Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Good stripping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

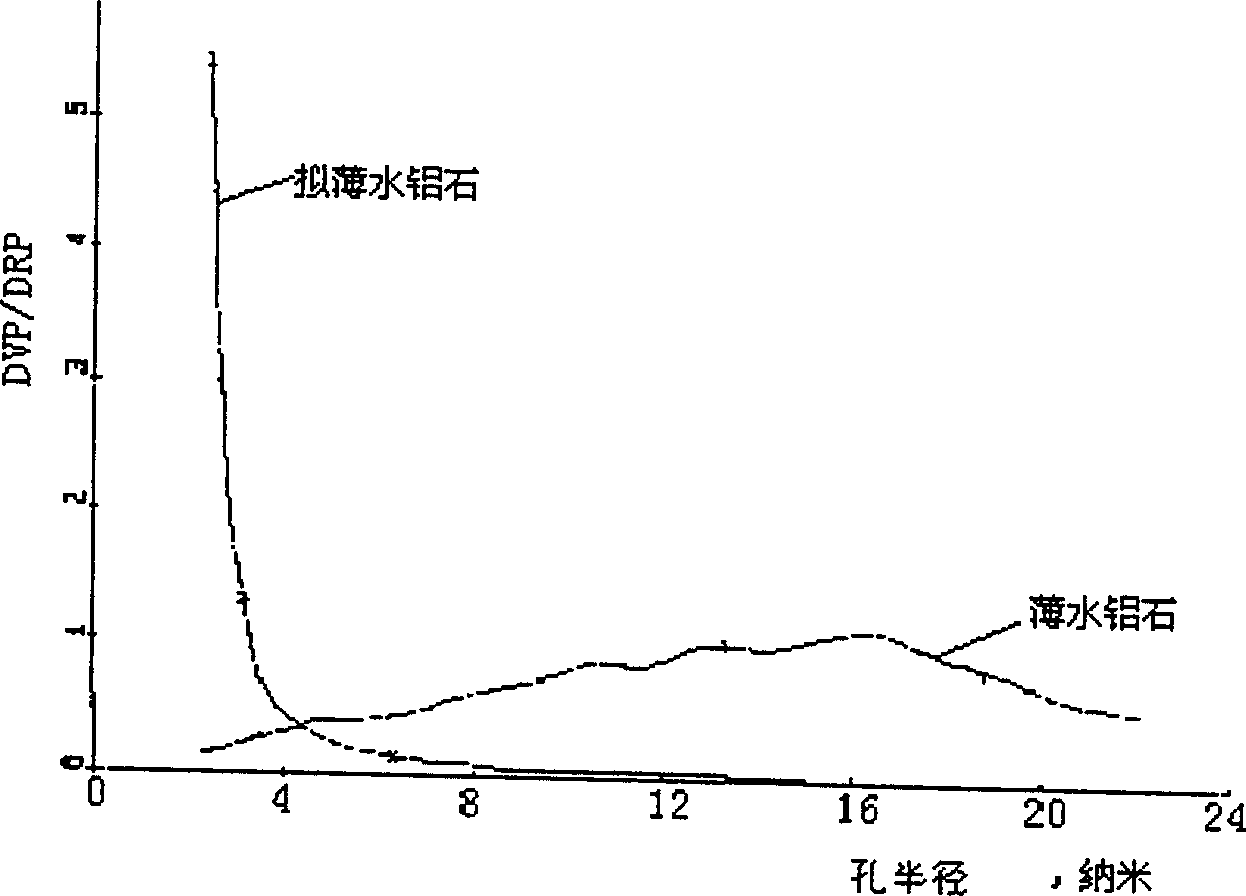

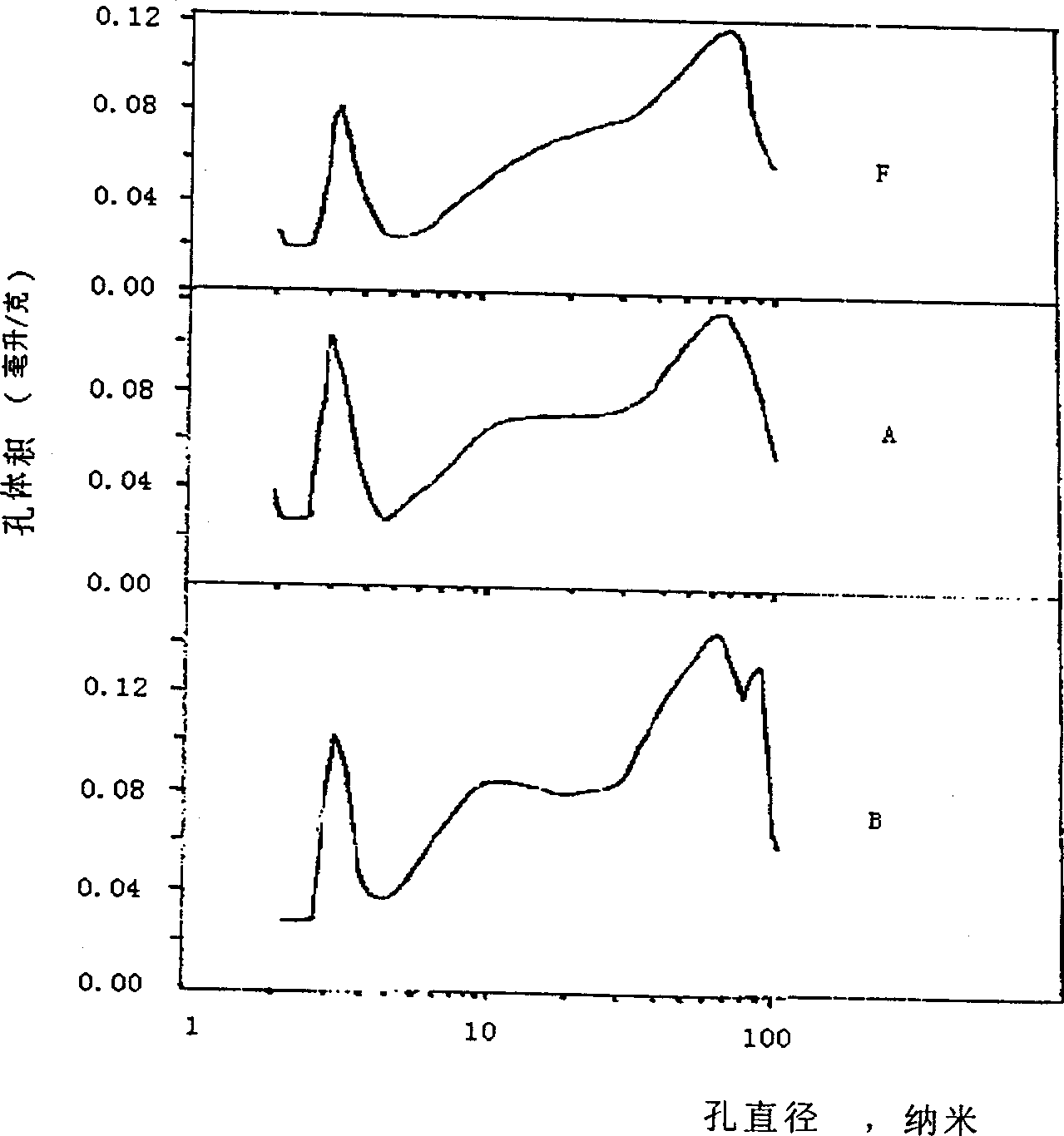

Catalytic cracking catalyst and its prepn

The catalytic cracking catalyst contains medium and large pore alumina with average pore size not smaller than 3 nm 5-60 wt%, zeolite 5-60 wt%, adhesive 5-40 wt% and clay 5-85 wt%. The preparation process includes mixing the said materials, spraying, roasting, washing and drying. Compared with conventional catalyst, the catalyst has strengthened heavy oil converting capacity, obviously improved gasoline and coke selectivity and strengthened heavy metal nickel resistance.

