Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Increase capacity extraction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of electrode foil for solid-state aluminum electrolytic capacitors

ActiveCN110517892AReduce disturbanceReduce generationAnodisationSolid electrolytic capacitorsElectrolysisElectrochemical anodization

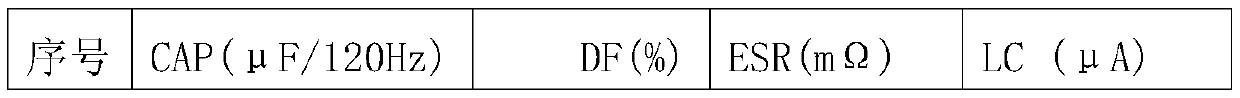

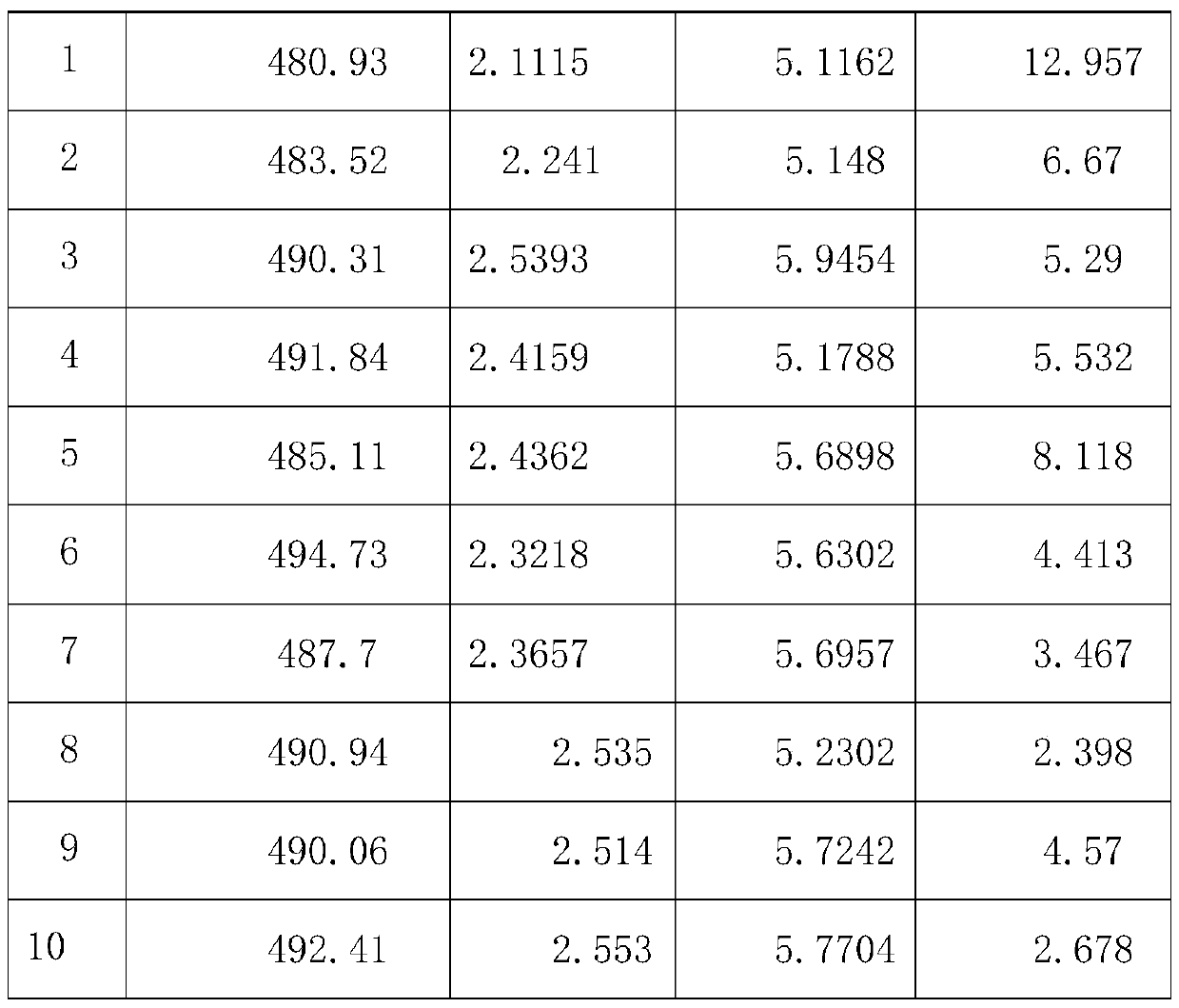

The invention relates to a manufacturing method of an electrode foil for solid-state aluminum electrolytic capacitors, which comprises a corrosion part and a formation part. The corrosion part comprises the following steps: pre-treating an electronic plain foil in a hydrochloric acid solution; carrying out hole-forming power-on corrosion on the foil in a mixed solution of hydrochloric acid and sulfuric acid; carrying out reaming power-on corrosion on the foil, and cleaning and soaking the foil; and washing the foil with running water and carrying out annealing to obtain an etched foil. The formation part comprises the following steps: boiling the etched foil for solid-state aluminum electrolytic capacitors in water; carrying out first-stage electrochemical anodic oxidation and first annealing heat treatment; carrying out second-stage electrochemical anodic oxidation, third-stage electrochemical anodic oxidation and second annealing heat treatment; carrying out fourth-stage electrochemical anodic oxidation and third annealing heat treatment; soaking the etched foil in phosphoric acid, soaking the etched foil in ammonium dihydrogen phosphate, and cleaning and drying the etched foil;and obtaining an electrode foil for solid-state aluminum electrolytic capacitors. The disturbance of tip current can be reduced, the generation of invalid small holes in the corrosion process can be reduced, and the capacity extraction rate of the solid foil can be increased. Moreover, the quality of the oxide film can be improved, the stability can be maintained, and the high-temperature stability of solid-state capacitors can be improved.

Owner:NANTONG HAIXING ELECTRONICS +2

Processing liquid and solid-state electrolytic capacitor with same

InactiveCN106548872AHigh voltageIncrease capacitySolid electrolytic capacitorsCapacitor electrolytes/absorbentsBenzoic acidCapacitance

The invention proposes a processing liquid, and relates to the technical field of a solid-state electrolytic capacitor. The processing liquid comprises a solute and a solvent, wherein the solute is an organic or inorganic acid compound, the solvent comprises a water polymer material and an organic solvent, the organic or inorganic acid compound is selected from one or more of phosphoric acid, boric acid, benzoic acid, adipic acid, azelaic acid, sebacic acid, isophthalic acid, phthalic acid, maleic acid, benzene sulfonic acid and citric acid, and the water polymer material is selected one or more of polyethylene alkylene glycol, polyvinyl alcohol, polyethylene glycol glyceryl alcohol ester, polyethylene glycol glyceryl alcohol ester, polyethylene glycol sorbitol ether, polyethylene glycol, polybutylene glycol, polyethylene glycol and polyethylene oxide which has non-volatile characteristic. The processing liquid and a traditional dispersion liquid are used in a matching way, thus, the development of the dispersion liquid is prevented, the production period is shortened, and the cost is reduced.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

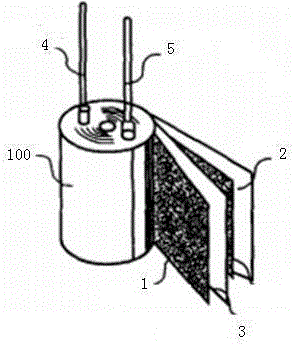

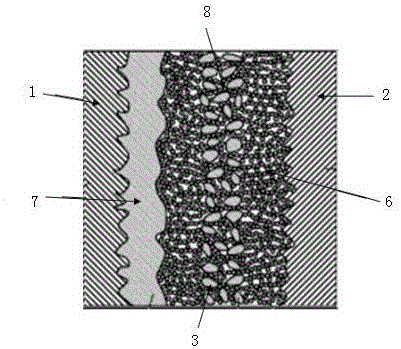

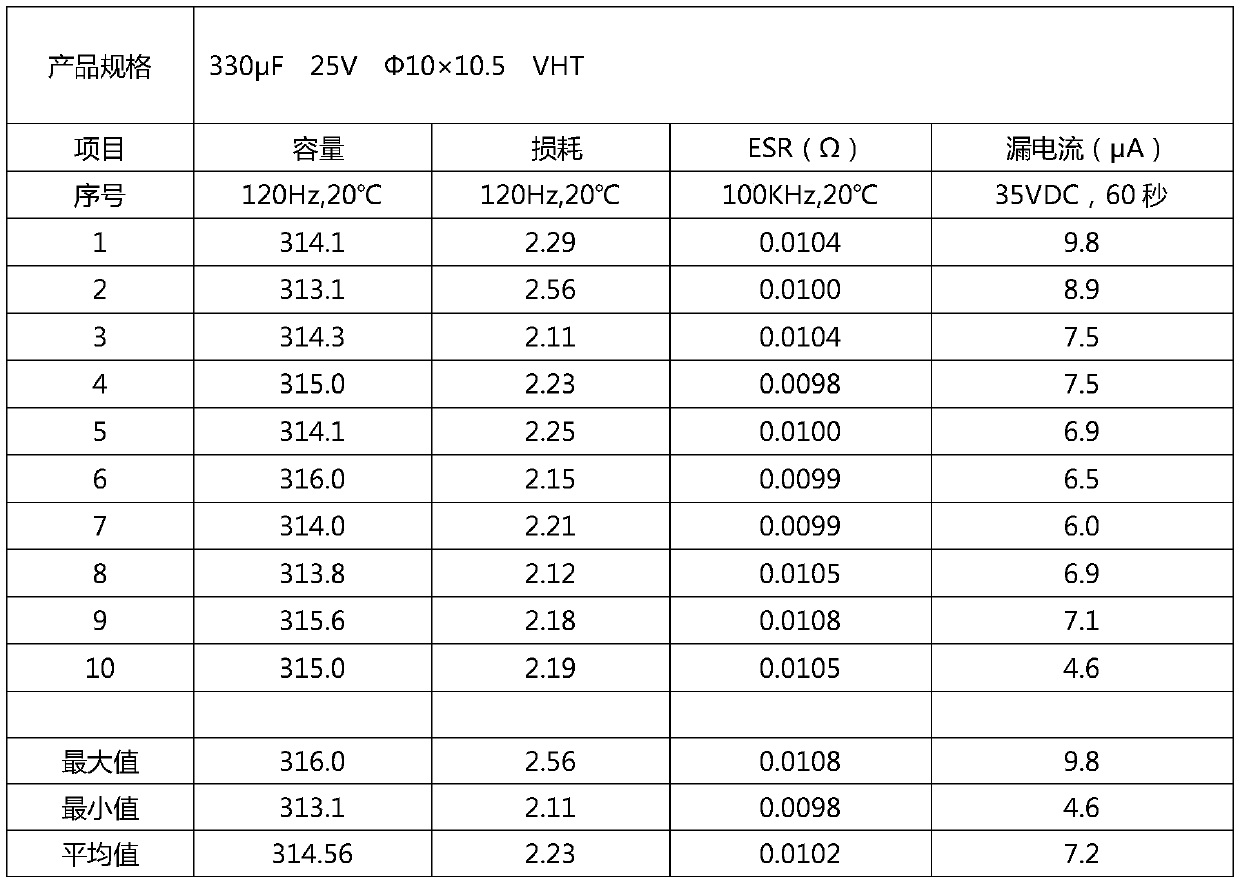

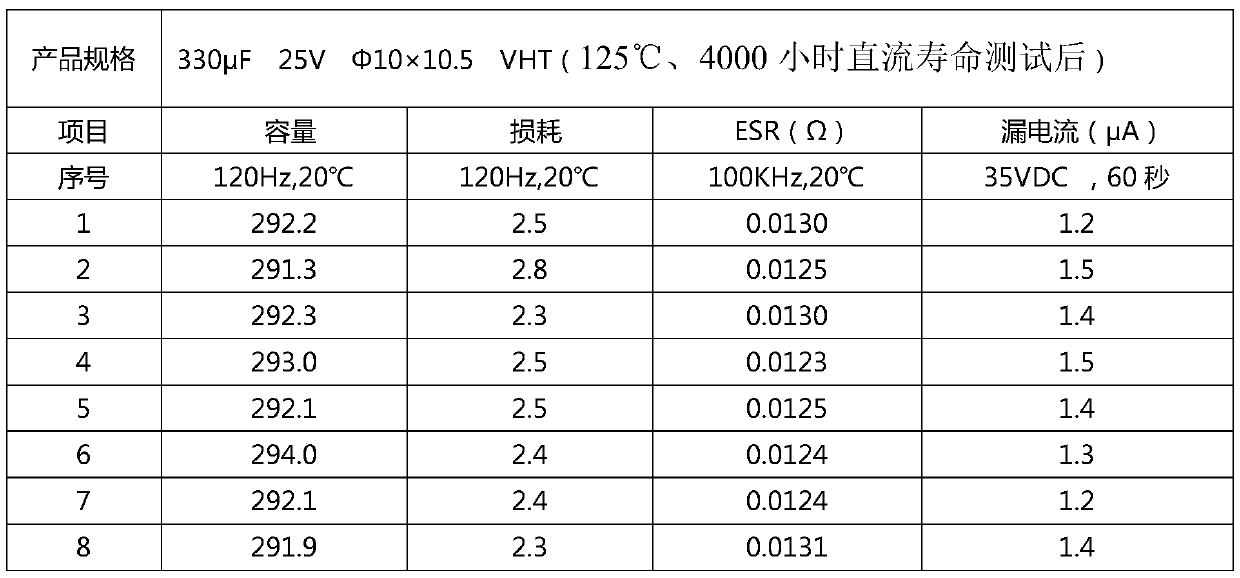

Solid-liquid mixed aluminum electrolytic capacitor and preparation method thereof

