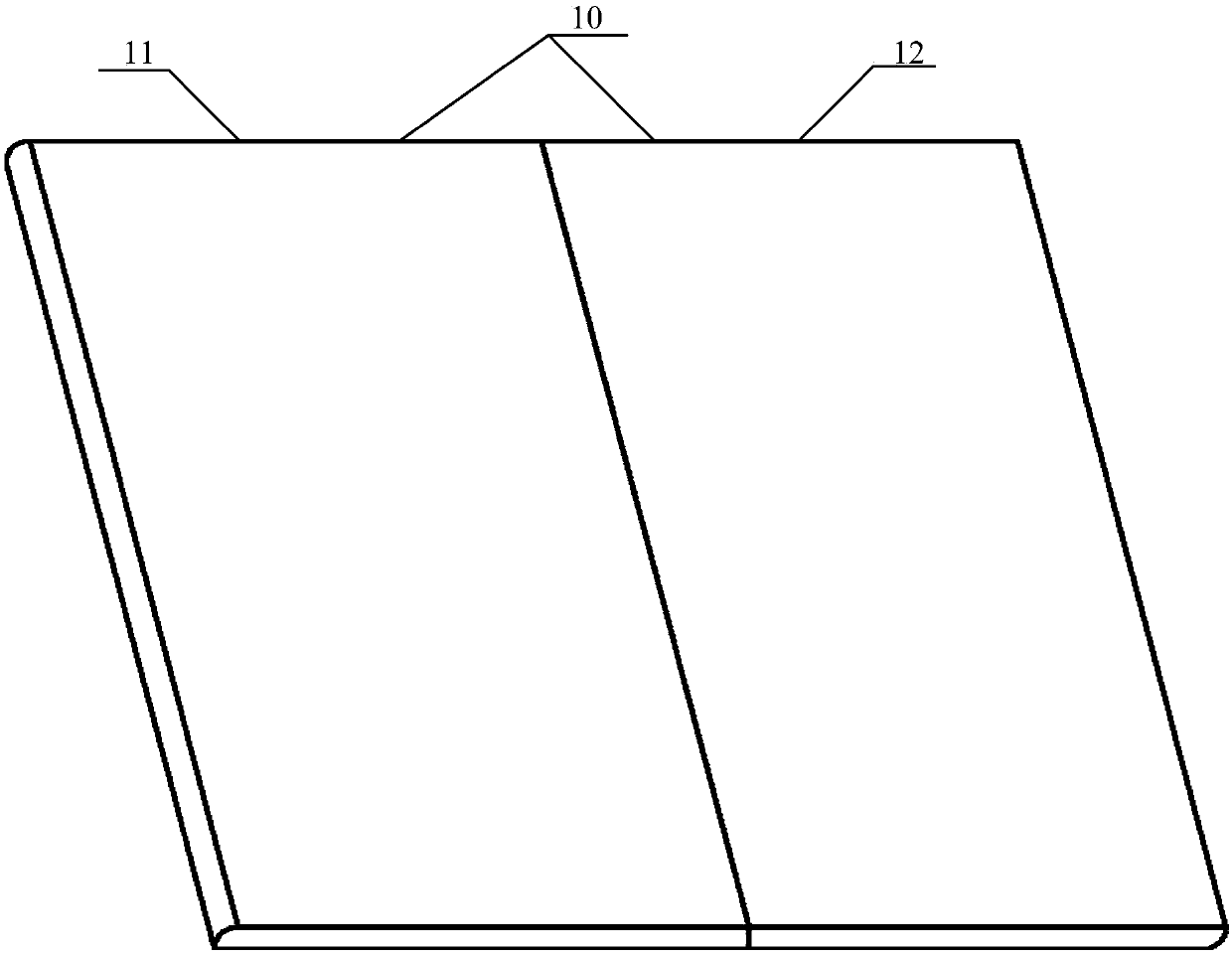

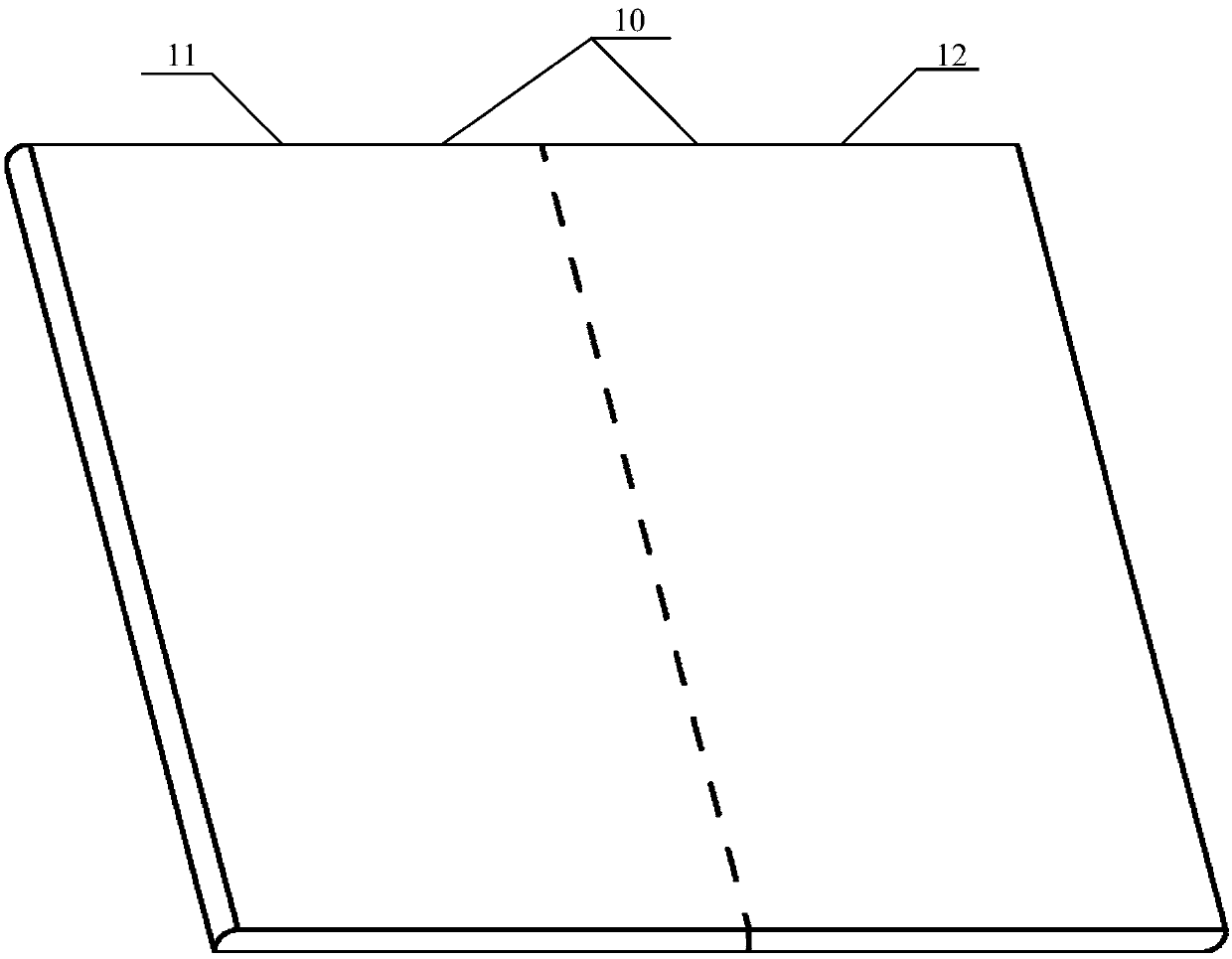

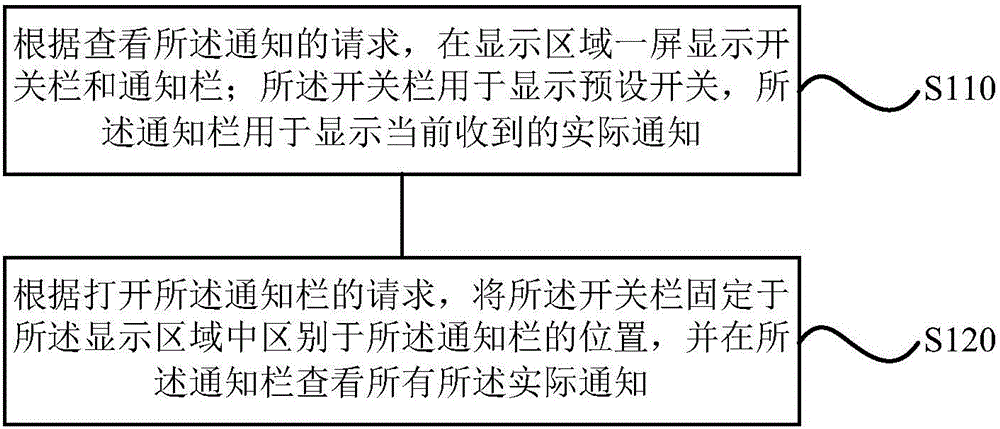

Shortcut operation panel display method and device and a storage medium

PendingCN109656439AImpact viewAffect operabilityDigital data processing detailsInput/output processes for data processingSoftware engineeringHome screen

The invention relates to a shortcut operation panel display method and device and a storage medium, and belongs to the technical field of terminals. The method comprises the steps of displaying a userinterface of a target application program in a main screen; And when the auxiliary screen is in the unfolded state, displaying a shortcut operation panel in the auxiliary screen, the shortcut operation panel comprising an icon of at least one shortcut operation function related to the target application program. The invention provides a display scheme of a shortcut operation panel for a terminalwith a folding display screen, when an auxiliary screen is in an unfolded state, a user interface of a target application program is displayed in a main screen, and the shortcut operation panel is displayed in the auxiliary screen; Due to the fact that the shortcut operation panel is displayed in the auxiliary screen, the display content in the main screen cannot be shielded, and the influence onviewing and operation of the display content in the main screen by a user is avoided.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

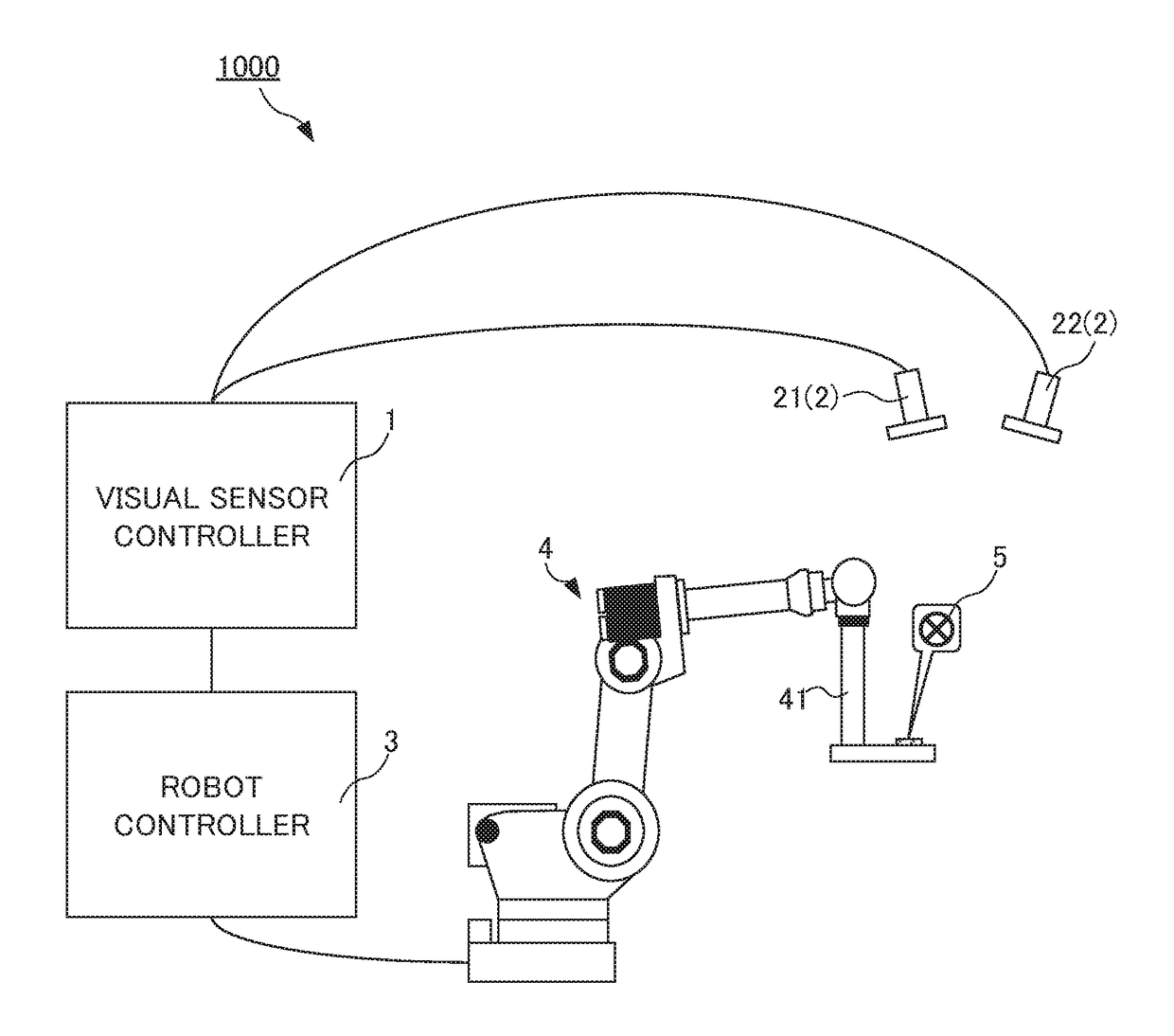

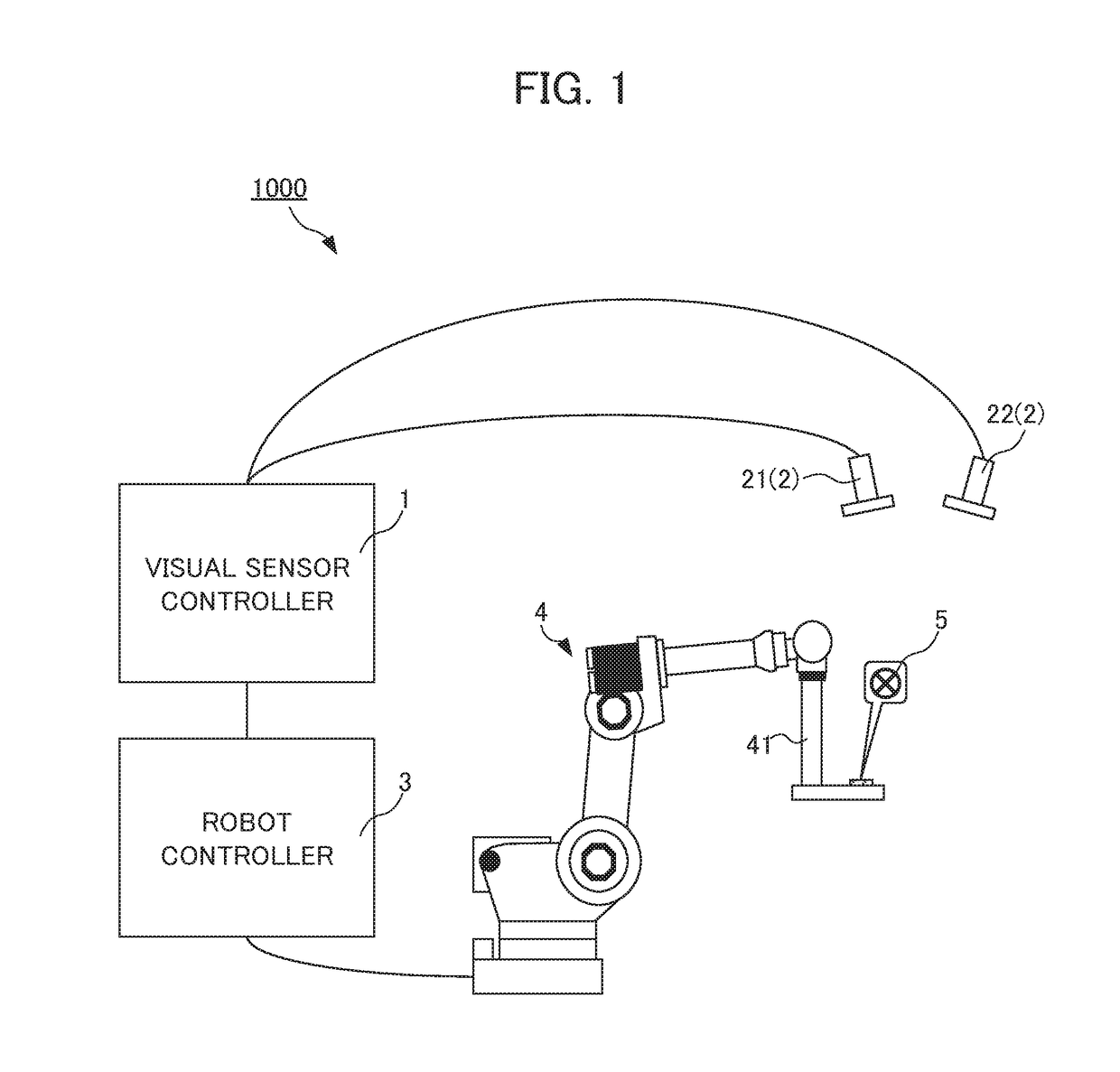

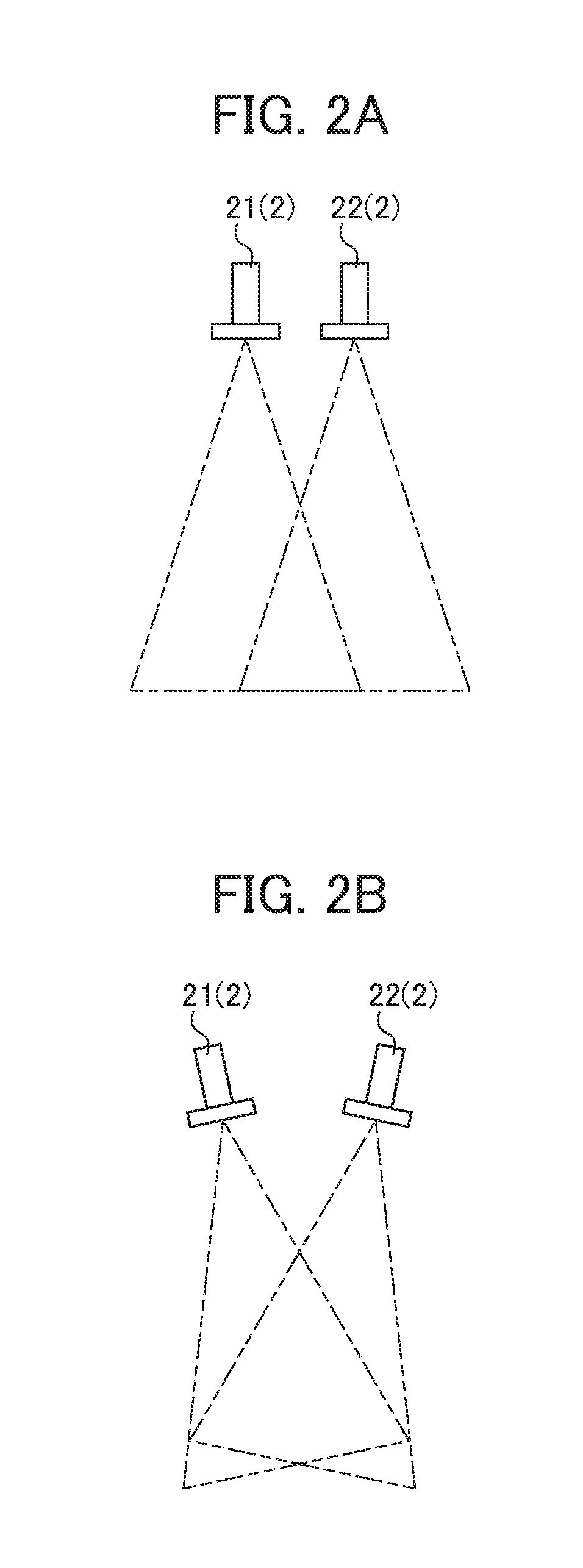

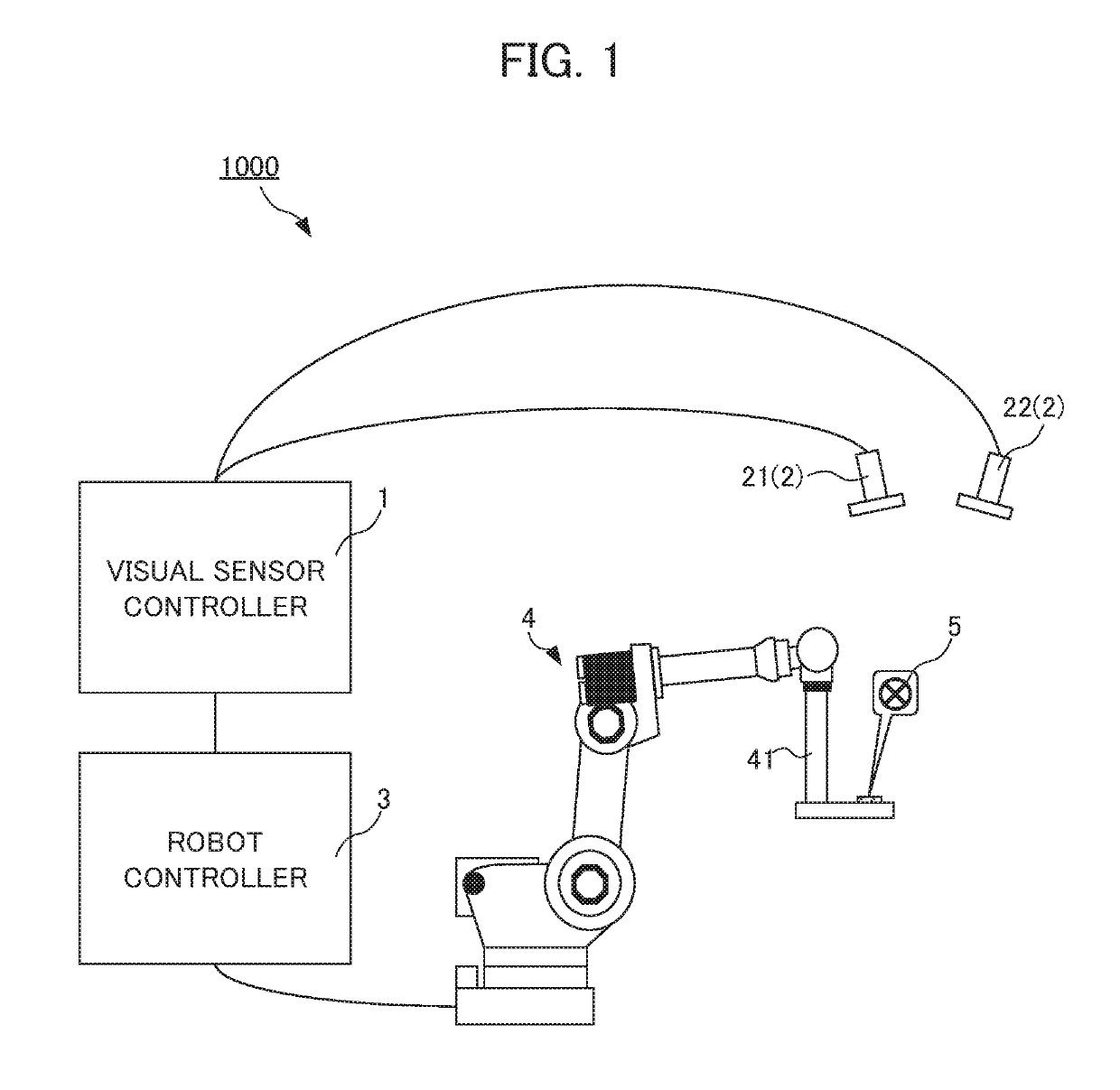

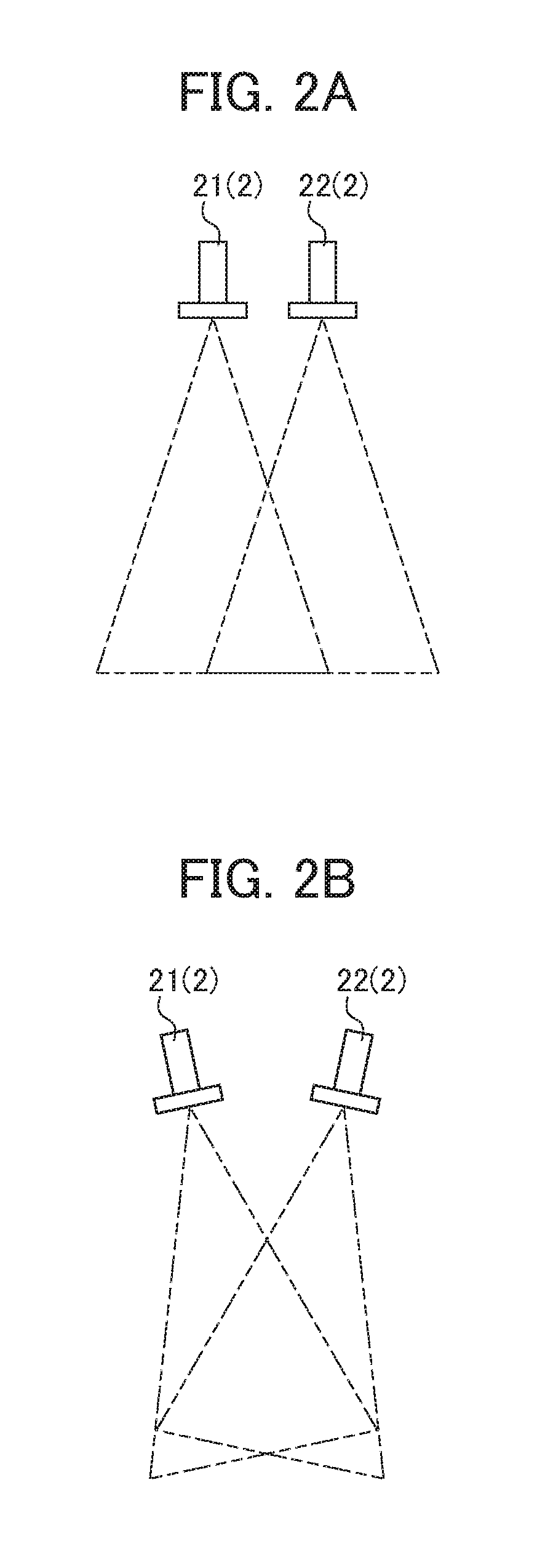

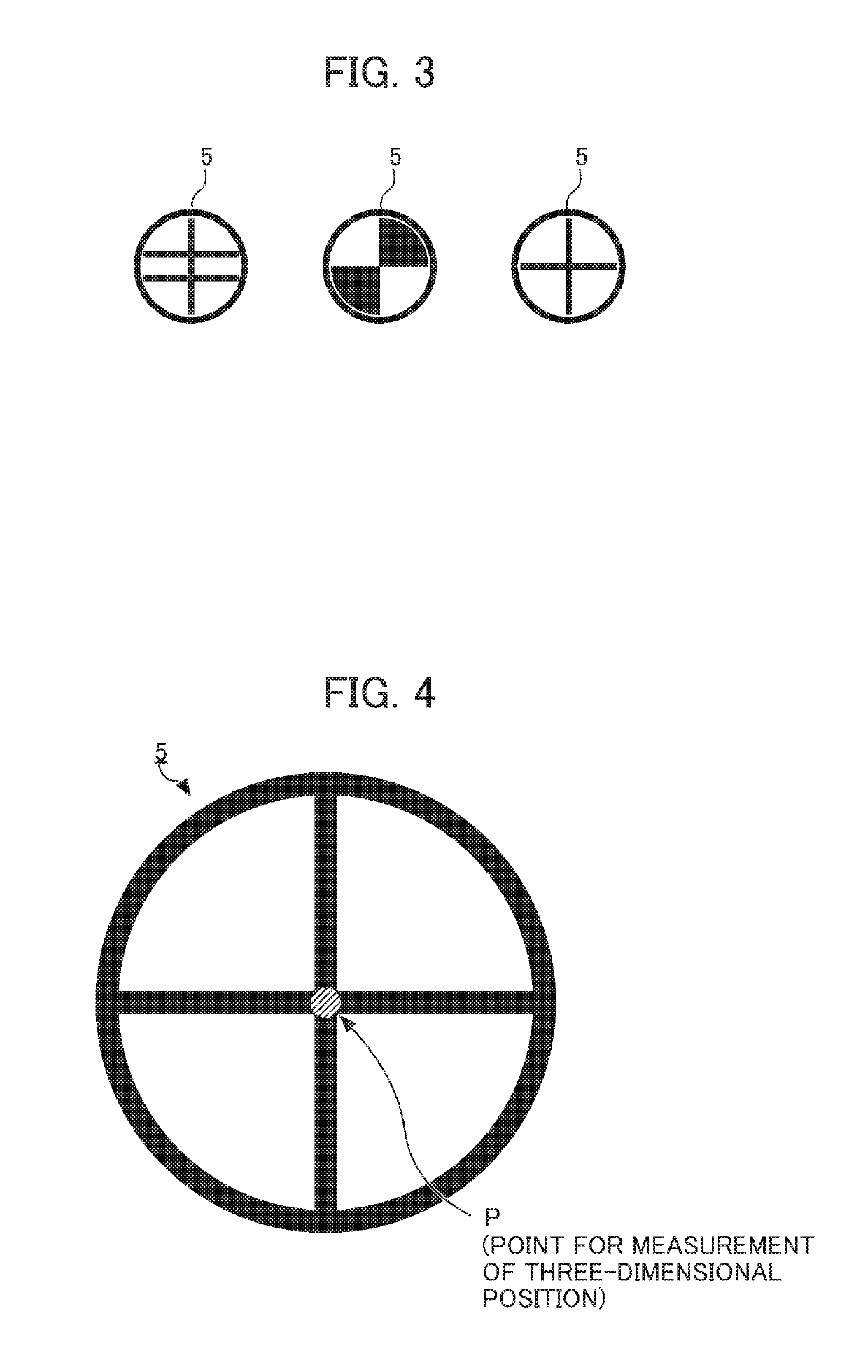

Calibration device, calibration method, and computer readable medium for visual sensor

ActiveUS20180194007A1Eliminate generationAffect operabilityImage enhancementProgramme-controlled manipulatorStereo cameraVision sensor

A parameter for detecting a target mark 5 is not required to be set for each camera repeatedly while a stereo camera 2 is calibrated. A calibration device 1 associates position information in an image coordinate system at a first camera 21 of a stereo camera 2, position information in an image coordinate system at a second camera 22 of the stereo camera 2, and position information in a robot coordinate system at a robot 4. The calibration device comprises: first parameter setting unit 102 that sets a first parameter for detecting a target mark 5 attached to the robot 4 from data about an image captured by the first camera 21; and a second parameter setting unit 104 that sets a second parameter for detecting the target mark 5 from data about an image captured by the second camera 22 based on the first parameter.