Owner:PETROCHINA CO LTD

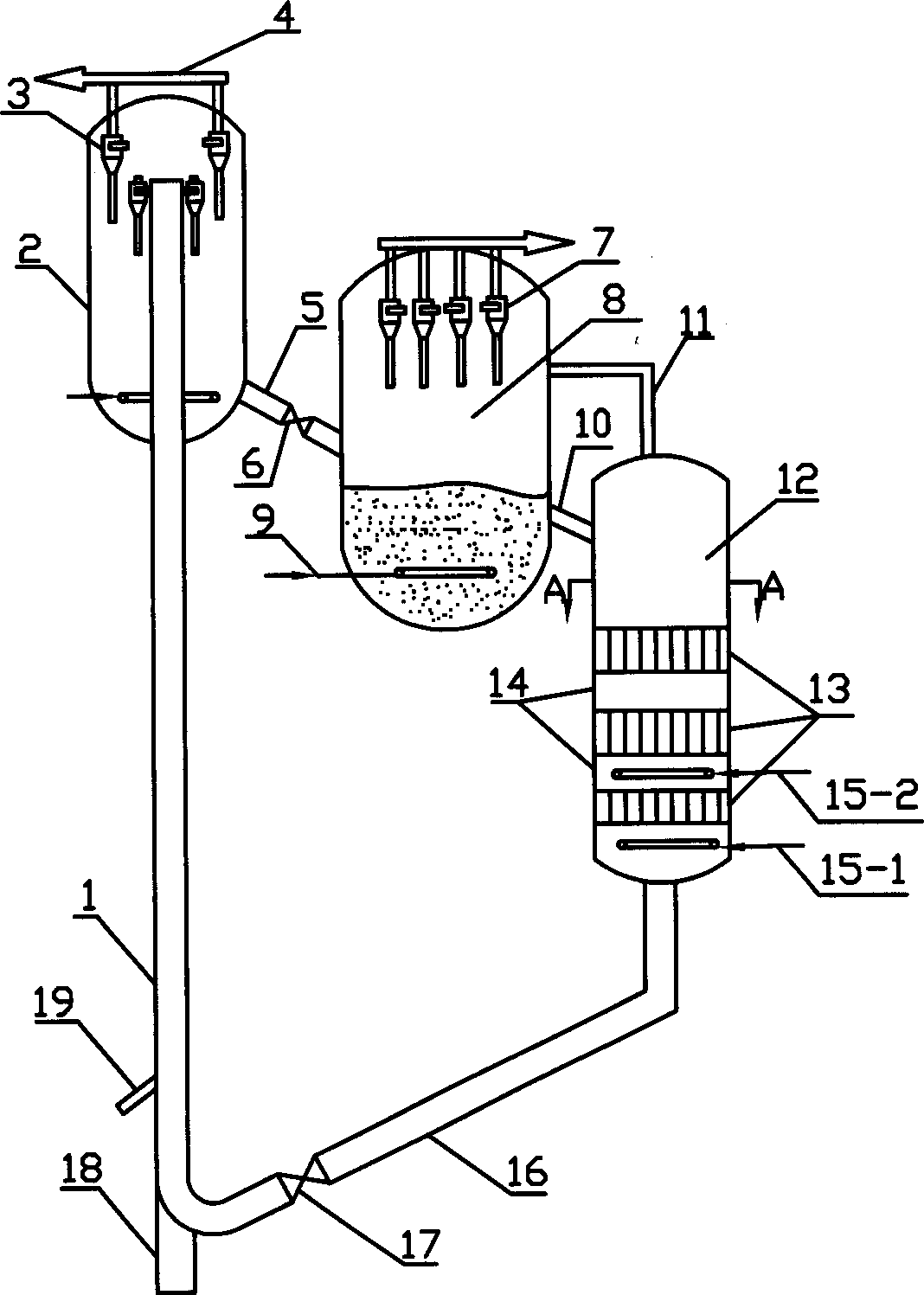

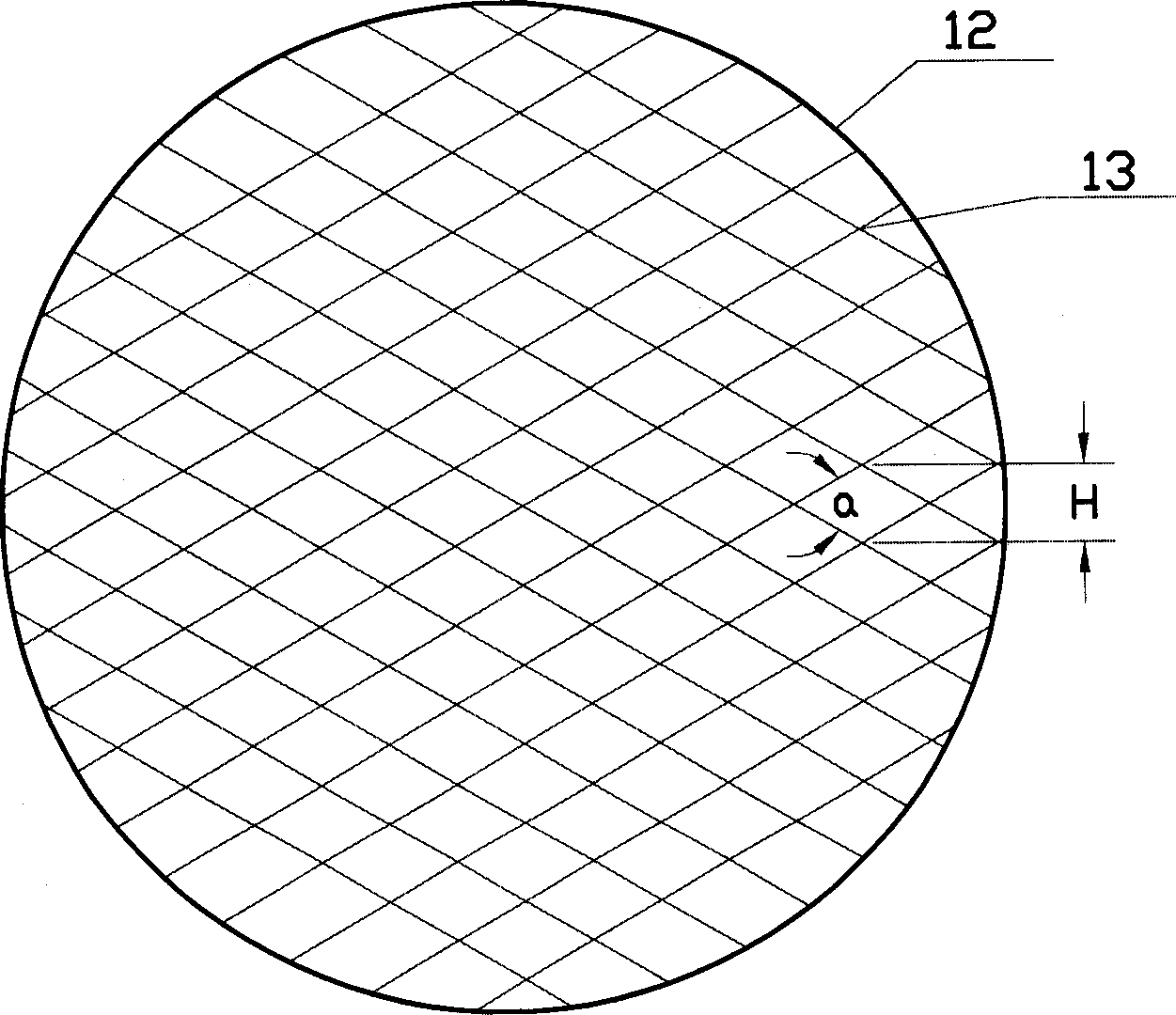

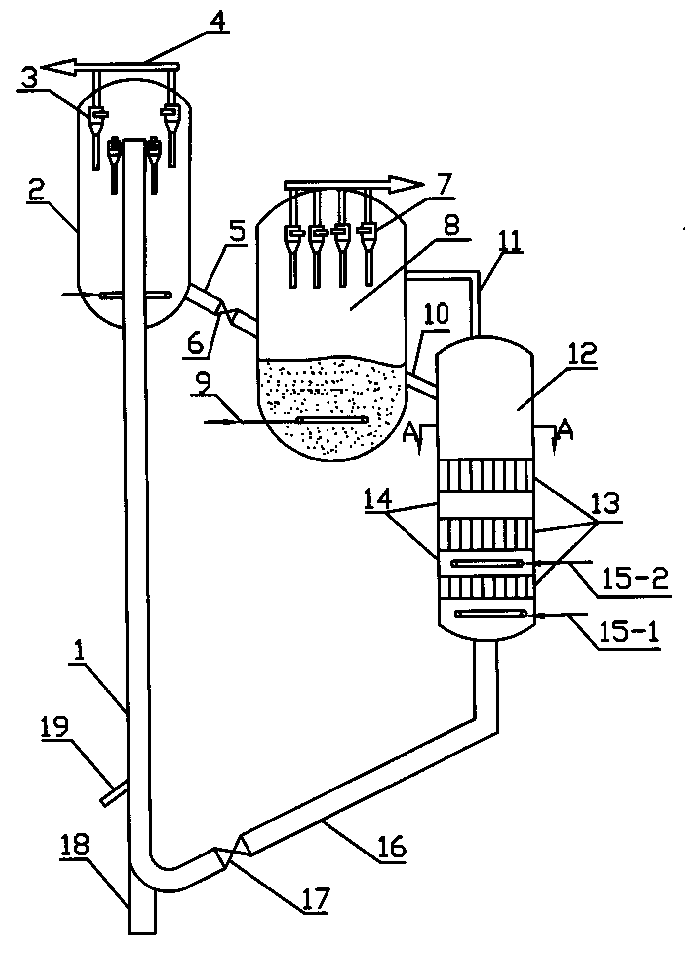

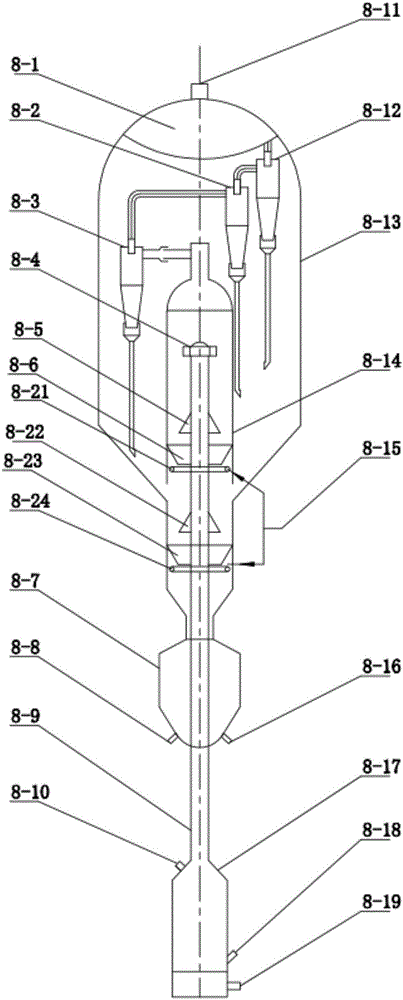

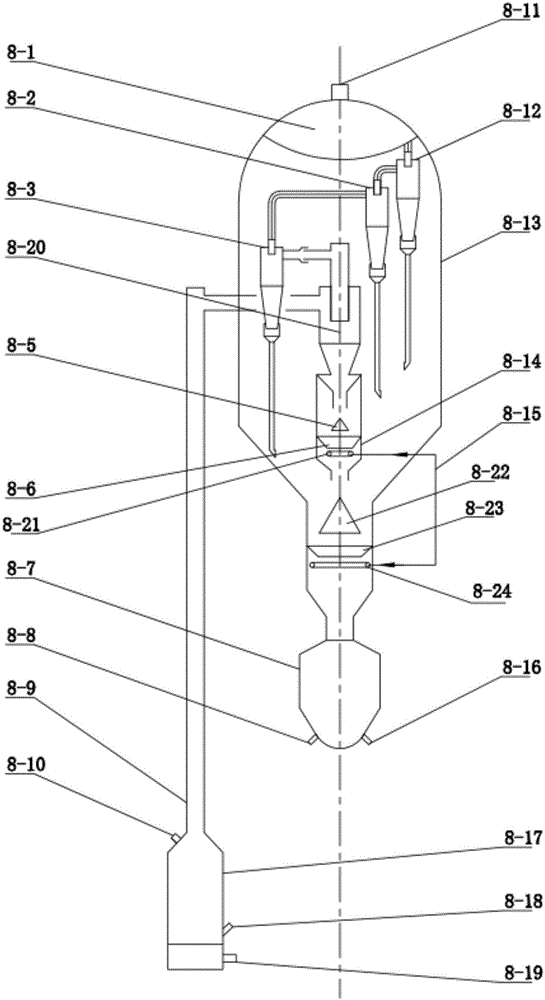

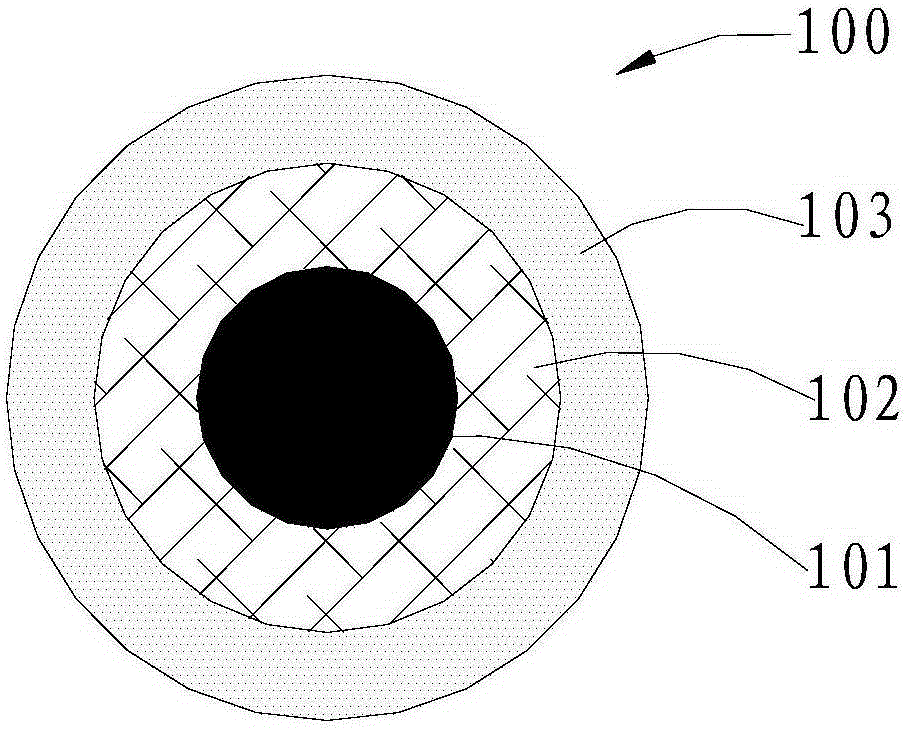

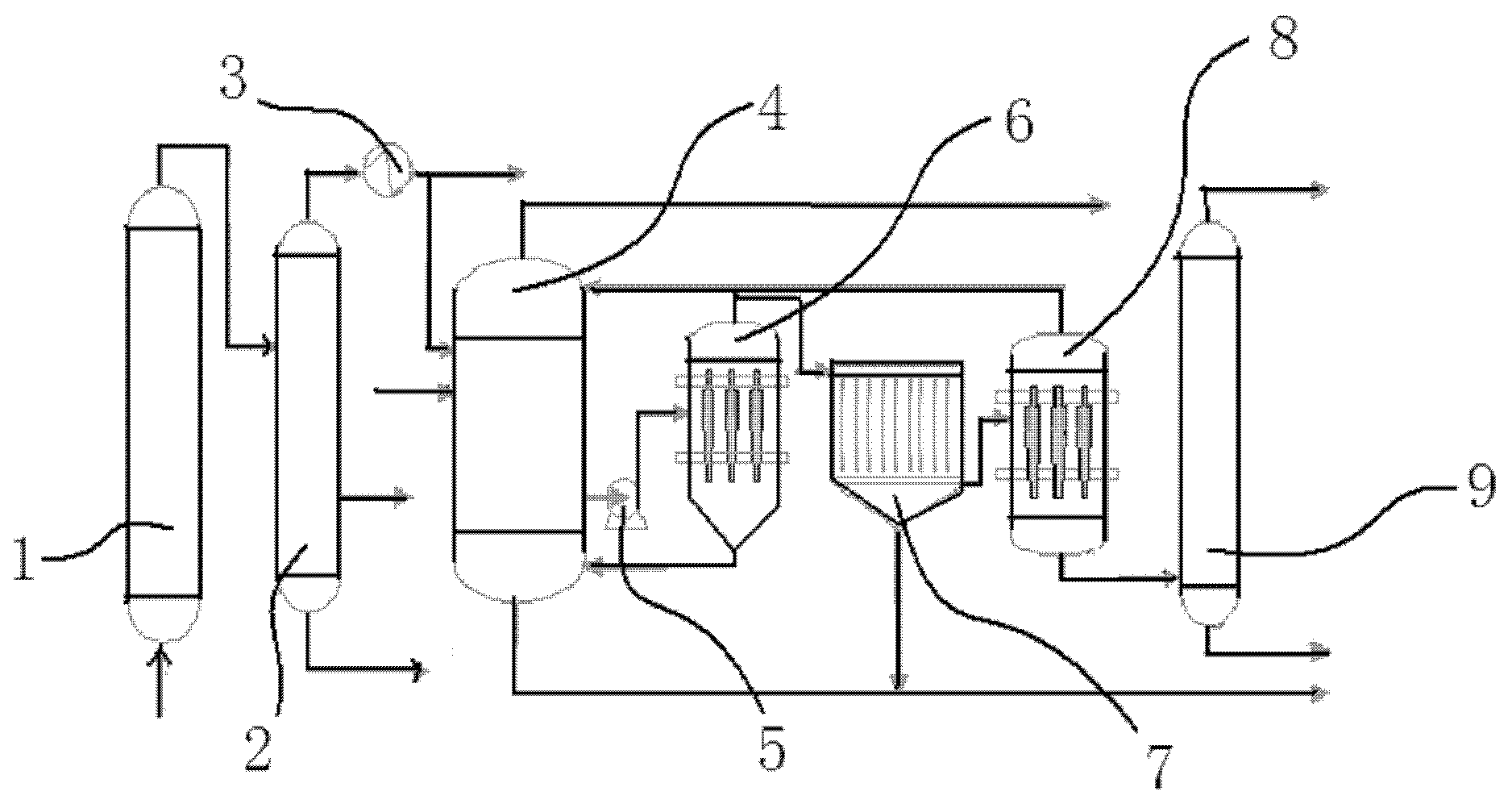

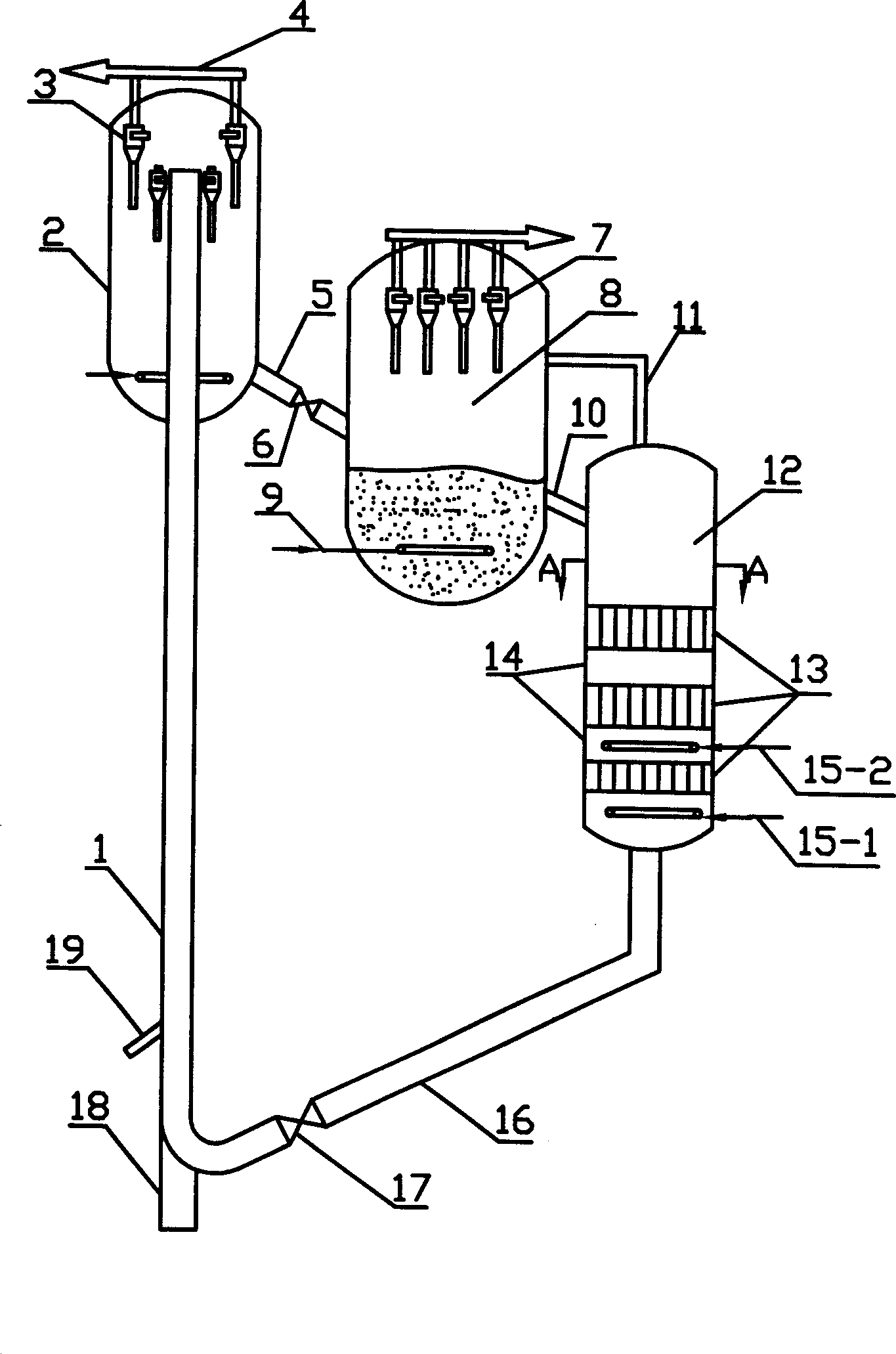

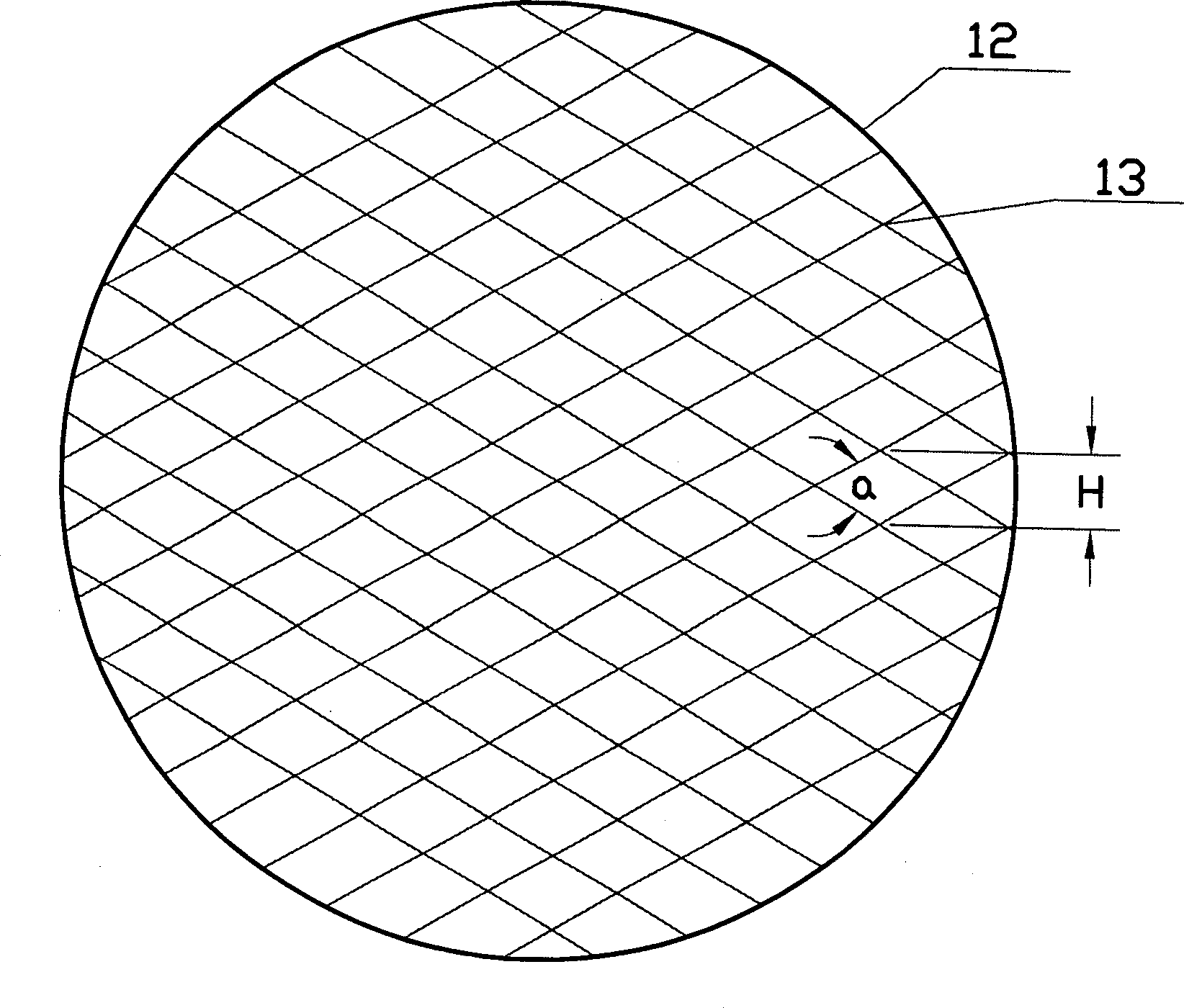

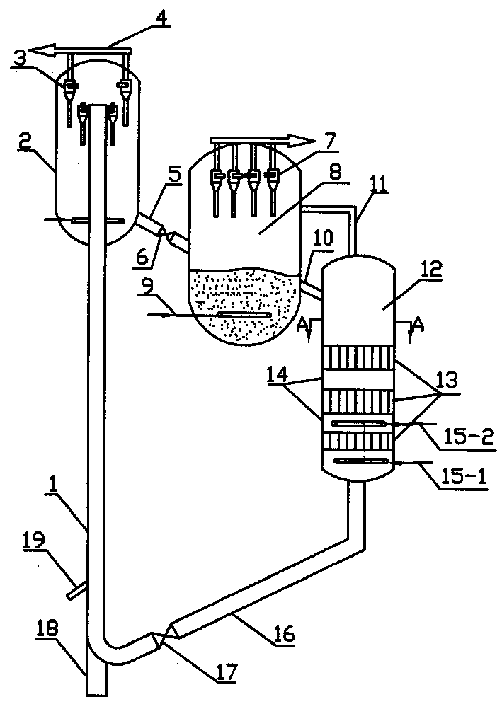

Stripping method and equipment for hydrocarbon catalytic converting catalyst

InactiveCN1335356AImprove uniformityPromote random contactCatalytic naphtha reformingCatalytic transformationEngineering

The present invention provides one method of raising the efficiency of stripping hydrocarbon converting catalyst and its equipment. According to the present invention, catalyst particle and strippingfluid are made to counterflow through one stripper with at least two layers of stuffing. The stuffing in the stuffing layers is crossed into diamond shaped grid plate parallel to the axis of the stripper. The stripper of the present invention has high efficiency. The present invention is especially suitable for catalytic conversion process of preparing olefin, the smoke impurity content in the regenerating agent is less than 0.05 vol%, and the stripper can be reduced in volume and equipment investment obviously.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

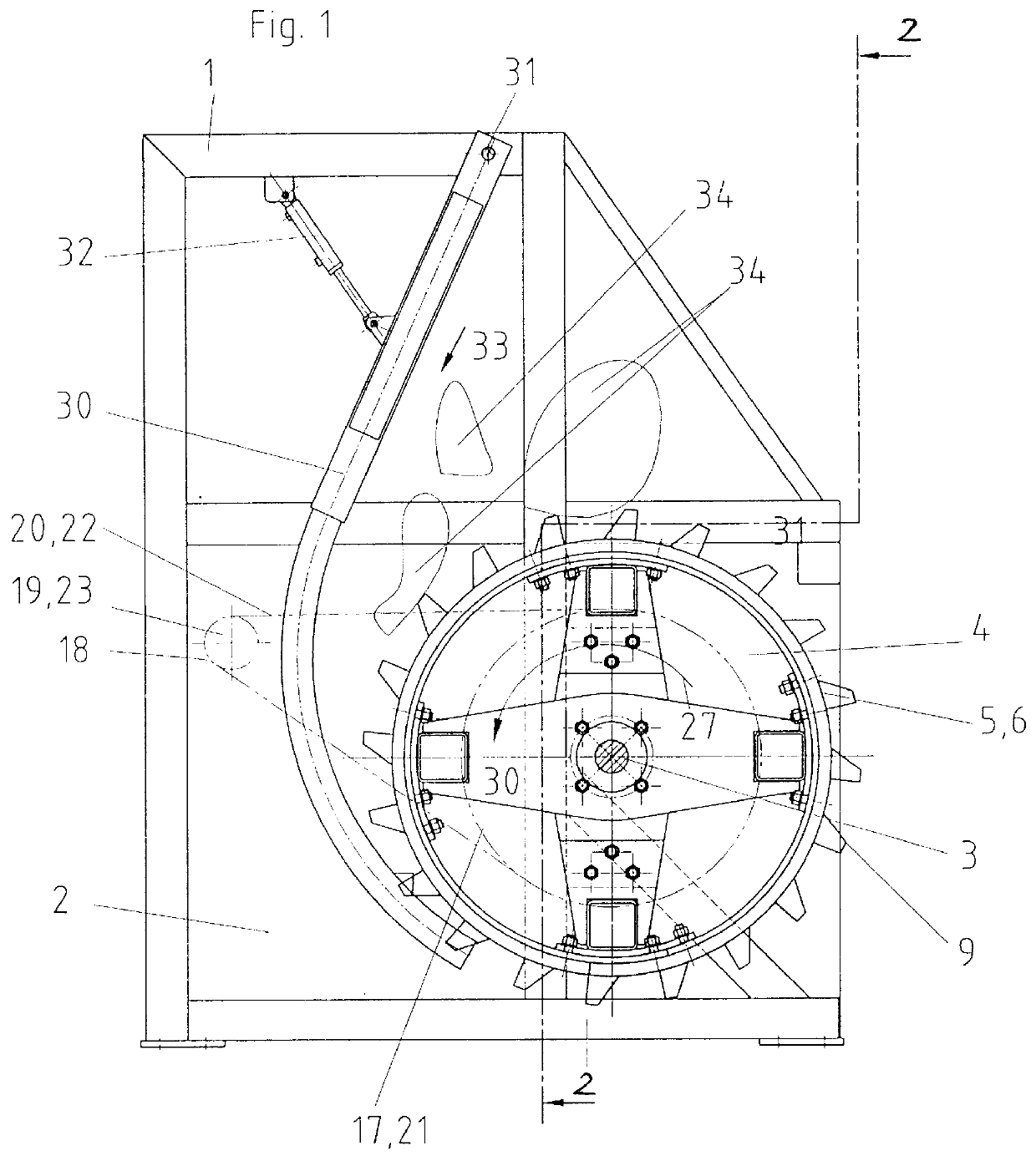

Device for ripping and tearing bags open

InactiveUS6089814AGood cleaning effectGood stripping effectSolid waste disposalBags openingEngineeringConductor Coil

Owner:BAYER MANFRED

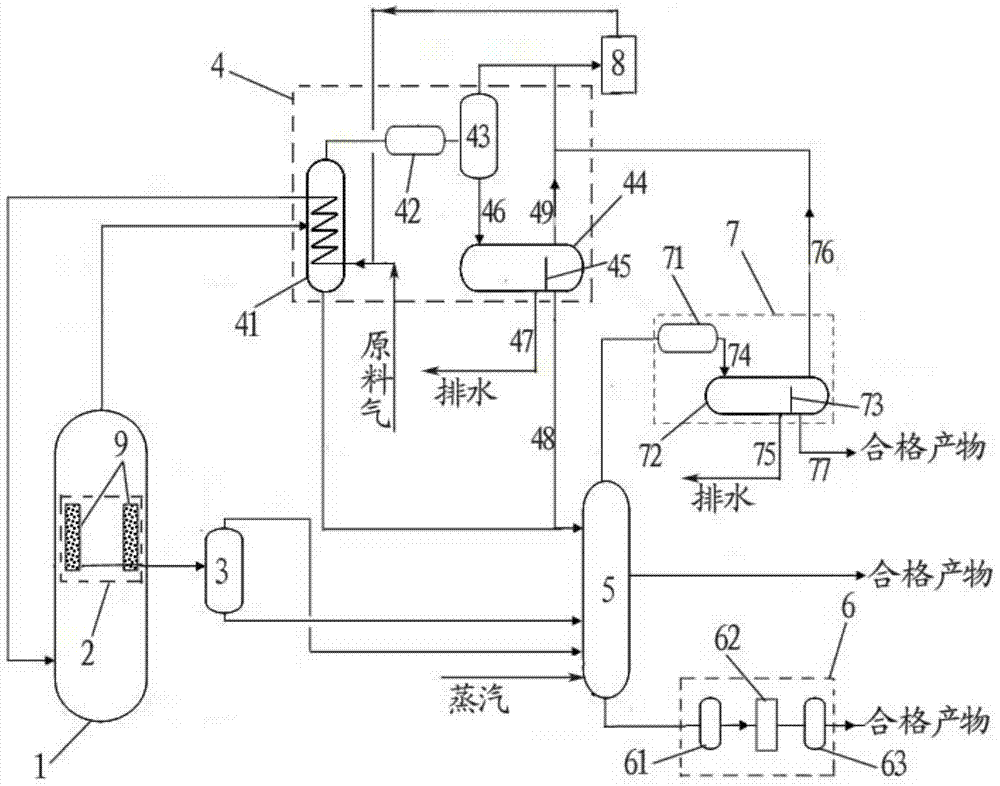

System and method for simultaneously producing methacrylic acid and methacrolein

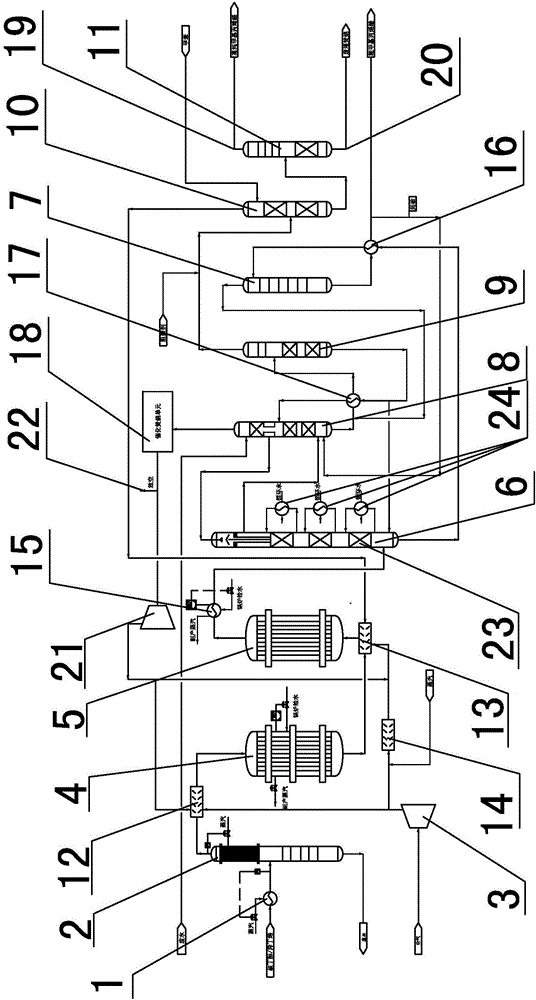

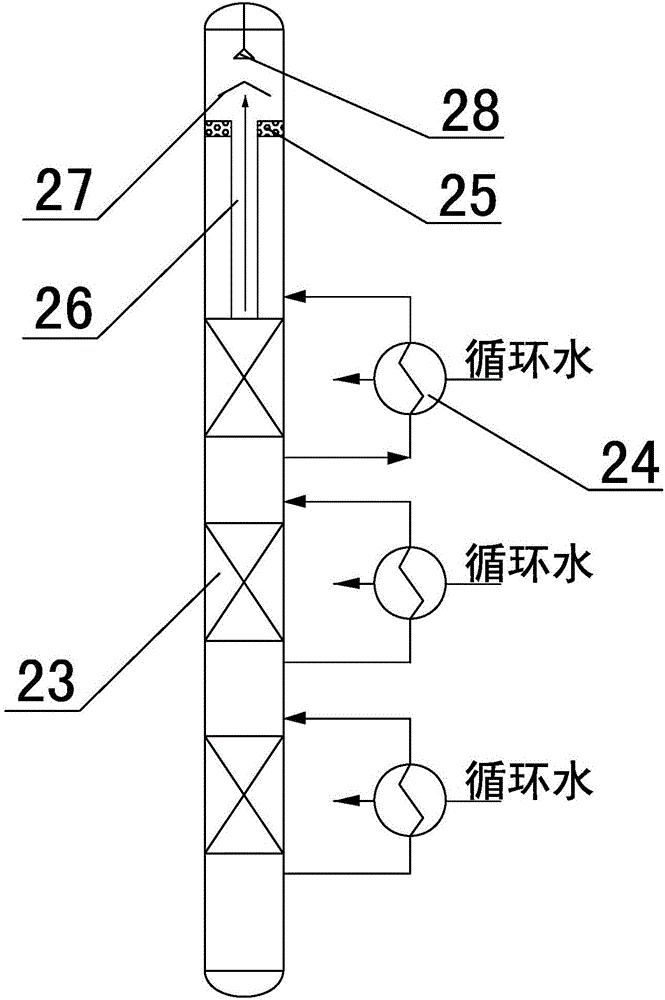

ActiveCN106631759AGuaranteed conversion rateGuaranteed pressureOrganic compound preparationChemical industryFixed bedAcid washing

The invention discloses a method and system for simultaneously producing methacrylic acid and methacrolein. The system comprises a raw material feed preheater, a raw material vaporizing tower, a first oxidation reactor, a second oxidation reactor, a rapid cooling / acid washing coupled tower, a methacrolein stripping tower, a methacrolein absorption tower, a methacrolein recovery tower, a methacrolein light component removal tower and a methacrolein heavy component removal tower. The method comprises the following steps: preheating and vaporizing a raw material tert-butyl alcohol or isobutylene; then mixing with air and water; feeding to a catalyst-filled fixed-bed reactor; performing oxidation reaction to generate methacrylic acid and methacrolein; and performing effective rapid cooling, absorption and rectification to finally obtain 99%wt methacrolein and 30%wt crude methacrylic acid. The method and system have the advantages that the reaction conversion rate is high, the unreacted raw material can be effectively recovered, impurities and solid particles are removed, and high-purity methacrylic acid and methacrolein are produced.

Owner:齐翔华利新材料有限公司

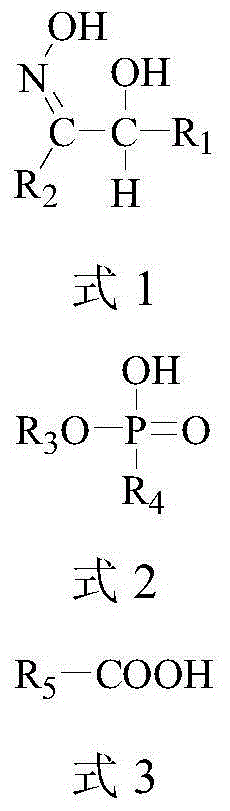

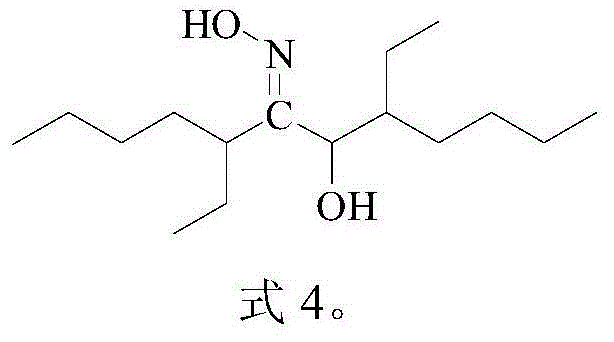

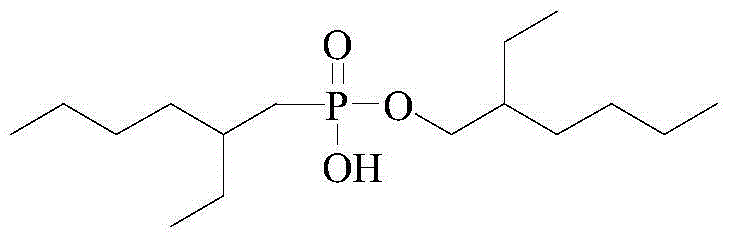

Method for selectively extracting and recycling gallium, germanium and indium from sulfuric acid leach liquid of zinc displacement residues

The invention discloses a method for selectively extracting and recycling gallium, germanium and indium from sulfuric acid leach liquid of zinc displacement residues. The method includes selectively extracting the germanium from the sulfuric acid leach liquid of the zinc displacement residues by the aid of synergistic extraction systems comprising hydroxamic chelate extraction agents and acidic phosphorus type extraction agents; recycling acid from germanium extraction raffinate by the aid of a diffusion dialysis process and finely adjusting the germanium extraction raffinate until a pH (potential of hydrogen) value of the germanium extraction raffinate is appropriate; selectively extracting the gallium and the indium from the germanium extraction raffinate by the aid of synergistic extraction systems comprising hydroxamic chelate extraction agents and carboxylic acid extraction agents. The method has the advantages that the germanium, the gallium and the indium can be effectively separated from foreign metal ions of iron, zinc, cadmium, nickel, cobalt and the like; the germanium, the gallium and the indium are high in recycling rate, good germanium, gallium, indium and foreign matter separation effects can be realized, technological processes are short, the extraction agents are long in service life and low in loss, and the method is low in cost and easy to industrialize.

