Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Control microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing carbon/carbon-silicon carbide ceramics base composite material

This invention discloses a preparation method for preparing C / C-SiC ceramic base compound material, which first of all deposits a pyrogenated carbon interface layer on the surface of a carbon fiber prefabricated body, then deposits pyrogenated carbon and SiC alternately to form a multi-layer (PyC / SiC)n matrix to get the C / C-SiC compound material. Since this invention applies PyC matrix to replace part of SiC matrix to form a multi-layer matrix, the dismatch of modulus between fiber and the matrix is released, when the PyC layer deflects, the crack peak stress is released steadily and energy cost by breakage is increased, and obdurability of the compound material is increased, the downward tensible-strength of 2-D C / C-SiC compound material is increased to 285.70-290.45MPa from 281.80MPa under room temperature, the downward fracture power of that under room temperature is increased to 12.50-13.64KJ.m-2 from 10.00KJm-2 and the tensible-strength is increased to 385.78-396.67MPa from 323.00MPa and control to C / C-SiC compound material micro-sturcture can be realized by controlling deposition time and times to control thickness and layers of the matrix.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

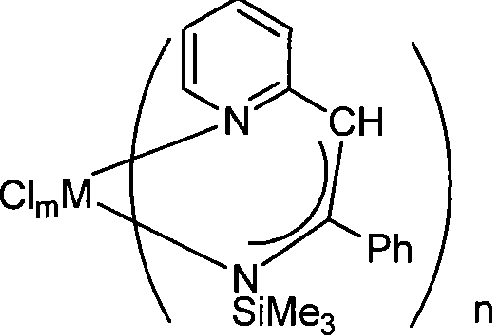

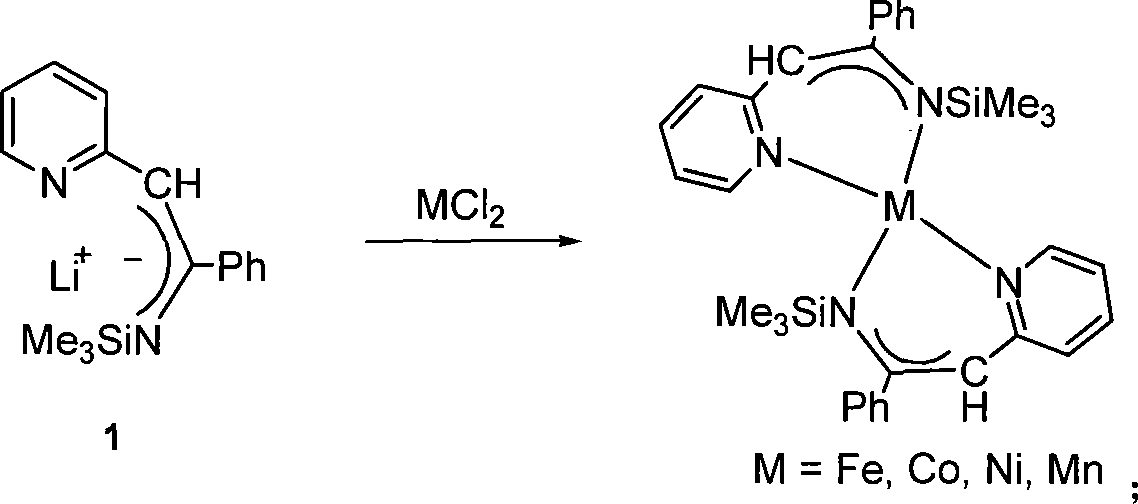

Metal complex using pyridine as matrix and synthetic method thereof

InactiveCN101085788ASimple stepsHigh yieldTin organic compoundsGermanium organic compoundsOrganic compoundHigh activity

The invention provides a metallic complex taking pyridine as parent body. It comprises following steps: taking picoline as raw material, placing trimethyl silicon base on substituent group after modification, carrying out addition reaction with benzenenitrile and getting a kind of metallic organic compound complexed witheta3-aza and pyridine. The method is characterized by temperate reaction condition, simple process, fast reaction speed and high productivity. The complex can be used as catalyst for alkene polymerization, and is characterized by long endurance, low cost, stable performance for oxygen atom and other foreign atoms in functional group, high activity and adjustable selectivity.