Owner:FANUC LTD

Treatment method for saline wastewater

InactiveCN103408191ASimple processReliable and efficient processMultistage water/sewage treatmentVaporizationTherapeutic effect

The invention discloses a treatment method for saline wastewater. The treatment method comprises the steps as follows: introducing saline wastewater into a regulation tank, and regulating the pH value to 7.5-9.5; adding salt-tolerant compound bacteria to a water body, performing a primary anaerobic biochemical reaction, damaging the structures of organic substances in the saline wastewater, and degrading partial organic substances; continuously introducing the water body into a reaction tank, regulating the pH value to 7-9, adding the salt-tolerant compound bacteria, and performing an aerobic reaction; performing MVR mechanical vaporization subjected to the reaction to the water body, and then leading out the water body from the reaction tank for recovering and standby. The treatment method adopts specific sequential process degradation steps in order, not only has a very good treatment effect, but also is simple in each individual treatment step, is convenient to operate and easy to implement, and does not generate extra hazardous solid waste.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

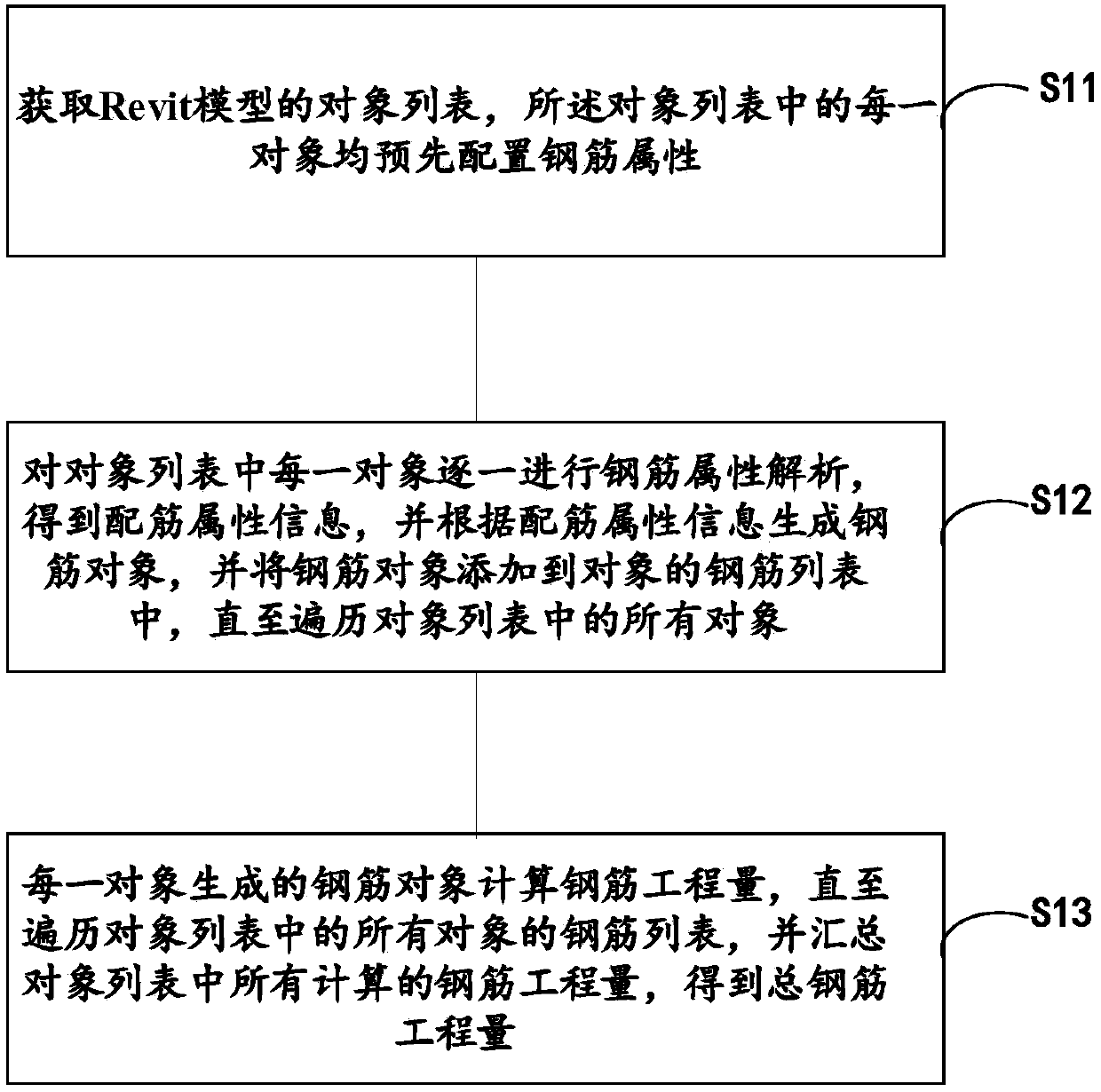

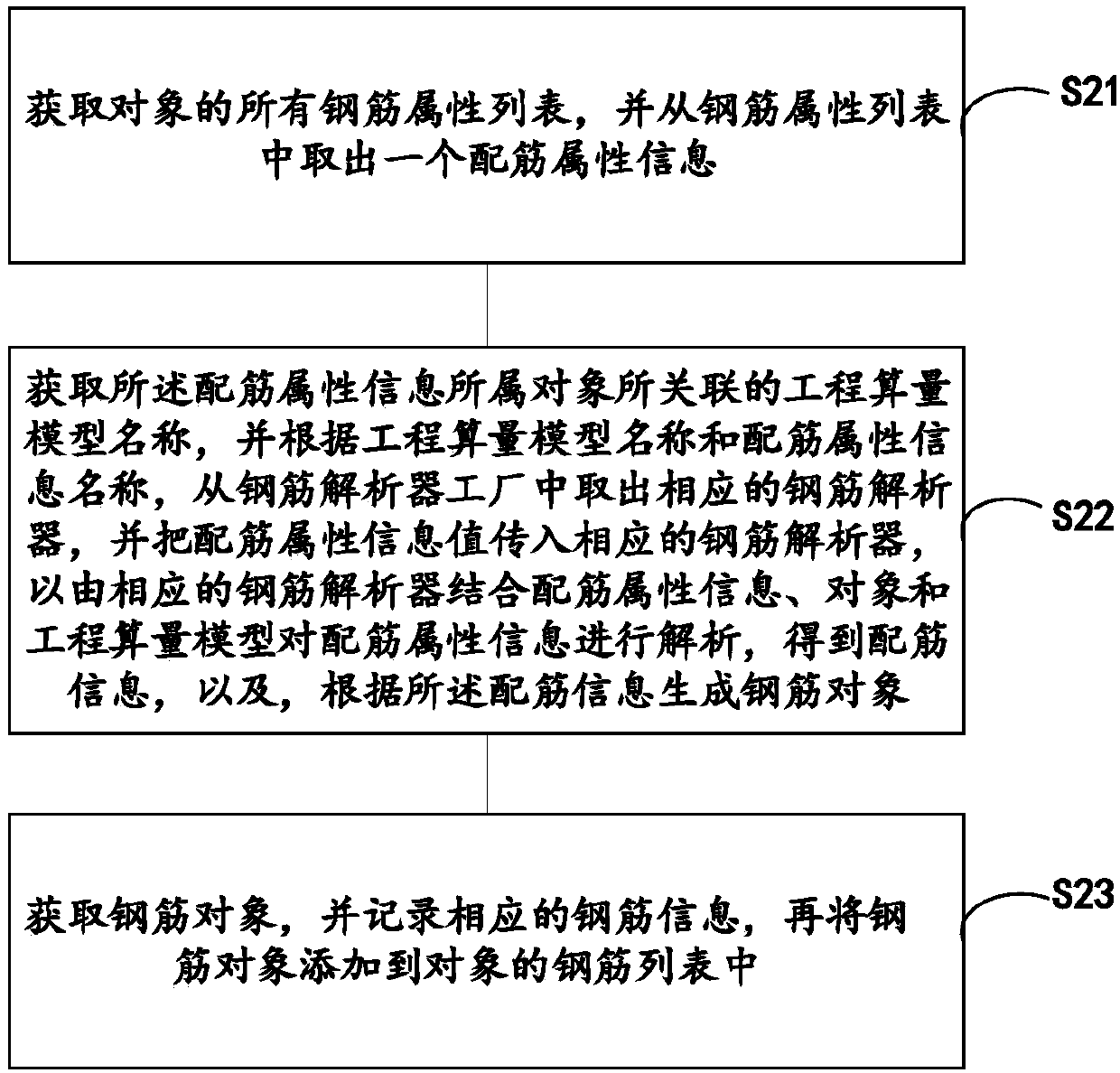

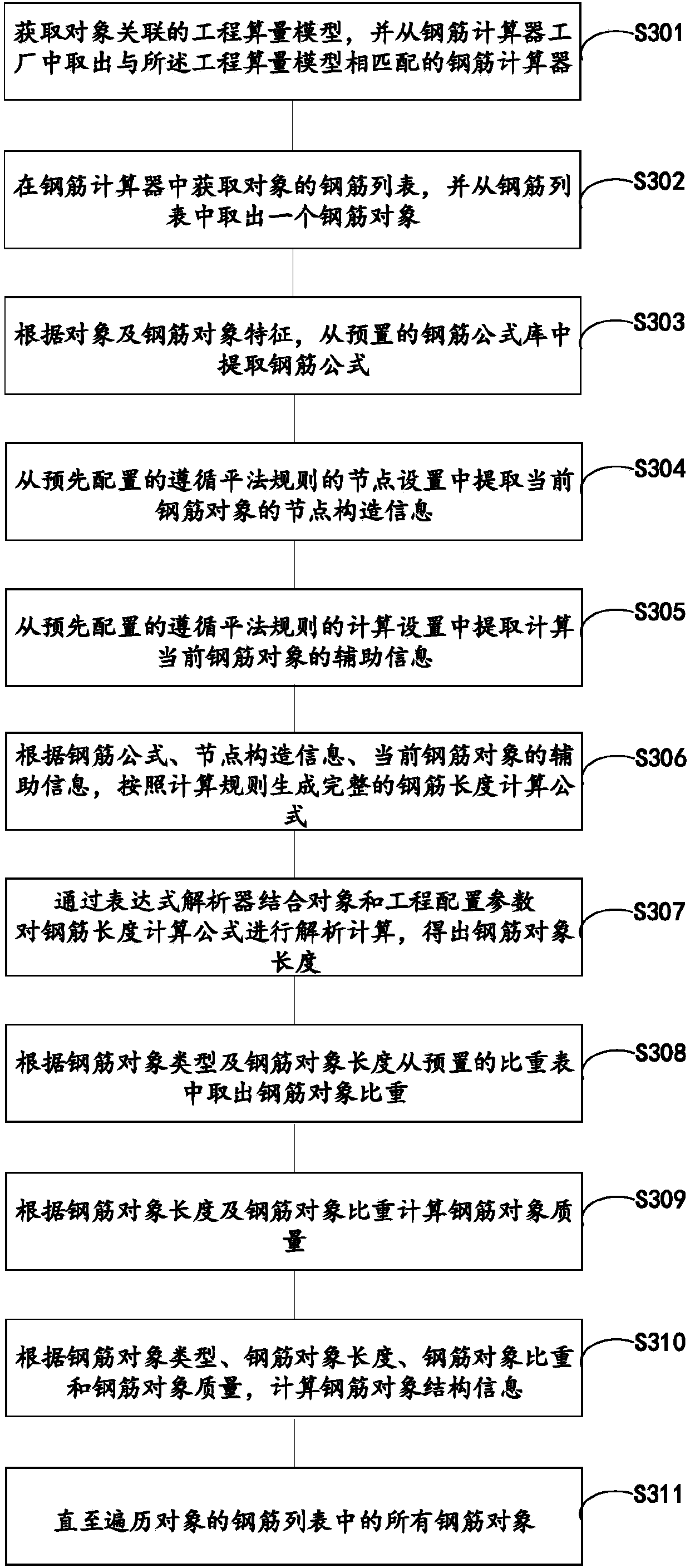

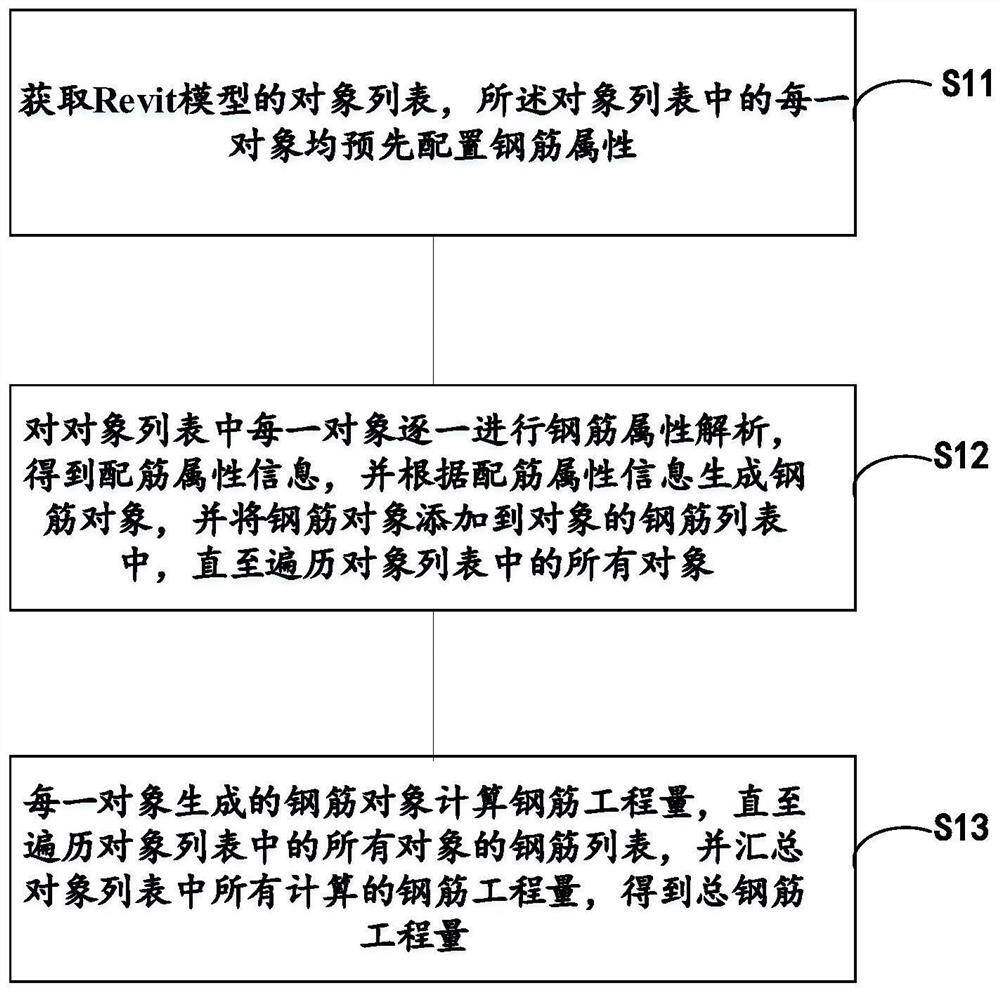

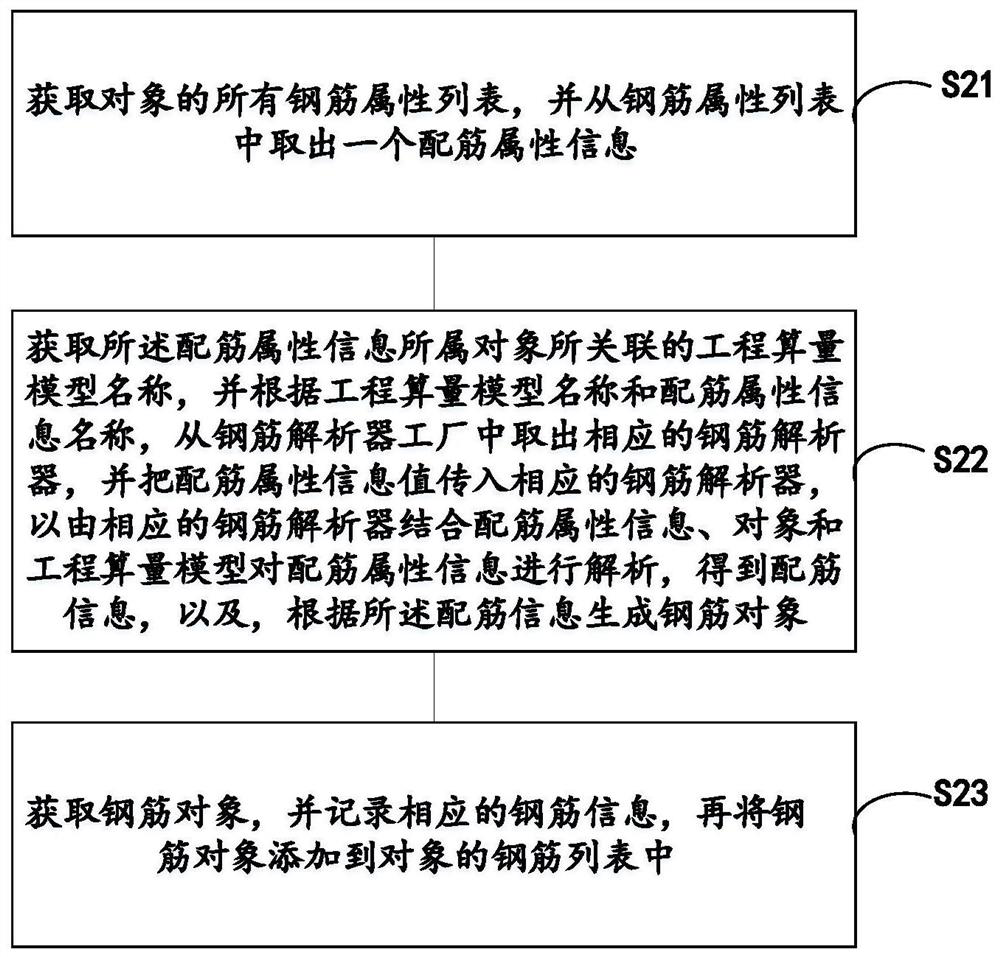

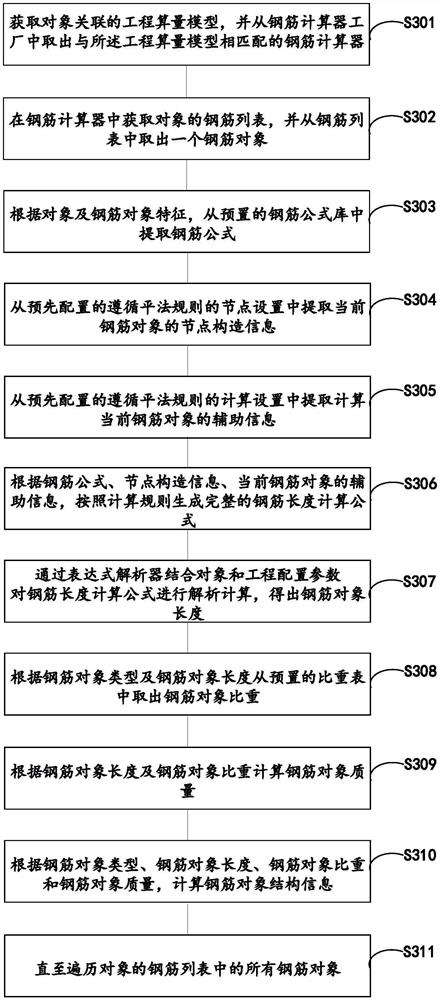

Revit-based steel bar calculation method and device, terminal device and medium

ActiveCN107944187AAffect operabilityEfficient computingGeometric CADDesign optimisation/simulationRebarTerminal equipment

The invention discloses a Revit-based steel bar calculation method and device, a terminal device and a medium. Steel bar property of each object in an object list of a Revit model can be analyzed, toobtain reinforcement attribute information; steel bar objects are generated according to the reinforcement attribute information, the steel bar engineering quantity is calculated for each steel bar object generated by each object until a steel bar list of all the objects in the object list is traversed, all calculated steel bar engineering quantity in the object list is summarized, and the total steel bar engineering quantity is obtained. That is, according to the technical scheme, a user only needs to configure the steel bar attribute information for the object that needs to calculate the steel bar engineering quantity in a structural model without the need to establish a steel bar model in Revit, no model data is added into existing Revit files in the whole calculation process, and the problem that due to the adding of plenty of steel bar model data, the mass of the Revit model is greatly increased, so that the operation performance of Revit is affected is solved.

