Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1882results about "Electrolytic capacitor manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid electrolytic capacitor containing a conductive polymer

ActiveUS7515396B2Hybrid capacitor electrolytesSolid electrolytic capacitorsOligomerConductive polymer

A method for forming an electrolytic capacitor is disclosed. The method includes forming a conductive polymer coating by polymerizing a monomer in the presence of less than a stoichiometric amount of an oxidative polymerization catalyst. The present inventor has found that the use of less than the stoichiometric amount of the oxidative polymerization catalyst per mole of monomer can slow the polymerization of the monomer, creating oligomers that are shorter in length than if fully polymerized into a polymer. Without wishing to be bound by theory, it is believed that these shorter oligomers provide better penetration into the porous anode. Thus, the resulting conductive polymer layer can be more intimately positioned with respect to the anode. As a result, the formed capacitor can exhibit better performance.

Owner:KYOCERA AVX COMPONENTS CORP

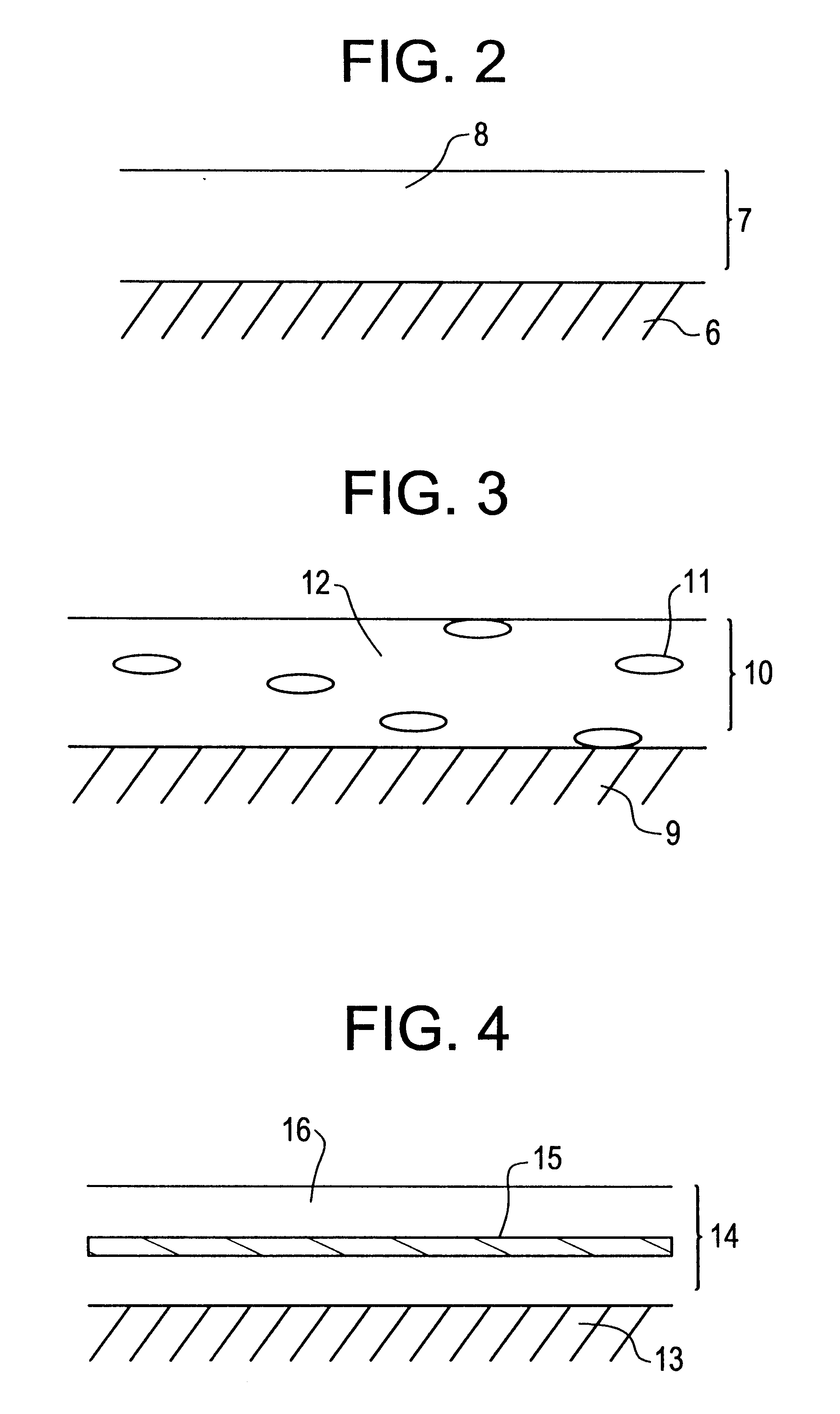

Process for the production of electrolyte capacitors of high nominal voltage

ActiveUS20070064376A1Lower equivalent series resistanceHigh nominal voltageSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisPhysical chemistry

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current for high nominal voltages, electrolyte capacitors produced by this process and the use of such electrolyte capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

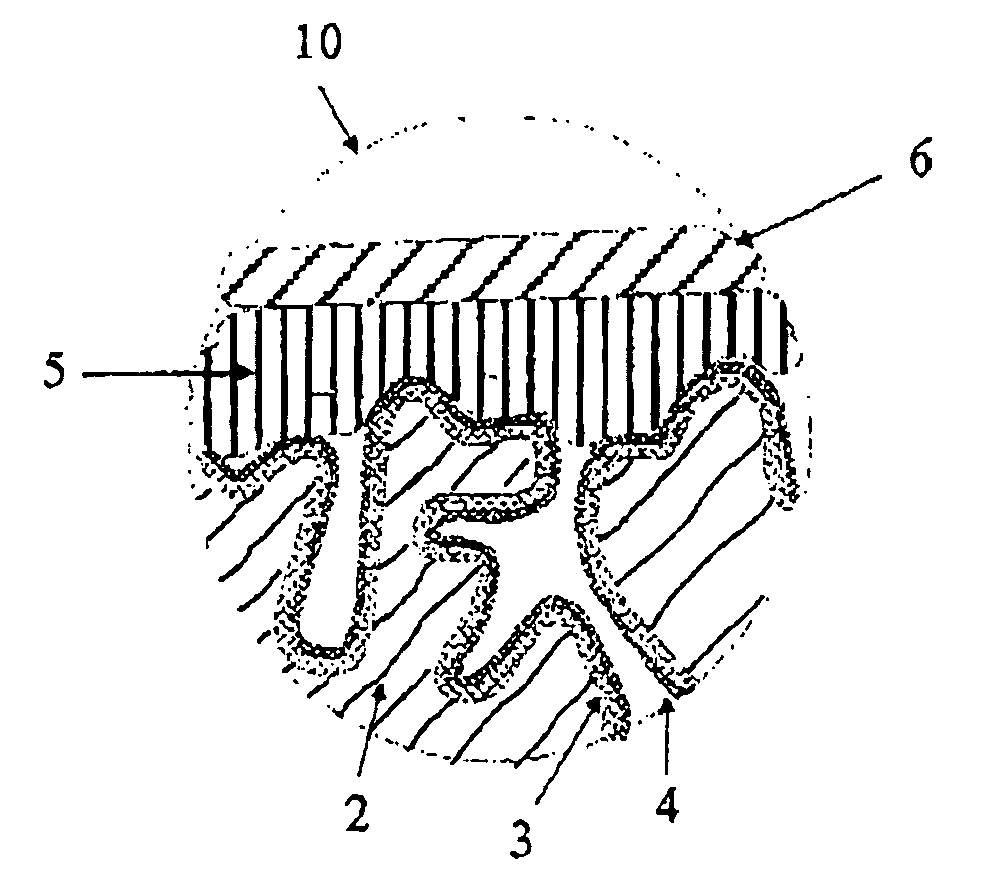

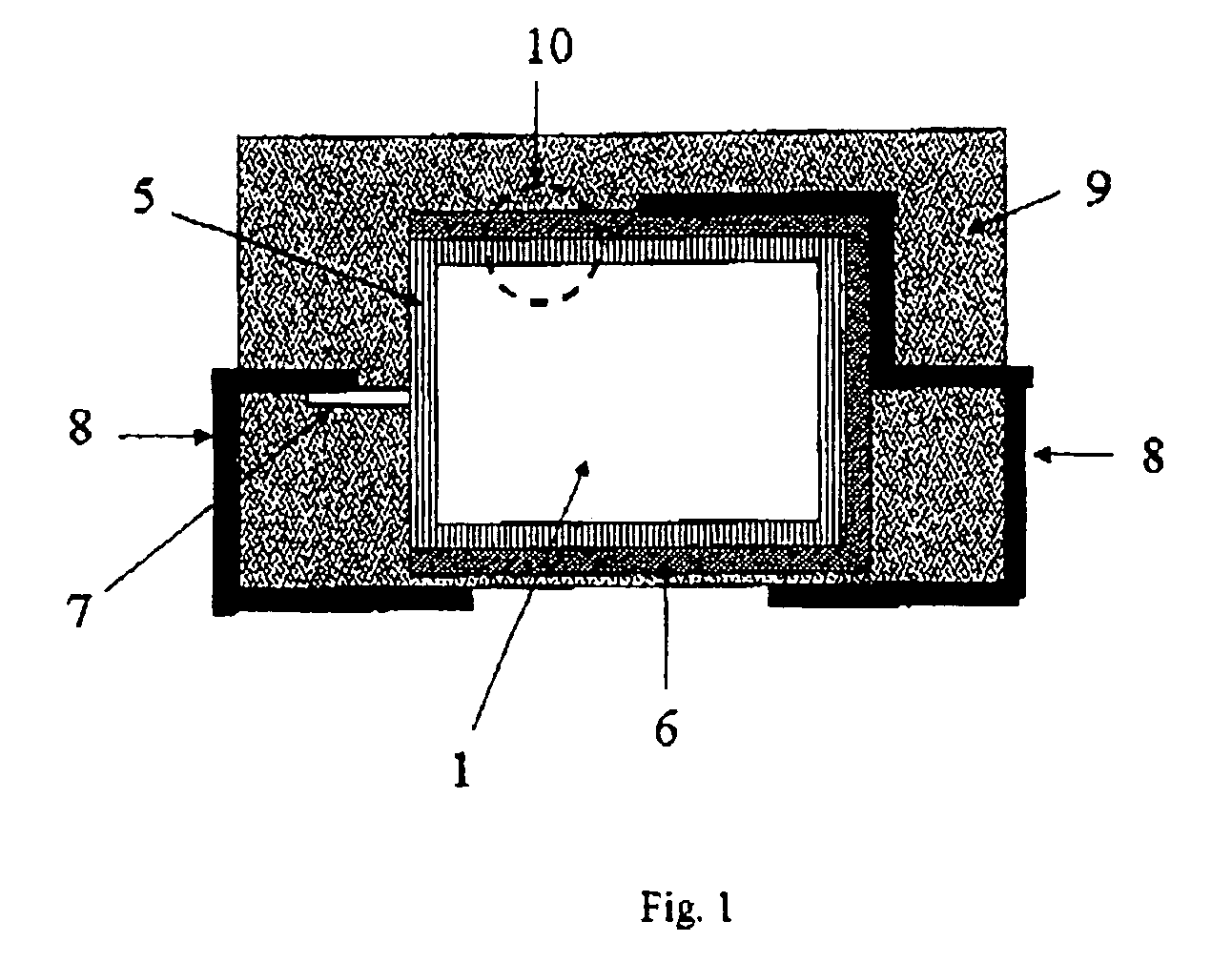

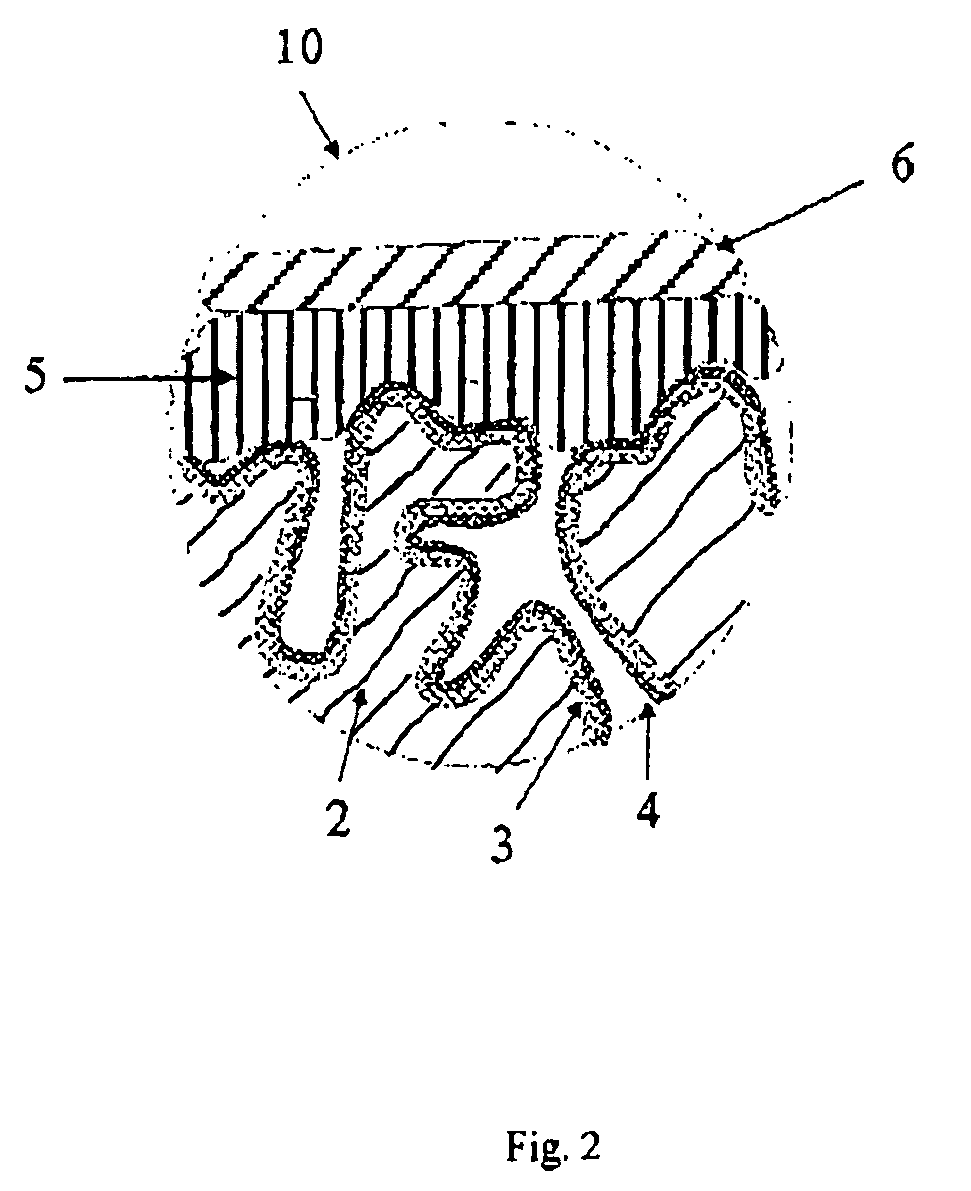

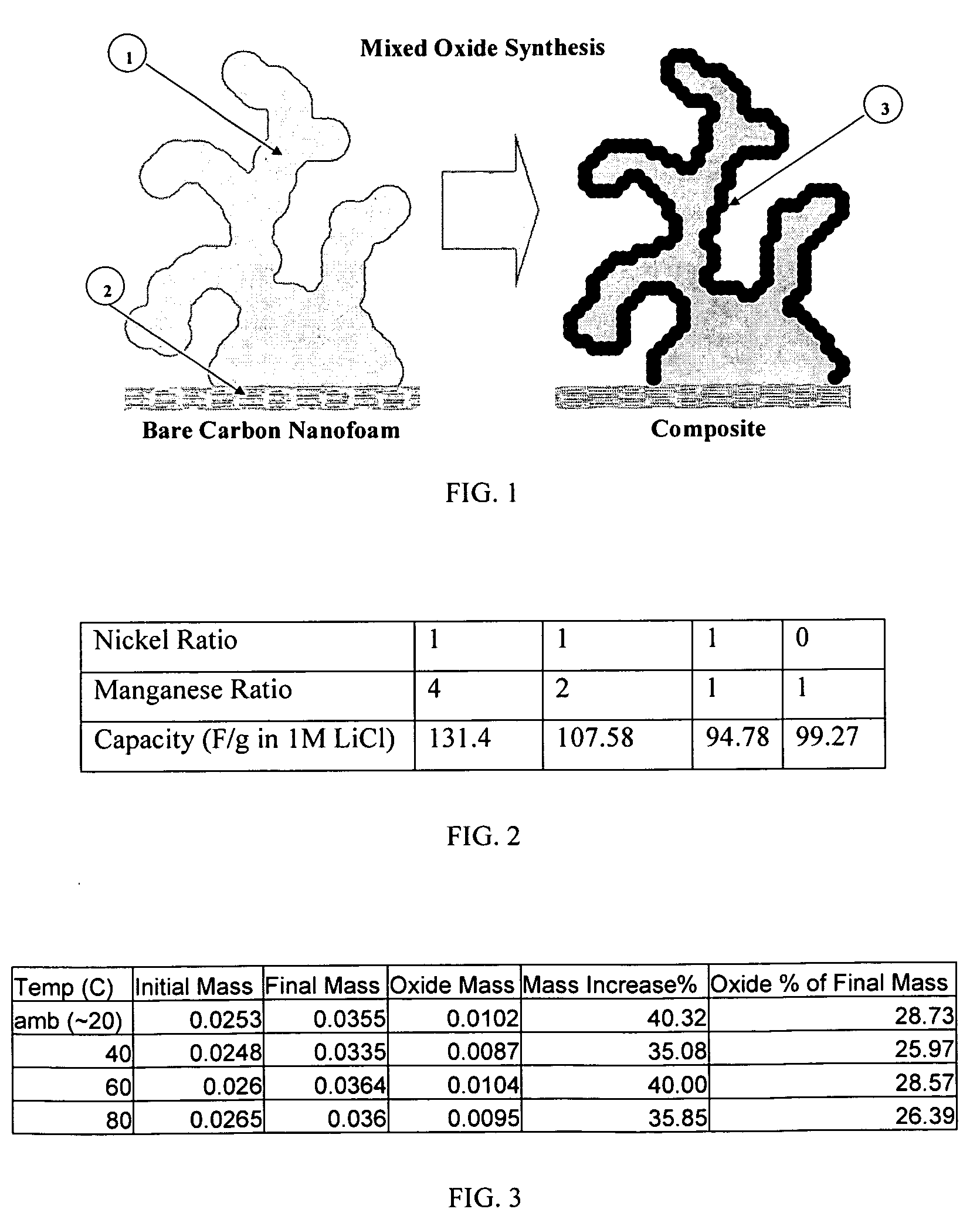

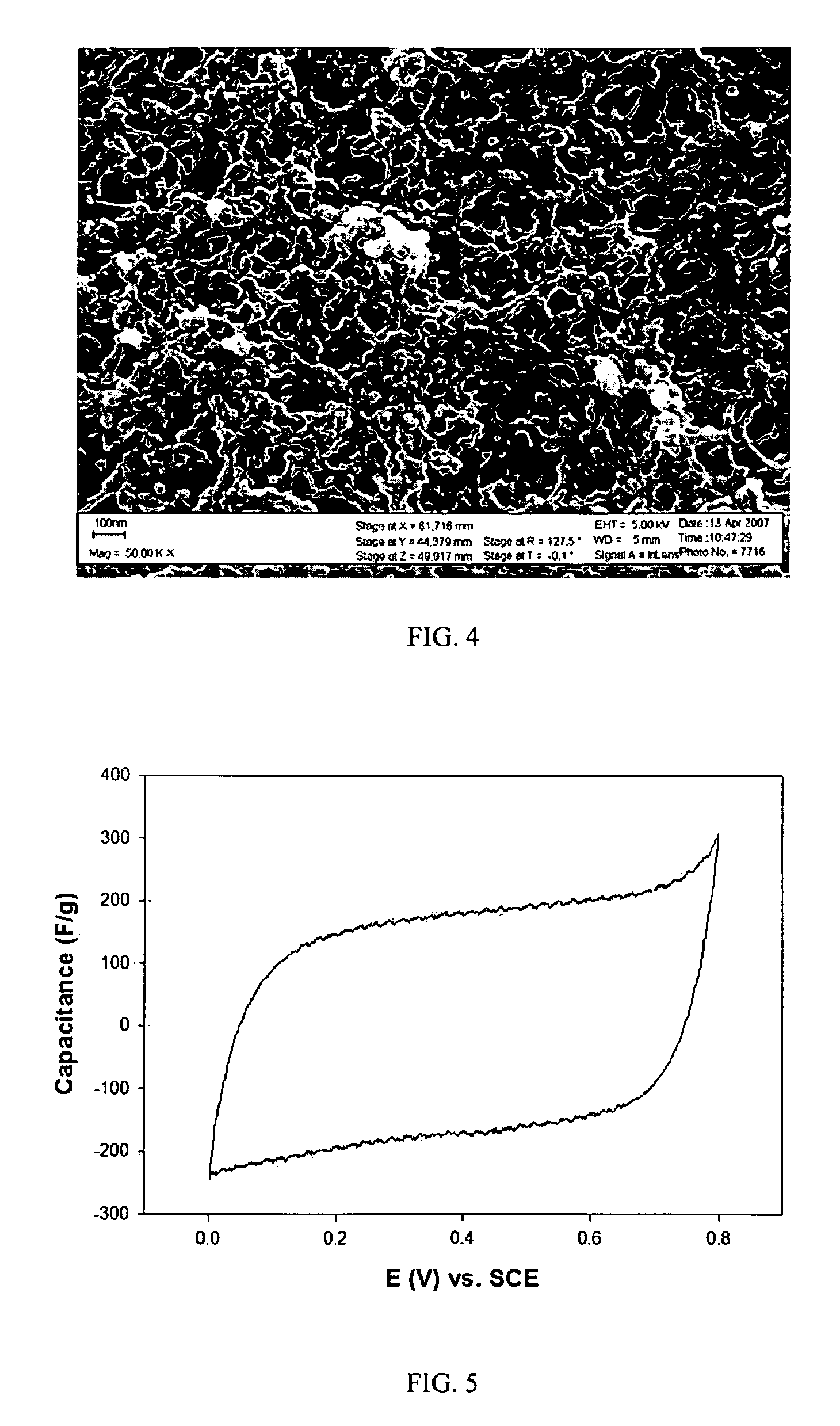

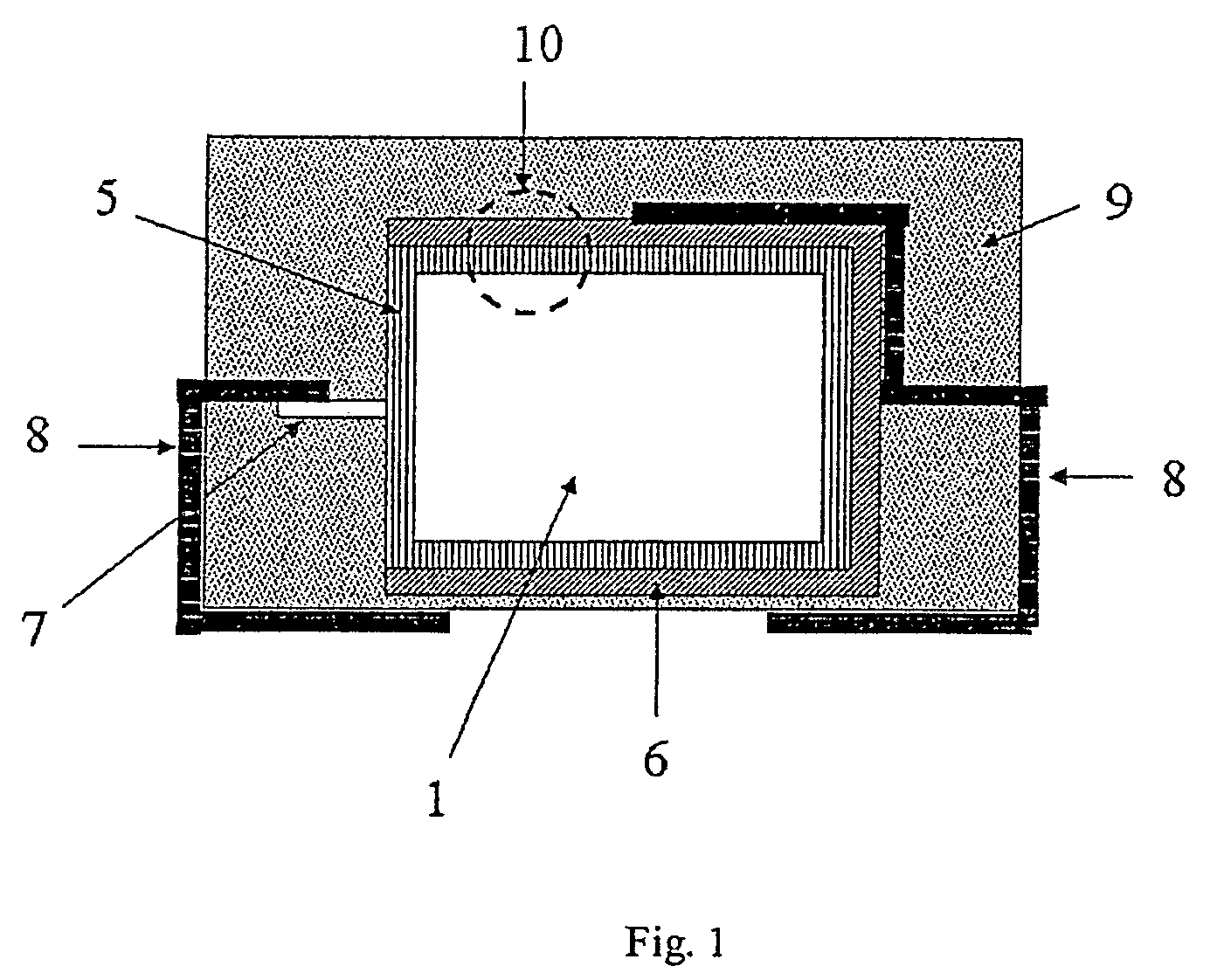

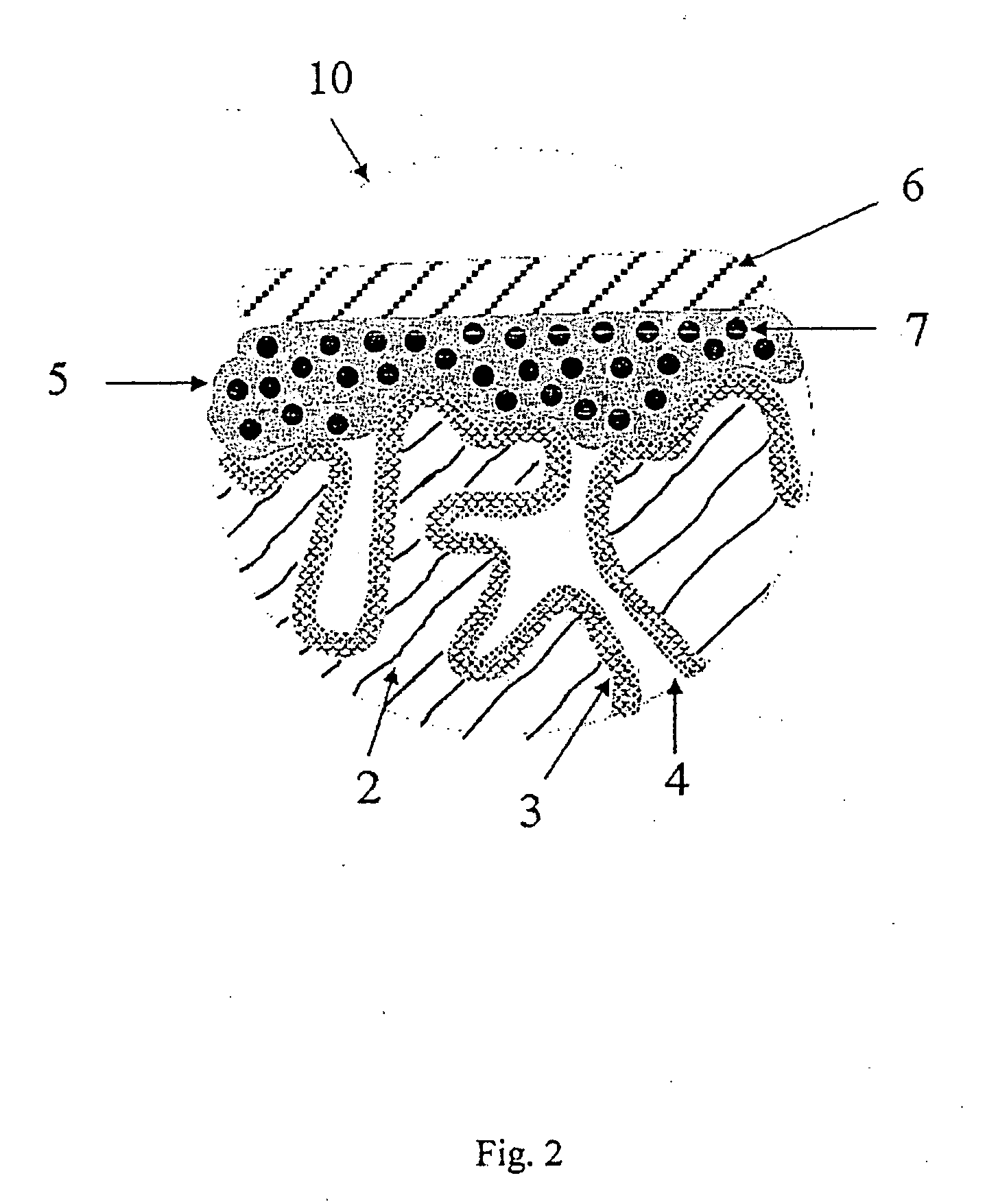

Composite electrode comprising a carbon structure coated with a thin film of mixed metal oxides for electrochemical energy storage

InactiveUS20090185327A1Increase capacityProlong lifeLiquid electrolytic capacitorsFinal product manufactureComposite electrodeMixed oxide

A composite electrode is created by forming a thin conformal coating of mixed metal oxides on a highly porous carbon structure. The highly porous carbon structure performs a role in the synthesis of the mixed oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of mixed metal oxides. The metal oxide mixture shall include two or more metal oxides. The composite electrode, a process for producing said composite electrode, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said composite electrode are disclosed.

Owner:SEYMOUR FRASER WADE

Solid electrolytic capacitor containing a conductive polymer

ActiveUS20080232037A1Hybrid capacitor electrolytesSolid electrolytic capacitorsOligomerConductive polymer

A method for forming an electrolytic capacitor is disclosed. The method includes forming a conductive polymer coating by polymerizing a monomer in the presence of less than a stoichiometric amount of an oxidative polymerization catalyst. The present inventor has found that the use of less than the stoichiometric amount of the oxidative polymerization catalyst per mole of monomer can slow the polymerization of the monomer, creating oligomers that are shorter in length than if fully polymerized into a polymer. Without wishing to be bound by theory, it is believed that these shorter oligomers provide better penetration into the porous anode. Thus, the resulting conductive polymer layer can be more intimately positioned with respect to the anode. As a result, the formed capacitor can exhibit better performance.