Owner:CENT SOUTH UNIV +1

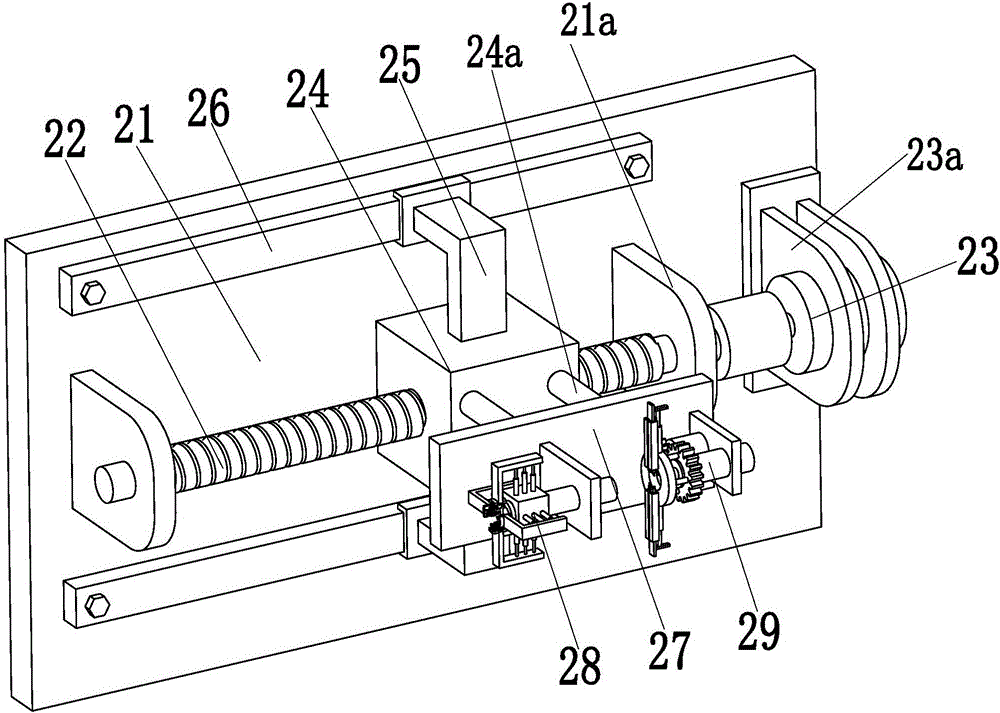

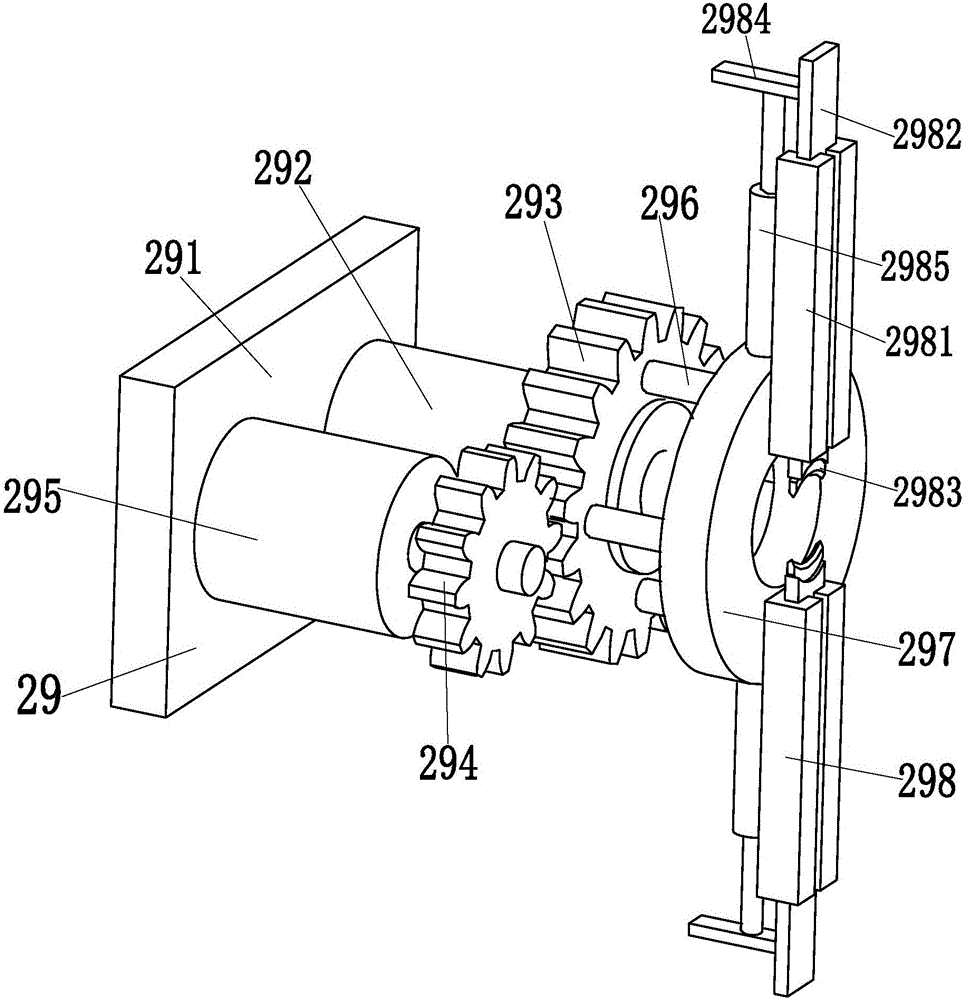

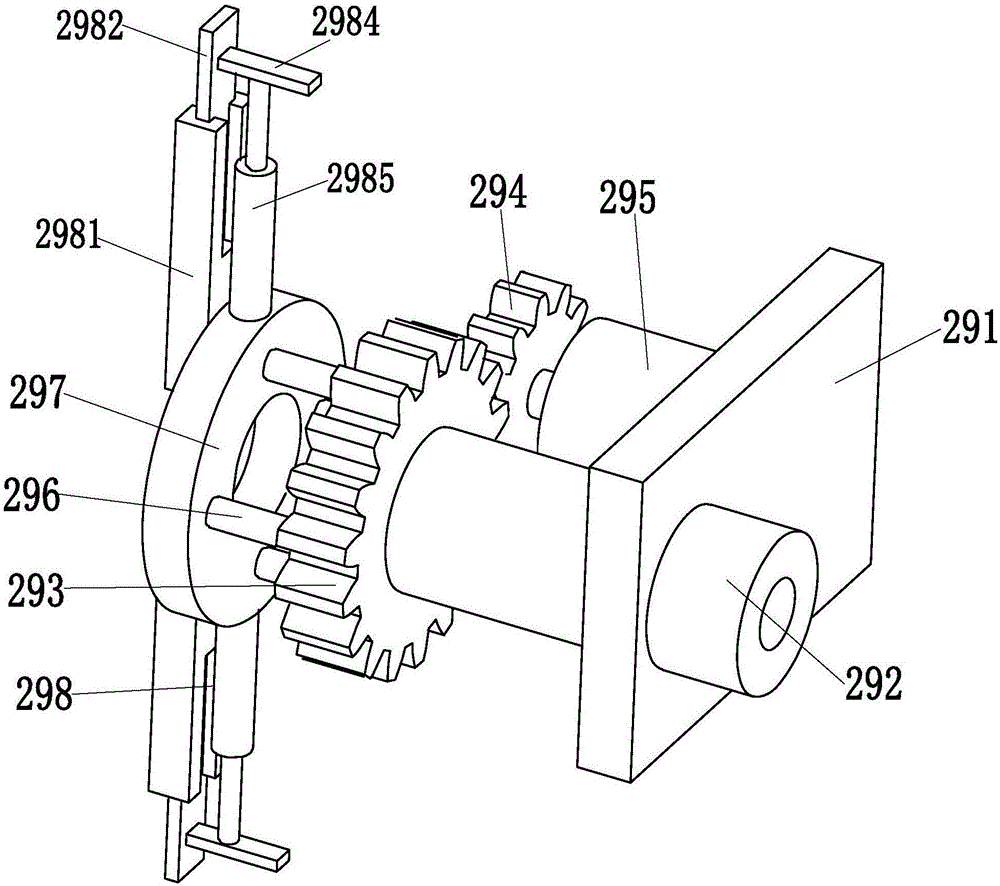

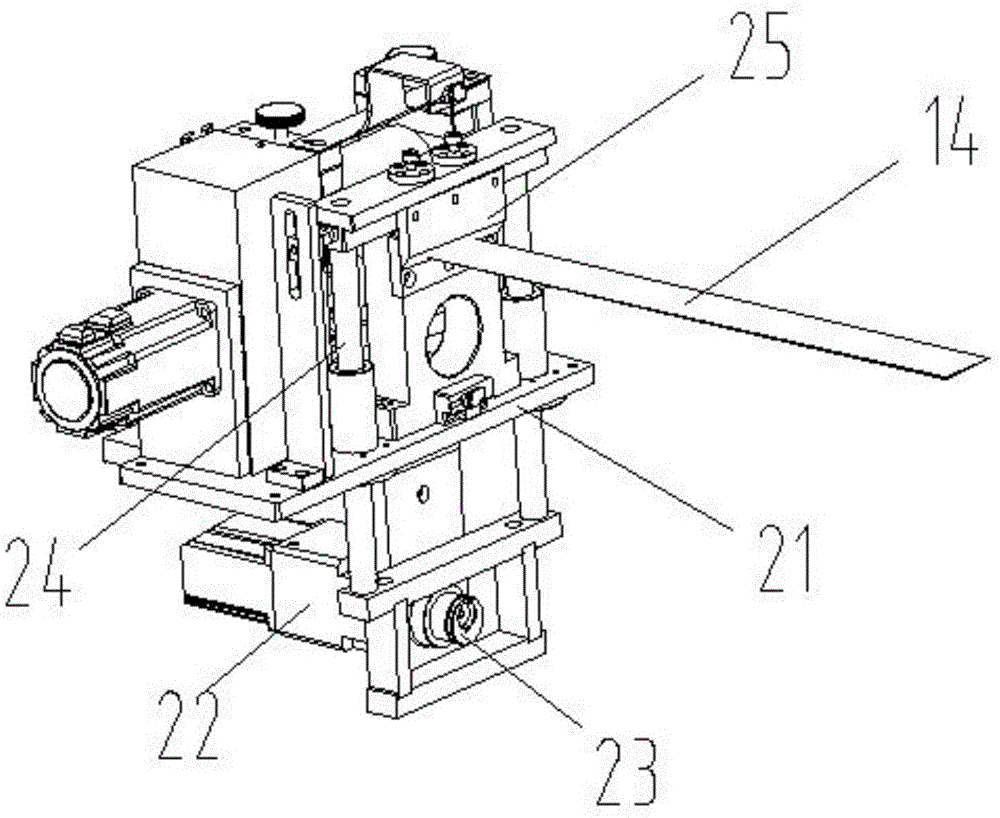

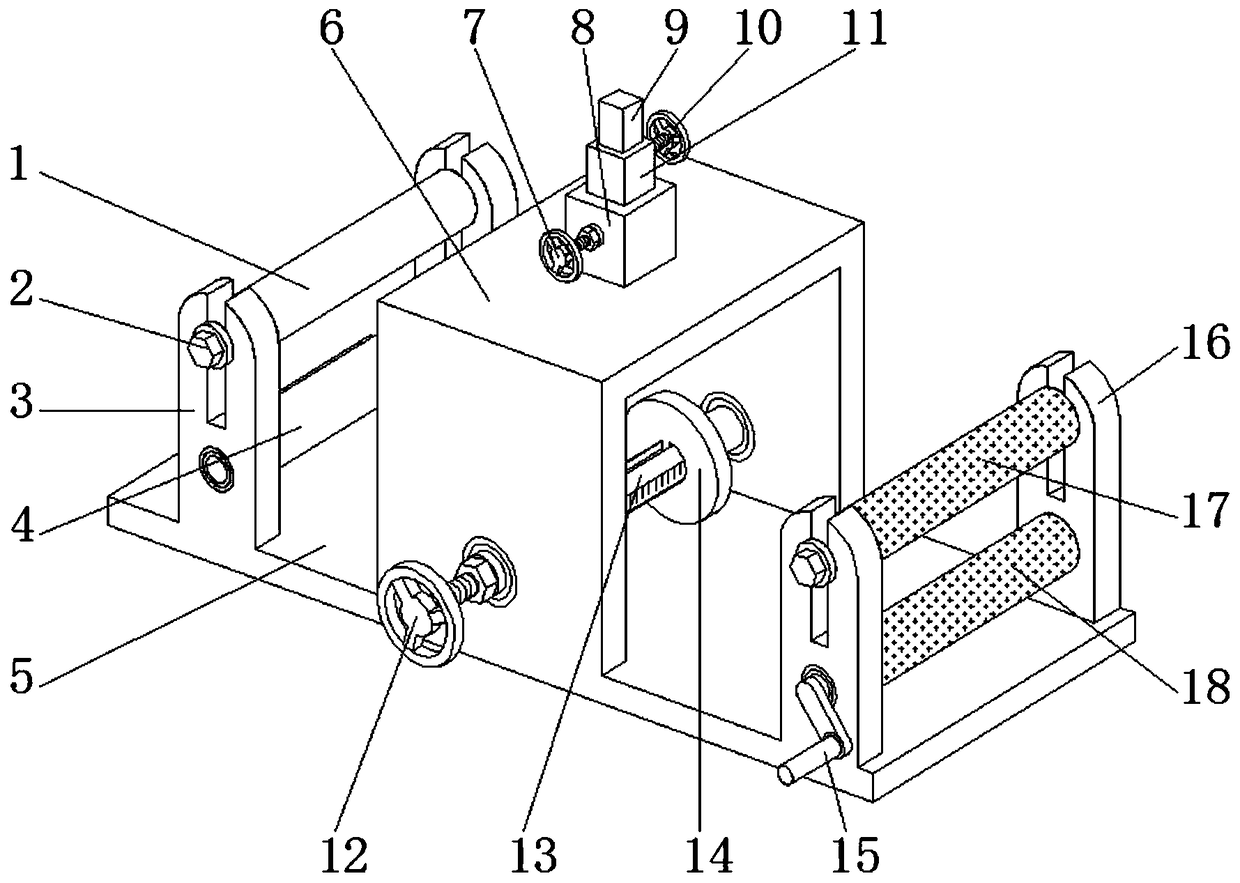

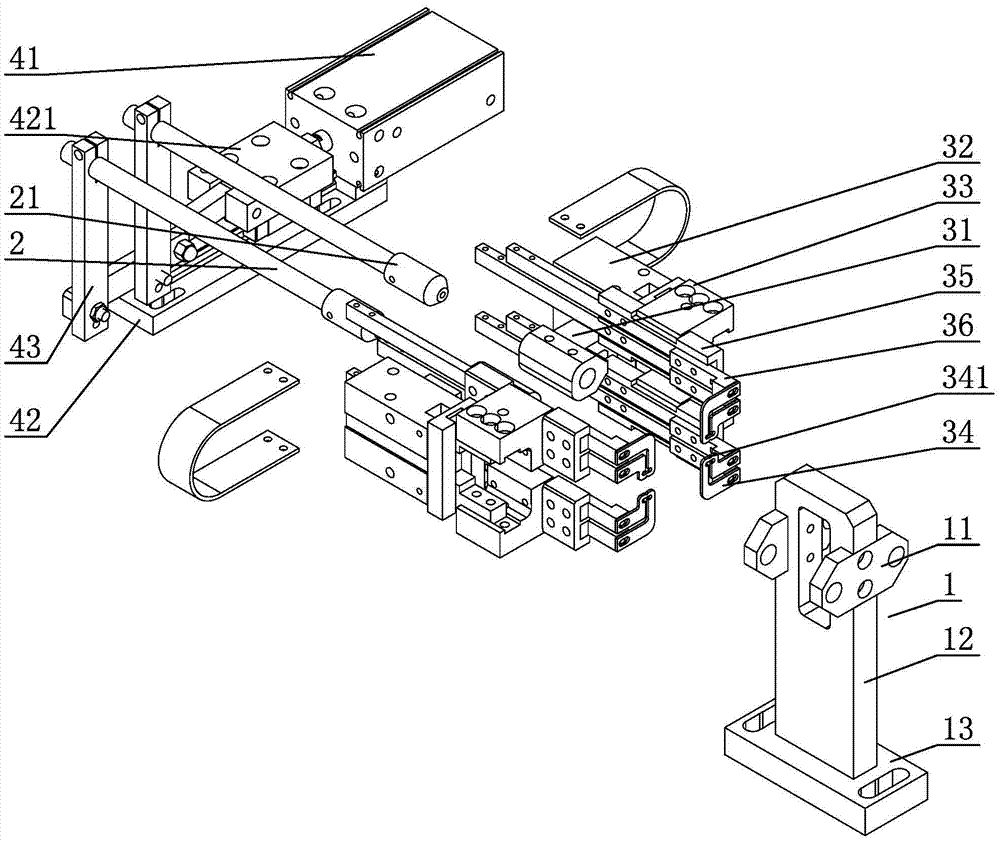

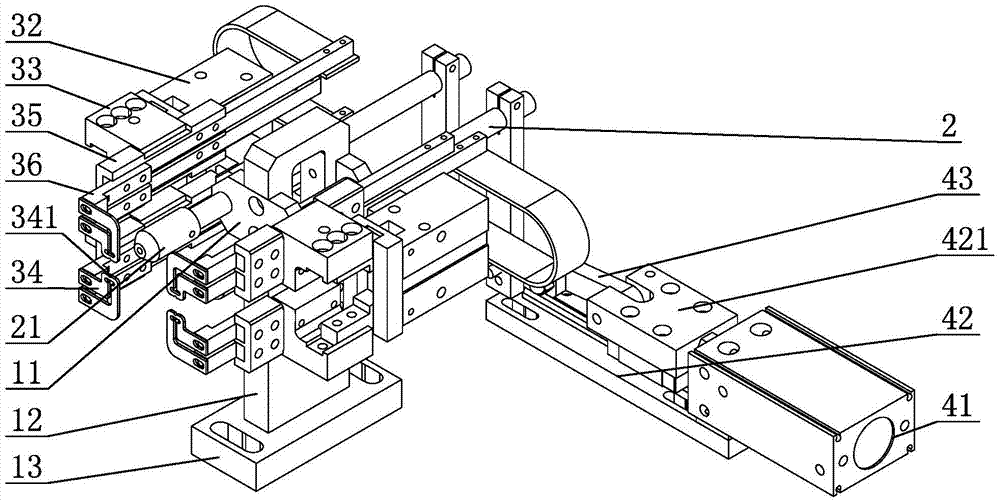

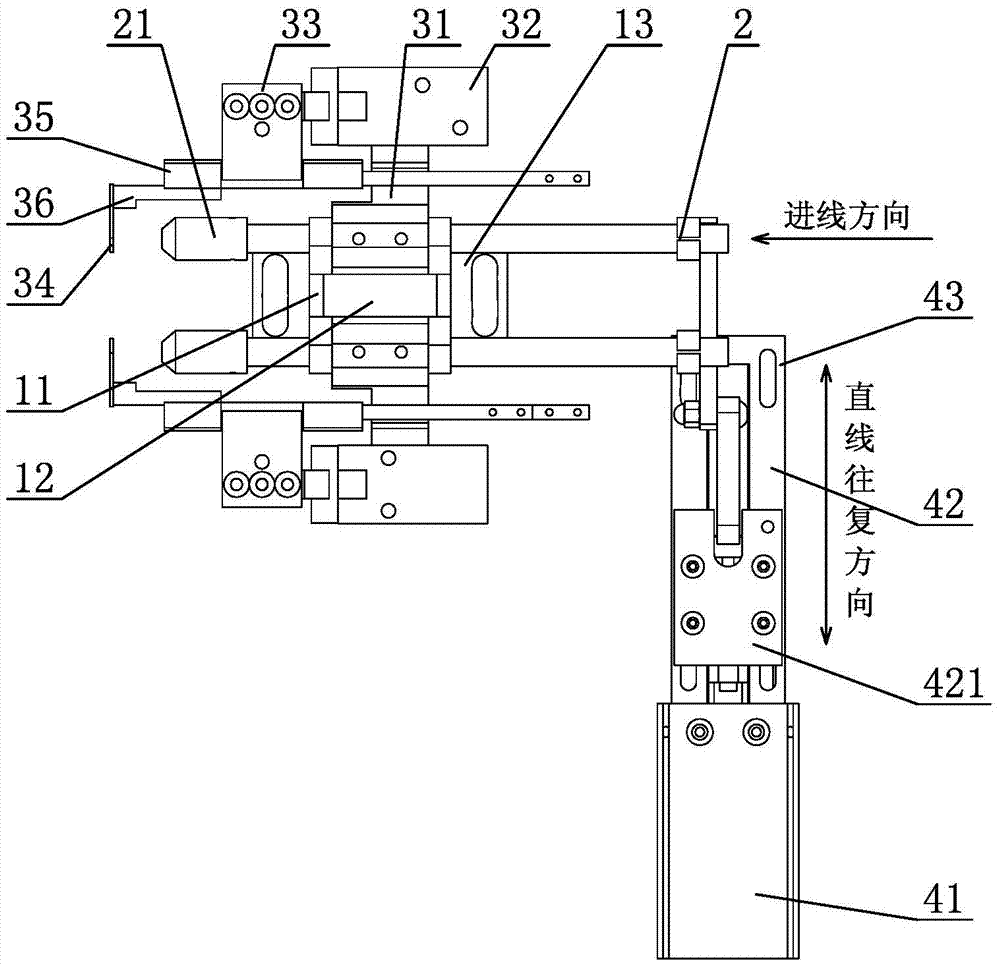

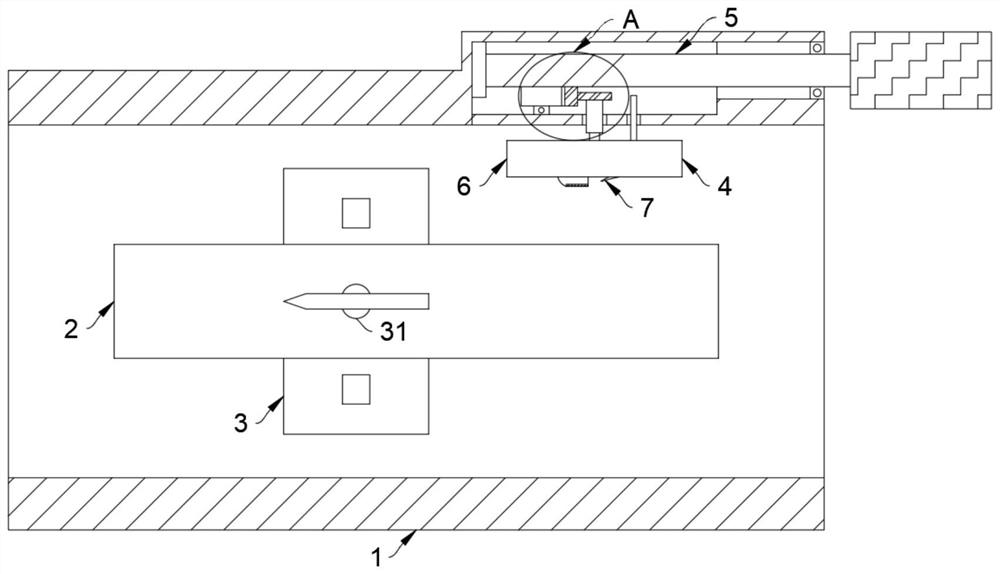

Vehicle wire harness girdling and peeling device

InactiveCN106229899AAchieve orientationNo guidance requiredApparatus for removing/armouring cablesCouplingEngineering

The invention relates to a vehicle wire harness girdling and peeling device which comprises a first support plate. Two moving lugs are respectively arranged on the side wall of the first support plate, and a movable screw is arranged between the two moving lugs through a bearing. A moving motor is arranged on the right end of the movable screw through a coupling, and the moving motor is arranged on a motor bracket. A moving block is arranged on the central section of the movable screw through threads, the upper and lower ends of the moving block are symmetrically provided with two moving slide bars, and the two moving slide bars are respectively mounted on two first linear slide rails. The two ends of each first linear slide rail is mounted on the side wall of the first support plate through screws. Four fixing posts are symmetrically welded on the side wall of the moving block, and a mounting plate is welded on the tail end of the four fixing posts. A wire peeling mechanism is arranged on the left side of the side wall of the mounting plate, and a girdling mechanism is arranged on the right side of the side wall of the mounting plate. Integrated processing function of automatically girdling and wire-peeling can be realized during vehicle wire harness processing.

Owner:YJH ELECTRICAL EQUIP

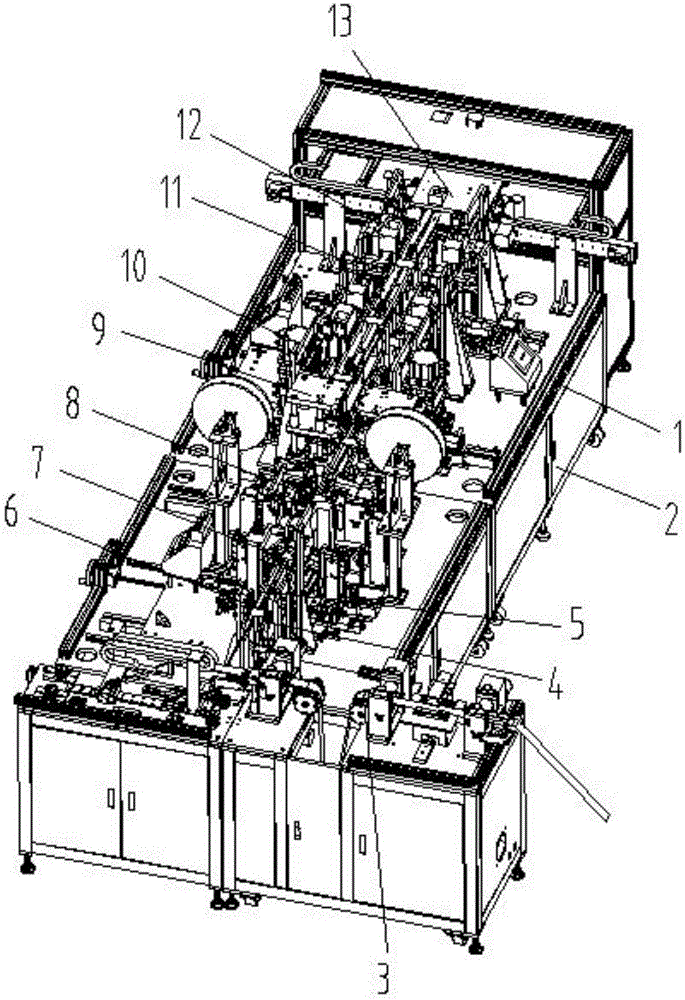

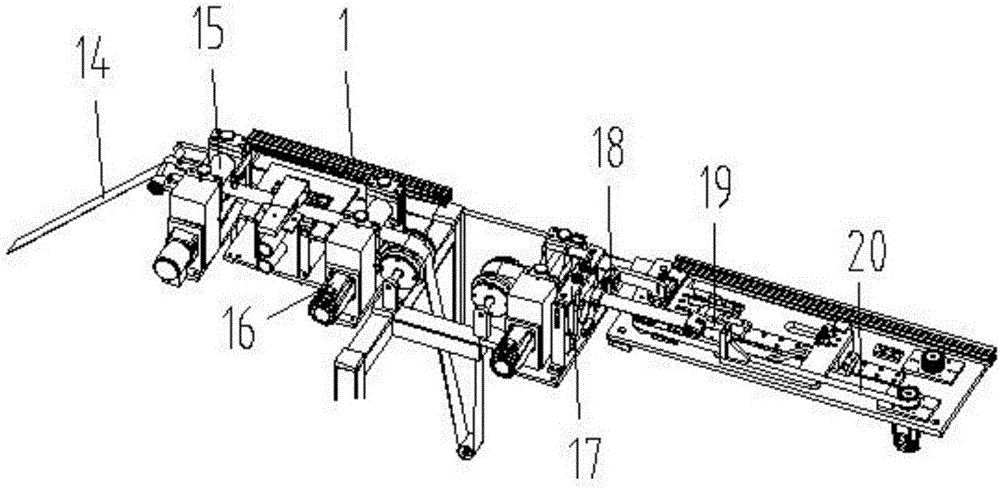

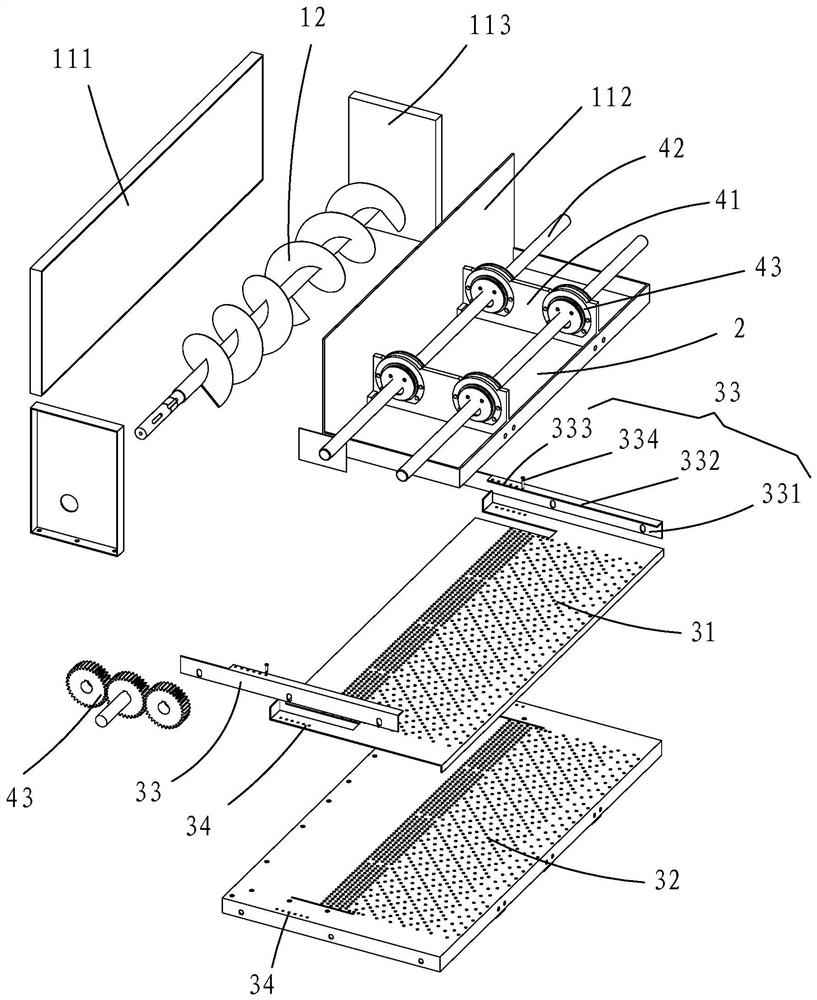

Fully-automated flexible flat cable pipe processing machine

ActiveCN106782888AImprove processing efficiencyImprove yield rateApparatus for feeding conductors/cablesDistribution controlVisual inspection

The invention relates to a fully-automated flexible flat cable pipe processing machine. The fully-automated flexible flat cable pipe processing machine comprises a frame and a power distribution control cabinet, wherein the frame is provided with a conveying chute and a feeding device which are matched with each other; the feeding device comprises a feeding forward-backward movement device, and the feeding forward-backward movement device is provided with a feeding left-right movement device; a feeding lifting device is arranged on the feeding left-right movement device, uniformly provided with a feeding clamp matched with products, and provided with a feeding guide rod matched with the conveying chute; the frame is sequentially provided with an edge spacing detecting device, a wire stripping device, an adhesive applying device, a heat pressing device, a trimming device, a visual inspection device and a circuit detecting device, which are matched with the products on the conveying chute. The fully-automated flexible flat cable pipe processing machine achieves fixed-distance product feeding through matching between the feeding device and the conveying chute and further achieves continuous and integrated flexible flat cable processing, thereby greatly improving the processing efficiency and the yield rate.