PendingCN110491674AIncrease capacity extraction rateReduce capacityCapacitor electrolytes/absorbentsCapacitanceUltrasound attenuation

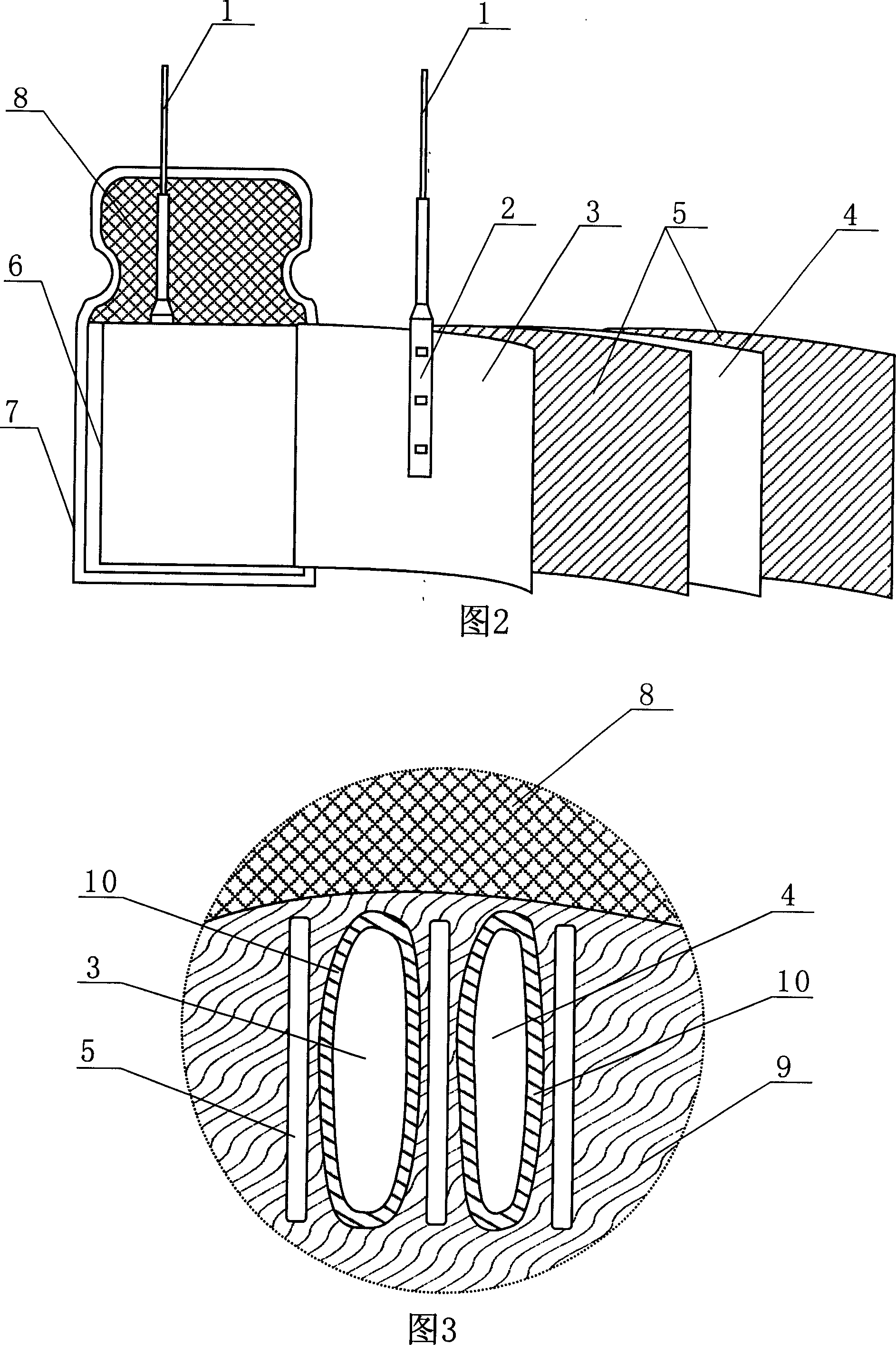

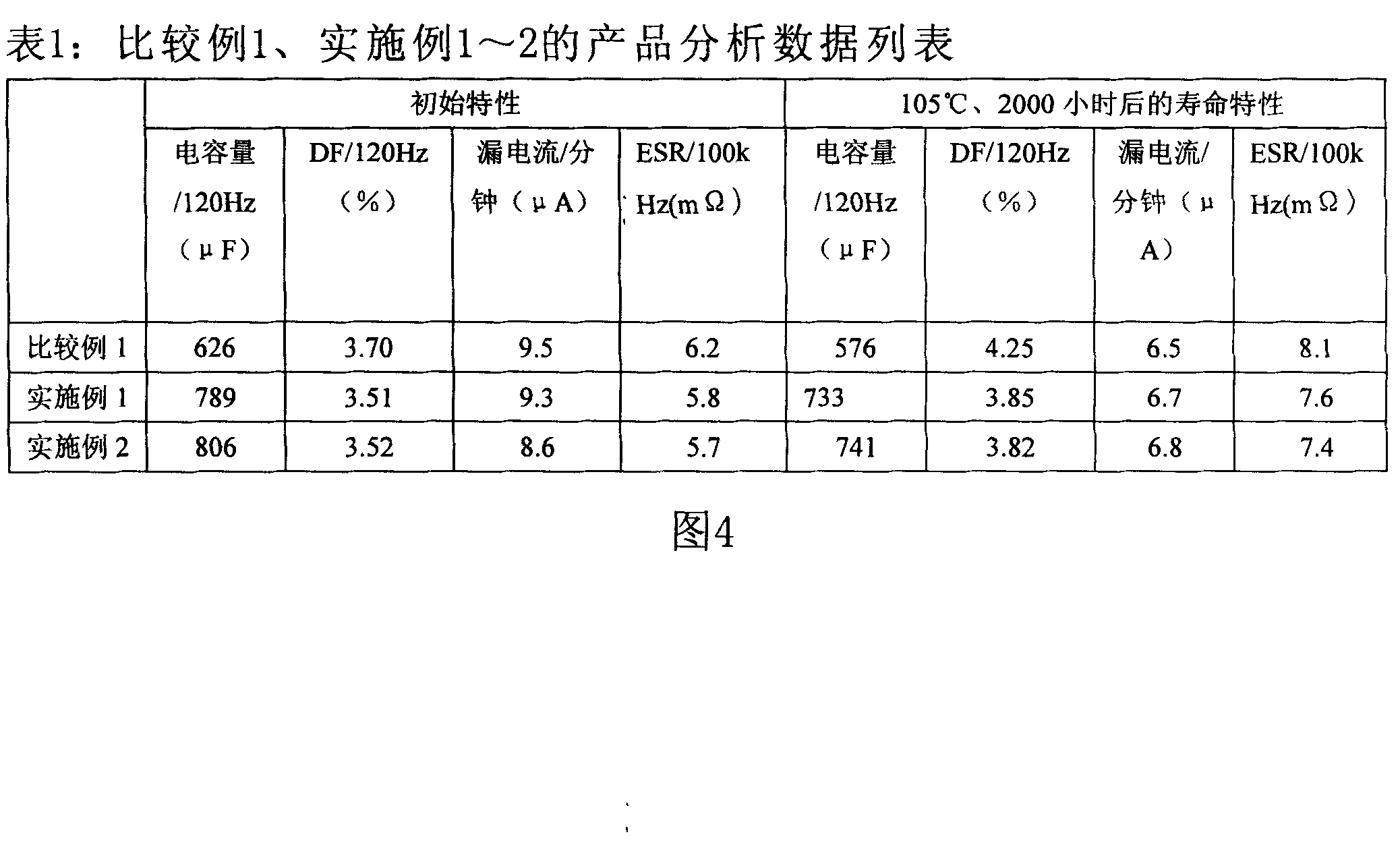

The invention provides a solid-liquid mixed aluminum electrolytic capacitor that comprises an aluminum shell and a core body arranged in the aluminum shell, and that is characterized in that the corebody comprises a cylindrical structure formed by winding a first electrolytic paper or a first diaphragm, a negative electrode carbon foil, a second electrolytic paper or a second diaphragm and a positive electrode formed foil; one end of an anode guide pin is connected with the positive electrode formed foil; one end of a cathode guide pin is connected with the negative electrode carbon foil; theother ends of the anode guide pin and the cathode guide pin are exposed out of the aluminum shell,, conductive polymers are arranged on the surfaces of the first electrolytic paper or the first diaphragm, the negative electrode carbon foil, the second electrolytic paper or the second diaphragm and the positive electrode formed foil, and electrolyte is adsorbed on the first electrolytic paper or the first diaphragm and the second electrolytic paper or the second diaphragm. According to the invention, the capacity extraction rate is high, the ESR is ultralow, and the capacity attenuation is low.

Owner:SHANGHAI YONGMING ELECTRONICS

A kind of manufacturing method of electrode foil for solid aluminum electrolytic capacitor

ActiveCN110517892BReduce disturbanceReduce generationAnodisationSolid electrolytic capacitorsElectrochemical anodizationPhosphoric acid

Owner:NANTONG HAIXING ELECTRONICS +2

Solid aluminum electrolytic capacitor cathode conductive film and preparation method and application thereof

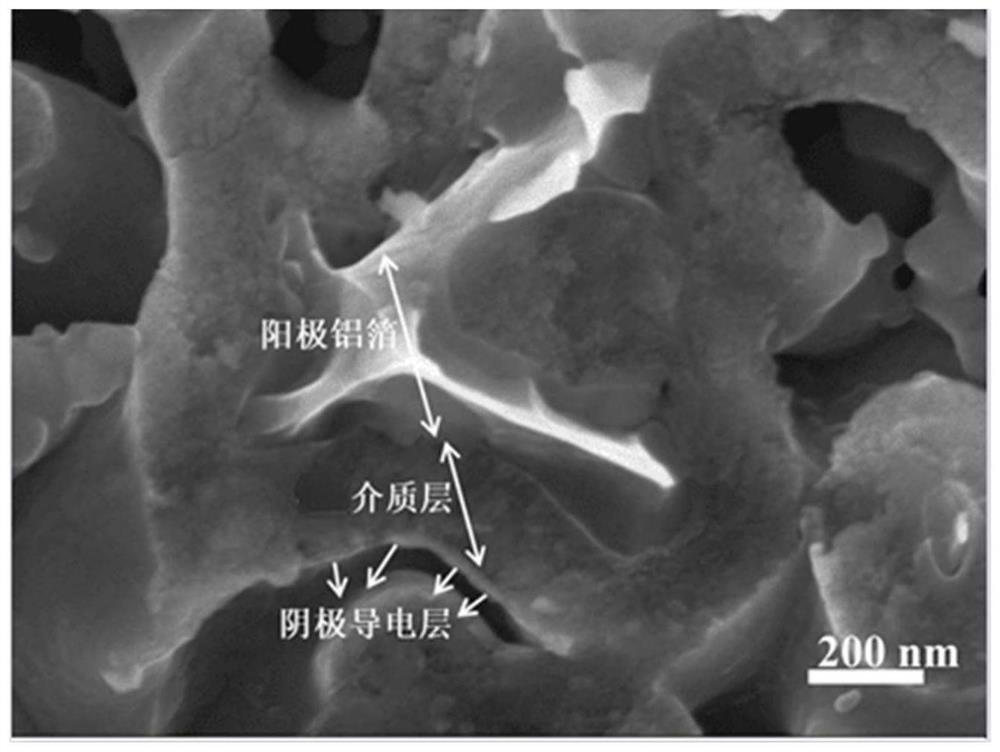

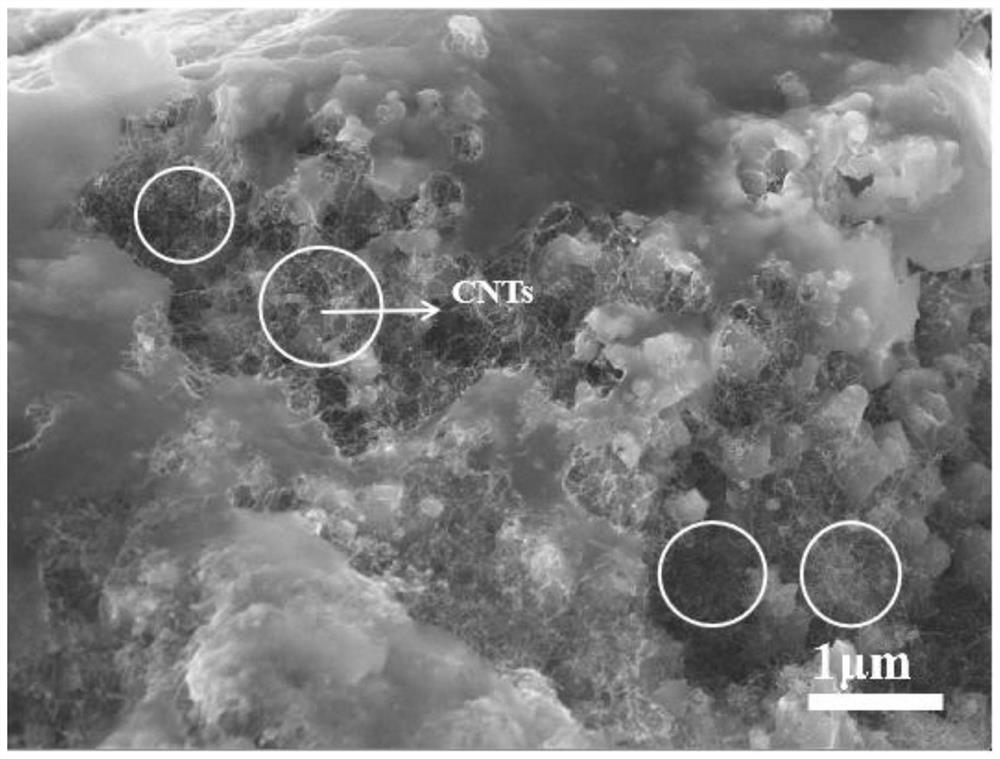

PendingCN113436889AIncrease capacity extraction rateImprove adhesionCapacitor electrodesMicro nanoAluminum foil

The invention discloses a solid aluminum electrolytic capacitor cathode conductive film and a preparation method and application thereof, and belongs to the field of aluminum electrolytic capacitors. The method comprises the following steps: depositing a conductive metal film on the surface of an anode foil dielectric layer of the aluminum electrolytic capacitor by using a vapor deposition method; and leading out a cathode electrode from the deposited conductive layer, namely preparing the conductive film on the surface of the anode foil dielectric layer of the aluminum electrolytic capacitor. According to the gas phase chemical method, the problem that solution molecules are difficult to enter micro holes in the surface of the anode aluminum foil in a liquid phase method is solved, so that the conductive film has high step coverage rate in the micro-nano holes, and the capacity extraction rate of the capacitor is improved. The conductive thin film prepared by adopting the gas phase chemical method has the advantages of compact structure, few impurities, good uniformity and the like.