Owner:SHANXI UNIV

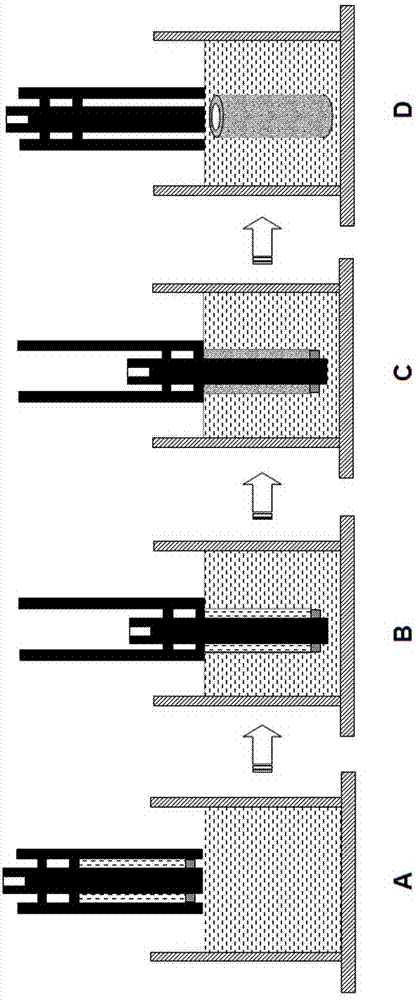

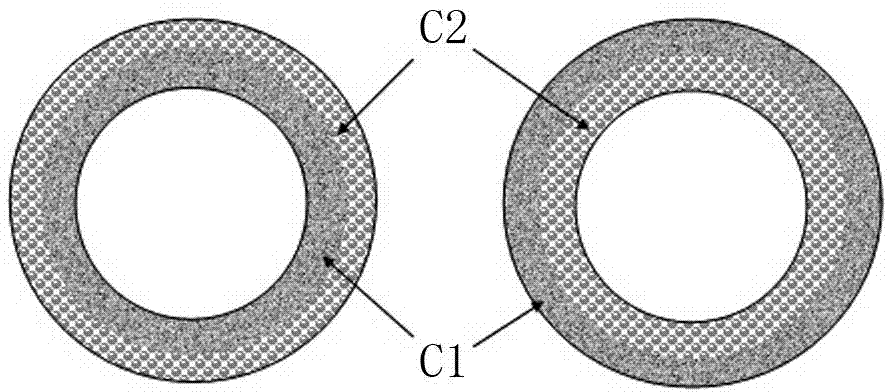

Preparation method of artificial blood vessel and its application

InactiveCN101284148AControl microstructureUnlimited lengthHollow filament manufactureNon-woven fabricsHollow fibre membraneOrganic solvent

The invention relates to a method for preparing an artificial vessel and the application thereof. The preparation method comprises the following steps: (1) in the preparation of membrane liquid, polymer that is 7 to 30 percent by weight proportion is added into organic solvent the weight proportion of which is 70 to 93 percent, so that casting solution is obtained through swelling and solution under the temperature between 40 DEG C and 80 DEG C; (2) in the preparation of the artificial vessel, a hollow fibre membrane is formed through the filtration and deaeration of the membrane liquid, serosity is squeezed out from a spinneret composed of two concentric tubes, the serosity which enters into precipitating bath through dry spinning then is processed through a post treatment process to obtain the artificial vessel. The method includes the application that the artificial vessel is transplanted to a physical organ or any organs which need quantities of vascular tissues to transport aliment, gas and waste. The artificial vessel obtained by using the preparation method has good adaptability, penetrability and biocompatibility, matches the self vessels, and has controllable outside diameter and wall thickness of the materials.