Owner:大千纺织(安徽)有限公司

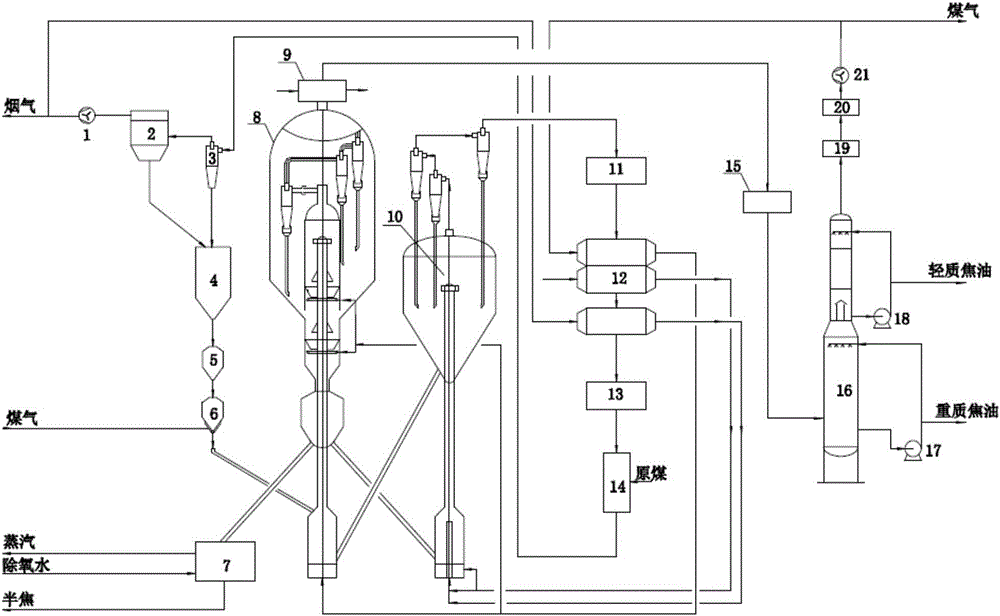

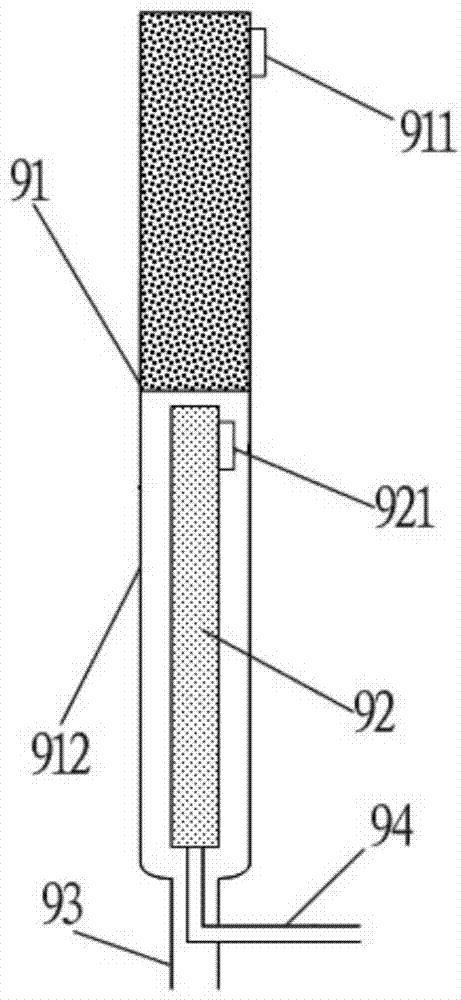

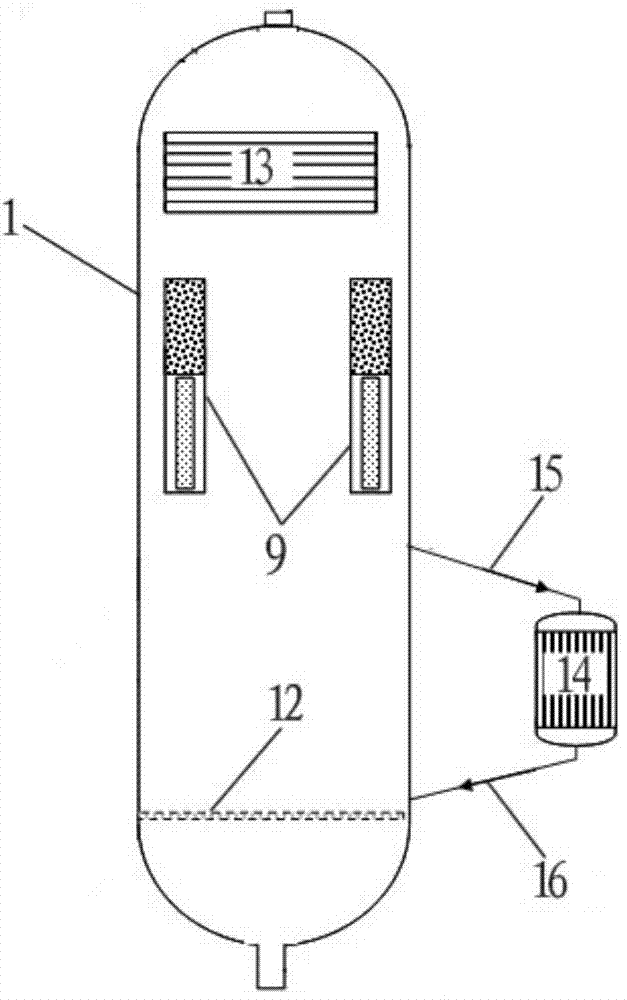

System and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with solid heat carrier

ActiveCN106753491AHigh yieldShort stayDirect heating destructive distillationSpecial form destructive distillationHeat carrierHigh energy

The invention relates to a system and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with a solid heat carrier. The system comprises a raw coal primary processing apparatus, a pyrolytic reaction separator, a semi-coke heating separator, a recycling apparatus, a coak tar recovering apparatus and a semi-coke cooling apparatus; a part of semi-coke powder discharged from the pyrolytic reaction separator enters the semi-coke heating separator, high-temperature smoke discharged from the semi-coke heating separator enters the recycling apparatus, the coal tar recovering apparatus produces coal tar and coal gas, and the semi-coke cooling apparatus produces semi-coke. In the existing coal tar preparation method, the coal pyrolytic optimization of the coal is not good, so that the existing coat tar preparation method has the technical problems of low oil yield, high investment and high energy consumption. The system for preparing the coal tar, gas and semi-coke by activating the coal gas and flash pyrolysing the coal with the solid heat carrier is rapid in pyrolysis, rapid in output and rapid in cooling.

Owner:陕西凯德利能源科技有限公司

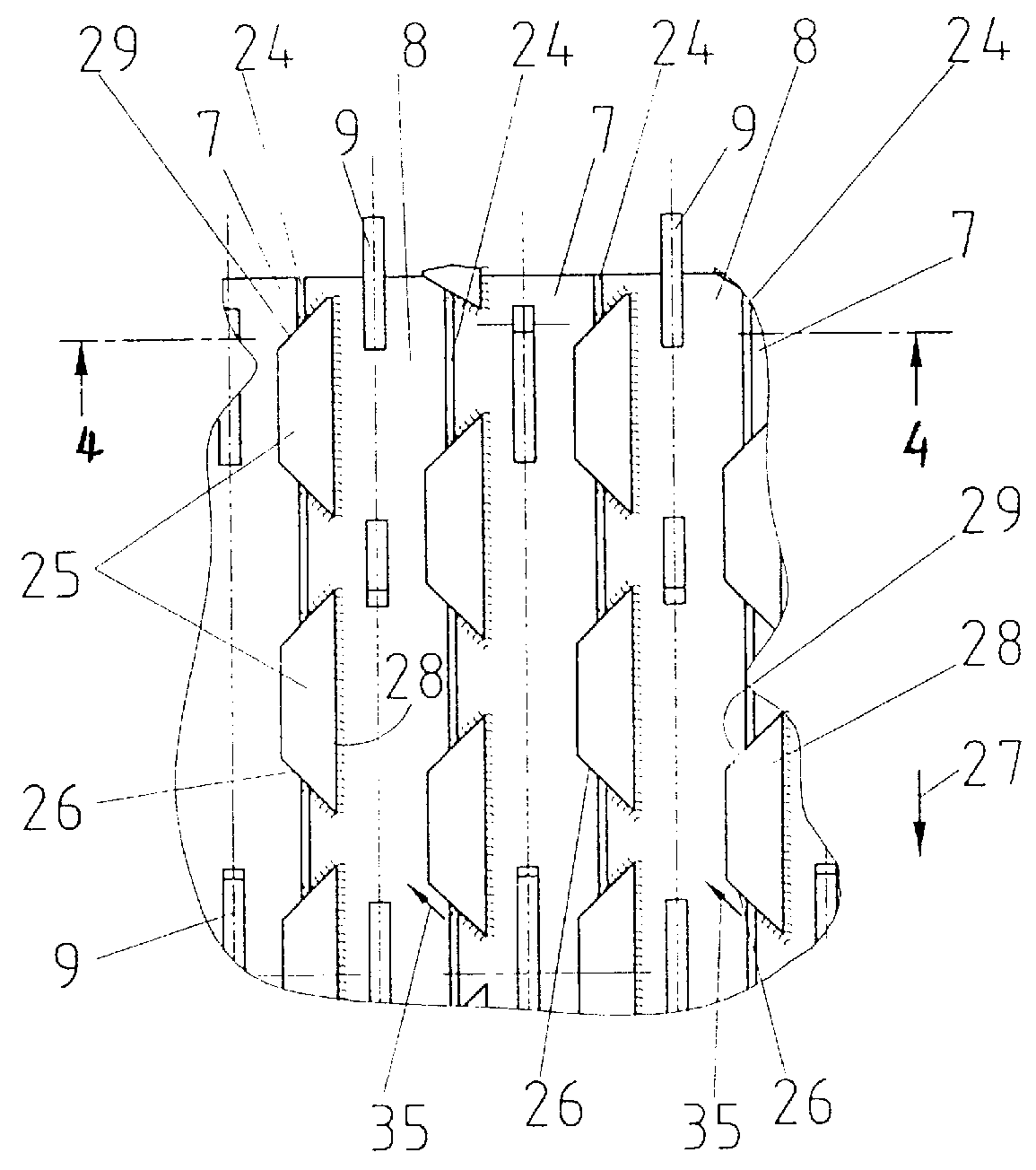

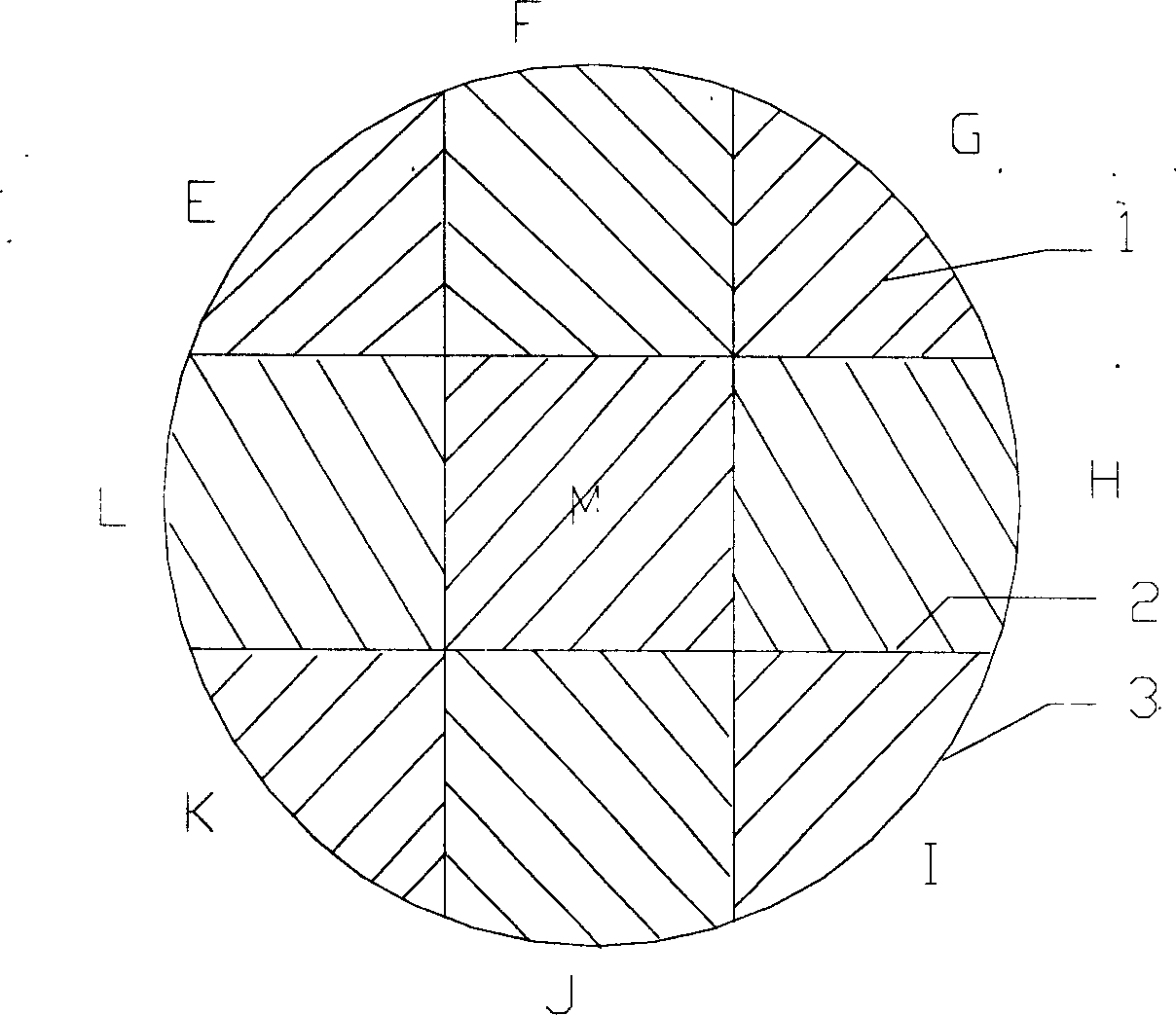

Inner component of tower disc type catalytic cracking stripping equipment

InactiveCN1191111CInhibitionAvoid formingCatalytic crackingChemical/physical processesTowerControl theory

Owner:CHINA PETROLEUM & CHEM CORP +1

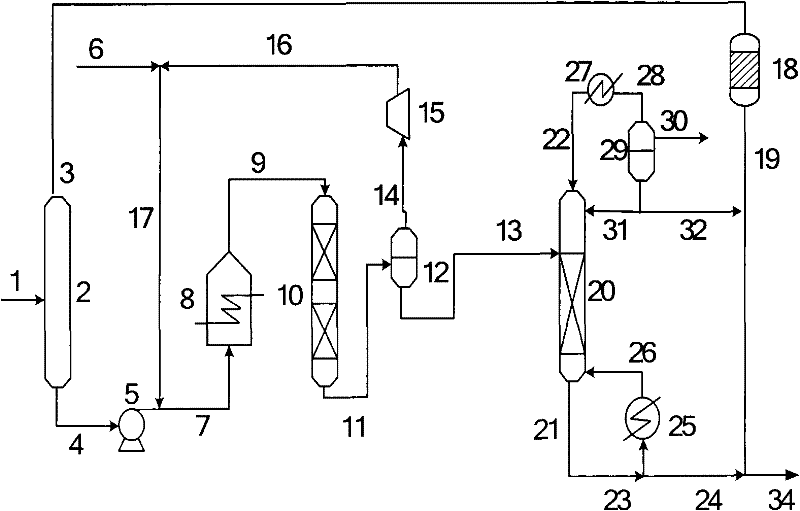

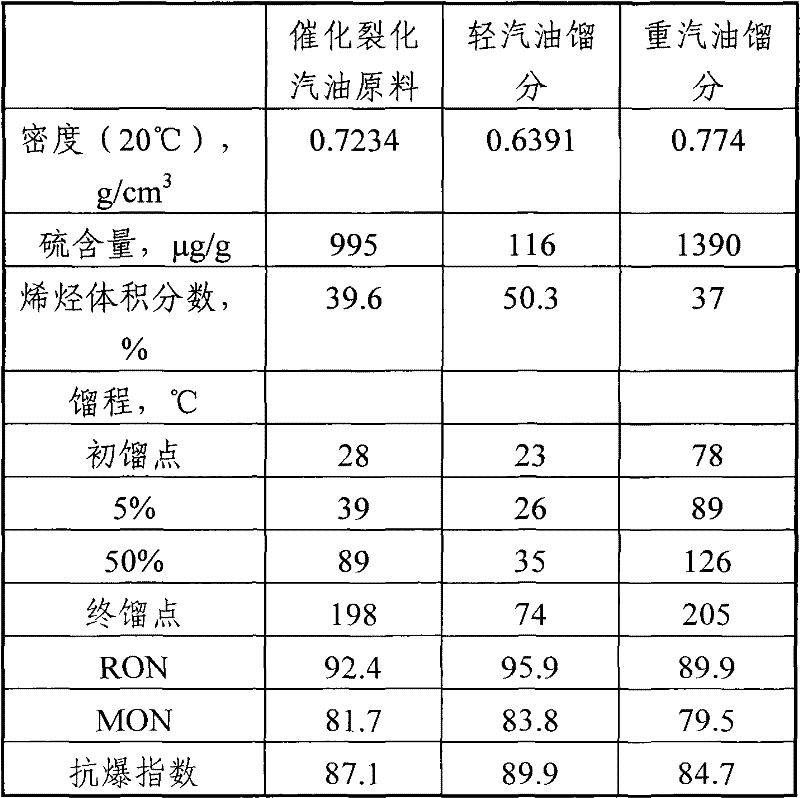

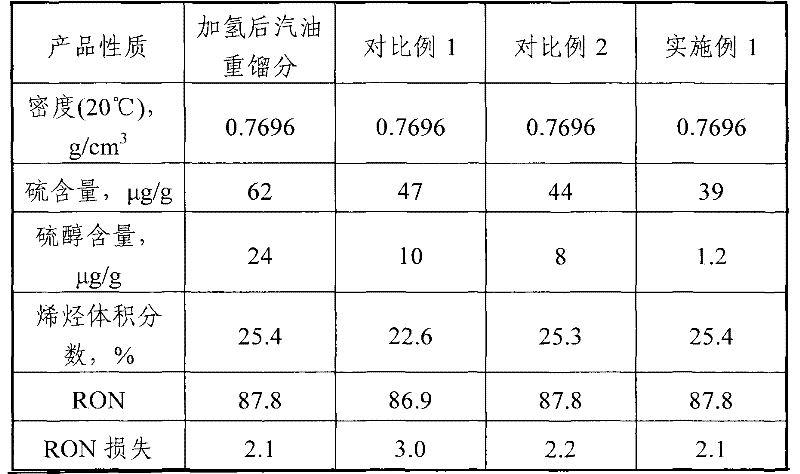

Method for producing low-sulfur gasoline by non-hydroforming sulfur and alcohol removal

ActiveCN102443432AAvoid lostExtended stayTreatment with hydrotreatment processesAlcohol contentCounter flow

The invention relates to a method for producing low-sulfur gasoline by non-hydroforming sulfur and alcohol removal, which comprises the following steps that: (1) gasoline raw materials are fractionated into light and heavy gasoline fractions, the light gasoline fractions are subjected to alkali washing sulfur and alcohol removal, and the heavy gasoline fractions are subjected to hydrogen desulfurization; and (2) the heavy gasoline fractions after the hydrogen desulfurization are introduced into a counter flow contact reactor, sulfur and alcohol removal catalysts are filled in positions under a material inlet of the reactor, steam stripping media which do not contain hydrogen gas are introduced into the bottom of the reactor, liquid phase ingredients of the heavy gasoline fractions in the counter flow reactor are in counter flow contact with the steam stripping media, the regeneration sulfur and alcohol in the materials are decomposed into olefin and hydrogen sulphide on catalysts, the heavy gasoline heavy ingredients after the sulfur and alcohol removal flow out from the tower bottom, heavy gasoline light ingredients, steam stripping media and hydrogen sulphide gas are discharged from the top of the reactor, the heavy gasoline light ingredients after the H2S removal, the heavy gasoline heavy ingredients after the sulfur and alcohol removal and the light gasoline fraction after the alkali washing are mixed to obtain the gasoline products. The gasoline product produced by adopting the method provided by the invention belongs to the gasoline product with the advantages that the sulfur and alcohol content is lower than 3mug / g, the sulfur content meets the Euro IV discharge standard, and in addition, the octane number loss is little.

Owner:CHINA PETROLEUM & CHEM CORP +1

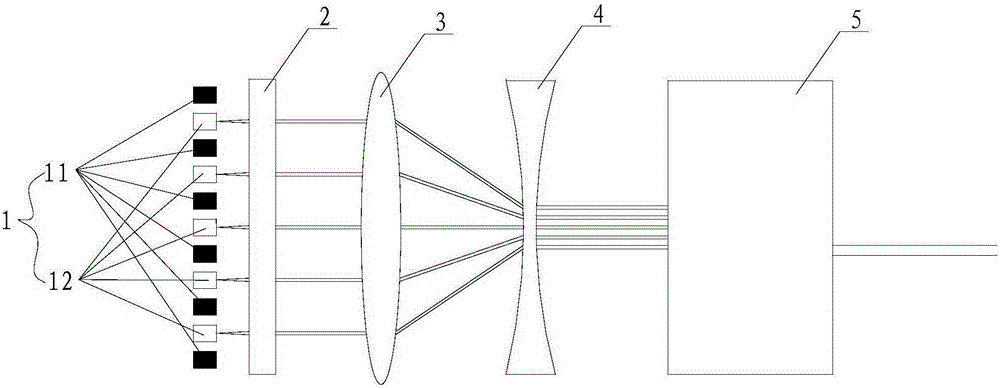

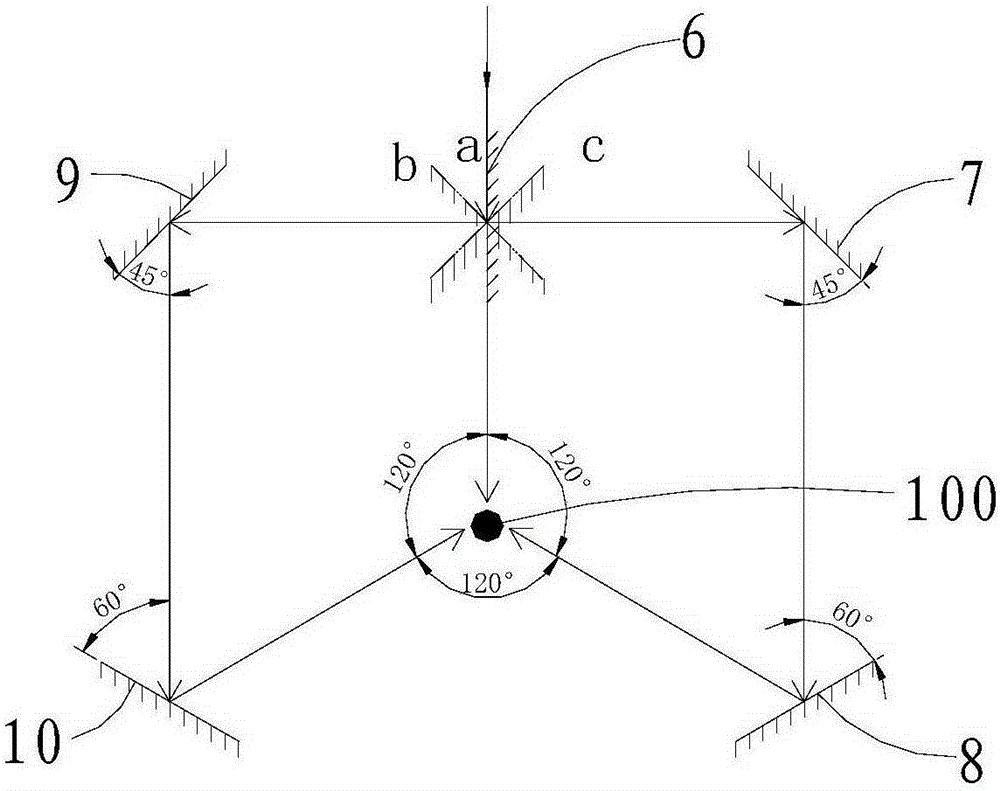

Hybrid wavelength laser wire-stripping method and wire-stripping apparatus of wire sheaths

InactiveCN105186391AGood stripping effectEasy to operateApparatus for removing/armouring cablesLaser beam welding apparatusLight beamLength wave

The invention discloses a hybrid wavelength laser wire-stripping method and wire-stripping apparatus of wire sheaths. A light source can emit laser beams with different wavelengths which are respectively correspondingly used for cutting and stripping the different wire sheaths, then after collimation, clustering and shaping processing are successively performed on the laser beams, the laser beams are divided into multiple cutting light beams by use of a splitting apparatus, and 360-degree blind-angle-free cutting stripping is performed on the wire sheaths. According to the invention, the wire stripping effect is good, the operation is also very convenient, and the efficiency is substantially improved.