Owner:KYOCERA AVX COMPONENTS CORP

Electrolytic capacitors with a polymeric outer layer and process for the production thereof

ActiveUS7411779B2Lower equivalent series resistanceIncrease coverageHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisConductive polymer

The invention relates to a process for the production of electrolytic capacitors with low equivalent series resistance and low residual current consisting of a solid electrolyte made of conductive polymers and an outer layer containing conductive polymers, to electrolytic capacitors produced by this process and to the use of such electrolytic capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Electrolyte capacitors having a polymeric outer layer and process for their production

ActiveUS7377947B2Increase coverageHybrid capacitor electrolytesHybrid capacitor electrodesConductive polymerCapacitor

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current, and which comprise a solid electrolyte of conductive polymers and an outer layer comprising conductive polymers applied in the form of a dispersion. Electrolyte capacitors produced by this process and the use of such electrolyte capacitors are also provided.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Process for the production of electrolyte capacitors of high nominal voltage

ActiveUS8313538B2Solid electrolytic capacitorsLiquid electrolytic capacitorsPhysical chemistryCapacitor

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current for high nominal voltages, electrolyte capacitors produced by this process and the use of such electrolyte capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

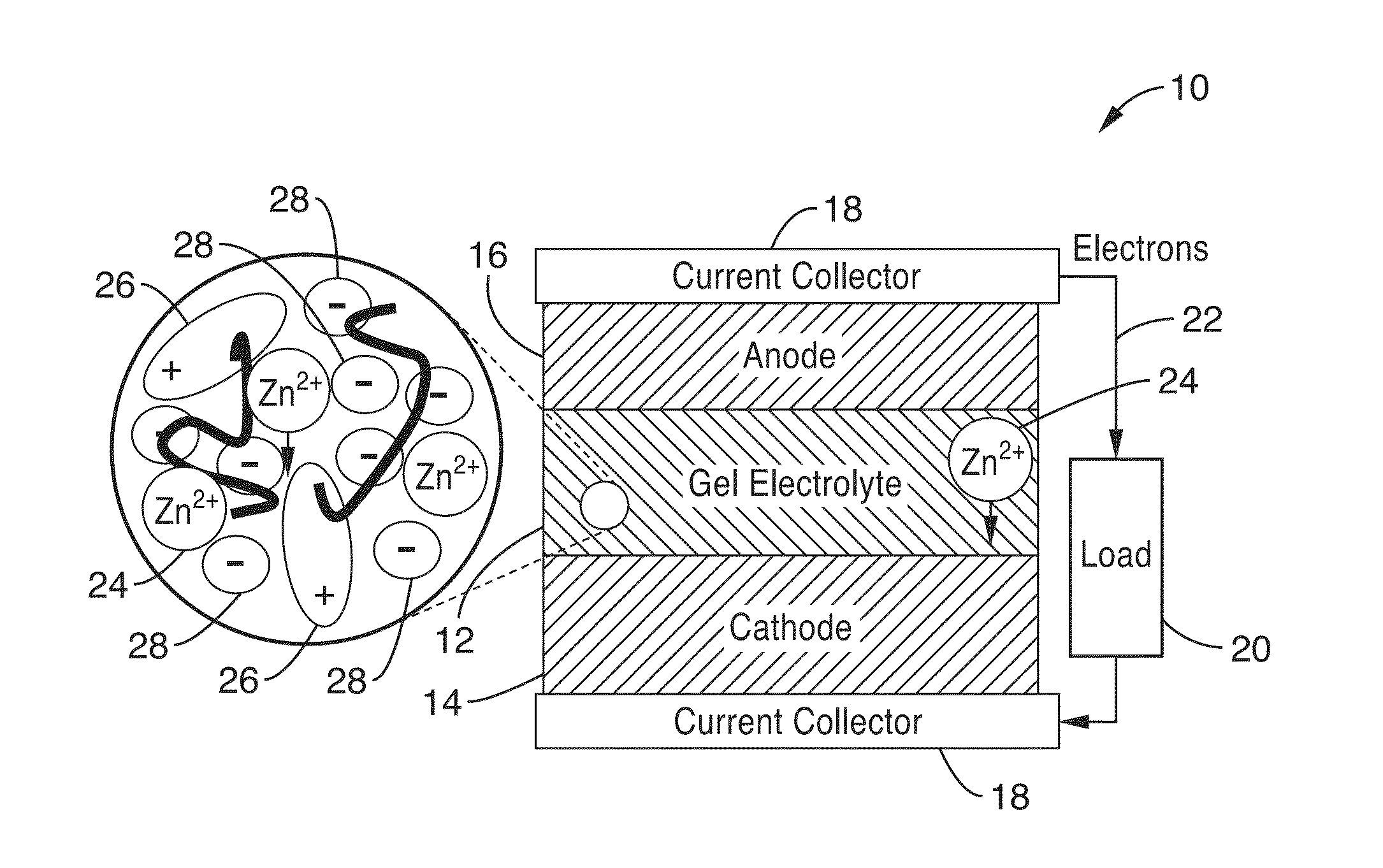

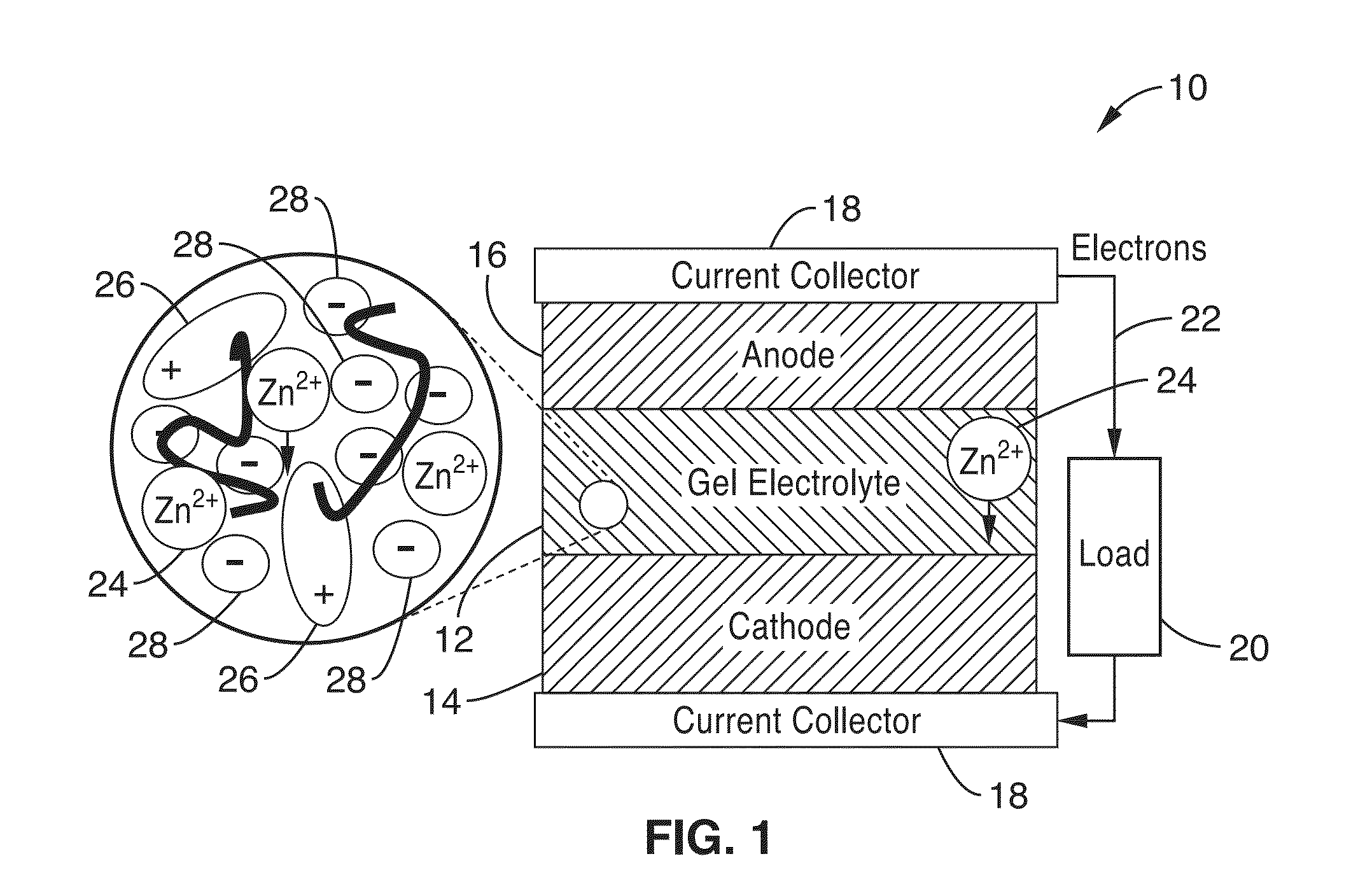

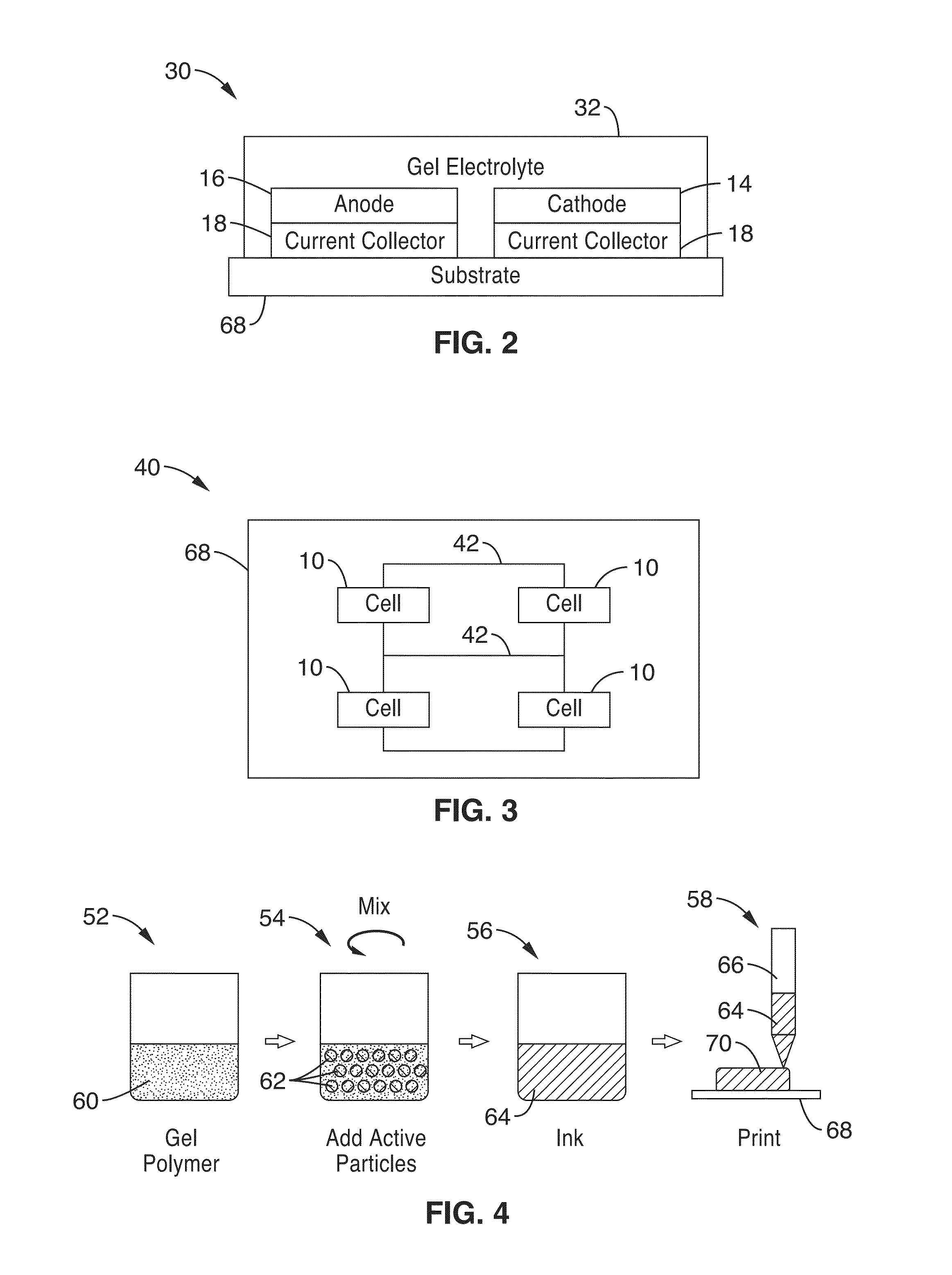

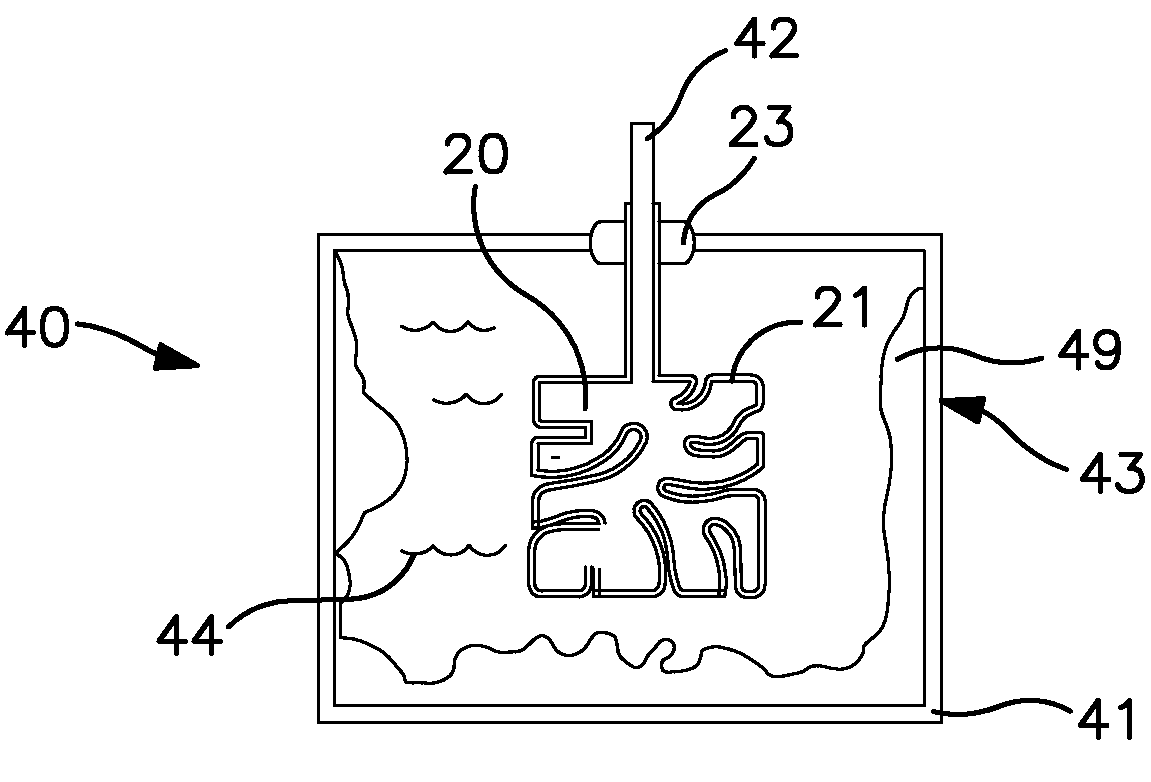

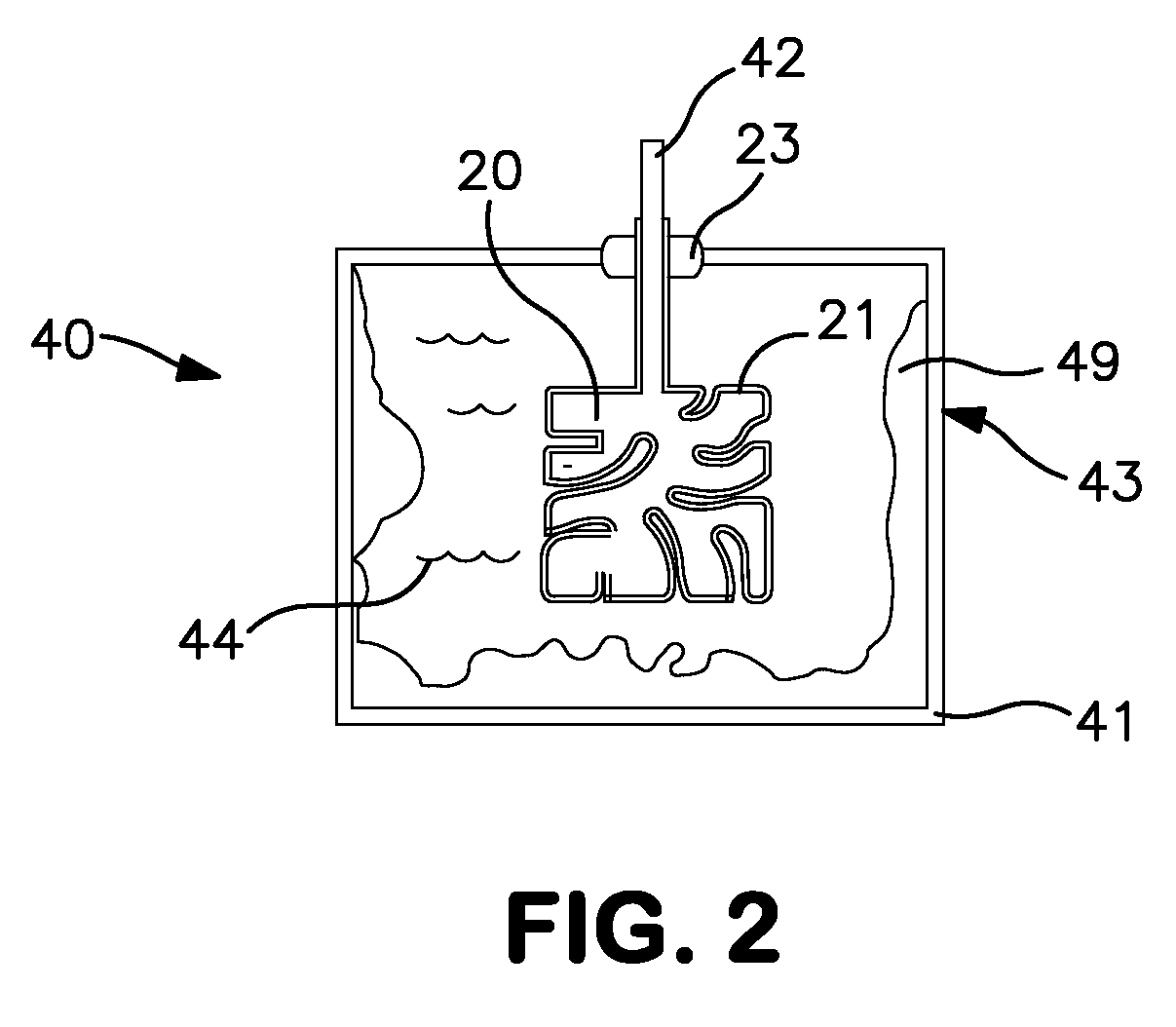

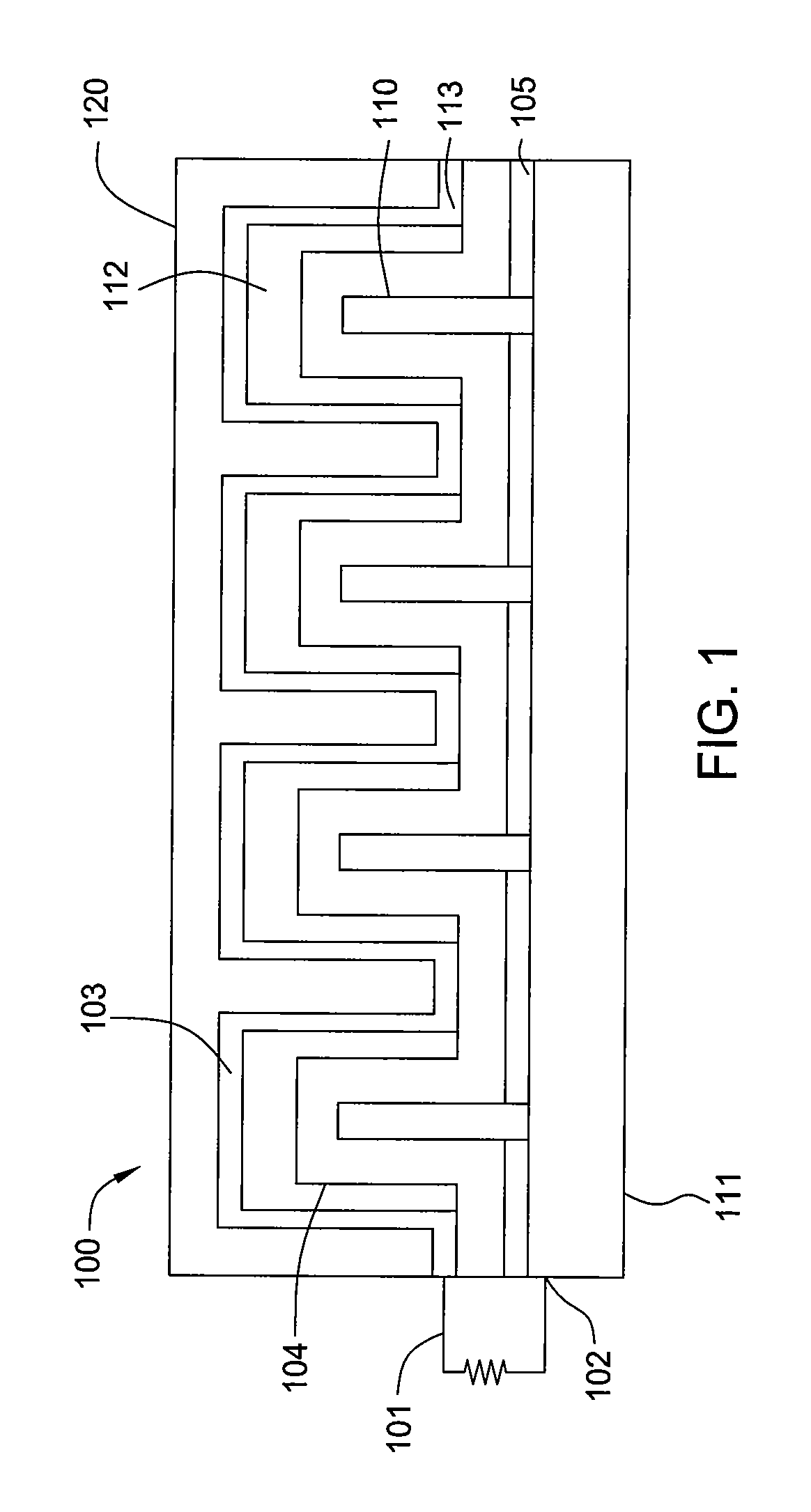

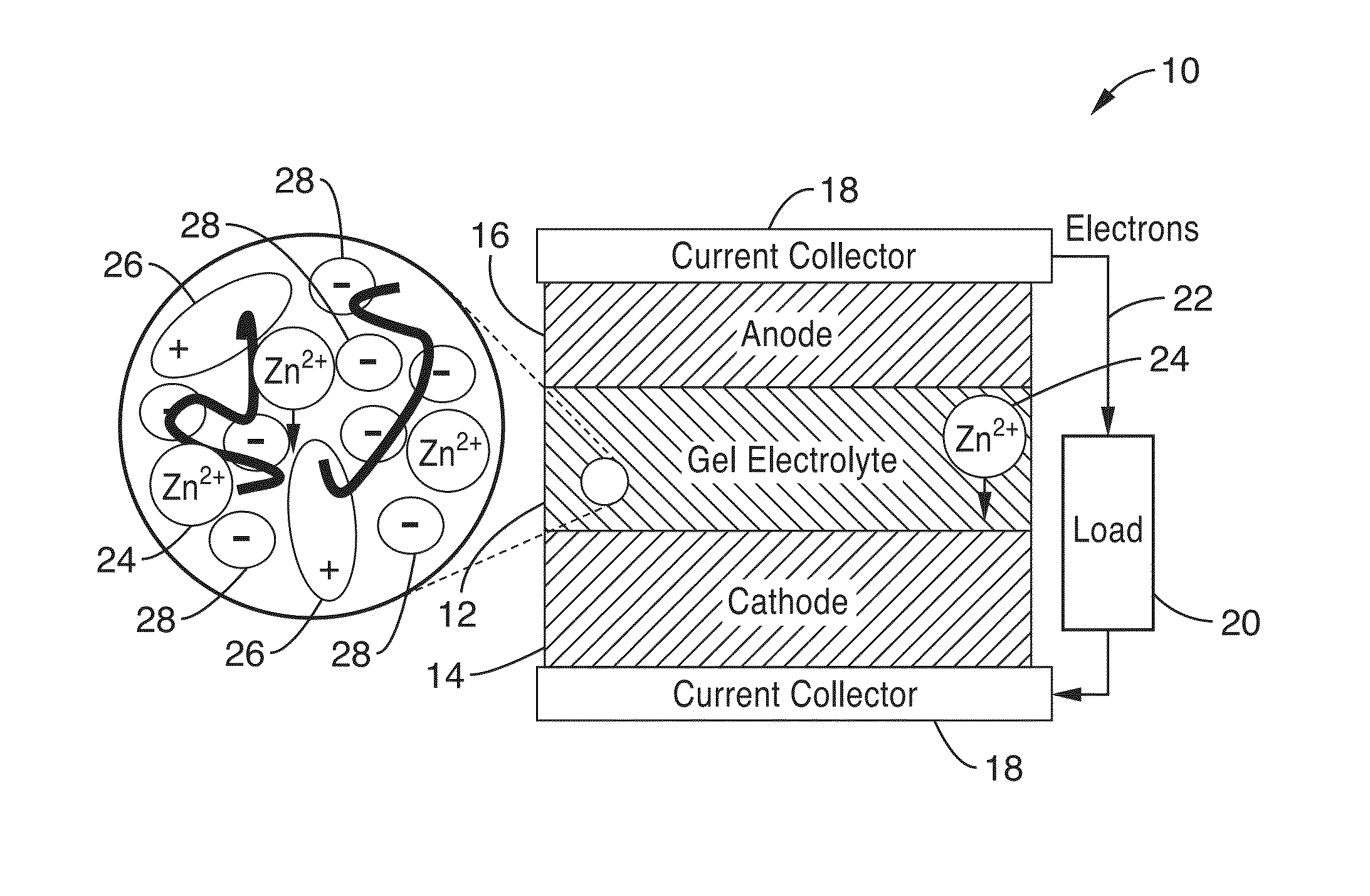

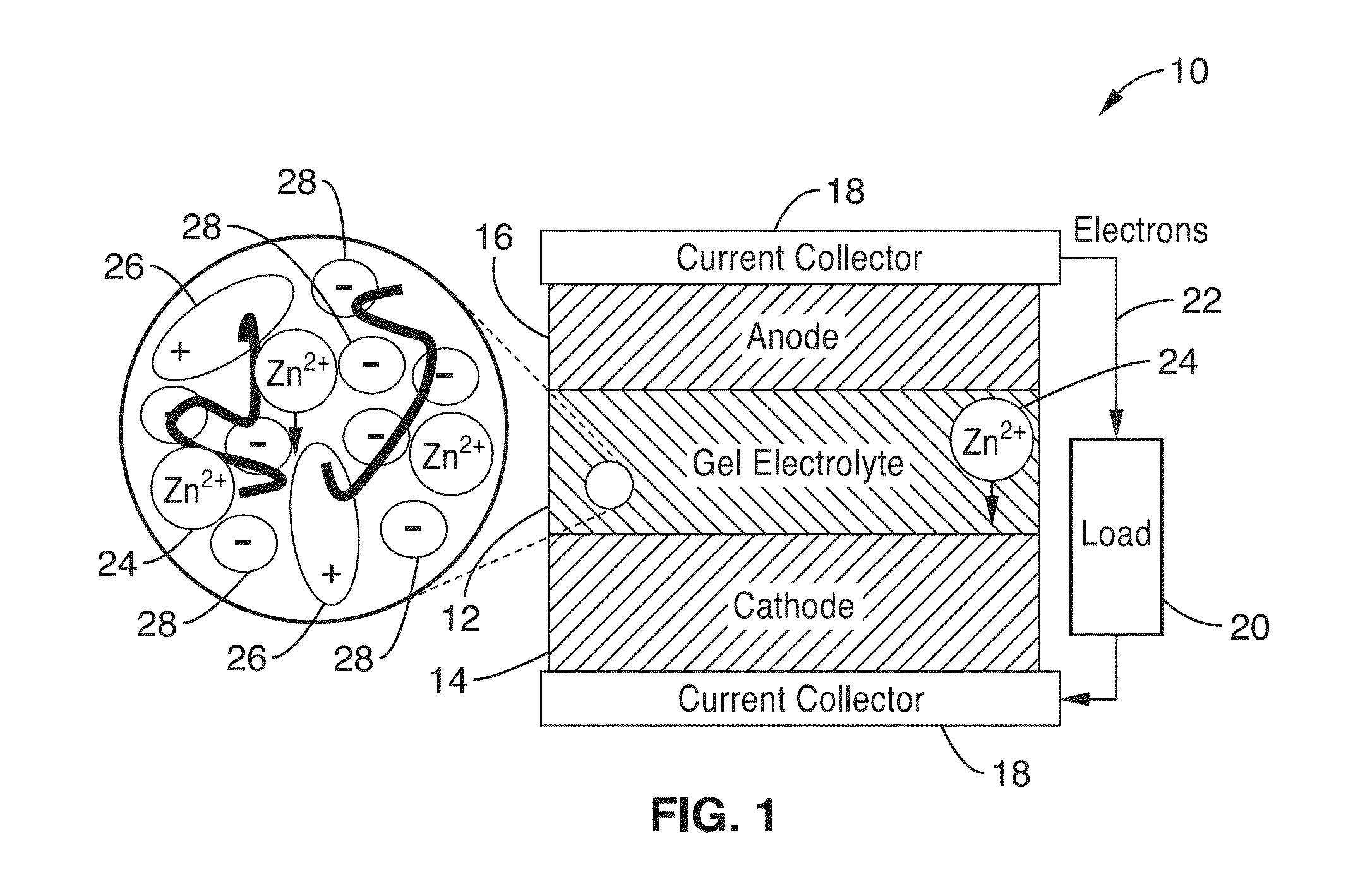

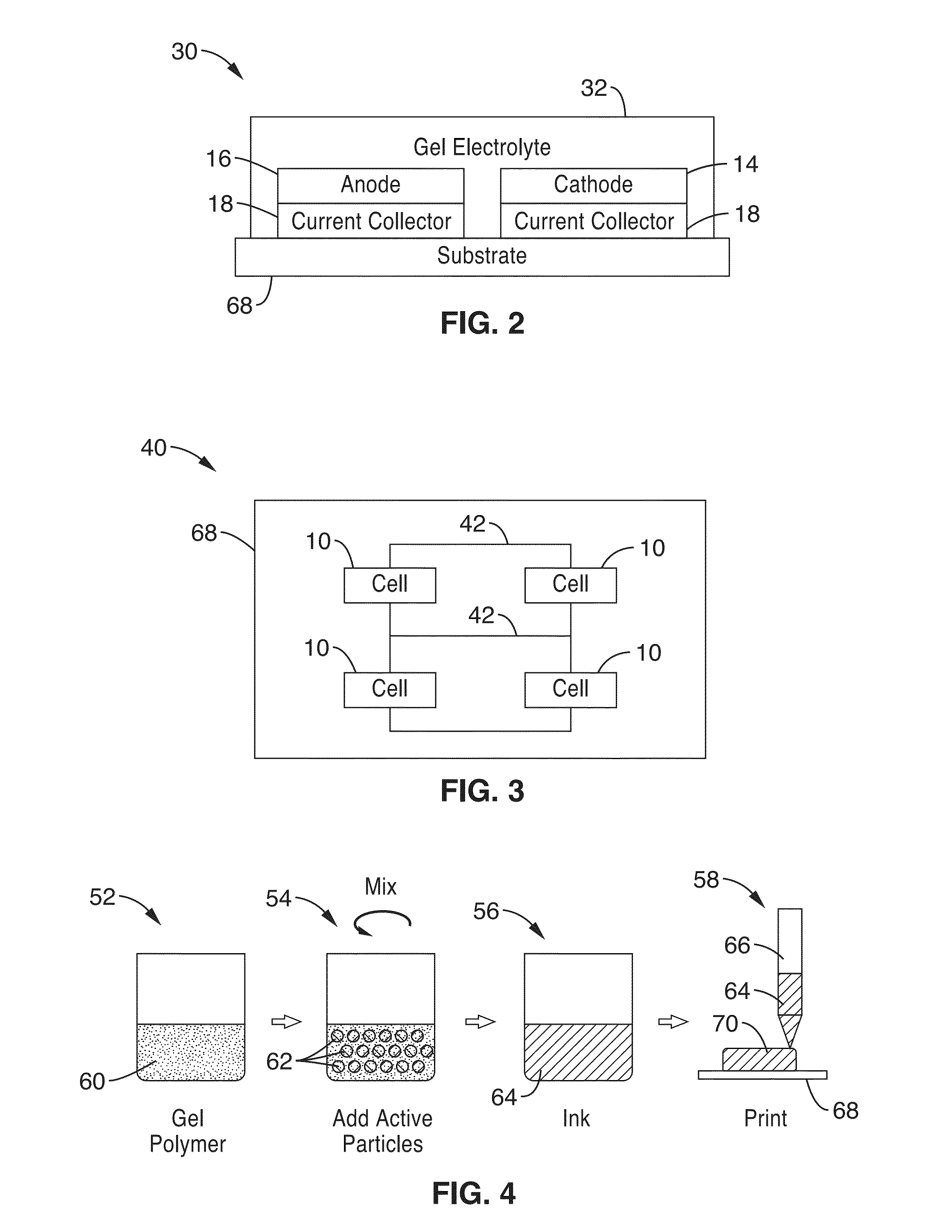

Ionic gel electrolyte, energy storage devices, and methods of manufacture thereof

ActiveUS20130280579A1Promote disseminationSolid electrolytic capacitorsLiquid electrolytic capacitorsPhysical separationElectrochemical cell

An electrochemical cell includes solid-state, printable anode layer, cathode layer and non-aqueous gel electrolyte layer coupled to the anode layer and cathode layer. The electrolyte layer provides physical separation between the anode layer and the cathode layer, and comprises a composition configured to provide ionic communication between the anode layer and cathode layer by facilitating transmission of multivalent ions between the anode layer and the cathode layer.