Owner:XI AN JIAOTONG UNIV

Method for removing adhesive in anode block of solid electrolytic capacitor

ActiveCN107680809AClean removalImprove electrical performance parametersSolid electrolytic capacitorsElectrolytic capacitor manufacturePorosityElectrolysis

The invention belongs to the technical field of manufacturing of electrolytic capacitors, and particularly discloses a method for removing an adhesive in an anode block of a solid electrolytic capacitor. Treatment is carried out through the following 11 steps of dissolving, spaying, drying, compression, reciprocating sifting, first elution, standing, second elution, third elution, boiling and drying in all, so that the adhesive and a solvent can be removed clean without a residue, improvement of electric performance parameters of the capacitor is facilitated, meanwhile, fine powder particles blocked in micropores and powder particles adhered to the surface of an anode blank are also burst through, the capacity extraction rate of the capacitor is improved, and the probability of crystallization when an anode is formed is reduced. According to the method, increase of the content of impurities of carbon and oxygen in the tantalum blank is effectively suppressed, the porosity in the tantalum blank is improved and the stability and the reliability of the tantalum electrolytic capacitor are improved.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

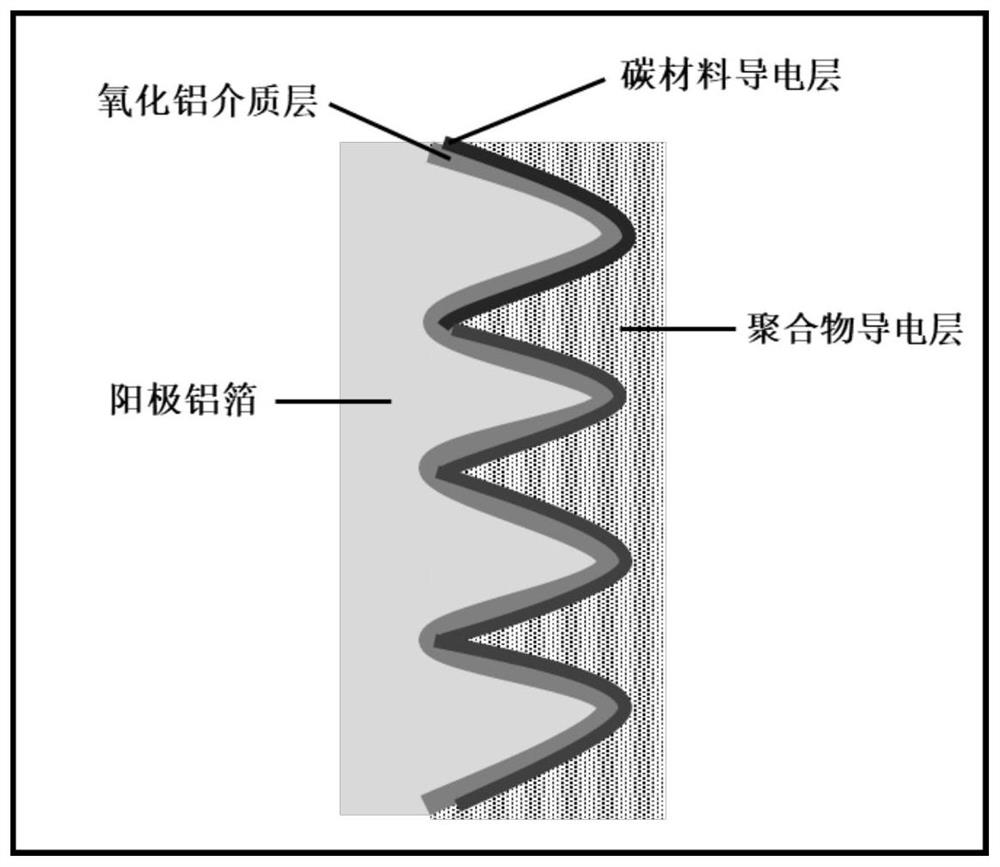

Method for preparing conductive polymer cathode in solid-state aluminum electrolytic capacitor

PendingCN113380550AImprove ladder coverageIncrease capacity extraction rateSolid electrolytic capacitorsCapacitor electrodesConductive polymerElectrochemistry

The invention discloses a method for preparing a conductive polymer cathode in a solid-state aluminum electrolytic capacitor, and belongs to the field of solid-state aluminum electrolytic capacitors. The method comprises the following steps: pre-depositing a conductive layer on the surface of an anode foil dielectric layer by adopting a chemical vapor deposition method; preparing a conductive polymer on the surface of the deposited conductive layer through an electrochemical method to form a composite conductive layer in a solid-state aluminum electrolytic capacitor; and carrying out cathode electrode extraction on the composite conductive layer to obtain the conductive polymer cathode. According to the invention, the adopted chemical vapor deposition technology avoids the problem that solution molecules are difficult to enter tiny holes in the surface of the anode aluminum foil in an impregnation method and a chemical polymerization method, and effectively avoid the damage of the solution to the dielectric layer.

Owner:XI AN JIAOTONG UNIV

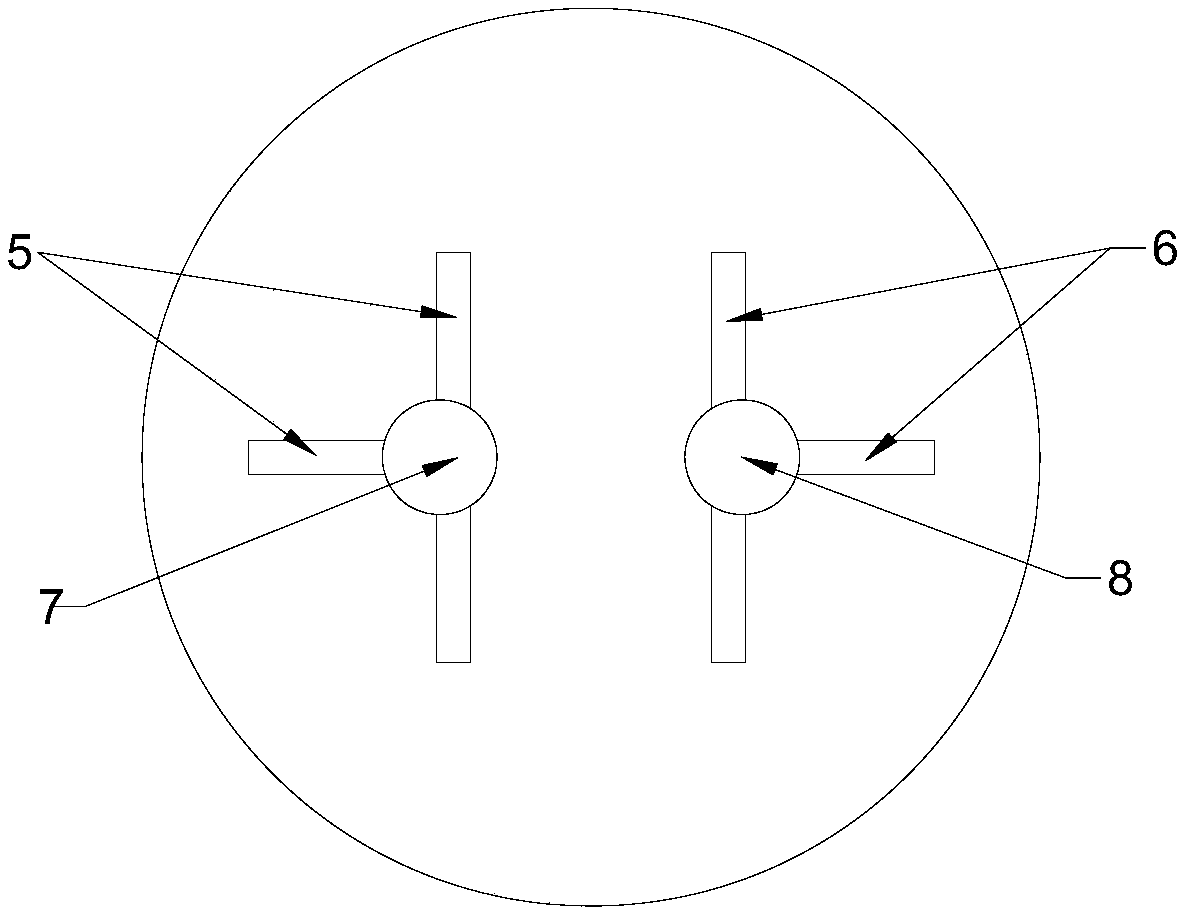

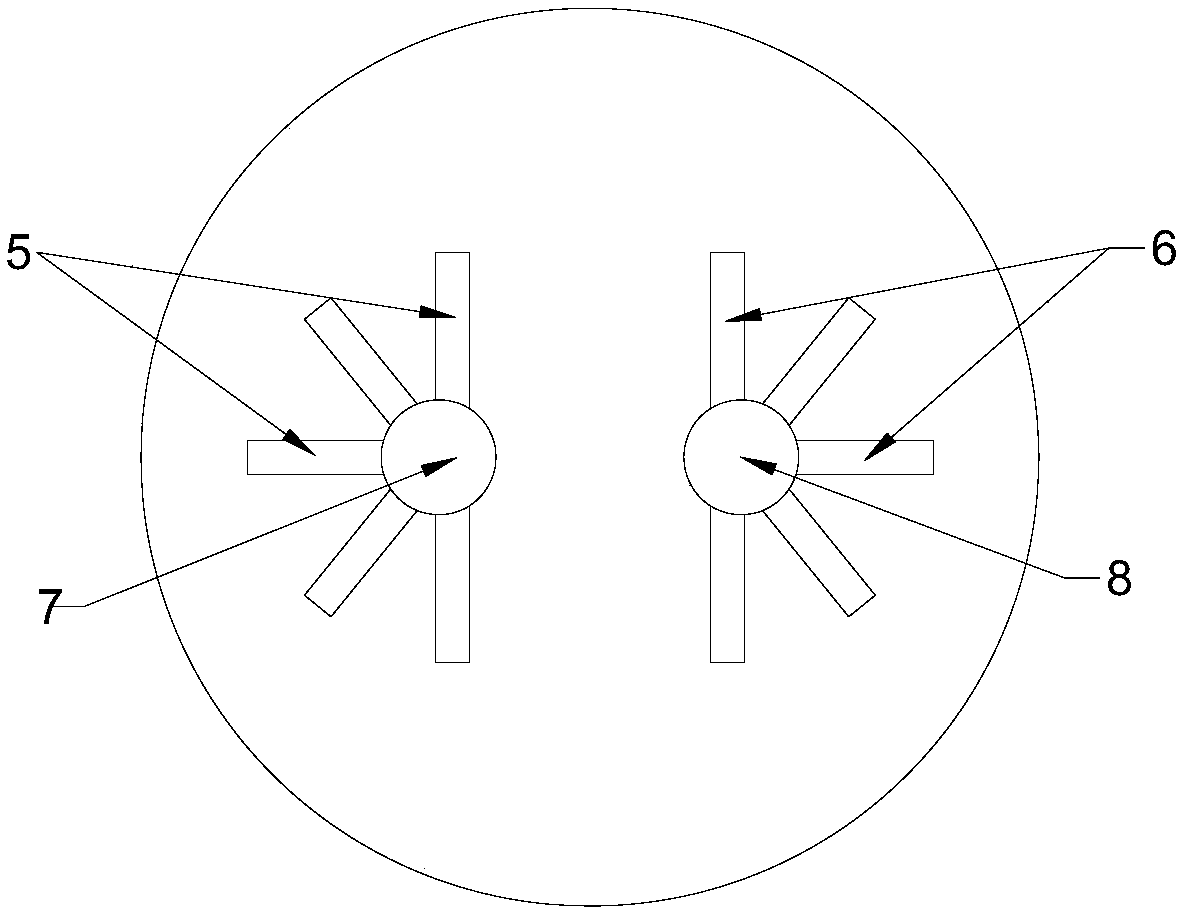

Wound type solid-state capacitor preparation method

InactiveCN108538589AReduce oxidationRecovery of oxidative capacitySolid electrolytic capacitorsElectrolytic capacitor manufactureCapacitancePolymer science

The invention relates to a wound type solid-state capacitor preparation method. According to the method, a monomer and an oxidant constituting a conductive polymer is mixed with a retarder, so that amixture solution can be obtained; a wound solid-state aluminum capacitor core is immersed in the mixture solution, so that the uniformly-mixed mixture solution can permeate the inside of the core; andthe core is arranged in a drying oven so as to be subjected to polymerization, so that the conductive polymer PEDOT is uniformly formed in the core. With the method of the invention adopted, four polymer preparation procedures, namely, monomer impregnation, drying, oxidant impregnation and polymerizing in a traditional process are simplified into an impregnation procedure and a polymerization procedure, and therefore, production efficiency can be effectively improved, the capacity extraction rate of a finished capacitor can be effectively improved, and the ESR of the finished capacitor can bereduced.