Owner:SUZHOU UNIV

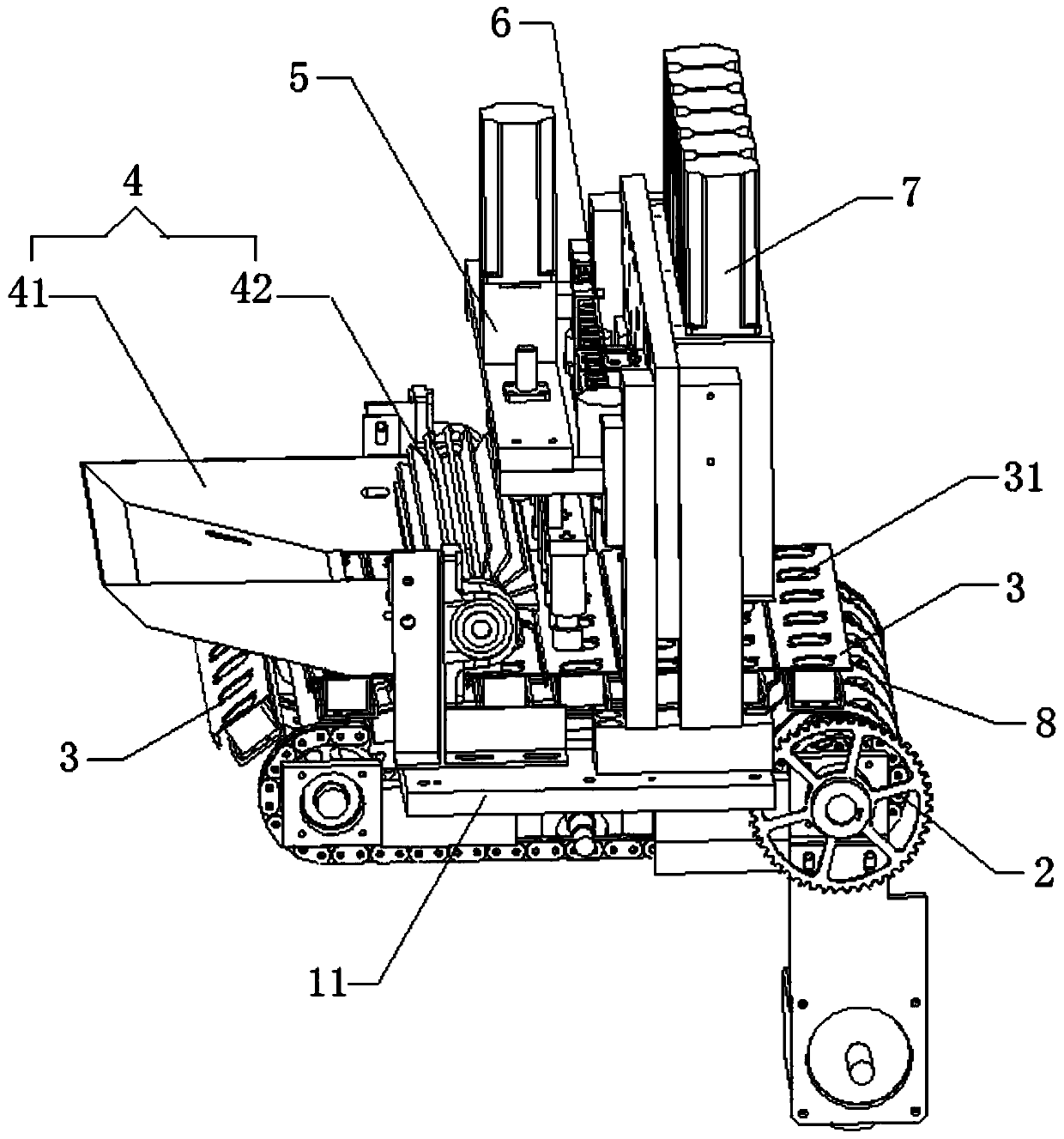

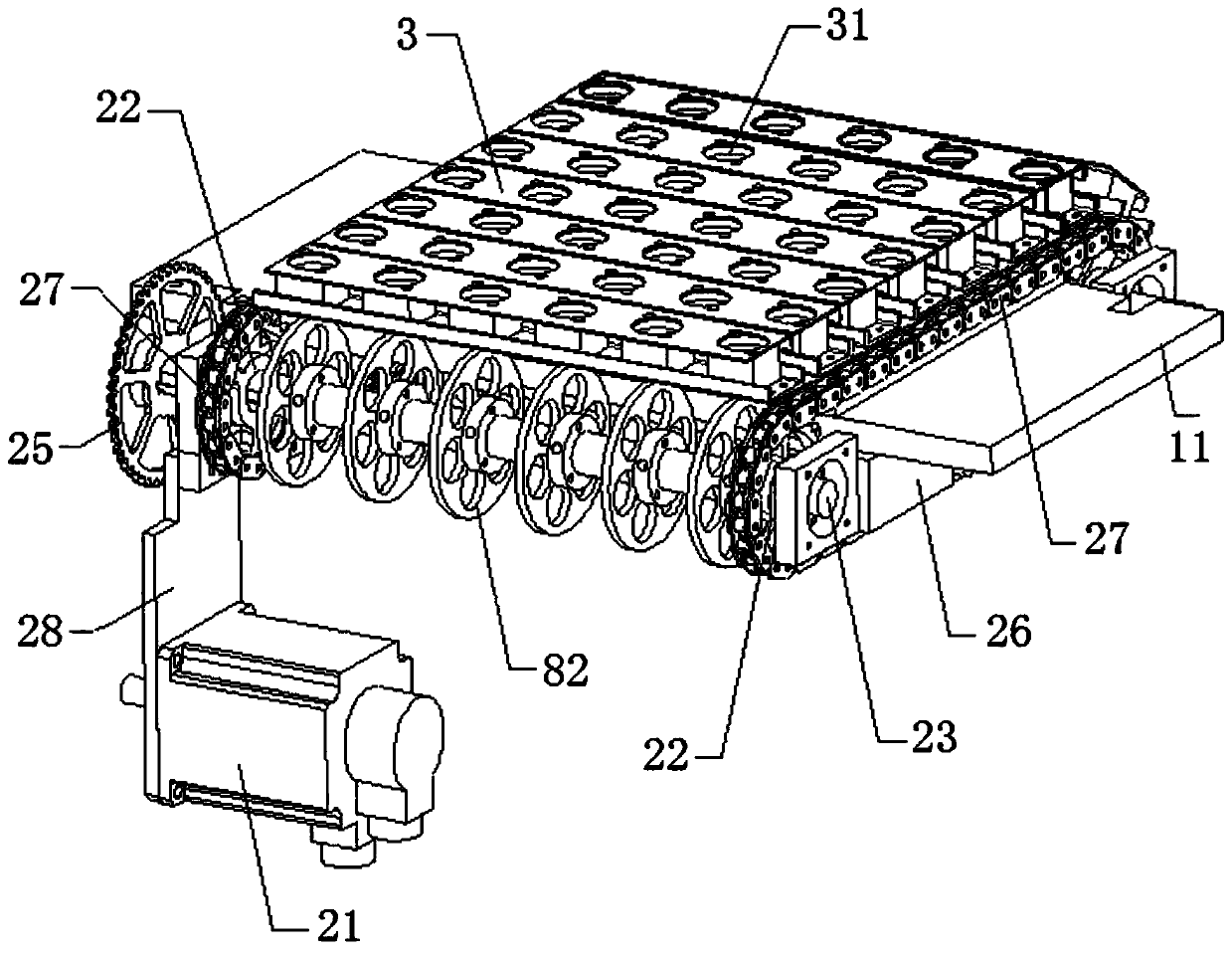

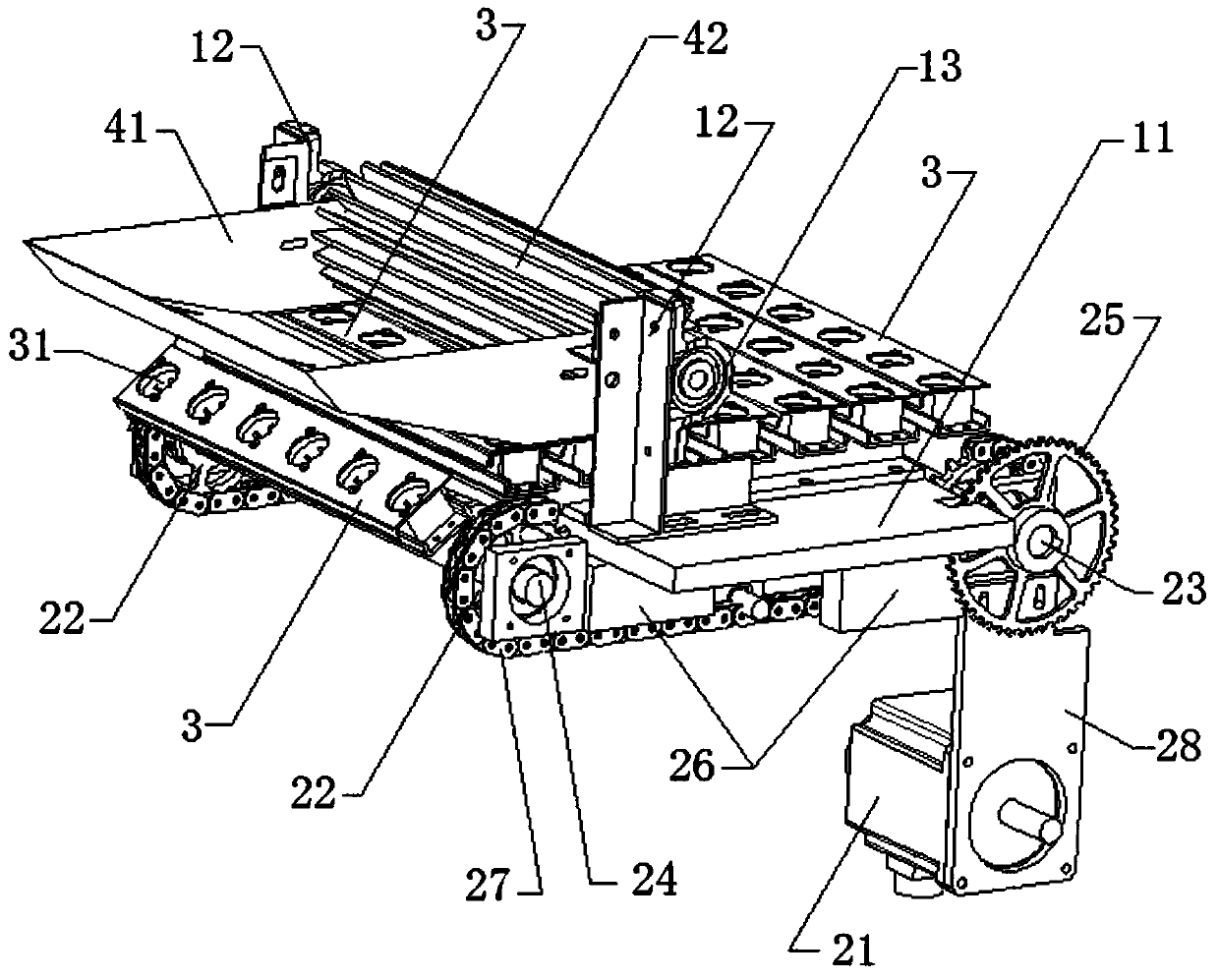

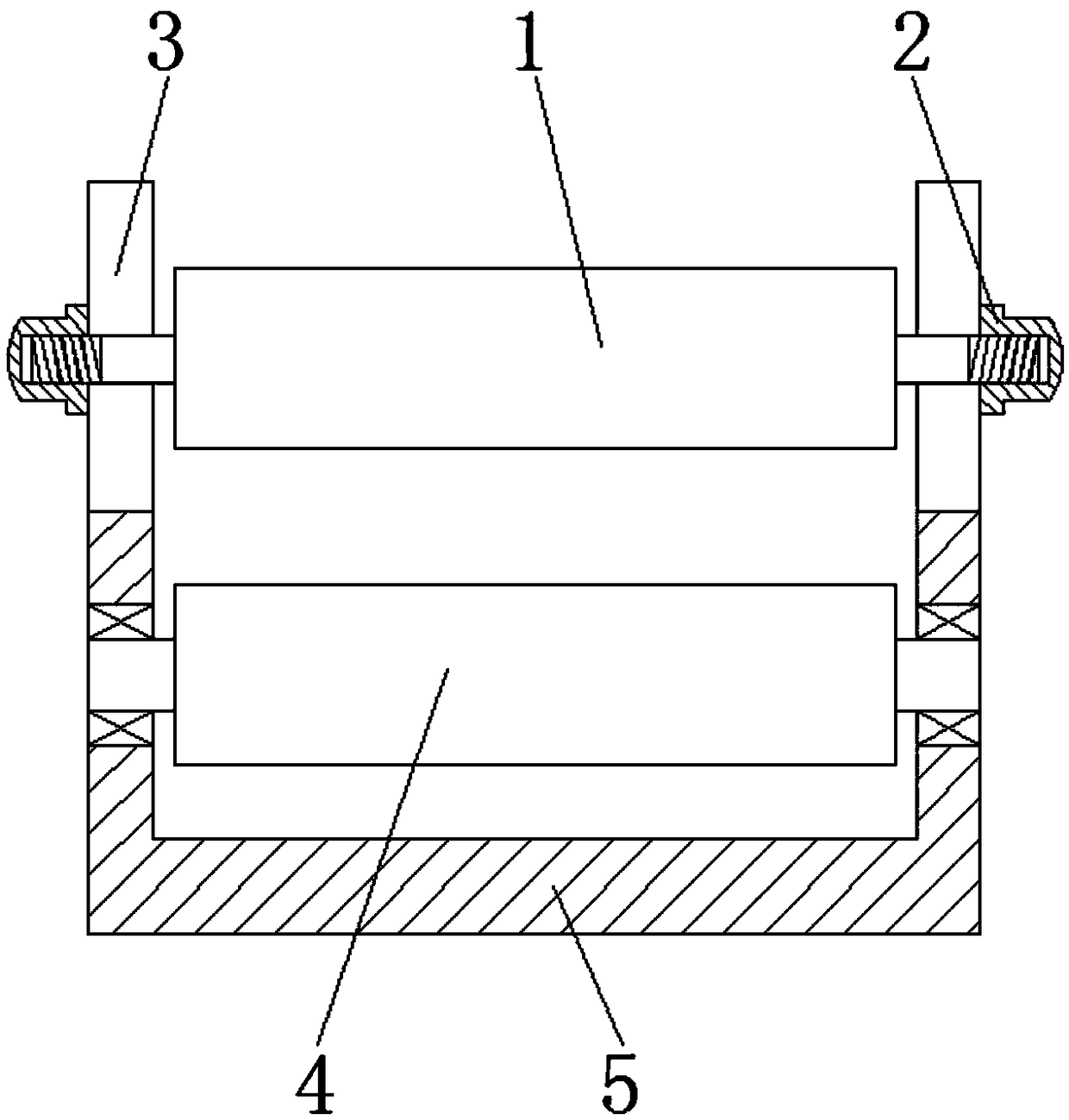

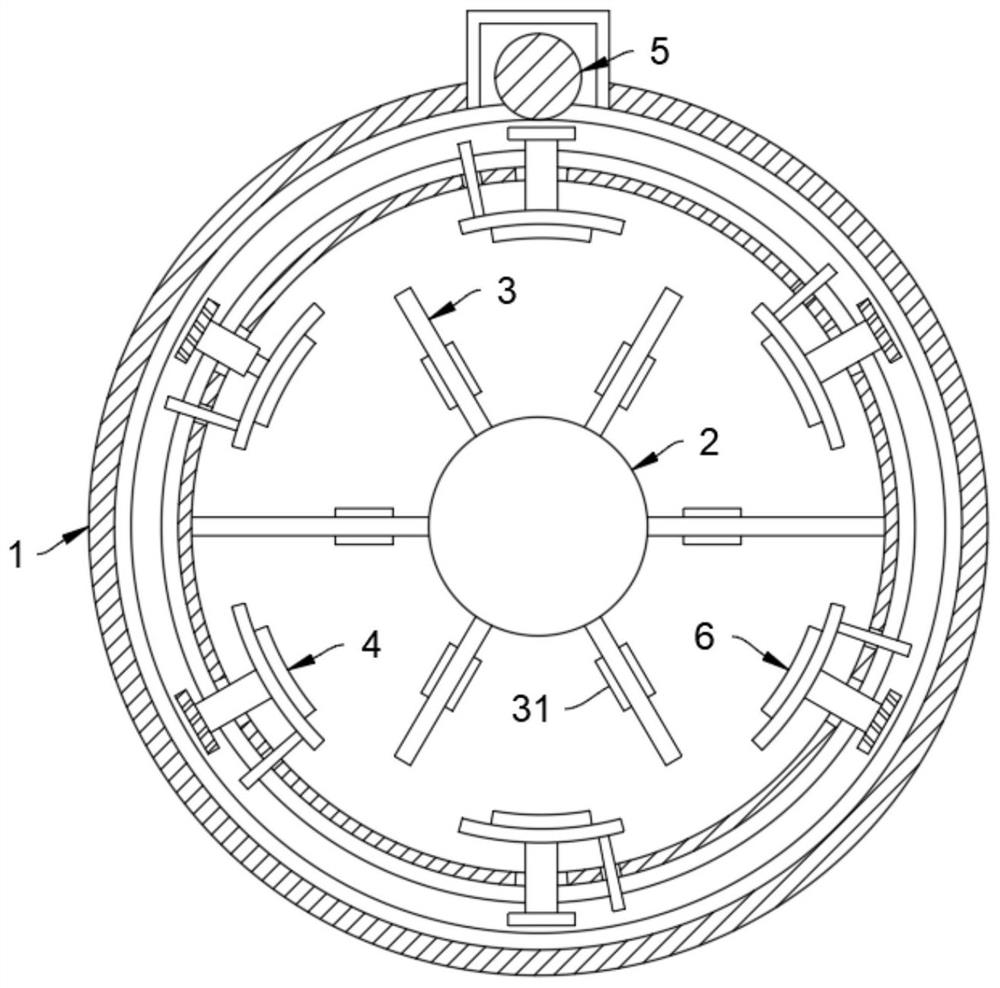

Full-automatic nut opening shell breaking machine

ActiveCN110679965AEasy to collectDoes not affect cycle feedingHuskingHullingEngineeringChain conveyor

The present invention provides a full-automatic nut opening shell breaking machine. The full-automatic nut opening shell breaking machine comprises a bearing plate, a plate chain conveyor, a pluralityof nut pressing molds, a material feeding mechanism, a pre-pressing mechanism, a scanning measuring mechanism, a pressing and smashing shell breaking mechanism, a material stripping mechanism and a PLC controller, the plate chain conveyor is used to drive multiple nut pressing molds to conduct circular moving, each nut pressing mold is provided with a plurality of die grooves for accommodating nuts, the material feeding mechanism, the pre-pressing mechanism, the scanning measuring mechanism and the pressing and smashing shell breaking mechanism are successively arranged on the bearing plate from left to right and all located above the plate chain conveyor, the scanning measuring mechanism is used to measure outline dimensions of the nuts in the plurality of the die grooves of the same nutpressing mold respectively, and the pressing and smashing shell breaking mechanism is used for respectively pressing and smashing of the nuts in the plurality of the die grooves of the same nut pressing mold. The nut opening shell breaking machine can respectively press and smash the nuts according to individual differences, can ensure that shells of each nut are opened but nut kernels are not smashed, can realize assembly line operations of automatic material feeding, measuring, pressing and smashing, and material stripping, and is high in automation degree.

Owner:合肥市云逸自动化设备有限公司

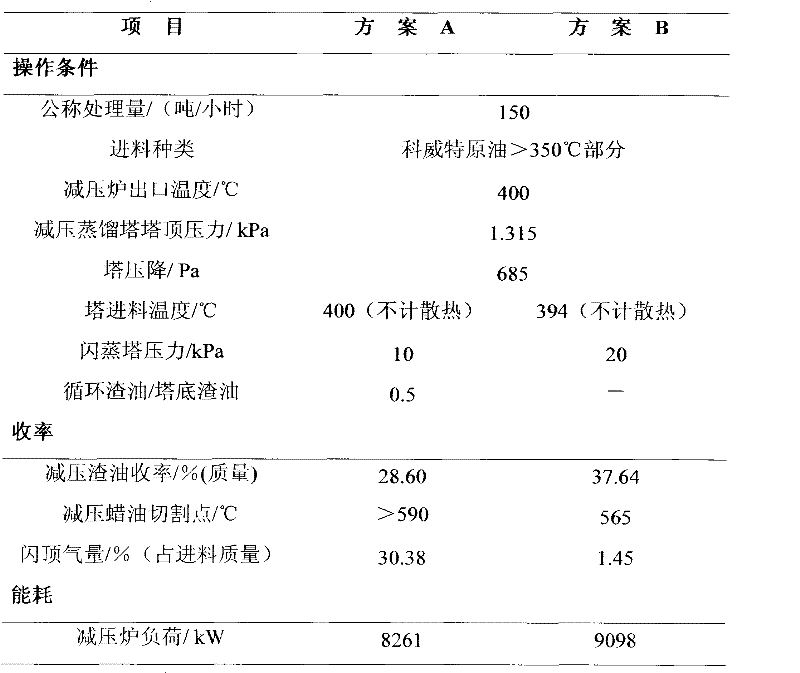

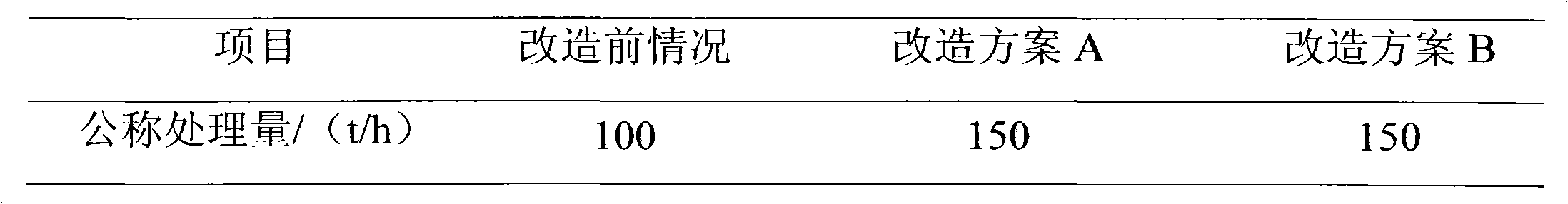

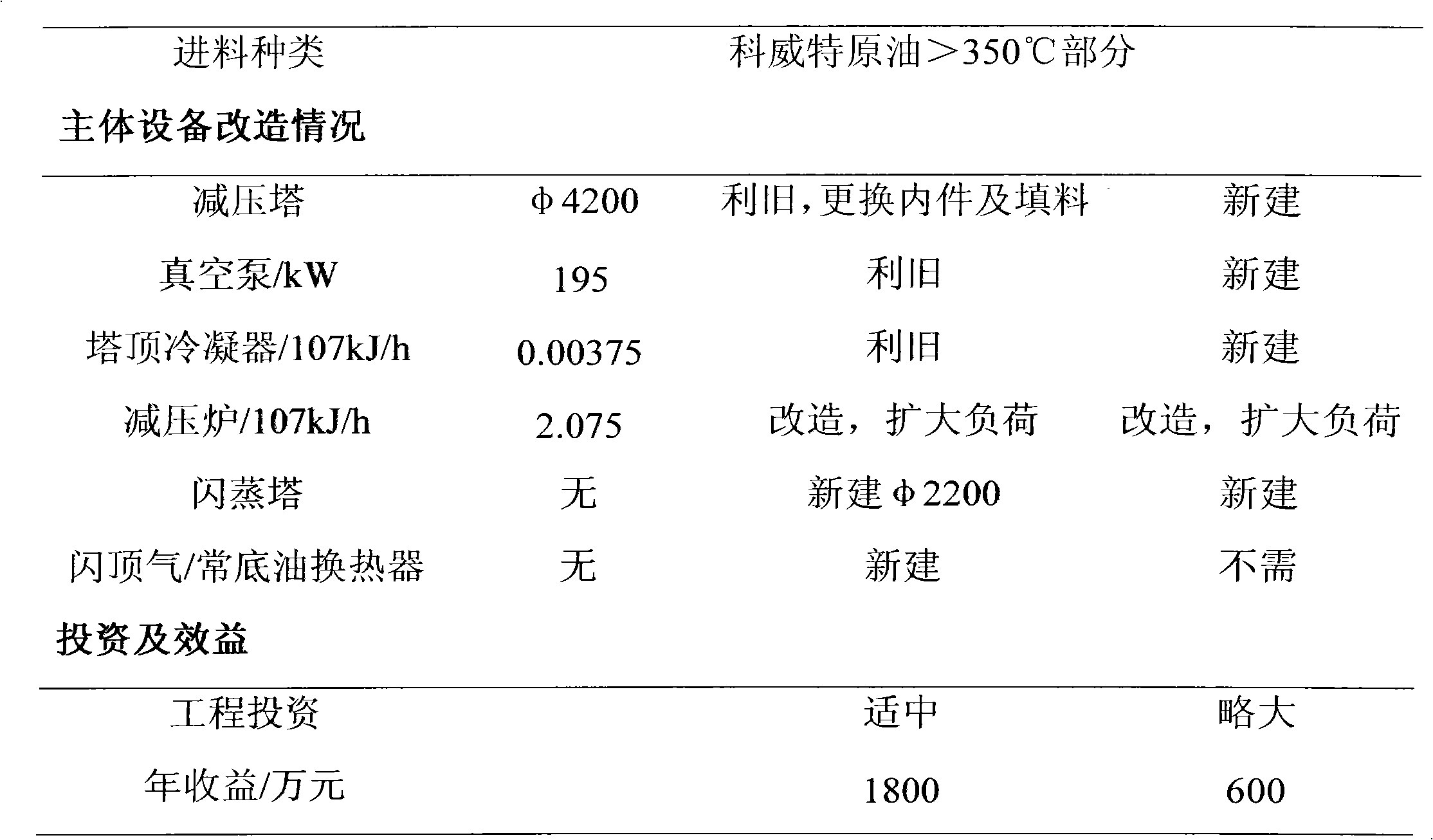

Crude oil deep drawing process method

The invention discloses a crude oil deep drawing process method. Partial pressure reduction slag oil cyclically returns to a position in front of a pressure reduction furnace to be mixed with heavy oil at the bottom of a normal pressure distillation tower for entering a pressure reduction flash distillation tower arranged in front of the pressure reduction furnace, high-temperature hydrogen or nitrogen or overheated steam accounting for 1 percent to 3 percent of the mass of inlet materials is introduced into the tower bottom of the pressure reduction flash distillation tower, the tower top gas phase of the pressure reduction flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, bottom oil of the pressure reduction flash distillation tower is introduced into the pressure reduction distillation tower for pressure reduction distillation after being heated through the pressure reduction furnace, pressure reduction fraction oil is extracted out from the side line of the pressure reduction distillation tower, pressure reduction slag oil is extracted from the tower bottom of the pressure reduction distillation tower, a part of the pressure reduction slag oil is sent out of the device, and a part of the pressure reduction slag oil cyclically returns to the pressure reduction flash distillation tower for recycling. In the method, heat carried by the high-temperature cyclic pressure reduction slag oil and the steam extraction effect of the high-temperature nitrogen are sufficiently utilized, and lighter fraction in the normal bottom oil is evaporated out in the pressure reduction flash distillation tower. The yield of the pressure reduction slag oil is reduced, and in addition, the load of the pressure reduction furnace is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

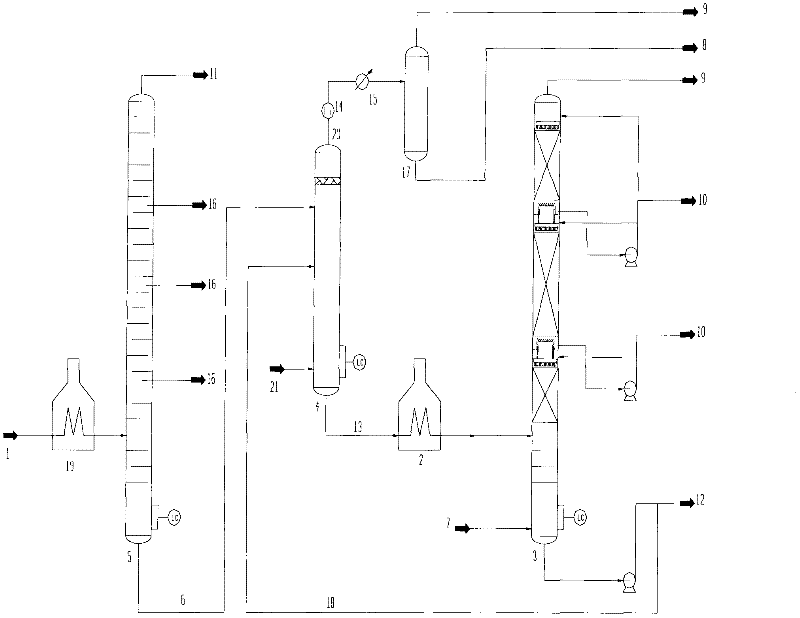

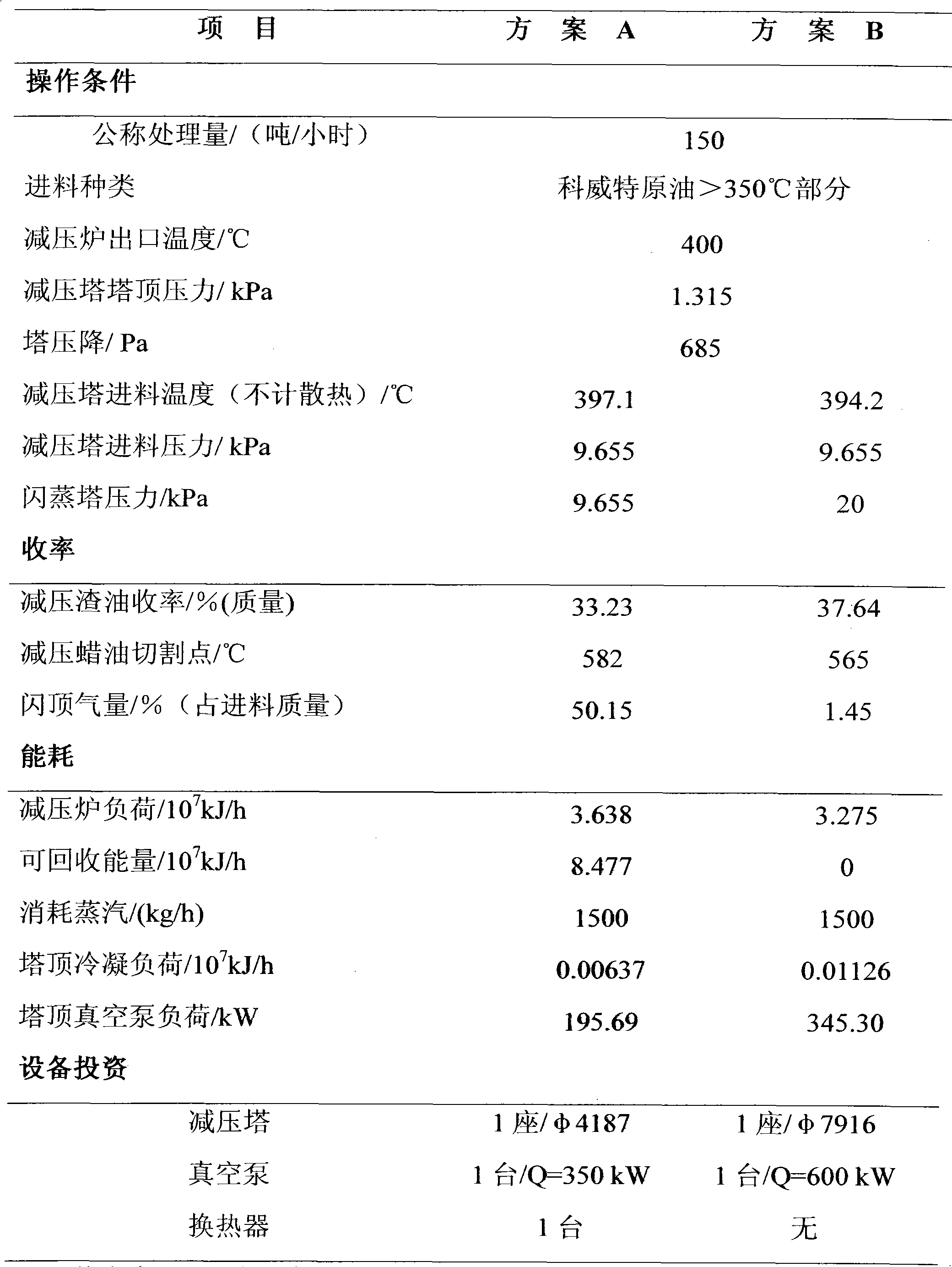

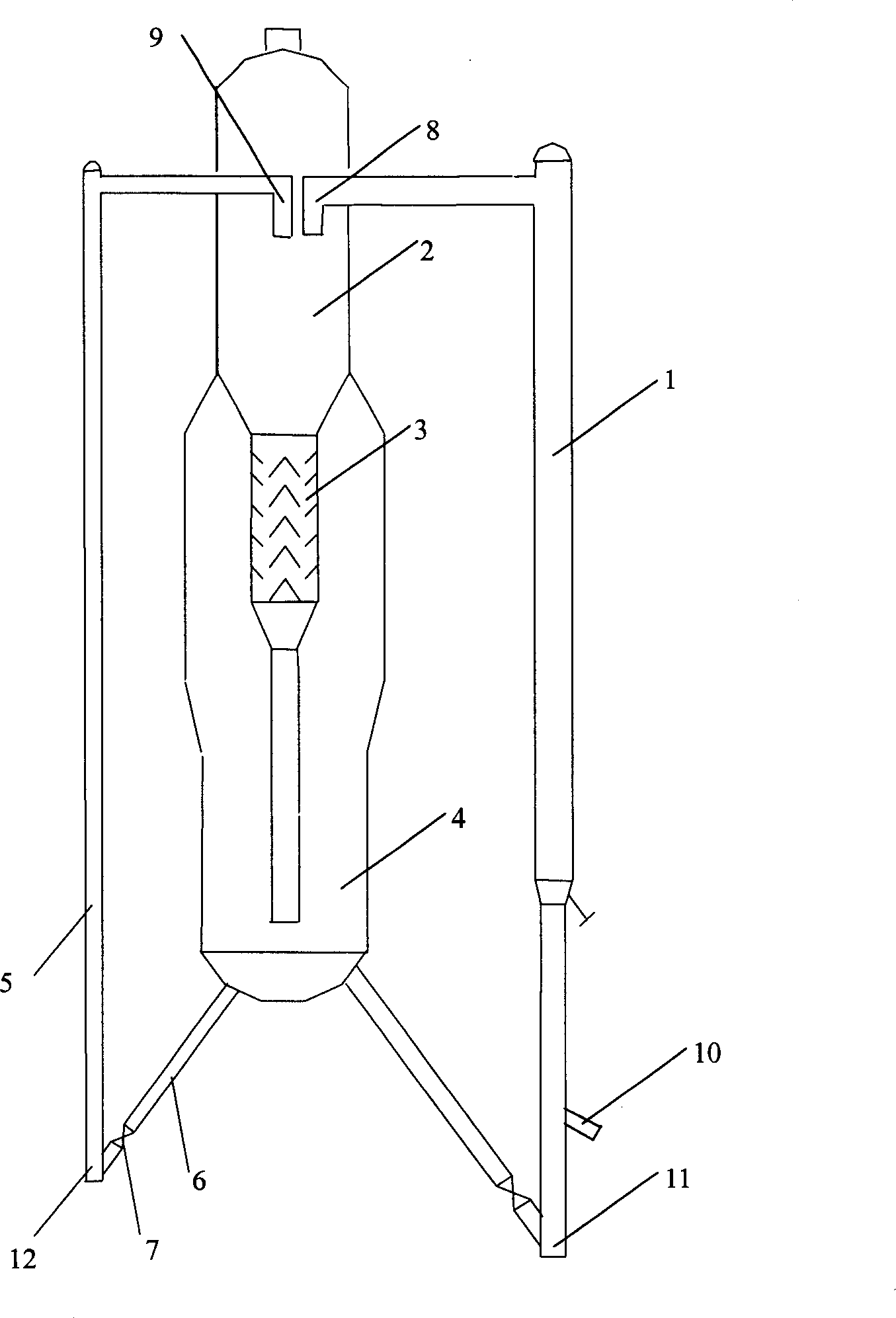

Crude oil pressure-reduced distillation method and device

InactiveCN102311754AEasy to separateGood stripping effectVacuum distillation separationVacuum distillationHydrogenGas phase