Owner:CCL LABEL INC +1

Process for the production of electrolyte capacitors

ActiveUS20080005878A1Lower equivalent series resistanceHeat stableCellsSolid electrolytic capacitorsElectrical resistance and conductanceElectrolysis

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current, electrolyte capacitors produced by this process and the use of such electrolyte capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

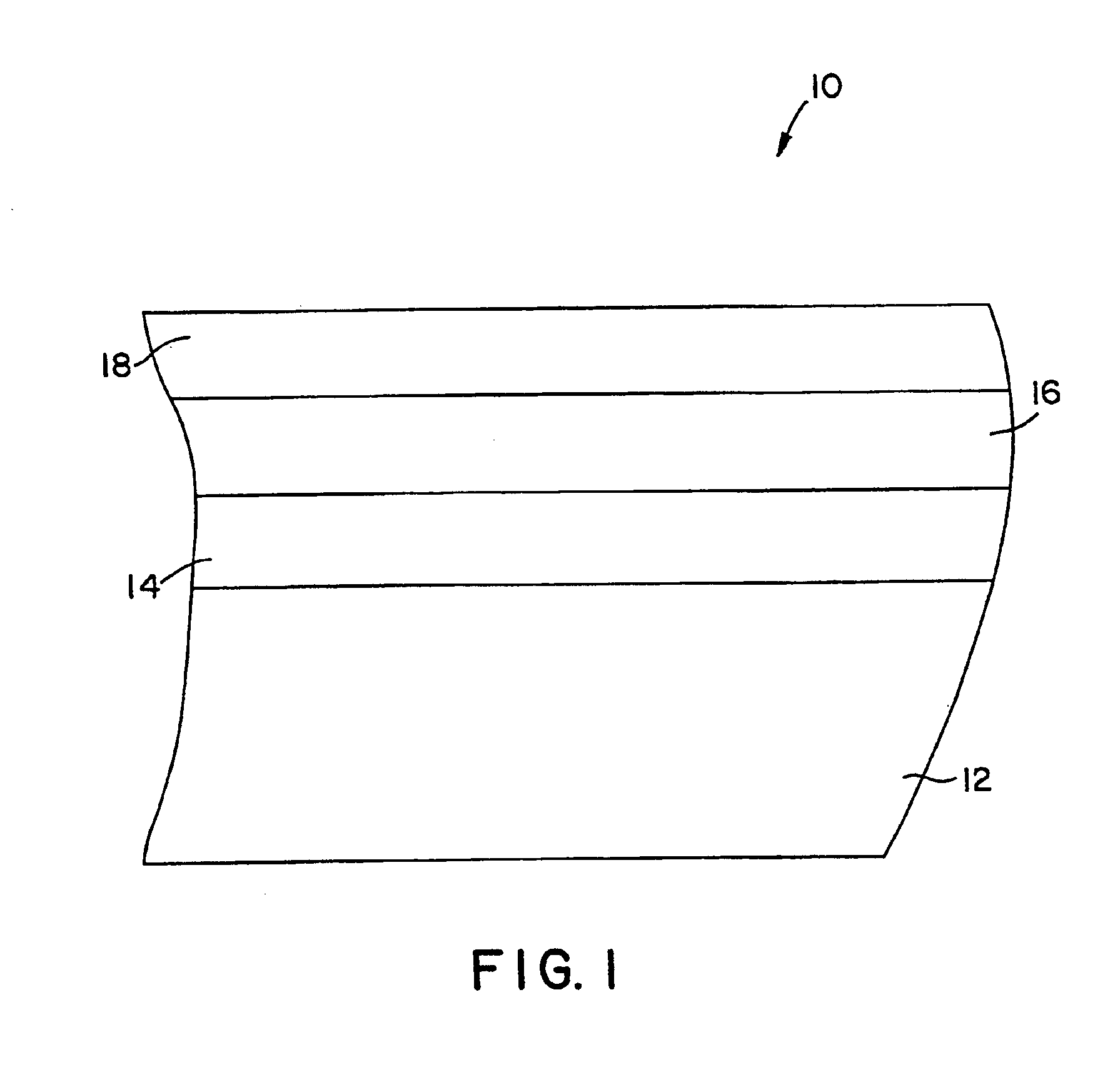

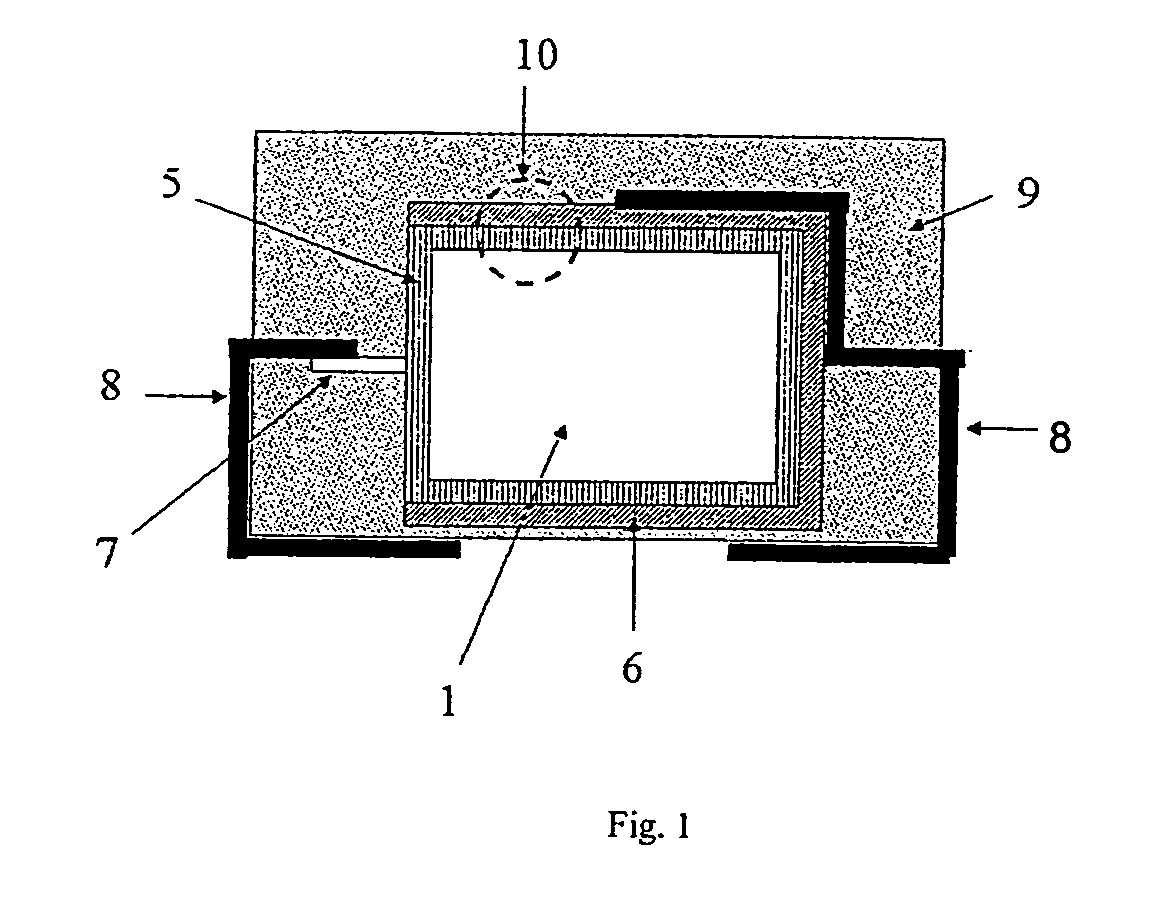

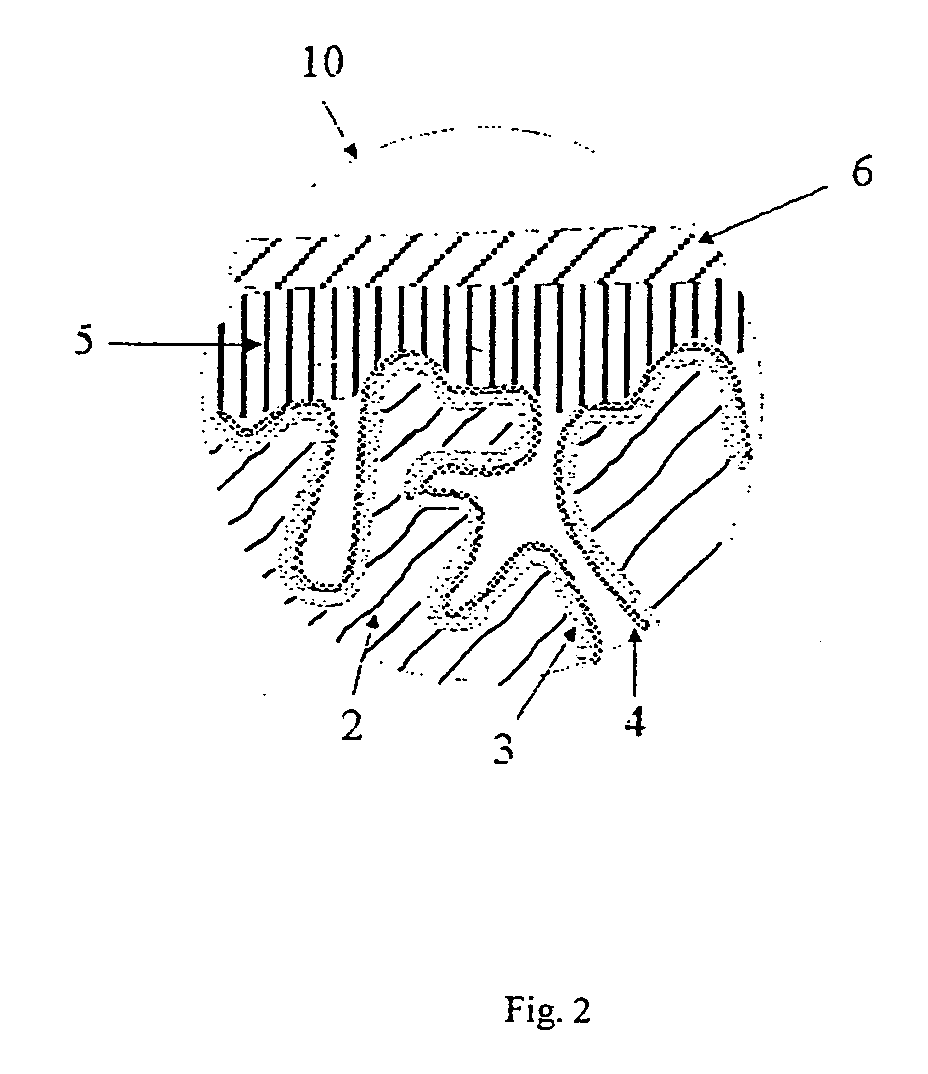

Protective coating for electrolytic capacitors

InactiveUS6864147B1Low dissipation factorLow leakage currentSolid electrolytic capacitorsSemiconductor/solid-state device manufacturingShellacElectrolysis

A solid electrolytic capacitor that comprises an anode that contains a valve-action metal (e.g., tantalum, niobium, and the like) and a dielectric film overlying the anode is provided. The capacitor also comprises a protective coating overlying the dielectric film, wherein the protective coating contains a relatively insulative, resinous material. For example, in one embodiment, the resinous material can be a drying oil, such as olive oil, linseed oil, tung oil, castor oil, soybean oil, shellac, and derivatives thereof. The capacitor also comprises a conductive polymer coating overlying the protective coating. As a result of the present invention, it has been discovered that a capacitor can be formed that can have a relatively low leakage current, dissipation factor, and equivalents series resistance.

Owner:KYOCERA AVX COMPONENTS CORP

Solid electrolytic capacitor and manufacturing method thereof

InactiveUS6215652B1Avoid volatilityIncrease capacitanceLiquid electrolytic capacitorsFixed capacitor dielectricElectrolysisMetal powder

A solid electrolytic capacitor is here disclosed in which a dielectric layer formed on the surface of an anode obtained by molding and then sintering a niobium metal powder which includes a niobium oxide layer and a niobium nitride region, and a method for manufacturing the solid electrolytic capacitor is also disclosed.

Owner:TOKIN CORP

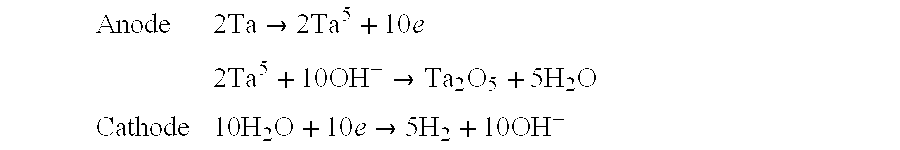

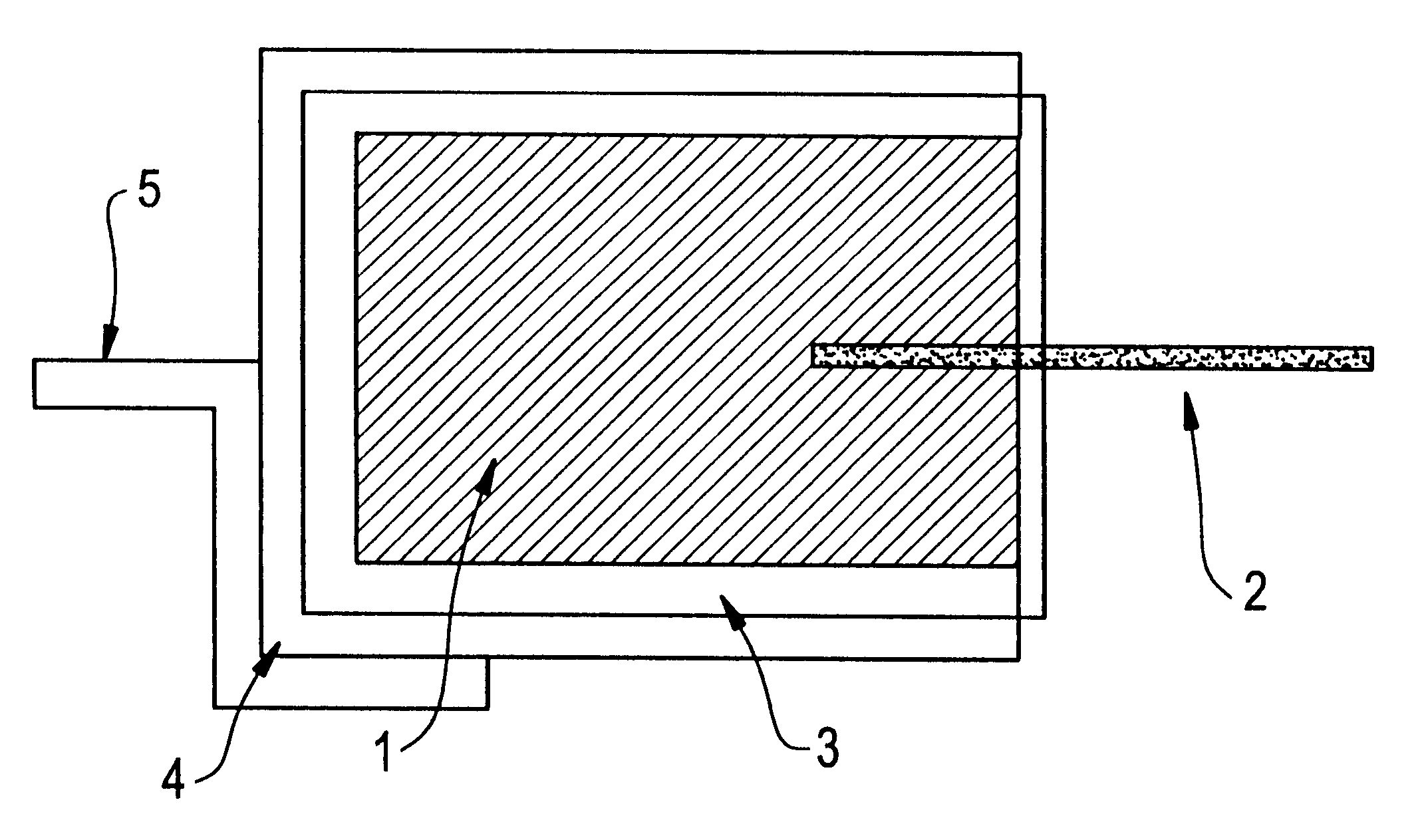

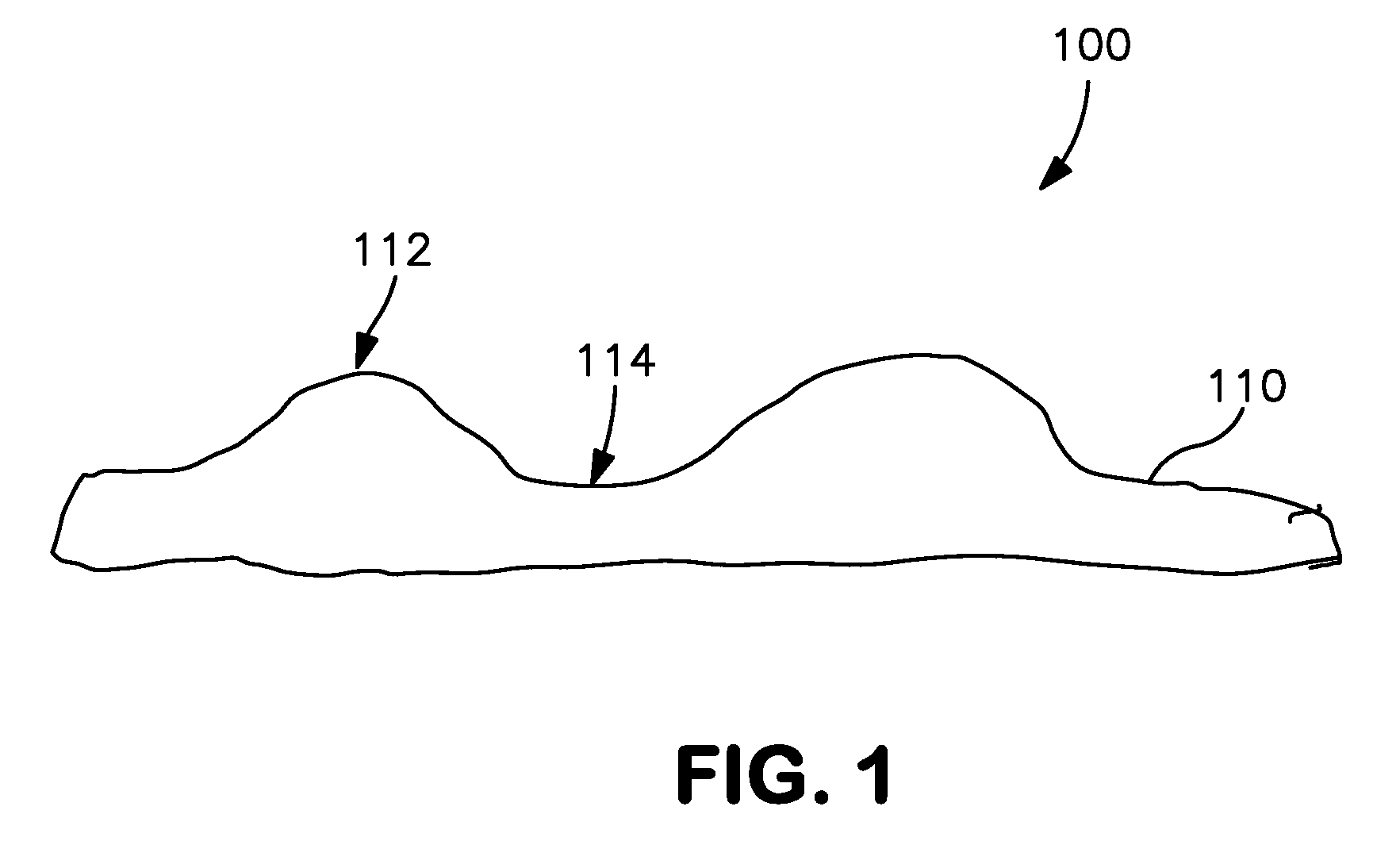

Cathode for Use in a Wet Capacitor

A cathode containing a metal substrate that possesses a micro-roughened surface imparted by spark anodization is provided. The surface is formed by contacting the substrate with an electrolytic solution and applying a voltage to form a dielectric sub-oxide layer. The voltage is raised to a sufficiently high level to initiate “sparking” at the surface of the substrate, which is believed to create high local surface temperatures sufficient to etch away the substrate. This results in the formation of a “micro-roughened” surface having a plurality elevated regions. These elevated regions can increase the effective surface area and thus allow for the formation of capacitors with increased cathode capacitance for a given size and / or capacitors with a reduced size for a given capacitance. The elevated regions may also exhibit excellent adhesion to additional electrochemically-active materials and provide enhanced stability in certain liquid electrolytes.

Owner:AVX CORP

Wet electrolytic capacitor containing a gelled working electrolyte

ActiveUS9105401B2Hybrid capacitor electrolytesCapacitor electrolytes/absorbentsElectrolysisConductive polymer

A wet electrolytic capacitor is provided. The capacitor contains an anode comprising an anodically oxidized pellet formed from a pressed and sintered powder, a cathode that contains a metal substrate coated with a conductive polymer, and a working electrolyte in communication with the anode and the cathode. The working electrolyte is in the form of a gel and comprises an ammonium salt of an organic acid, inorganic oxide particles, an acid, and a solvent system that comprises water. The working electrolyte has a pH value of from about 5.0 to about 8.0.

Owner:KYOCERA AVX COMPONENTS CORP

Process for the production of electrolyte capacitors

ActiveUS8058135B2Lower equivalent series resistanceHeat stableSolid electrolytic capacitorsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceElectrolysis

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Conductive polymer solution, conductive coating, condenser and process for manufacturing condenser

ActiveUS20090021894A1Improve conductivityLow ESRNon-metal conductorsHybrid capacitor separatorsHeat resistanceConductive coating

The object of the present invention is to provide a condenser that exhibits excellent conductivity of the solid electrolyte layer, and has a low ESR, a high degree of heat resistance, and a high withstand voltage. A condenser of the present invention includes an anode composed of a valve metal, a dielectric layer formed by oxidation of the surface of the anode, and a solid electrolyte layer formed on the surface of the dielectric layer, wherein the solid electrolyte layer contains a π-conjugated conductive polymer, a polyanion, and an amide compound.

Owner:SHIN-ETSU POLYMER CO LTD

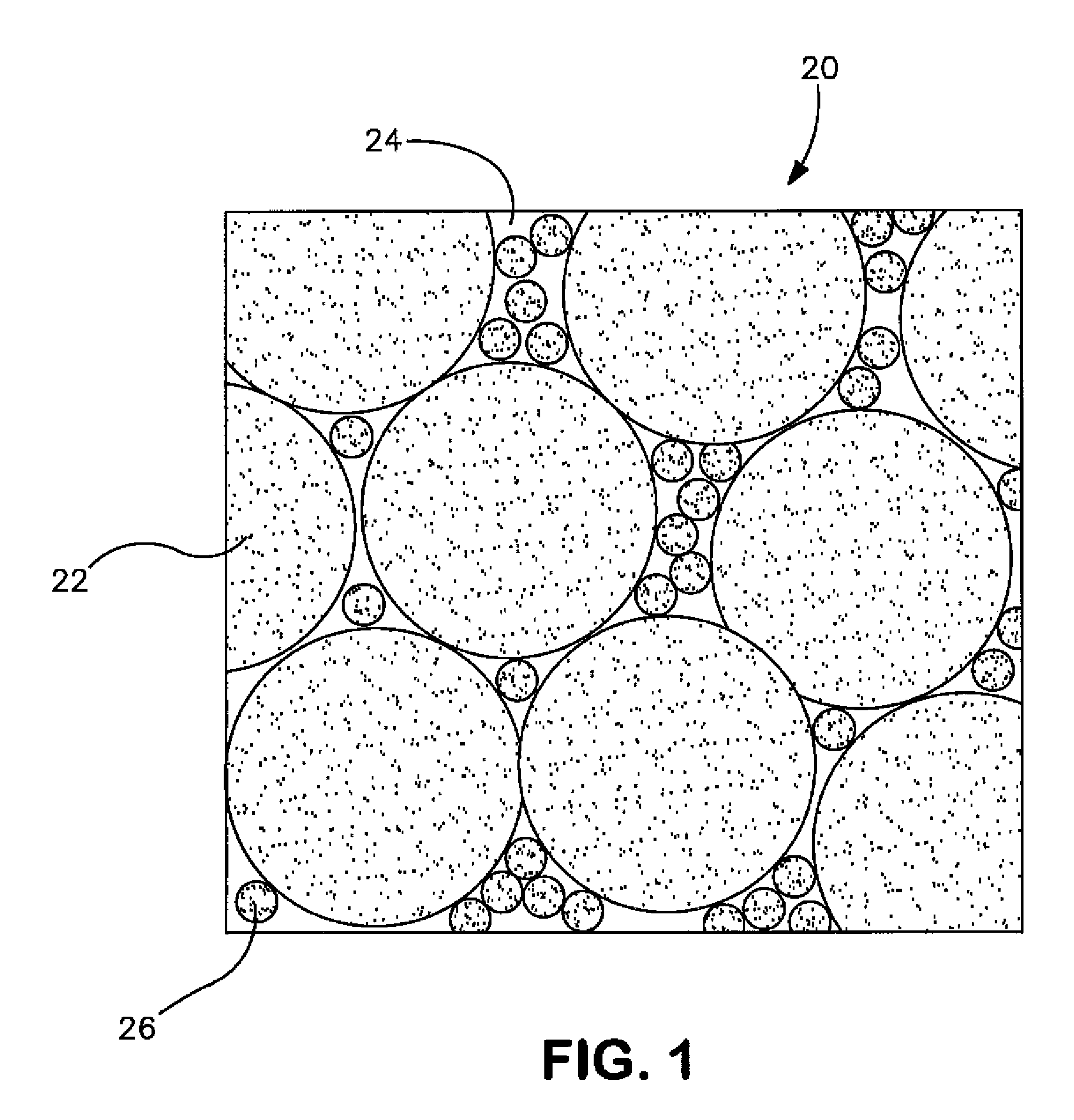

Capacitor Anode Formed From a Powder Containing Coarse Agglomerates and Fine Agglomerates

A pressed anode formed from an electrically conductive powder that contains a plurality of coarse agglomerates and fine agglomerates is provided. The fine agglomerates have an average size smaller than that of the coarse agglomerates so that the resulting powder contains two or more distinct particle sizes, i.e., a “bimodal” distribution. In this manner, the fine agglomerates can effectively occupy the pores defined between adjacent coarse agglomerates (“inter-agglomerate pores”). Through the occupation of the empty pores, the fine agglomerates can increase the apparent density of the resulting powder, which improves volumetric efficiency.