Owner:YIYANG WANJINGYUAN ELECTRONICS

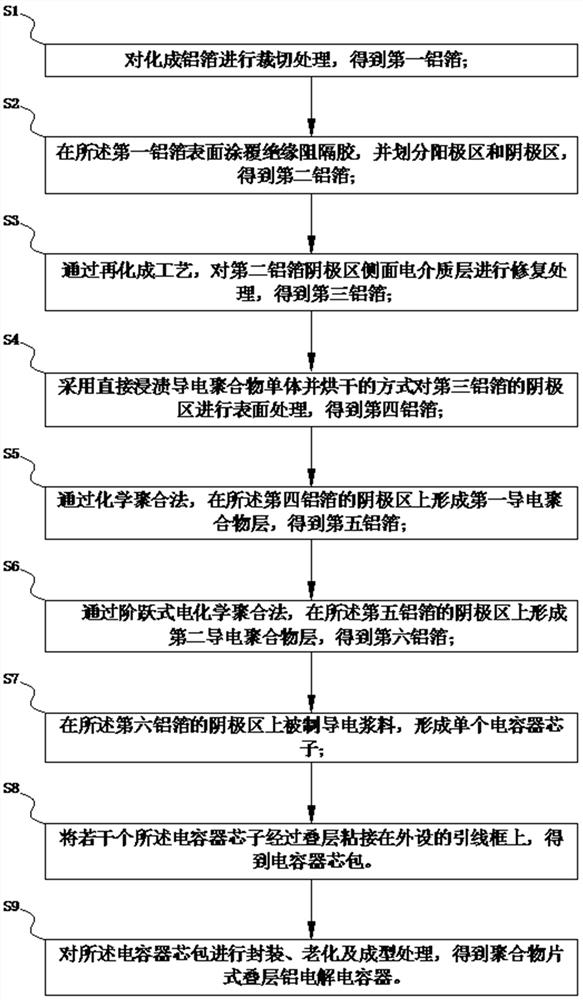

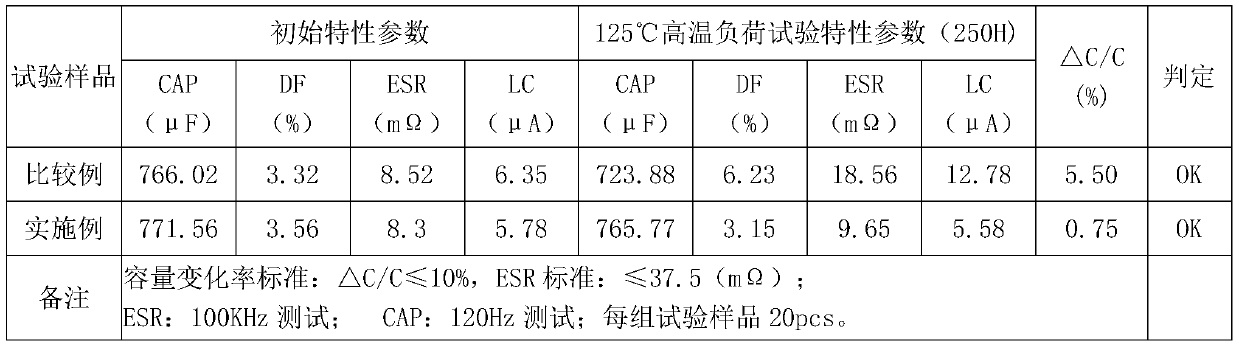

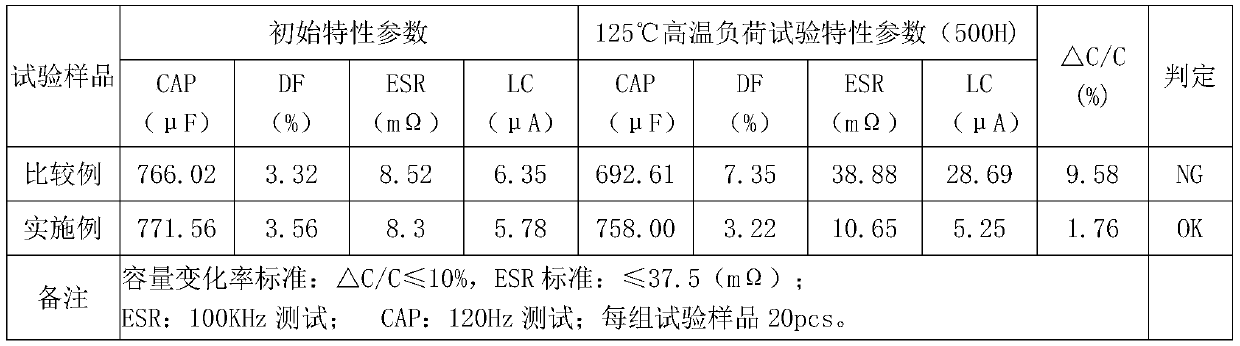

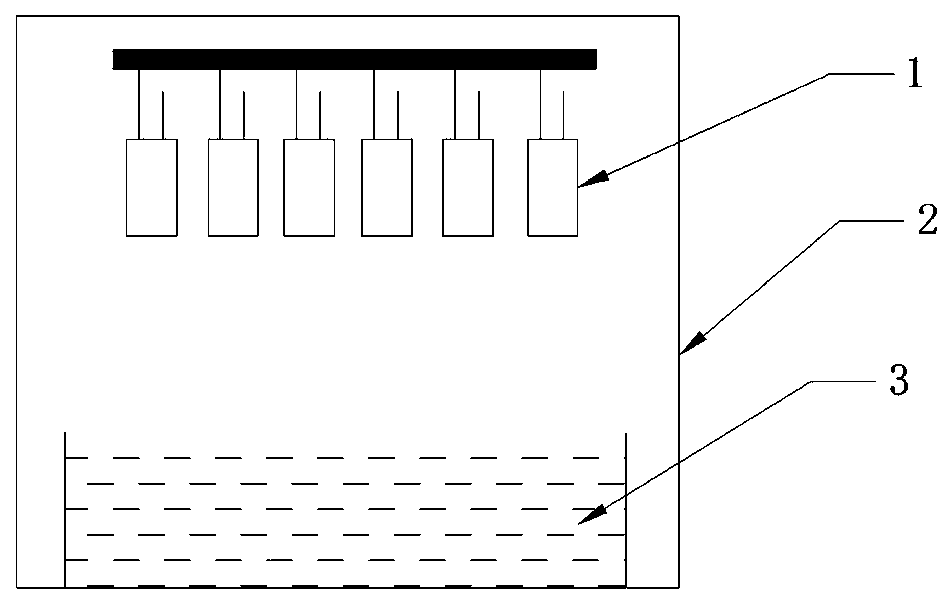

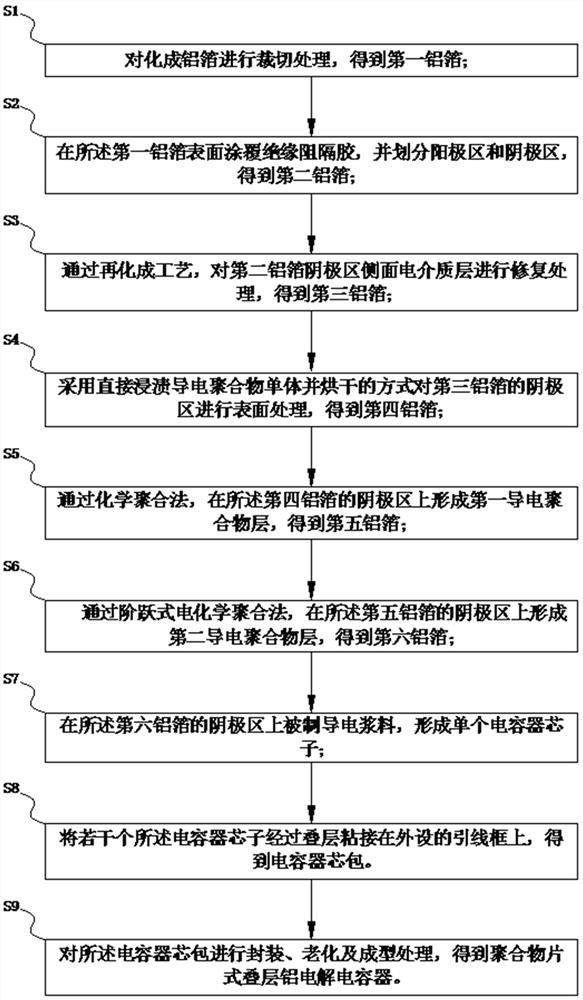

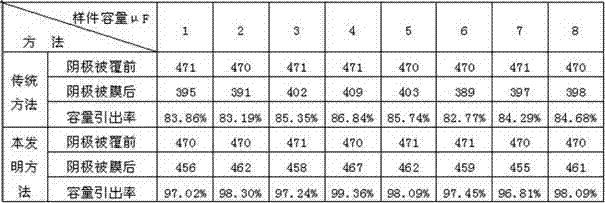

Preparation method of low-voltage high-capacity polymer chip type laminated aluminum electrolytic capacitor

ActiveCN112164590AIncrease capacityIncrease capacity extraction rateSolid electrolytic capacitorsElectrolytic capacitor manufactureAluminum electrolytic capacitorAluminum electrolysis

The invention discloses a preparation method of a low-voltage high-capacity polymer chip type laminated aluminum electrolytic capacitor, and the method comprises the following steps: performing surface treatment on a formed foil in a mode of impregnating a conductive polymer monomer and drying, replacing a coupling agent pretreatment process, matching a chemical polymerization mode, and supplementing a step type electrochemical polymerization mode to achieve a synergistic effect of the conductive polymer monomer and the polymer chip type laminated aluminum electrolytic capacitor; the capacityextraction rate of the formed foil is greatly improved, so that the capacity of a finished product is improved, the requirement of the low-voltage high-capacity polymer chip type laminated aluminum electrolytic capacitor on the capacity is met, the yield of the finished product is improved, and considerable economic benefits are brought.

Owner:福建国光新业科技股份有限公司

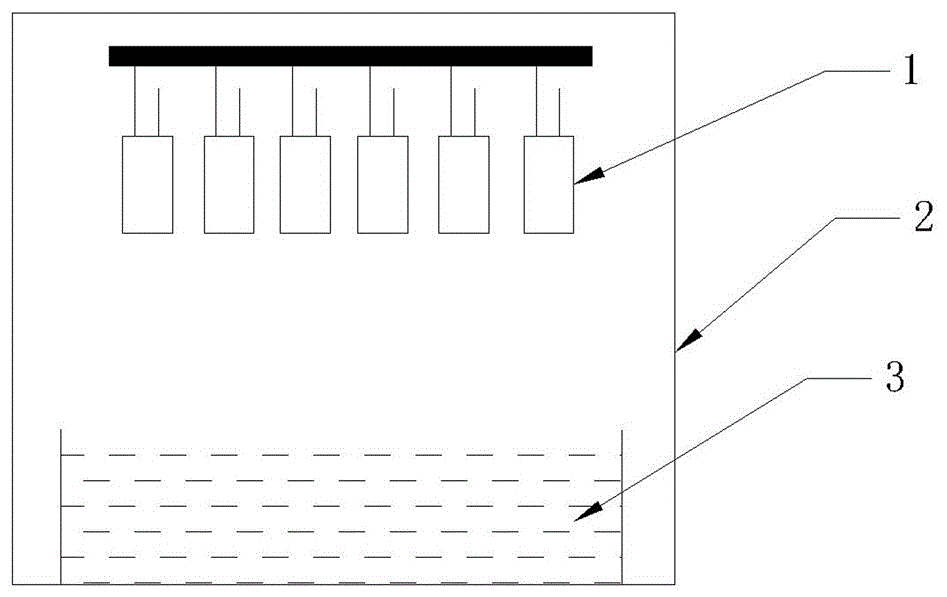

Capacitor element impregnating method

ActiveCN105788890AIncrease capacity extraction rateImprove efficiencyDrying/impregnating machinesVacuum furnaceAluminium foil

The invention discloses a capacitor element impregnating method, and the method comprises the following steps: 1), enabling a conducting polymer monomer to be placed in a vacuum furnace, and enabling an element to be placed above the conducting polymer monomer; 2), sealing the vacuum furnace, and carrying out the vacuum pumping of the vacuum furnace; 3), enabling the internal temperature of the vacuum furnace to rise 50-100 DEG C, maintaining the temperature for 1-30min; enabling the internal temperature of the vacuum furnace to gradually decrease to the indoor temperature to 5 DEC C, and maintaining the temperature for 1-30min; 4), enabling the element comprising the conducting polymer monomer to be taken out from the vacuum furnace, carrying out the impregnating of an oxidizing agent, and generating a PEDT. The method employs the strong volatility of the conducting polymer monomer, enables the conducting polymer monomer to be able to be placed in a vacuum furnace room in a gaseous phase in a vacuum environment, reduces the temperature to enable monomer molecules to be condensed in the element after a gaseous impregnating time period under the higher temperature, and enables the monomer molecules to enter in an aluminium foil gap better.