Owner:XIAMEN HYMAKE TECH

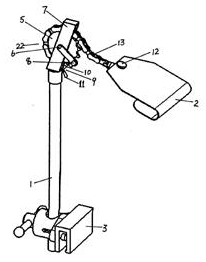

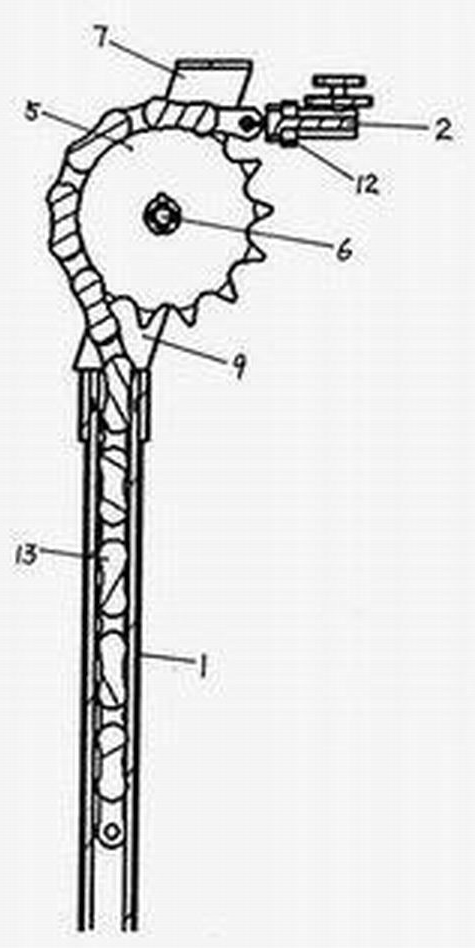

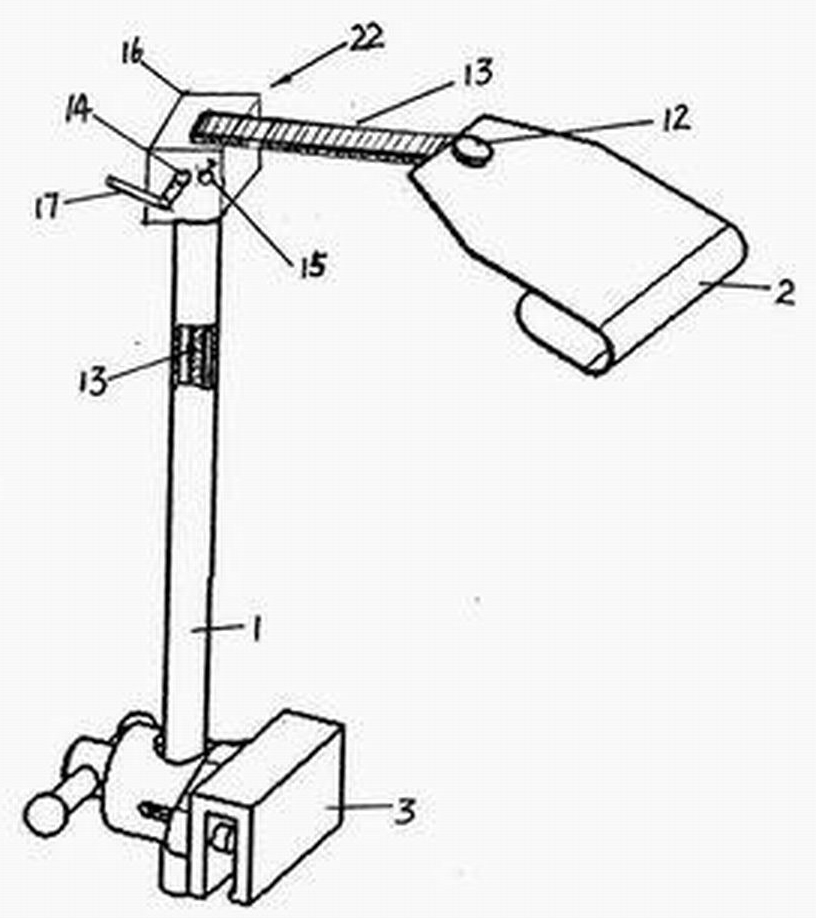

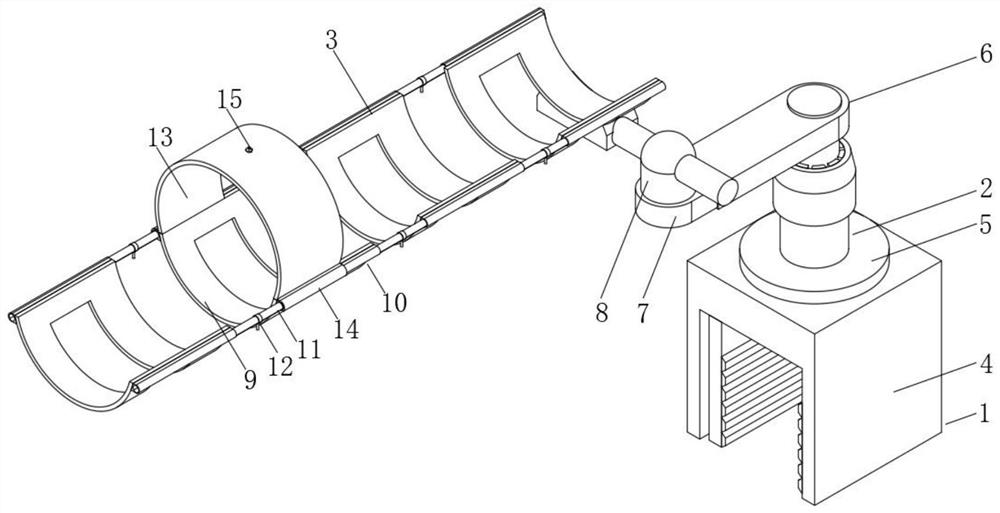

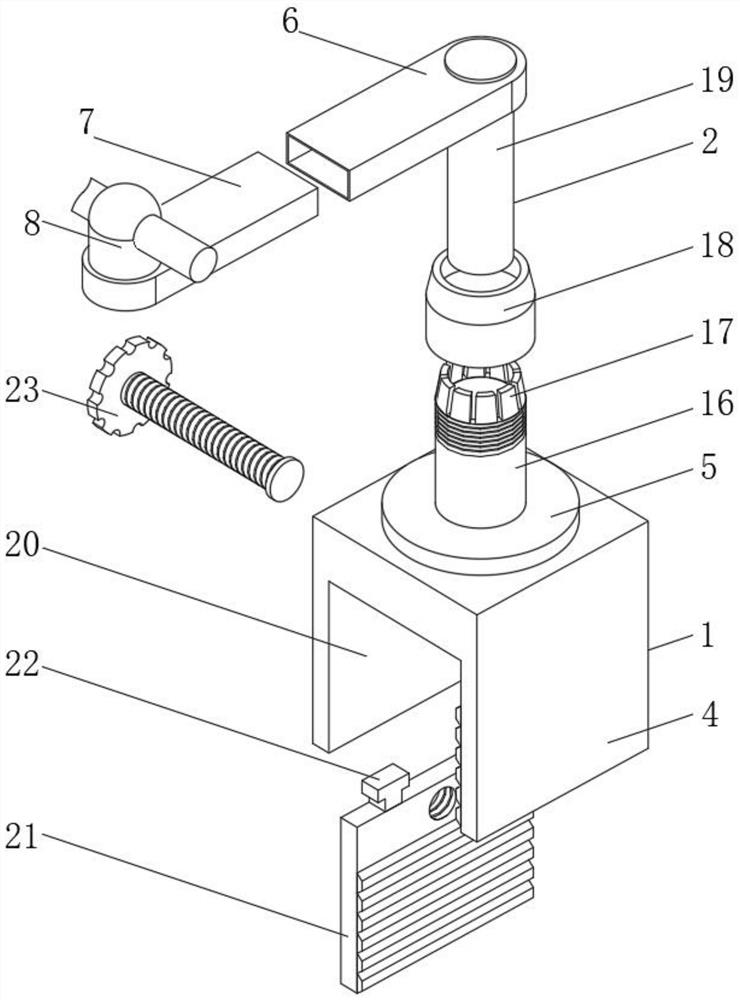

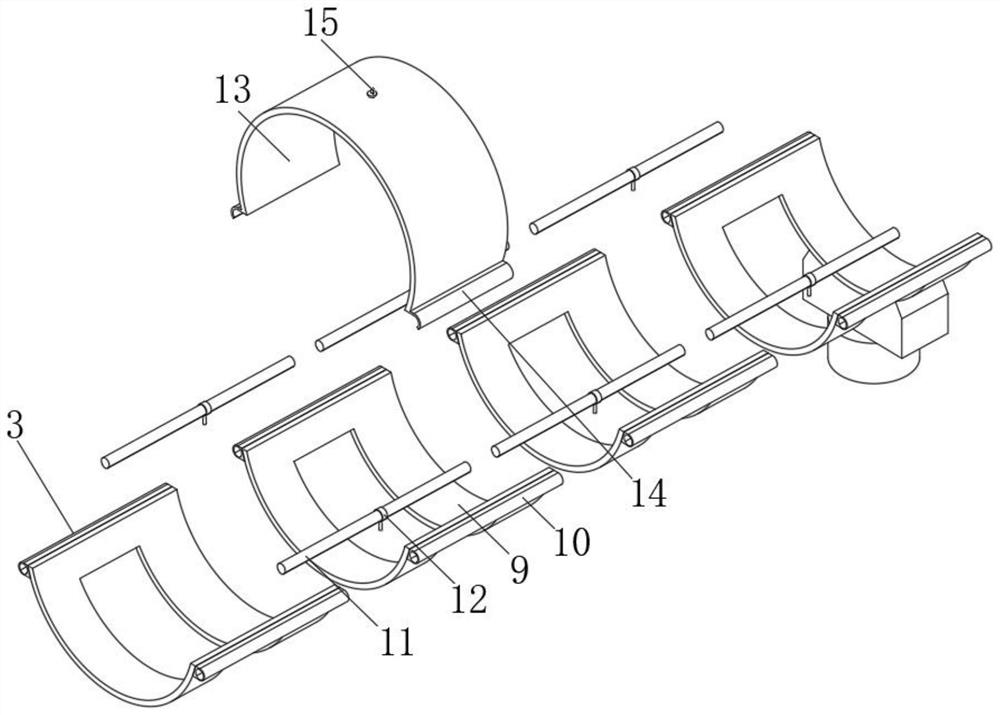

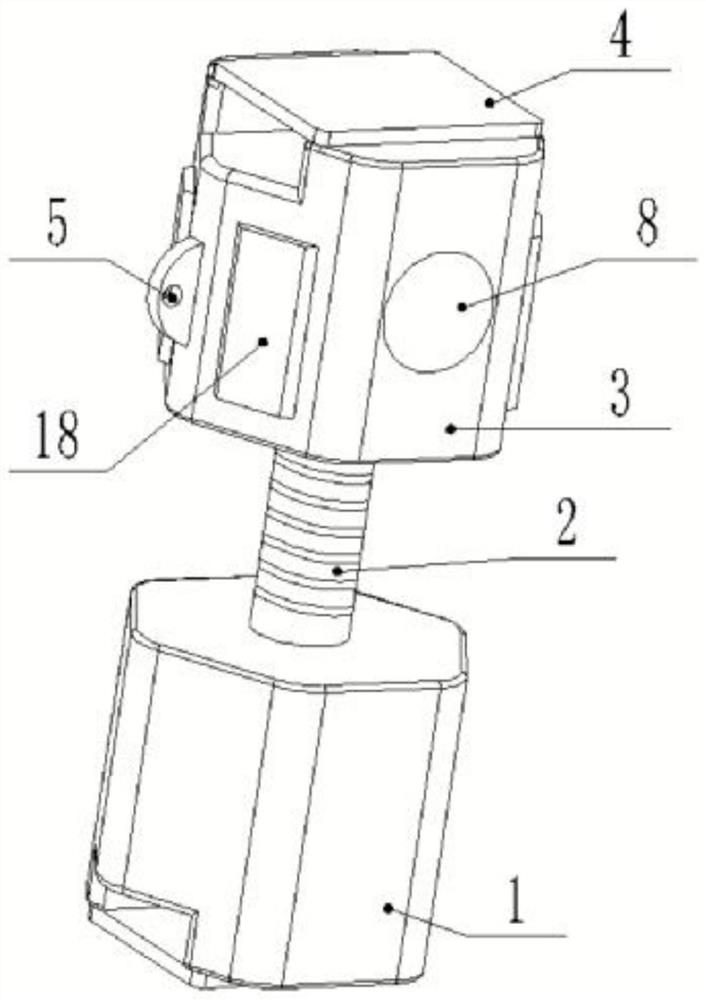

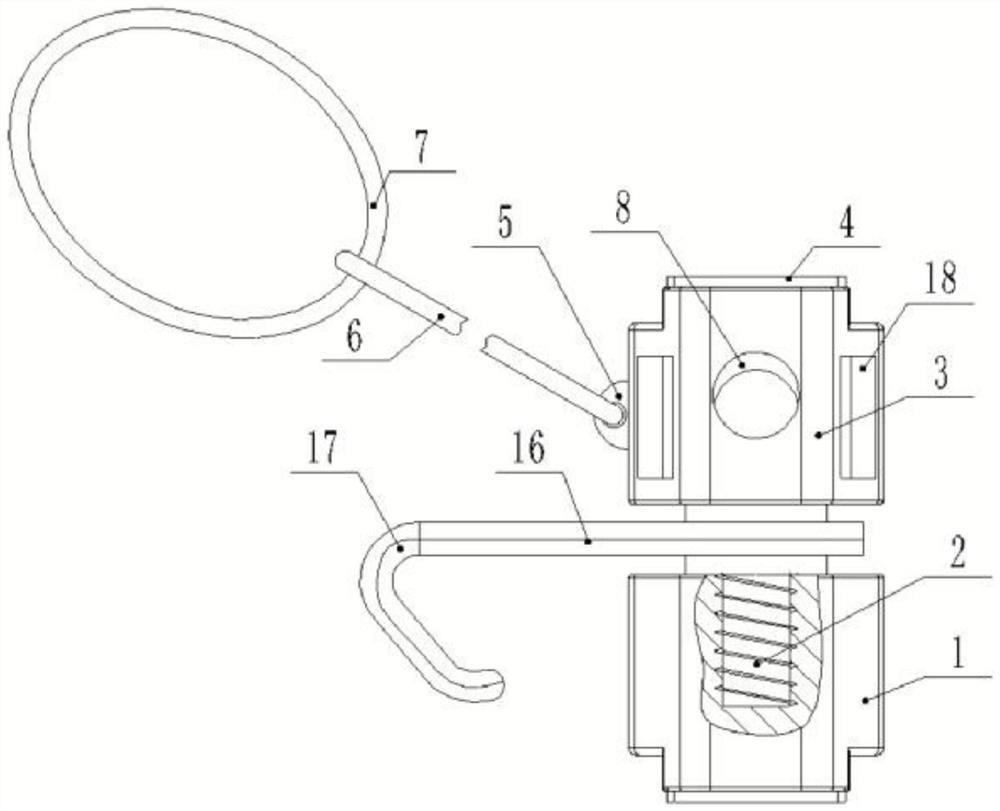

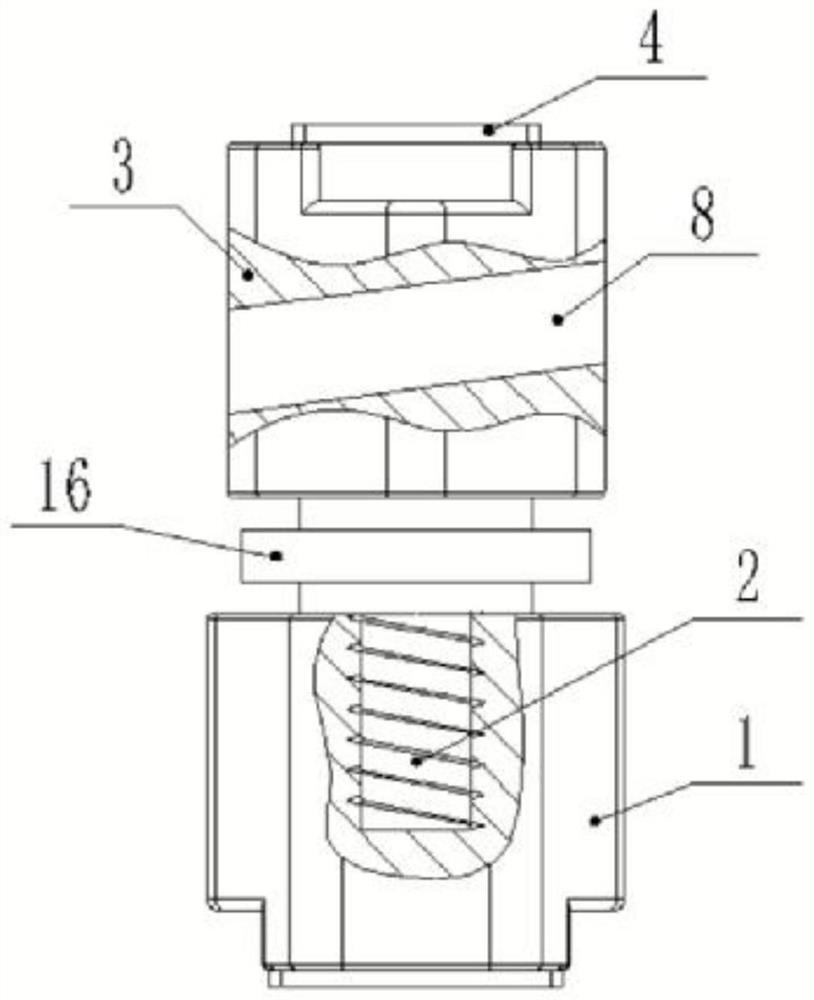

Operation retractor with draw-off chain rope

The invention discloses an operation retractor with a draw-off chain rope, comprising a stand column (1) and a hook plate (2), wherein the stand column (1) is in a fixed structure or a liftable structure; the stand column (1) is directly connected with an operating bed or is connected with the operating bed through a fixed mount (3). The operation retractor is characterized in that the hook plate (2) is connected with one end of the draw-off chain rope (13), the other end of the draw-off chain rope (13) stretches into the cavity of the stand column (1) through a driving device (22) installed on the stand column (1). The invention has simple structure, small volume, no occupied space except the operating bed and good operation field of view, can randomly move on the side of the operating bed according to demands, and can be used for retraction of operation incisions at any part of human trunk.