Owner:AVX CORP

Electrolyte capacitors having a polymeric outer layer and process for their production

ActiveUS20060236531A1Increase coverageHybrid capacitor electrolytesHybrid capacitor electrodesElectrical resistance and conductanceElectrolysis

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current, and which comprise a solid electrolyte of conductive polymers and an outer layer comprising conductive polymers applied in the form of a dispersion. Electrolyte capacitors produced by this process and the use of such electrolyte capacitors are also provided.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

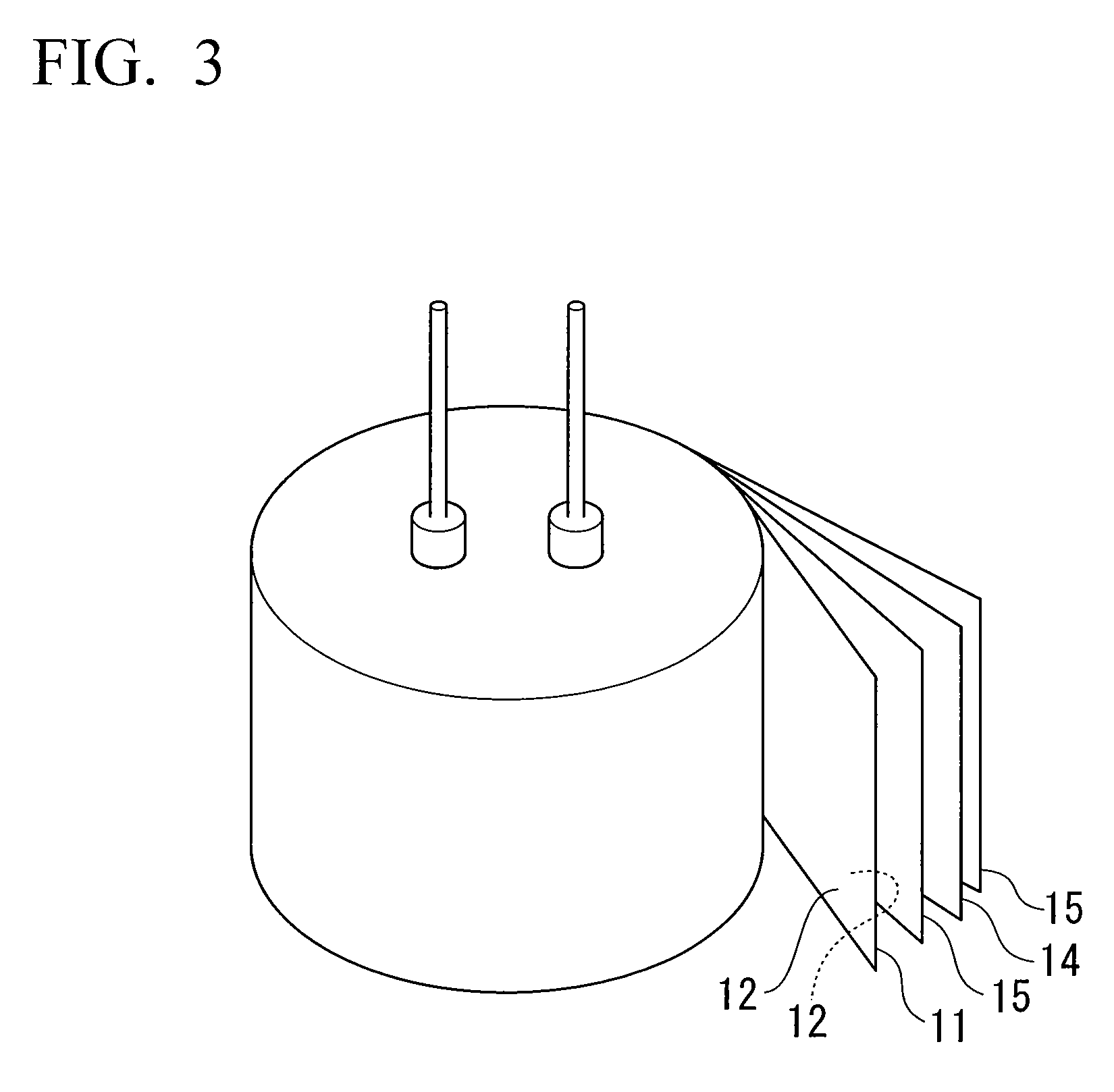

Solid electrolytic capacitor and method for producing the same

ActiveUS7388741B2Increase capacitanceLower equivalent series resistanceSolid electrolytic capacitorsLiquid electrolytic capacitorsCapacitanceConductive polymer

Owner:MURATA MFG CO LTD

Conductive polymer and method for producing the same, conductive polymer dispersion, and solid electrolytic capacitor and method for producing the same

InactiveUS20110233450A1Improve conductivityLow ESRHybrid capacitor electrolytesSolid electrolytic capacitorsPolymer sciencePersulfate

The present exemplary embodiment provides a conductive polymer having high conductivity and a method for producing the same, and a conductive polymer dispersion, and further provides a solid electrolytic capacitor having low ESR and a method for producing the same. A conductive polymer is produced by a method including the steps of dissolving a sulfonic acid group-containing resin having a weight average molecular weight of 2,000 or more and 50,000 or less and a compound represented by the following formula (1) in a solvent; mixing at least one monomer selected from pyrrole, thiophene, and derivatives thereof in an obtained solution; subjecting the monomer to chemical oxidative polymerization, using a persulfate, to obtain a conductive polymer; and washing the conductive polymer to remove the compound represented by the formula (1) contained in the conductive polymer.CnHn+2(OH)n (1)wherein n represents an integer of 3 to 6.

Owner:TOKIN CORP

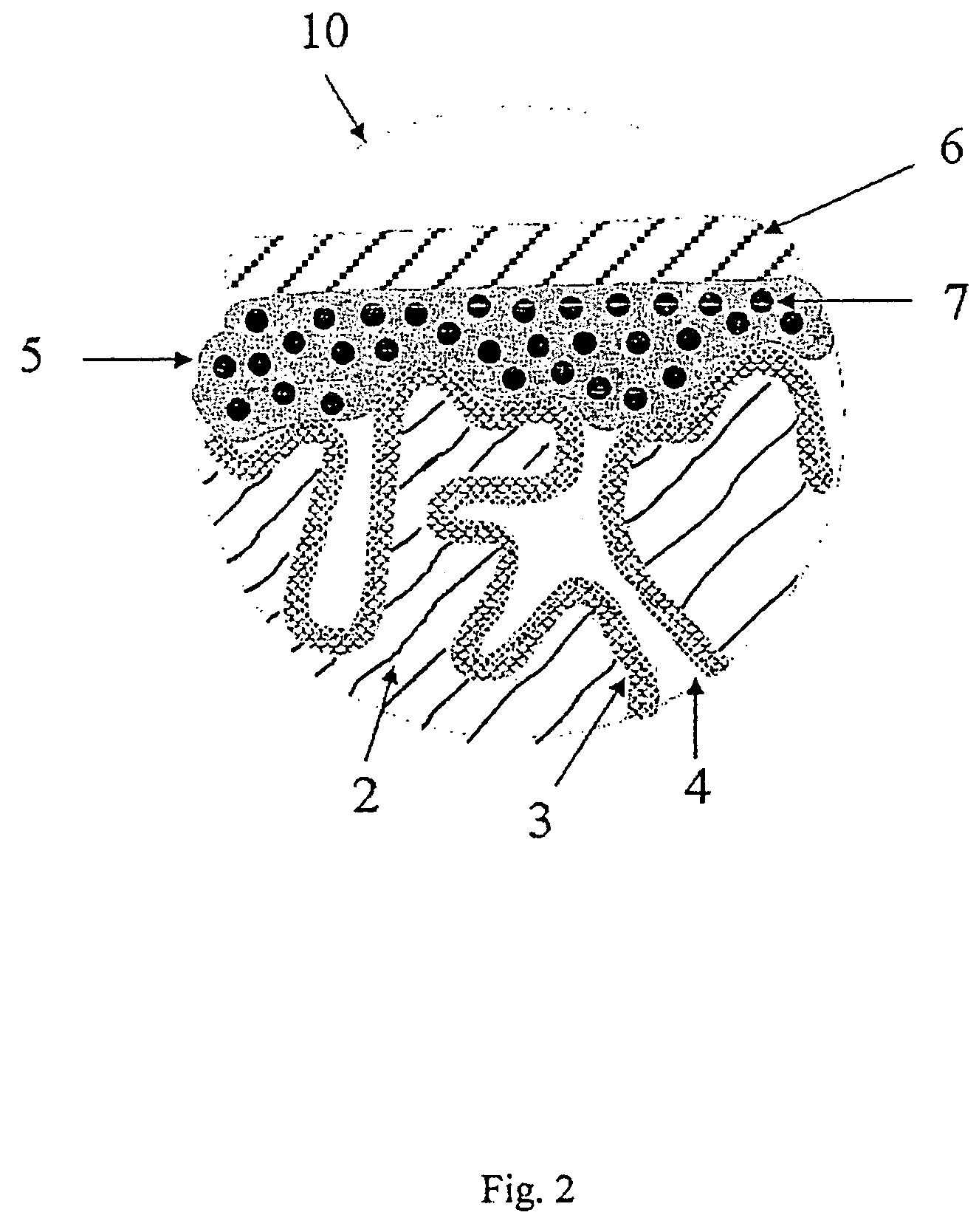

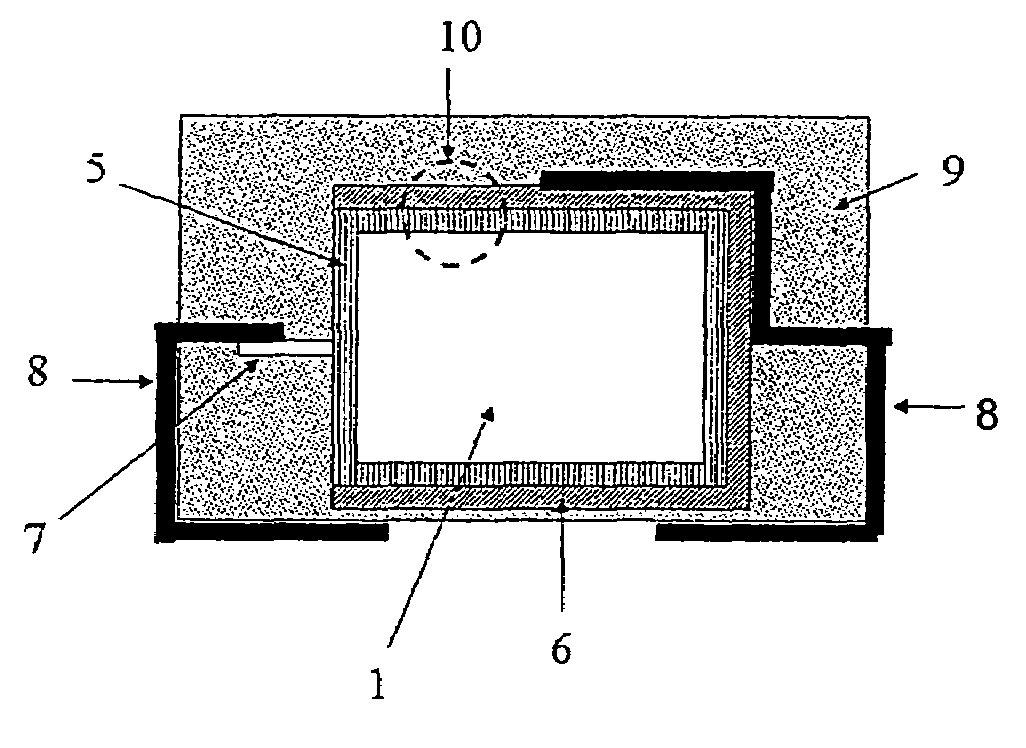

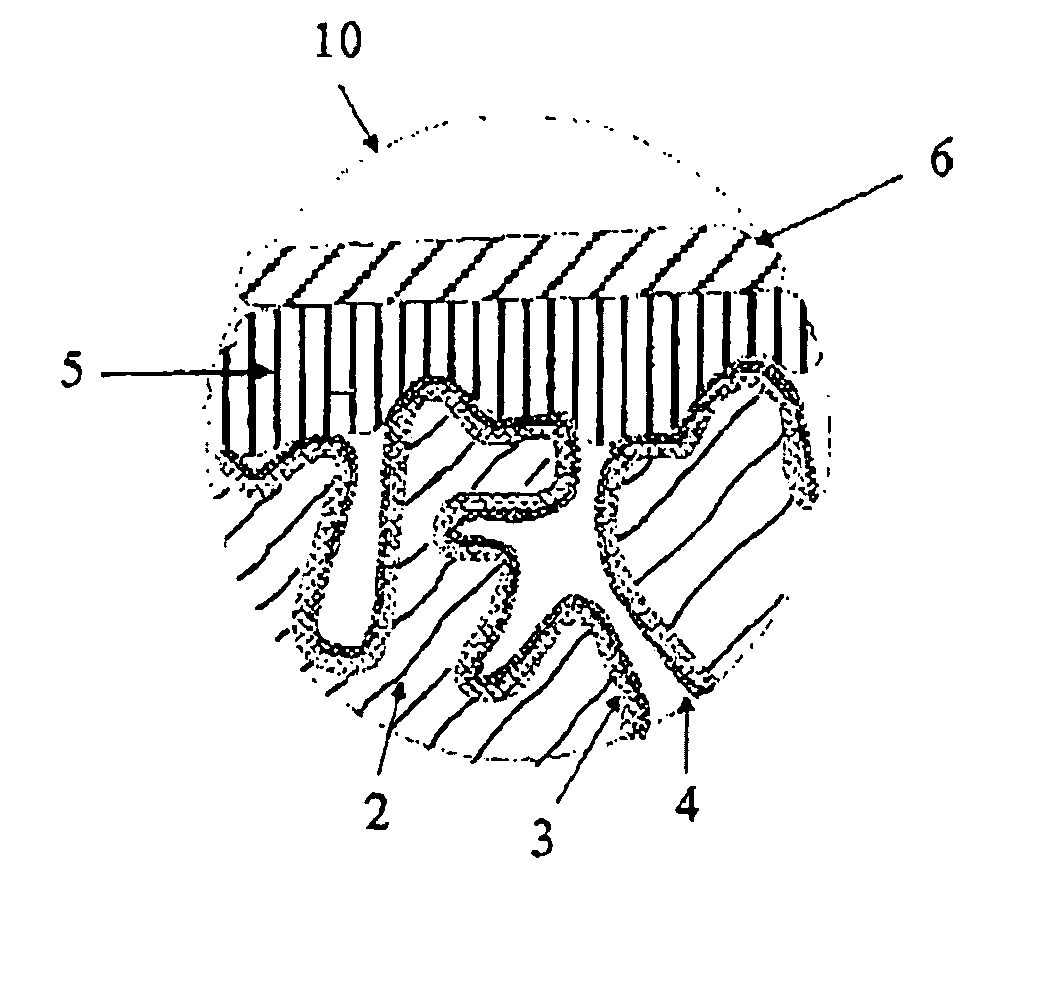

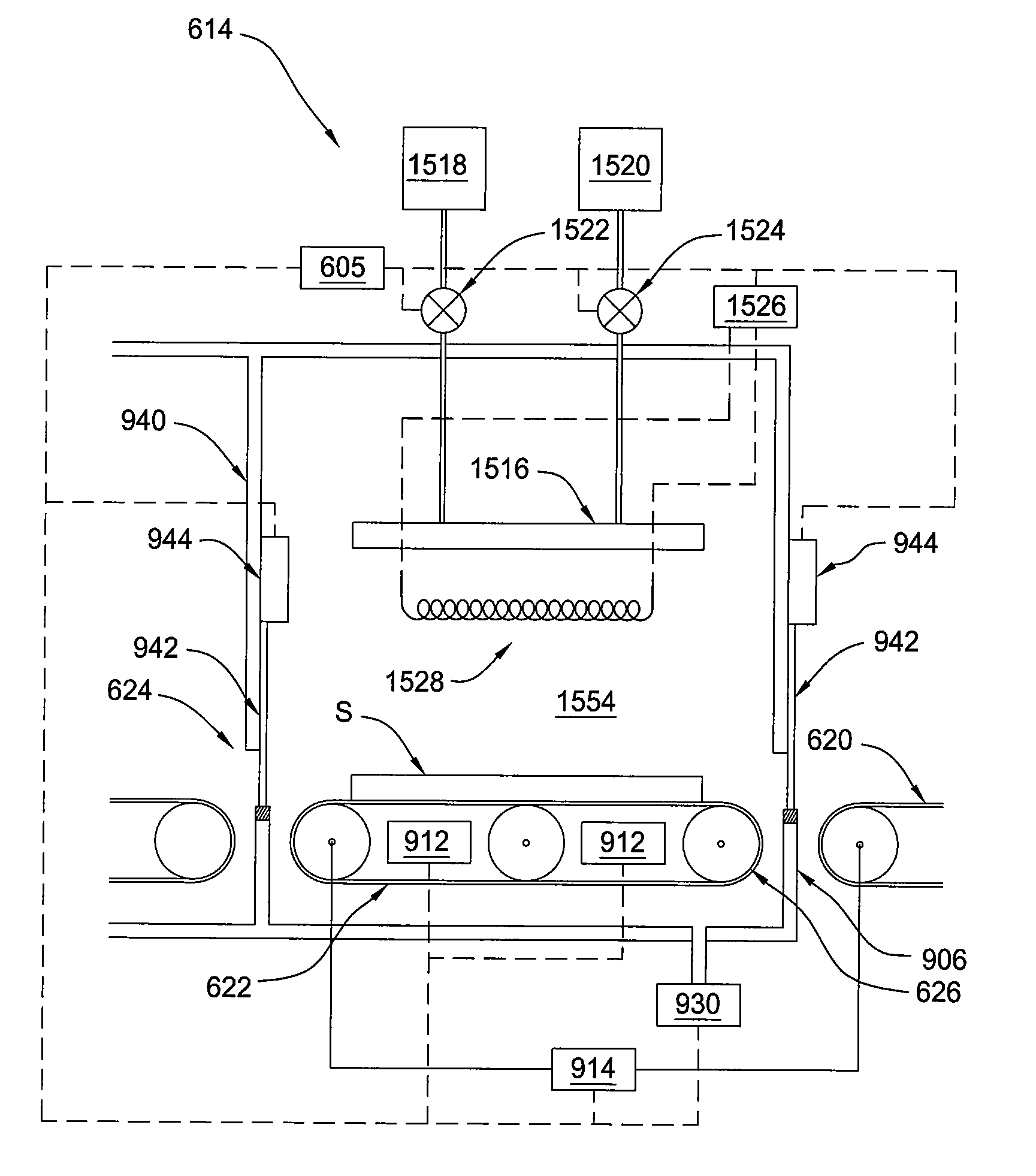

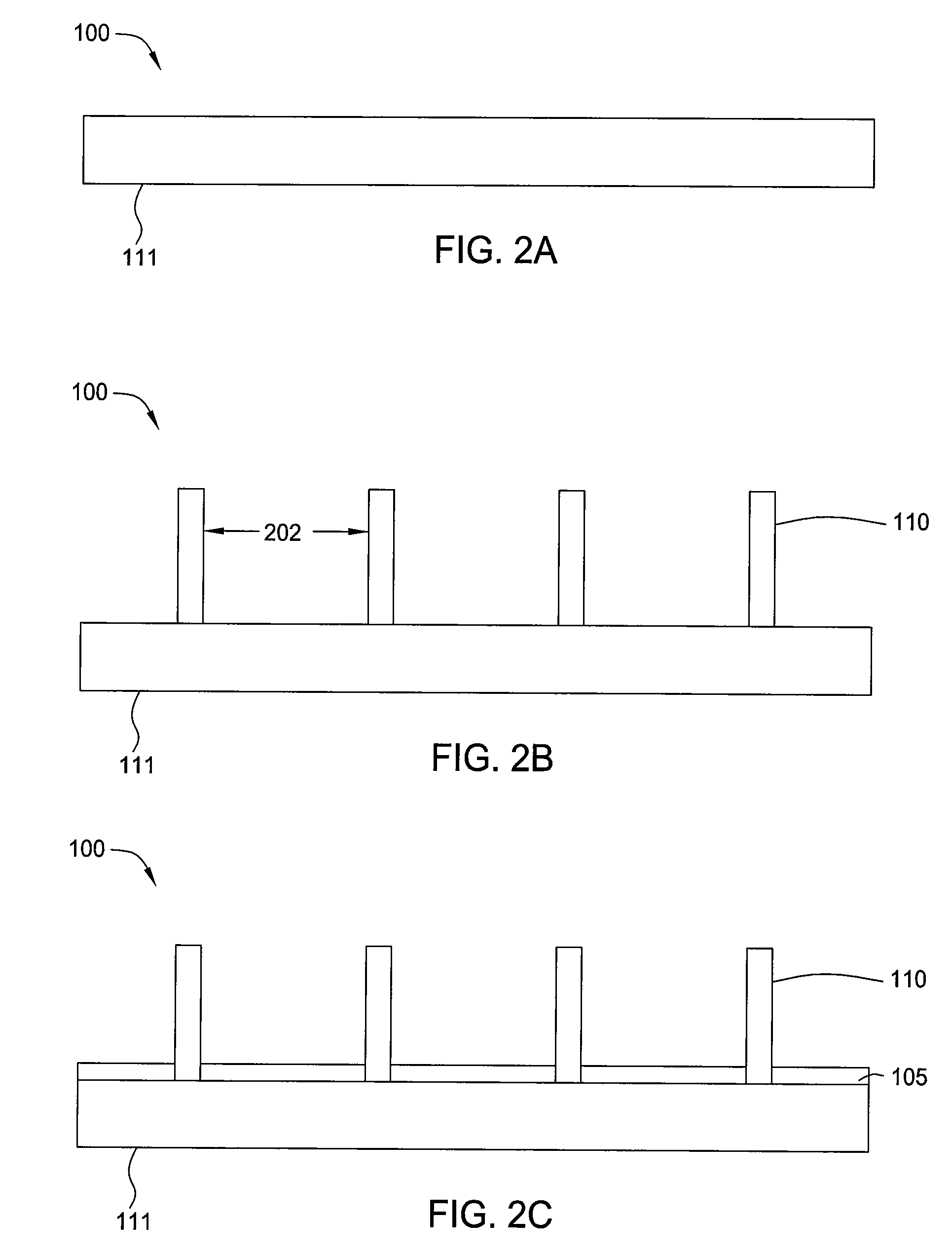

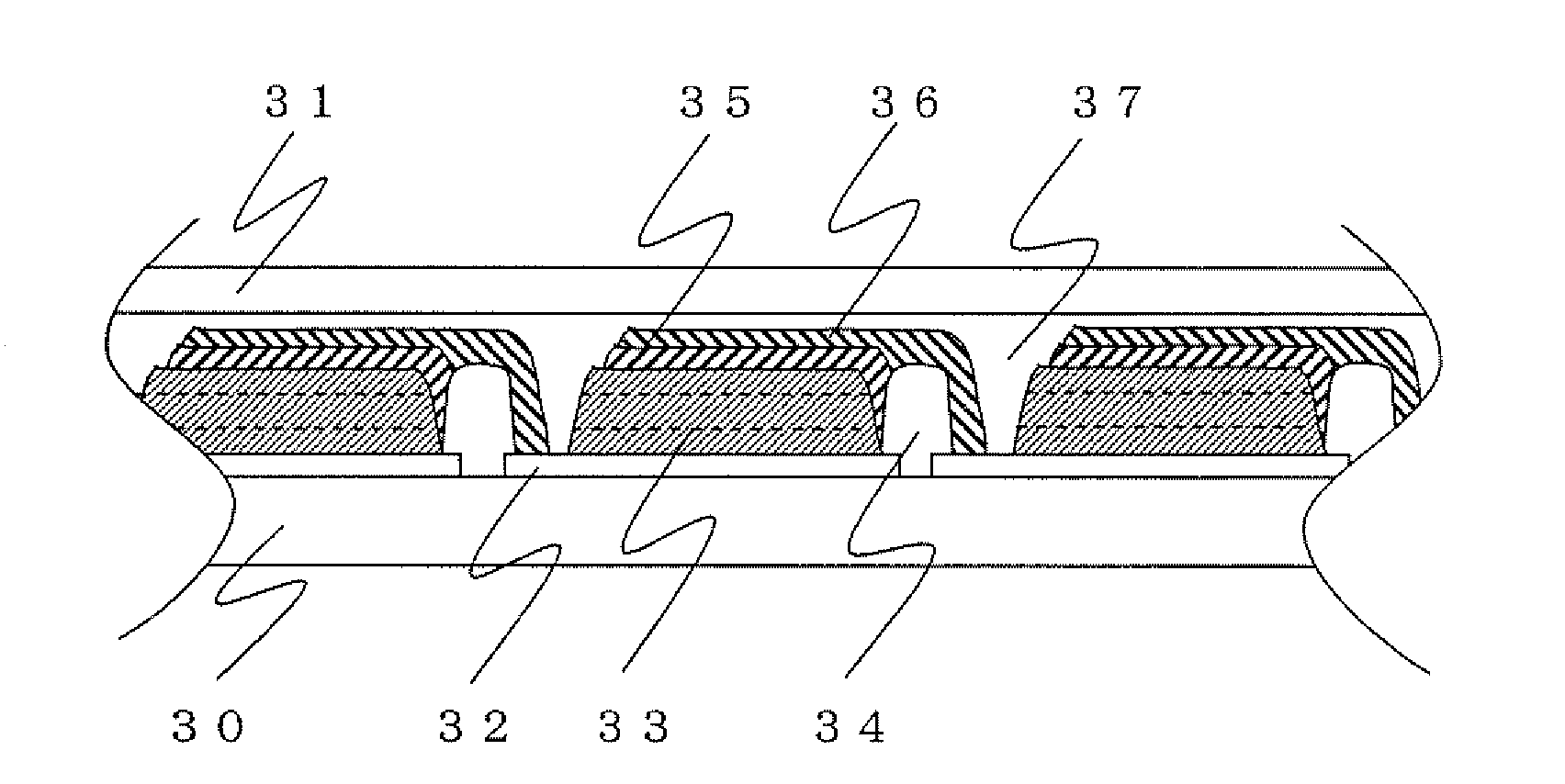

3D approach on battery and supercapacitor fabrication by initiation chemical vapor deposition techniques

Methods and apparatus for forming energy storage devices are provided. In one embodiment a method of producing an energy storage device is provided. The method comprises positioning an anodic current collector into a processing region, depositing one or more three-dimensional electrodes separated by a finite distance on a surface of the anodic current collector such that portions of the surface of the anodic current collector remain exposed, depositing a conformal polymeric layer over the anodic current collector and the one or more three-dimensional electrodes using iCVD techniques comprising flowing a gaseous monomer into the processing region, flowing a gaseous initiator into the processing region through a heated filament to form a reactive gas mixture of the gaseous monomer and the gaseous initiator, wherein the heated filament is heated to a temperature between about 300° C. and about 600° C., and depositing a conformal layer of cathodic material over the conformal polymeric layer.

Owner:APPLIED MATERIALS INC

Ionic gel electrolyte, energy storage devices, and methods of manufacture thereof

ActiveUS20140059820A1Promote disseminationSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrochemical cellChemical engineering

An electrochemical cell includes solid-state, printable anode layer, cathode layer and non-aqueous gel electrolyte layer coupled to the anode layer and cathode layer. The electrolyte layer provides physical separation between the anode layer and the cathode layer, and comprises a composition configured to provide ionic communication between the anode layer and cathode layer by facilitating transmission of multivalent ions between the anode layer and the cathode layer.