The invention discloses a crude oil pressure-reduced distillation method and a crude oil pressure-reduced distillation device. A flash tower is arranged between a reduced-pressure furnace and a reduced-pressure distillation tower, an oil transfer line is eliminated, a reduced-pressure distillation raw material is heated in the reduced-pressure furnace and directly enter the flash tower, a small amount of stripping gas is introduced into the flash tower, and the liquid phase, namely flash bottom oil, obtained by gas-liquid separation in the flash tower is introduced into the reduced-pressure distillation tower; and a gas phase, namely flash top gas, discharged from the top of the flash tower is condensed into a liquid phase to be led out of the device. A high-temperature hydrogen or inert gas is introduced into the bottom of the flash tower. When the pressure-reduced distillation method and the pressure-reduced distillation device, in which the flash tower for high-temperature hydrogen or inert gas stripping flash tower is arranged behind the reduced-pressure furnace, are used, the yield of a reduced-pressure fraction oil is increased, the conventional reduced-pressure oil transfer line is not used, the operation load of the reduced-pressure furnace is lowered, and the tower diameter of the reduced-pressure tower can be reduced properly; therefore, equipment investment is reduced, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and equipment for raising effect of steam stripping at stripping section of catalytic cracking

A method for increasing the stripping effect of the stripping segment in catalytic cracking apparatus by adding catalyst delivering tube to increase the temp of stripping segment by 10-40 deg.C features that part of regenerated catalyst is delivered into settling unit via catalyst lifting tube for mixing with the catalyst to be generated from lift-tube reactor and then being delivered into stripping segment, and the rest of regenerated catalyst is directly delivered in the lift-tube reactor for cyclic use.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

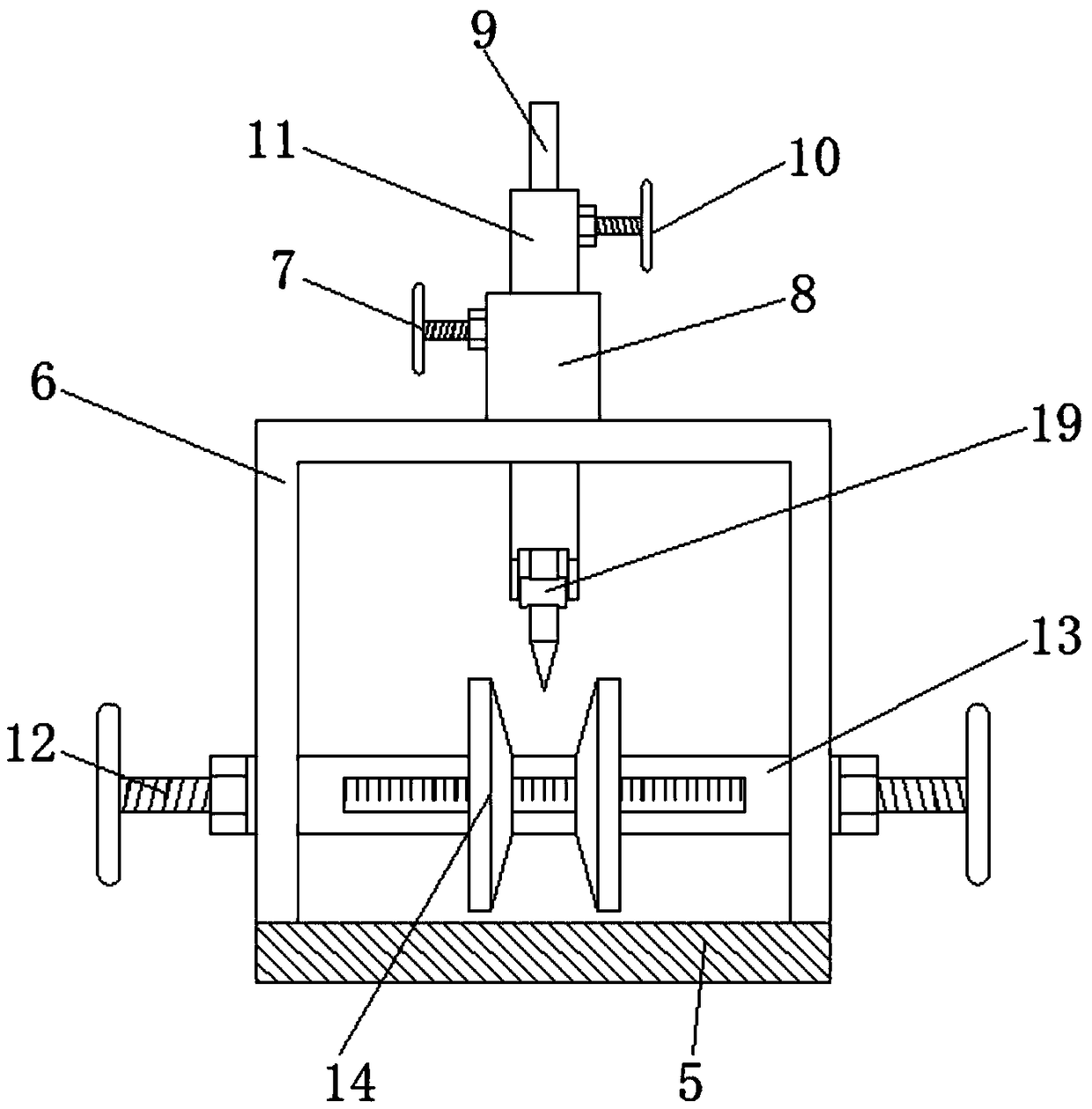

Manual stripping device capable of being applicable to cables in different sizes

InactiveCN108736385AEasy to useGuaranteed steady stateApparatus for removing/armouring cablesWork performancePulp and paper industry

Owner:安徽协创科技产业园有限公司

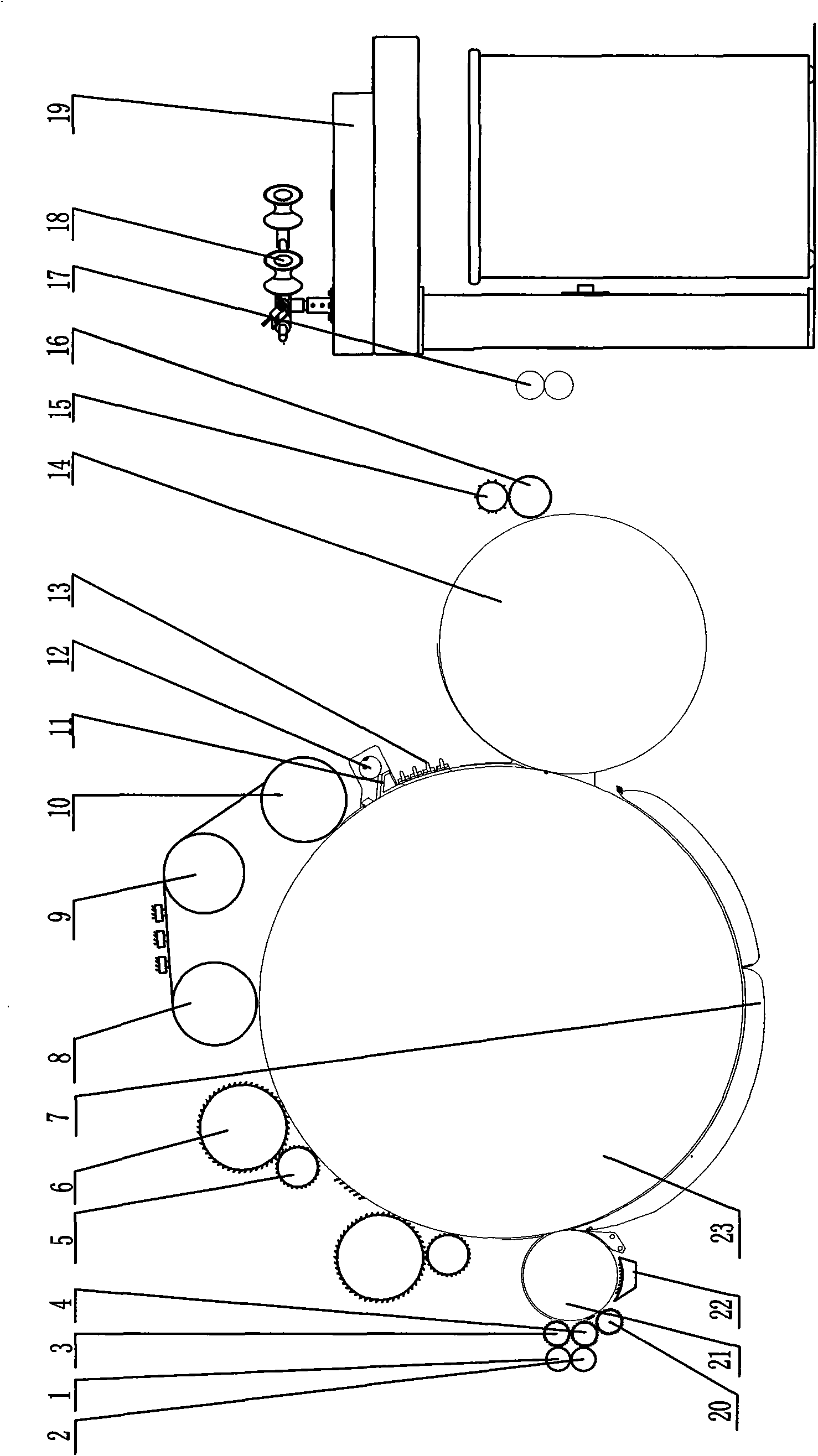

Multicomponent fiber carding machine

The invention discloses a multicomponent fiber carding machine, comprising a feeding mechanism, a carding mechanism, a stripping mechanism and a coiler mechanism. The carding machine is characterizedin that the carding mechanism comprises a cylinder, at least a work roll and wiper roll set, an upper rotating cover board and a front fixed cover board, wherein, one work roll and wiper roll set is provided with a work roll and a wiper roll; a rear carding area is formed between the work roll and wiper roll set and the cylinder, an upper carding area is formed between the upper rotating cover board and the cylinder and a front carding area is formed between the front fixed cover board and the cylinder. Under the premise of ensuring the multicomponent fiber carding effect, the carding machinenot only reduces the space occupied by equipment and greatly lowers the damage rate of the fiber, but also drastically increases the production efficiency.

Owner:青岛东佳纺机(集团)有限公司

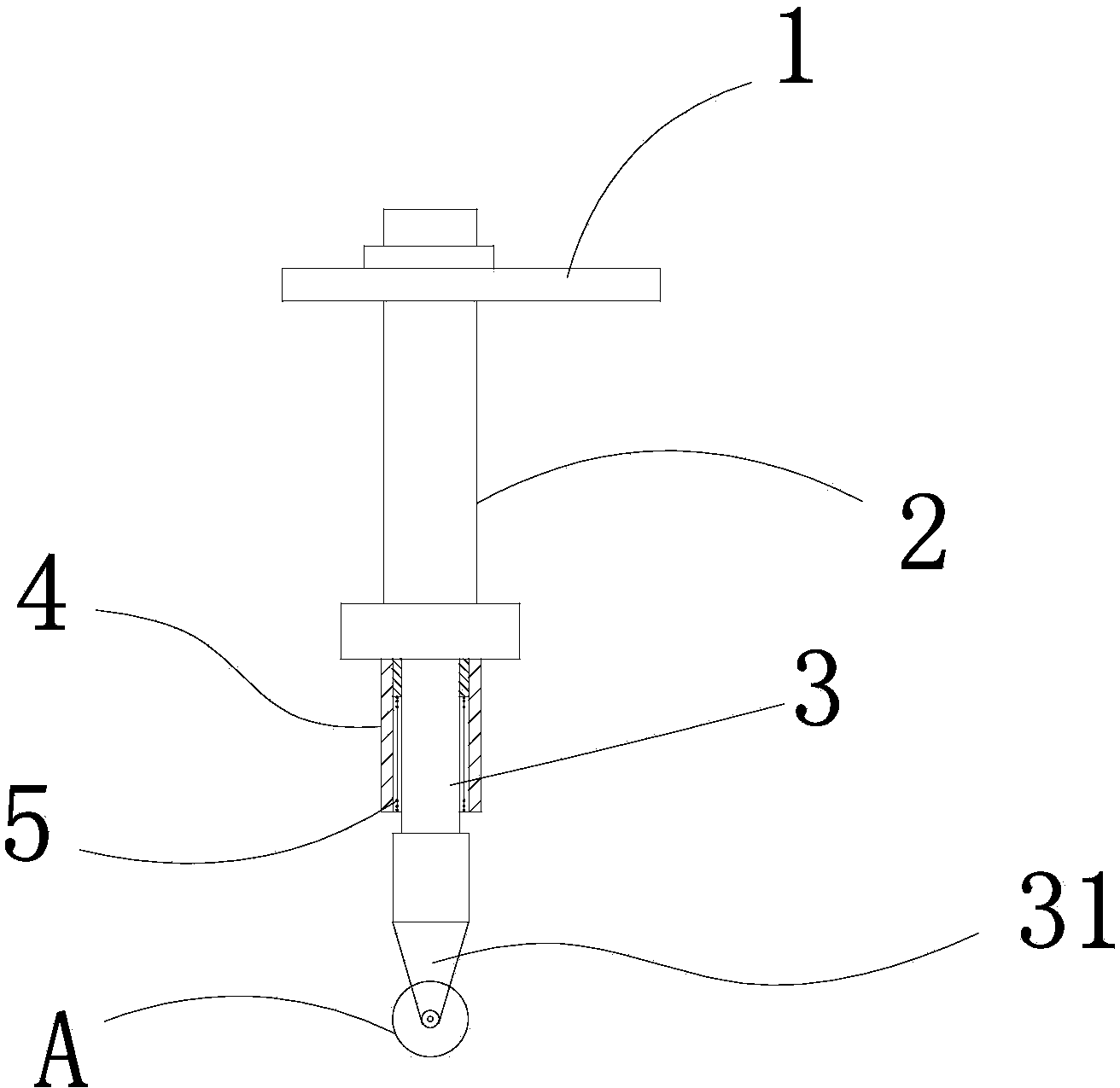

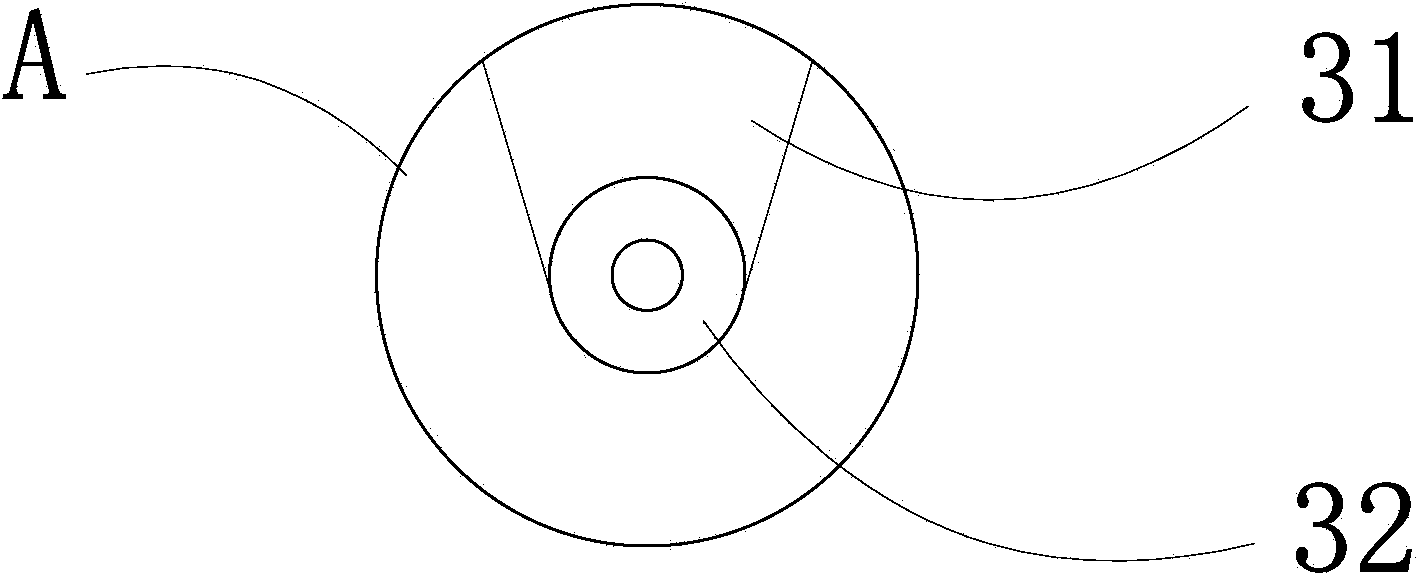

Label stripping plate for labeling machine for packaging

InactiveCN103832644ASimple structureGood stripping effectLamination ancillary operationsLaminationEngineeringRADIUS

The invention relates to a label stripping plate for a labeling machine for packaging. The label stripping plate is used for stripping adhesive sticker labels on adhesive sticker tapes, and is characterized by comprising a body, wherein a groove is formed in the upper surface of the body; a compression roller is arranged in the groove; a slope, a first transition arc and a second transition arc are formed in the end of the body; the curvature radius of the first transition arc is smaller than the curvature radius of the second transition arc. The label stripping plate is simple in structure and has the advantages of good label stripping effect and high label stripping efficiency compared with the traditional label stripping plate for the labeling machine for packaging.

