Method for crystallizing and separating para xylene

A technology for p-xylene and crystallization separation, applied in crystallization purification/separation, organic chemistry, etc., can solve the problems of complex operation and high investment in xylene, and achieve the effect of cheap price, low investment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

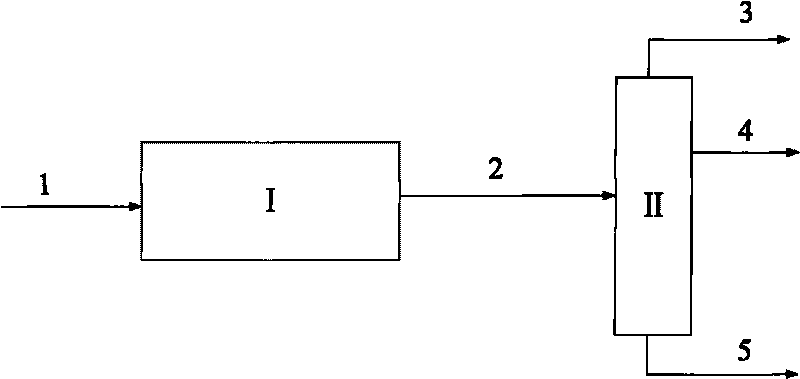

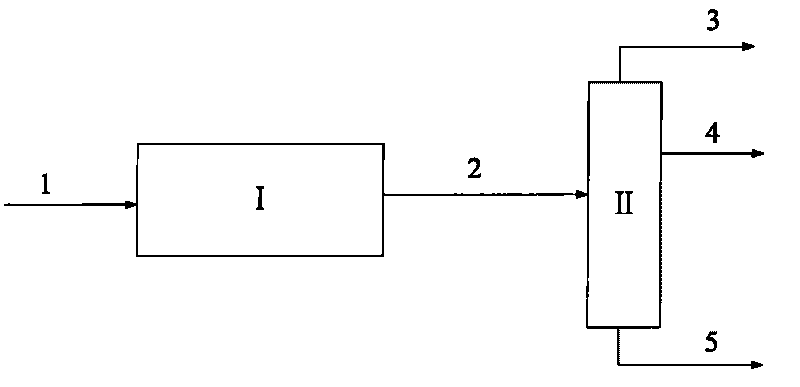

[0015] according to figure 1 As shown, the mixed xylene raw materials are sent to the scraping wall crystallizer, and the crystallization temperature is -10°C to form a slurry. The slurry is sent to a hydraulic tower scrubber for filtration, washing and crystal purification. The washing liquid / crystal With a weight ratio of 0.2, pure p-xylene was obtained. After the test runs stably, the composition of each stream is shown in Table 1.

[0016] The composition (% by weight) of each stream in the embodiment 1 of table 1

[0017] component

Embodiment 2

[0019] according to figure 1 As shown, the mixed xylene raw material is sent to the stirring crystallizer, and the crystallization temperature is -60°C, and the slurry is sent to the gravity tower scrubber, and after filtration, washing and crystal purification, the washing liquid / crystal weight ratio is 0.5, Pure p-xylene was obtained. After the test runs stably, the composition of each stream is shown in Table 2.

[0020] The composition (% by weight) of each stream in the embodiment 2 of table 2

[0021] component

Embodiment 3

[0023] according to figure 1 As shown, the mixed xylene raw materials are sent to the scraping wall crystallizer, and the crystallization temperature is 5°C to form a slurry. The slurry is sent to a mechanical tower scrubber for filtration, washing and crystal purification. The washing liquid / crystal With a weight ratio of 0.05, pure p-xylene was obtained. After the test runs stably, the composition of each stream is shown in Table 3.

[0024] The composition (% by weight) of each stream in the embodiment 3 of table 3

[0025] component

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com