Owner:CCL LABEL INC +1

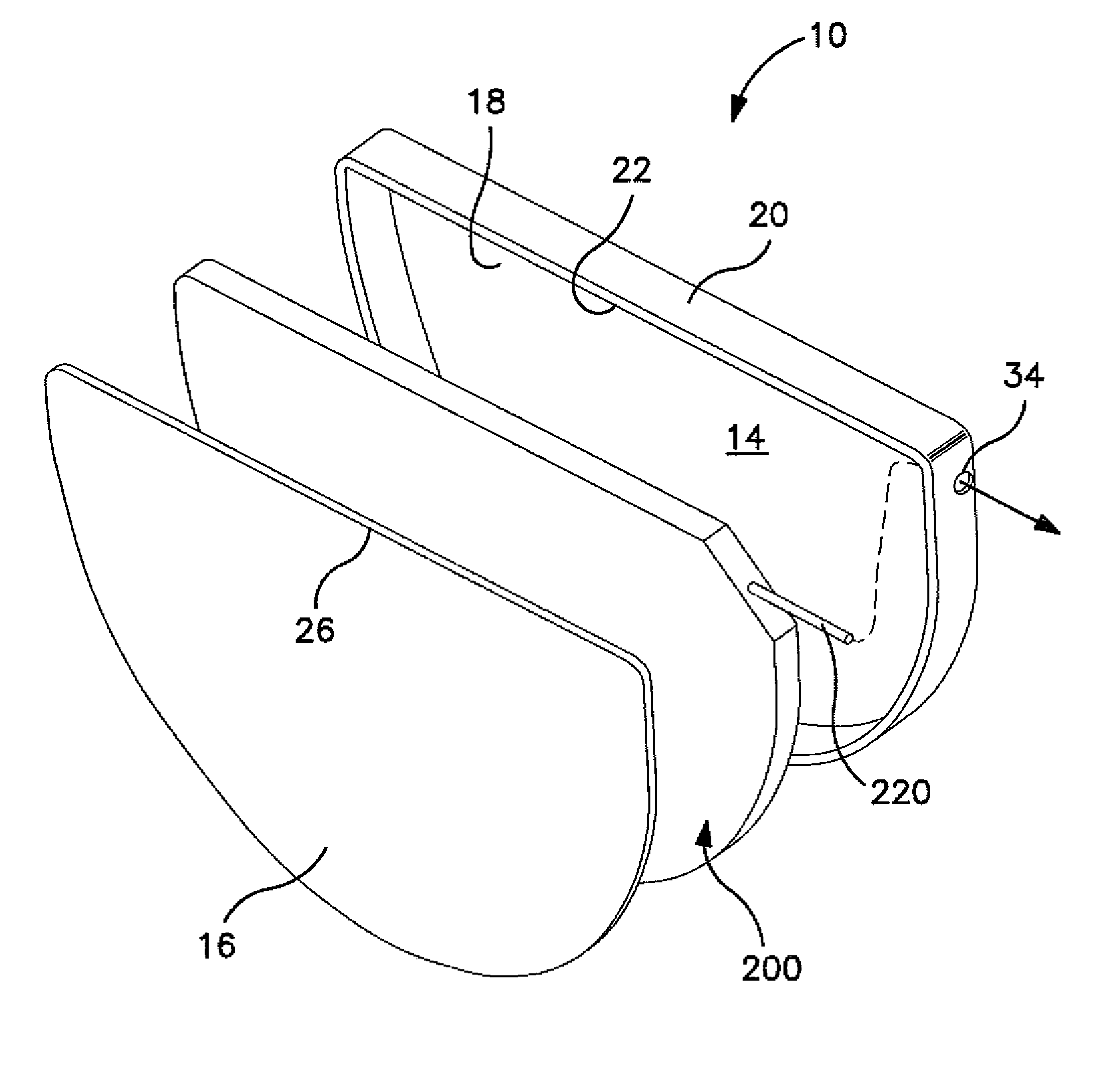

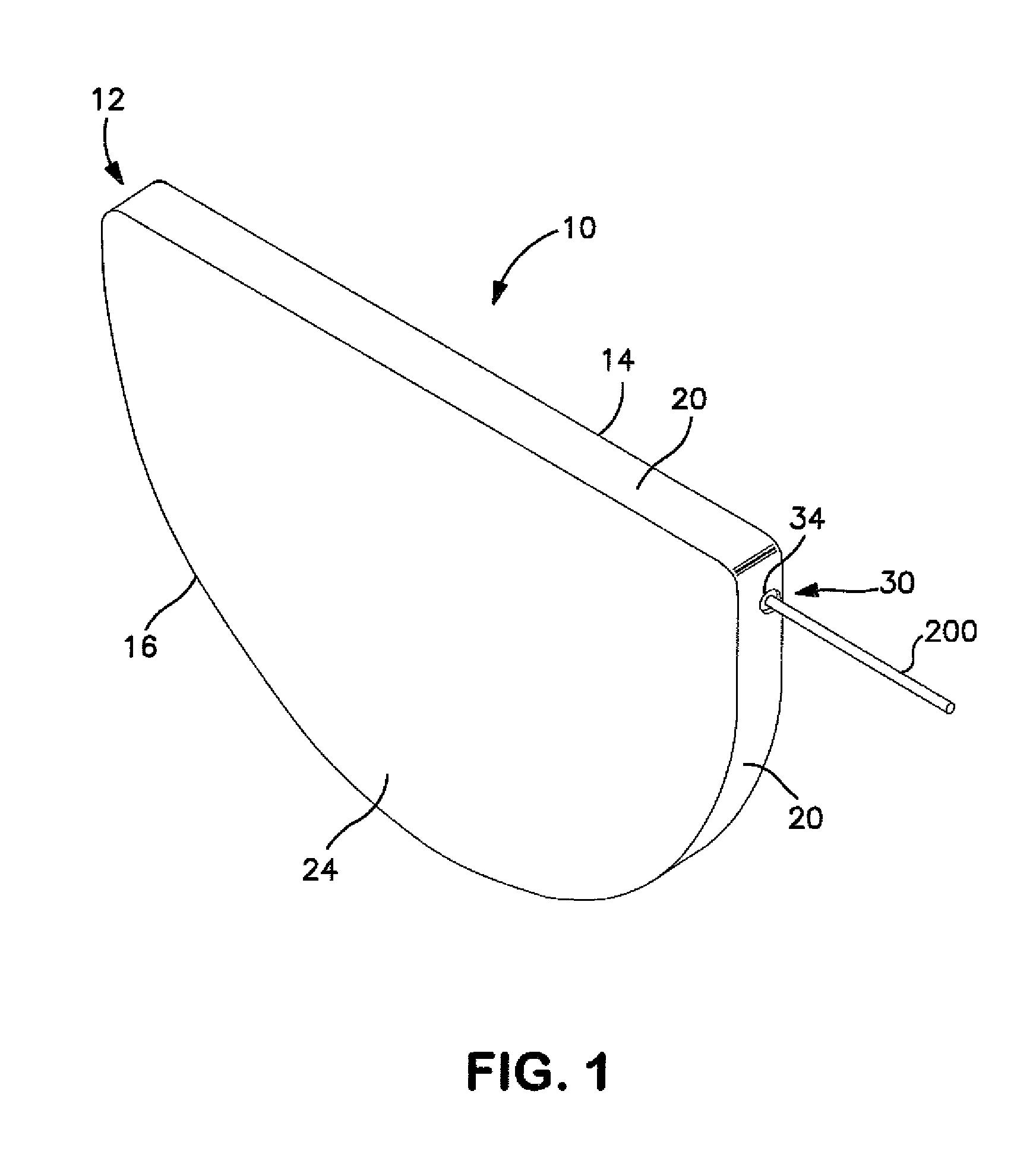

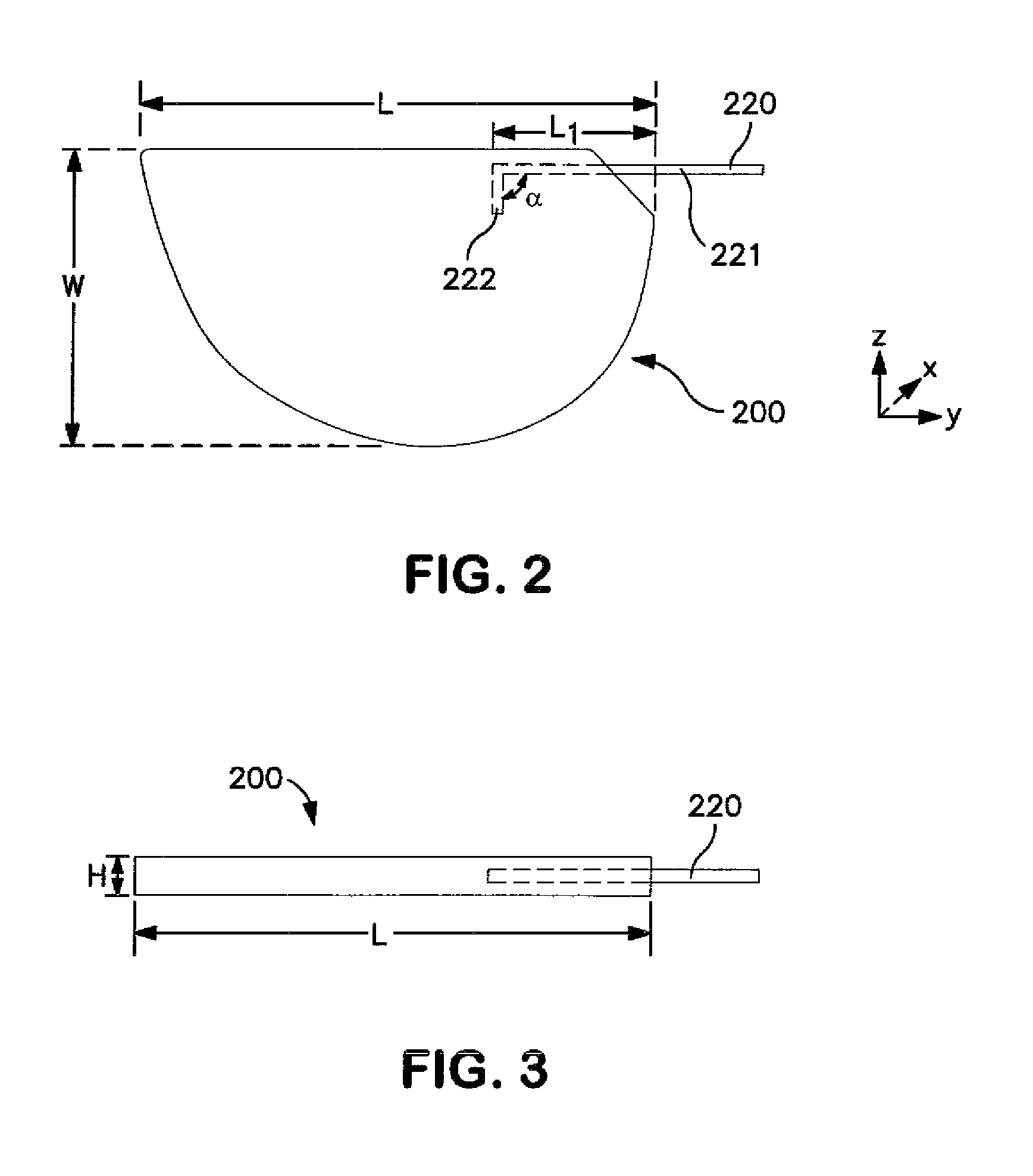

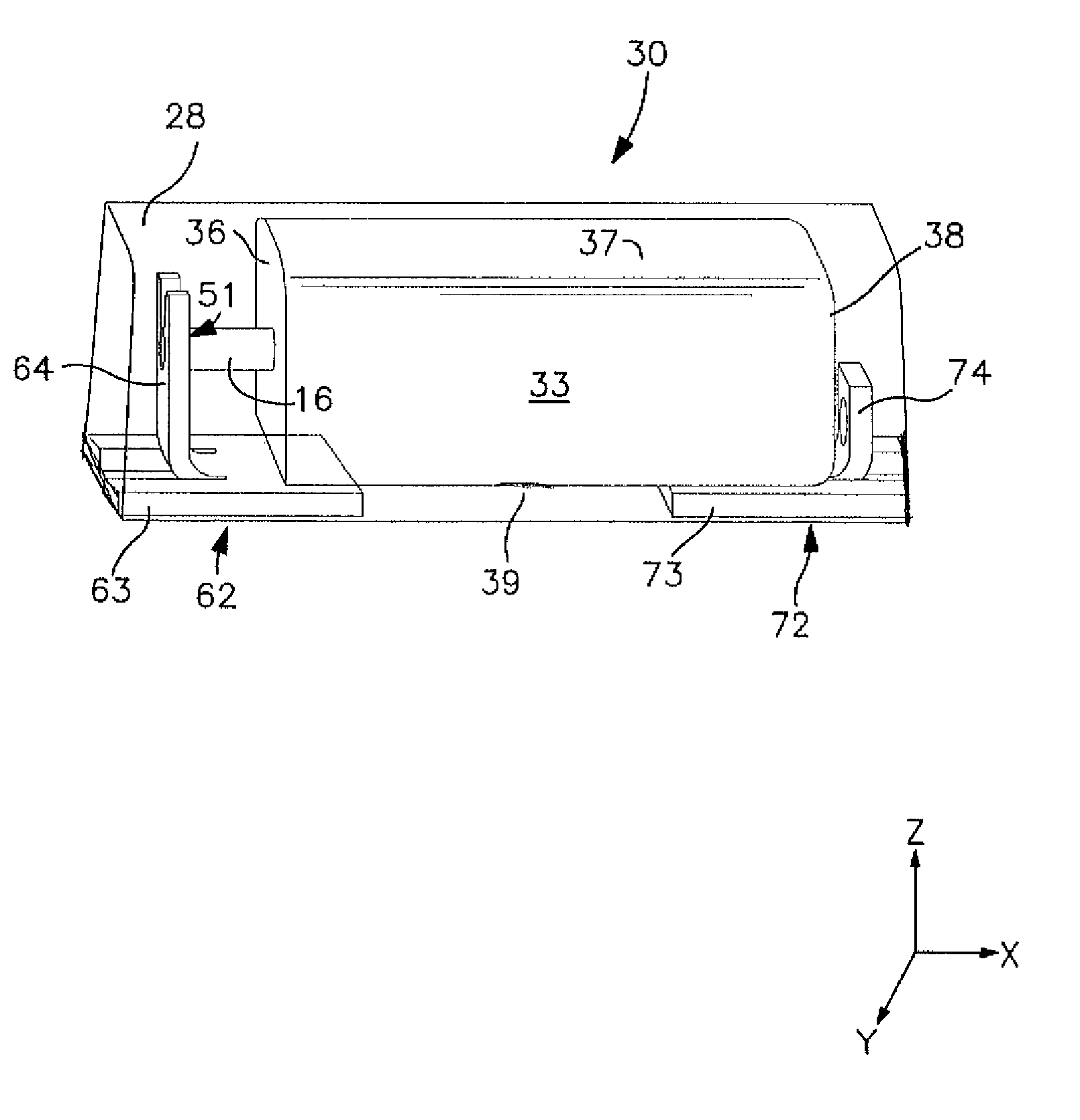

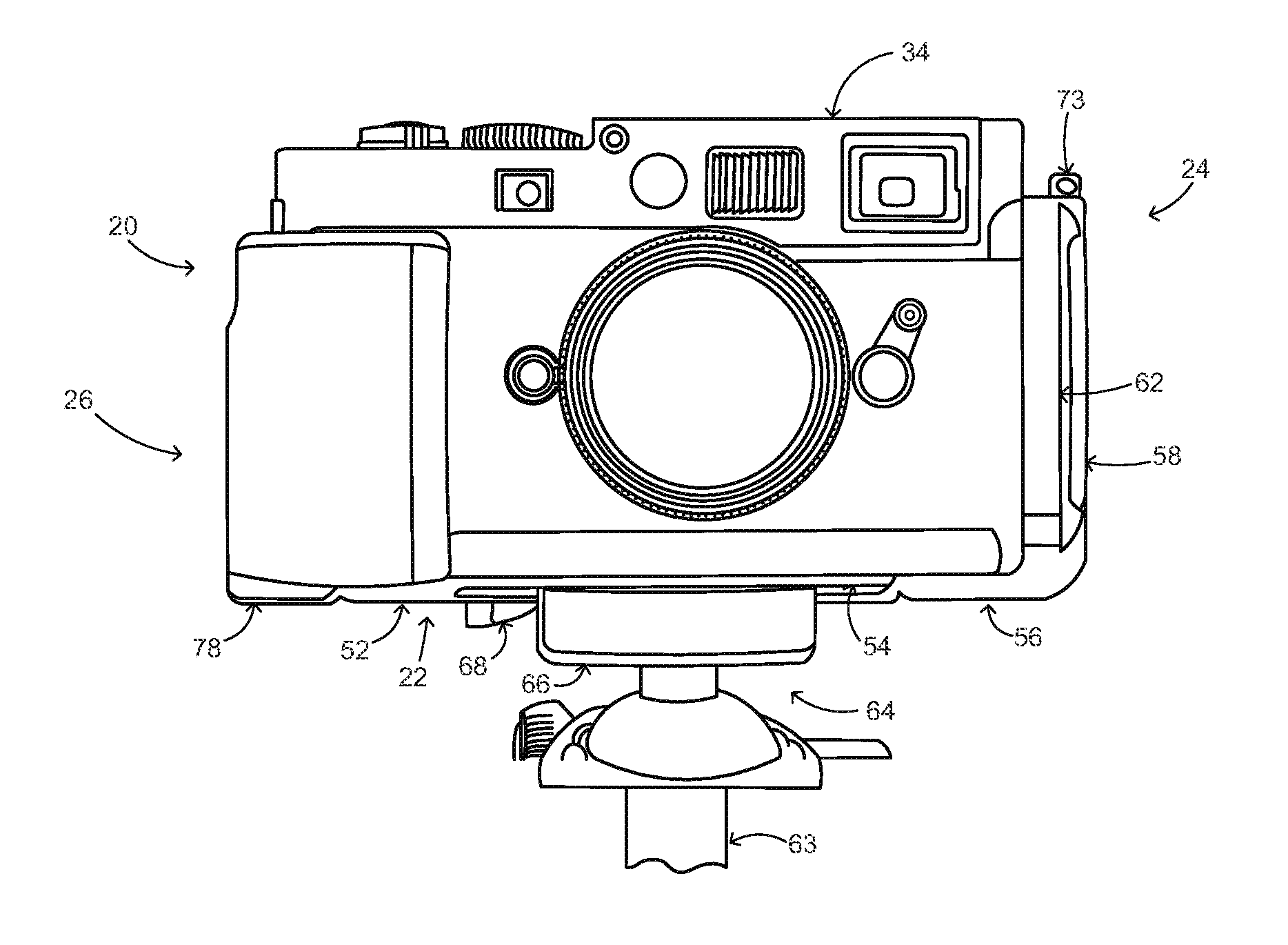

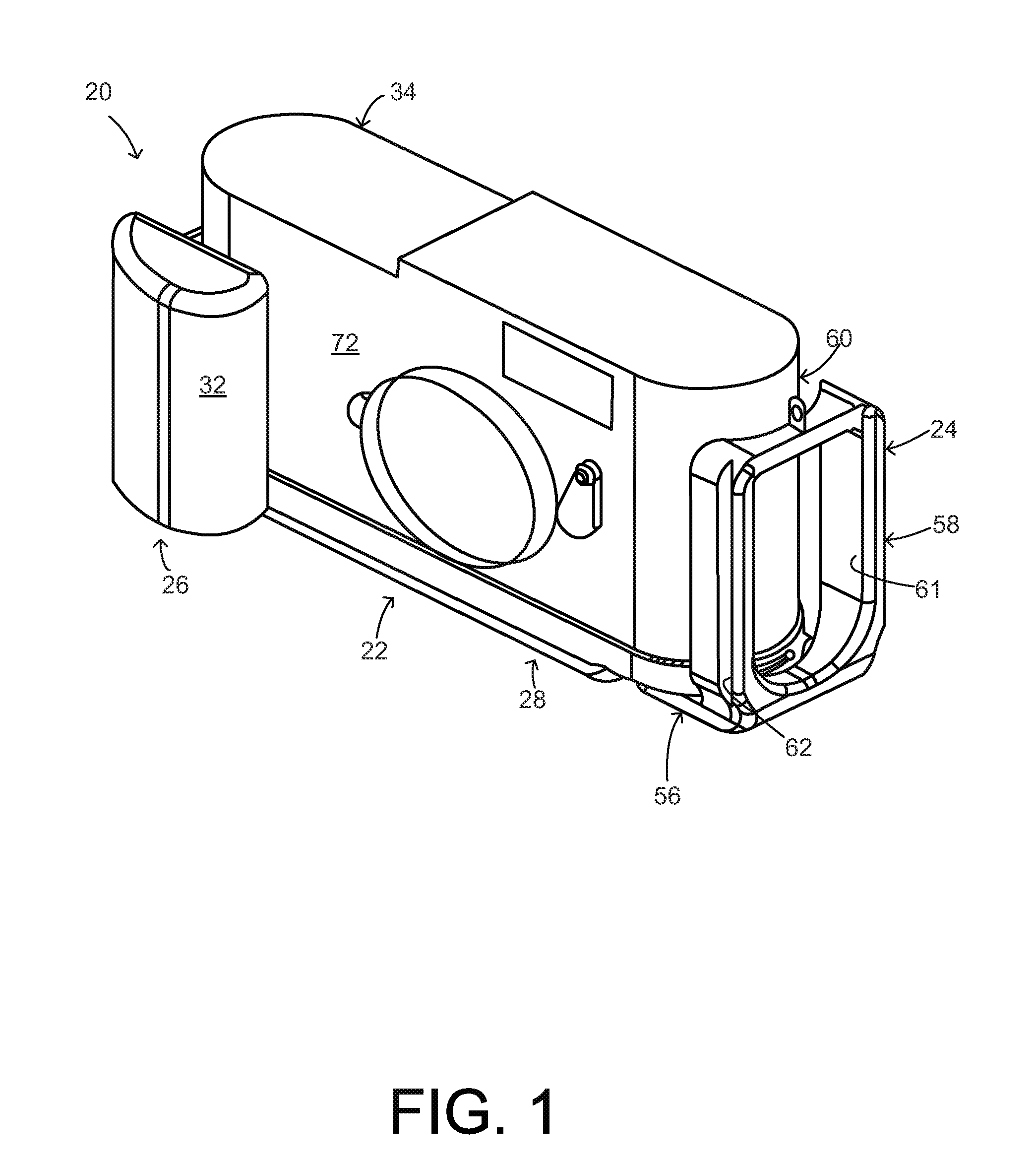

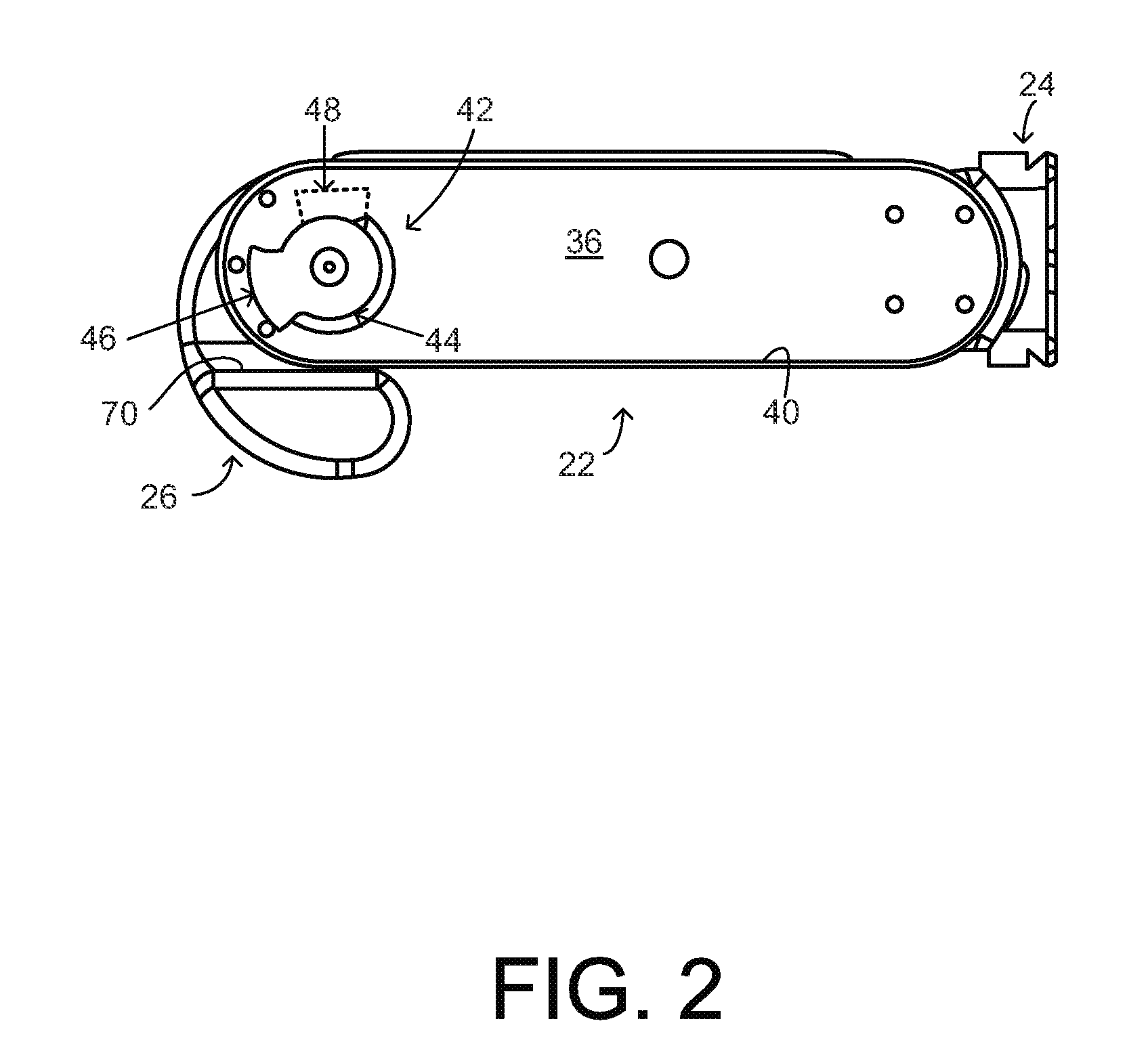

Camera mounting assembly

ActiveUS20120106944A1Improve balanceQuick installationSolid electrolytic capacitorsCapacitor electrolytes/absorbentsFast releaseMechanical engineering

A camera mounting assembly includes a base member or plate for holding a camera and a side member or plate. In an exemplary embodiment, lower slots on the base plate or side slots on the side plate are gripped by a vertical support's quick-release mechanism to mount the camera in a landscape or portrait orientation, respectively, the camera being generally centered and evenly balanced over the support in either case. The side member is detachably fastened to the base member, which modular construction permits separately timed purchase of the base member and side member as allowed by the user's budget and further permits breakdown of the assembly for ease of transport. The side member may be generally L-shaped with a lower arm length less than the side arm length, which also facilitates transport. Other components may be detachably added such as a hand grip facilitating freehand shooting with the camera.

Owner:REALLY RIGHT STUFF

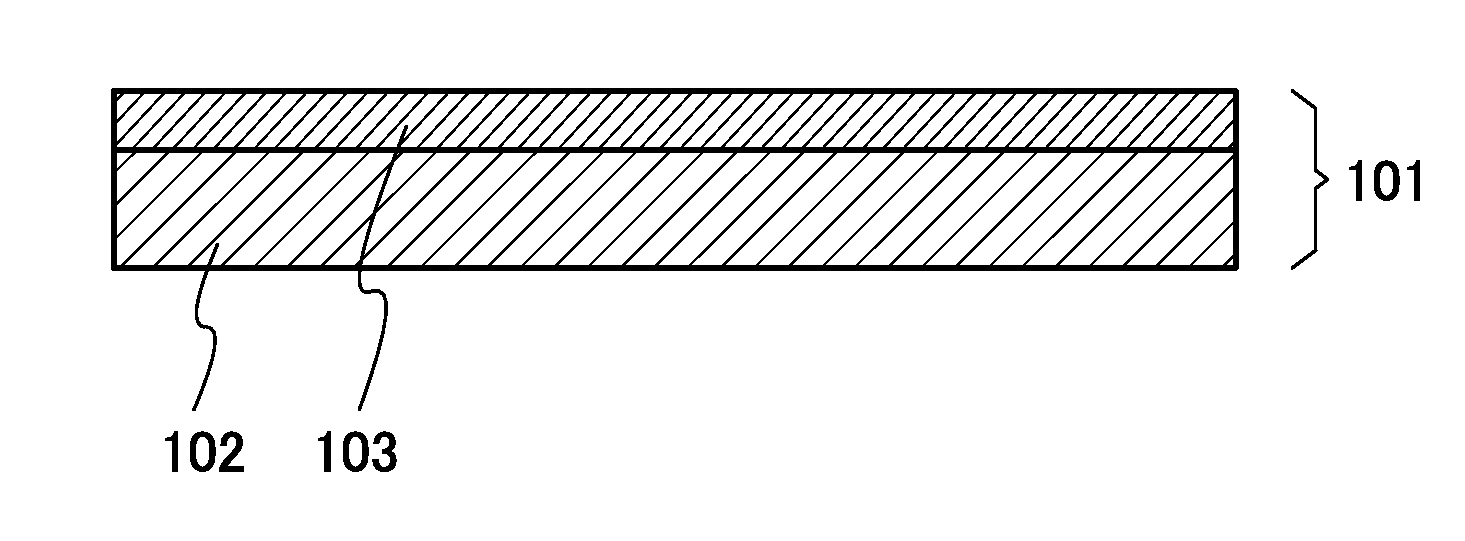

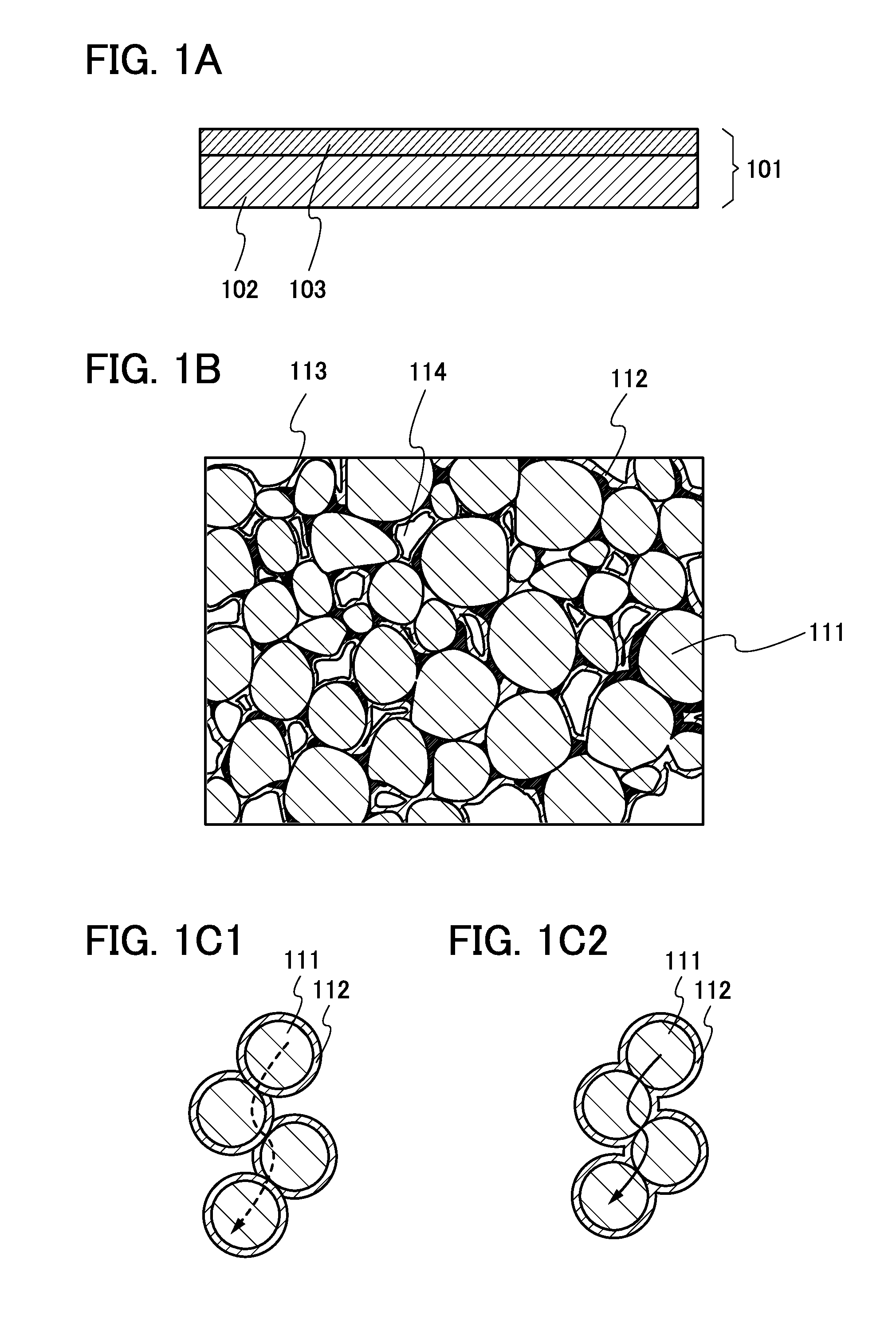

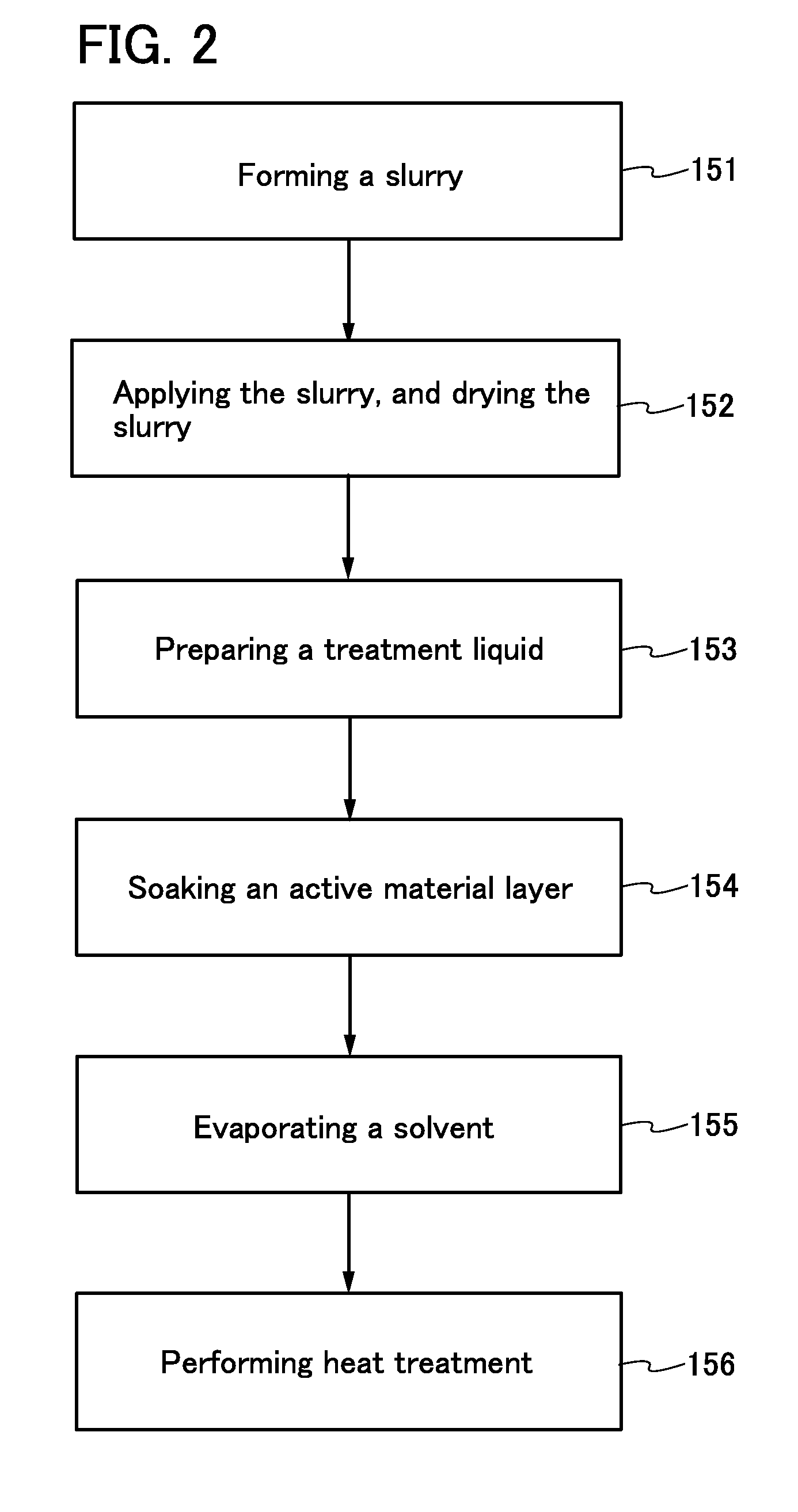

Electrode for power storage device, power storage device, and manufacturing method of electrode for power storage device

ActiveUS20140127567A1Minimize electrochemical decompositionMinimizing reactionHybrid capacitor electrodesActive material electrodesDecompositionSilicon oxide

To improve the long-term cycle performance of a lithium-ion battery or a lithium-ion capacitor by minimizing the decomposition reaction of an electrolytic solution and the like as a side reaction of charge and discharge in the repeated charge and discharge cycles of the lithium-ion battery or the lithium-ion capacitor. A current collector and an active material layer over the current collector are included in an electrode for a power storage device. The active material layer includes a plurality of active material particles and silicon oxide. The surface of one of the active material particles has a region that is in contact with one of the other active material particles. The surface of the active material particle except the region is partly or entirely covered with the silicon oxide.