Owner:HUNAN AIHUA GRP

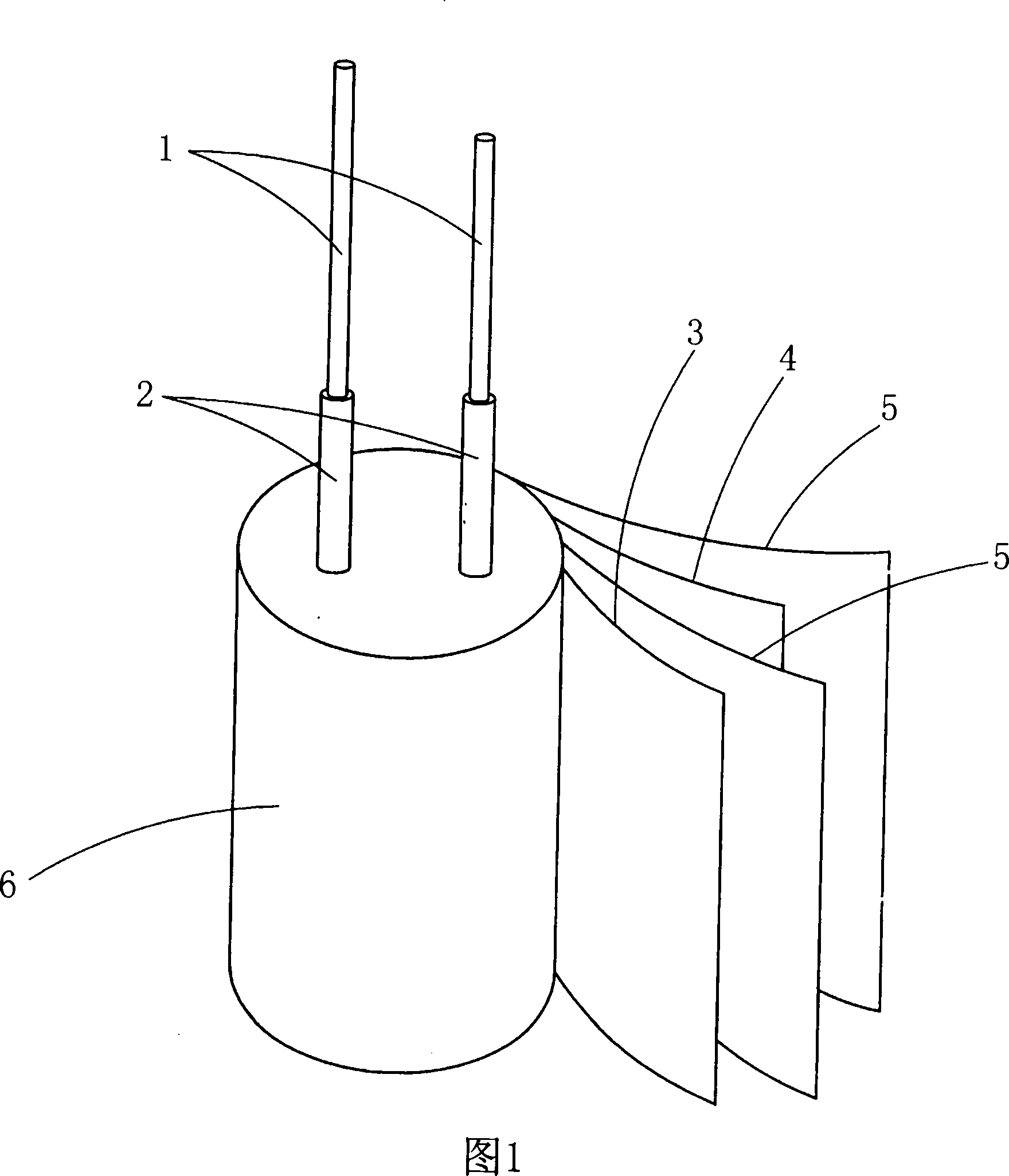

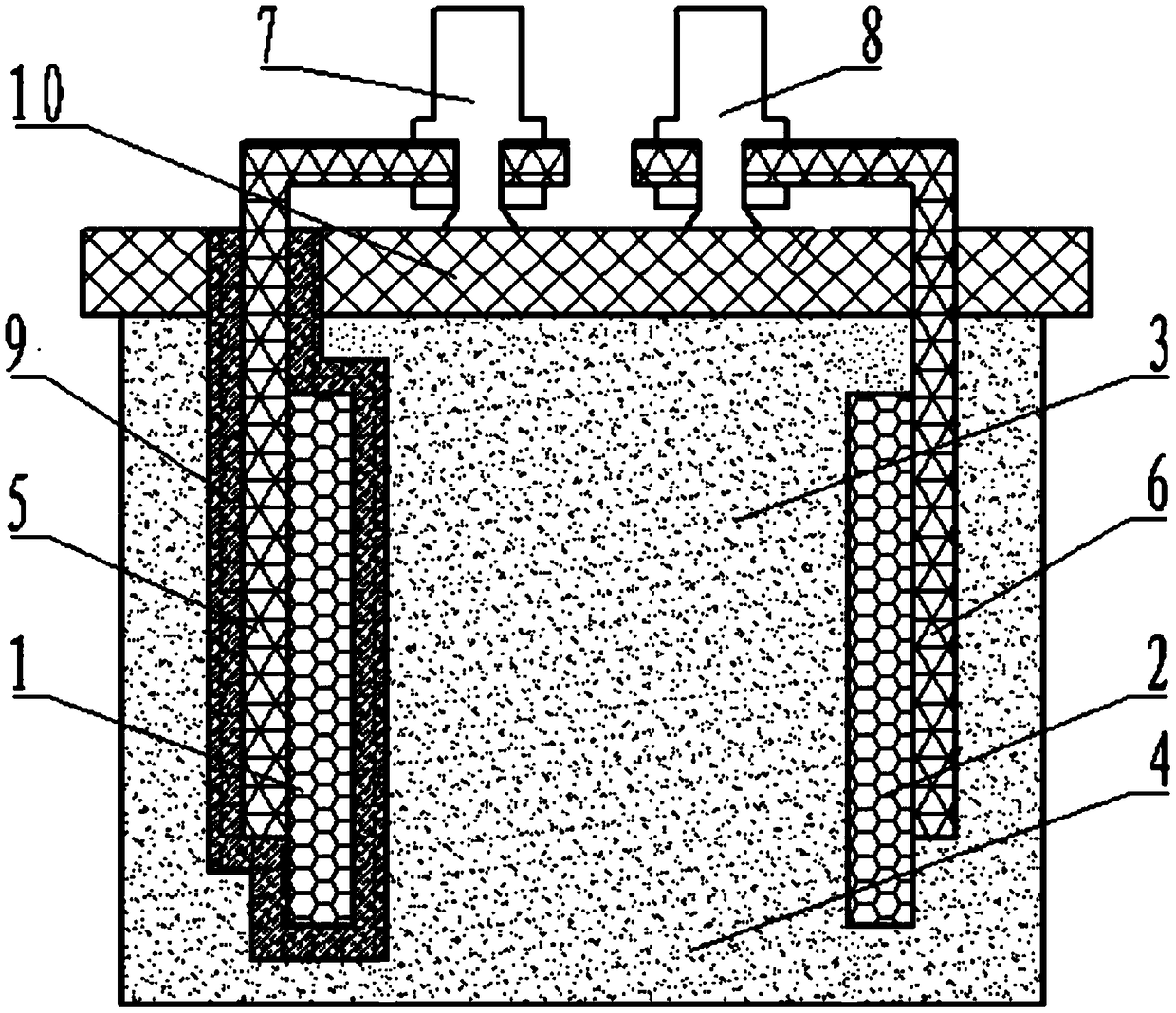

High-specific volume cathode foil solid electrolytic capacitor and preparing method thereof

ActiveCN1862729BLower equivalent series resistanceHigher than the surfaceSolid electrolytic capacitorsCapacitor electrodesCapacitanceElectrolysis

This invention relates to high specific volume cathode foil solid electrolytic capacitor and its preparation method. This invention provides rolling type solid electrolytic capacitor that dielectric medium is high conductivity polymer, purpose made high specific volume cathode foil is used in the capacitor, so the electric capacity is large, resistor is low. This invention includes aluminum shell, two outgoing line that welded on aluminum peduncle, the peduncle is connected to the cathode and anode foils, the foils wind into capacitor core after isolated by membrane. The core is set in the shell, a layer alumina is brought to the aluminum foil of the cathode foil, and a layer of titanium, titanium nitride or titanium carbonitride membrane is formed on the alumina surface. Solid conductingmaterial is set on the membrane between the two poles. The content of the capacitor in this invention is large, ESR is low, life is long, capability is reliable, it can be widely applied to modern communication, computer, and high performance civil and military digital product.

Owner:STARZEON ELECTRONICS DONGGUAN

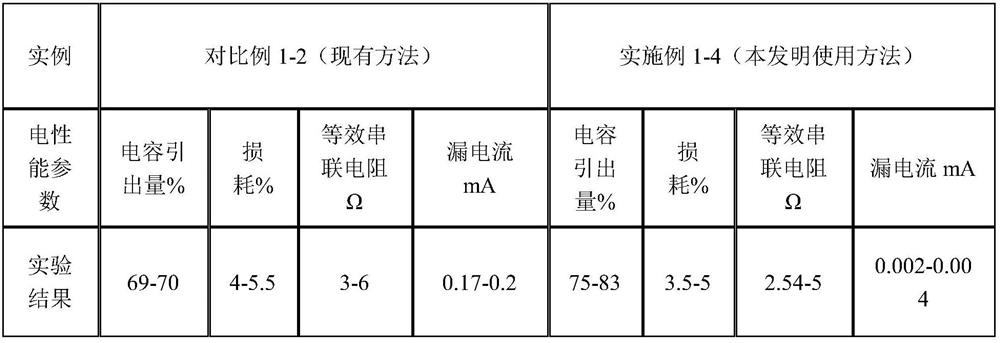

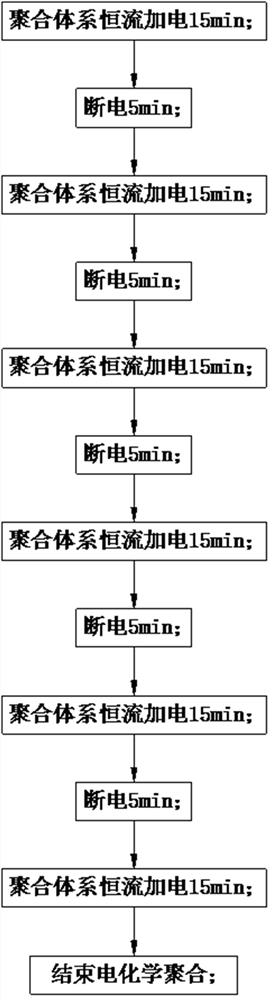

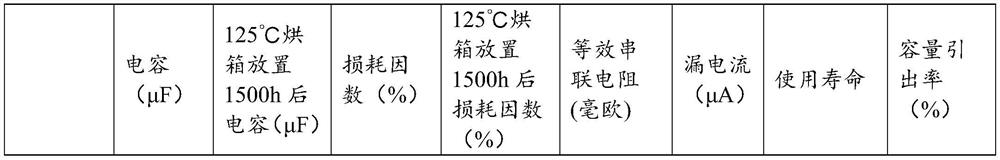

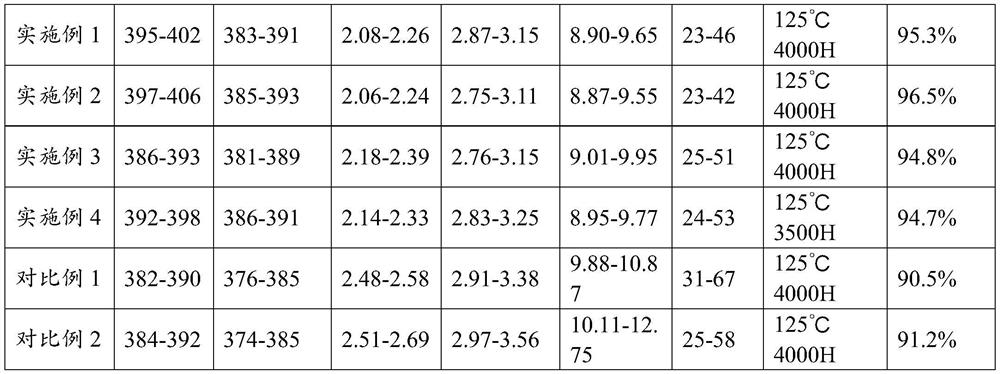

Fabrication process of solid-state aluminum electrolytic capacitor with high capacity leading-out rate

InactiveCN109741955AIncrease capacity extraction rateReduce leakage currentSolid electrolytic capacitorsElectrolysisEngineering

The invention discloses a fabrication process of a solid-state aluminum electrolytic capacitor with high capacity leading-out rate, relates to the field of aluminum electrolytic capacitors and aims tosolve the problem of relatively large leakage current and low capacity leading-out rate. Improvement is performed on the basis of a traditional process, a DC voltage is applied to a prime during polymerization drying after a monomer and an oxidization agent is impregnated or a macromolecule dispersion liquid is only impregnated, and grouping and aging are performed to form a product. The preparedproduct has the advantages of high capacity leading-out rate and lower leakage current.