Owner:WUXI ZHONGHUAN PACKAGING

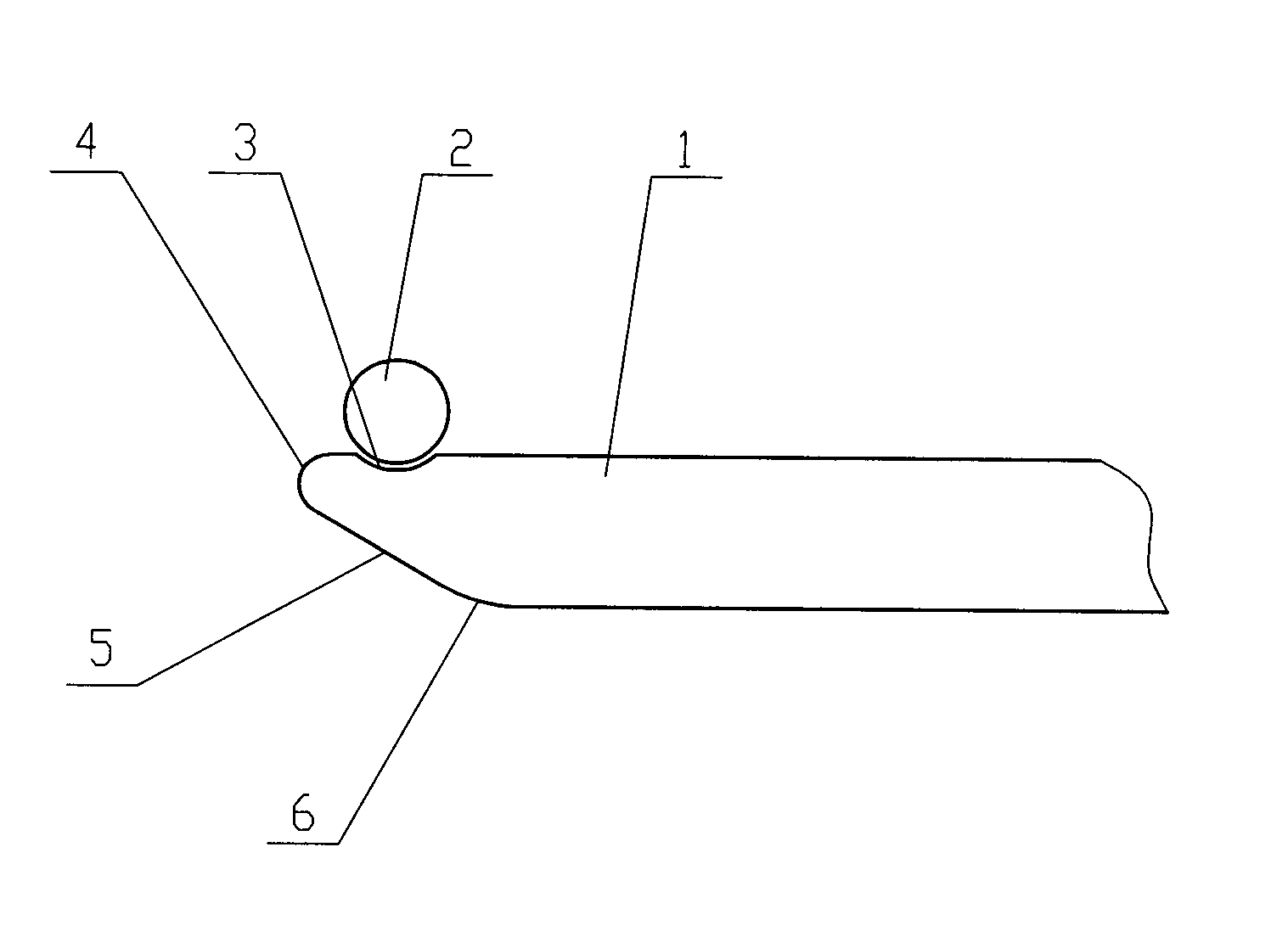

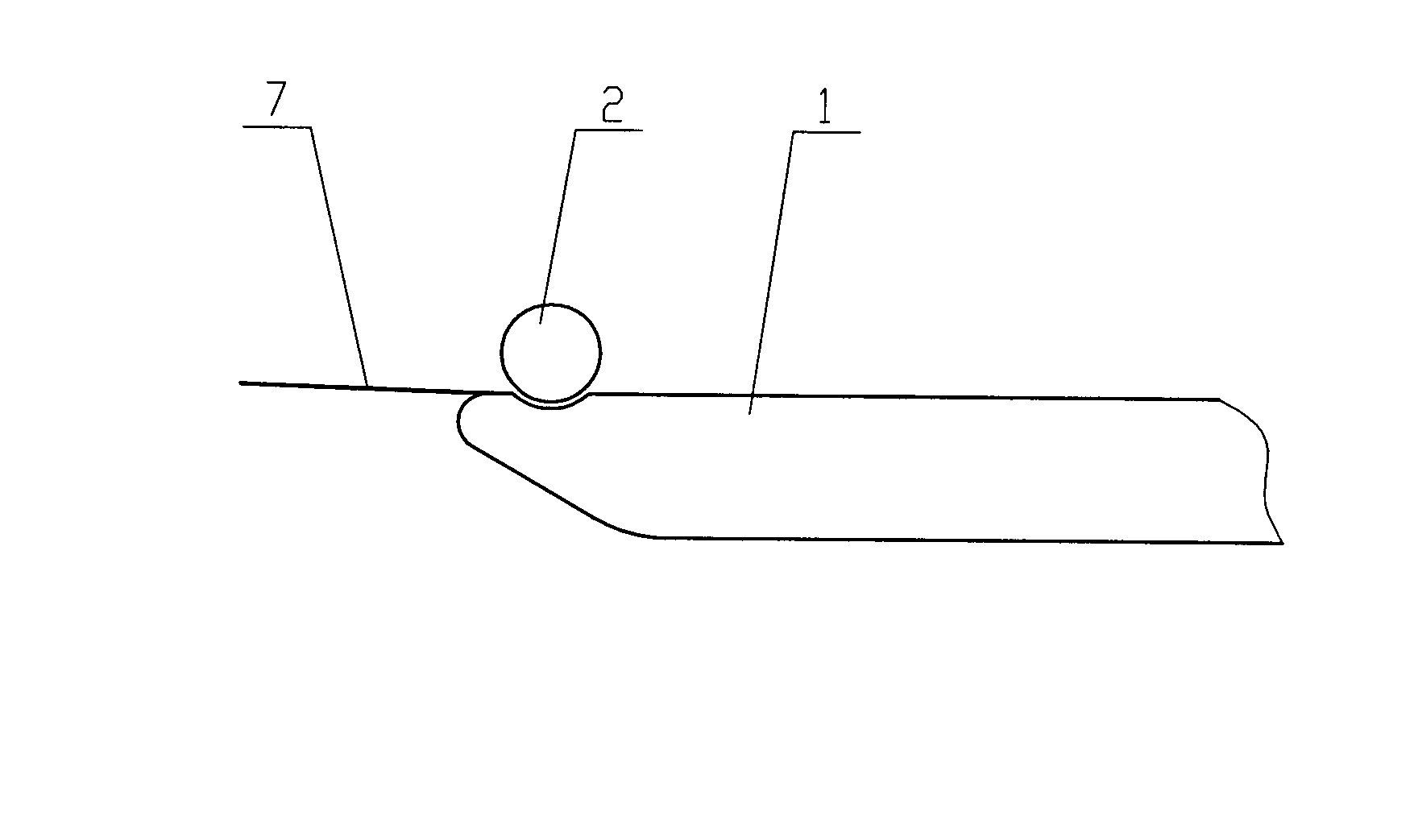

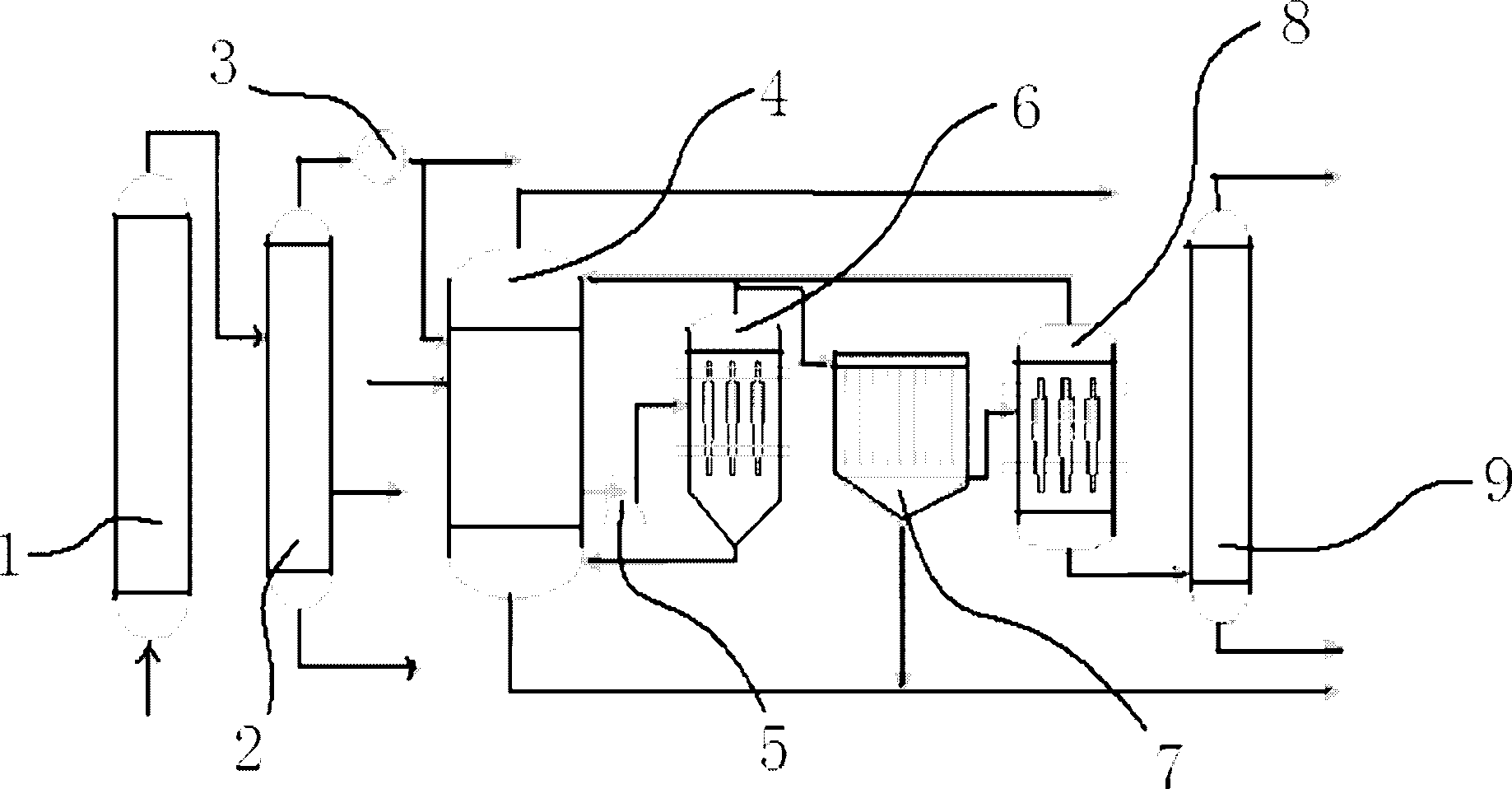

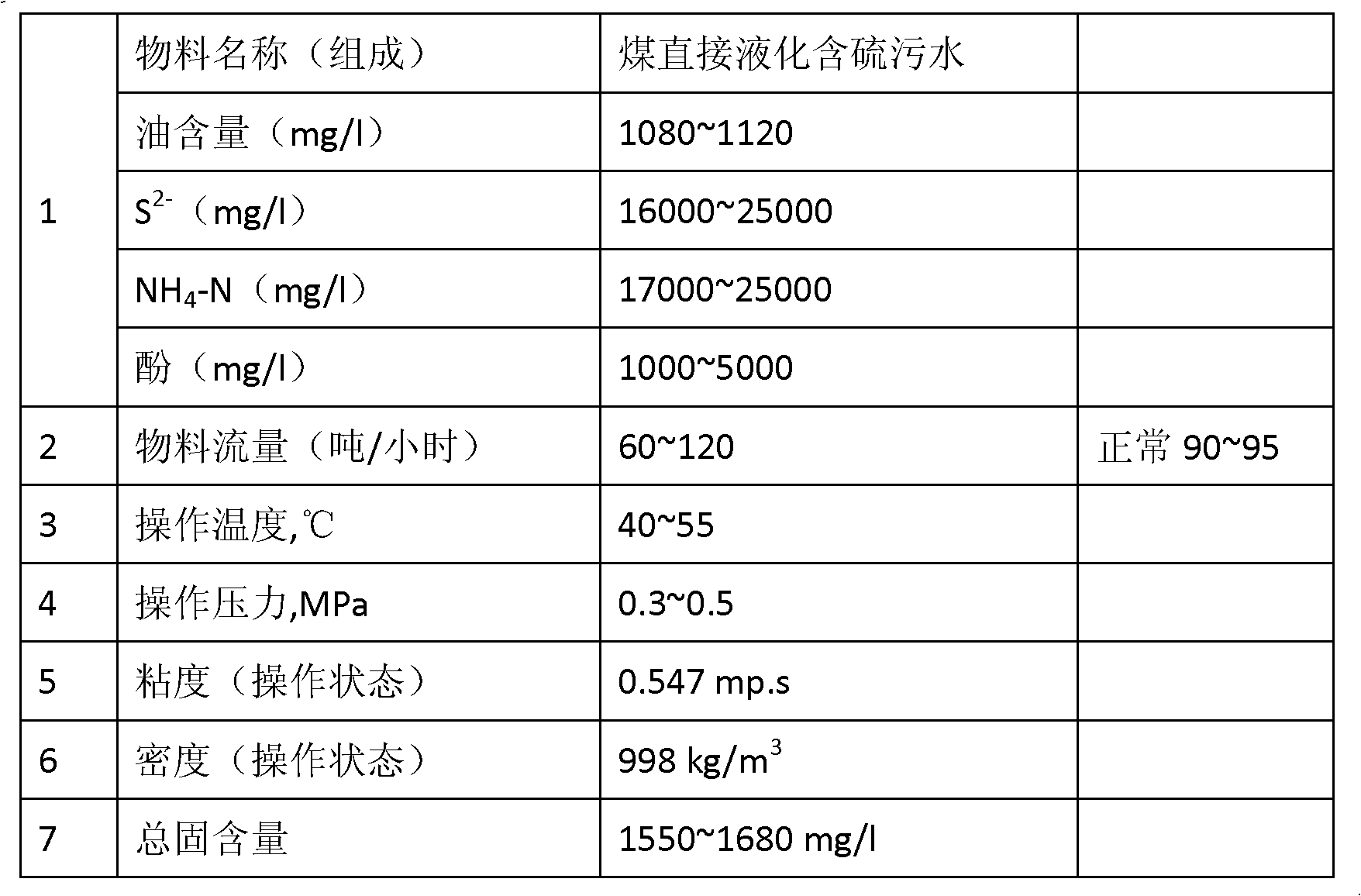

Method and device for removing coal dust and oil by enabling coal to be directly liquefied and generate sulphur-bearing waste water

ActiveCN102583821APrevent sediment cloggingReduce loadWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesCycloneCoal dust

The invention discloses a method and a device for removing coal dust and oil by enabling coal to be directly liquefied and generate sulphur-bearing waste water in the technical field of coal conversion. The method and the device can avoid deposition blocking of the coal dust in a stripping tower, reduce loads of a steam stripping device and improve steam stripping effect, the running cycle of the device is prolonged, simultaneously recycling of dirty oil is facilitated, the processing loss of the device is reduced, and the economic benefit of the device is improved. Besides, a micro cyclone separator and a cyclone deoiler which are adopted in the device are high in separating efficiency, long in continuous running cycle, small in occupied area, high in impact resistance and simple to operate and maintain. The method and the device are characterized in that the device for removing the coal dust and the oil by enabling the coal to be directly liquefied and generate the sulphur-bearing waste water comprises an adjusting tank, a sewage pump, the micro cyclone separator, a precision filter, the cyclone deoiler and the stripping tower; and sewage finally enters into the stripping tower to be treated after the sewage is treated by the adjusting tank, the sewage pump, the micro cyclone separator, the precision filter and the cyclone deoiler.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

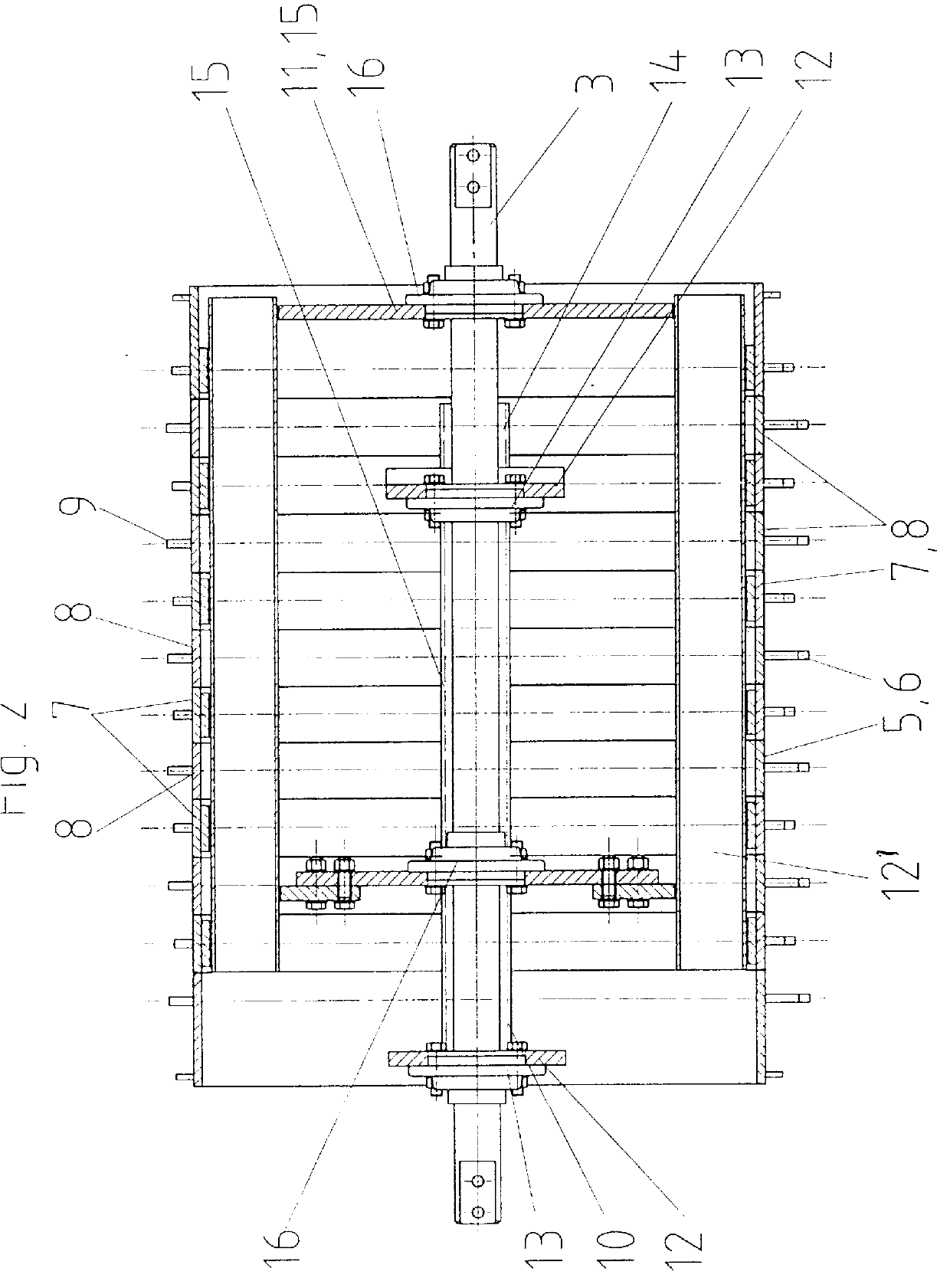

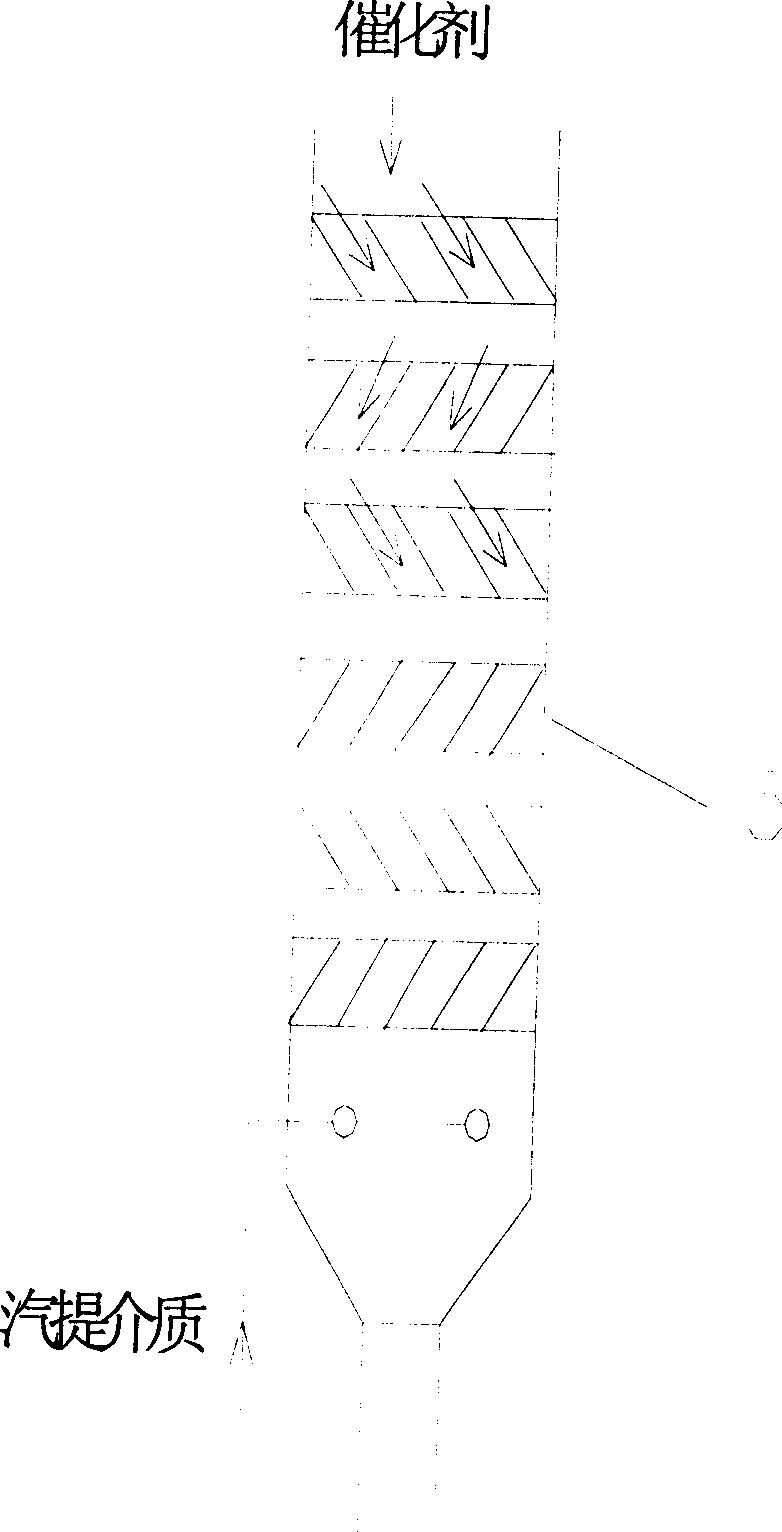

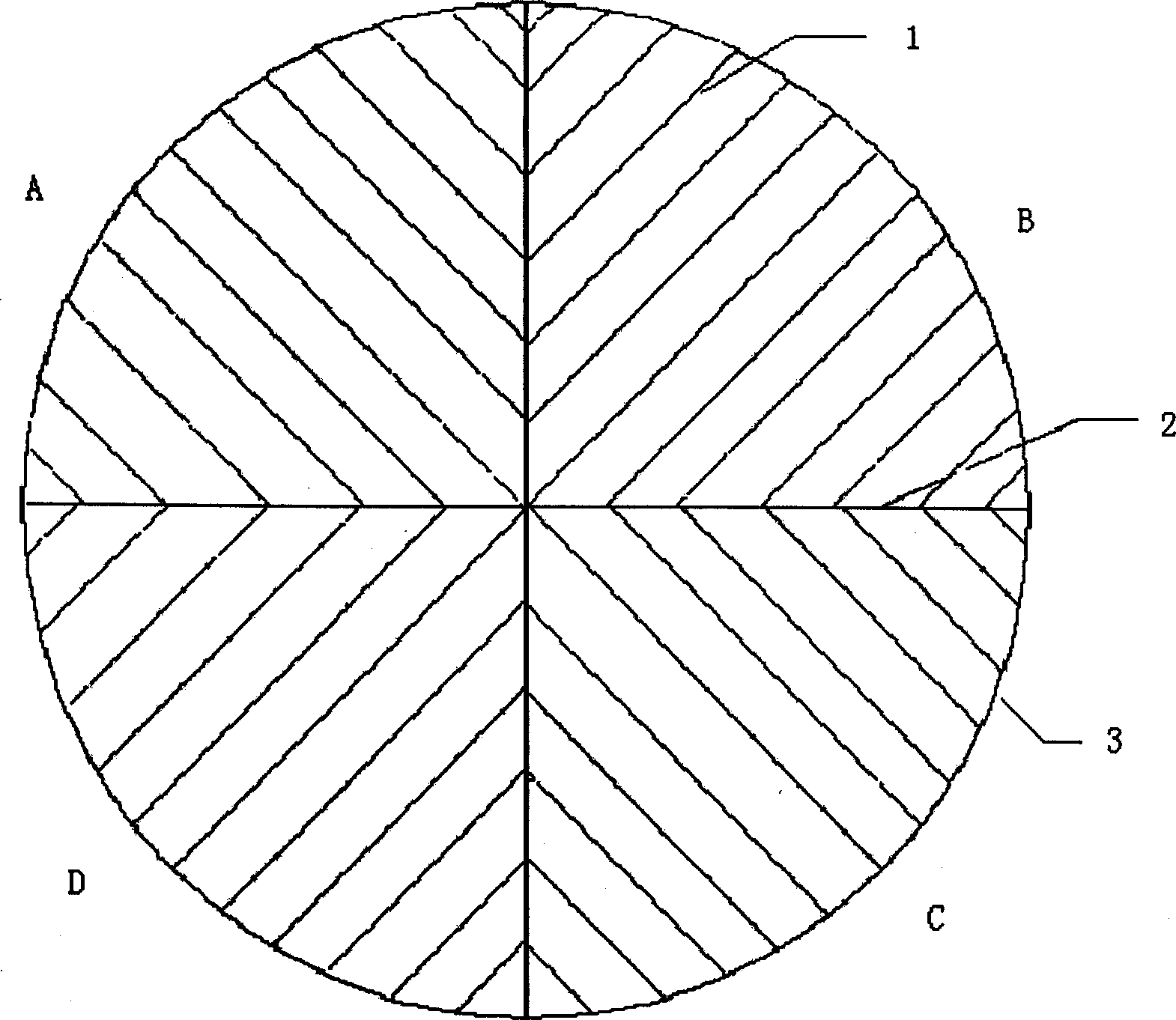

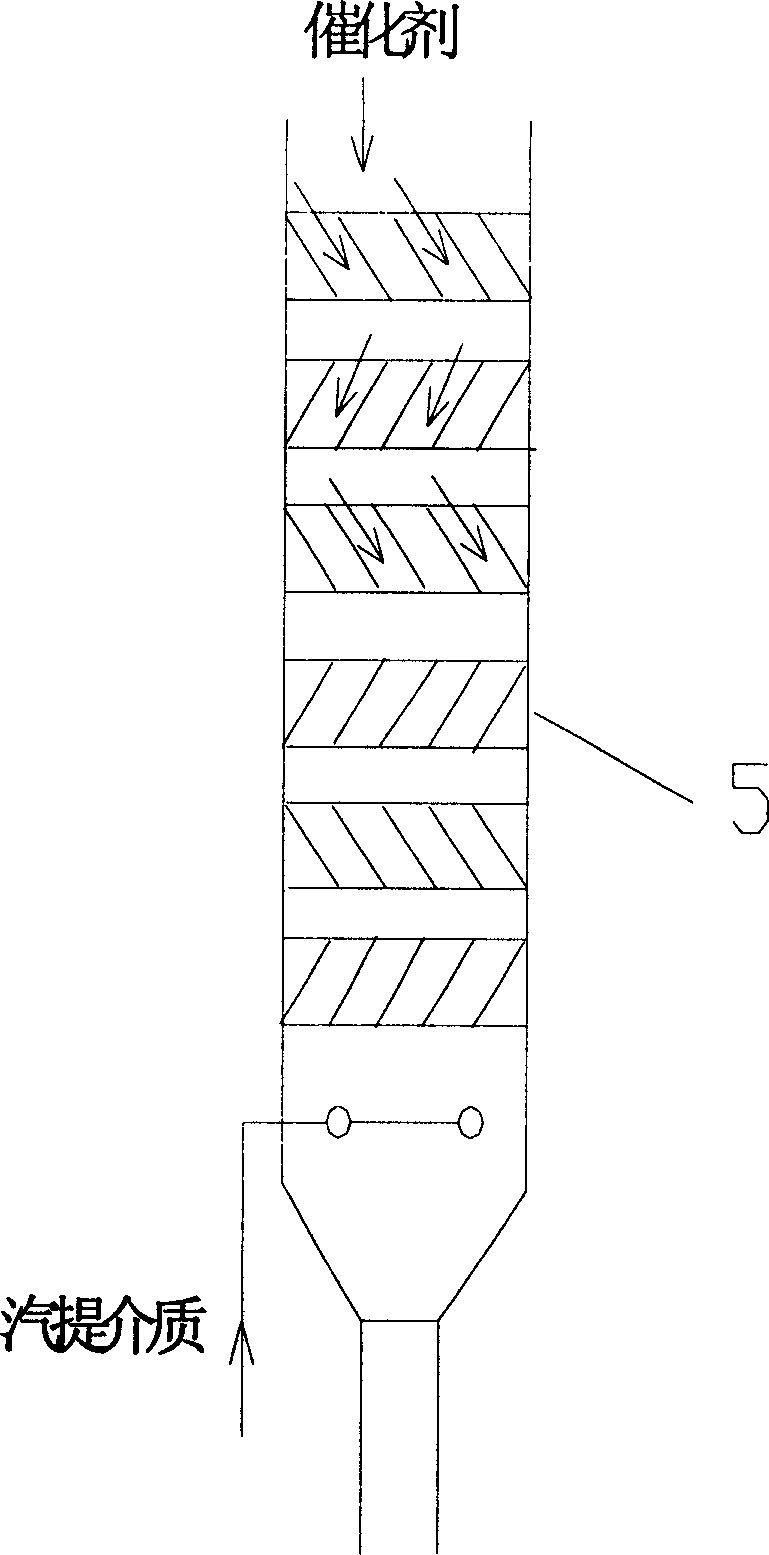

Stripping method for reclaimable catalyst

InactiveCN1485405AComprehensive contactIntensify exerciseCatalytic crackingCatalyst regeneration/reactivationPetroleumAir stripping

A method of catalytically cracking regenerative catalysts with gas stripping. It comprises: a regenerative catalyst after reaction entering a gas stripping machine, contacting refluently with medium for gas stripping, removing petroleum hydrocarbon, then the regenerative catalyst leaving the gas stripping machine. The gas stripping machine has inner members with configuration of four-storey column trays or more. the regenerative catalyst and gas stripping medium all change their flowing directions when passing every storey of inner member.

Owner:CHINA PETROLEUM & CHEM CORP +1

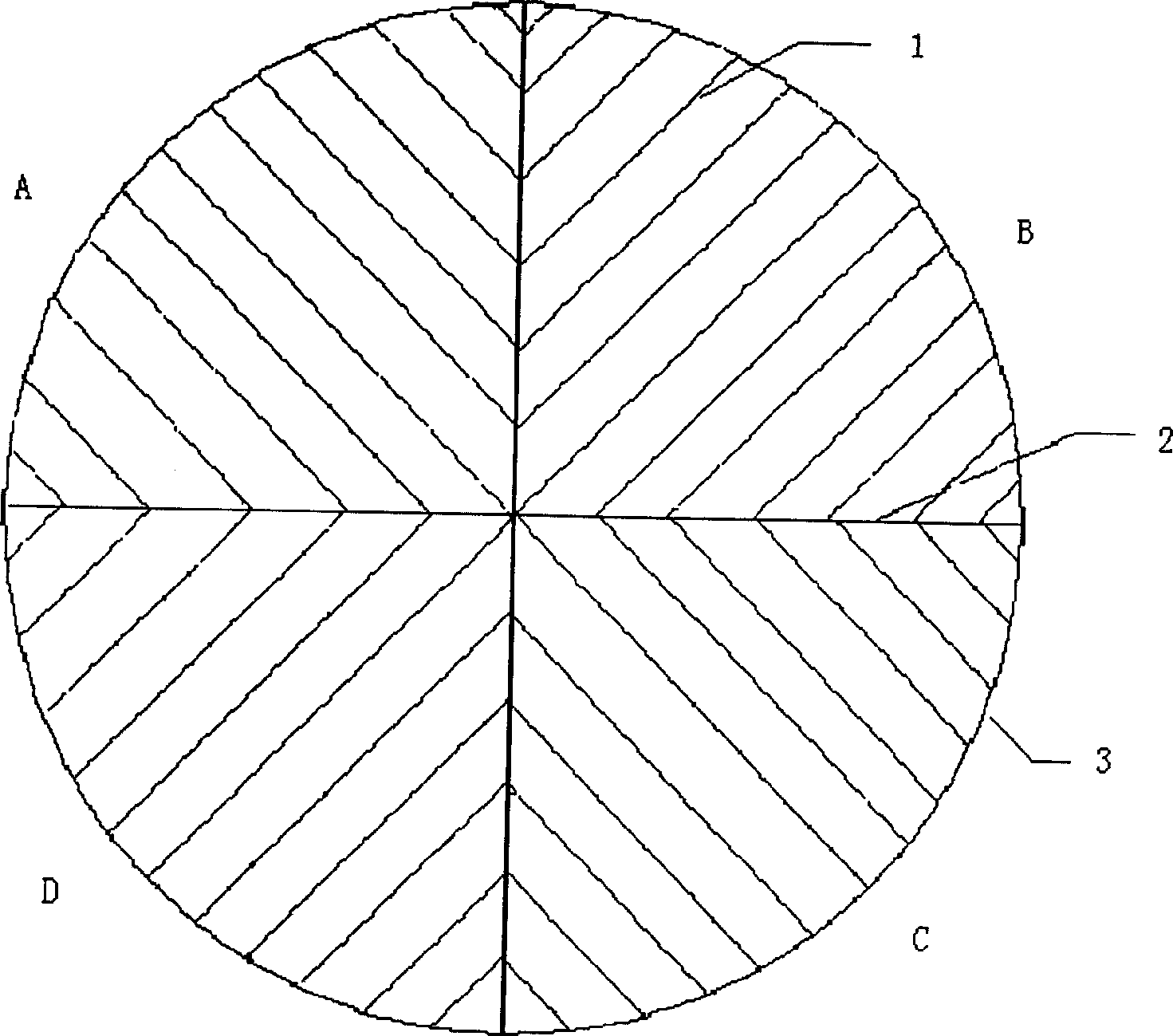

Stripping method and equipment for hydrocarbon catalytic converting catalyst

InactiveCN1136295CImprove uniformityAvoid backmixingCatalytic naphtha reformingCatalytic transformationIt equipment

The present invention provides one method of raising the efficiency of stripping hydrocarbon converting catalyst and its equipment. According to the present invention, catalyst particle and stripping fluid are made to counterflow through one stripper with at least two layers of stuffing. The stuffing in the stuffing layers is crossed into diamond shaped grid plate parallel to the axis of the stripper. The stripper of the present invention has high efficiency. The present invention is especially suitable for catalytic conversion process of preparing olefin, the smoke impurity content in the regenerating agent is less than 0.05 vol%, and the stripper can be reduced in volume and equipment investment obviously.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

Method for catalyzing urea hydrolysis by using nano aluminum oxide

PendingCN113184879AEasy to recycleLarge specific surface areaGas treatmentPhysical/chemical process catalystsPtru catalystWater vapor

The invention provides a method for catalyzing urea hydrolysis by using nano aluminum oxide, and relates to the field of power plant flue gas denitration. The method for catalyzing urea hydrolysis by using nano-alumina comprises the following steps: preparing nano-alumina, carrying out urea catalytic hydrolysis reaction in a hydrolysis reactor by using nano-alumina as a catalyst, and installing a steam jet system at the lower part of the hydrolysis reactor. The technology has the following effects: water vapor is used as a steam stripping medium, gas generated by hydrolysis reaction is stripped out in time, the water vapor passes through a steam jet system, the turbulence degree of a urea solution is enhanced, gas-liquid mass transfer is enhanced, the generated gas is favorably discharged, and NH3 is prevented from being dissolved in water and a reverse reaction is prevented; and the high-speed gas fluid can disturb the suspended catalyst nano aluminum oxide in the hydrolyzer, so that the urea solution is in more sufficient contact with the catalyst, the catalytic hydrolysis reaction is facilitated, and the problems existing in a fixed bed reactor are solved.