Owner:SEMICON ENERGY LAB CO LTD

Electrolytic capacitors with a polymeric outer layer and process for the production thereof

ActiveUS20070171597A1Good edge coverageSimple and reliably reproducibleHybrid capacitor electrolytesSolid electrolytic capacitorsCapacitanceElectrolysis

The invention relates to a process for the production of electrolytic capacitors with low equivalent series resistance and low residual current consisting of a solid electrolyte made of conductive polymers and an outer layer containing conductive polymers, to electrolytic capacitors produced by this process and to the use of such electrolytic capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Process for solid electrolytic capacitors using polymer slurries

ActiveUS8808403B2Improve performanceImprove electrical performanceSolid electrolytic capacitorsLiquid electrolytic capacitorsDielectricElectrolysis

A process for forming a solid electrolytic capacitor and an electrolytic capacitor formed by the process. The process includes: providing an anode wherein the anode comprises a porous body and an anode wire extending from the porous body; apply a thin polymer layer onto the dielectric, andforming a dielectric on the porous body to form an anodized anode;applying a first slurry to the anodized anode to form a blocking layer wherein the first slurry comprises a first conducting polymer with an median particle size of at least 0.05 μm forming a layer of crosslinker on the blocking layer; andapplying a layer of a second conducting polymer on the layer of crosslinker.

Owner:KEMET ELECTRONICS CORP

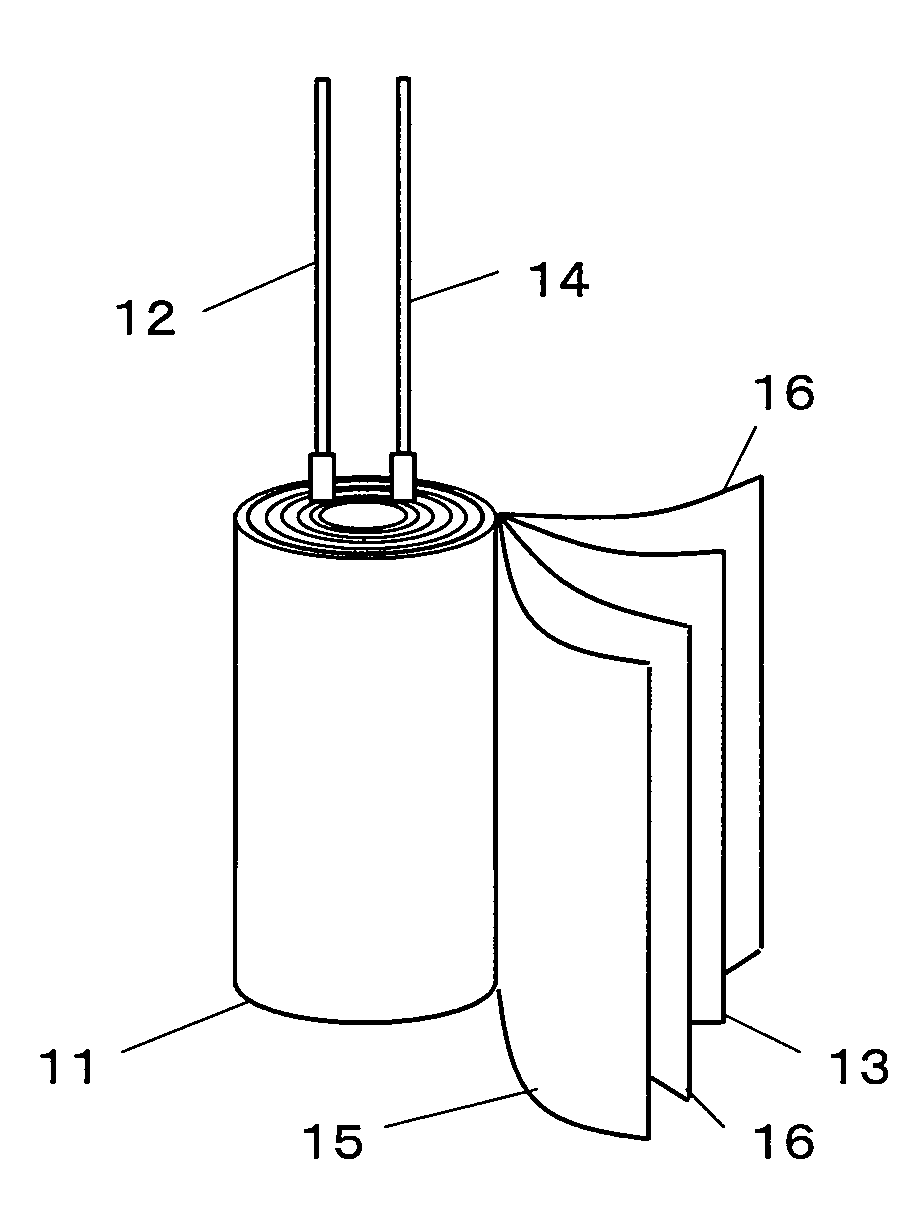

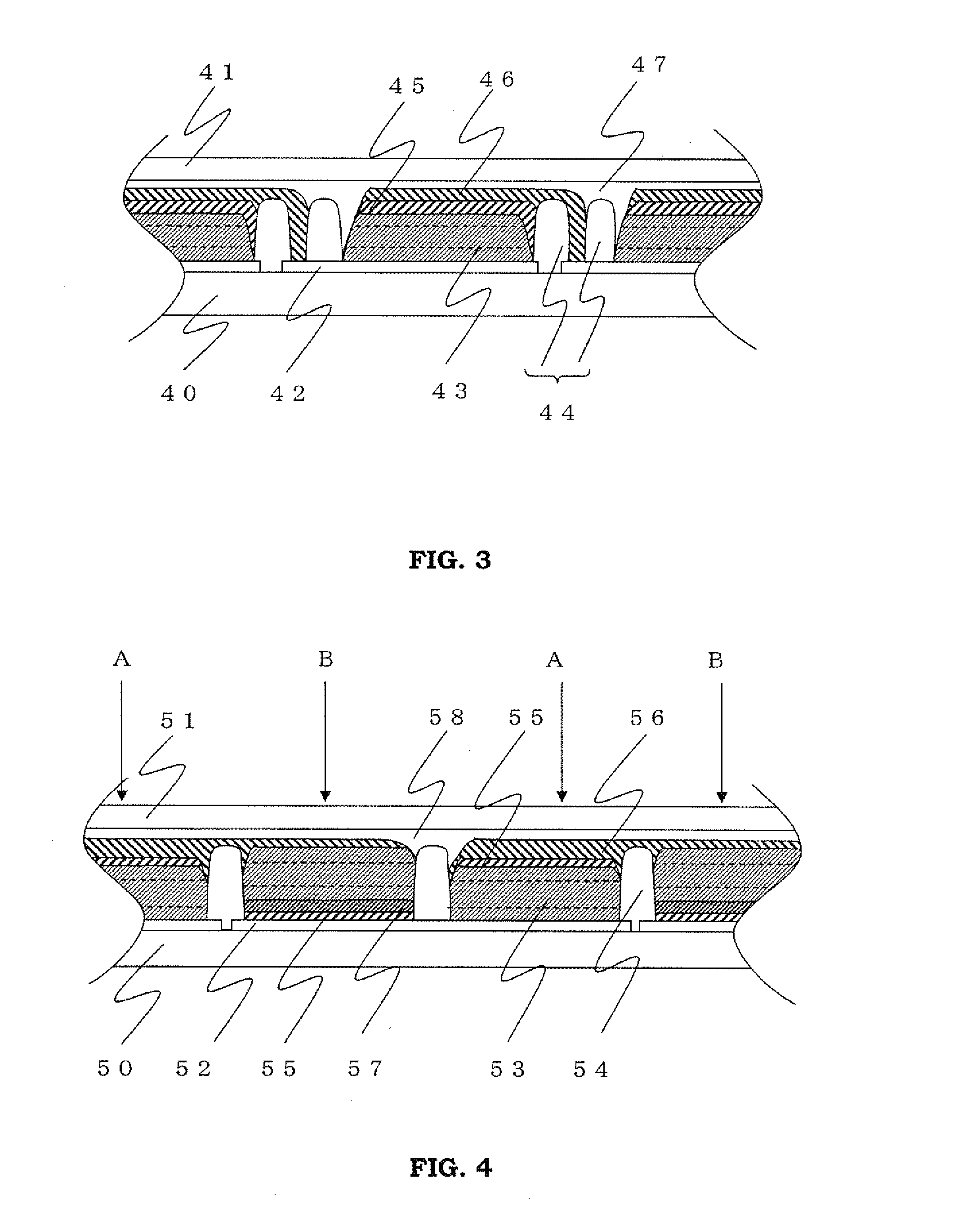

Energy device, method for manufacturing the same, and apparatus including the same

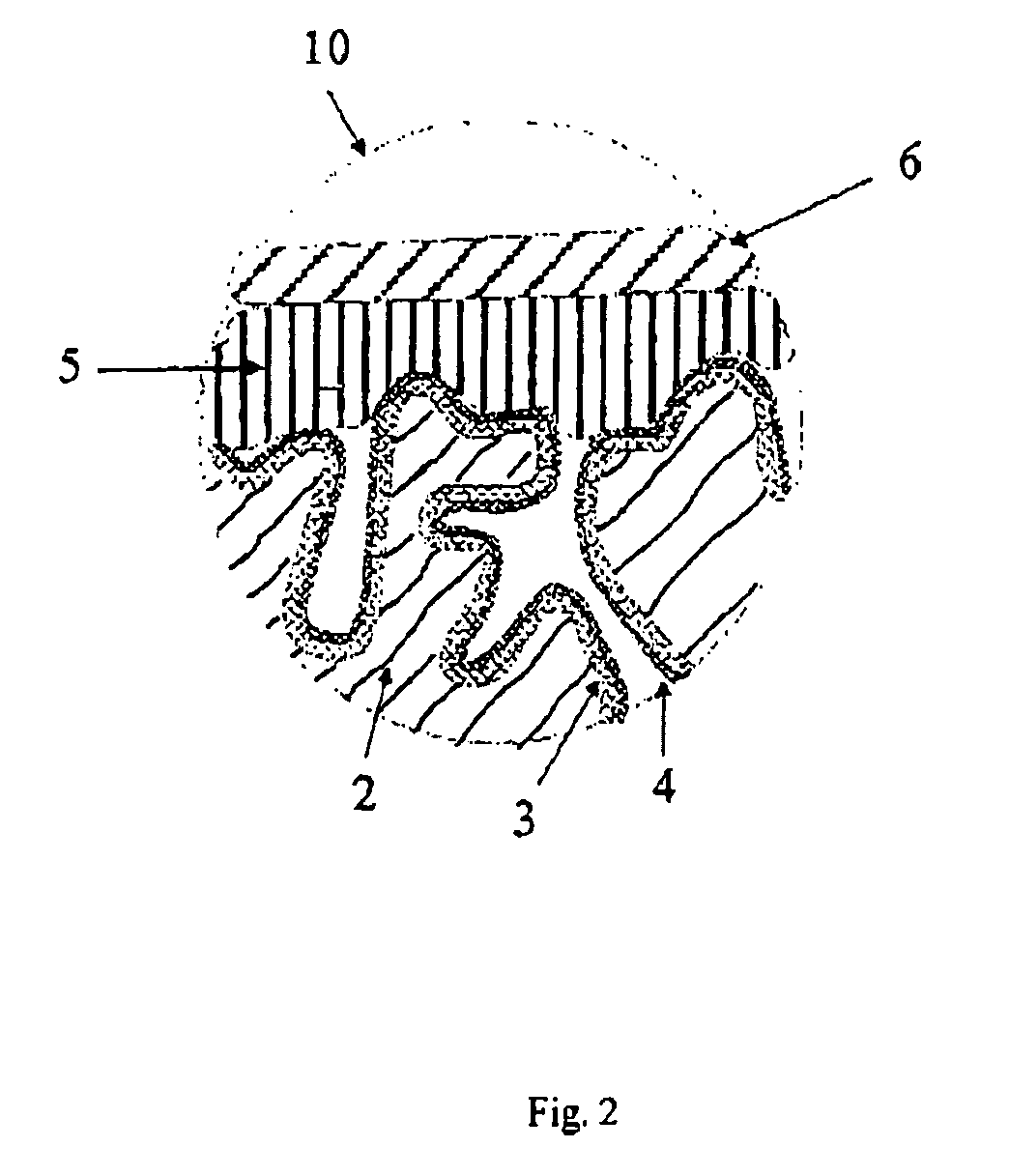

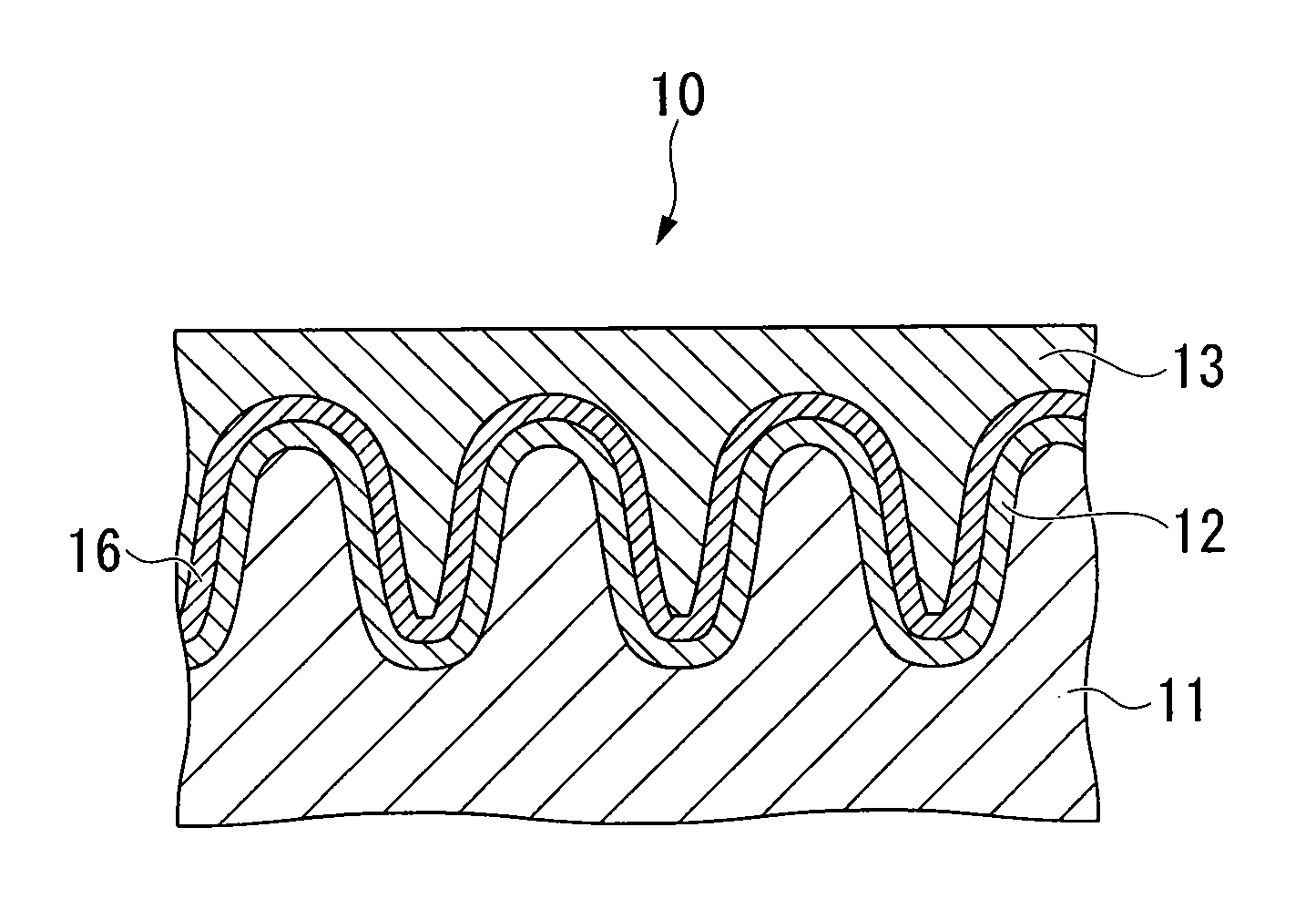

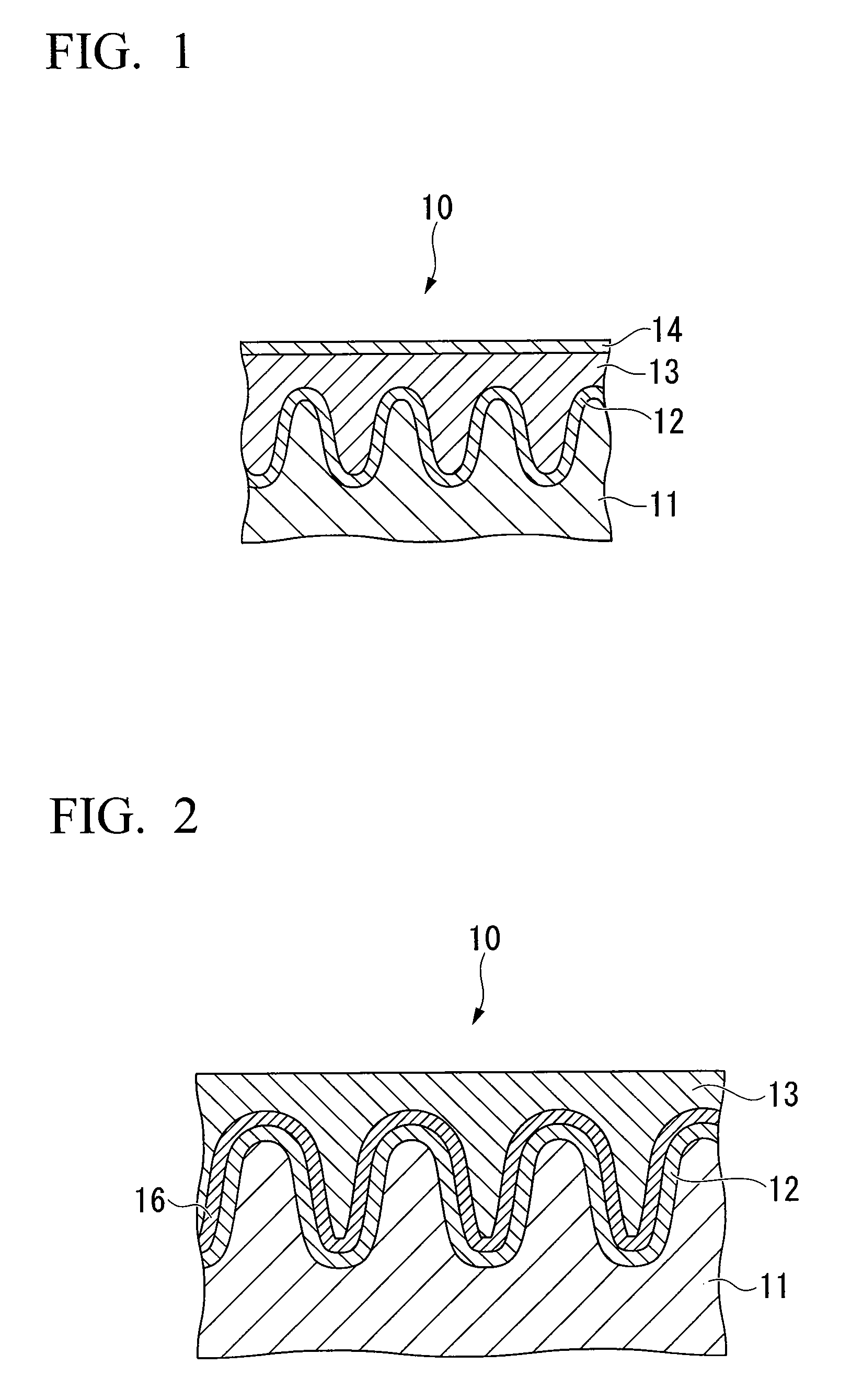

ActiveUS20100086837A1Reduce the possibilityPrevent peelingHybrid capacitor electrodesFinal product manufactureCarbon nanotubeEnergy device

The present invention provides an energy device including a carbon nanotube electrode which prevents a carbon nanotube from peeling from an electric conductor. The energy device includes rolled electrode bodies, wherein at least one of the electrode bodies is formed such that a carbon nanotube layer is formed on the electric conductor, and concave regions are formed in a stripe shape on the carbon nanotube layer so as to extend in a direction parallel to a roll axis.

