Open-type rubber refining machine

An open rubber mixing machine, a pair of technology, applied in the field of chemical machinery, can solve the problems of accelerated machine aging, personal safety impact of surrounding operators, temperature rise, etc., and achieve the effect of preventing local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

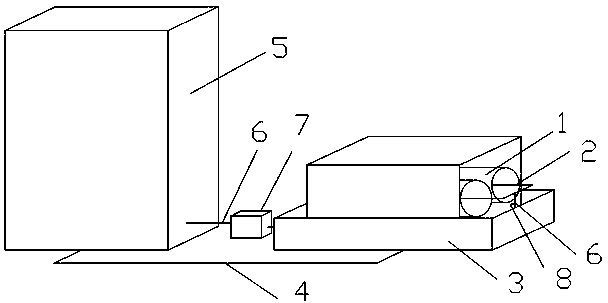

[0010] Such as figure 1 A kind of open type rubber mixing machine shown comprises a pair of rollers 1, and one end of the rollers 1 is connected to a transmission device, and it rotates automatically under the braking of the transmission device. The inside of the rollers 1 has a cavity, and the other end is The opening is provided with a water inlet pipe 2 extending into the cavity through the opening of the roller, and a sump 3 is arranged below the roller 1, and the sump 3 is connected back to the water storage tank 5 through the return pipe 4.

Embodiment 2

[0012] Referring to Example 1, the water storage tank 5 is connected to the water inlet pipe 2 through a water connection pipe 6 , and a water pump 7 and a control valve 8 are provided on the water connection pipe 6 .

Embodiment 3

[0014] Referring to Embodiments 1 and 2, the level of the connecting water pipe 6 is higher than that of the return pipe 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com