Owner:SHANDONG ACAD OF CHINESE MEDICINE +1

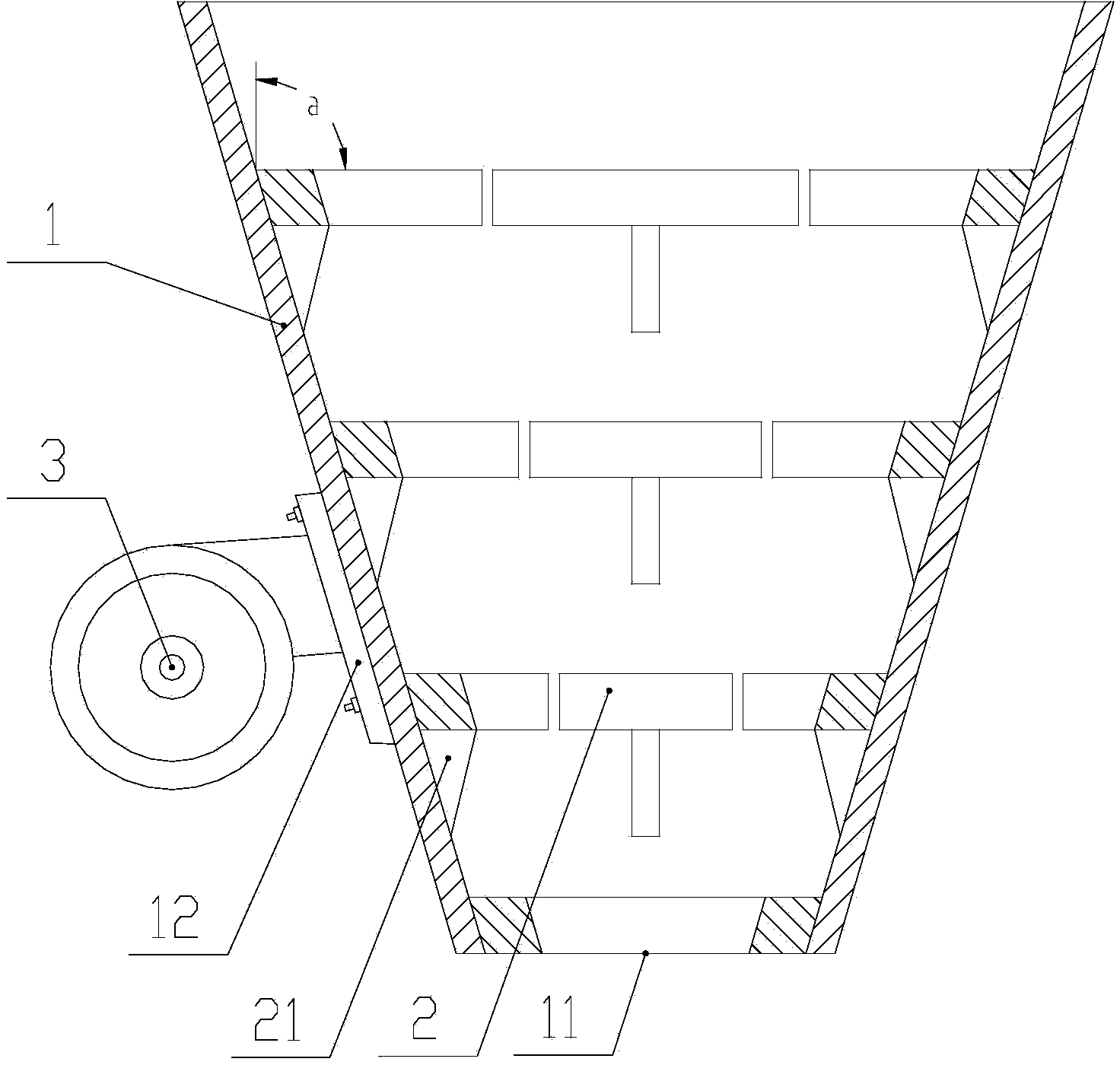

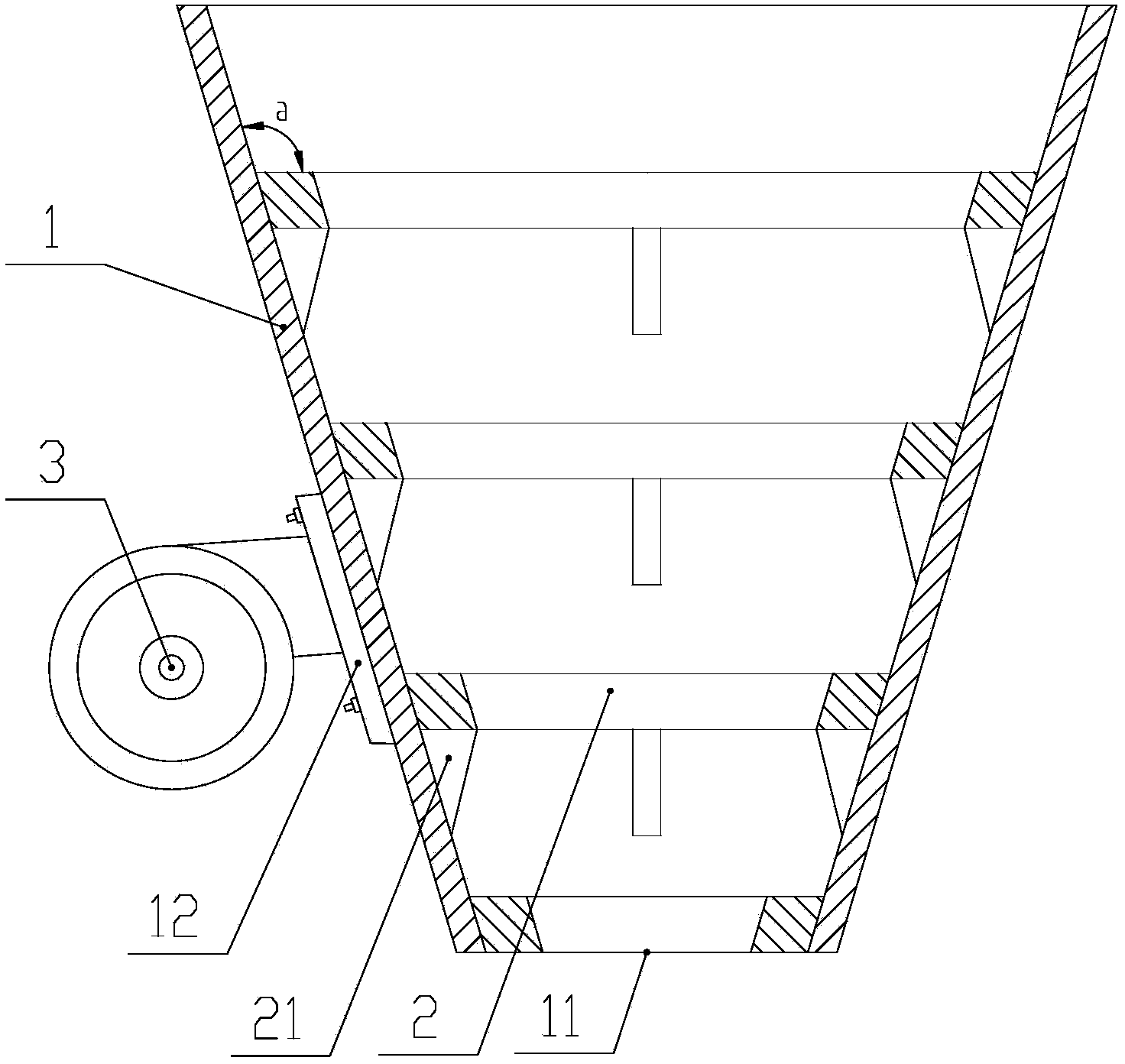

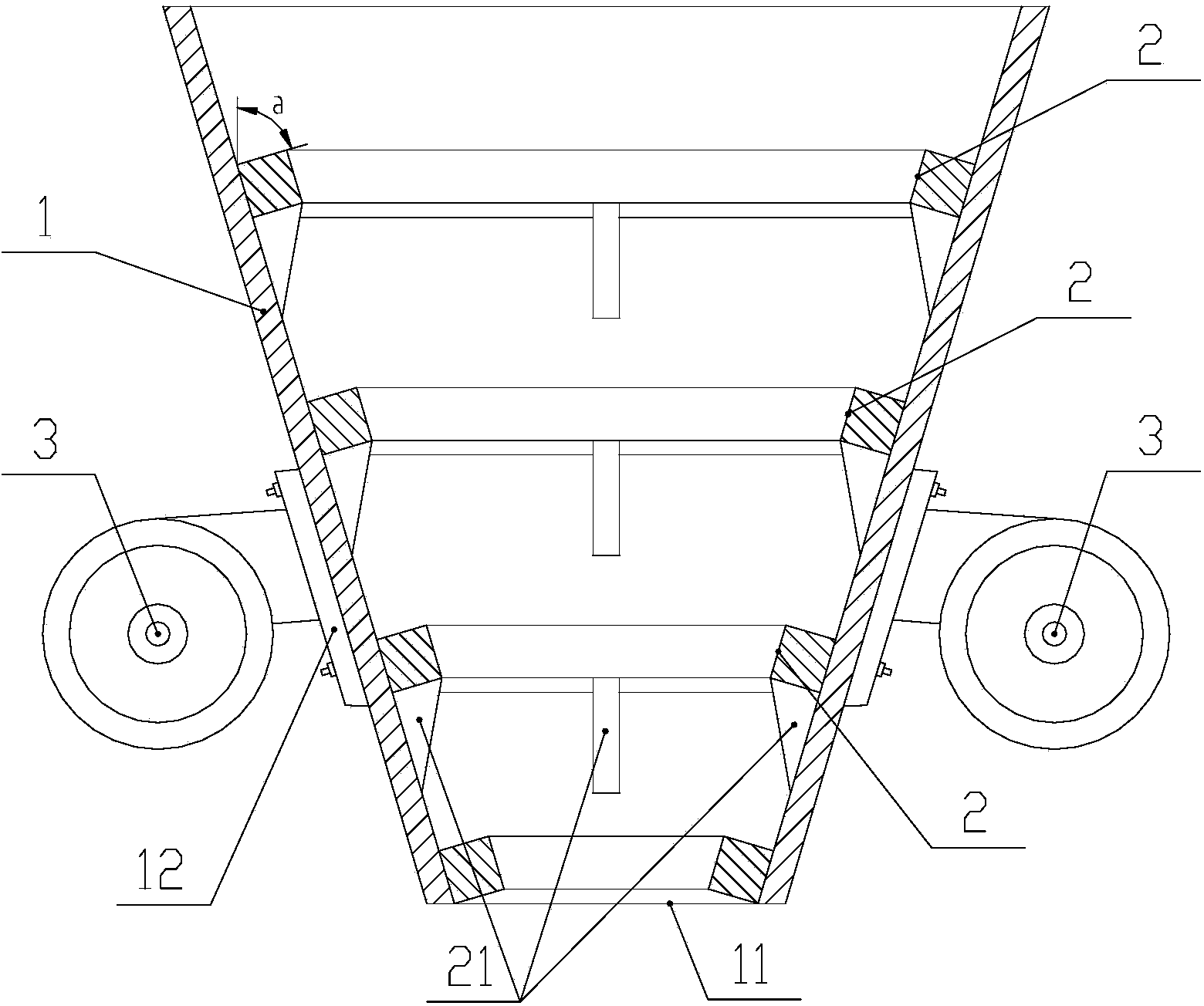

Ore feeding hopper device

ActiveCN104176516AReduce wearImprove wear resistanceLarge containersLoading/unloadingEngineeringWear resistance

The invention discloses an ore feeding hopper device which is low in cost, easy to clean and capable of achieving continuous and stable discharging. The ore feeding hopper device comprises a hopper body, wherein the lower end of the hopper body is provided with a discharging port. The ore feeding hopper device further comprises at least two barrier plate layers and at least one stripping device, wherein the barrier plate layers are arranged along the inner circumference of the hopper body by one circle and sequentially arranged in the hopper body from bottom to top in a spaced mode, and the included angle a between the upper surface of each barrier plate layer and the vertical upward direction is smaller than or equal to 90 degrees; the stripping device is installed on the outer wall of the hopper body and can vibrate and / or rap the hopper body so as to enable ore to fall off. The barrier plate layers indirectly improve abrasion resistance of the hopper device, cost is lower, and the hopper device is good in abrasion resistance, easier to manufacture and suitable for application and popularization. The stripping device can guarantee continuity and stability of discharging and meanwhile facilitates cleaning and maintaining of the interior of the hopper device.

Owner:四川安宁铁钛股份有限公司

Thermal wire stripping apparatus

InactiveCN106981844ARealize automatic strippingSimple designApparatus for removing/armouring cablesFiberEngineering

The invention relates to a thermal wire stripping apparatus which includes a supporting pedestal which is provided with a wire mechanism and a wire scalding mechanism. The wire mechanism is intended for transporting an electrical wire. The wire scalding mechanism is disposed at a position corresponding to the head end of the wire mechanism, and is intended for clamping a wire sheath of the electrical wire and conducting thermal scalding. The tail end of the wire mechanism is connected to a rotating apparatus which drives the wire mechanism to rotate the electrical wire back and forth. The head end of the wire mechanism is an electrical wire output end, and the tail end is and an electrical wire input end. When the head end of the wire mechanism outputs an electrical wire, and the wire scalding mechanism clamps the electrical wire and thermally scalds the electrical wire, the rotating apparatus drives the wire mechanism to rotate the electrical wire back and forth, such that the wire sheath of the electrical wire is evenly heated at 360 degrees and is fused. According to the invention, the apparatus herein can rotate the electrical wire in the process of thermal stripping, the wire sheath of the electrical wire can be evenly heated at 360 degrees on the wire scalding mechanism and be fused in real sense, thus realizing automatic wire stripping. The apparatus herein has the characteristics of simple design, scientific structure, high automation and excellent wire stripping effects. The apparatus herein can be designated to strip fiber braided wires, can greatly increase production efficiency and is applicable to promotion for enterprises.

Owner:黄志刚

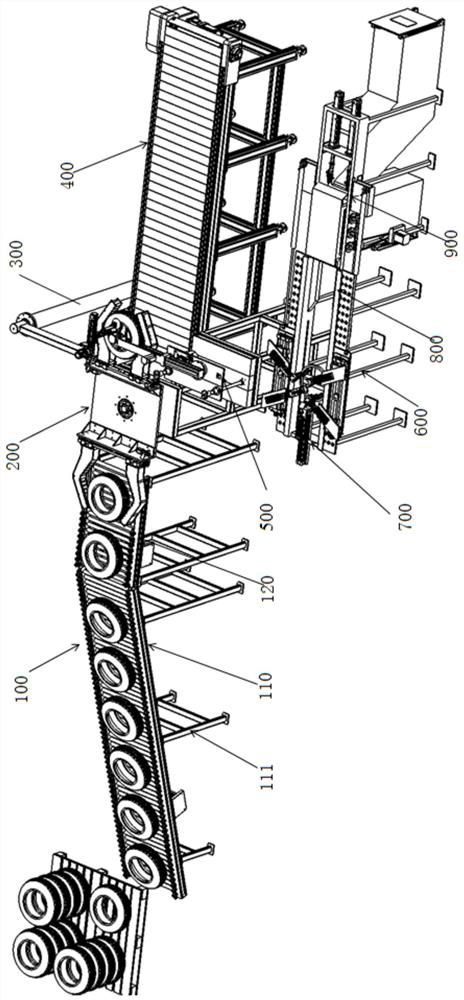

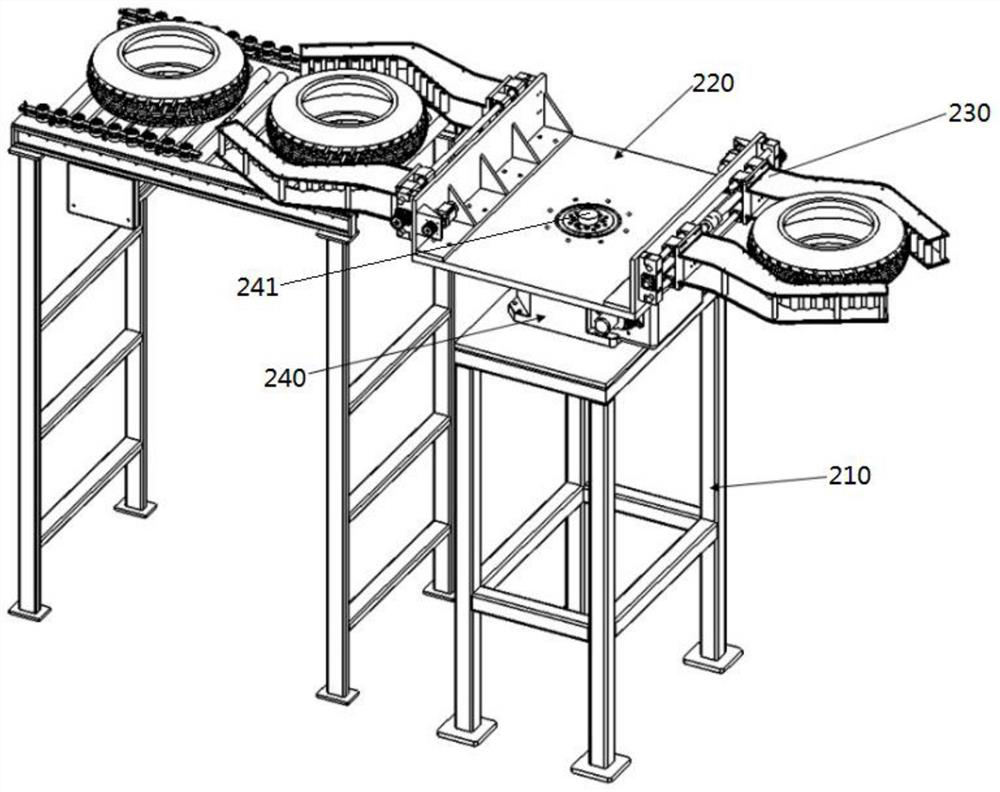

Full-automatic waste tire circular-cutting and tire bead cutting and wire stripping system and method

PendingCN111619039ARealize comprehensive utilizationMeet processingPlastic recyclingGrain treatmentsTire beadProcess engineering

The invention relates to a full-automatic waste tire circular-cutting and tire bead cutting and wire stripping system. The system comprises a tire circular-cutting and conveying device, a tire bead carrying device and a tire bead cutting and wire stripping device; the tire circular-cutting and conveying device comprises a front-end conveying mechanism, a rotating carrying mechanism for carrying and assisting in circular cutting, a tire bead circular-cutting mechanism for cutting off tire beads of waste tires and a back-end conveying mechanism for conveying out the waste tires with the tire beads cut; the tire bead carrying device is arranged on one side of a tire bead circular-cutting device, assists the tire bead circular-cutting device in tire bead cutting and conveys the tire beads cuteach time to a tire bead cutting and wire stripping module; the tire bead cutting and wire stripping device comprises a workbench mechanism, a tire bead cutting mechanism, a tire bead pulling mechanism and a tire bead wire stripping mechanism; the tire bead cutting mechanism is arranged on the workbench mechanism and is used for cutting off and leveling the tire beads; the tire bead pulling mechanism is used for conveying the cut and leveled tire beads to the tire bead wire stripping mechanism; and the tire bead wire stripping mechanism is used for stripping steel wires out of the tire beads.The system has the beneficial effects that a relatively perfect waste tire processing system and manner is provided and has the relatively high scientificity and logicality.

Owner:SAILUN GRP CO LTD +1

Reciprocating rolling material forming device

A reciprocating rolling material forming device comprises a feeding mechanism, a rolling plate and a bearing plate, wherein the rolling plate and the bearing plate are arranged in parallel, the bearing plate is located below the rolling plate, and a plurality of holes are formed in the bearing plate; the feeding mechanism is located at the same ends of the rolling plate and the bearing plate, andmaterials enter the gap between the rolling plate and the bearing plate from the feeding mechanism; at least one of the rolling plate and the bearing plate is connected with a driving mechanism, and the driving mechanism is connected with a first power source; and the first power source drives the driving mechanism to drive at least one of the rolling plate and the bearing plate to do reciprocating synchronous circular motion, so that the materials on the bearing plate are rolled and poked, and the materials are extruded and formed from the holes of the bearing plate located below. According to the device, the materials are periodically and intermittently rolled, so that the formed materials are short, accumulation is avoided, and the evaporation area can be enlarged.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

Fischer-Tropsch synthesis system and method

ActiveCN104711006AEasy to removeAchieve removalLiquid hydrocarbon mixture productionChemical/physical processesSlurryChemistry

The invention discloses a Fischer-Tropsch synthesis system and method. The Fischer-Tropsch synthesis system comprises a slurry bed reactor, a first filtering device, a first separation device, a second separation device and a stripping tower. According to the system and the method, all devices are matched, so that fine catalyst particles in the reactor can be effectively removed, the fine catalyst particles in a discharged product can be effectively separated, a separation process is scientific and reasonable in design, the problems of aggregation of the fine catalyst particles in the slurry bed reactor and difficulty in the separation of the fine catalyst particles in the synthesized product are solved, and the Fischer-Tropsch synthesis system can run continuously and stably.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Raw bamboo slitting equipment capable of achieving quick removal of bamboo joint

InactiveCN112025883AQuick removalRealize clamping limit workMulti-purpose machinesCane mechanical workingKnife bladesIndustrial engineering

The invention belongs to the field of bamboo processing, and particularly relates to raw bamboo slitting equipment capable of achieving quick removal of a bamboo joint. The raw bamboo slitting equipment comprises a cylinder, and the barrel is fixedly connected with a cutting shaft; the cutting shaft is provided with a plurality of groups of cutting blades, and the barrel is movably connected witha clamping device; and the clamping device comprises a transmission mechanism and a clamping mechanism. The transmission mechanism is fixedly connected with the clamping mechanism, and the clamping mechanism is rotationally connected with a telescopic blade. According to the raw bamboo slitting equipment capable of achieving quick removal of the bamboo joint, the bamboo joint on the edge of a rawbamboo can be removed to a certain extent in the slitting process, and the processing efficiency of raw bamboo slitting is improved, and the raw bamboo slitting equipment is suitable for promotion widely.

Owner:HUZHOU YUEBIN INTELLIGENT TECH CO LTD

Environment-friendly high-purity cerium dioxide extraction method

ActiveCN107758719AReduce pollutionInterchangeableRare earth metal oxides/hydroxidesRare earth metal compounds preparation/treatmentRare earthCerium

The invention belongs to the technical field of separation and purification of rare earth, and particularly relates to an environment-friendly high-purity cerium dioxide extraction method. The methodcomprises the following steps: (1) extracting: mixing a cerium chloride material liquid and an extracting agent at the volume ratio of 1:(1.2-1.5), extracting, separating, adding hydrotalcite whose weight is 4-6% of the weight of the extracting agent at the same time, conducting ultrasonic dispersion for 20-30 minutes, leaving to stand, then separating, recycling a solid phase, inputting an organic phase into a reextraction procedure; (2) reextracting: taking an oxalic acid solution, wherein the volume of the oxalic acid solution is 1.5-2.0 times the volume of the organic phase, reextracting at the temperature of 50-60 DEG C, conducting ultrasonic dispersion for 20-30 minutes, filtering to obtain a precipitate; (3) oxidizing: firing and oxidizing the obtained precipitate at the temperatureof 1000-1100 DEG C for 12-15 hours, and obtaining the high-purity cerium dioxide. The method abandons the traditional alkaline saponification causing serious ammonia nitrogen pollution, and the artificial hydrotalcite is used to implement ion exchange in the extraction process, so that the balanced acidity of the system is maintained, and the environmental pollution is reduced.

Owner:DEQING XINGBANG RARE EARTH NEW MATERIALS

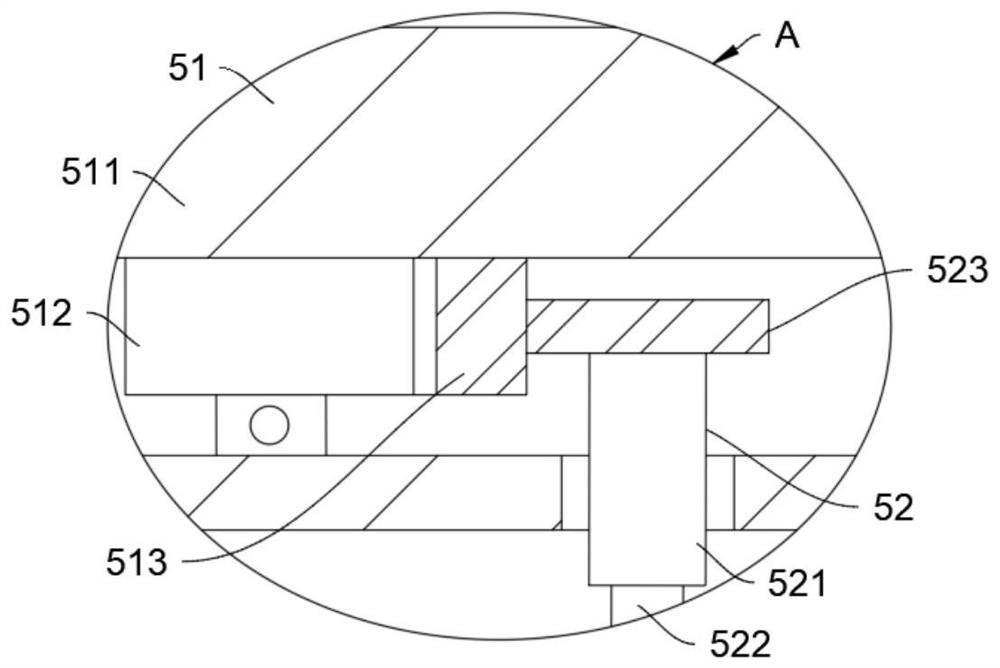

Elastic label pushing device of labeling machine

InactiveCN104176346AReduce shockFacilitate strippingLabelling machinesArticle deliveryEngineeringPiston rod

The invention relates to an elastic label pushing device of a labeling machine. The elastic label pushing device of the labeling machine comprises a label pushing head which is installed at the end part of a piston rod of an air cylinder, and the air cylinder is fixedly connected to a rack by means of a support plate; the upper end of the label pushing head is connected with the piston rod of the air cylinder by means of an elastic sleeve in a sliding mode; the lower end of the label pushing head is provided with a conical label pushing part; the end part of the conical label pushing part is provided with a guide roller. The elastic label pushing device of the labeling machine is simple in structure; the rolling guide roller and the label pushing head are combined, so that the friction between the label pushing device and a label band is reduced effectively, a label is convenient to strip, and the label stripping speed is increased; the elastic connection between the label pushing head and the air cylinder reduces the impact to the label band, and the label stripping effect is better.

Owner:WUXI ZHANGJINGYU STEEL MACHINERY PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com