Owner:PANASONIC CORP

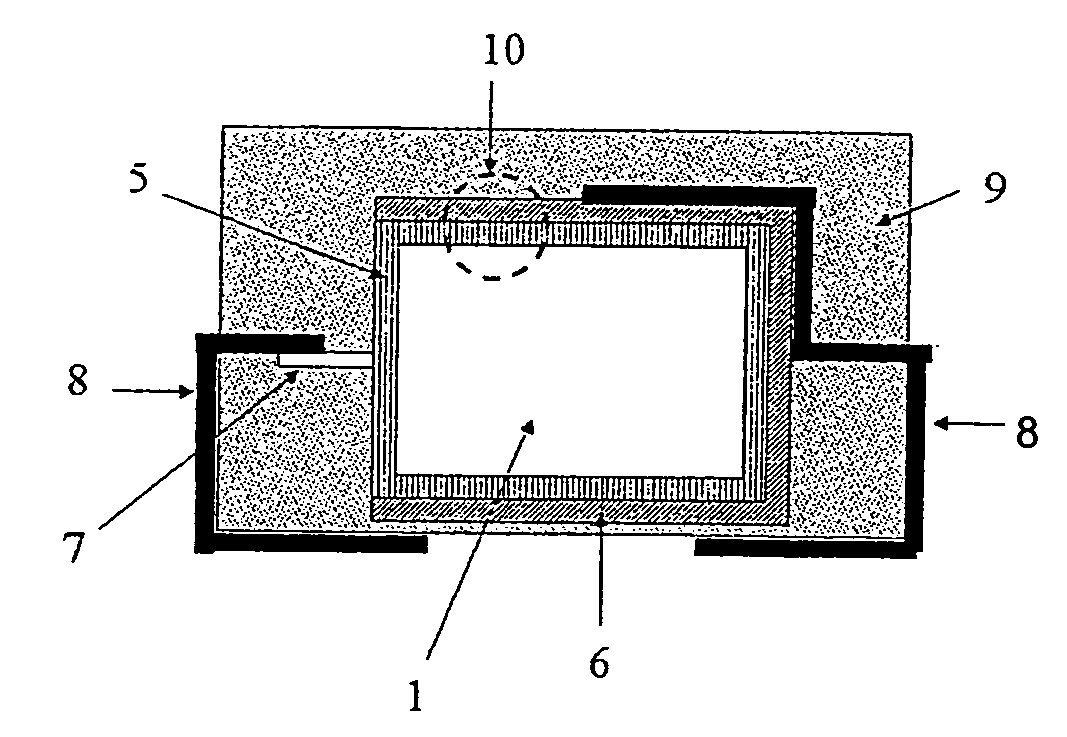

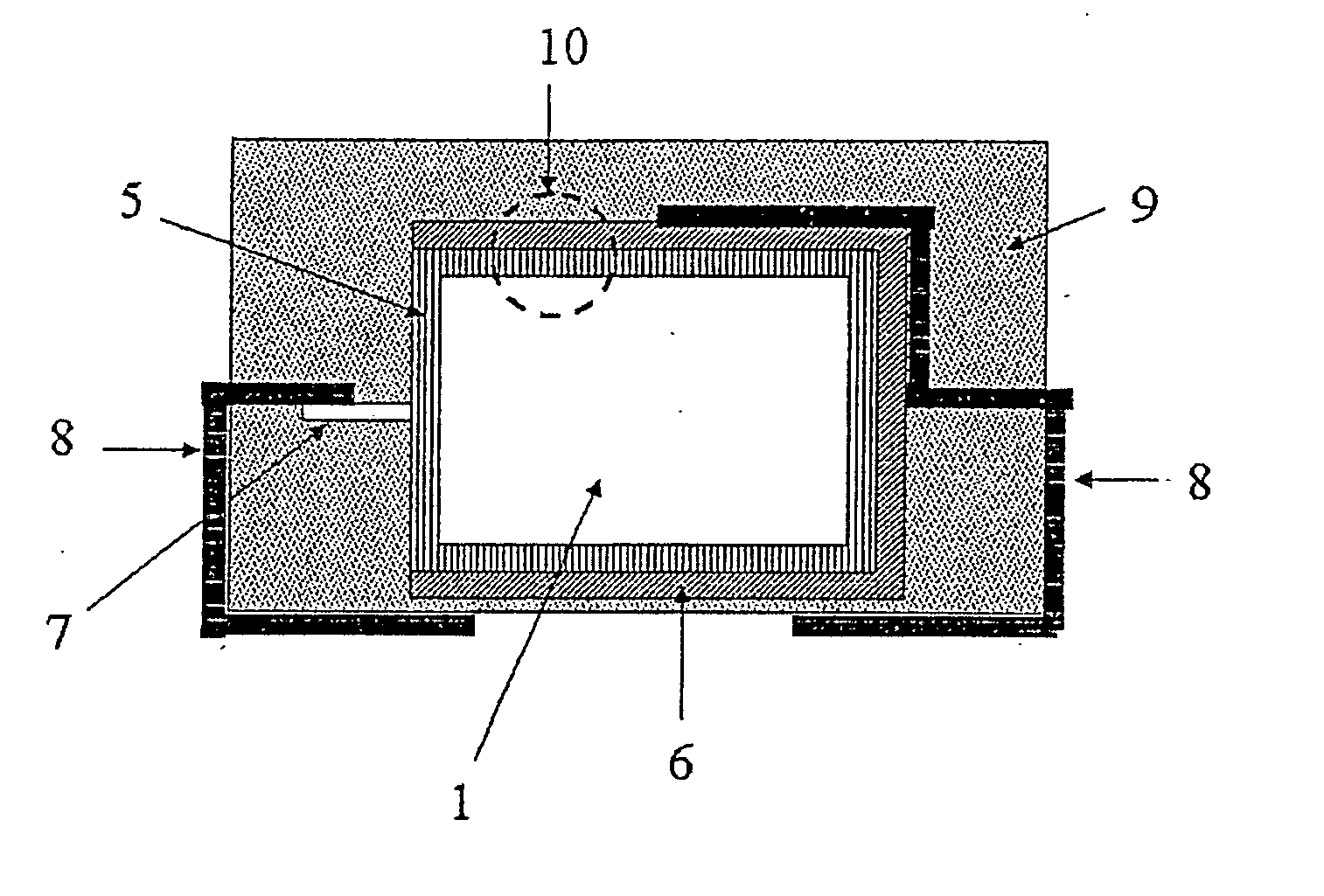

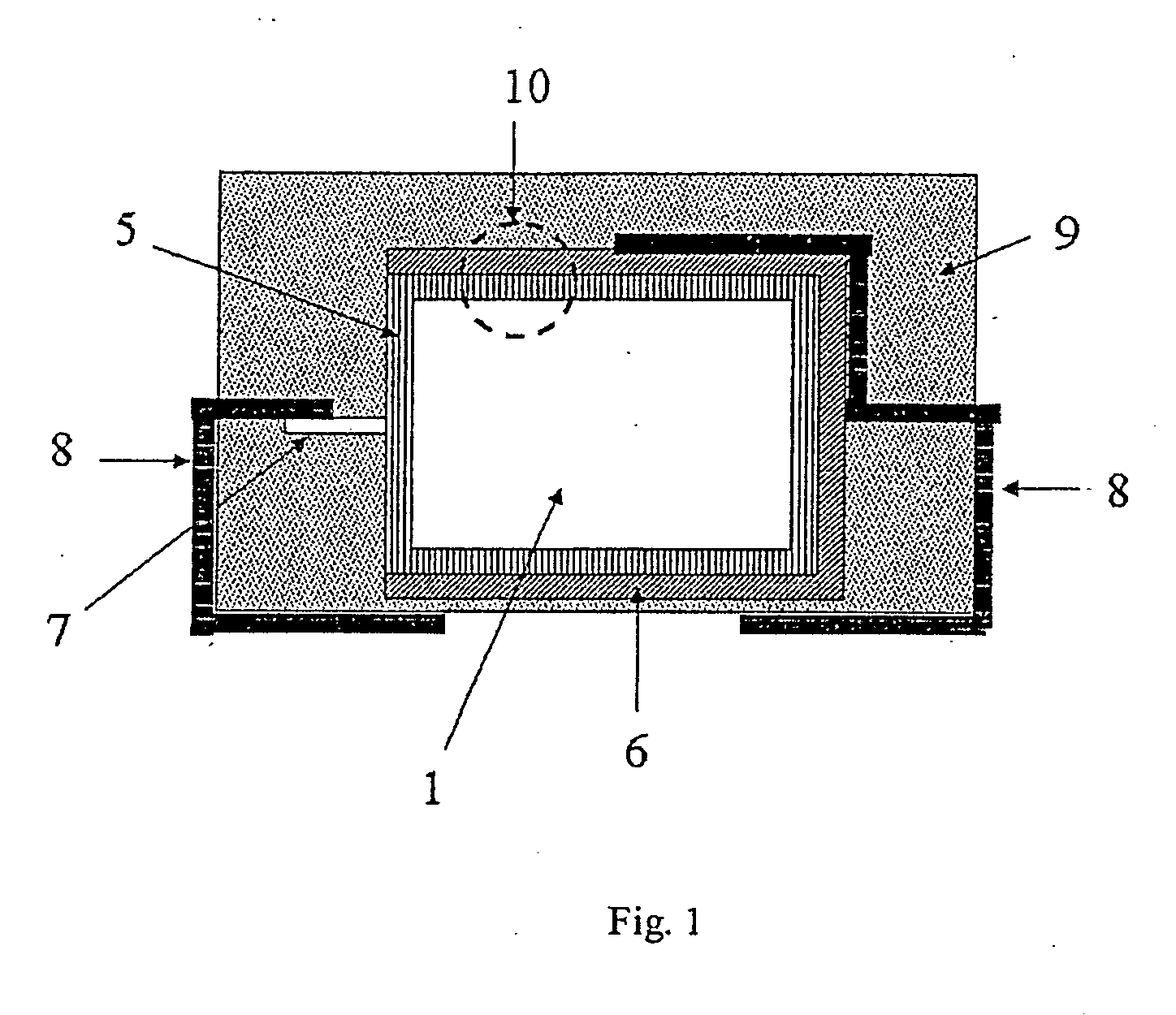

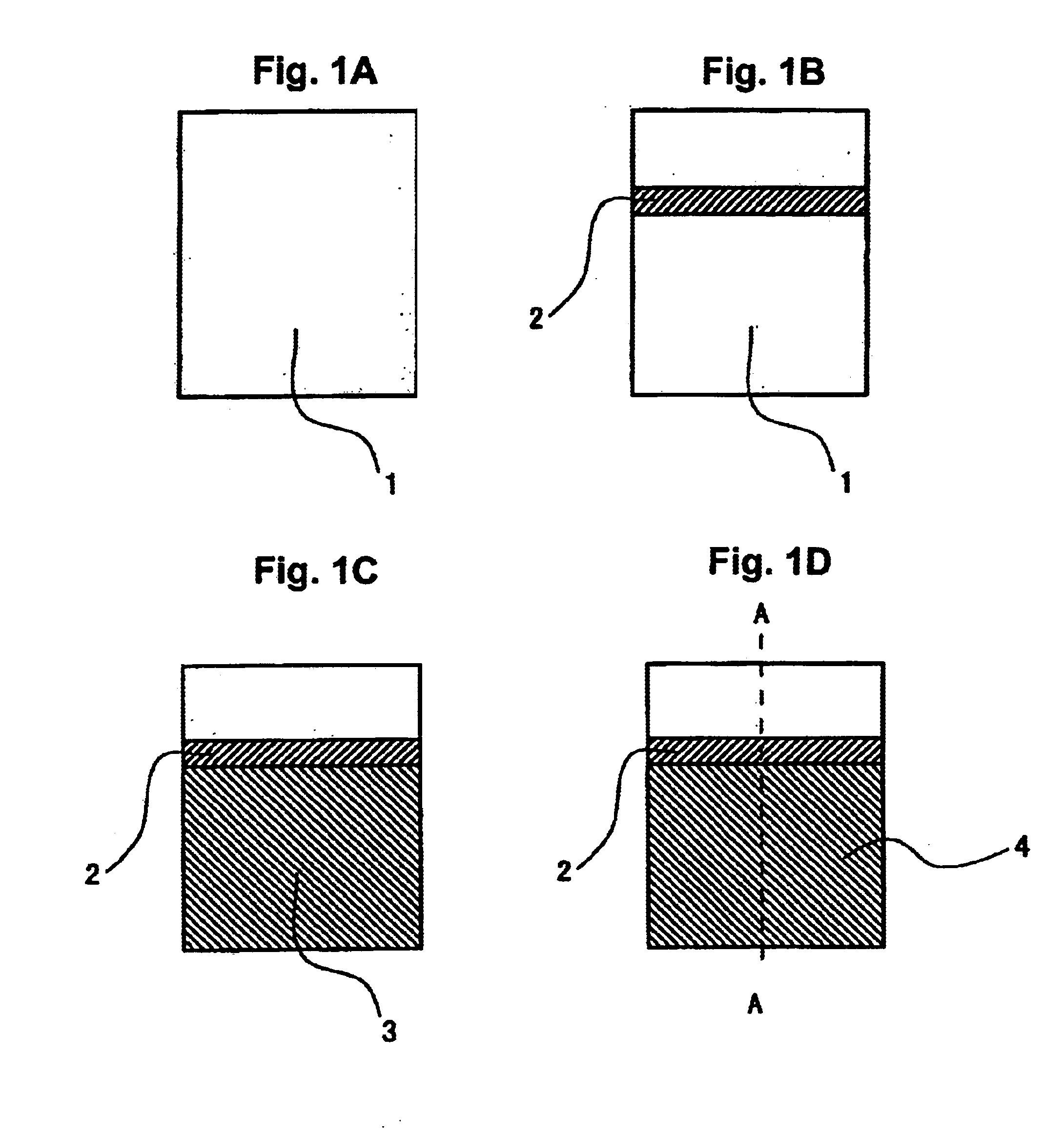

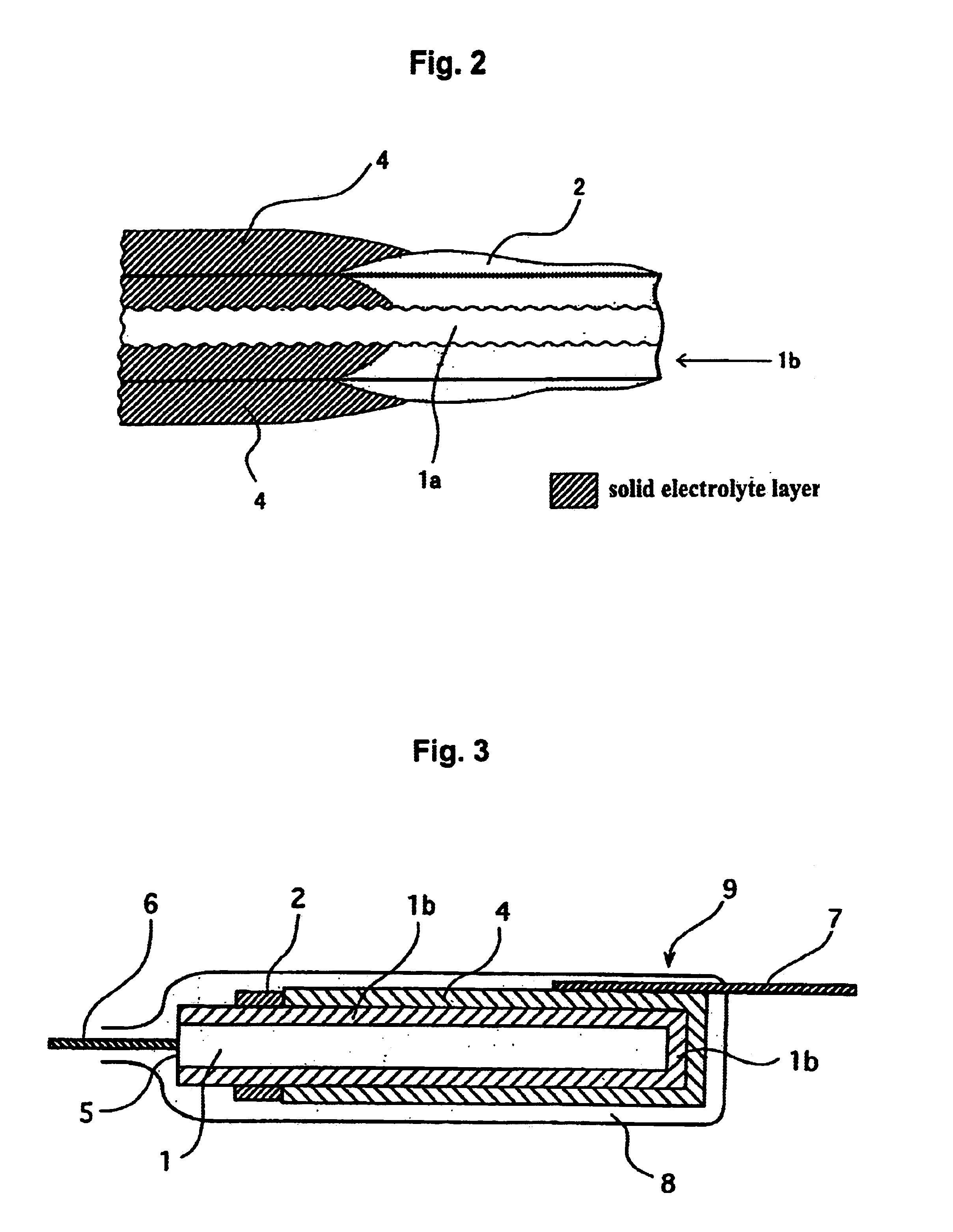

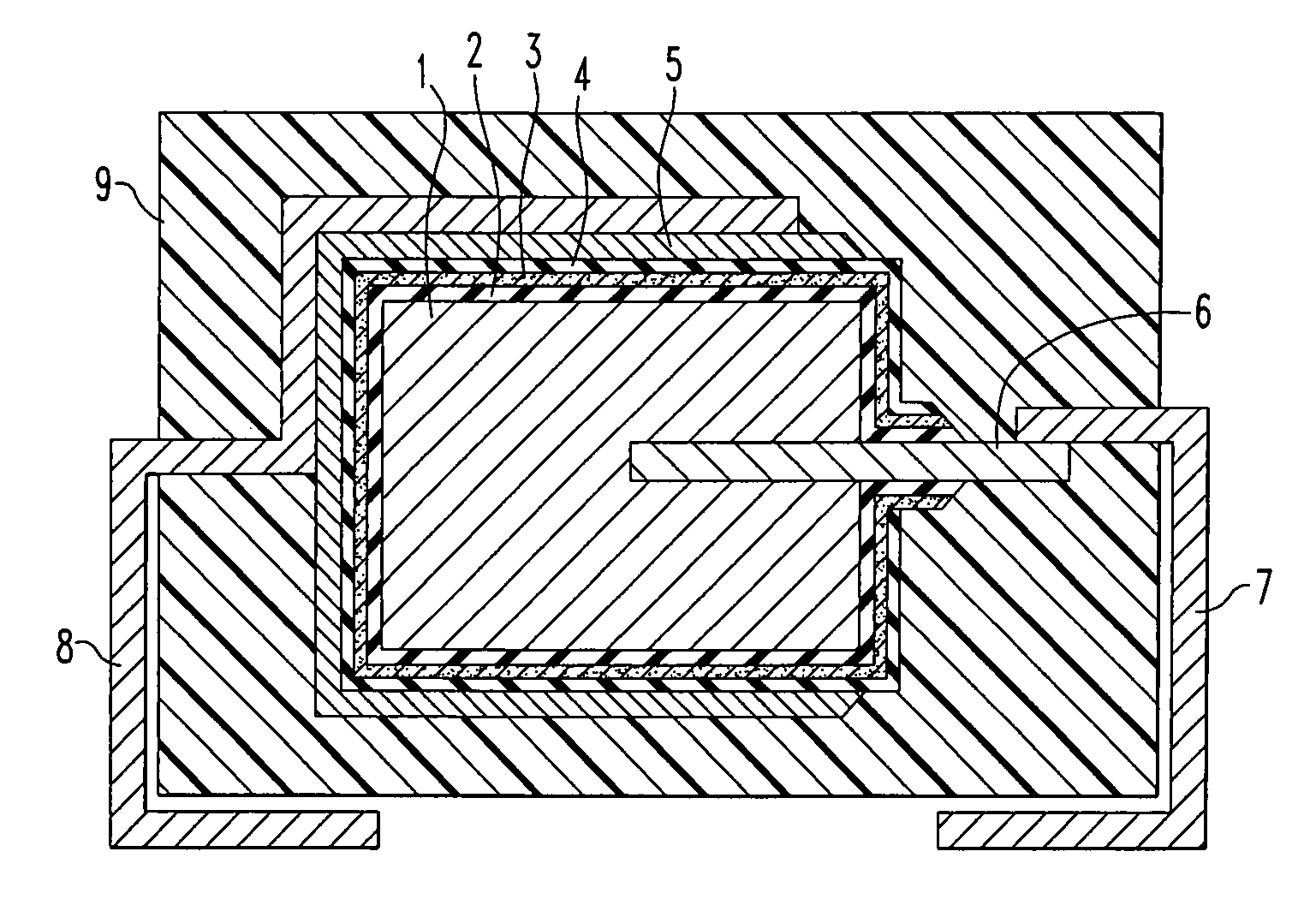

Solid electrolytic capacitor and method for producing the same

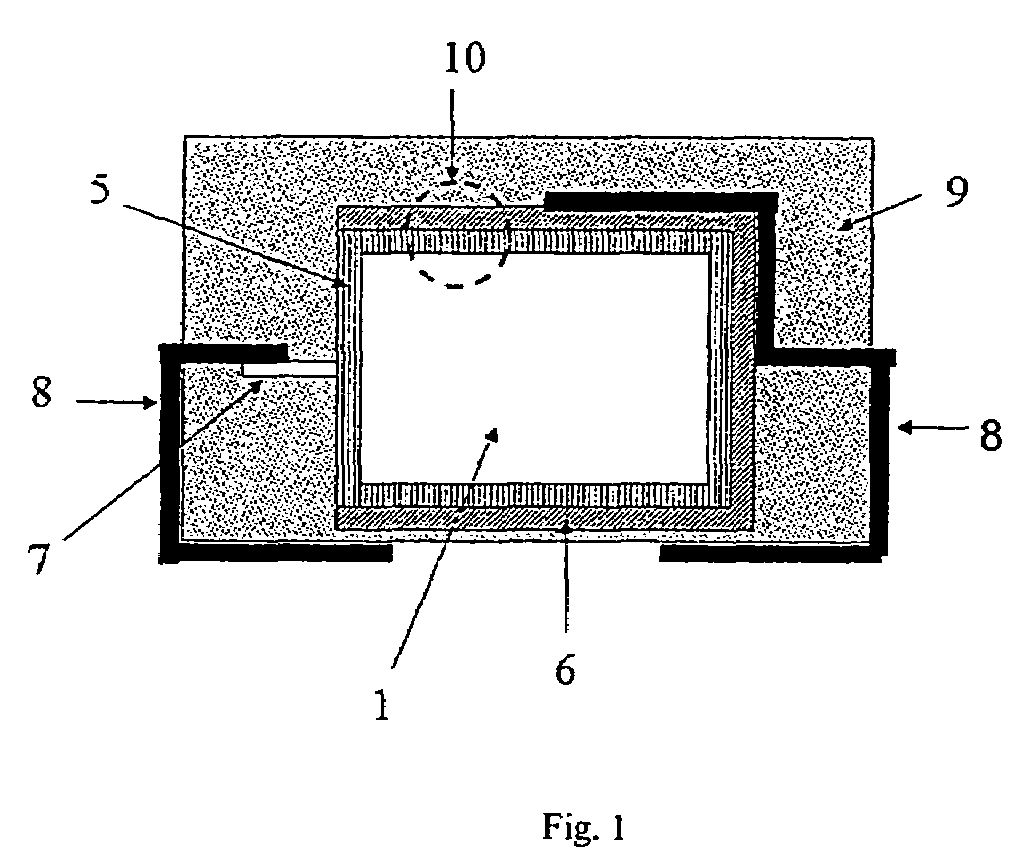

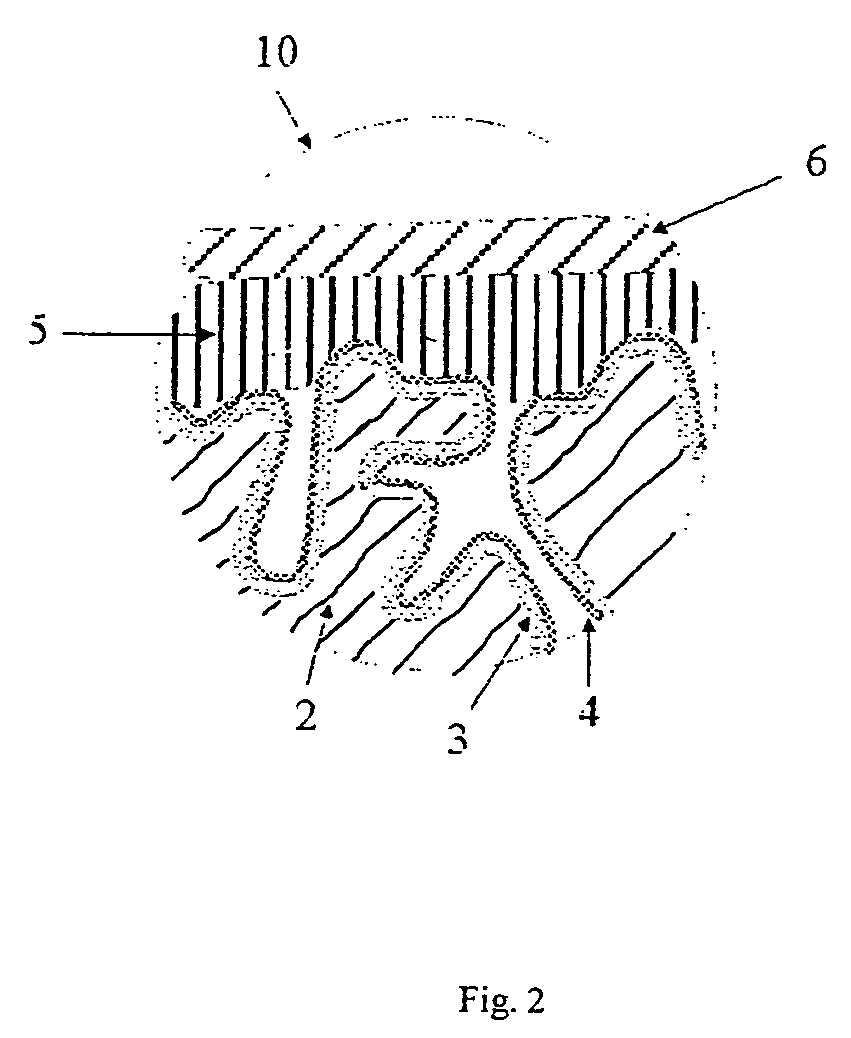

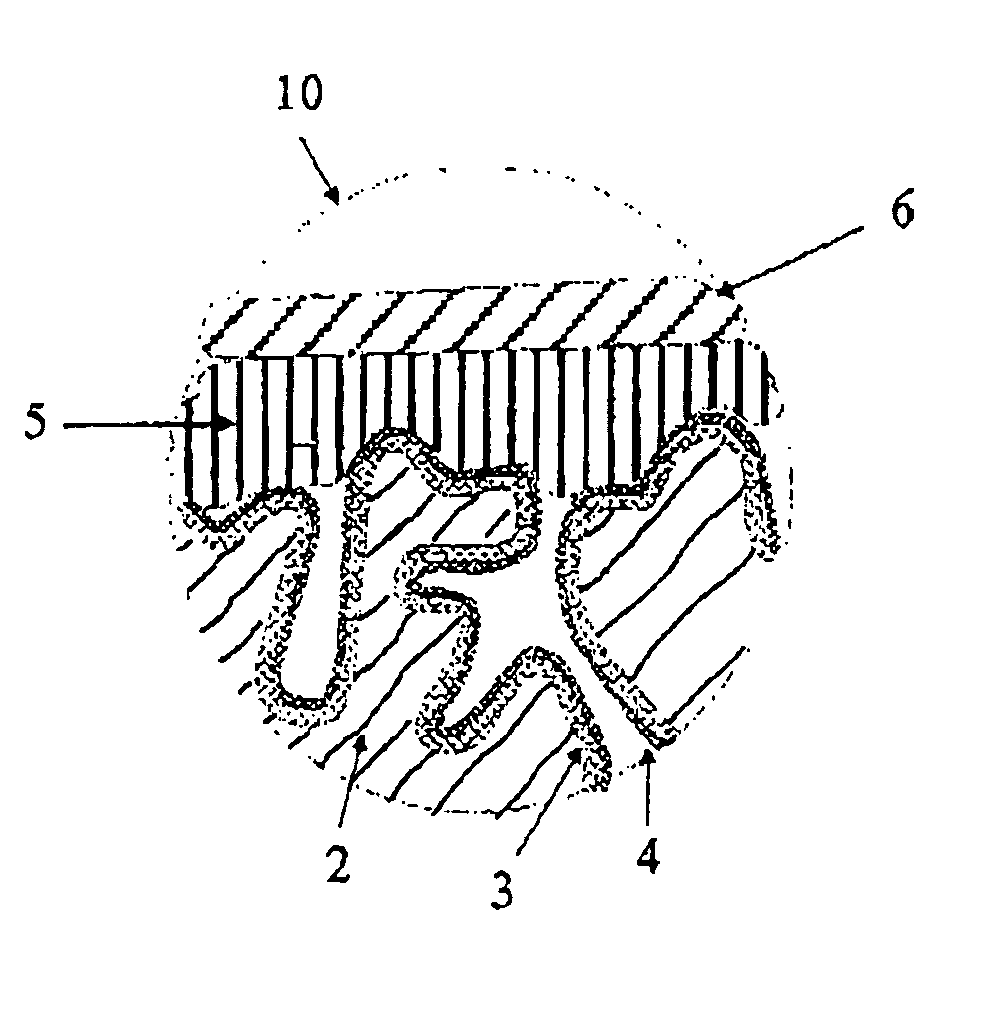

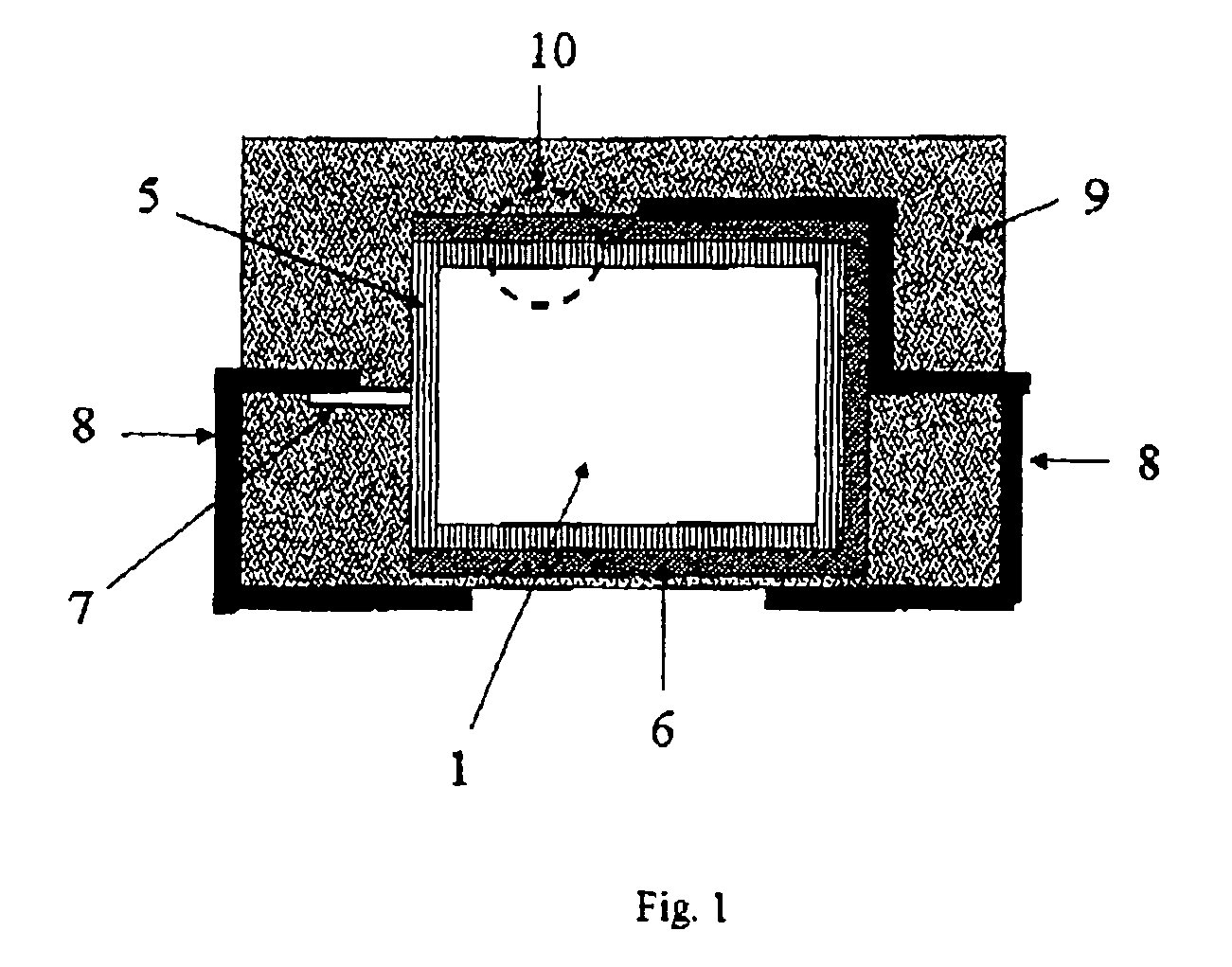

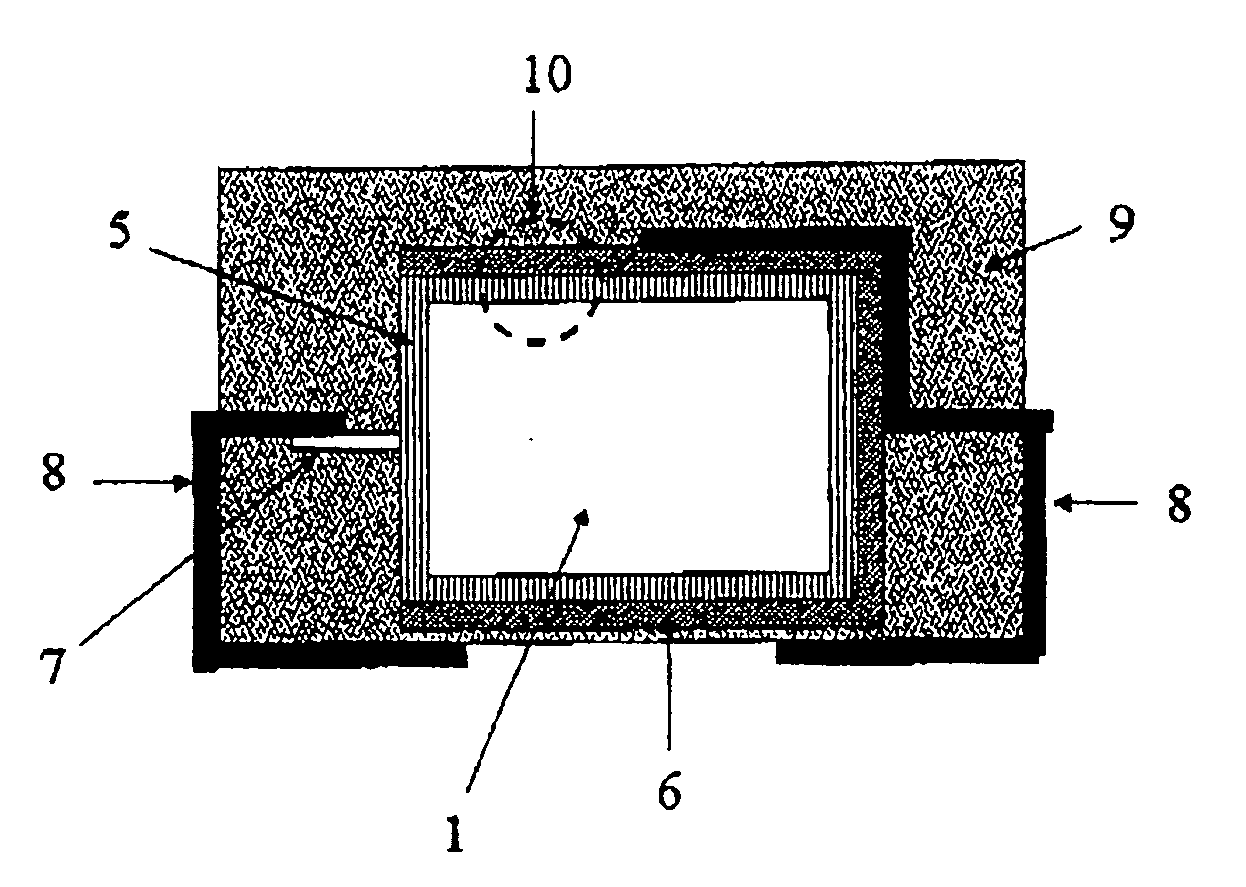

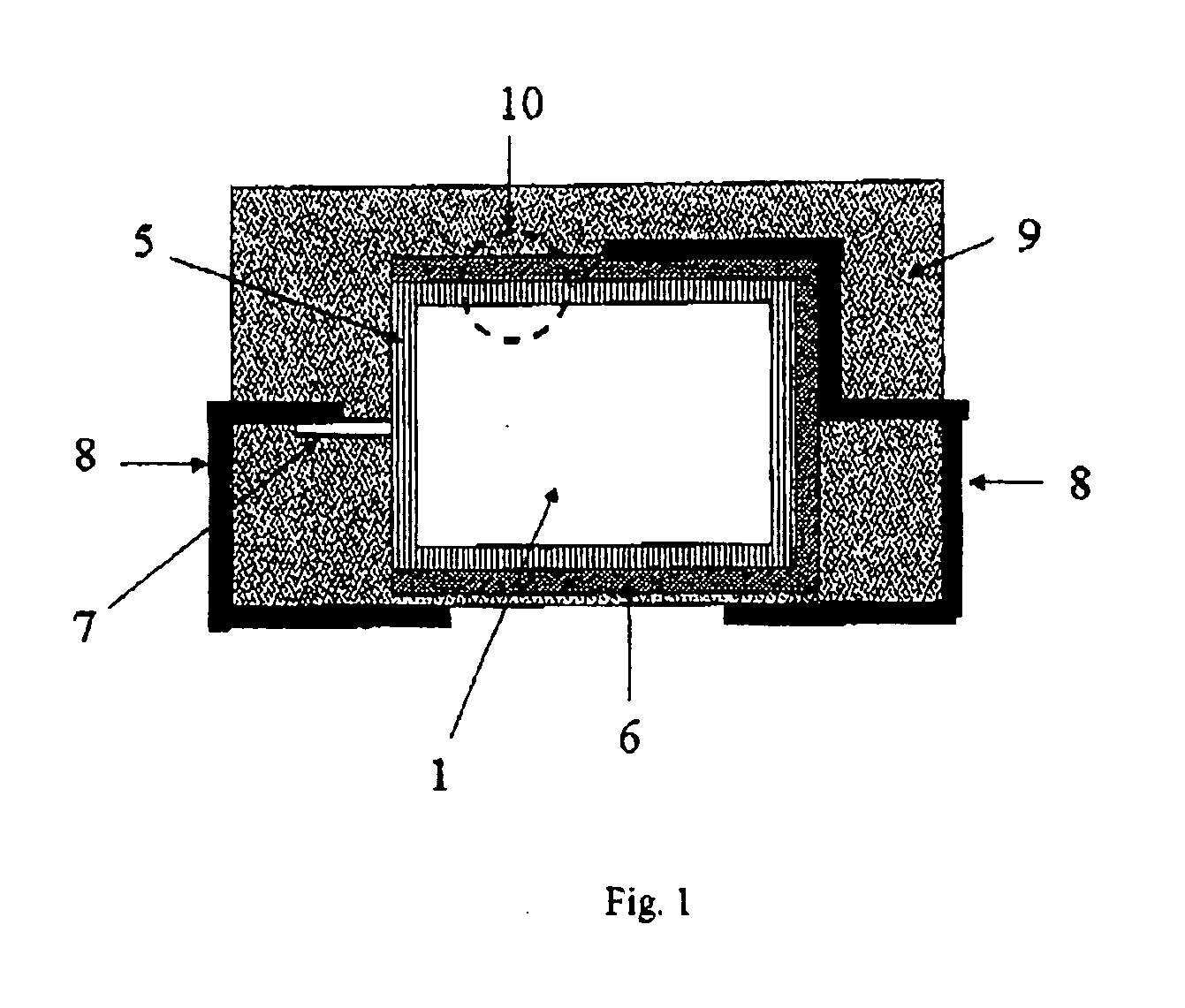

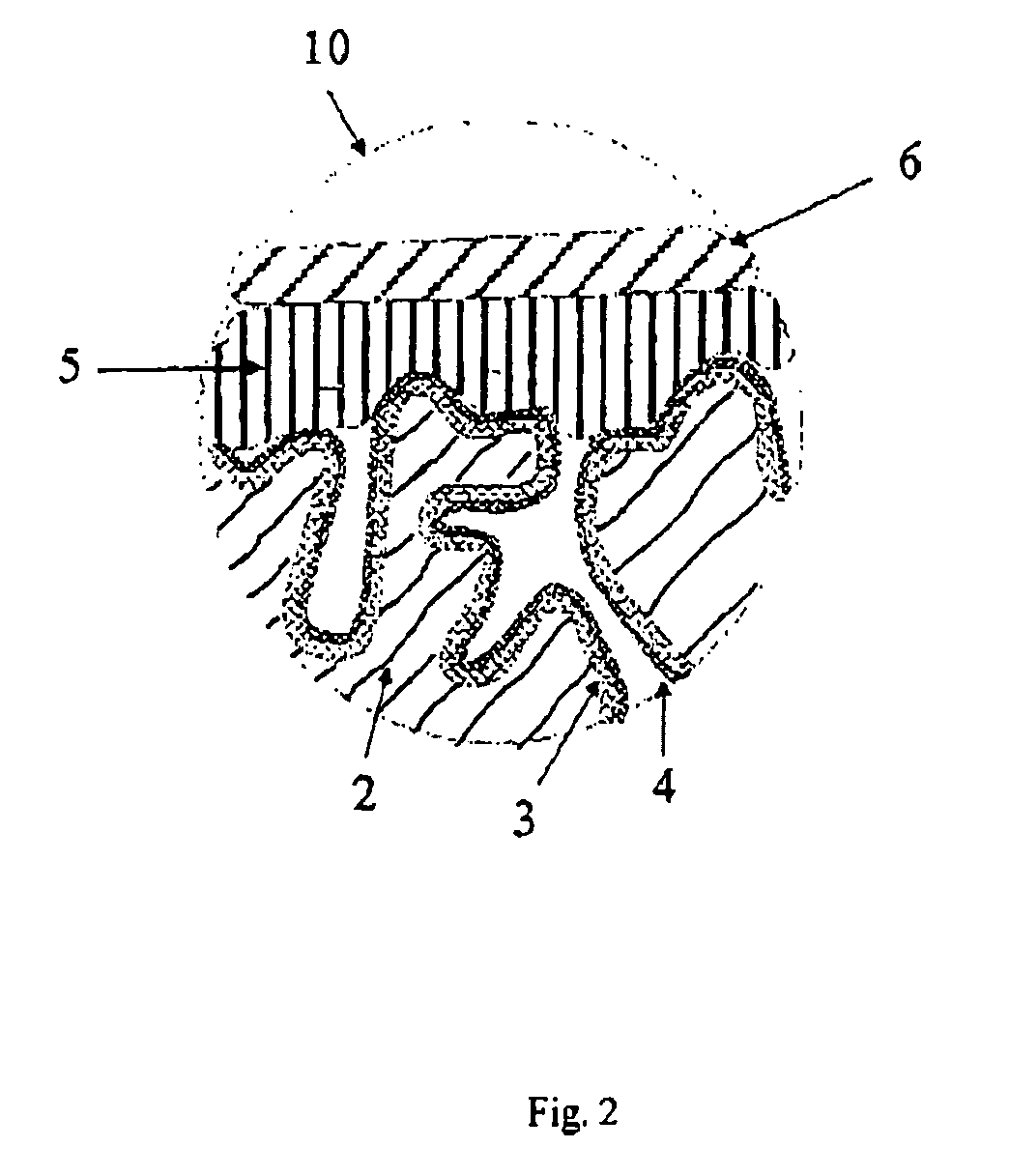

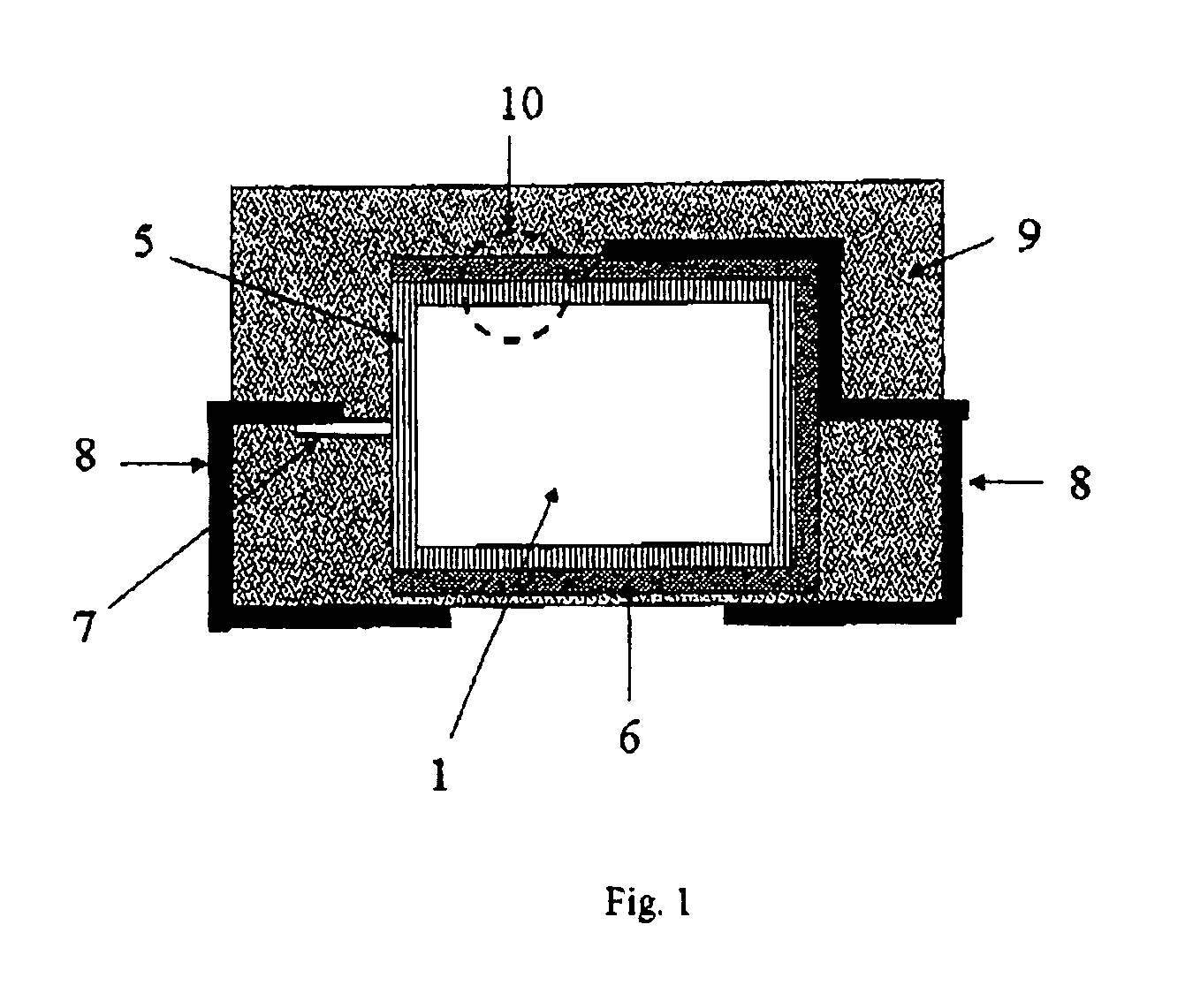

InactiveUS6890363B1Efficient executionImprove leakage currentHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisMetallic materials

The present invention relates to a solid electrolytic capacitor having a masking structure in which the insulation between the anode part and the cathode part can be ensured without fail, to its production method, to a method for coating a masking agent on a solid electrolytic capacitor substrate, and to an apparatus therefor. According to the present invention, the masking material covers the dielectric film on the metal material having valve action and sufficiently infiltrates into the core metal made of a metal having valve action while the solid electrolyte is masked by the masking material without fail, so that a solid electrolytic capacitor can be produced that has a reduced leakage current and a reduced stress generated at the reflow treatment or the like.

Owner:MURATA MFG CO LTD

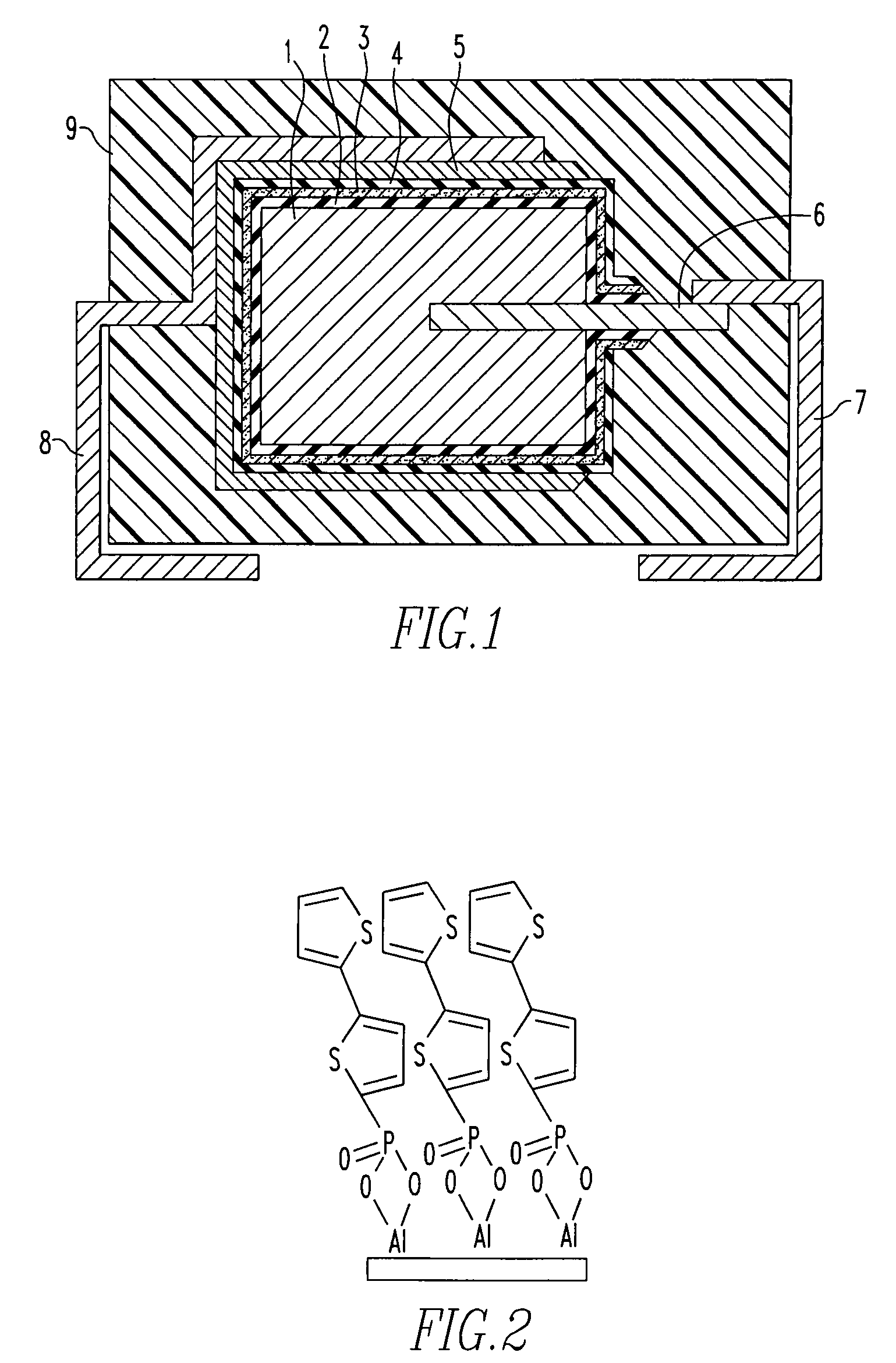

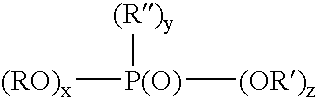

Solid electrolytic capacitors

InactiveUS7471503B2Hybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisOrganophosphorous compounds

A solid electrolytic capacitor is disclosed. The capacitor comprises an organophosphorus material positioned between the dielectric layer and the polymeric electrolyte layer. The organophosphorus compound improves the interlayer adhesion between the dielectric and electrolyte layers.

Owner:ACULON +1

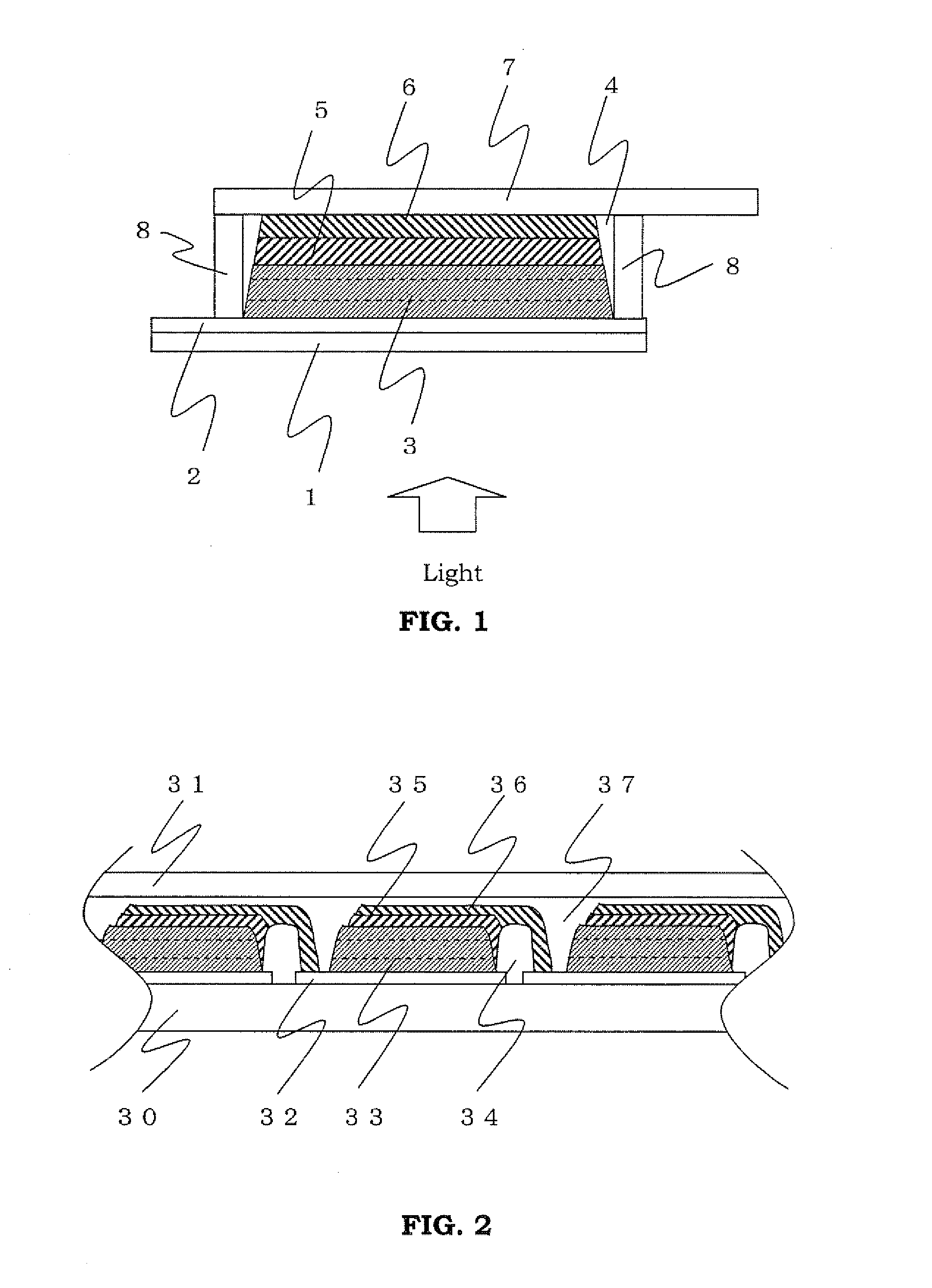

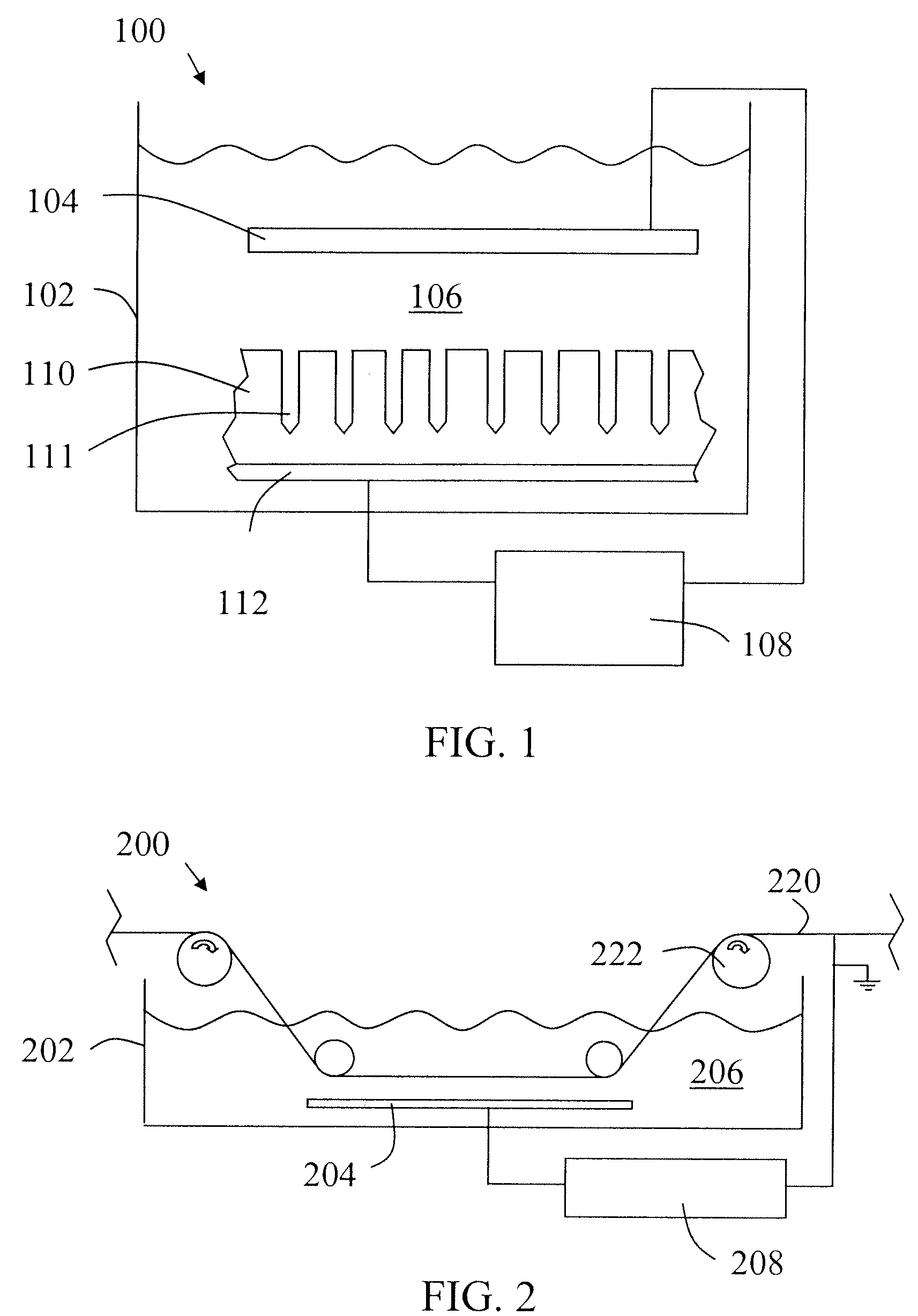

