Aviation blade forming tool and process based on carbon-ceramic material

A technology for aviation blades and forming tooling, applied in the field of aviation blade molds, can solve the problems of difficult processing of air film grooves, eccentric mold positioning, etc., and achieve the effect of easy processing and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

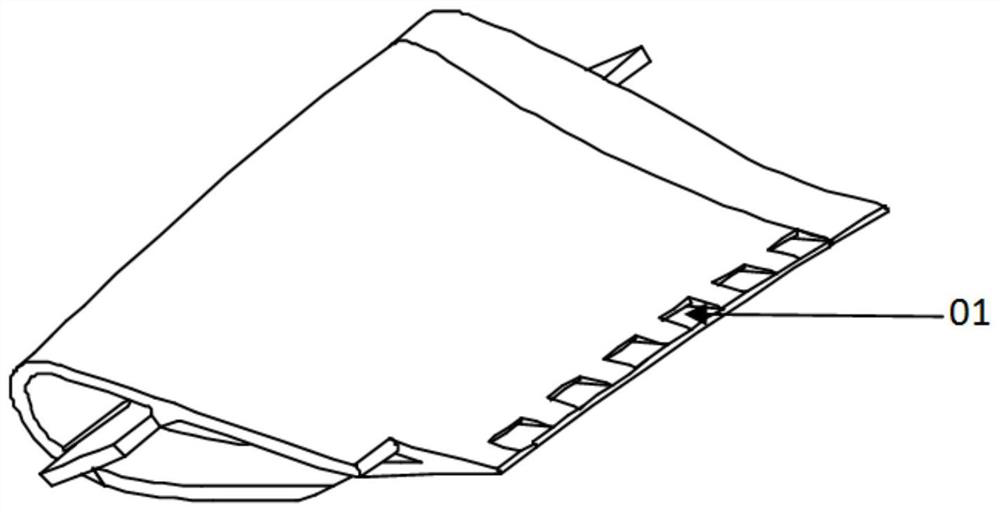

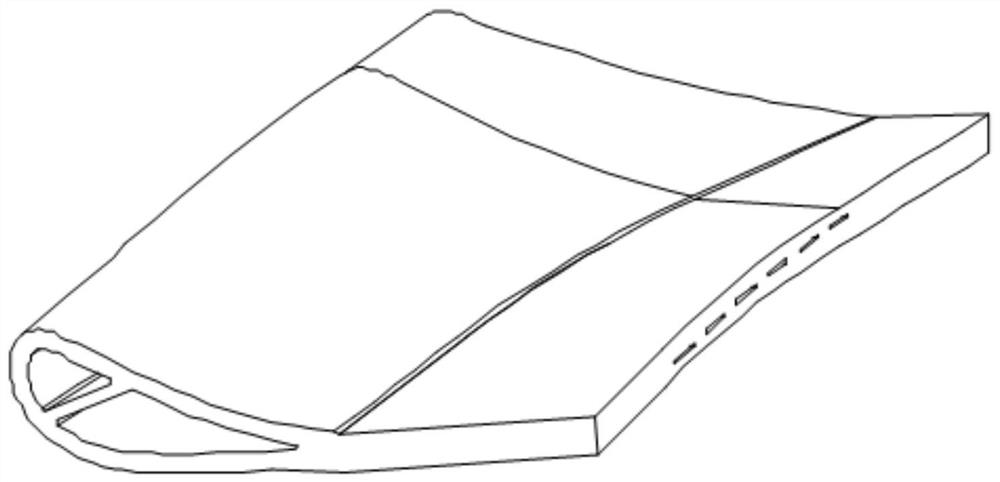

[0064] like figure 1 As shown, it is a schematic diagram of the structure of the blade to be processed in this embodiment, and it can be seen that a plurality of air film holes 01 are opened thereon. figure 2 It is a schematic diagram of the fiber fabric structure, and a plurality of air film holes are correspondingly opened on it. Because the opening size of the air film hole is generally less than 10*10mm, the depth is about 30mm, and the profile is a curved surface, it cannot be processed by a tool holder. Therefore the present invention designs a kind of forming tooling, utilizes forming tooling in the process of wrapping the fiber fabric with the surface of the inner mold, processes the air film groove at the corresponding part of the fiber fabric, and the air film hole is naturally formed during the blade forming process.

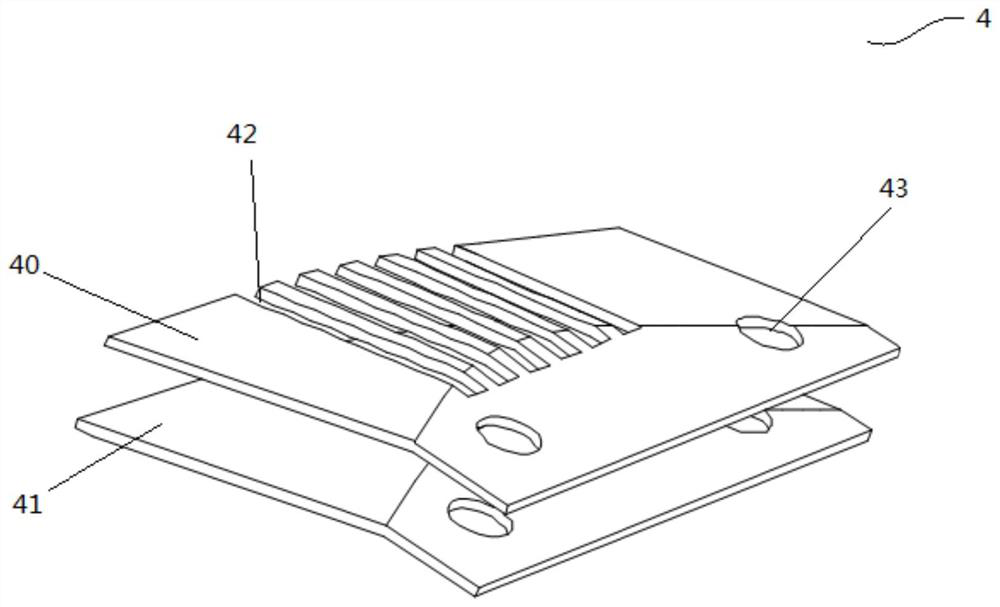

[0065] to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com