Owner:YIYANG AIHUA FUXIAN ELECTRONICS

Treatment fluid for improving withstand voltage of solid capacitor and preparation method of solid capacitor

ActiveCN109300696AEasy to produceImprove decay rateSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCapacitanceSolvent

The invention discloses a treatment fluid for improving the withstand voltage of a solid capacitor. The treatment fluid is prepared from raw materials including a solvent and a solute, the solvent comprises a water-system high-molecular material and an organic solvent, the water-system high-molecular material includes a macromolecular compound in the molecular weight of 200-1000 and a macromolecular compound in the molecular weight of 2000-10000, and the solute comprises an organic and / or inorganic acid as well as amine which can react with the organic and / or inorganic acid to generate salt. The invention also discloses a preparation method of the solid capacitor in which the treatment fluid is used. After that a capacitor core of the solid capacitor is impregnated in the treatment fluid,an oxide film defect in the surface of an aluminum foil of the capacitor core is overcome, short circuit is inhibited, the withstand voltage is improved by 30% to 50%, the voltage characteristic is improved, the capacity attenuation change rate is reduced, the capacity leading-out rate is improved, the reliability is improved, and the solid capacitor of higher capacitor and small size can be produced.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

A lead foil leads out a conductive polymer aluminum electrolytic capacitor

ActiveCN108987115AEffective isolationImplement export structureCapacitor terminalsCapacitanceElectrolysis

The invention discloses a lead foil lead-out conductive polymer aluminum electrolytic capacitor belonging to the technical field of capacitors. The lead foil lead-out conductive polymer aluminum electrolytic capacitor comprises an anode electrode foil, a cathode electrode foil, an isolation pap, a conductive polymer, an anode lead-out conductive foil, a cathode lead-out conductive foil, a positiveelectrode lead-out terminal, a negative electrode lead-out terminal, an oxide film and an isolation layer, wherein that conductive foil leads-out conductive polymer aluminum electrolytic capacitor comprise an anode electrode foil, a cathode electrode foil, a cathode lead-out conductive foil and an isolation layer. A method for manufacture a conductive polymer aluminum electrolytic capacitor withconductive foil extraction includes that step of impregnating and vacuum drying to form a continuous and stable electrolyte layer on the electrode foil, thereby improve the capacitance extraction rateof the capacitor. The electrolytic capacitor structure can be provided with multiple pairs of lead-out conductive foils on the single capacitor core, so that the capacitor can obtain lower ESR and higher capacitance lead-out rate; and the electrolytic capacitor structure can be provided with multiple pairs of lead-out conductive foils on the single capacitor core. At the same time, a novel manufacturing method is provided, which ensures that a large-size capacitor core can be fully filled with conductive polymer by drying at low temperature in vacuum, so as to obtain a continuous electrolytelayer and to overcome the difficulties of the prior art.

Owner:江西联晟电子股份有限公司

Manufacturing method of laminated aluminum electrolytic capacitor and capacitor manufactured by method

ActiveCN111048315AControl microstructureControl thicknessLiquid electrolytic capacitorsElectrolytic capacitor manufactureSpinningAluminum electrolytic capacitor

The invention provides a manufacturing method of a laminated aluminum electrolytic capacitor. The method comprises a slicing process, a piercing riveting process, an electrostatic spinning process, astacking process, an impregnation process and a packaging process. The electrostatic spinning process is that filamentous electrolytic paper is directly spun on the surface of an anode foil by using an electrostatic spinning technology after the piercing riveting process and is attached to the surface of the anode foil and replaces separated electrolytic paper in the traditional technology.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Manufacturing method of laminated aluminum electrolytic capacitor and capacitor manufactured by the method

ActiveCN111048315BControl thicknessLow densityLiquid electrolytic capacitorsElectrolytic capacitor manufactureCapacitanceSpinning

The invention provides a method for manufacturing a laminated aluminum electrolytic capacitor, comprising a slicing process, a riveting process, an electrospinning process, a stacking process, an impregnation process, and a packaging process, wherein the electrospinning process is performed in the riveting process After that, electrospinning technology is used to directly spin on the surface of the anode foil to prepare filamentary electrolytic paper, which is attached to the surface of the anode foil to replace the separated electrolytic paper in the traditional technology.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

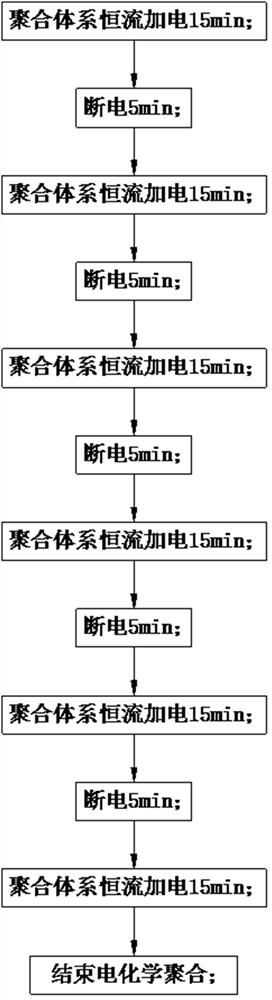

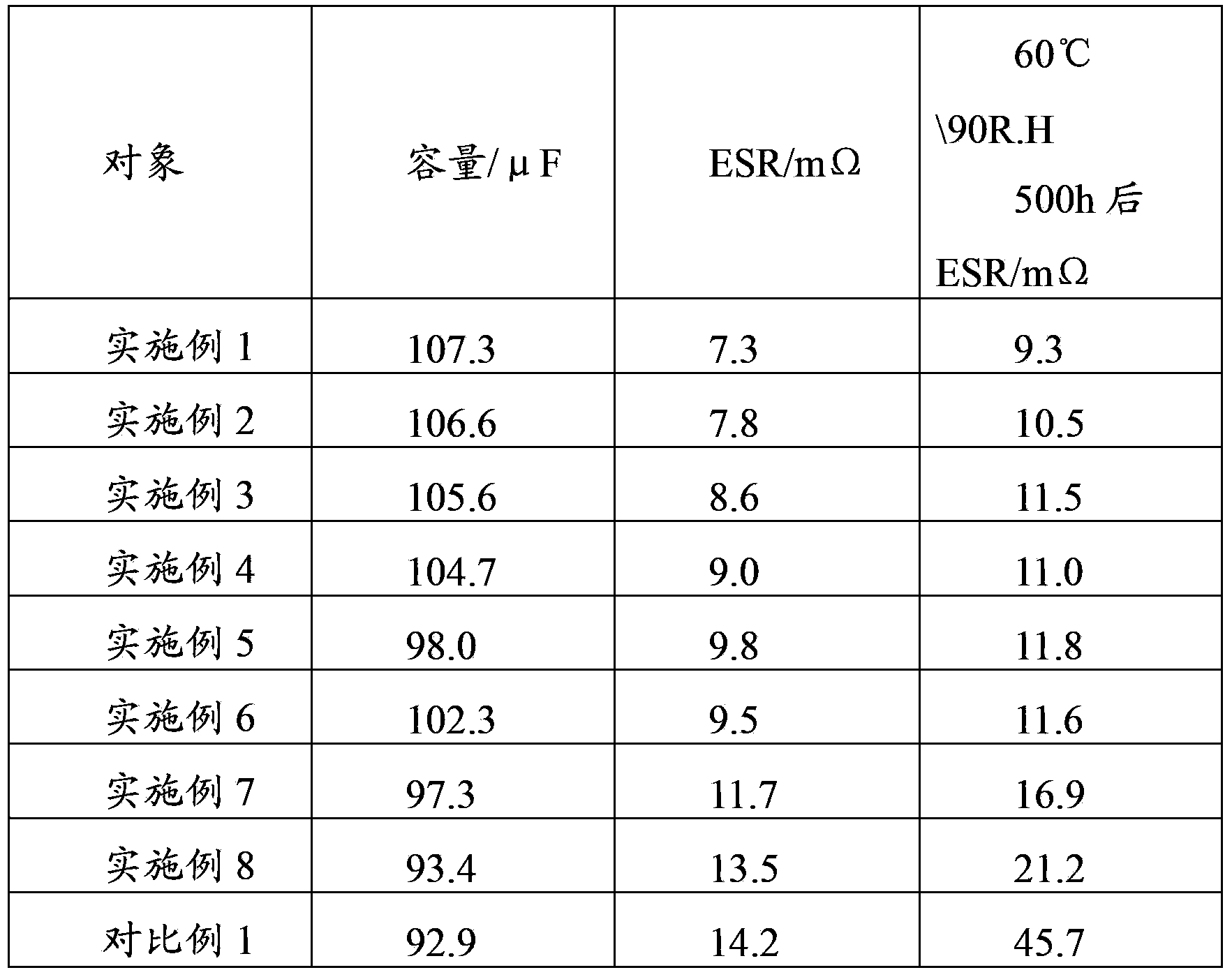

Electrochemical polymerization solution and electrochemical polymerization process for preparing solid electrolyte layer on capacitor

ActiveCN102115599BGeneralLow toxicityElectrolysis componentsCapacitor electrolytes/absorbentsCapacitanceSolvent

The invention provides an electrochemical polymerization solution and an electrochemical polymerization process for preparing a solid electrolyte layer on a capacitor. In the electrochemical polymerization solution, water, an organic solvent containing hydroxyl groups, a mixed solution of water and the organic solvent containing hydroxyl groups or a mixture of more than two kinds of organic solvents is taken as the solvent. The electrochemical polymerization process comprising the following steps: an anode body provided with a first solid electrolyte layer on the surface is connected with an external electrode to serve as an anode, a conductive electrode is adopted as a cathode, the constant current polymerization is performed in the electrochemical polymerization solution, then the anode and the cathode are cleaned and dried after being taken out, and a second solid electrolyte layer is prepared. The electrochemical polymerization solution has the advantages of wide raw materials, extremely low toxicity and easily-controlled large-scale production. Through the adoption of the electrochemical polymerization process, the rate of capacitance withdrawing of the solid electrolytic capacitor can be promoted, the ESR (equivalent series resistance) can be reduced, and the reliability can be enhanced at high temperature and high humidity.

Owner:福建国光新业科技股份有限公司

Manufacturing method of low-voltage formed foil for solid aluminum electrolytic capacitor

ActiveCN113106518AIncrease capacity extraction rateSmooth entrySolid electrolytic capacitorsSurface reaction electrolytic coatingCrystalline oxideOrganic polymer

The invention discloses a manufacturing method of a low-voltage formed foil for a solid aluminum electrolytic capacitor. The method mainly comprises the processes of five-stage formation treatment, primary water washing, intermediate treatment, primary heat treatment, primary repair formation, secondary water washing, hydration-resistant treatment, secondary heat treatment, secondary repair formation and drying treatment. The intermediate treatment step is achieved by putting the aluminum foil subjected to primary water washing into 0.5-5wt% of an ammonia water solution and carrying out dipping treatment for 0.5-3min at the temperature of 30-50 DEG C. The temperature of the primary heat treatment is 400-450 DEG C, and the treatment time is 4-6 minutes. A hydrated film on the surface of the formed foil can be eliminated in the intermediate treatment process, so that an organic polymer can smoothly enter the capacitor, and the capacity extraction rate of the device is further improved. The gap of the hydrated film is larger than that of a crystalline oxide film, so that the leakage current of the aluminum electrolytic capacitor is large, the problem can be well solved after the hydrated film is eliminated through the intermediate treatment step, and the leakage current of the formed foil is effectively reduced.