Owner:DONGHUA UNIV

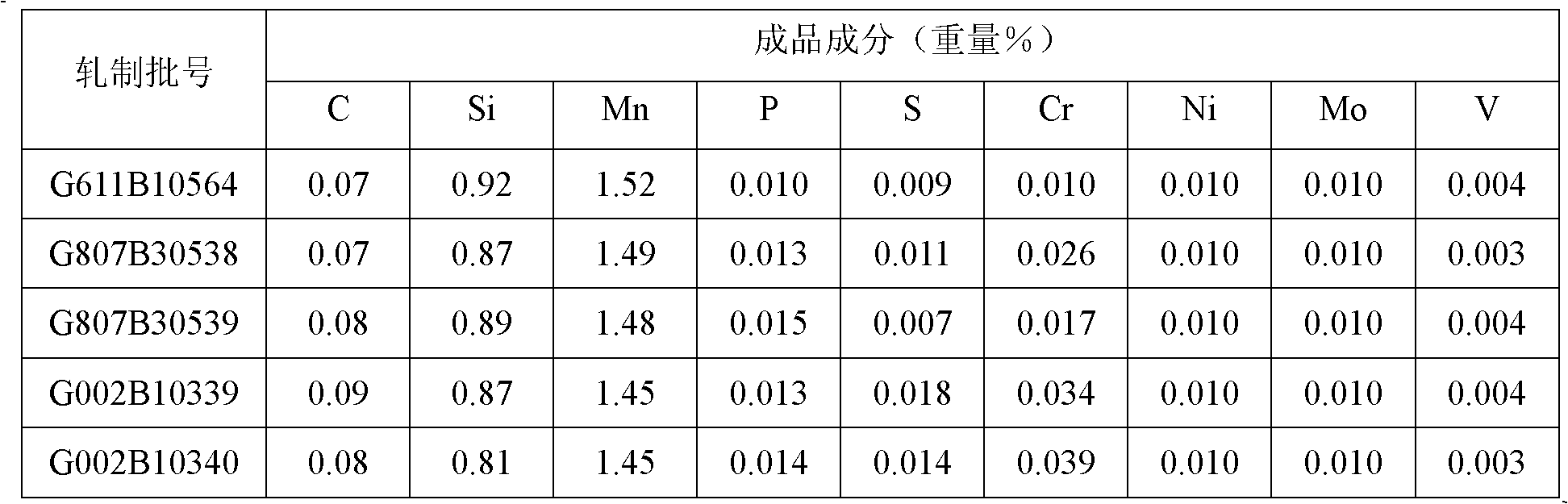

Production method for optimizing drawing performance of steel wire rod for carbon steel welding wire

ActiveCN102218448AExcellent drawing performanceControl microstructureTemperature control deviceMetal rolling arrangementsCarbon steelMicrostructure

The invention relates to a production method for optimizing the drawing performance of a steel wire rod for a carbon steel welding wire, belonging to the technical field of steel production. The technology path comprises the following steps of billet chemical composition control and inspection, heating of a walking heating furnace, rough rolling, top cutting by a flying shear, middle rolling, precision rolling in advance, high-speed precision rolling, sending and clamping, as well as spinning, temperature controlling, and disperse coil cooling, collecting coils, and steel wire rod inspection. The method is characterized in that through optimizing the technology parameters of operation key points, the effective control to microstructure of the steel wire rod for the carbon steel welding wire on a high-speed wire rod production line short of slow cooling capability is realized, and the frequent brittleness problem caused by the common structure reason in the drawing process, especially the high-speed drawing process of the steel wire rod for the carbon steel welding wire on produced on the production line is solved. The method has the advantages that the effective control of the steel wire rod structure for the carbon steel wire on the traditional high-speed line material production line can be realized without prolonging the length of slow cooling, and the generation of the low-temperature hard phase structure is avoided, thus the drawing performance of the steel wire rod is changed, and the requirement of drawing use of the type of the steel wire rod is met.