Owner:JIANGSU HAIZE MEDICAL TECH DEV

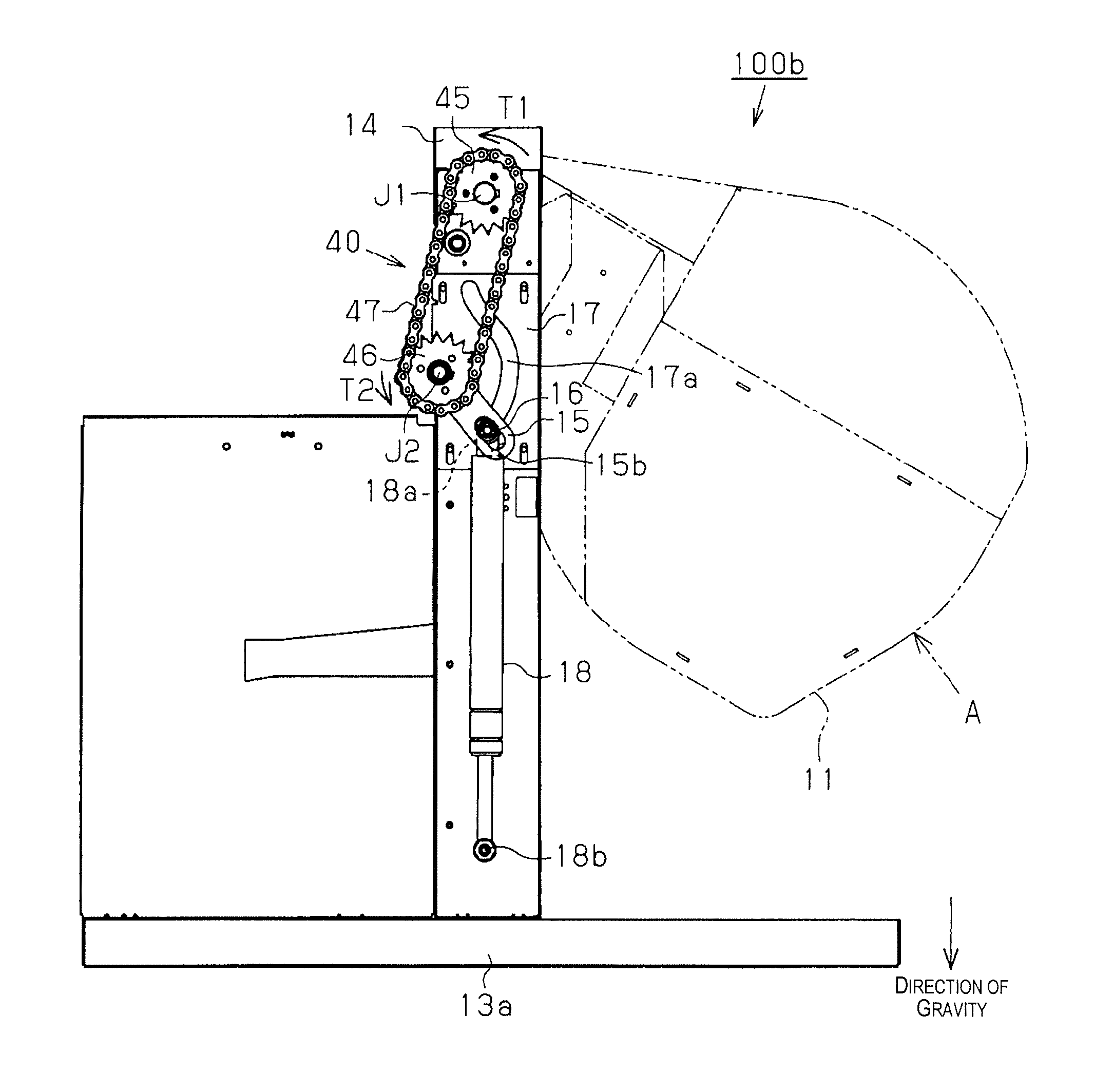

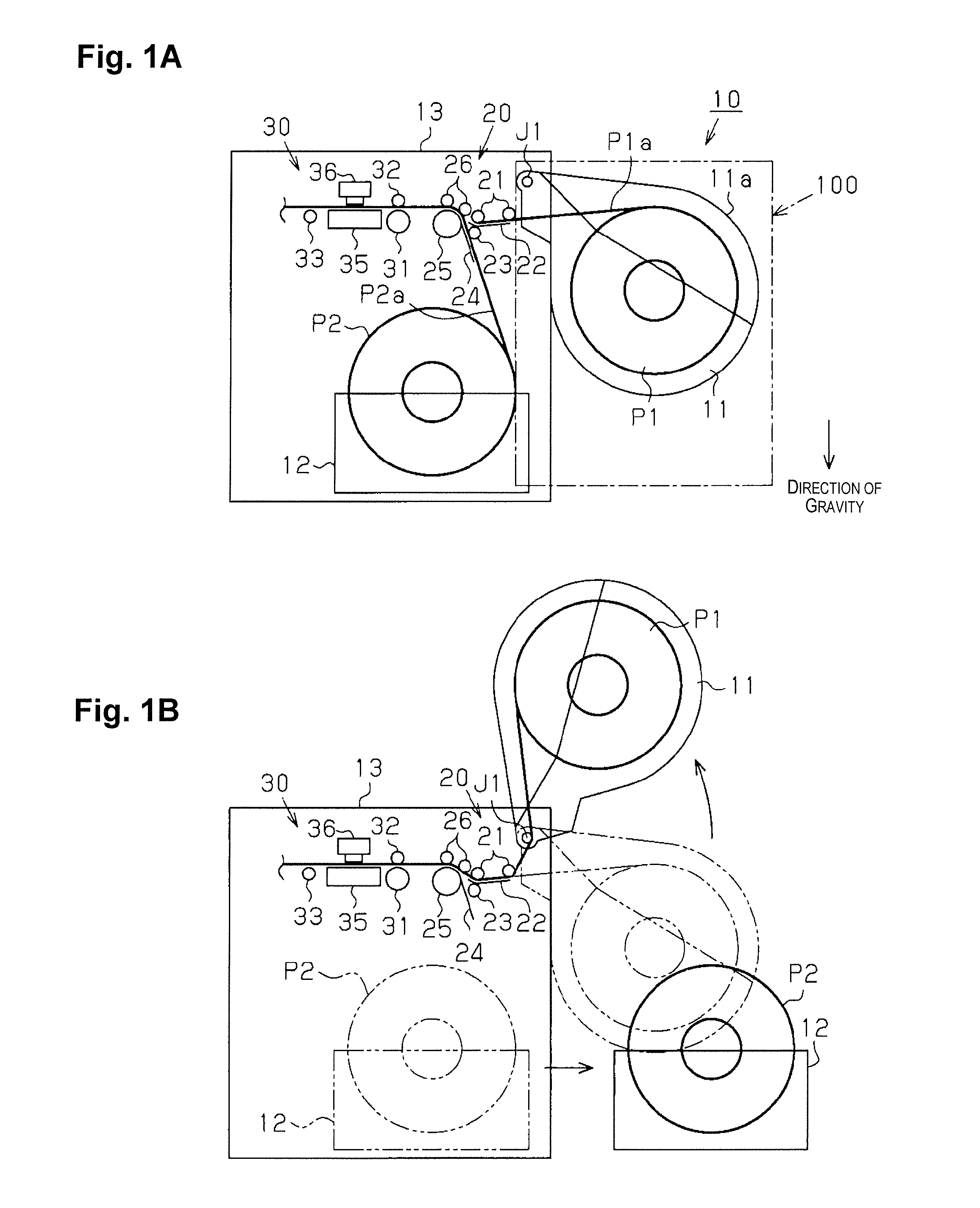

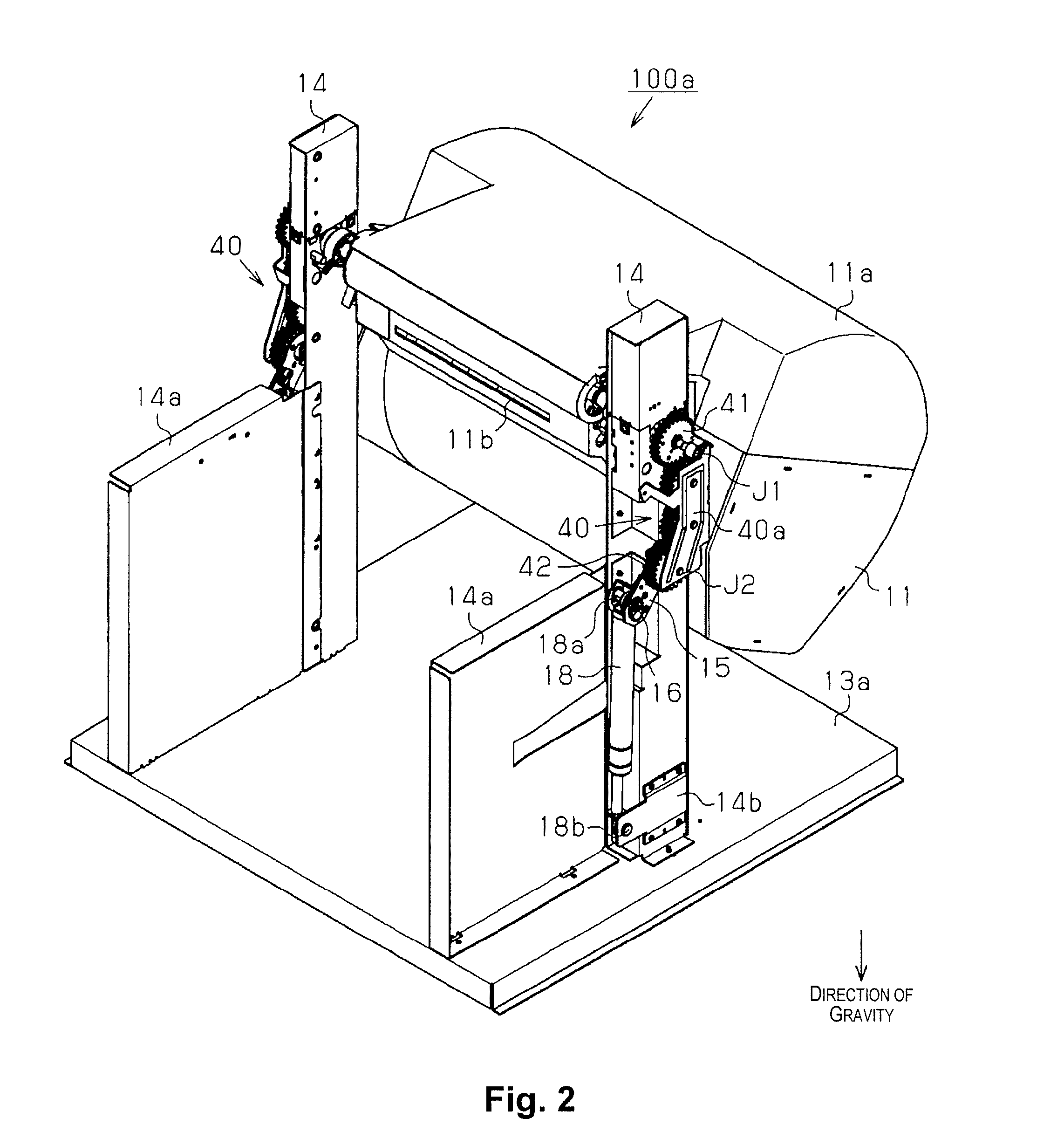

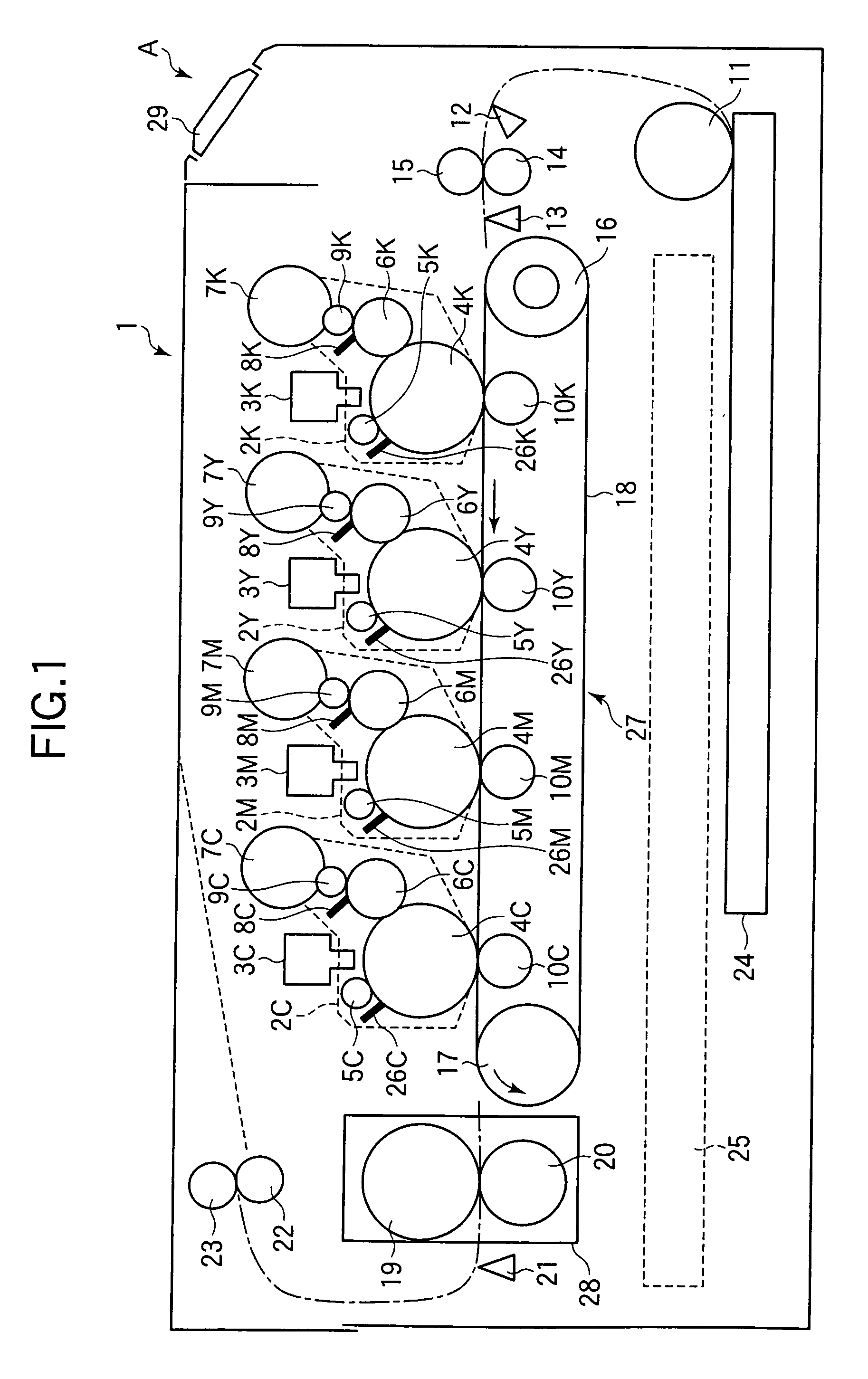

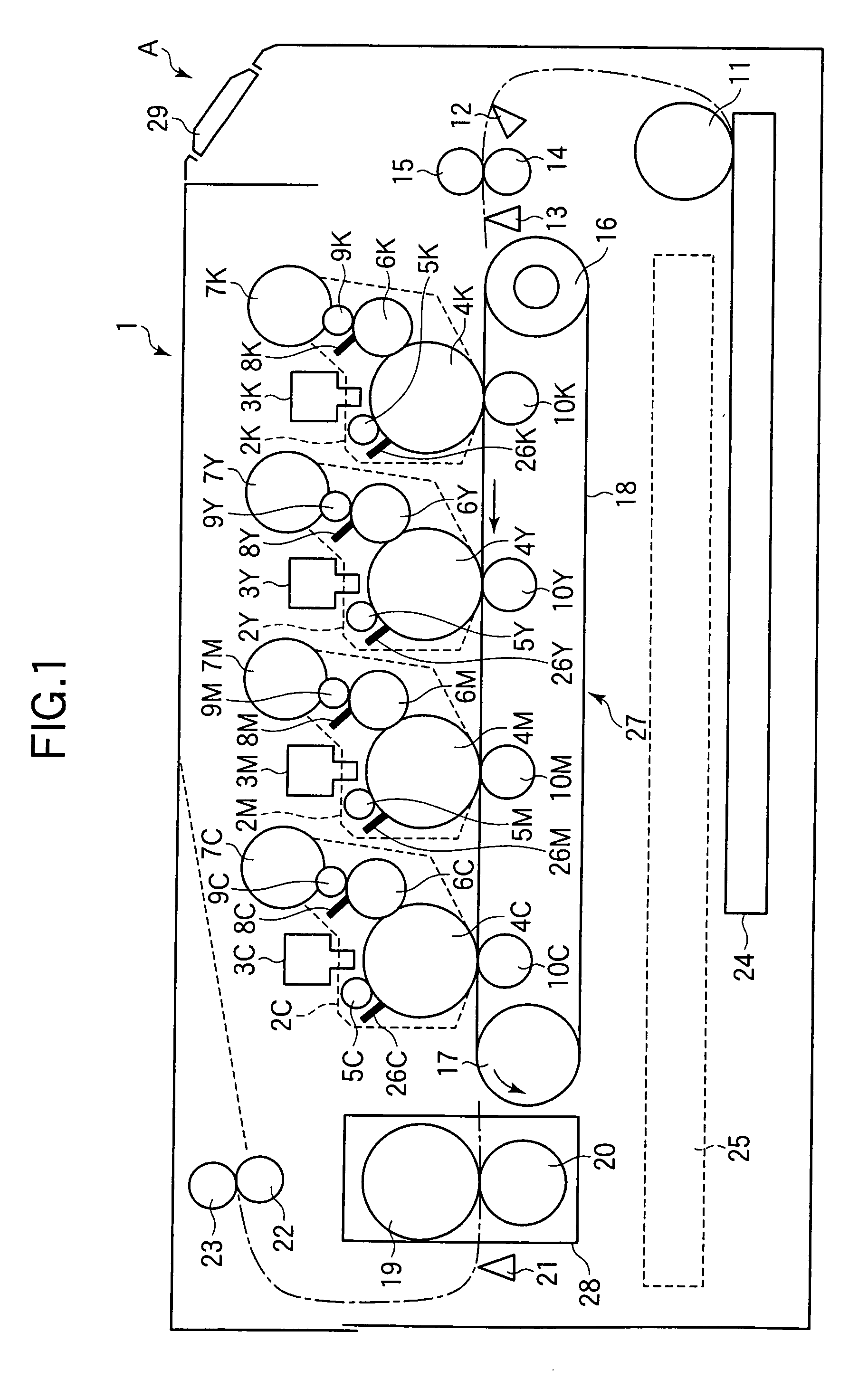

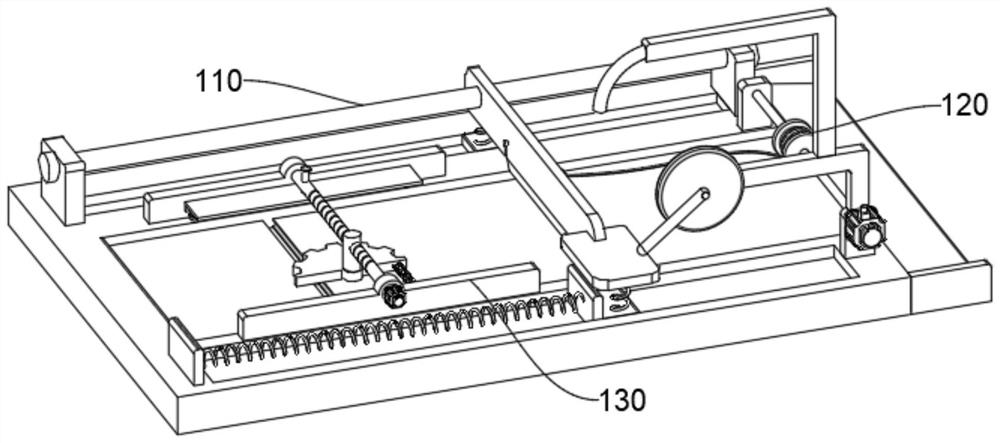

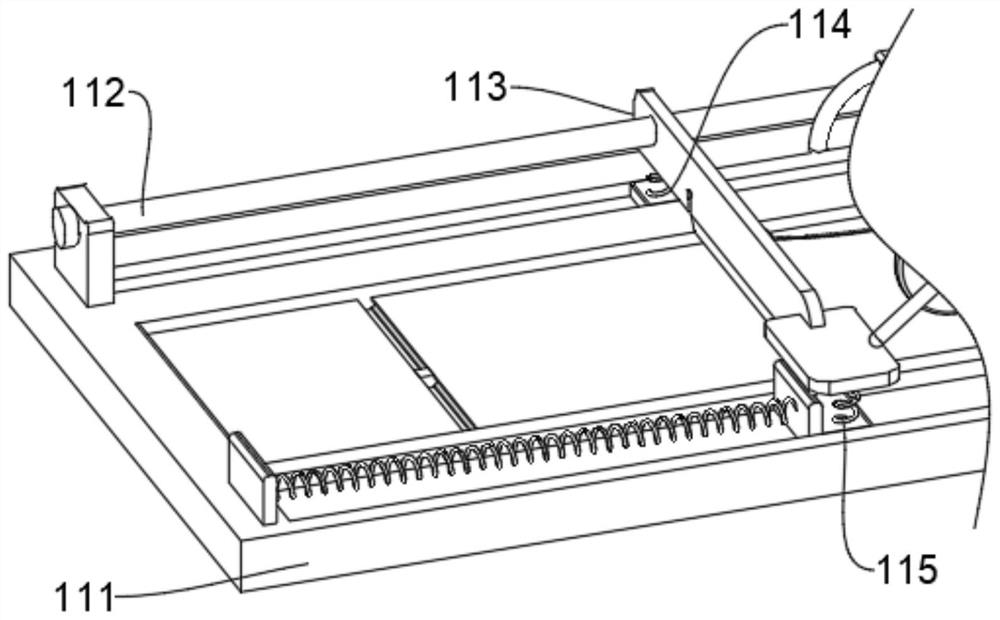

Rolled medium accommadation device and liquid ejection device

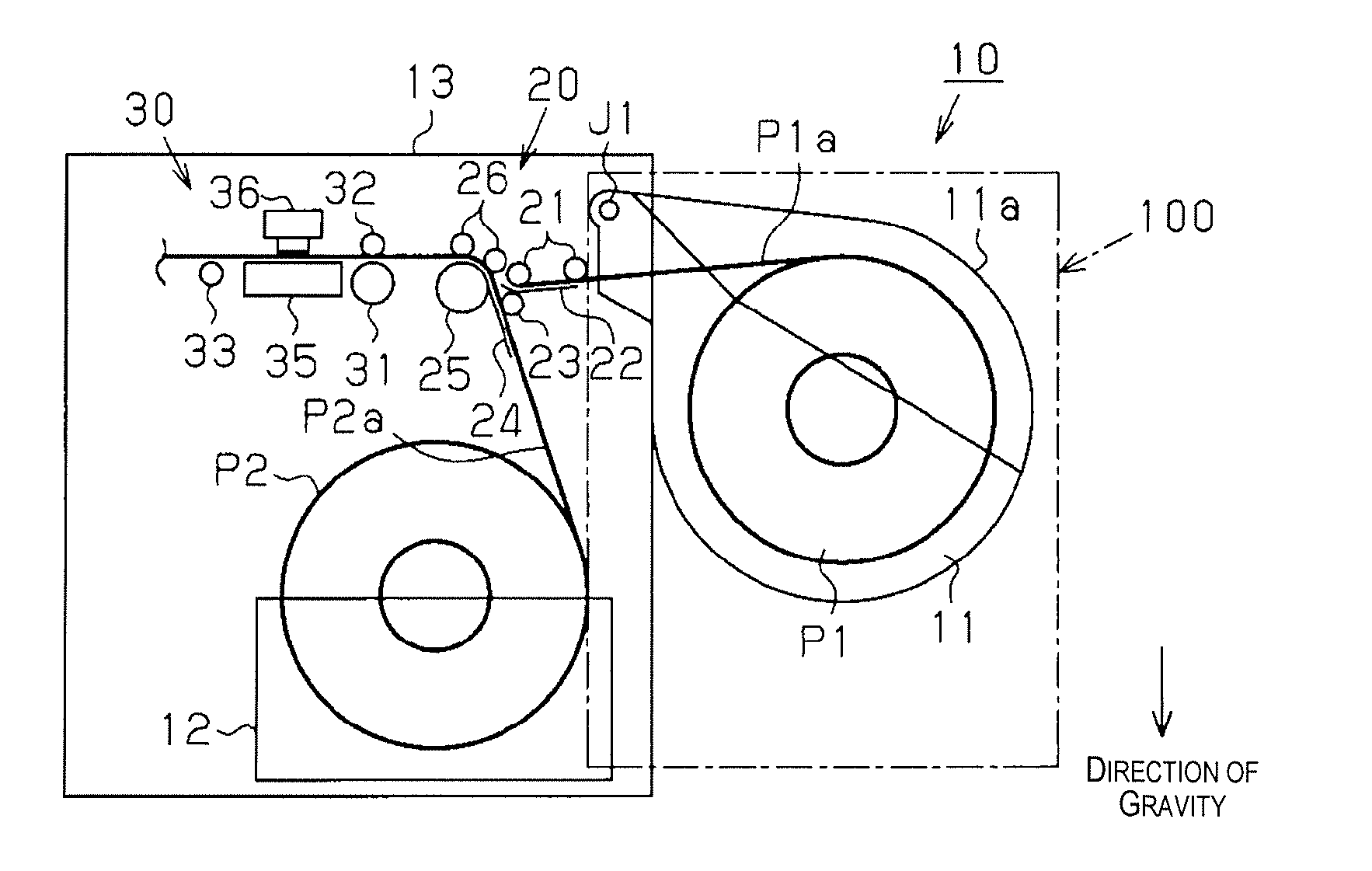

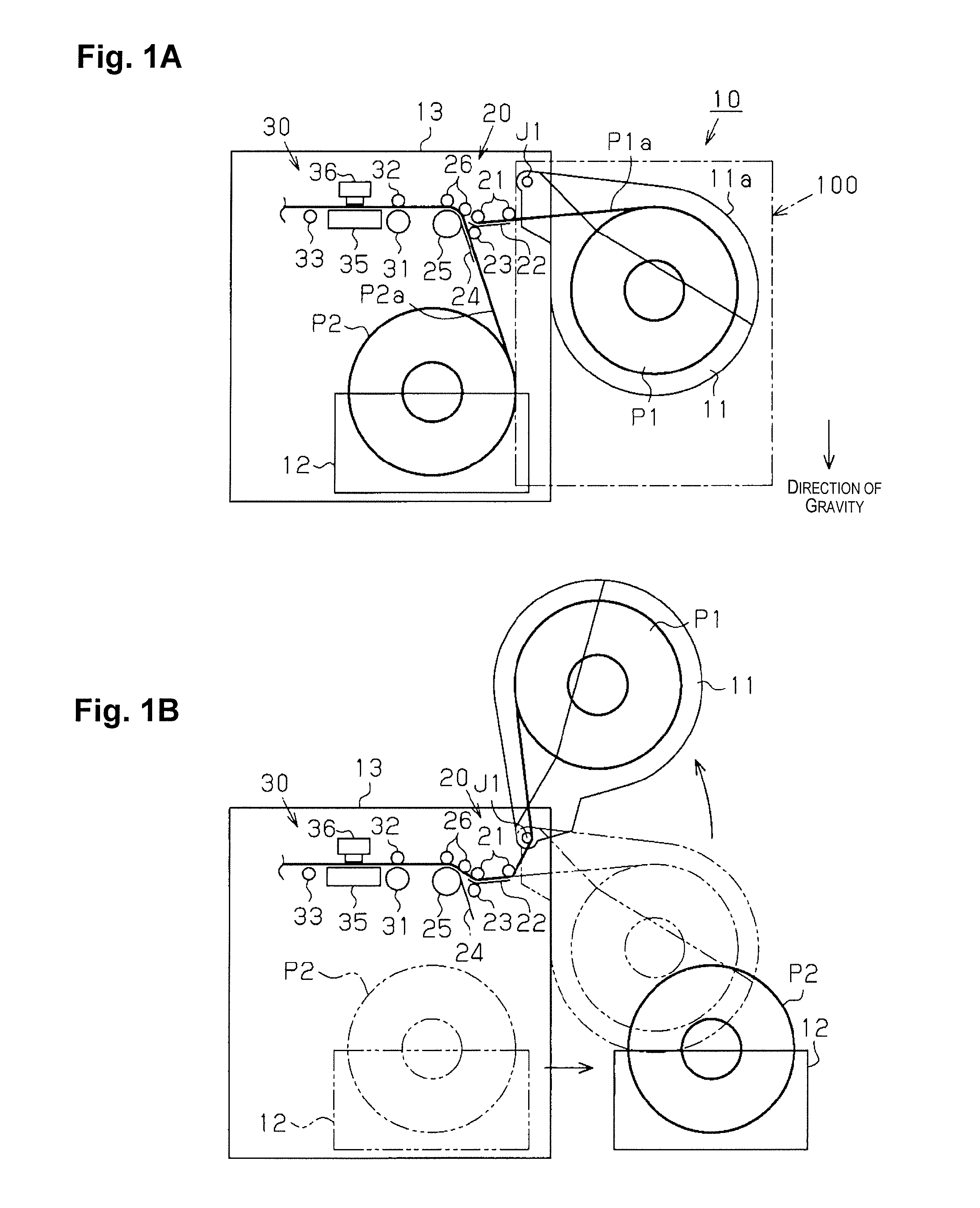

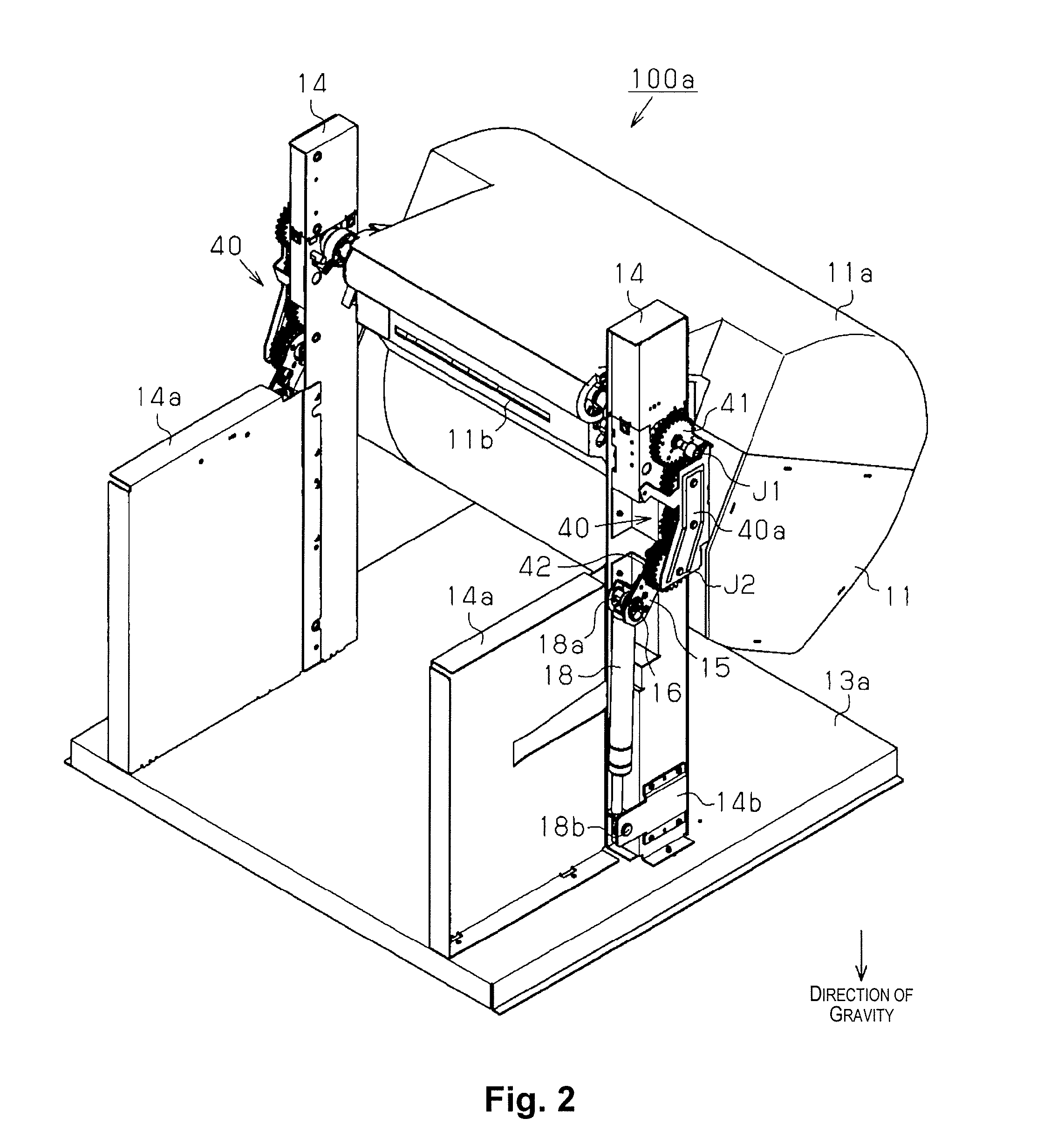

ActiveUS20110216140A1Lower manufacturing requirementsManufacturing load reducedFilament handlingOther printing apparatusClassical mechanicsEngineering

A rolled medium accommodation device includes a rolled medium accommodation unit which swings around a first shaft, a lever member which swings around a second shaft in conjunction with swinging of the rolled medium accommodation unit, a shaft member capable of moving in a direction intersecting an axial direction of the second shaft, and urging unit configured to apply rotational torque around the second shaft to the lever member. Due to the rotational torque, the rolled medium accommodation unit is subjected to force whereby the rolled medium accommodation unit is swung in a direction opposite that of gravity around the first shaft from a low position to a high position higher than the low position, and the shaft member moves so that the distance between a center of the shaft member and a center of the second shaft is greater in the high position than in the low position.

Owner:SEIKO EPSON CORP

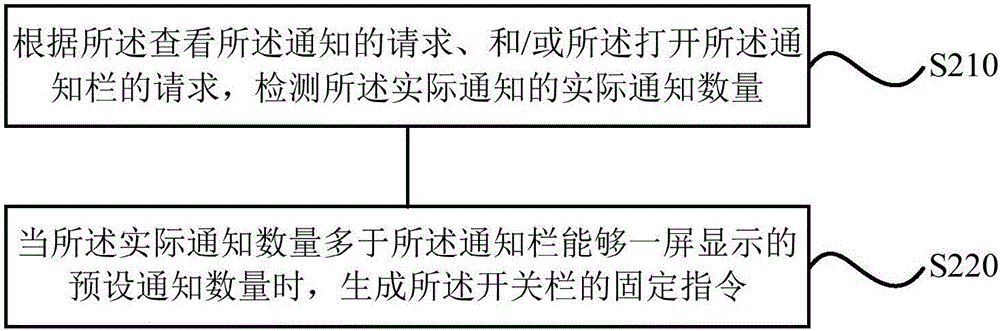

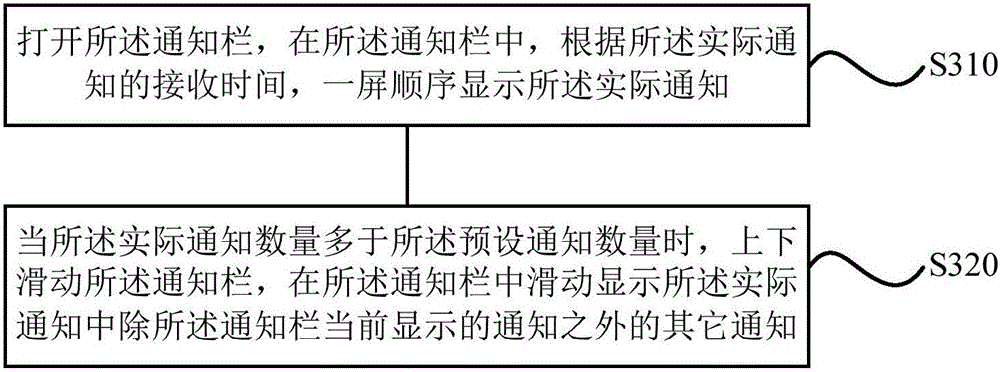

Method and device for checking message, and terminal

InactiveCN105975148AEasy to operateDoes not affect normal useExecution for user interfacesInput/output processes for data processingComputer terminalComputer engineering

Owner:GREE ELECTRIC APPLIANCES INC

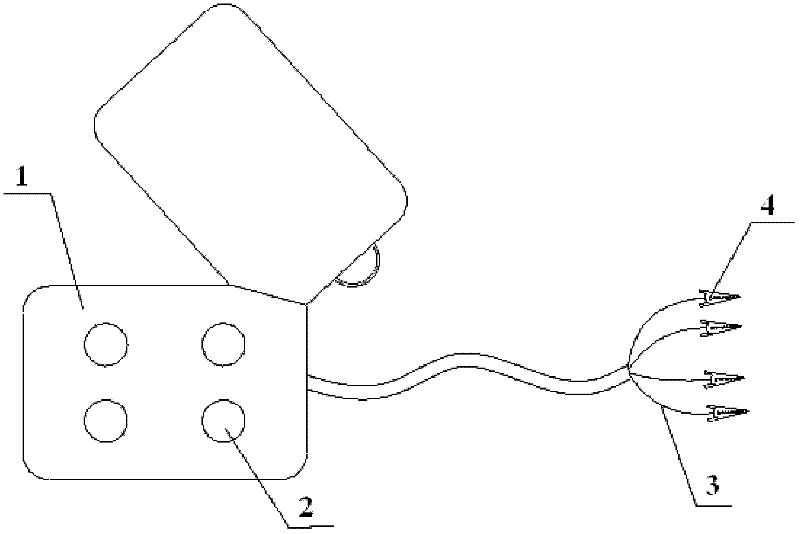

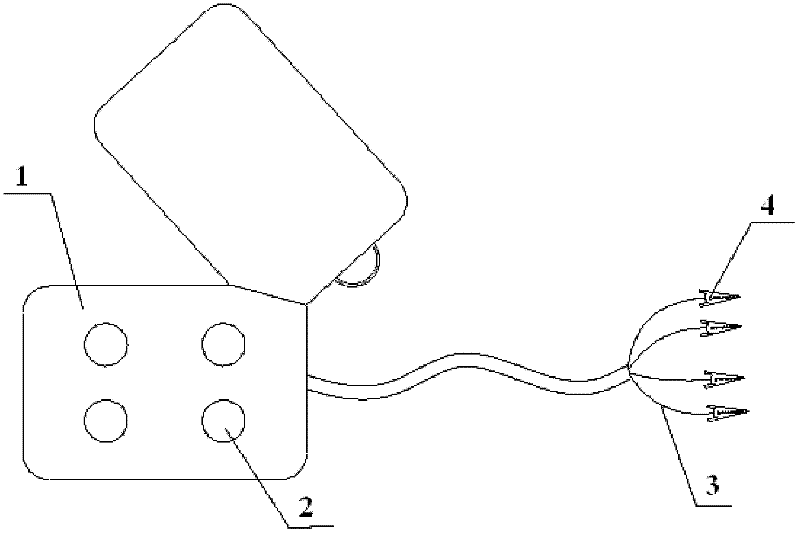

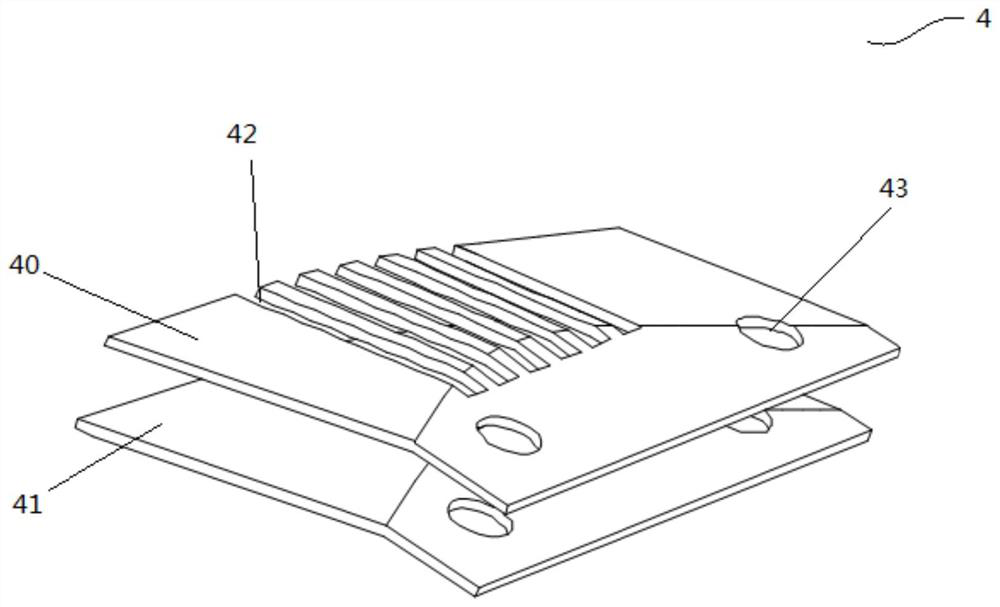

Electrode plate set for electrocardio monitoring

InactiveCN102641123AEasy maintenanceEasy to replaceDiagnostic recording/measuringSensorsSignal qualityEngineering

The invention discloses an electrode plate set for electrocardio monitoring. The electrode plate set comprises at least three electrode plates, wherein the three electrode plates are arranged on a mat, and no distance is left among the three electrode plates; the three electrode plates are respectively connected with a lead, and the free-end of the lead is connected with a connector which is matched with an electrocardio monitor; and the lead forms a multi-core lead. The electrode plate set has the following advantages that: 1, the single electrode plate set and the single multi-core lead are adopted to complete routine electrocardio monitoring, and the electrode plates are simple to operate, maintain and change; 2, the single electrode plate set and the single multi-core lead are simply distributed on the surface of the chest of a patient, so a plurality of electrode plates and leads which are arranged at a plurality of parts are prevented from being disorderly distributed to influence operation and rescue; and 3, the single electrode plate set and the single multi-core lead are beneficial to the stability of the monitoring signal quality and the searching of problems, and the risk of the monitoring signal interference and indistinguishability which are easily caused by faults and patient movement due to the electrode plates adhered onto the skins of a plurality parts of the chest and a plurality of running leads is reduced.