Owner:NANTONG HAIXING ELECTRONICS +2

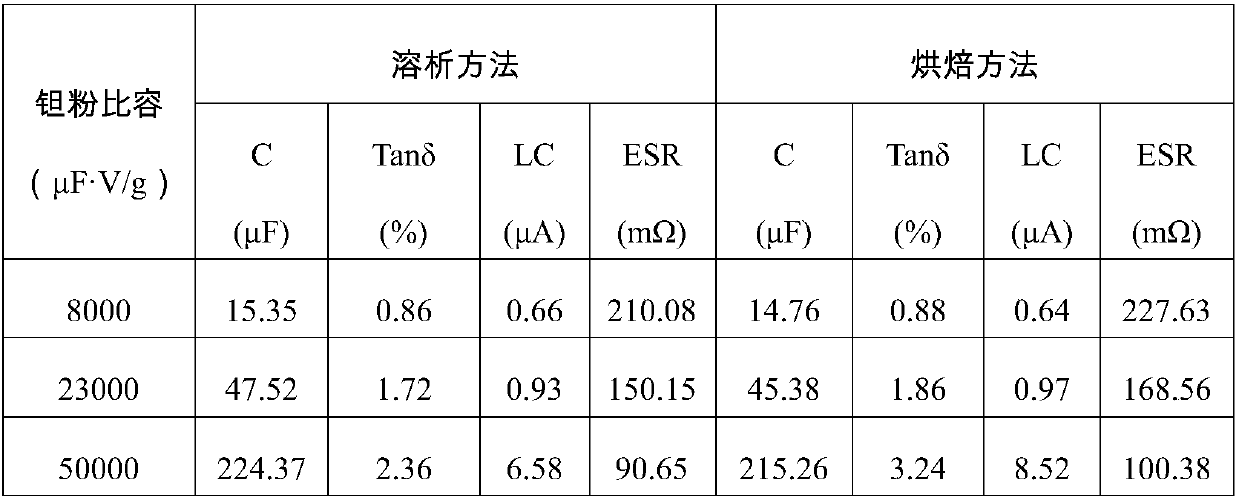

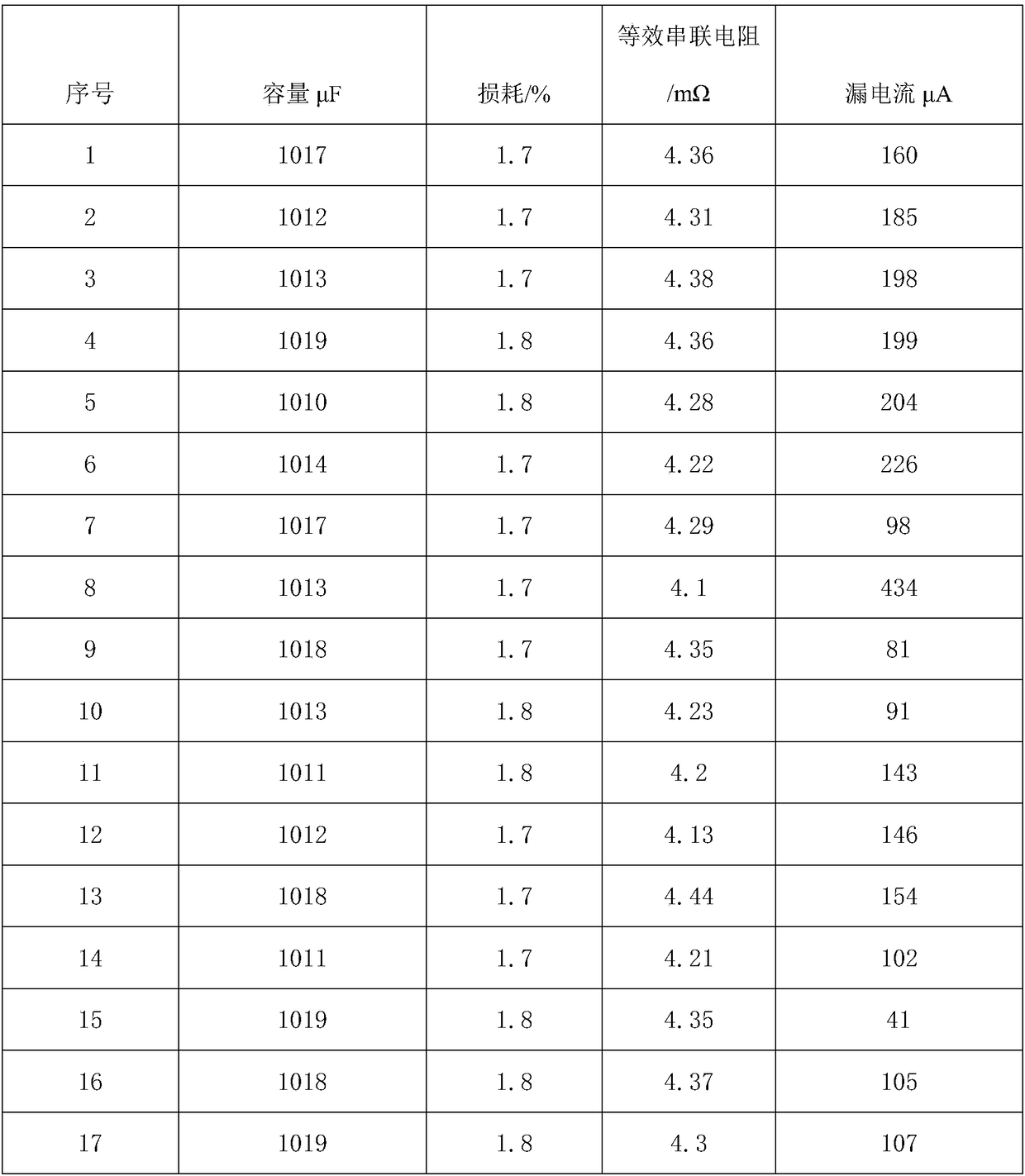

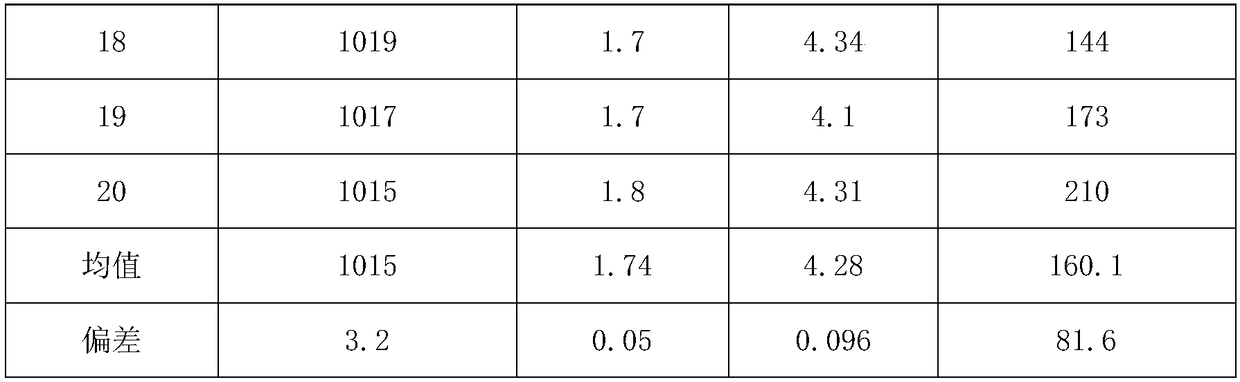

A method for manufacturing a cathode guide layer of a chip-type conductive polymer tantalum capacitor

ActiveCN105609313BHydrolysis rate mitigationHigh affinityElectrolytic capacitorsCoatingsGas phaseConductive polymer

The invention discloses a manufacturing method for a cathode guide layer of a chip-type conductive polymer tantalum capacitor. The manufacturing method comprises the following steps: dipping an anode tantalum block of which the surface is attached with a Ta<2>O<5> dielectric layer into a treating fluid for 1-2 minutes, and taking out the anode tantalum block at a speed of 0.01-5.0mm / min; placing the anode tantalum block at 20-30 DEG C for 5-30 minutes, and carrying out drying and film forming at 50-260 DEG C to form the cathode guide layer of the chip-type conductive polymer tantalum capacitor. The treating liquid comprises the following raw materials in percentage by weight: 0.005%-2.0% of a silane coupling agent, 0.01%-0.1% of fumed silica, 3%-15% of water and the balance of a solvent. The chip-type conductive polymer tantalum capacitor which is further prepared by the cathode guide layer of the chip-type conductive polymer tantalum capacitor manufactured by the manufacturing method has the characteristics of high capacity extraction ratio, low loss, low equivalent series resistance and low leak current.

Owner:SHENZHEN SURPASS STRUCTURE CERAMICS CO LTD

A kind of manufacturing method of low voltage formed foil for solid aluminum electrolytic capacitor

ActiveCN113106518BIncrease capacity extraction rateSmooth entrySolid electrolytic capacitorsSurface reaction electrolytic coatingCrystalline oxideHydration reaction

The invention discloses a method for manufacturing low-voltage forming foil for solid aluminum electrolytic capacitors, which mainly includes five stages of forming treatment, primary water washing, intermediate treatment, primary heat treatment, primary repair forming, secondary water washing, hydration resistance treatment, secondary heat treatment, and secondary In the process of repairing chemical formation and drying, the intermediate treatment step is to put the aluminum foil that has been washed once into 0.5-5 wt% ammonia solution, and immerse it at 30-50°C for 0.5-3 min; the temperature of the first heat treatment is 400 ~450℃, processing time 4~6 min. The intermediate treatment process can eliminate the hydration film on the surface of the foil, so that the organic polymer can enter the capacitor smoothly, thereby improving the capacity extraction rate of the device; and the hydration film has a larger gap than the crystalline oxide film, which will lead to a large leakage current of the aluminum electrolytic capacitor , After eliminating the hydration film through the intermediate treatment step, this problem can be solved well, and then the leakage current of the formed foil can be effectively reduced.

Owner:NANTONG HAIXING ELECTRONICS +2

Laminated electrolytic capacitor and manufacturing method thereof

ActiveCN111613447AAvoid piercingIncrease lossElectrolytic capacitorsElectrolytic agentAluminium electrolysis