Dye sensitized solar cell and dye-sensitized solar cell module

InactiveUS20100012166A1Low costImprove performancePV power plantsCell component detailsCharge carrierPhotoelectric conversion

A dye-sensitized solar cell formed by layering a conductive layer; a photoelectric conversion layer in which a dye is adsorbed in a porous semiconductor layer and the layer is filled with a carrier transporting material; and a counter electrode including only a counter electrode conductive layer or including a catalyst layer and a counter electrode conductive layer on a support made of a light transmitting material,in which the photoelectric conversion layer is brought into contact with the counter electrode; the porous semiconductor layer forming the photoelectric conversion layer has two or more layers with different light scattering properties; and the two or more porous semiconductor layers are layered in an order of from a layer with lower light scattering property to a layer with higher light scattering property from a light receiving face side of the dye-sensitized solar cell.

Owner:SHARP KK

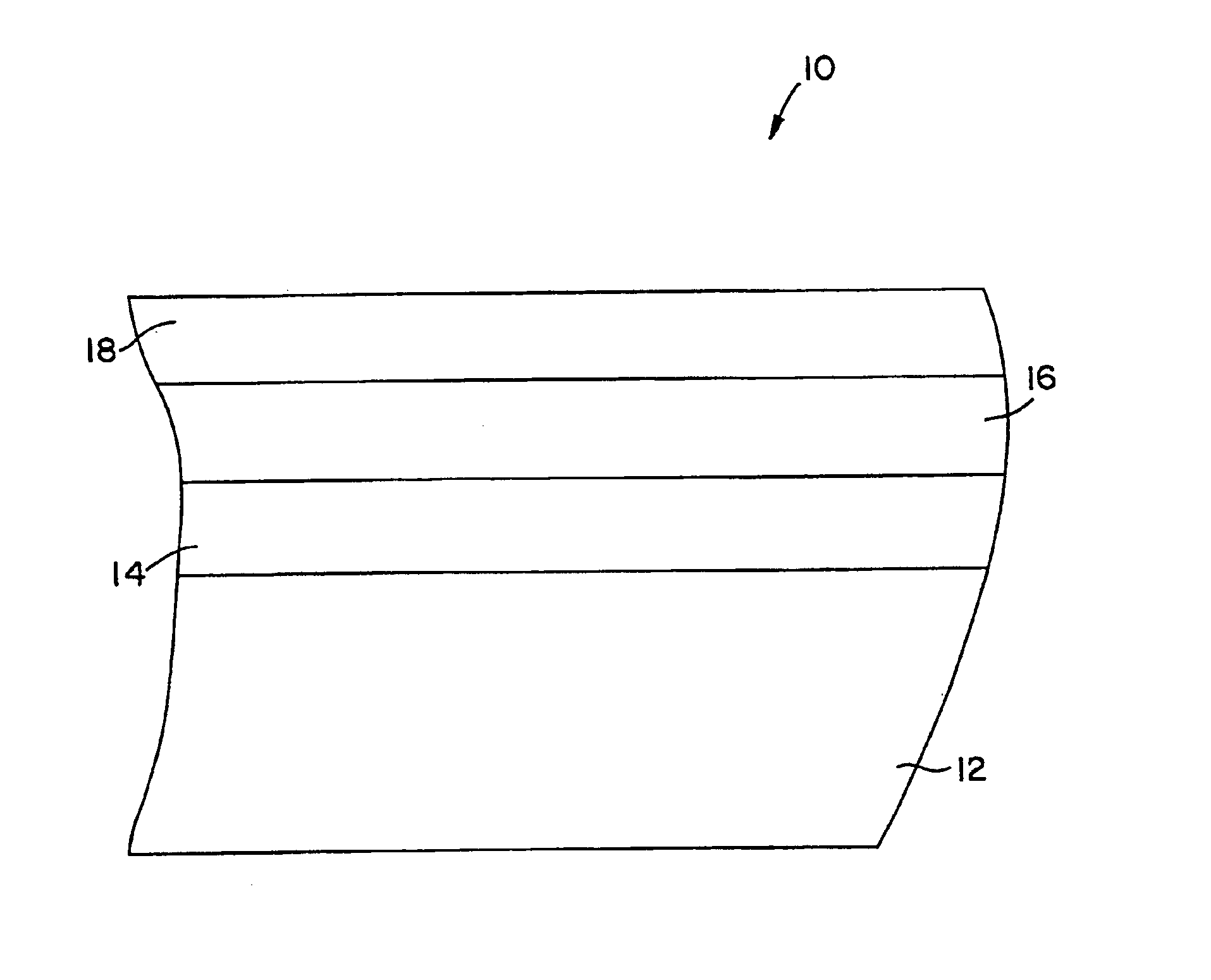

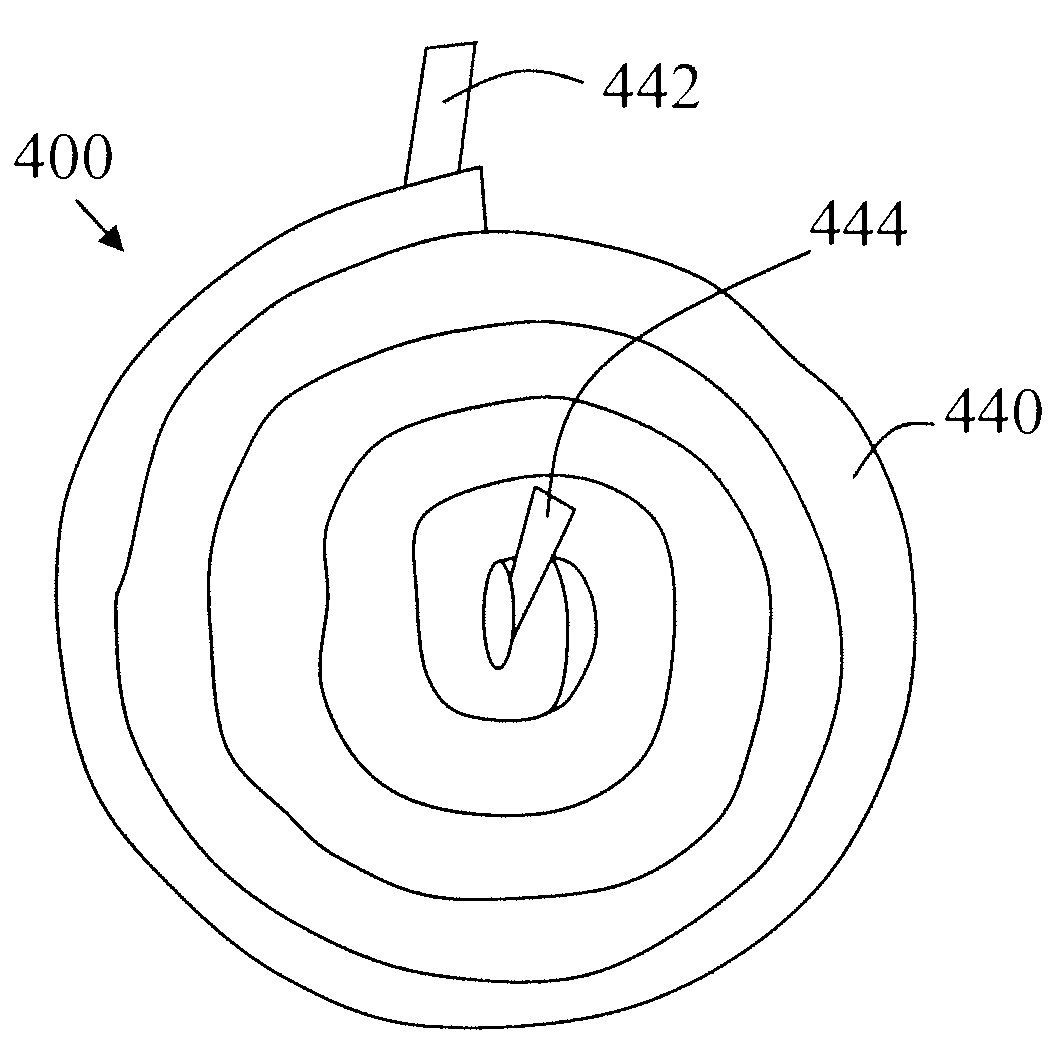

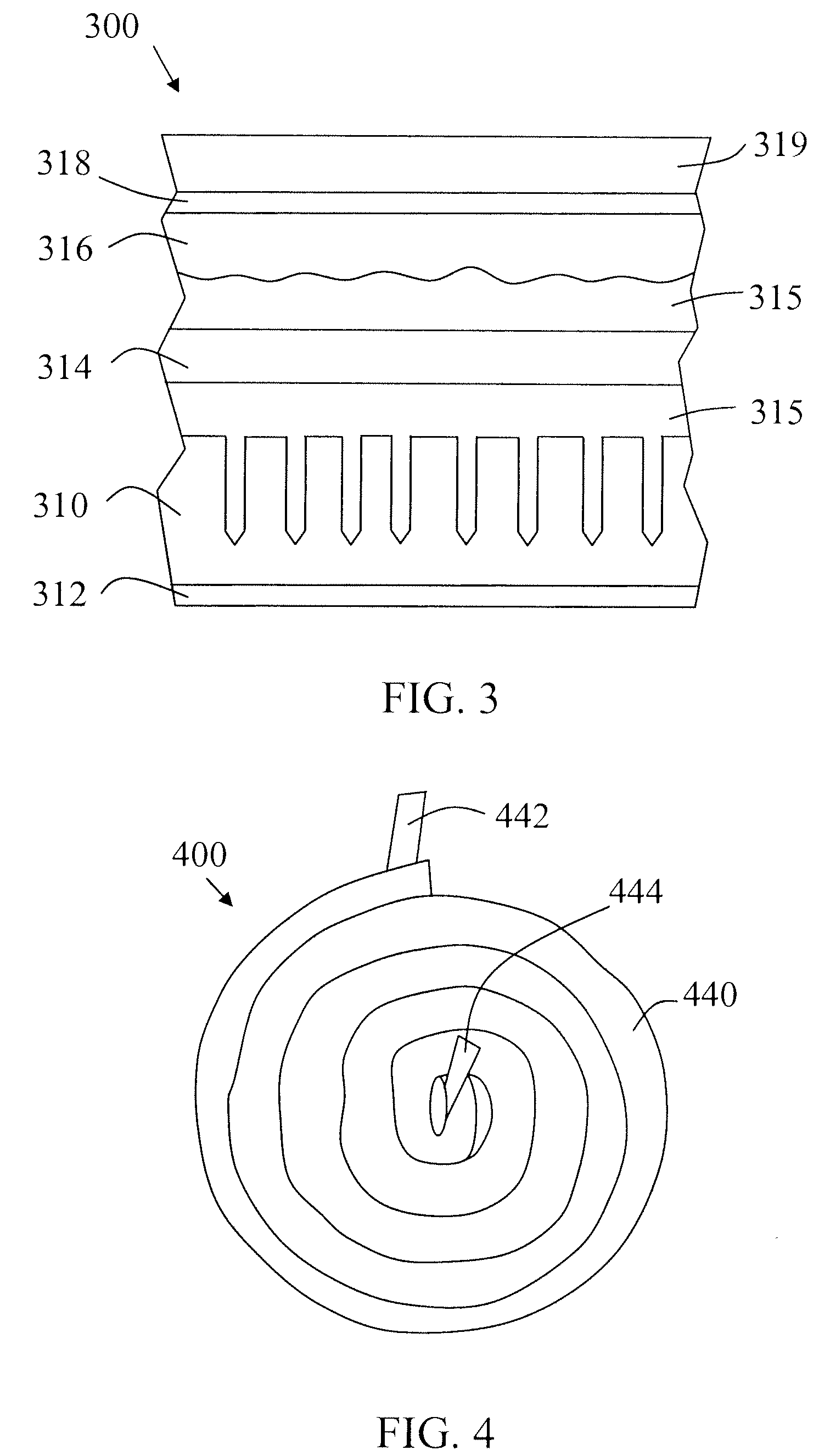

Energy storage device with porous electrode

A method of fabricating an energy storage device with a large surface area electrode comprises: providing an electrically conductive substrate; depositing a semiconductor layer on the electrically conductive substrate, the semiconductor layer being a first electrode; anodizing the semiconductor layer, wherein the anodization forms pores in the semiconductor layer, increasing the surface area of the first electrode; after the anodization, providing an electrolyte and a second electrode to form the energy storage device. The substrate may be a continuous film and the electrode of the energy storage device may be fabricated using linear processing tools. The semiconductor may be silicon and the deposition tool may be a thermal spray tool. Furthermore, the semiconductor layer may be amorphous. The energy storage device may be rolled into a cylindrical shape. The energy storage device may be a battery, a capacitor or an ultracapacitor.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com