Construction technology of 10KA-level rare earth electrolysis cell

A construction technique and electrolytic cell technology, applied in the direction of cells, etc., to achieve the effects of avoiding the accident of slotting, suppressing excessive surface temperature, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

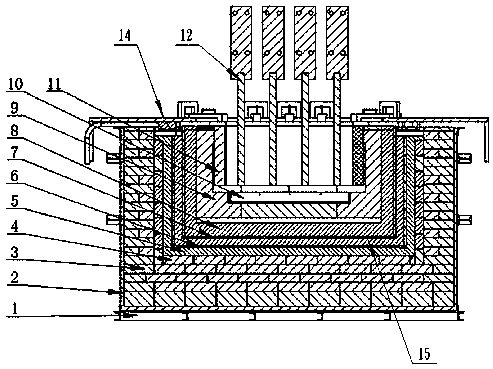

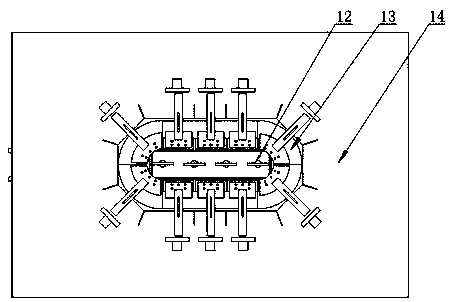

[0052] Embodiment: A kind of 10KA level rare earth electrolyzer structure, its construction technology comprises the following steps:

[0053] Step 1. Take the pretreated tank shell 1, lay a layer of aluminum silicate fiber felt (fiber insulation layer 2) with a thickness of 2-4cm on the inner wall of the tank shell 1, and then use diatom mud insulation bricks (Refer to specification 230×115×65mm) Insulation layer 3 with a bottom thickness of 30-35cm and a side wall thickness of 20-25cm requires staggered gaps between each layer of bricks;

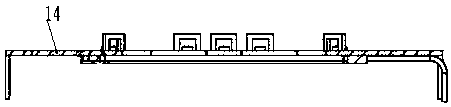

[0054] Step 2. Spread a layer of heat insulation layer 4 with a thickness of 6.5cm on the end face of the insulation layer 3 with clay refractory bricks (reference specification 230×115×65mm). Lay and compact a layer of magnesia material with a thickness of 5-10cm on the layer 4 to form the first refractory layer 5. There is a φ25mm PVC pipe (i.e. exhaust pipe), and then the first steel sleeve (i.e. the first metal sleeve 6) is placed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com