Owner:SHOUGANG CORPORATION

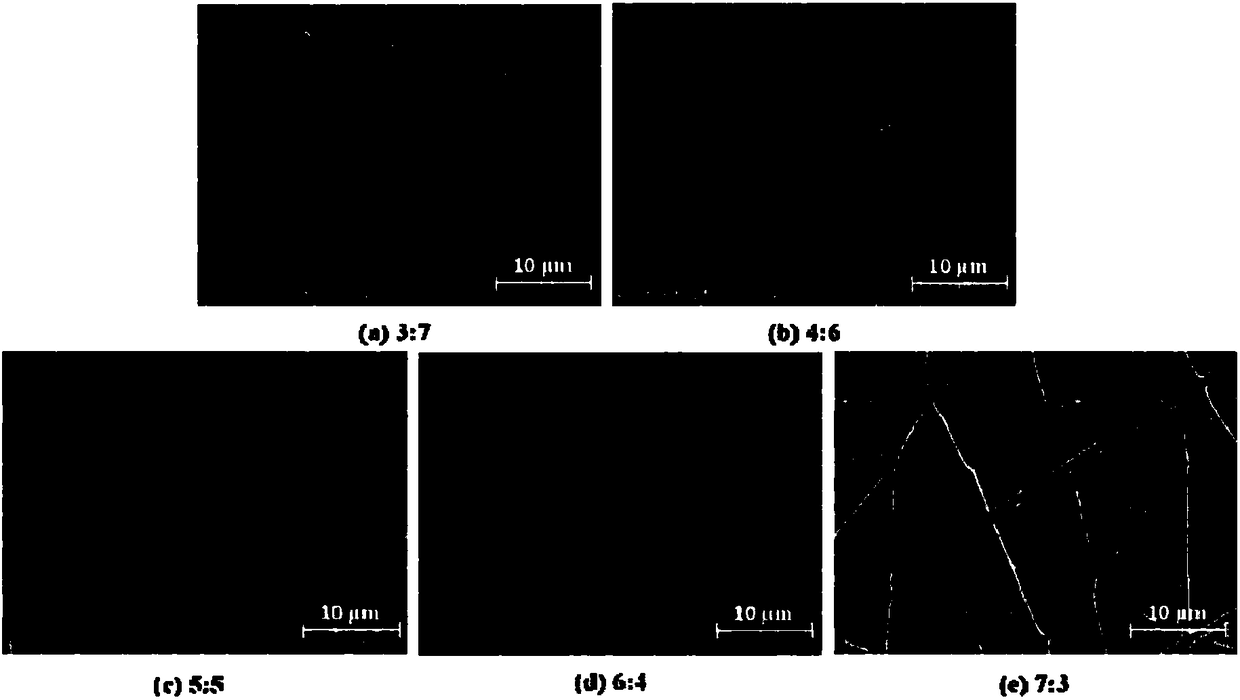

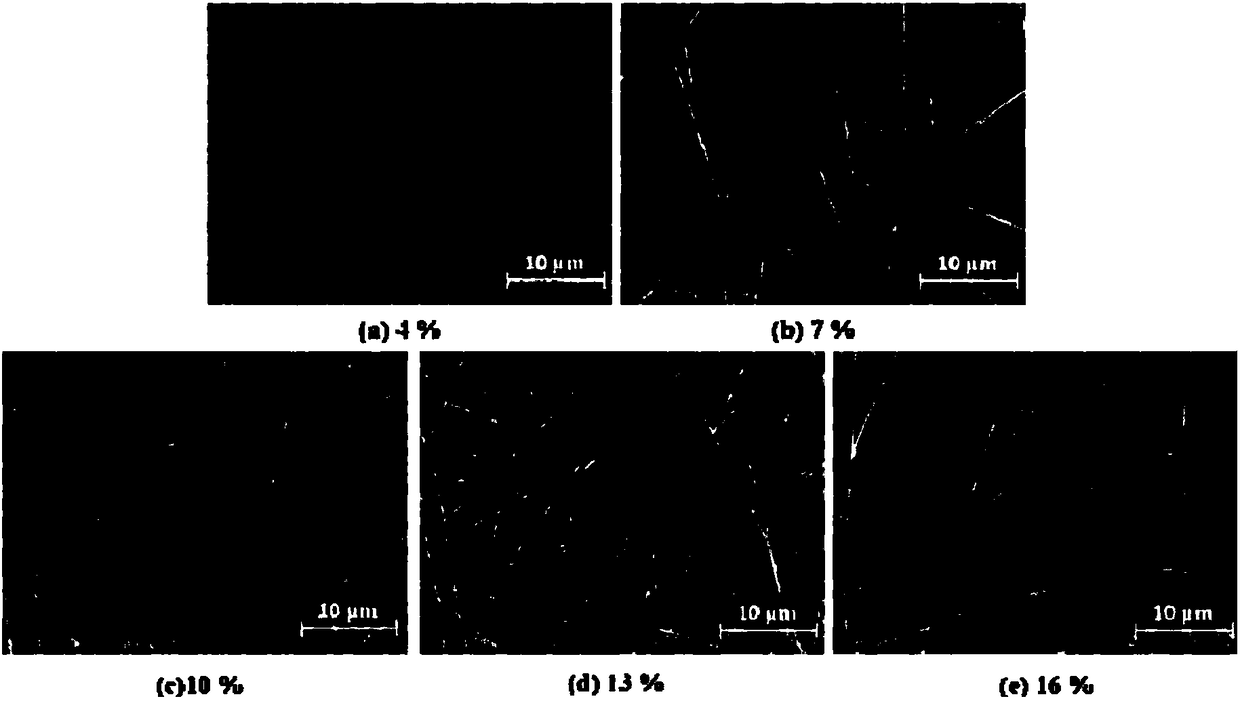

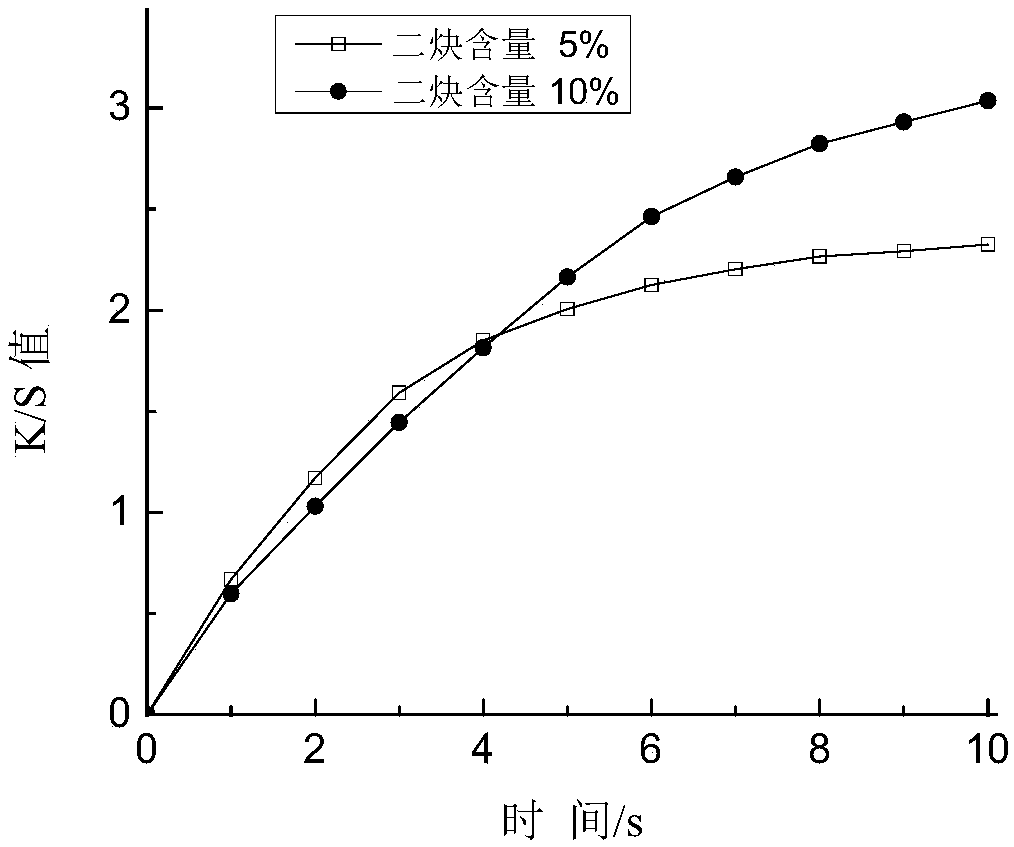

Preparation method, obtained material and application of photo/thermal dichromic fiber

ActiveCN108547010AControl microstructureImprove responsivenessConjugated synthetic polymer artificial filamentsArtifical filament manufactureResponse sensitivityFiber

The invention discloses a preparation method, an obtained material and application of photo / thermal dichromic fiber. The dichromic fiber is formed through recombination of a diyne compound and a high-molecular polymer / heat-set polyurethane mixed polymer serving as a spinning base material by adopting an electrostatic spinning method. Compared with the prior art, the equipment needed in the preparation method is simple, the cost is low, the technology is controllable, the prepared photo / thermal dichromic fiber is stable in property and has the higher response sensitivity, has two different discoloring effects, and can be applied to the fields of textile and garment, chemical anti-fake, sensors and the like.