Owner:卢才义 +1

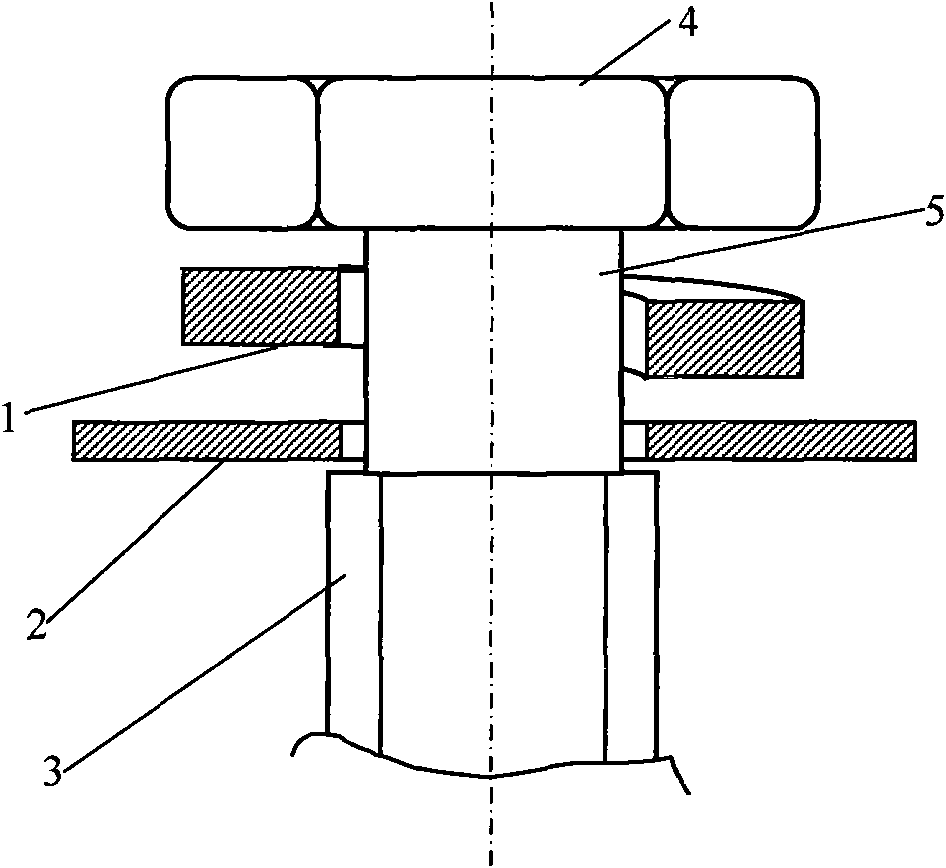

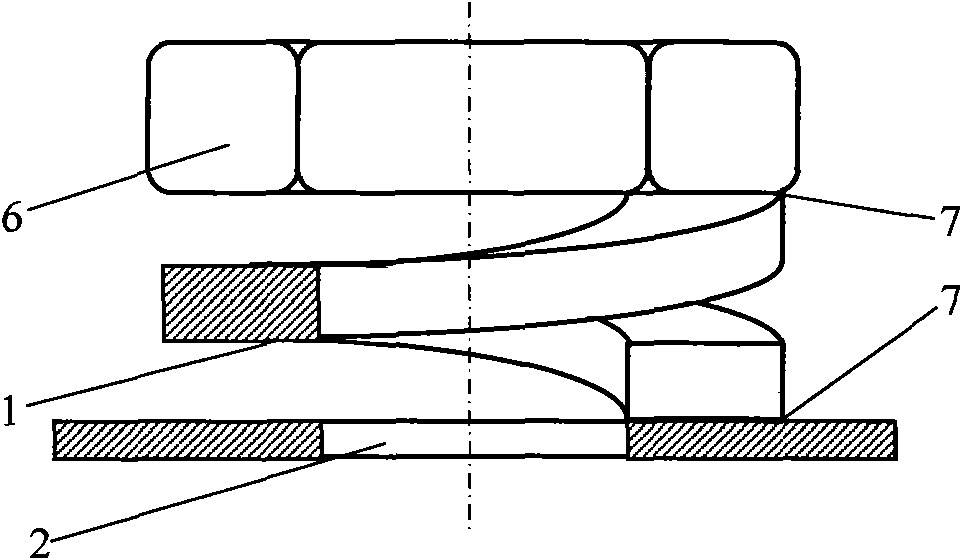

Integrative fastener

InactiveCN101625008AReduce the difficulty of operationImprove work efficiencyNutsBoltsEngineeringCushion

The invention relates to an integrative fastener which can be used as an own flat cushion, a spring cushion screw rod and a screw nut, satisfy the requirement on the screw rod and the screw nut in an installation site, avoid influencing installation and firm operation by various conditions or leaking to add the flat cushion and the spring cushion for various conditions, in particular to a situation which is not beneficial to operating, the addition of the flat cushion and the spring cushion wastes time and labor and is dangerous, the flat cushion and the spring cushion are arranged on the screw rod, and a set of combined screw rod parts is formed by matching sizes, the flat cushion and the spring cushion are arranged on the screw nut, an integrative combined screw nut part is formed by the micro-connection of switchable combined points, consequently, the operation difficulty is greatly reduced, and the operation efficiency can be greatly increased.

Owner:黄艳芳

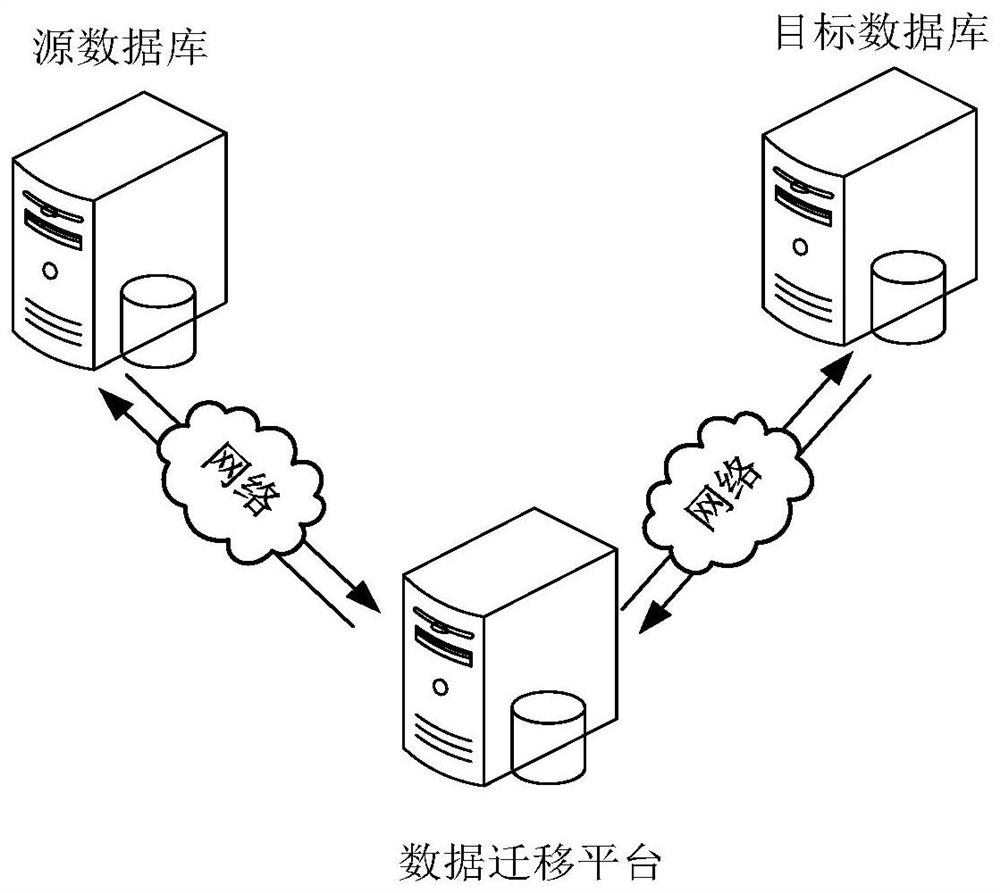

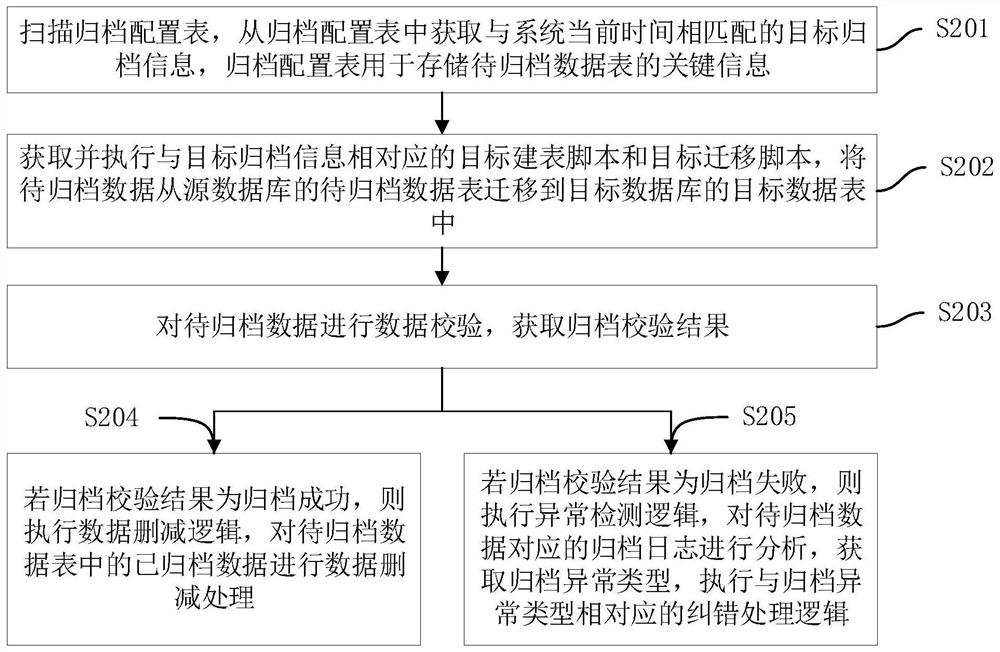

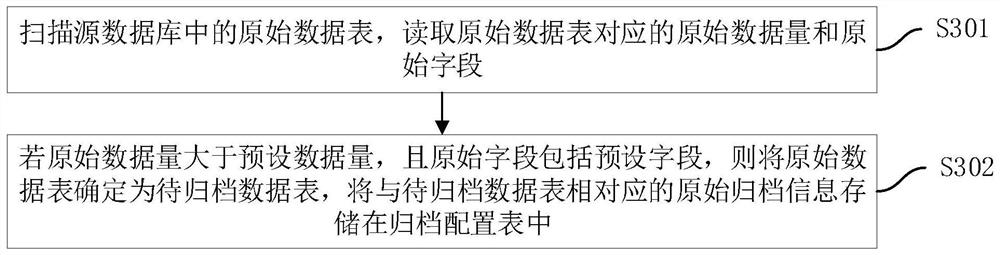

Data archiving processing method and device, computer equipment and storage medium

PendingCN112181945AGuaranteed accuracyImprove accuracyDatabase updatingDatabase distribution/replicationDatasheetSource Data Verification

The invention relates to the technical field of data processing, and discloses a data archiving processing method and device, computer equipment and a storage medium. The method comprises the steps: scanning an archiving configuration table, and acquiring target archiving information matched with the current time of a system from the archiving configuration table; obtaining and executing a targettable establishing script and a target migration script corresponding to the target archiving information, and migrating the to-be-archived data from a to-be-archived data table of the source databaseto a target data table of the target database; carrying out data verification on the to-be-archived data, and archiving a verification result; and if the archiving verification result shows that archiving succeeds, executing data deletion logic, and performing data deletion processing on the archived data in the to-be-archived data table. The method can guarantee the intelligence and automation of data archiving processing, guarantees the data accuracy, and reduces the storage cost. The invention also relates to the field of block chains, namely, to-be-archived data can be stored in a block chain node, namely, a target database constructed based on a block chain technology.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

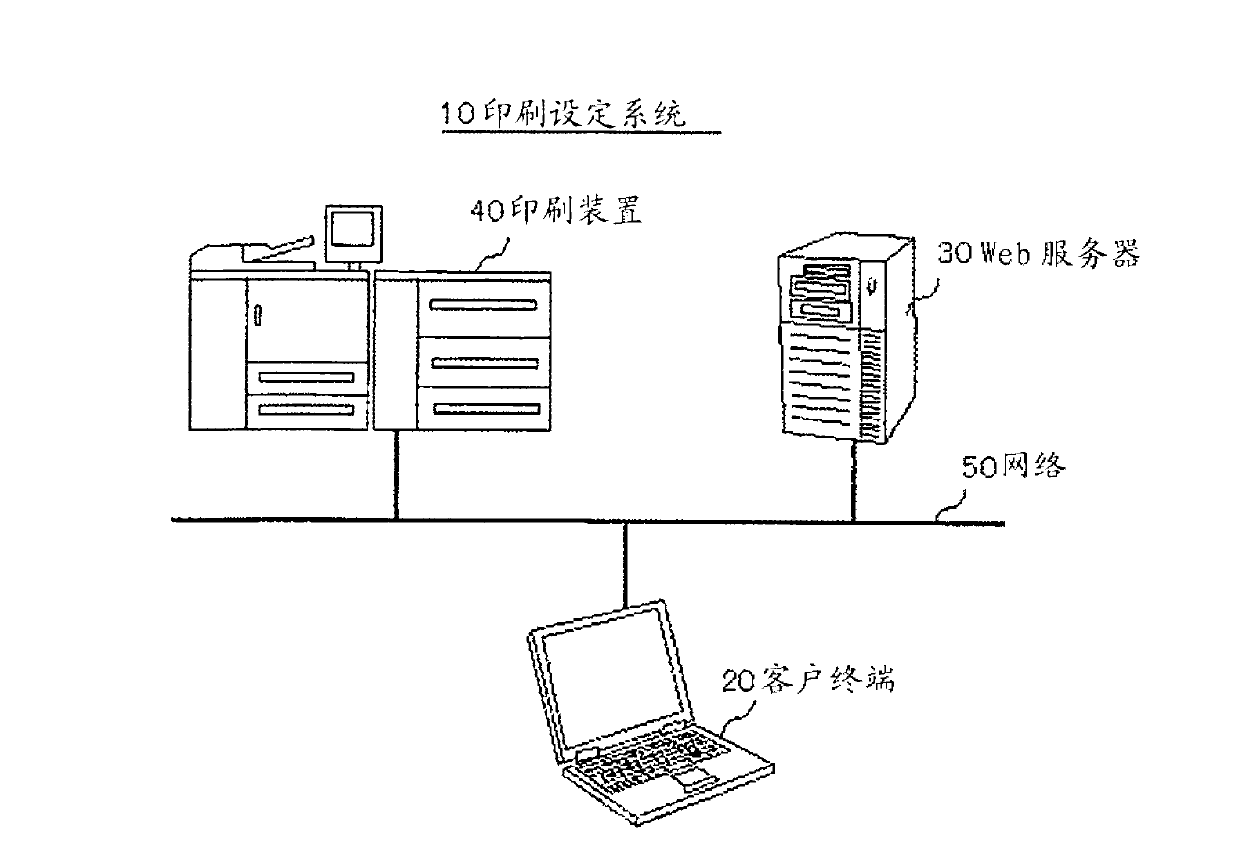

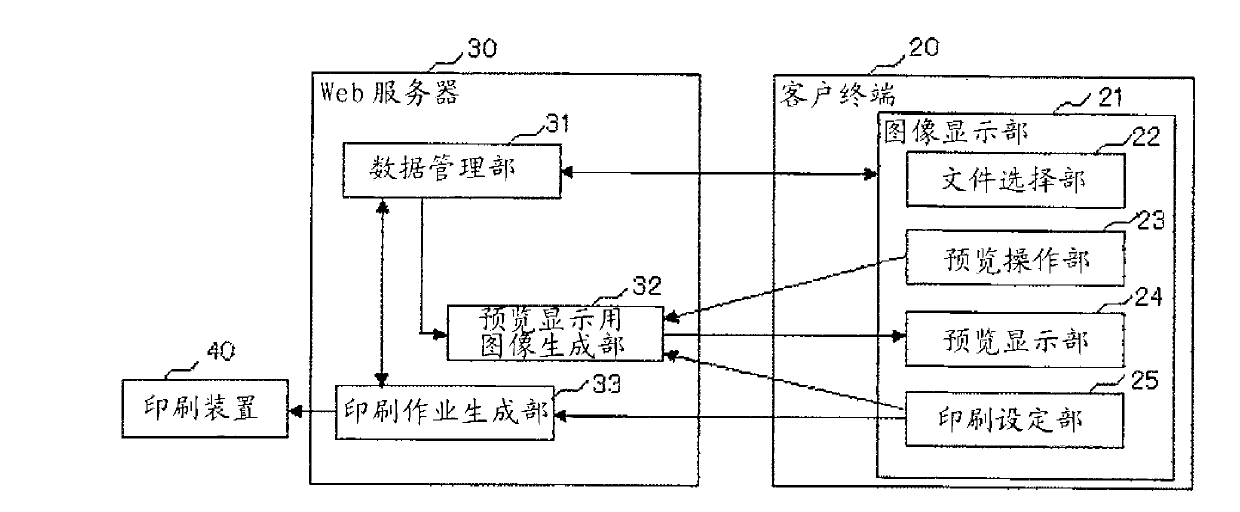

Printing system, preview display control program and preview display control method

ActiveCN103139417AAffect performanceAffect operabilityPictoral communicationDigital output to print unitsComputer graphics (images)Web server

A printing system including a client terminal, a printing apparatus, and a Web server for allowing the client terminal to display a print preview image, wherein the client terminal includes: a print setting section which, when a print setting is changed on a screen notifies the Web server of the changed print setting and requires creation of a print preview image, and when a predetermined time period has elapsed after the change, requests the print preview image reflecting the changed print setting; and a preview display section which displays the image acquired from the Web server, and wherein the Web server includes: a control section which, when the changed print setting is notified, creates the print preview image by reflecting the change, and when the print preview image is required, sends the print preview image reflecting the changed print setting to the client terminal.

Owner:KONICA MINOLTA BUSINESS TECH INC

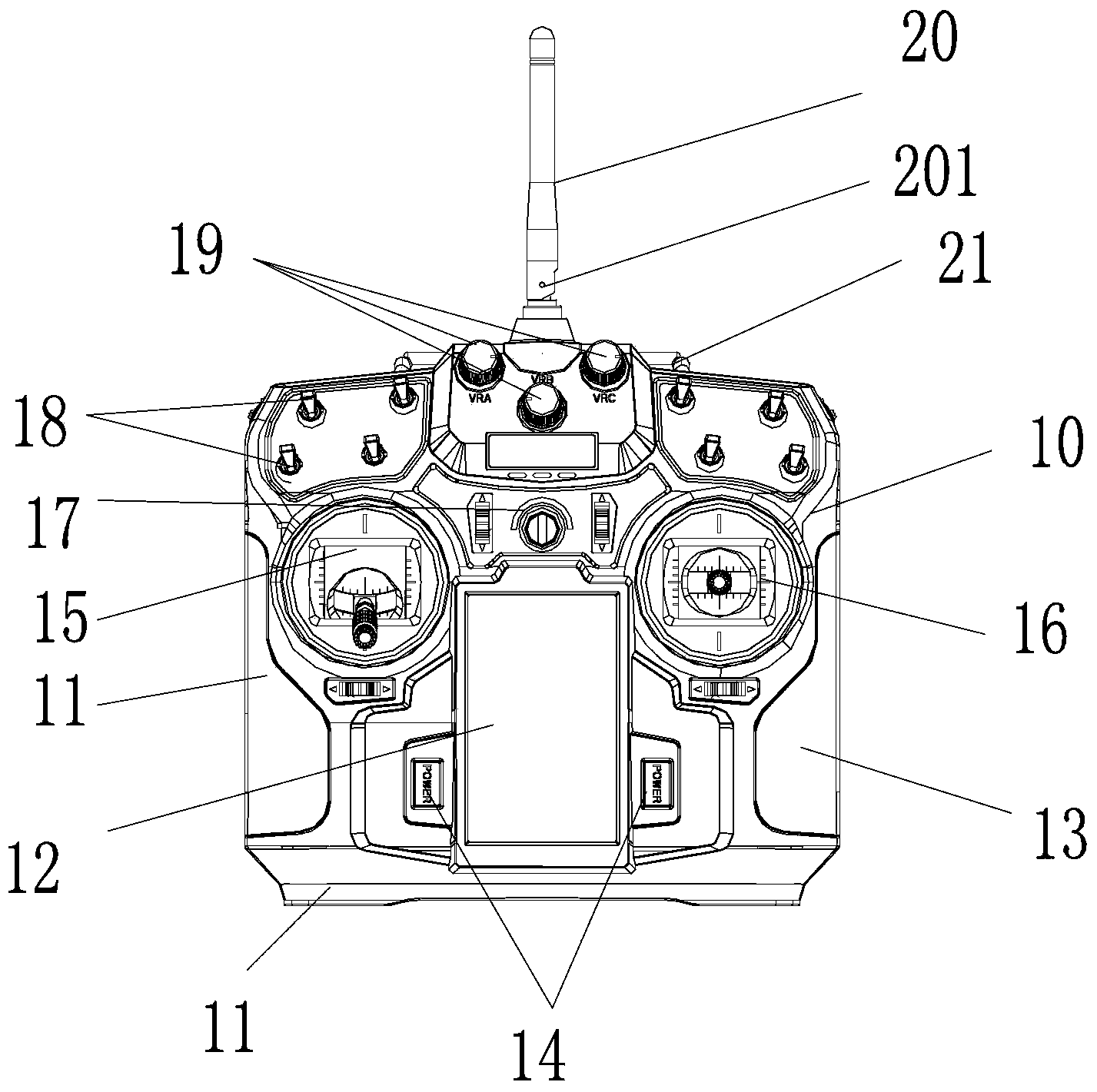

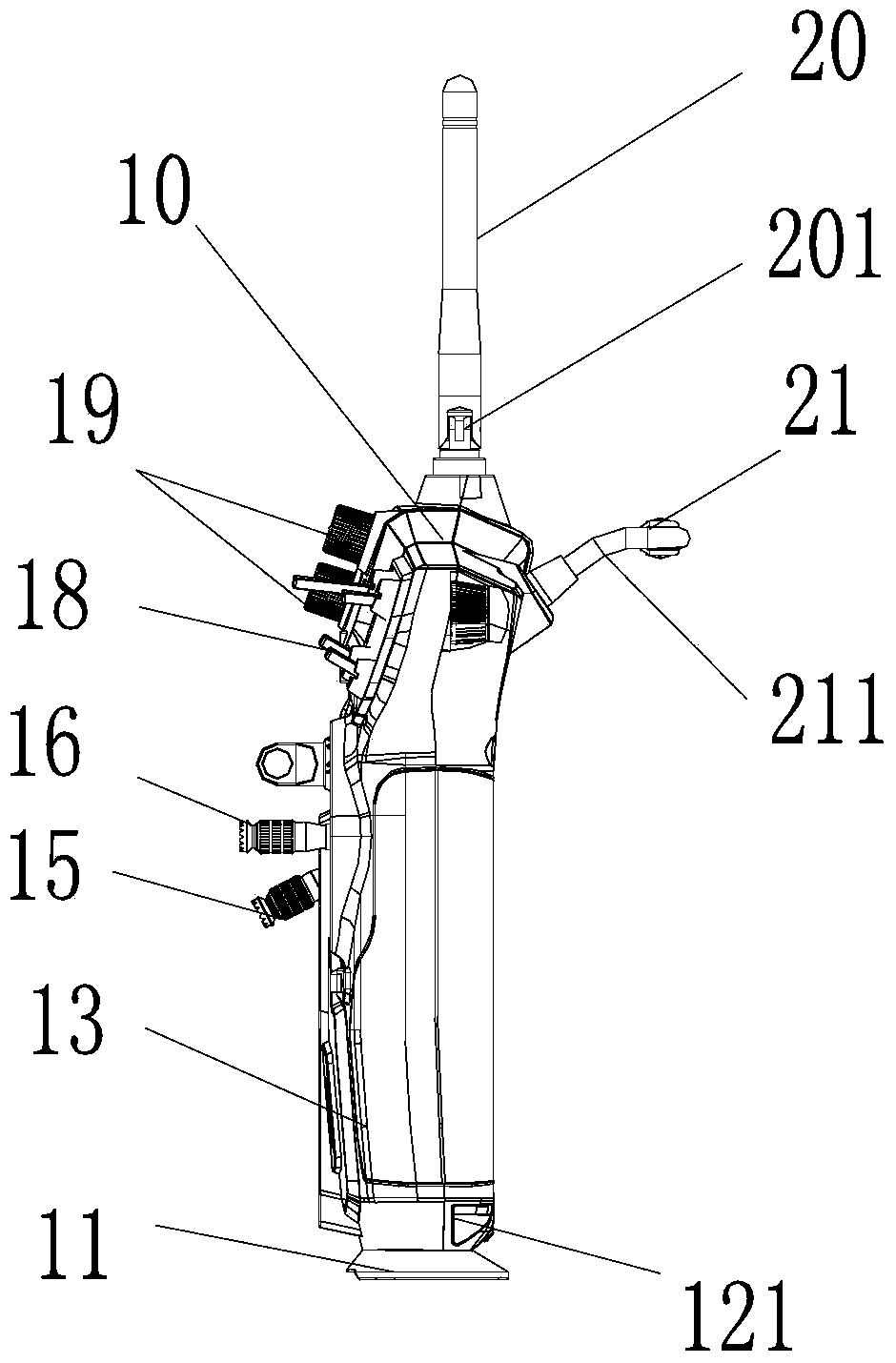

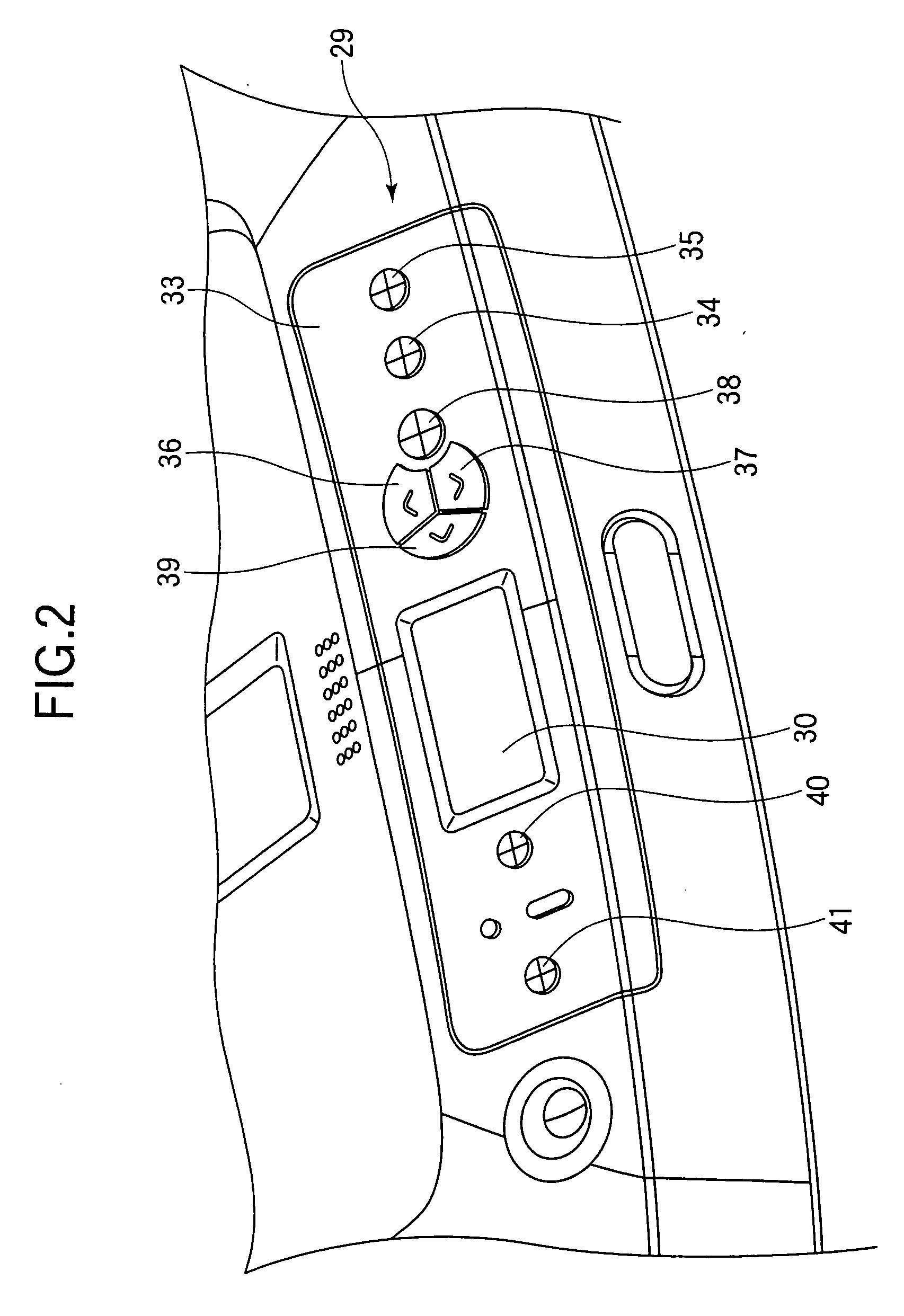

Model remote controller

The invention discloses a model remote controller, which comprises a remote controller body and a control circuit arranged in the remote controller body. The model remote controller is characterized in that two power supply switches and a rotating potentiometer are arranged on the remote controller body, the potentiometer has a pressing hidden function, the two power supply switches and the rotating potentiometer are connected with the control circuit, and the two power supply switches simultaneously control the on-off state of the model remote controller. The model remote controller has the advantages that through the design adopting double power supply switches, the problem of mistake on-off operation of the remote controller can be avoided; through the design of the rotating potentiometer with the pressing hidden function, the problems of remote control operation influence and regulation state change because the rotating potentiometer is often touched are avoided; meanwhile, the anti-slip deign of a base, a holding handle and a lifting handle is also added, and the integral anti-slip effect of the remote controller is improved.