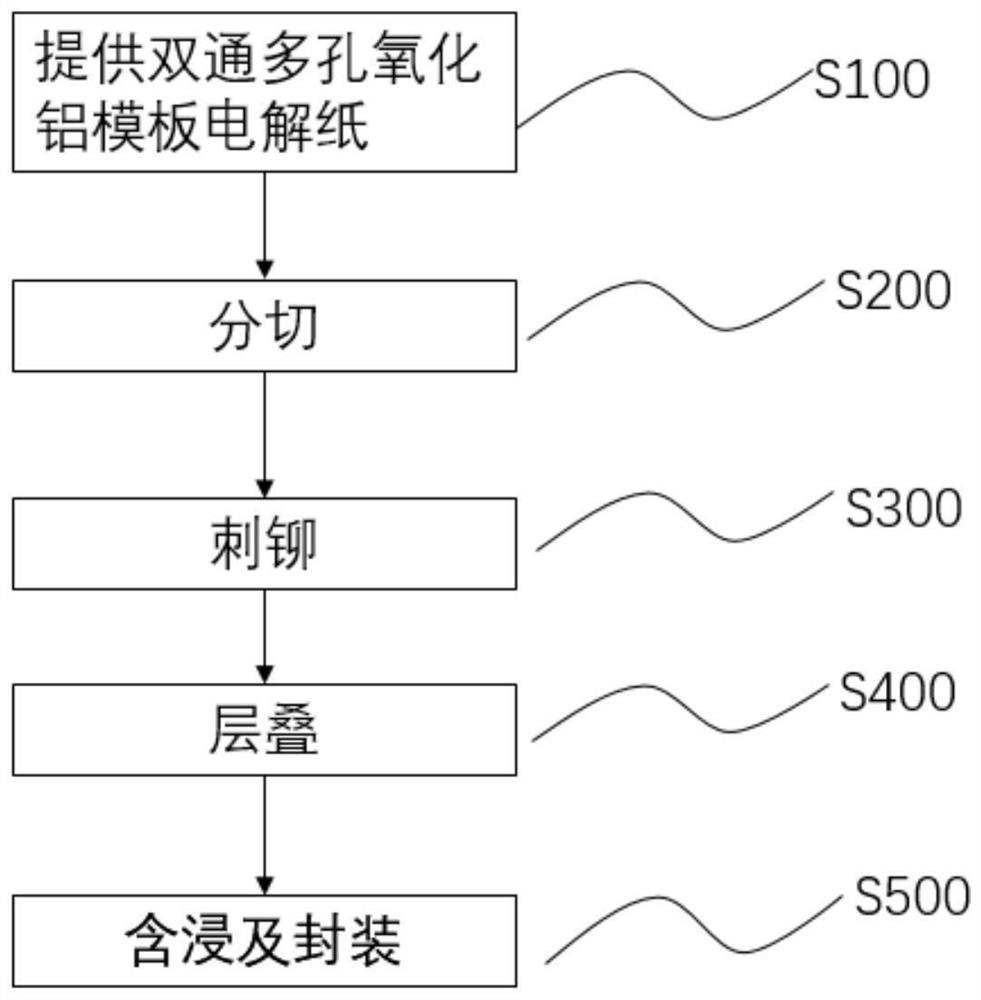

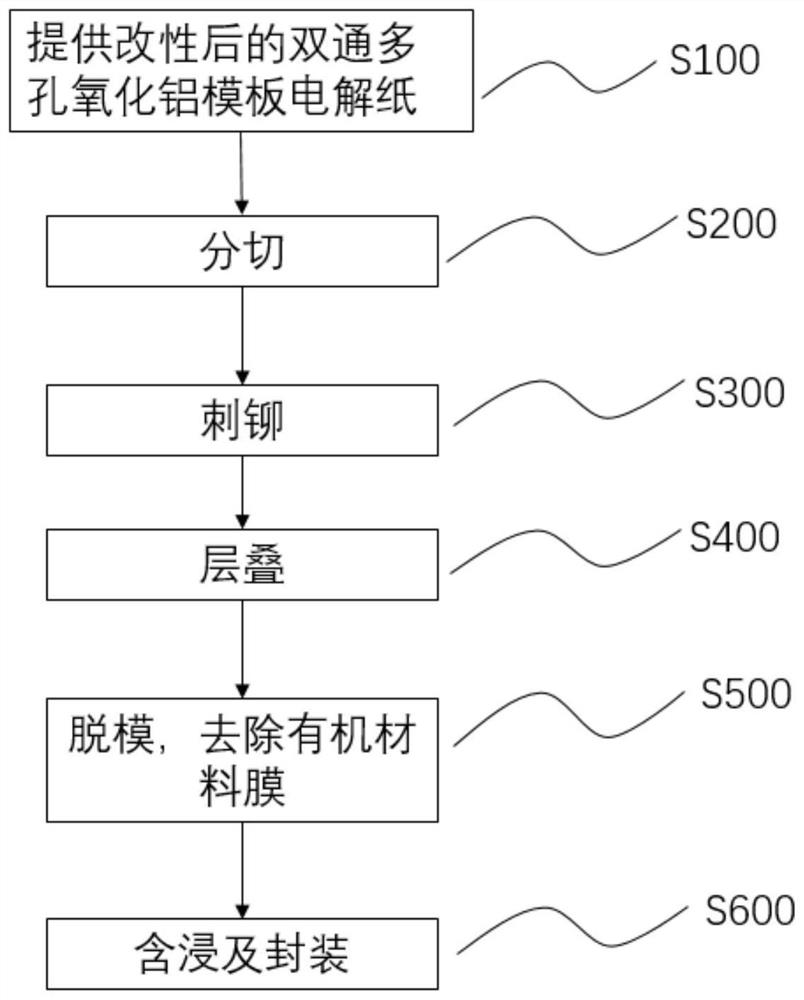

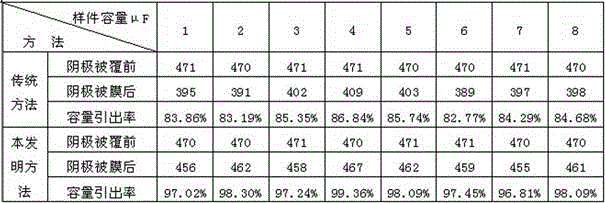

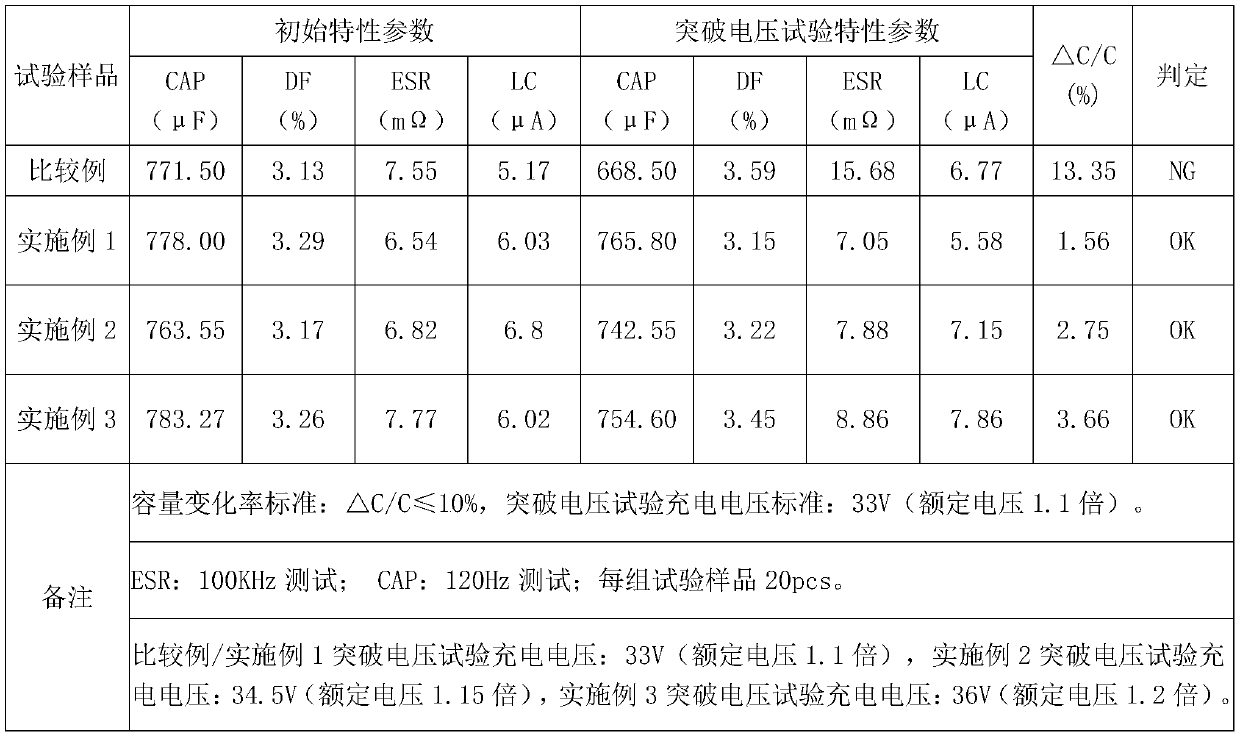

The invention provides a laminated aluminum electrolytic capacitor and a manufacturing method thereof. The manufacturing method comprises the following steps of providing a modified or unmodified bi-pass porous alumina template electrolytic paper; slitting; piercing and riveting; laminating; optionally demoulding; impregnating and packaging. According to the present invention, a bi-pass porous alumina template replaces a traditional electrolytic paper to be applied to the aluminum electrolytic capacitor, so that the problem of perforation of the electrolytic paper in the aluminum electrolyticcapacitor is avoided; meanwhile, the liquid content of an adsorption electrolyte is increased, so that the capacity extraction rate is increased, the loss and heating of the aluminum electrolytic capacitor are improved, and the service life of the aluminum electrolytic capacitor is prolonged.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Manufacturing method for cathode guide layer of chip-type conductive polymer tantalum capacitor

ActiveCN105609313AImprove continuityHydrolysis rate mitigationElectrolytic capacitorsCoatingsSolventLarge capacity

The invention discloses a manufacturing method for a cathode guide layer of a chip-type conductive polymer tantalum capacitor. The manufacturing method comprises the following steps: dipping an anode tantalum block of which the surface is attached with a Ta<2>O<5> dielectric layer into a treating fluid for 1-2 minutes, and taking out the anode tantalum block at a speed of 0.01-5.0mm / min; placing the anode tantalum block at 20-30 DEG C for 5-30 minutes, and carrying out drying and film forming at 50-260 DEG C to form the cathode guide layer of the chip-type conductive polymer tantalum capacitor. The treating liquid comprises the following raw materials in percentage by weight: 0.005%-2.0% of a silane coupling agent, 0.01%-0.1% of fumed silica, 3%-15% of water and the balance of a solvent. The chip-type conductive polymer tantalum capacitor which is further prepared by the cathode guide layer of the chip-type conductive polymer tantalum capacitor manufactured by the manufacturing method has the characteristics of high capacity extraction ratio, low loss, low equivalent series resistance and low leak current.

Owner:SHENZHEN SURPASS STRUCTURE CERAMICS CO LTD

Preparation method of dielectric film for improving capacity extraction rate of solid electrolyte tantalum capacitor

ActiveCN103489654BIncrease capacityIncrease capacity extraction rateSolid electrolytic capacitorsCapacitor dielectric layersManganese oxideHigh capacitance

The invention discloses a method for preparing a dielectric film to improve the extraction rate of the capacity of a solid electrolyte tantalum capacitor; it aims to provide a method for uniformly preparing a manganese dioxide dielectric film on the surface of an anode tantalum block made of ultra-high specific volume tantalum powder, so as to improve the capacity of the capacitor. Method of capacity extraction rate. The method is to immerse the anode tantalum block in the manganese nitrate solution at a speed of 0.5-1.5 mm / min, keep it for 2-4 minutes, and the immersion depth is 1 / 5-1 / 4 of the height of the anode tantalum block; press 0.5-1.5 mm Immerse the above-mentioned anode tantalum block in the above-mentioned manganese nitrate solution at a speed of 0.5-1.5 mm / min, and then put it into the decomposition furnace Manganese dioxide dielectric membrane was prepared. Adopting the invention improves the impregnation process, so it can increase the extraction rate of capacitor capacity; it is an impregnation method for the cathode solution of the solid electrolyte tantalum capacitor.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

A method for removing binder in solid electrolytic capacitor anode block

ActiveCN107680809BClean removalImprove electrical performance parametersSolid electrolytic capacitorsElectrolytic capacitor manufacturePorosityManufacturing technology

The invention belongs to the technical field of manufacturing of electrolytic capacitors, and particularly discloses a method for removing an adhesive in an anode block of a solid electrolytic capacitor. Treatment is carried out through the following 11 steps of dissolving, spaying, drying, compression, reciprocating sifting, first elution, standing, second elution, third elution, boiling and drying in all, so that the adhesive and a solvent can be removed clean without a residue, improvement of electric performance parameters of the capacitor is facilitated, meanwhile, fine powder particles blocked in micropores and powder particles adhered to the surface of an anode blank are also burst through, the capacity extraction rate of the capacitor is improved, and the probability of crystallization when an anode is formed is reduced. According to the method, increase of the content of impurities of carbon and oxygen in the tantalum blank is effectively suppressed, the porosity in the tantalum blank is improved and the stability and the reliability of the tantalum electrolytic capacitor are improved.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Treatment liquid for improving withstand voltage of solid capacitors and preparation method of solid capacitors

ActiveCN109300696BEasy to produceImprove decay rateSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCapacitanceMaterials science

The invention discloses a treatment fluid for improving the withstand voltage of a solid capacitor. The treatment fluid is prepared from raw materials including a solvent and a solute, the solvent comprises a water-system high-molecular material and an organic solvent, the water-system high-molecular material includes a macromolecular compound in the molecular weight of 200-1000 and a macromolecular compound in the molecular weight of 2000-10000, and the solute comprises an organic and / or inorganic acid as well as amine which can react with the organic and / or inorganic acid to generate salt. The invention also discloses a preparation method of the solid capacitor in which the treatment fluid is used. After that a capacitor core of the solid capacitor is impregnated in the treatment fluid,an oxide film defect in the surface of an aluminum foil of the capacitor core is overcome, short circuit is inhibited, the withstand voltage is improved by 30% to 50%, the voltage characteristic is improved, the capacity attenuation change rate is reduced, the capacity leading-out rate is improved, the reliability is improved, and the solid capacitor of higher capacitor and small size can be produced.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

A kind of impregnation method of capacitor element

ActiveCN105788890BIncrease capacity extraction rateImprove efficiencyDrying/impregnating machinesVacuum pumpingGas phase

The invention discloses a capacitor element impregnating method, and the method comprises the following steps: 1), enabling a conducting polymer monomer to be placed in a vacuum furnace, and enabling an element to be placed above the conducting polymer monomer; 2), sealing the vacuum furnace, and carrying out the vacuum pumping of the vacuum furnace; 3), enabling the internal temperature of the vacuum furnace to rise 50-100 DEG C, maintaining the temperature for 1-30min; enabling the internal temperature of the vacuum furnace to gradually decrease to the indoor temperature to 5 DEC C, and maintaining the temperature for 1-30min; 4), enabling the element comprising the conducting polymer monomer to be taken out from the vacuum furnace, carrying out the impregnating of an oxidizing agent, and generating a PEDT. The method employs the strong volatility of the conducting polymer monomer, enables the conducting polymer monomer to be able to be placed in a vacuum furnace room in a gaseous phase in a vacuum environment, reduces the temperature to enable monomer molecules to be condensed in the element after a gaseous impregnating time period under the higher temperature, and enables the monomer molecules to enter in an aluminium foil gap better.

Owner:HUNAN AIHUA GRP

Preparation method of a low-voltage large-capacity polymer chip laminated aluminum electrolytic capacitor

ActiveCN112164590BIncrease capacityIncrease capacity extraction rateSolid electrolytic capacitorsElectrolytic capacitor manufactureAluminium electrolysisPhysical chemistry

The invention discloses a method for preparing a low-voltage and large-capacity polymer chip-type laminated aluminum electrolytic capacitor. The method of impregnating a conductive polymer monomer and drying the surface of the formed foil is used to replace the pre-treatment process of the coupling agent. Matching chemical polymerization method, supplemented by step-type electrochemical polymerization method, the synergistic effect of the two greatly improves the capacity lead-out rate of the formed foil, thereby increasing the capacity of the finished product and meeting the capacity requirements of low-voltage large-capacity polymer chip laminated aluminum electrolytic capacitors. Requirements, improve the yield rate of finished products, and bring considerable economic benefits.

Owner:福建国光新业科技股份有限公司

Low-impedance solid-liquid mixed electrolyte as well as preparation method and application thereof

ActiveCN113658802ASmall particle sizeImprove performanceCapacitor electrolytes/absorbentsElectrolytic agentPhysical chemistry

The invention belongs to the technical field of electrolyte, and discloses low-impedance solid-liquid mixed electrolyte as well as a preparation method and application thereof. The solid-liquid mixed electrolyte comprises a PEDOT / PSS polymer. The operation of preparing the PEDOT / PSS polymer comprises step-by-step polymerization and ultrasonic stirring. The low-impedance solid-liquid mixed electrolyte is excellent in performance, and a capacitor prepared from the low-impedance solid-liquid mixed electrolyte has better capacity extraction rate, high temperature resistance and conductivity.

Owner:ZHUHAI LEAGUER CAPACITOR

Dielectric film preparation method for improving capacity extraction rate of solid electrolyte tantalum capacitor

ActiveCN103489654AIncrease ratingsImproving the impregnation processSolid electrolytic capacitorsCapacitor dielectric layersDielectricTantalum capacitor

The invention discloses a dielectric film preparation method for improving the capacity extraction rate of a solid electrolyte tantalum capacitor and aims to provide a method for uniformly preparing manganese dioxide dielectric films on surface of an anode tantalum block made of ultra-high specific volume tantalum powder so as to improve the capacity extraction rate of a capacitor. The method comprises the following steps: immersing the anode tantalum block in a manganese nitrate solution according to a speed of 0.5-1.5mm / min, and keeping 2-4 minutes, wherein the immersion depth is 1 / 5-1 / 4 of the height of the anode tantalum block; totally immersing the anode tantalum block into the manganese nitrate solution according to the speed of 0.5-1.5mm / min, and keeping 3-5 minutes; taking the anode tantalum block out of the manganese nitrate solution according to the speed of 0.5-1.5mm / min, and putting the anode tantalum block into a decomposing furnace for preparing the manganese dioxide dielectric films. According to the method, because an impregnation technology is improved, the capacity extraction rate of the capacitor can be improved; the method is a method for impregnating the solid electrolyte tantalum capacitor in a cathode solution.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Positive pole mixed powder for producing positive pole of solid electrolytic capacitor

InactiveCN103730258AImprove liquidityReduce frictionElectrolytic capacitorsUltrasound attenuationElectrolysis

The invention discloses positive pole mixed powder for producing a positive pole of a solid electrolytic capacitor. The positive pole mixed powder for producing the positive pole of the solid electrolytic capacitor comprises positive pole powder, dimethyl sulfone and solvent; the weight of the dimethyl sulfone is 1 to 20 % of the positive pole powder; the weight of the dimethyl sulfone is 0.5 to 30 % of the solvent. The positive pole mixed powder for producing the positive pole of the solid electrolytic capacitor has the advantages of enabling mobility of tantalum powder to be high, being less in residual of elements such as carbon and oxygen after dewaxing, enabling volume extraction rate to be improved by 5 to 8%, accordingly reducing the processing difficulty of a subsequent process (negative pole production) and enabling the leakage current attenuation speed of products to be improved.

Owner:SHENZHEN SUNLORD ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com