Process for preparing rubber compound of ethylene propylene diene monomer waterproof roll

A technology of waterproof membrane and EPDM, which is applied in the field of compound rubber preparation technology of EPDM waterproof membrane, can solve the problems of high labor intensity and high energy consumption, and achieve the reduction of labor intensity, reduction of environmental pollution, The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

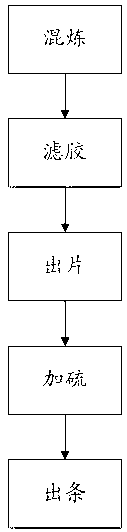

[0020] see figure 1 , the embodiment of the present invention provides the preparation process of the mixed rubber of EPDM waterproofing membrane, comprising the following steps:

[0021] a. Mixing, put the prepared raw materials into the internal mixing chamber of the internal mixer for internal mixing for 6 minutes, and discharge continuous rubber strips;

[0022] b. Filtering rubber, continuously add continuous rubber strips into the feeding port of the rubber filtering machine, and cut off the rubber strips with a thin steel wire when the length of the filtered rubber strips is 500-600mm;

[0023] c. To output the film, put the cut rubber st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com