Owner:FLYSKY TECH CO LTD

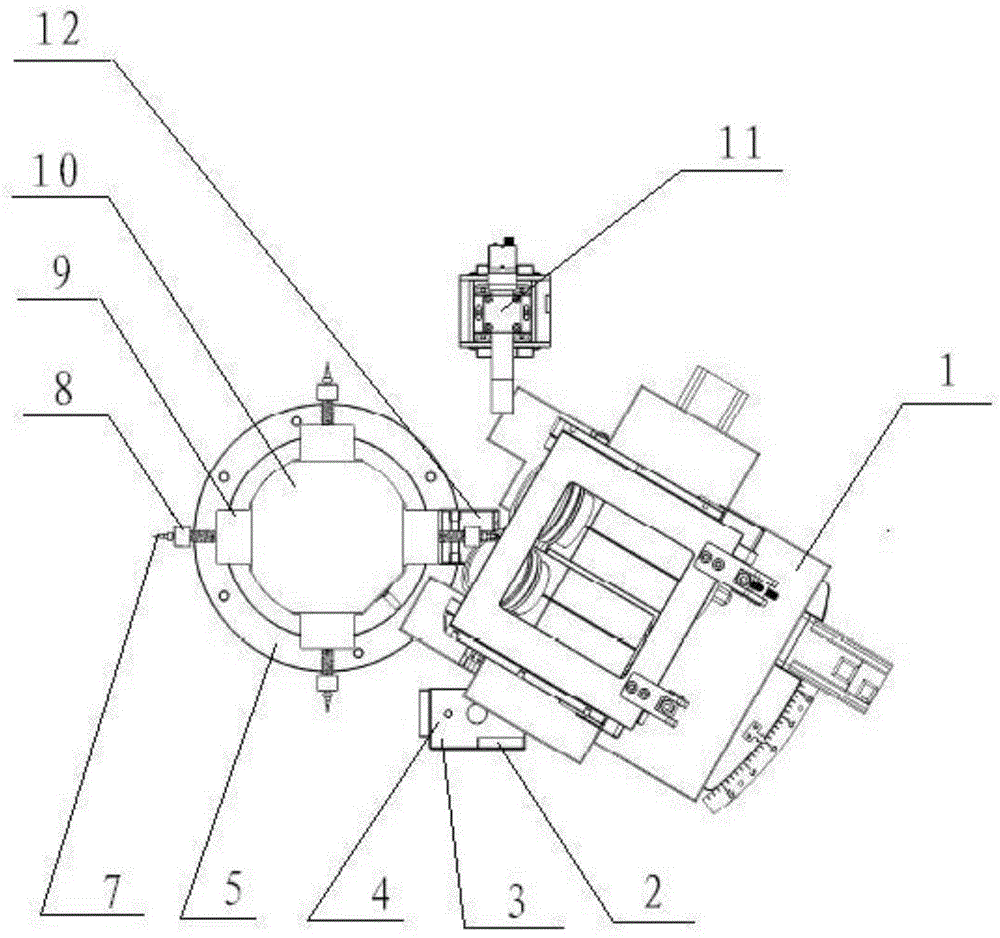

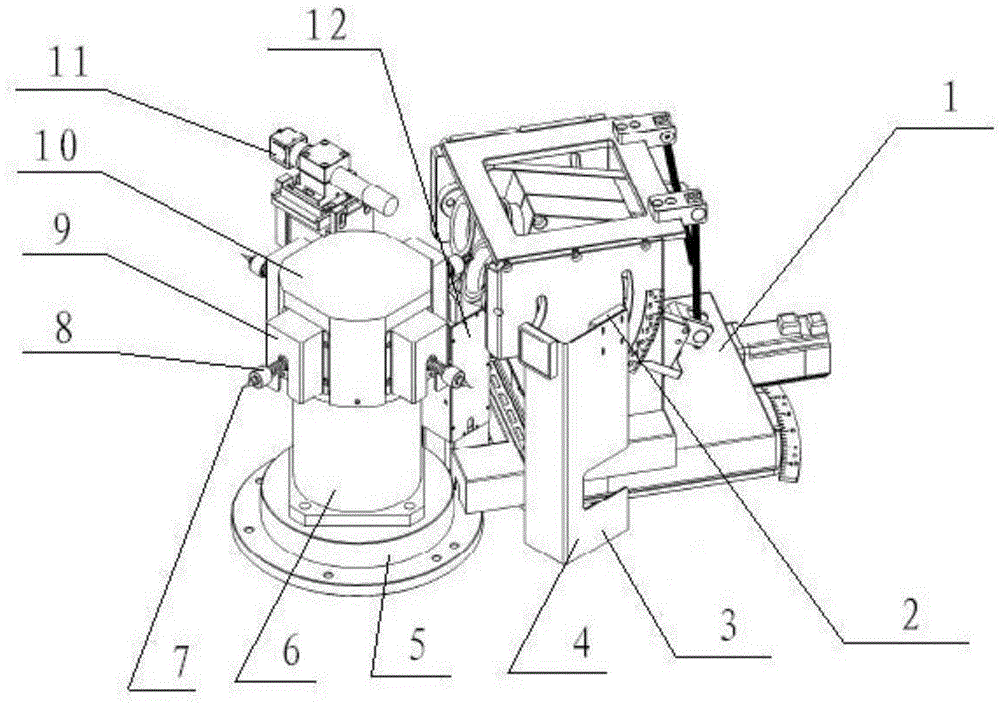

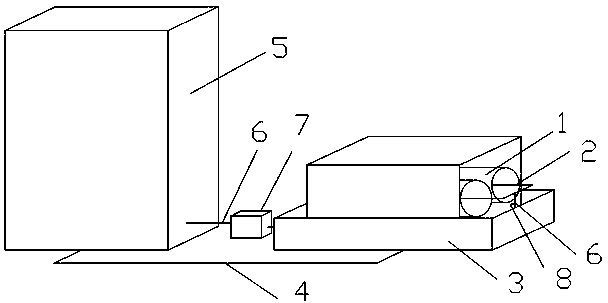

Grinding device

InactiveCN104308676AAffect the resultAffect operabilityGrinding wheel securing apparatusOther manufacturing equipments/toolsEngineeringDrill bit

The invention provides a grinding device which is used for a full-automatic drill bit grinding device and comprises a rotary table, wherein a drill bit is fixed on the rotary table; a grinding positioning mechanism is arranged on one side of the rotary table; a shooting control mechanism which is used for the length and diameter image output of the drill bit is close to the grinding positioning mechanism and is provided with a camera; the camera can be perpendicular to the drill bit; the grinding device further comprises a grinding mechanism the position of which is adjusted according to the image output. According to the grinding device, during the grinding of the drill bit, the image output of the drill bit fixed on the rotary table is implemented by the shooting control mechanism, the position of the grinding mechanism is controlled by the judgment of a computer, and the drill bit is ground so that one device can meet the machining demands of drill pins of various sizes effectively, and the position of the grinding mechanism does not need to be adjusted manually; moreover, before the grinding mechanism grinds the drill bit, the grinding positioning mechanism positions the drill bit, so that the position offset of the drill bit, which can affect the grinding effect of the drill bit, is avoided when the grinding mechanism grinds the drill bit.

Owner:昆山仁特机械有限公司

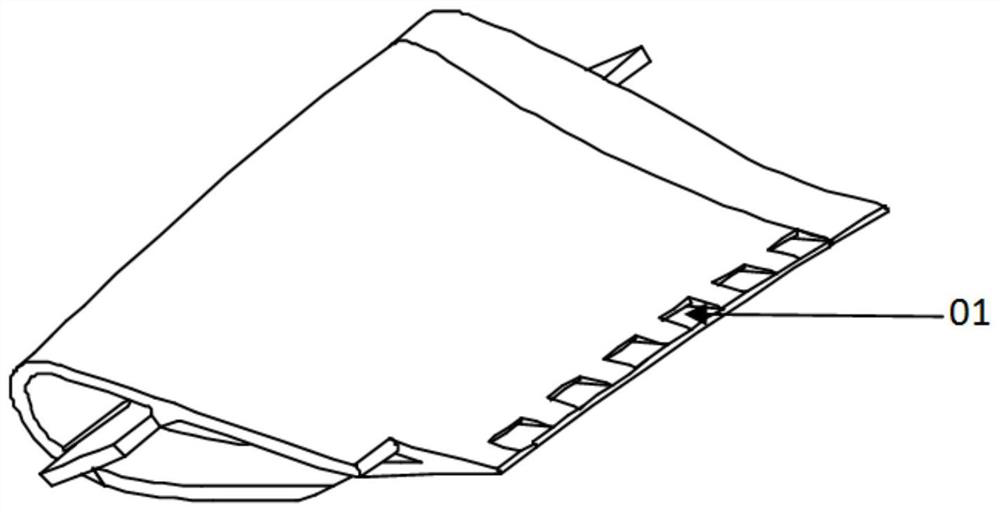

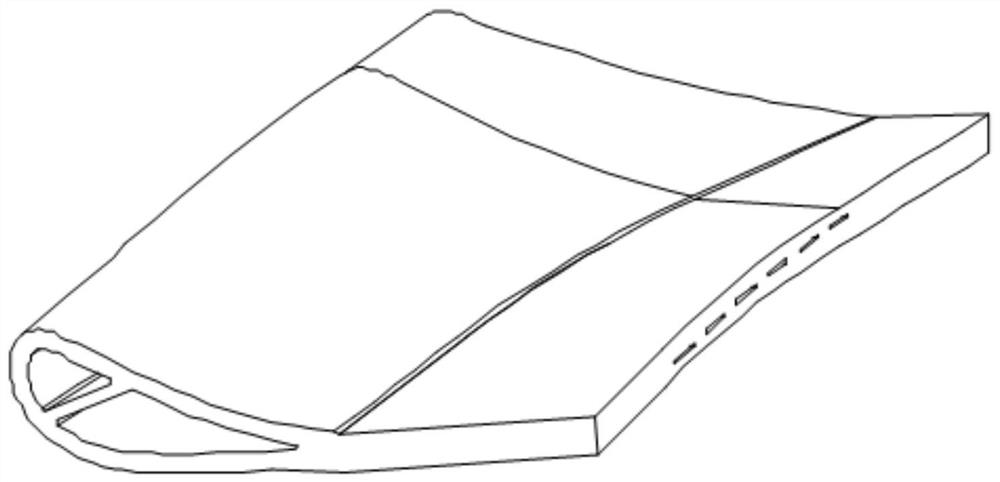

Aviation blade forming tool and process based on carbon-ceramic material

The invention provides an aviation blade forming tool and a process based on a carbon-ceramic material, and solves the problems of mold positioning eccentricity and difficulty in air film groove machining after forming in the forming process by adopting an existing forming mold. A forming tool comprises an inner die, an outer die, a clamping plate assembly and a limiting tool. The clamping plate assembly is used for being matched with the inner die and the outer die to achieve positioning of the inner die and the outer die. The limiting tool is used for machining an air film groove in the corresponding portion of the fiber fabric in the process that the fiber fabric is wrapped by the molded surface of the inner die. In the machining process, the relative positions of the air film grooves and the relative positions of the air film grooves and the fiber fabric are accurately positioned through the limiting tool, and blade scrapping caused by errors caused by manual measurement is prevented; the relative positions of the inner die and the outer die are fixed through the clamping plate assembly, and the situation that due to relative sliding of the inner laminated and the outer die inthe forming process, the fiber fabric profile (wall thickness and curvature) is changed, and later blade machining operability and blade performance are affected is prevented.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Rolled medium accommodation device and liquid ejection device

ActiveUS8348417B2High torquePowerfulOther printing apparatusWebs handlingEngineeringMechanical engineering

A rolled medium accommodation device includes a rolled medium accommodation unit which swings around a first shaft, a lever member which swings around a second shaft in conjunction with swinging of the rolled medium accommodation unit, a shaft member capable of moving in a direction intersecting an axial direction of the second shaft, and urging unit configured to apply rotational torque around the second shaft to the lever member. Due to the rotational torque, the rolled medium accommodation unit is subjected to force whereby the rolled medium accommodation unit is swung in a direction opposite that of gravity around the first shaft from a low position to a high position higher than the low position, and the shaft member moves so that the distance between a center of the shaft member and a center of the second shaft is greater in the high position than in the low position.

Owner:SEIKO EPSON CORP

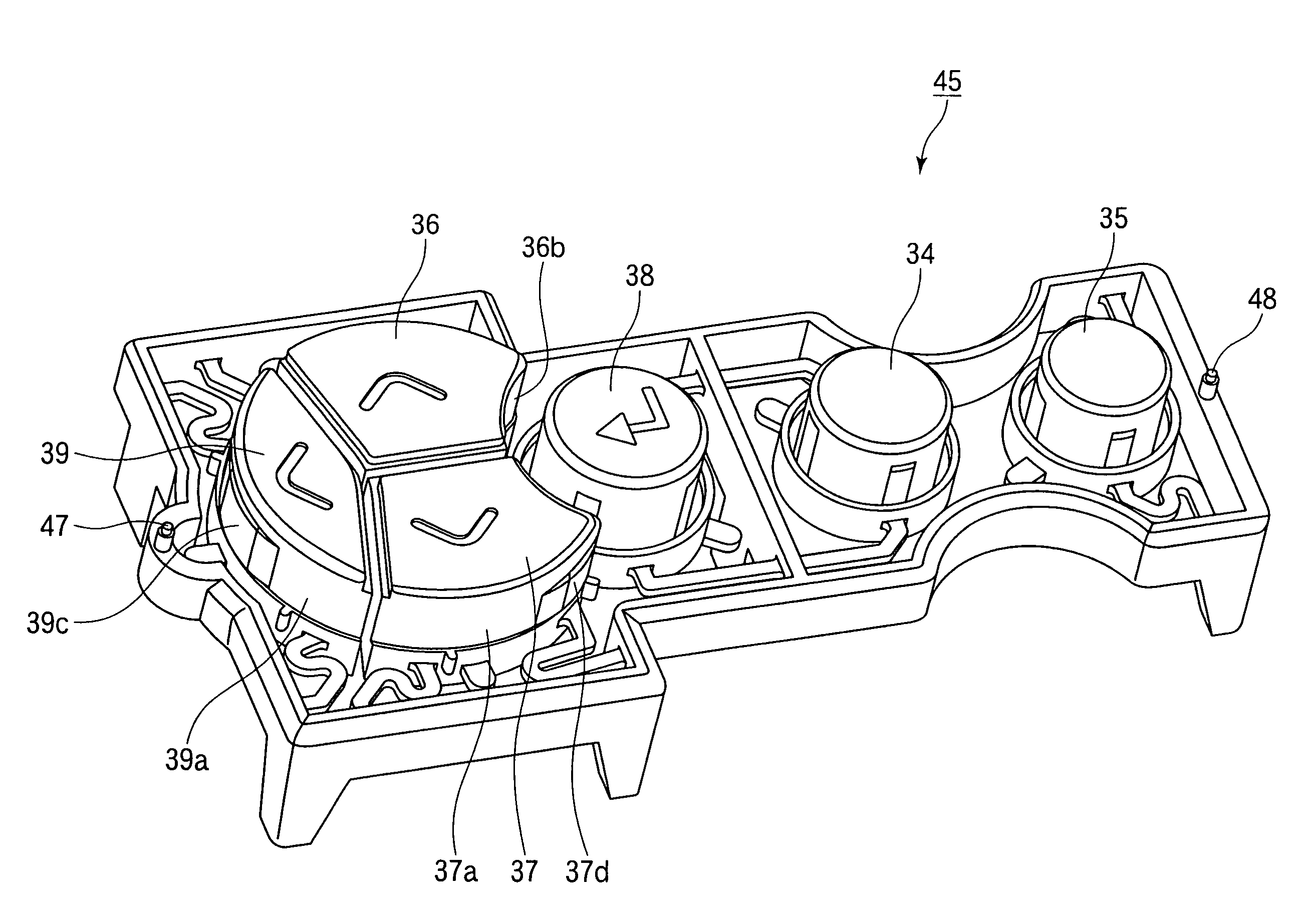

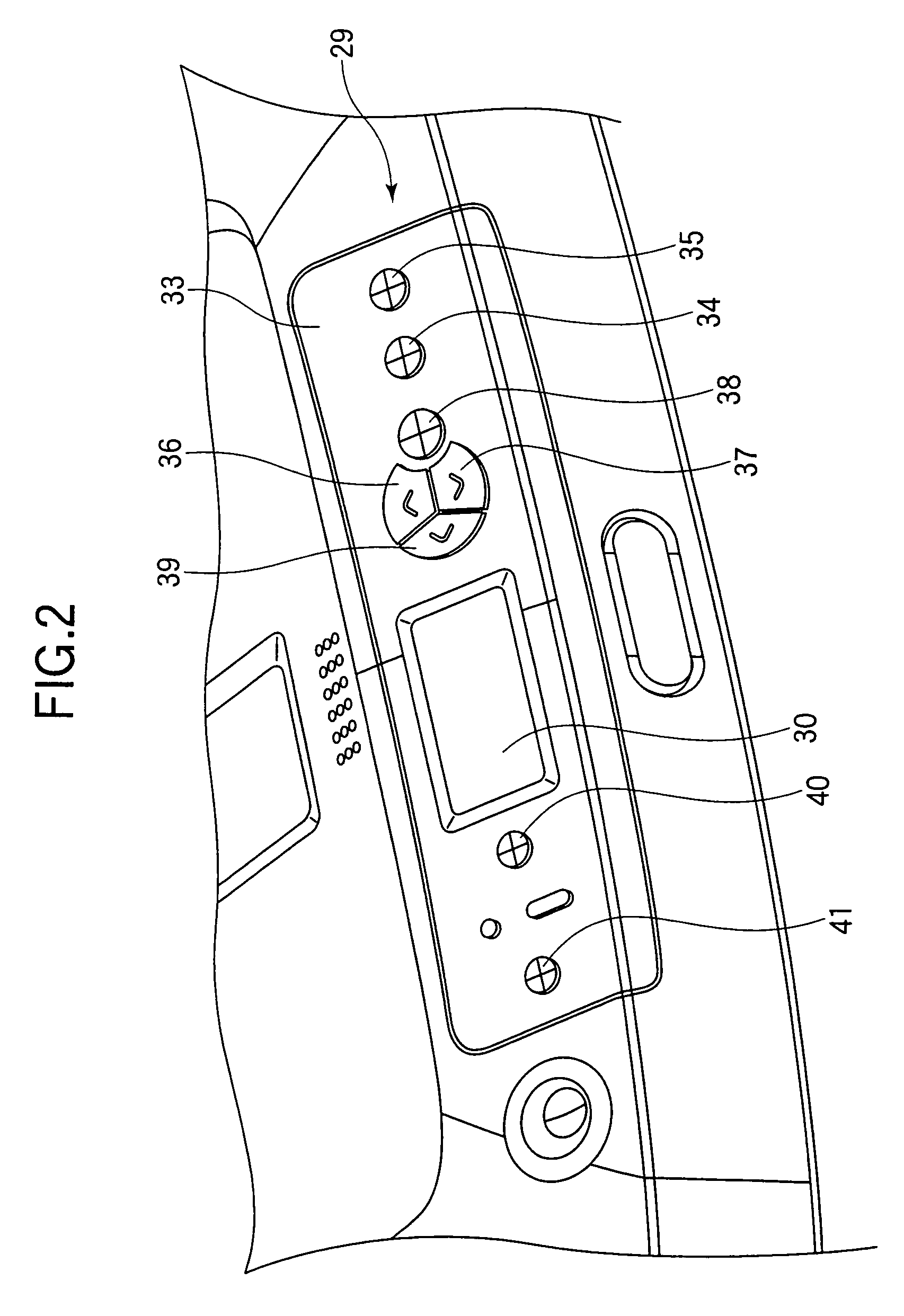

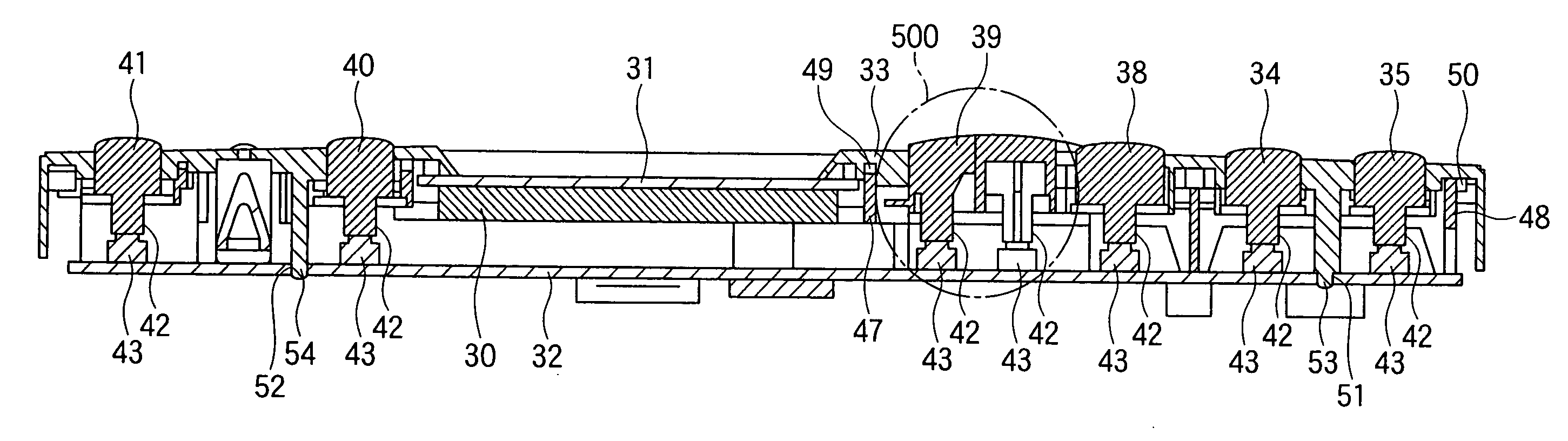

Button key assembly and electronic apparatus that employs the button key assembly

InactiveUS8878083B2Easy to operateAffect operabilityEmergency actuatorsEmergency casingsEngineeringElectronic equipment

Owner:OKI DATA CORP

Button key assembly and electronic apparatus that employs the button key assembly

InactiveUS20090322569A1Easy to operateAffect operabilityEmergency actuatorsEmergency casingsEngineeringElectronic equipment

Owner:OKI DATA CORP

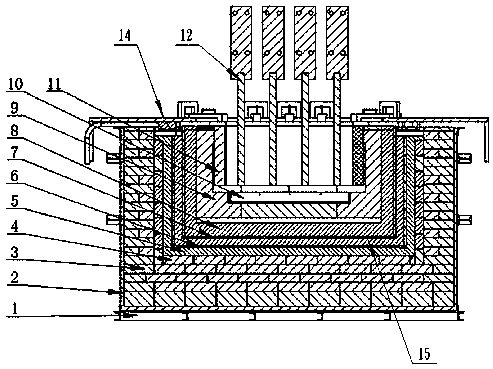

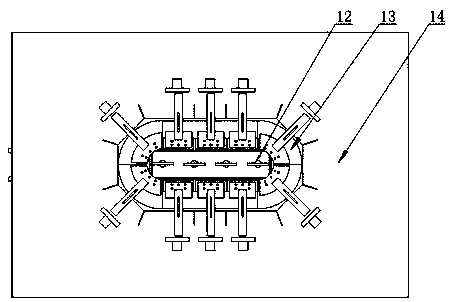

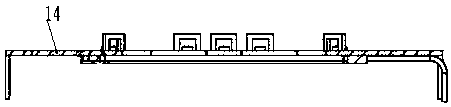

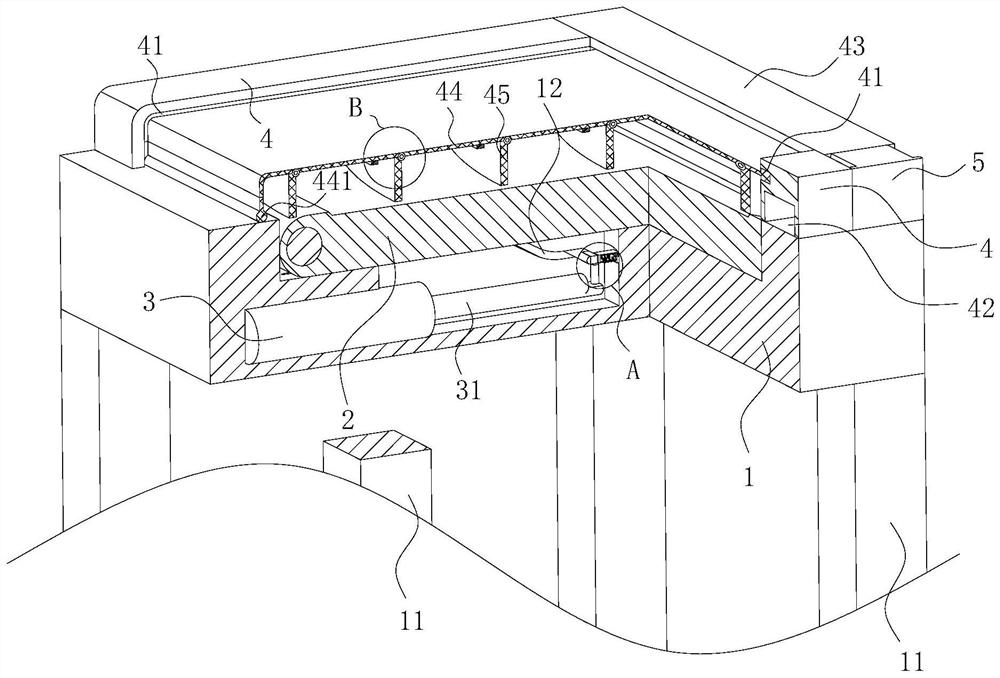

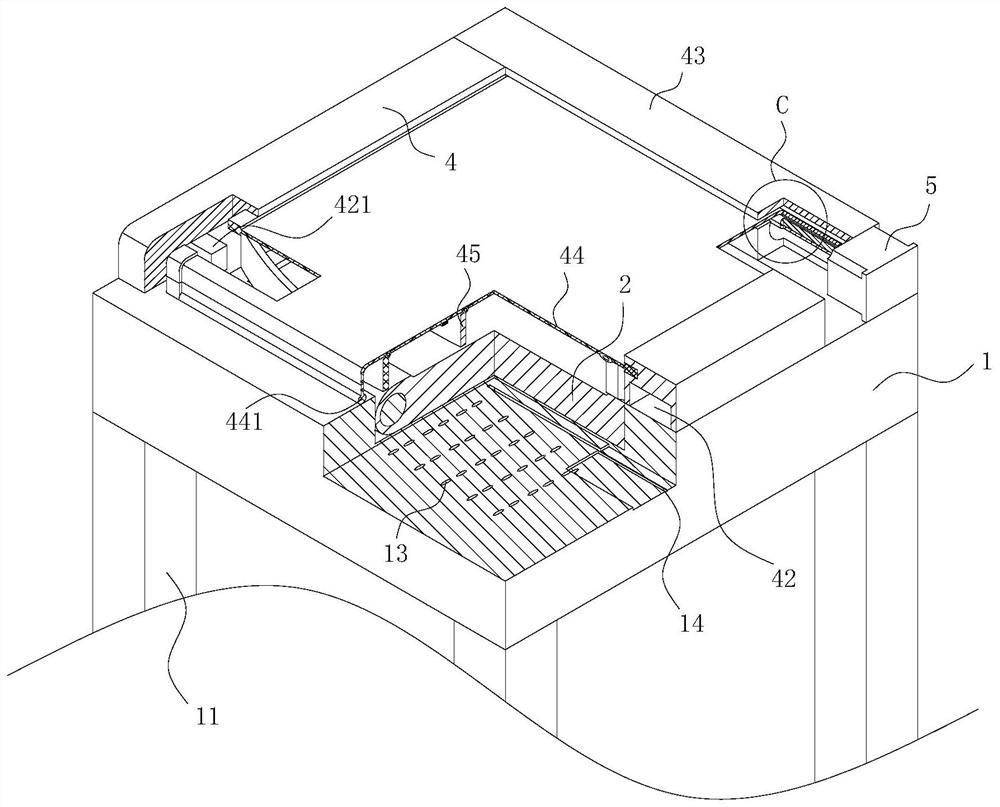

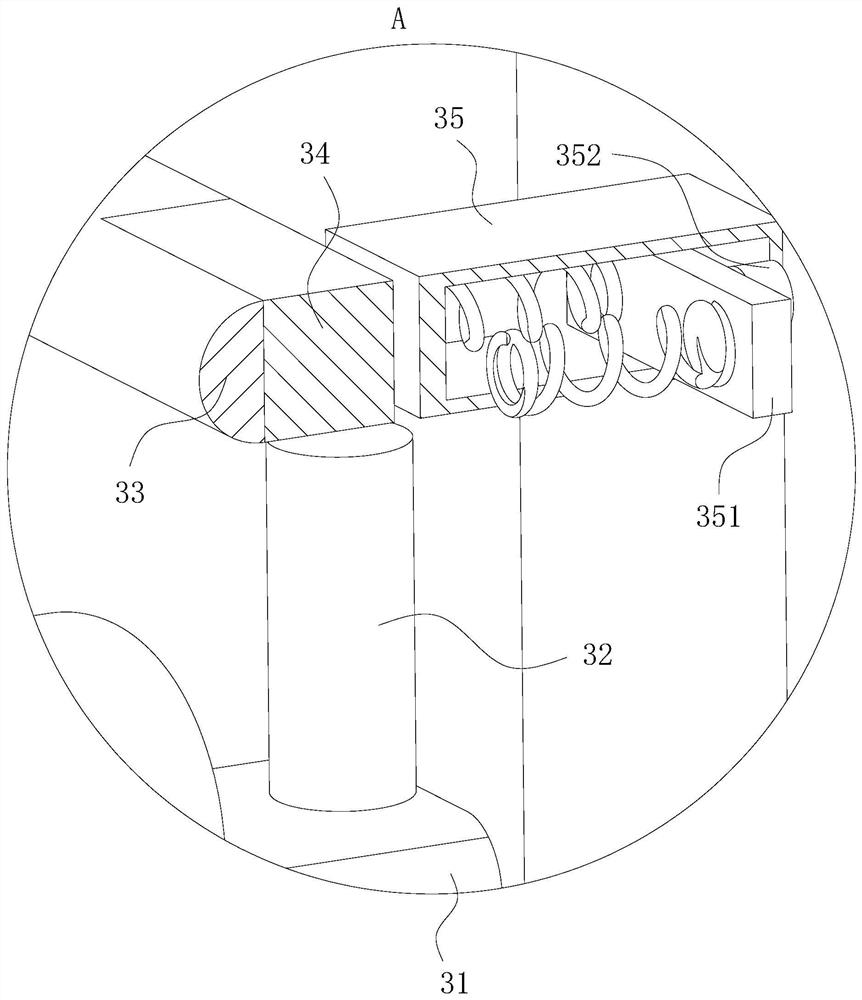

Construction technology of 10KA-level rare earth electrolysis cell

The invention discloses a construction technology of a 10KA-level rare earth electrolysis cell. The technology comprises following steps: step 1, a thermal insulating layer is laid on the inner wall of a cell casing; step 2, a first refractory layer is laid above the thermal insulating layer, and a first metal sleeve is arranged above the first refractory layer; step 3, a second metal sleeve is arranged in the first metal sleeve; step 4, an electrolysis cell is put in the second metal sleeve; step 5, a corundum gasket is laid at an opening of the electrolysis cell; step 6, a furnace table board is mounted at the top of the electrolysis cell, and an anode is fixedly mounted on the furnace table board; step 7, a crucible is mounted at the bottom of the electrolysis cell. According to the construction technology of the electrolysis cell, the electrolysis cell is tighter and firmer in structure, good in thermal-insulating and anti-seep effect and high in structural stability and has the characteristics of high output, low energy consumption, long service life, low unit consumption of raw materials, high yield and the like, current of the electrolysis cell is 10KA or higher, and the problems of a conventional electrolysis cell are solved.

