Stripping method for reclaimable catalyst

A technology of standby catalyst and standby agent, which is applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve problems such as limiting the stripping effect, achieve improved stripping effect, and be easy to implement , the effect of suppressing the generation of large bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] This example illustrates that the stripping efficiency can be significantly improved by adopting the stripping method of the spent catalyst provided by the present invention.

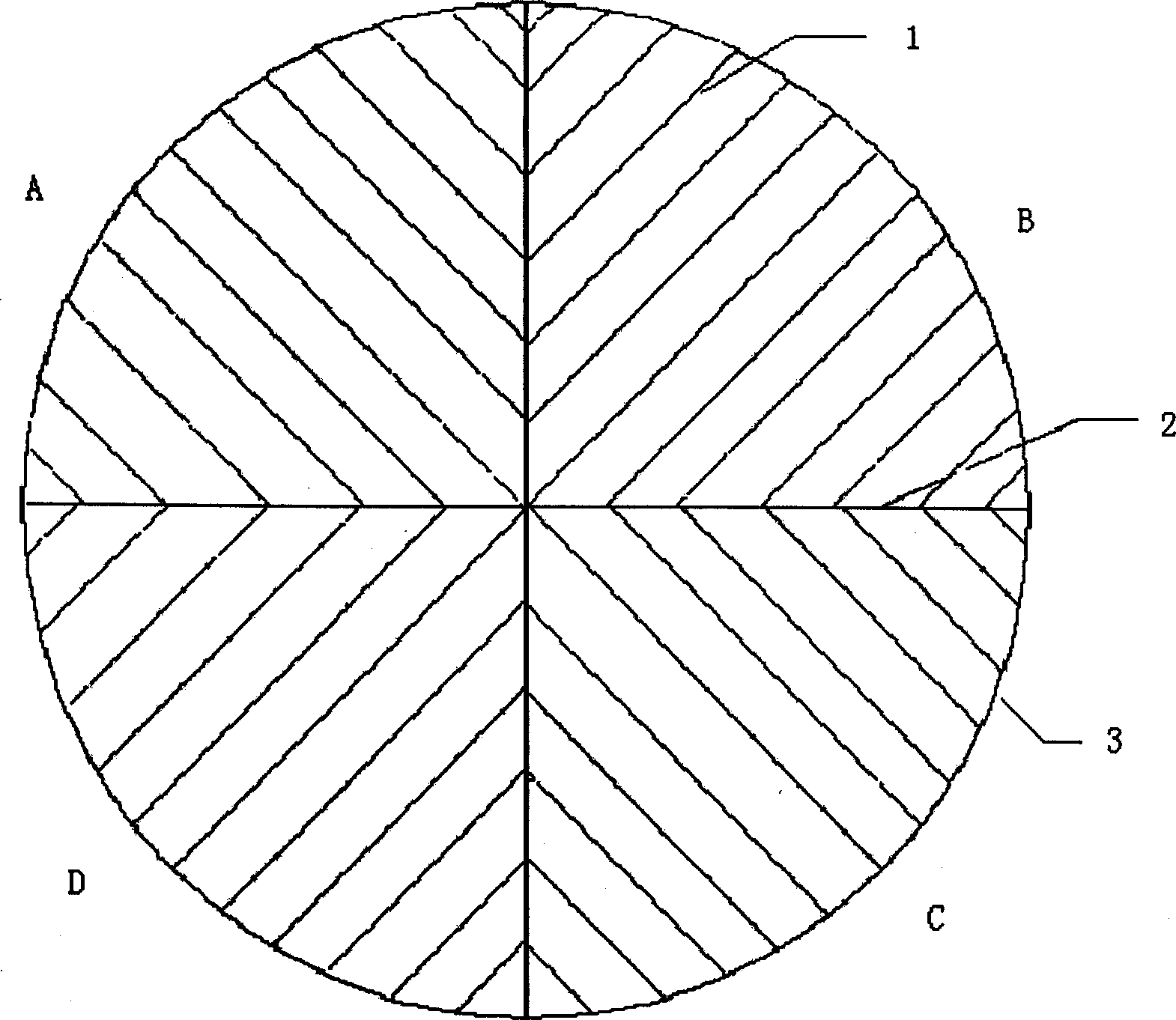

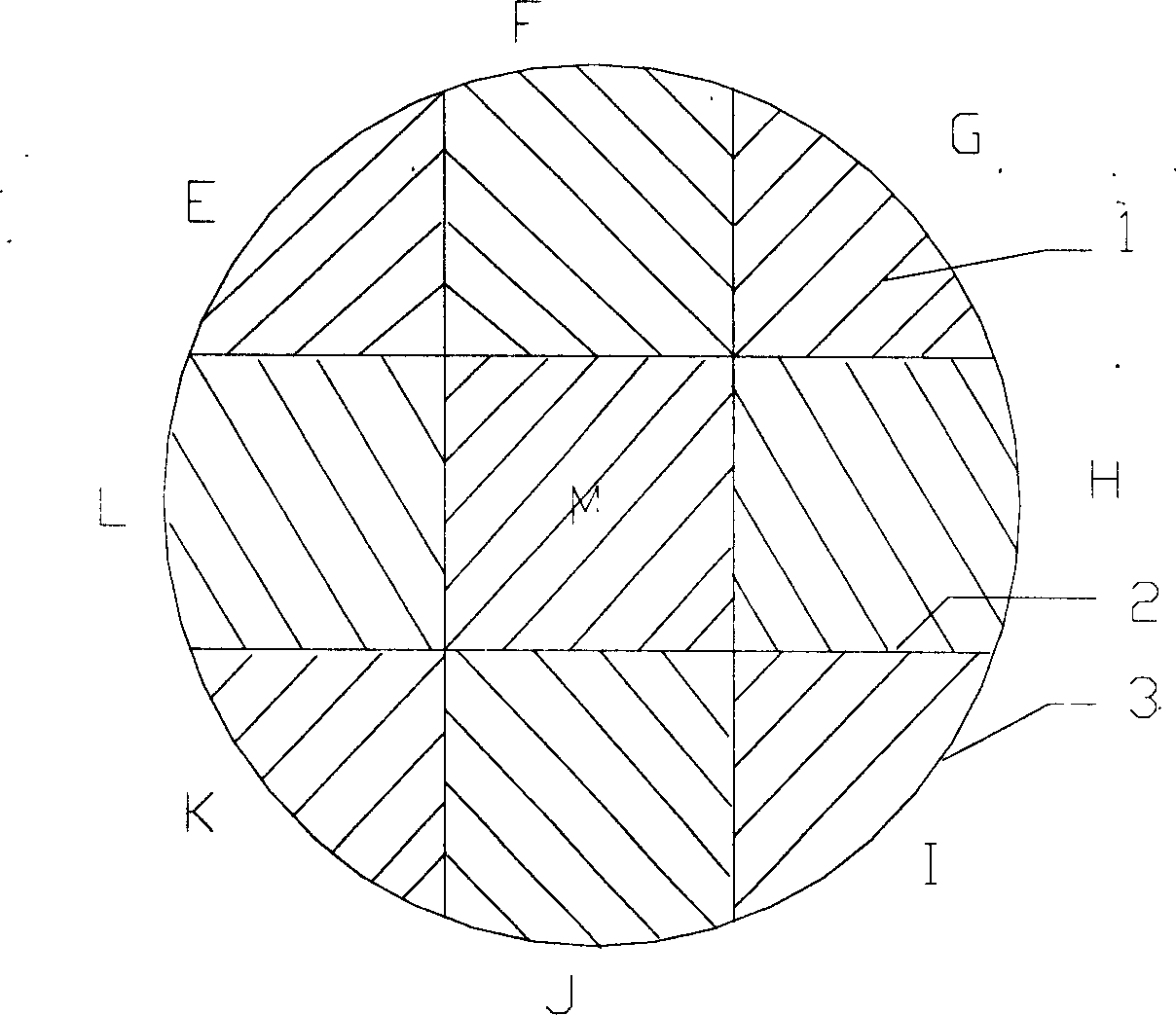

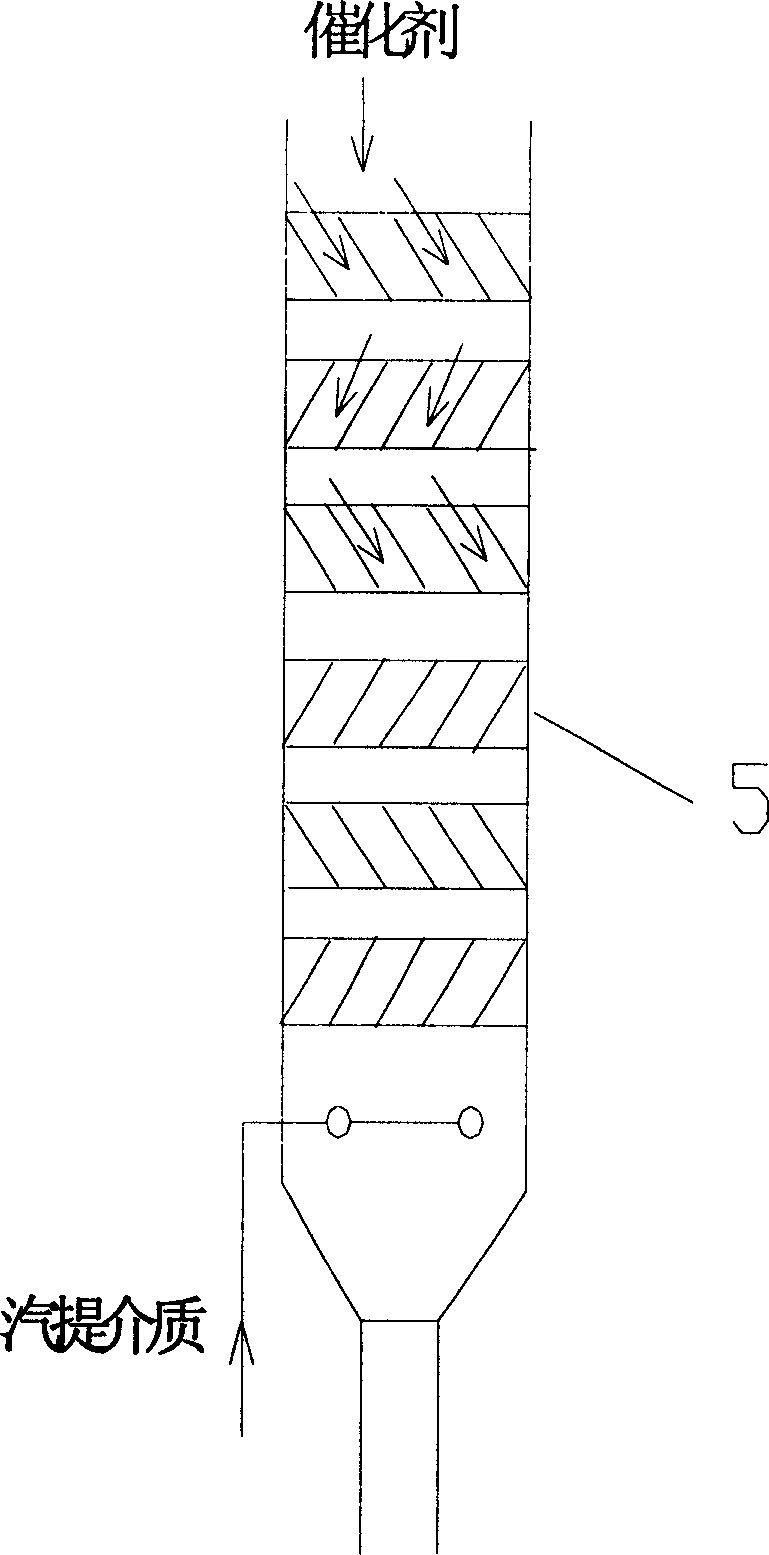

[0039] Transform the stripper of the medium-sized riser catalytic cracking unit, adopt the internal member of the present invention, the structure of the internal member is as follows figure 1 shown. The inner diameter of the stripper is 500mm, and there are 4 internal components in the stripper. The height of the inner member is 100mm, and each inner member is divided into 4 areas. The baffle sheet in each area is 45° to the horizontal direction. The inner members are placed horizontally from top to bottom along the axial direction, and make the axial adjacent The inclination directions of the upper and lower corresponding baffle pieces in the inner member are different. If the upper layer is inclined clockwise, the lower layer is inclined counterclockwise, and vice versa. The interval betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com