Owner:中稀(凉山)稀土有限公司

Calibration device, calibration method, and computer readable medium for visual sensor

ActiveUS10434654B2Affect operabilityUnnecessary timeImage enhancementProgramme-controlled manipulatorStereo cameraVision sensor

A parameter for detecting a target mark 5 is not required to be set for each camera repeatedly while a stereo camera 2 is calibrated. A calibration device 1 associates position information in an image coordinate system at a first camera 21 of a stereo camera 2, position information in an image coordinate system at a second camera 22 of the stereo camera 2, and position information in a robot coordinate system at a robot 4. The calibration device comprises: first parameter setting unit 102 that sets a first parameter for detecting a target mark 5 attached to the robot 4 from data about an image captured by the first camera 21; and a second parameter setting unit 104 that sets a second parameter for detecting the target mark 5 from data about an image captured by the second camera 22 based on the first parameter.

Owner:FANUC LTD

Medical information display device

InactiveCN112130625AEasy to viewAvoid problems such as reflectionsDigital data processing detailsCleaning using toolsMedical equipmentDisplay device

The invention belongs to the technical field of medical equipment, and particularly relates to a medical information display device which comprises a mounting plate, and supporting legs are fixedly mounted on the lower surface of the mounting plate. A mounting groove is formed in the upper surface of the mounting plate; a touch screen is rotationally mounted in the mounting groove; an electric push rod is mounted in the mounting groove; an extension rod of the electric push rod is connected with a pull rope; the other end of the pull rope is fixedly connected to the lifting roller; the liftingroller is positioned below the touch screen; the center line of the lifting roller is parallel to the center line of the rotating shaft; an elastic band is fixedly connected to the lower surface of the touch screen; the other end of the elastic band is fixedly connected to the bottom surface of the mounting groove; the elastic band is positioned at one end, away from the rotating shaft, of the touch screen; the device is flexible in display position and convenient for a patient to watch, and meanwhile, the device can be conveniently cleaned, disinfected and sterilized, so that germ spreadingis avoided.

Owner:宿州市久协医药信息咨询有限公司

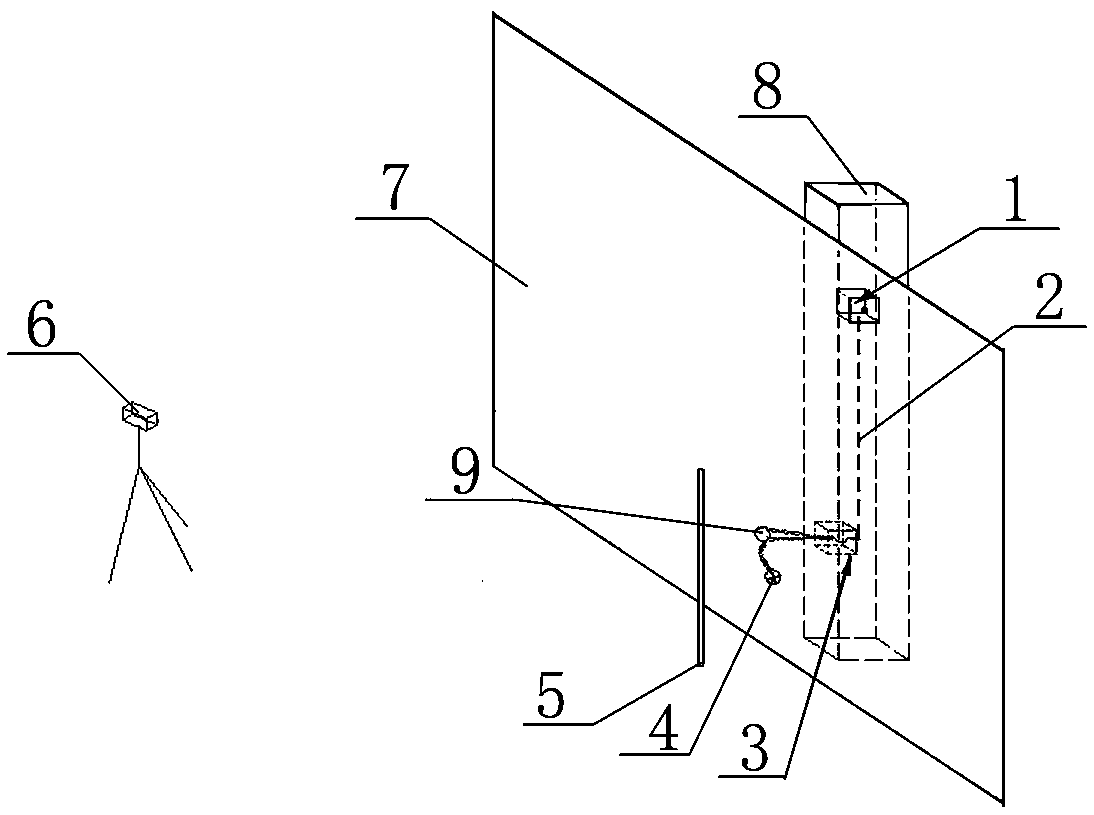

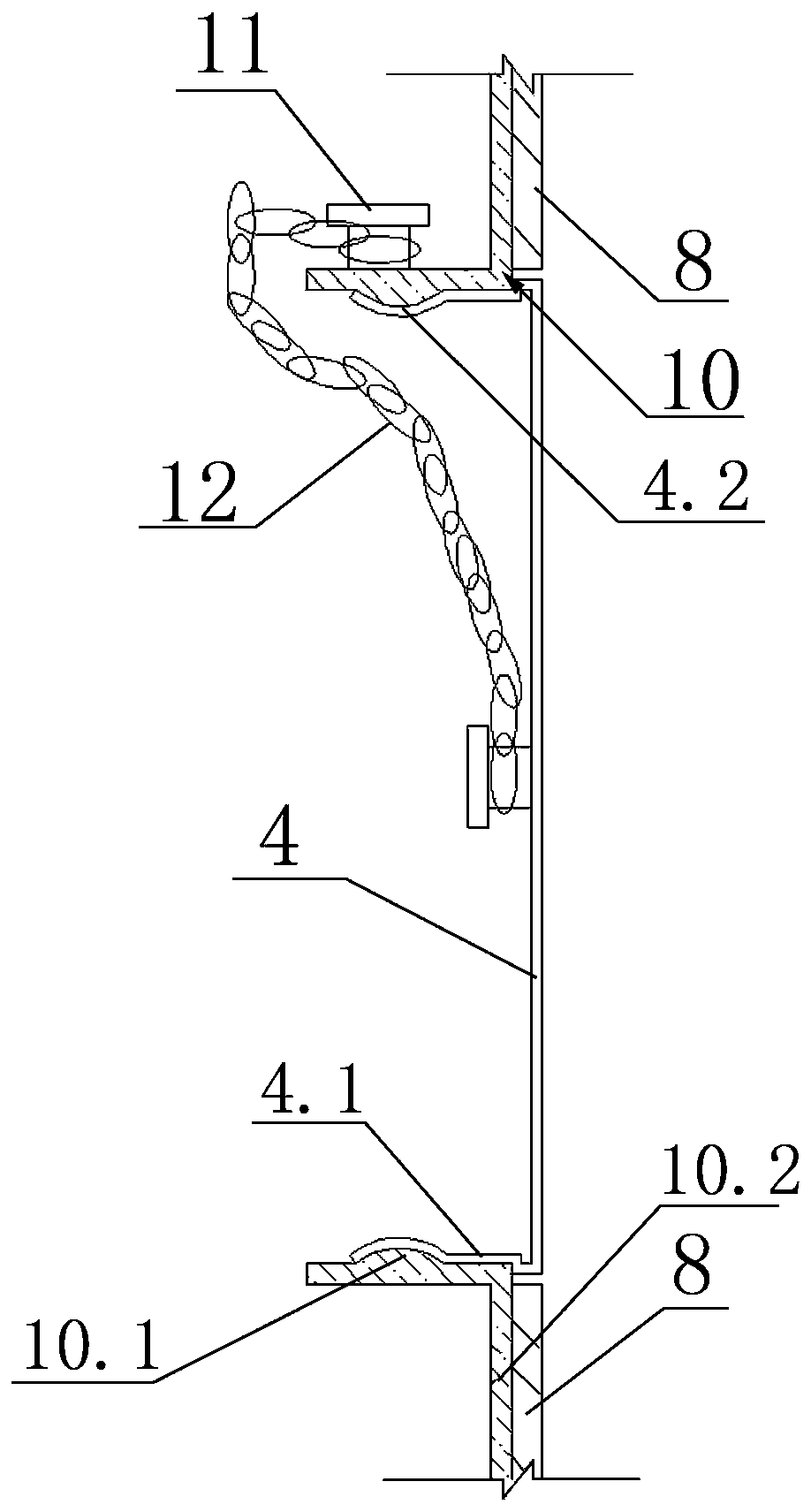

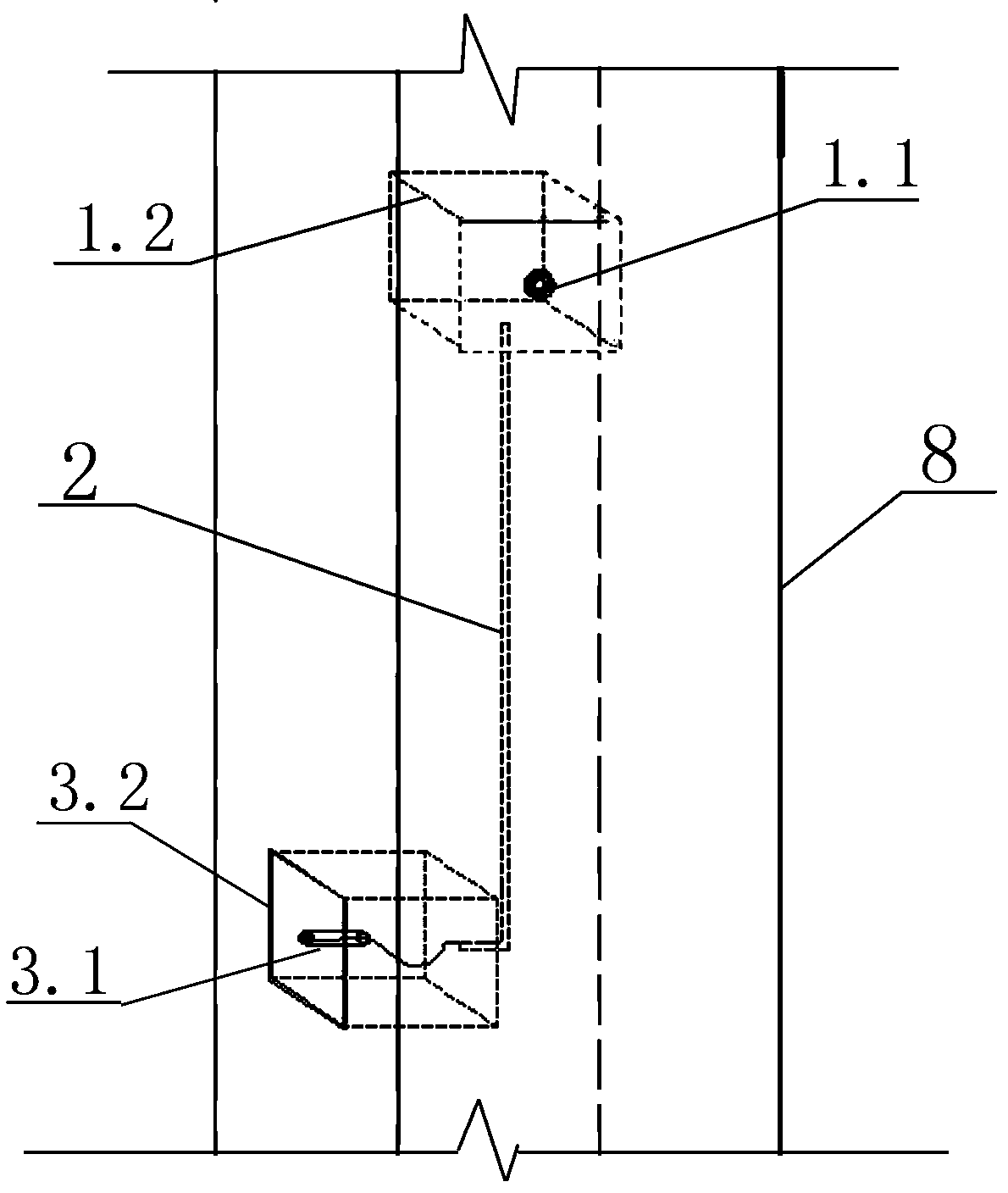

Invisible settlement observation point system and construction method thereof

PendingCN109708613AAffect aestheticsAffect operabilityMeasuring points markingHeight/levelling measurementObservation pointEngineering

The invention discloses an invisible settlement observation point system and a construction method thereof. The system includes a control device, a wire pipe, a laser emission device, a telemeter rodand a leveling instrument; the control device, the wire pipe and the laser emission device are installed on a main body structure on the inner side of a curtain wall; the laser emission device is installed at the position of designing laser emission points; the control device is installed on the inner side surface of the main body structure; the wire pipe is connected between the control device and the laser emission device; the emitting of a laser of the laser emission device can be controlled by the control device; the position, corresponding to the laser emission device, on the curtain wallis provided with a hole; the laser of the laser emission device can be emitted to the outside of the curtain wall through the hole; a window cover is installed on the hole; the telemeter rod is arranged on the outer side of the curtain wall corresponding to the hole; and the leveling instrument is arranged on the ground on the outer side of the curtain wall and close to the curtain wall. Thus, the technical problems, that traditional construction methods affect the beauty of building appearance, are difficult in operation and cannot truthfully reflect the settlement of buildings, can be solved.

Owner:CHINA CONSTR FIRST BUREAU GRP INTERIOR FITOUT ENG +1

Open-type rubber refining machine

The invention discloses an open-type rubber refining machine. The open-type rubber refining machine comprises a pair of rollers, a transmission device is connected to one ends the rollers, under the brake of the transmission device, the rollers rotate, a cavity is formed in each roller, an opening is formed in the other end of each roller, water inlet pipes are arranged to stretch into the cavities through the openings of the rollers, and a water collecting pool is arranged below the rollers and connected to a water storage box through a return pipe. Compared with the prior art, by designing the rollers into a cavity form and introducing cooling water to cool the rollers, heat generated during friction of the rollers can be timely dissipated, and it is prevented that continuous productionand operation personnel are influenced when local temperature is too high.

Owner:JIANGSU GEPU NEW MATERIALS CO LTD

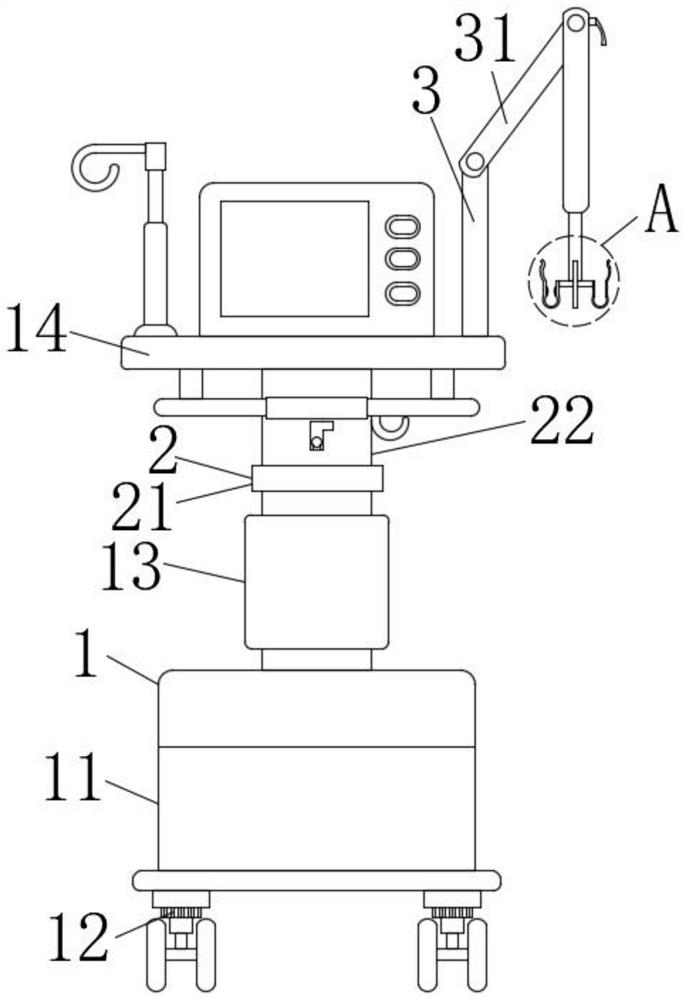

Convenient-to-use novel newborn breathing device

InactiveCN111956922AEasy to monitorNot easy to cause sheddingRespiratorsMedical equipmentFull Term Neonate

The invention relates to the technical field of medical equipment, in particular to a convenient-to-use novel newborn breathing device. The convenient-to-use novel newborn breathing device comprises amachine body and a tray, wherein the machine body comprises a rack; rotating wheels are fixedly connected to the bottom end of the rack; the tray is fixedly connected to the surface of the rack; a supporting disc is fixedly connected to the top end of the rack; a rotating mechanism is arranged on the surface of the rack; the rotating mechanism comprises a rotating drum; the surface of the rack isfixedly connected with the rotating drum; the inner side of the rotating drum is movably connected with a supporting rod; the bottom end of the supporting rod is fixedly connected with a rotating disc; a fixing groove is formed in the inner side of the rotating drum; and a connecting rod is connected to the inner side of a connecting groove in a sliding mode. Angle rotation of the equipment is facilitated, operation of the equipment in a narrow space and monitoring of data of the equipment are facilitated, and due to the fact that a pipeline is fixedly connected with the equipment, falling ofthe pipeline is not likely to be caused, and the use stability of a nasal plug is not affected.

Owner:苏娟

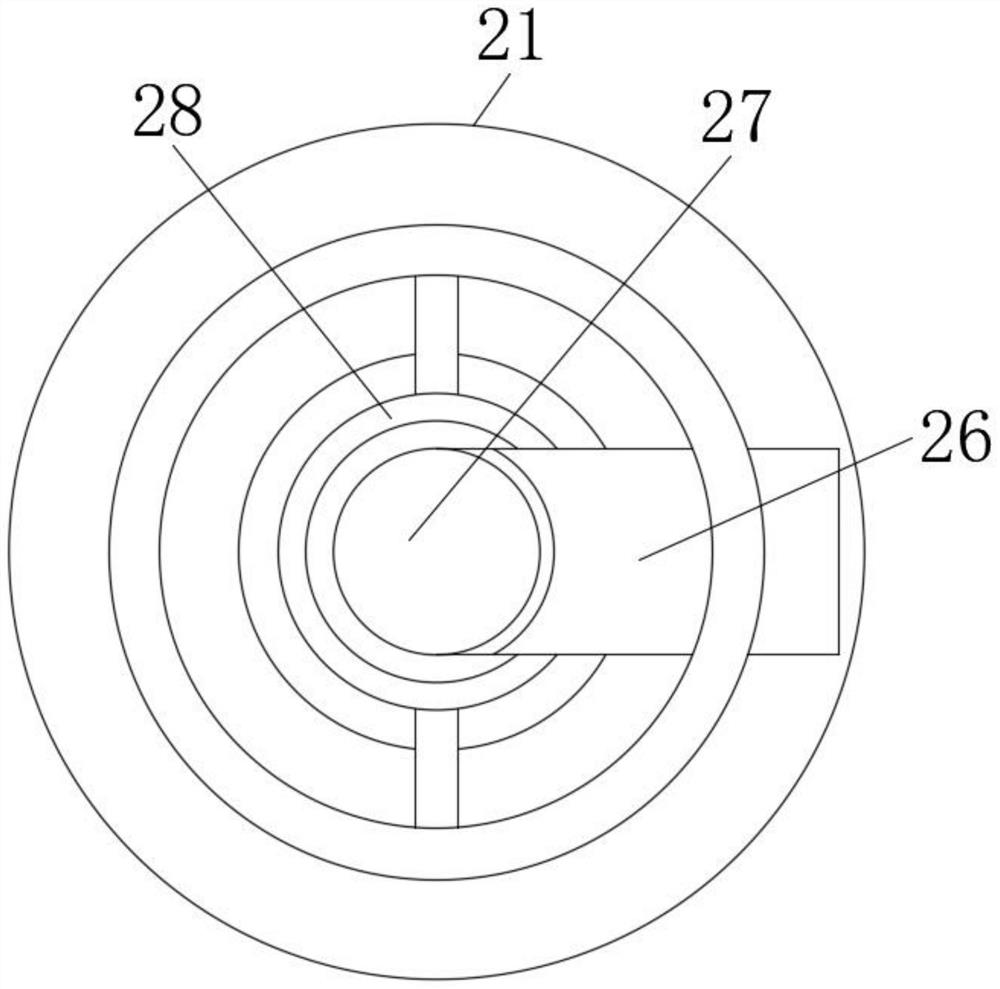

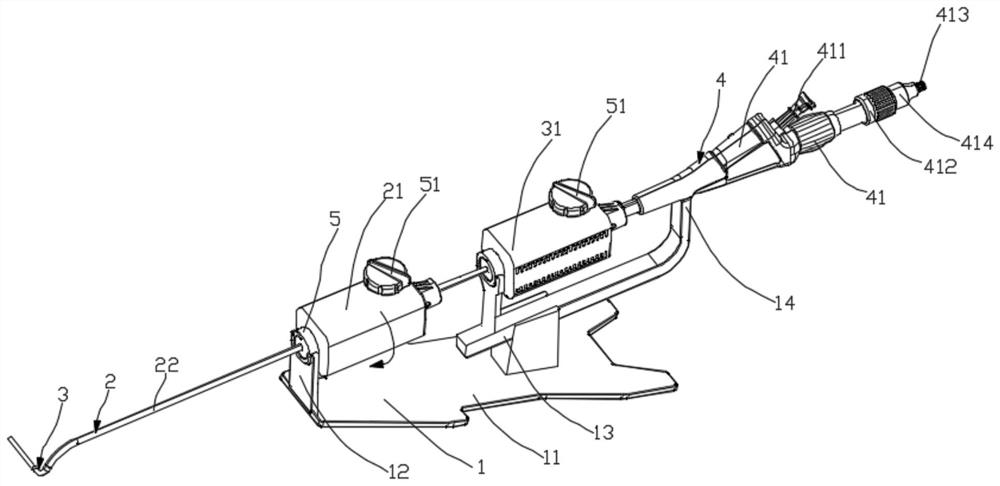

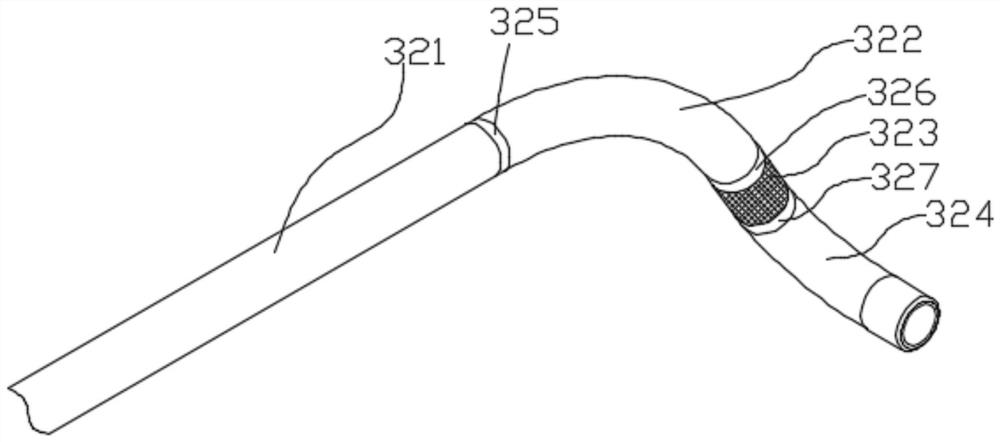

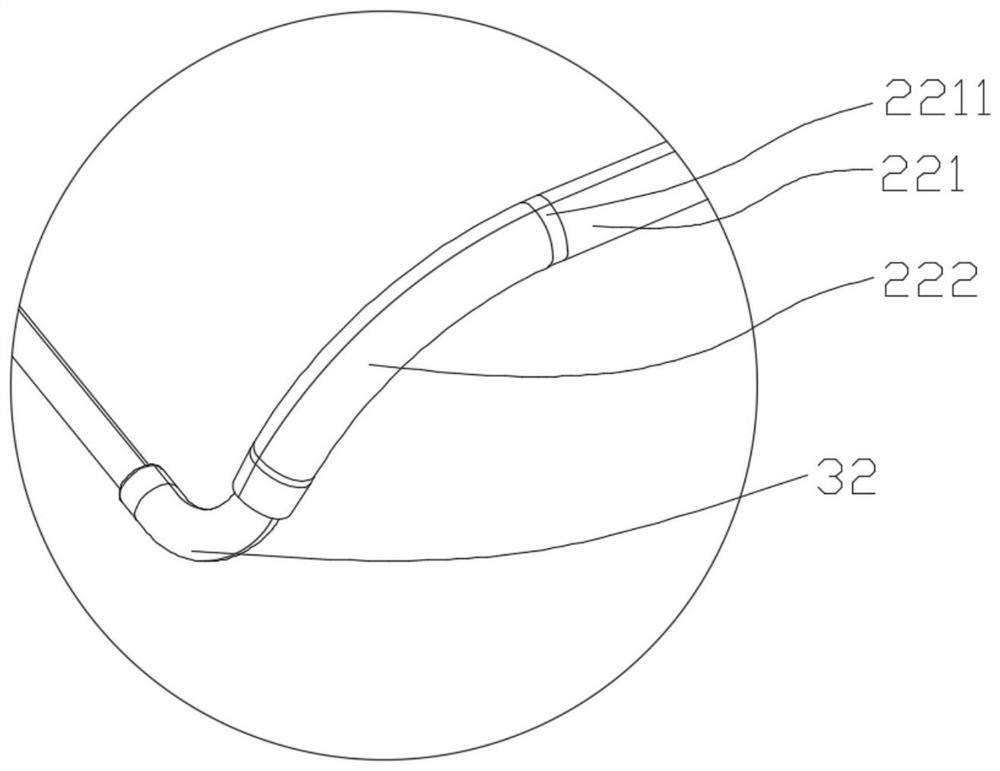

Intervention system for delivering valve clip

PendingCN113509292AConvenient for clinical operationIncrease freedomHeart valvesApparatus instrumentsSelf adaptive

The invention relates to the field of medical instruments, in particular to an intervention system for conveying a valve clip. The system comprises a fixed support, a first conveying module, a second conveying module and a third conveying module; the first conveying module comprises a first control body and a first conveying pipe, and the second conveying module comprises a second control body and a second conveying pipe; the first conveying module and the second conveying module are each provided with a rotary locking mechanism, the rotary locking mechanisms are fixed to the fixing supports in a matched mode, and the rotary locking mechanisms can lock the rotation angle in real time. The first conveying pipe comprises a first pipe body and a bent section; the second conveying pipe comprises a second pipe body, a self-adaptive section, a maintaining section and a bending adjusting section; the self-adaptive section and the bending section are axially overlapped; the retaining section and the bending section are axially arranged in a staggered mode or part of the retaining section and the bending section are axially arranged in an overlapped mode, the third conveying module comprises a third control body and a third conveying assembly, and part of the third conveying assembly is arranged in the second conveying pipe.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

A revit-based reinforcement calculation method, device, terminal equipment and medium

ActiveCN107944187BAffect operabilityEfficient computingGeometric CADDesign optimisation/simulationTerminal equipmentComputation process

The invention discloses a Revit-based steel bar calculation method and device, a terminal device and a medium. Steel bar property of each object in an object list of a Revit model can be analyzed, toobtain reinforcement attribute information; steel bar objects are generated according to the reinforcement attribute information, the steel bar engineering quantity is calculated for each steel bar object generated by each object until a steel bar list of all the objects in the object list is traversed, all calculated steel bar engineering quantity in the object list is summarized, and the total steel bar engineering quantity is obtained. That is, according to the technical scheme, a user only needs to configure the steel bar attribute information for the object that needs to calculate the steel bar engineering quantity in a structural model without the need to establish a steel bar model in Revit, no model data is added into existing Revit files in the whole calculation process, and the problem that due to the adding of plenty of steel bar model data, the mass of the Revit model is greatly increased, so that the operation performance of Revit is affected is solved.

Owner:XIAMEN HYMAKE TECH

Automatic mechanical cutting device and using method thereof

InactiveCN114161498AIncreased precisionSpeed up sortingMetal working apparatusAutomatic transmissionElectric machinery

The invention relates to the technical field of cutting devices, in particular to an automatic mechanical cutting device and a using method thereof. The device comprises a cutting mechanism, the cutting mechanism at least comprises a cutting body, the cutting body comprises a cutting table, a fixing rod is installed on the surface of the cutting table through block plates symmetrically arranged at the ends, the surface of the fixing rod is rotationally connected with a tool rest, a cutting tool is arranged in the tool rest, a tool handle is installed at one end of the tool rest, and a return plate is installed below the tool handle through an upper spring; and the automatic transmission body comprises a fixing frame installed on the cutting table, one end of the fixing frame is rotationally connected with a wheel disc, one end face of the wheel disc is rotationally connected with a wheel disc motor, and a guide rod is installed at one end of the surface of the wheel disc. According to the automatic material cutting device, automatic material cutting operation can be conducted on small or fragile materials, manpower is saved, and waste of resources is reduced.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

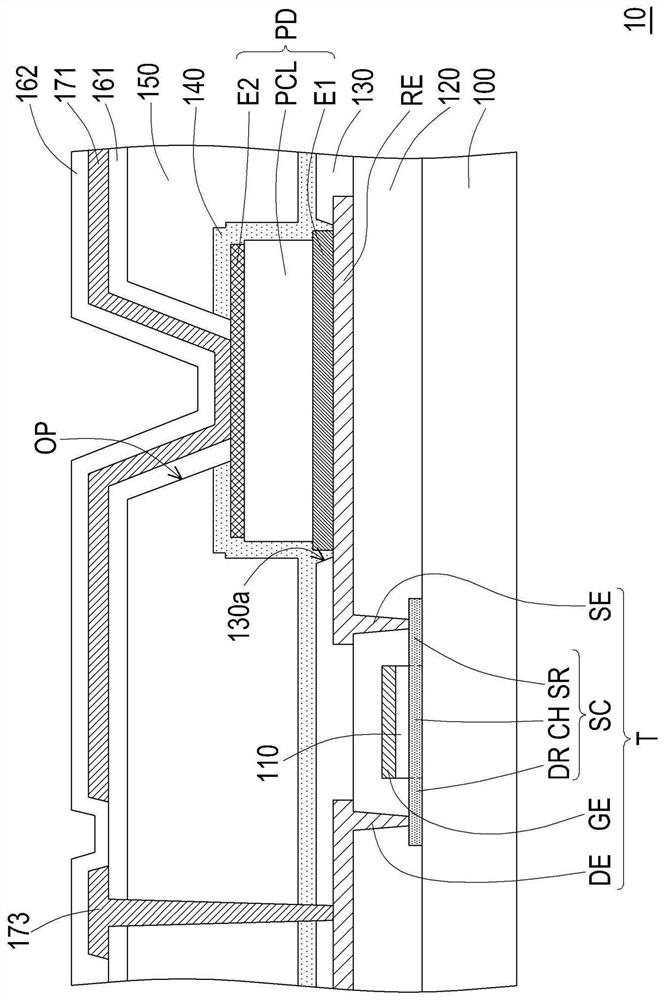

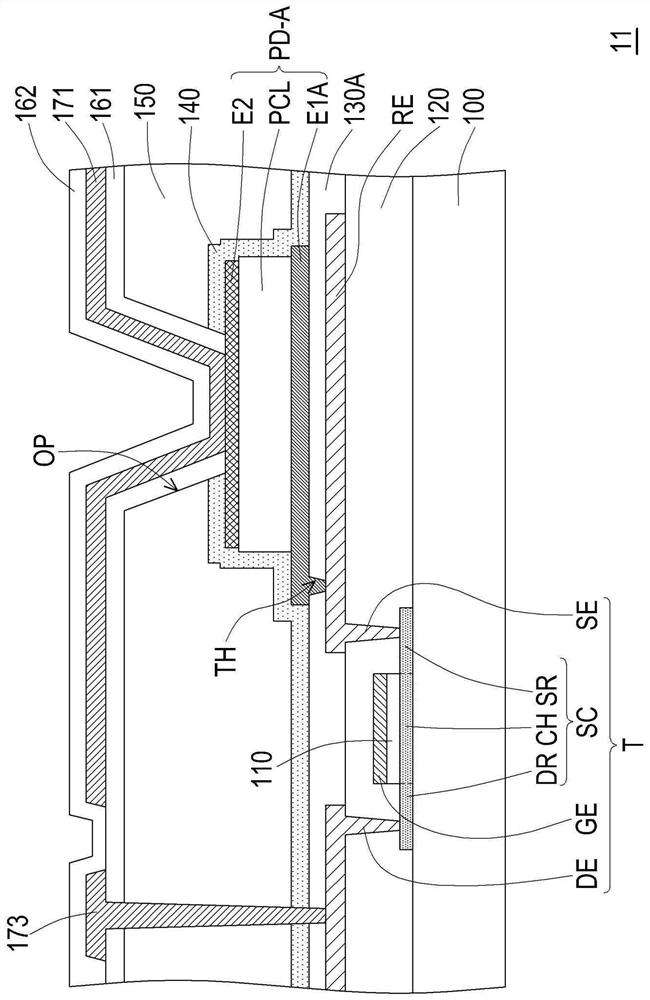

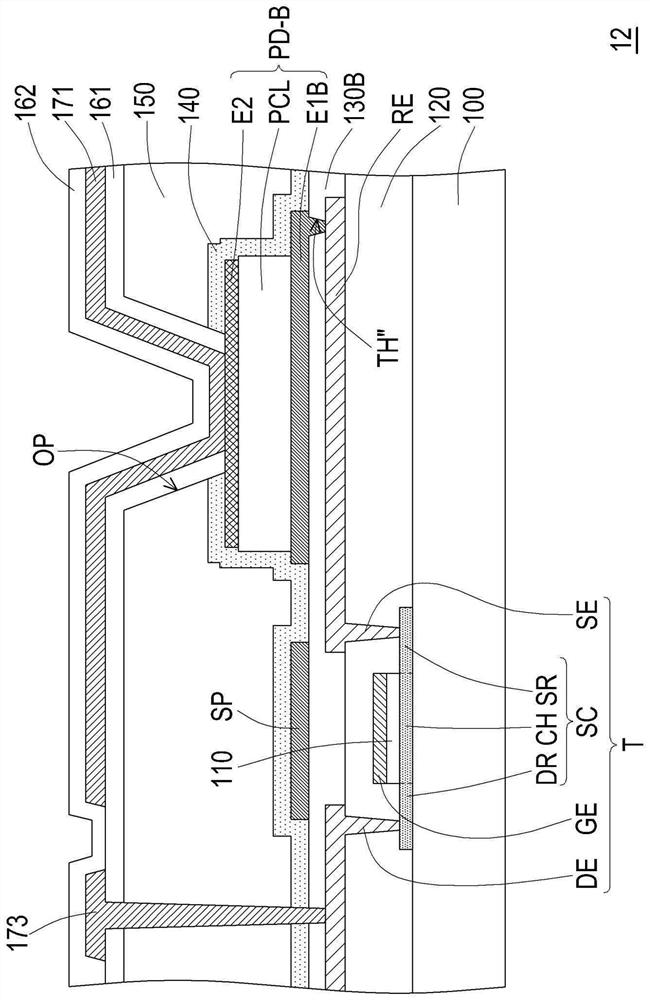

Photosensitive element substrate

PendingCN114709232AAffect operabilityAffect stabilityTransistorSolid-state devicesEngineeringPhotoelectric conversion

The invention discloses a photosensitive element substrate. The photosensitive element substrate comprises a substrate, an active element and a photosensitive element, the active element and the photosensitive element are arranged on the substrate. The active element has a semiconductor pattern and a gate. The semiconductor pattern is disposed between the substrate and the gate. The photosensitive element is electrically connected with the active element. The photosensitive element has a photoelectric conversion layer, and a first electrode and a second electrode disposed on opposite sides of the photoelectric conversion layer. The first electrode is located between the photoelectric conversion layer and the semiconductor pattern, and the material of the first electrode includes a metal oxide.

Owner:AU OPTRONICS CORP

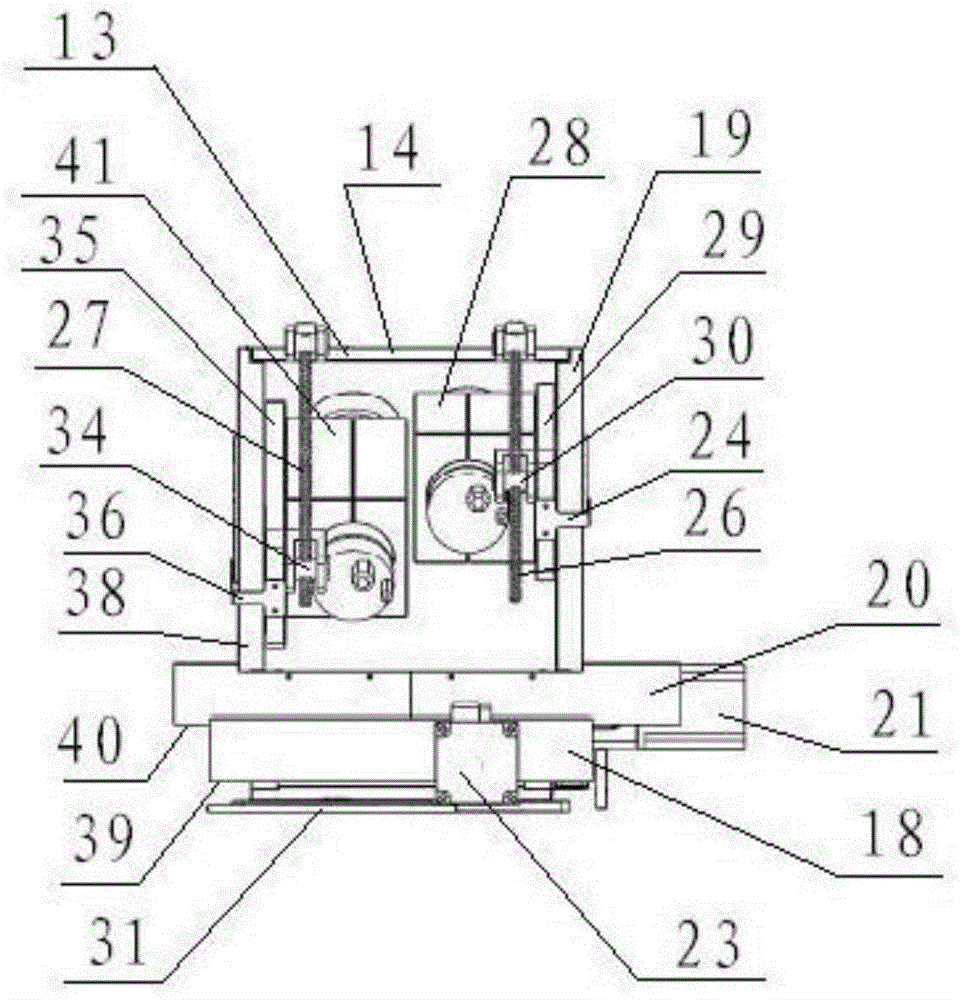

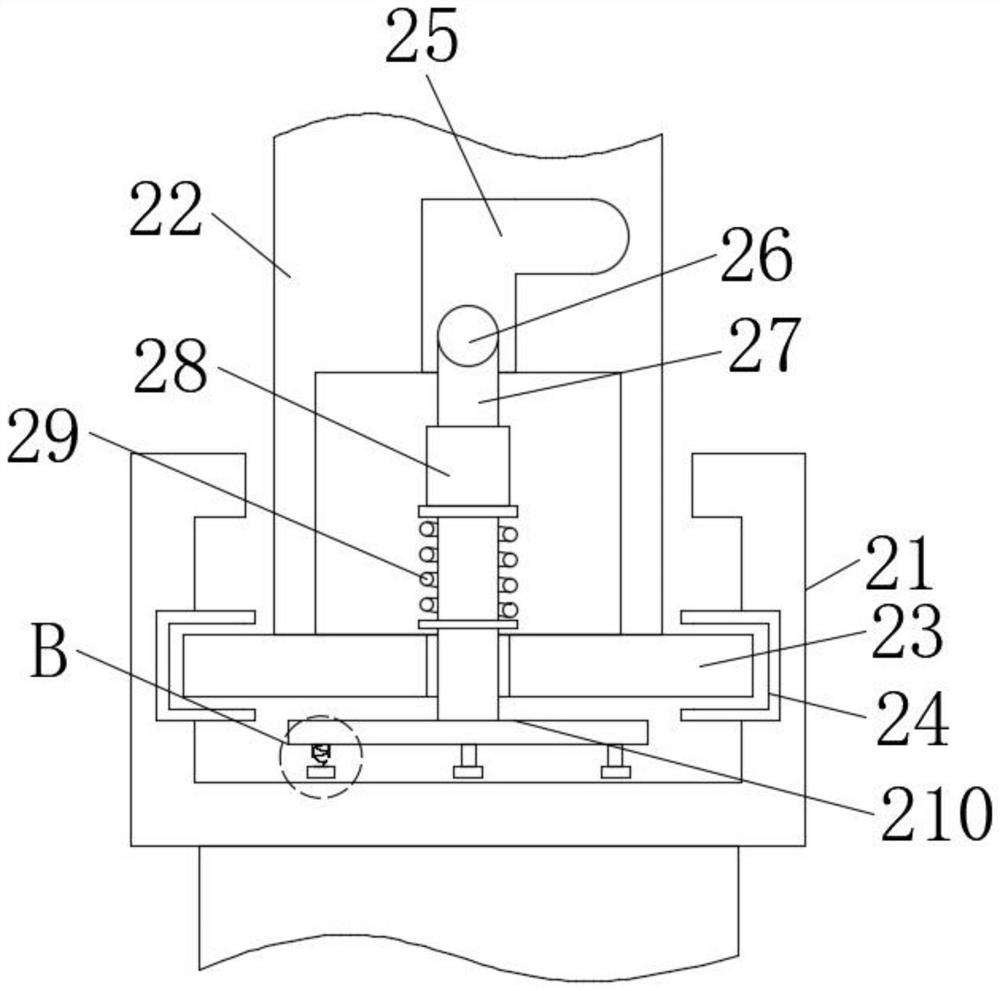

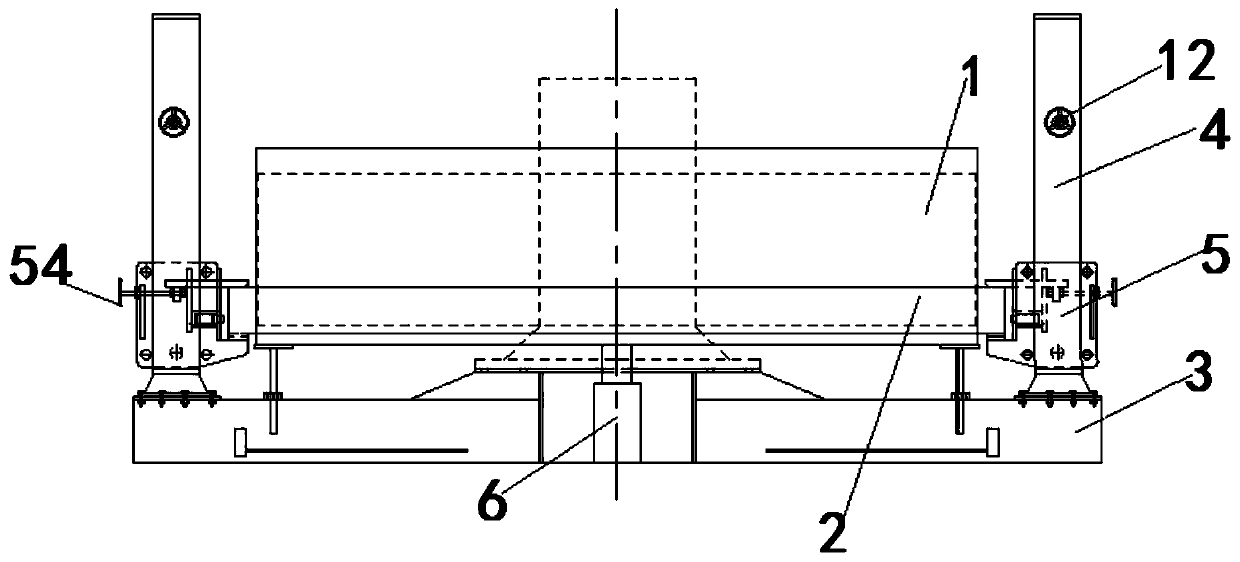

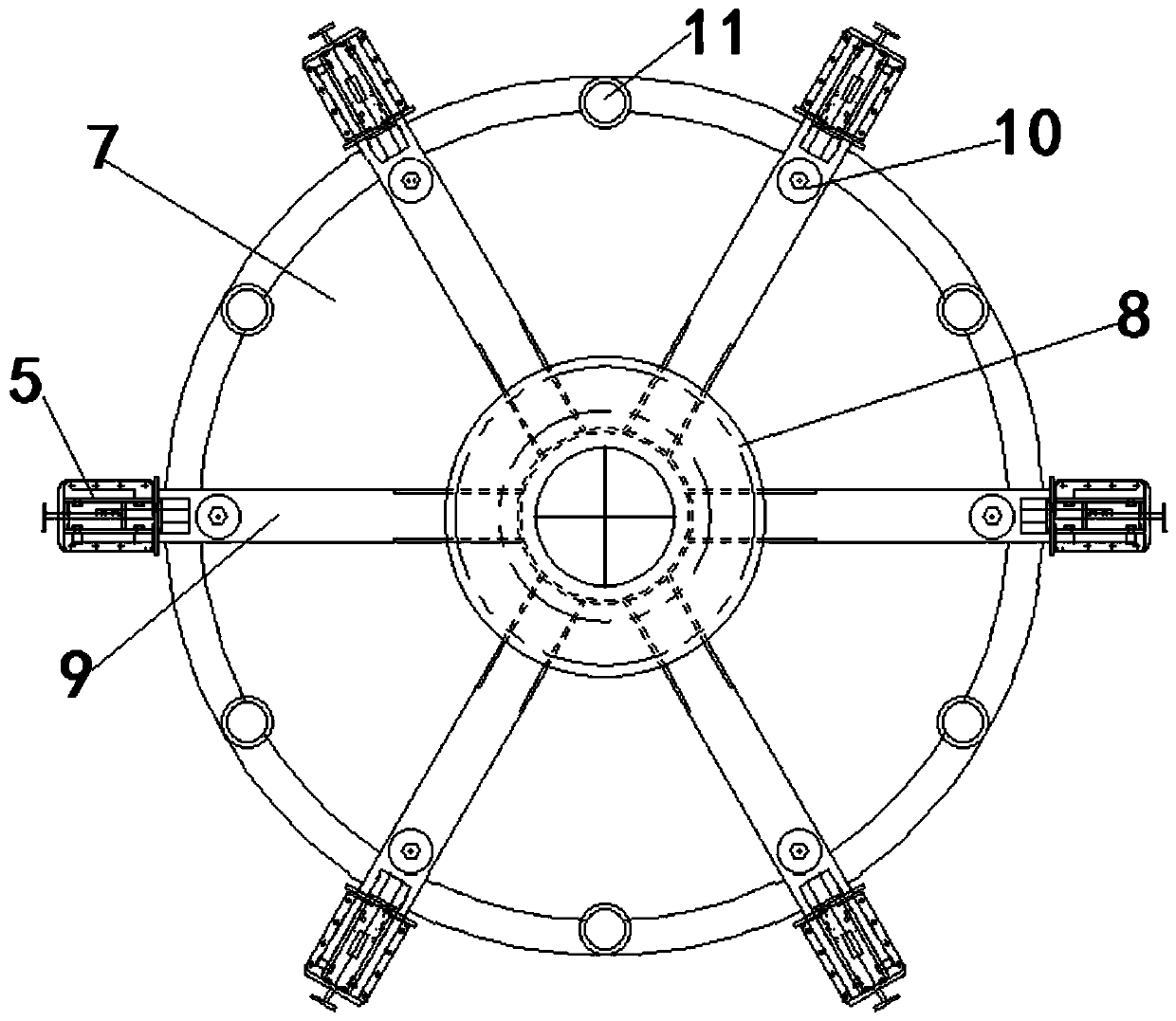

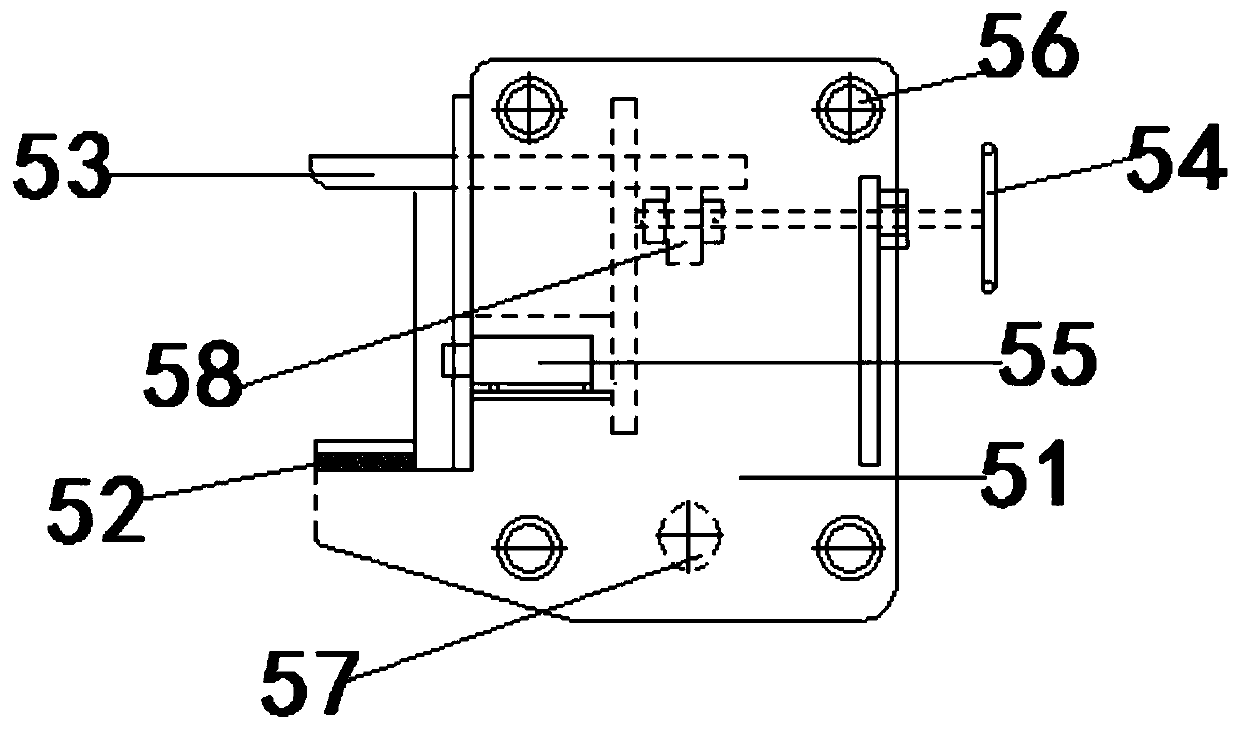

Motor stator and rotor assembling and separating device

ActiveCN110971089AGuaranteed levelnessAvoid tilting,Centering/balancing rotorsElectric machineClassical mechanics

The invention discloses a motor stator and rotor assembling and separating device, and is applied to a motor. The motor comprises a stator and a rotor. A reinforcing ring is nested outside the rotor.The motor stator and rotor assembly and separation device comprises a base for supporting a motor, a stand column which is vertically arranged on the base, a clamping jaw device which is used for clamping and fixing a reinforcing ring, and a synchronous lifting device which is arranged on the base, can ascend and descend and is used for providing power for assembling or separating a rotor; the clamping jaw device is movably arranged on the stand column so that the clamping jaw device can ascend and descend synchronously when the synchronous lifting device ascends and descends. By using the motor stator and rotor assembling and separating device provided by the invention, the assembling or separating operation efficiency of large and medium-sized motor stators and rotors can be improved, and the separating and assembling quality of the motor stators and rotors can be effectively ensured.

Owner:BAOTOU CRRC MOTOR CO LTD

Support for intravenous infusion arm in operation

PendingCN114082050AEffective bondageAffect the positionOperating tablesInfusion needlesSurgical ManipulationDisplay device

The invention discloses a support for an intravenous infusion arm in operation. The support comprises a mounting structure, the top of the mounting structure is provided with an adjusting structure, the top of the adjusting structure is provided with an arm support structure, the arm support structure is composed of four support rings and a lantern ring, a retraction structure is arranged between every two adjacent support rings, and a camera is mounted in the center of the lantern ring. According to the support for the intravenous infusion arm in the operation, the arm of a patient can be effectively bound in the operation, the phenomenon that the arm of the patient opens in the operation process to affect the standing position of a doctor and the operation operation can be effectively avoided, the camera is arranged, the camera can be wirelessly connected with an external display device to make medical staff conveniently check the infusion condition of the puncture point position of venous infusion of the patient at any time, the use effect is better, the camera can slide through the lantern ring to adjust the position, the puncture point position of the patient can be aligned in time, and the applicability is high.

Owner:朱梦麟

Adjustable support for oral treatment

PendingCN114469382AAvoid fatigueAvoid bitesSuction devicesInstruments for stereotaxic surgeryOral treatmentDentistry

The invention discloses an adjustable bracket for oral treatment, which comprises a lower occlusion seat, and an adjusting mechanism is mounted on the lower occlusion seat; the adjusting mechanism comprises a lifting screw, an upper occlusion seat, a plurality of tooth occlusion pads and an anti-falling structure; the lifting screw is connected to the lower occlusion seat in a screwed mode, the upper occlusion seat is installed at the top end of the lifting screw, the tooth occlusion pads are arranged on the upper occlusion seat and the lower occlusion seat respectively, and the anti-falling structure is installed on one side of the upper occlusion seat. A patient is prevented from unautonomously biting an operation doctor and biting a diagnosis and treatment instrument; the height of the device can be adjusted, so that a doctor can conveniently treat the oral cavity; the device can be arranged on the opposite side, and operation of a doctor is not affected. The device has a supporting effect on a patient with limited mouth opening; the device is used by old people and children, operation is convenient, and treatment time is saved.

Owner:天津汉元科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com