Owner:JIANGNAN UNIV

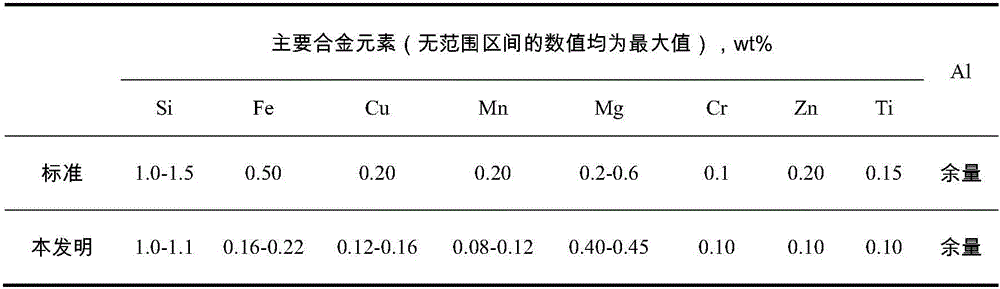

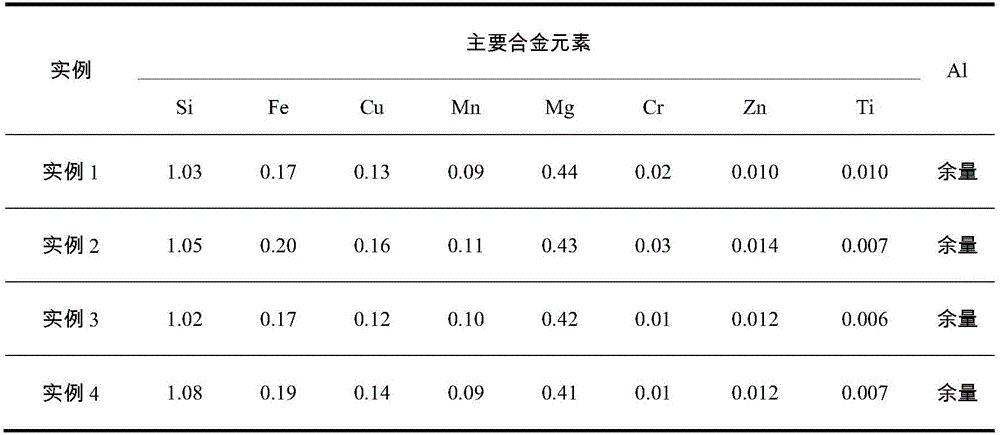

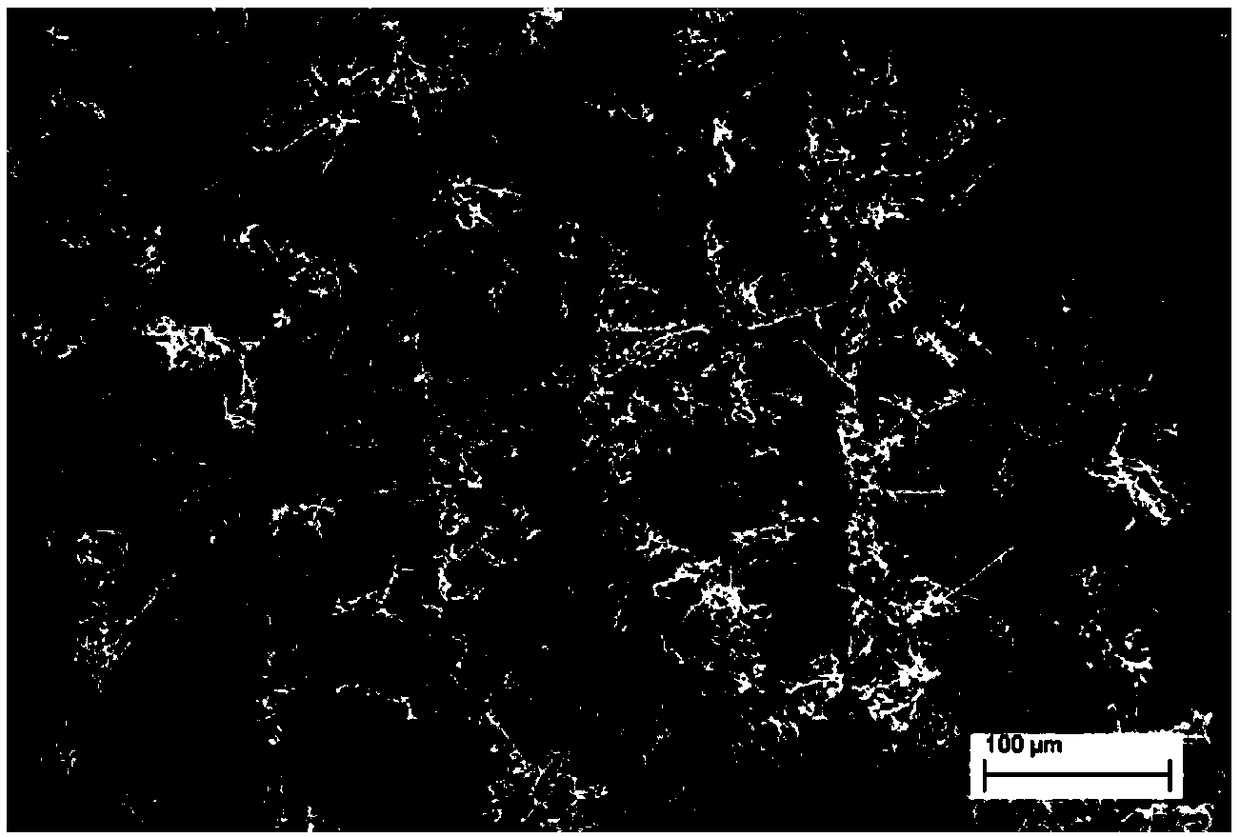

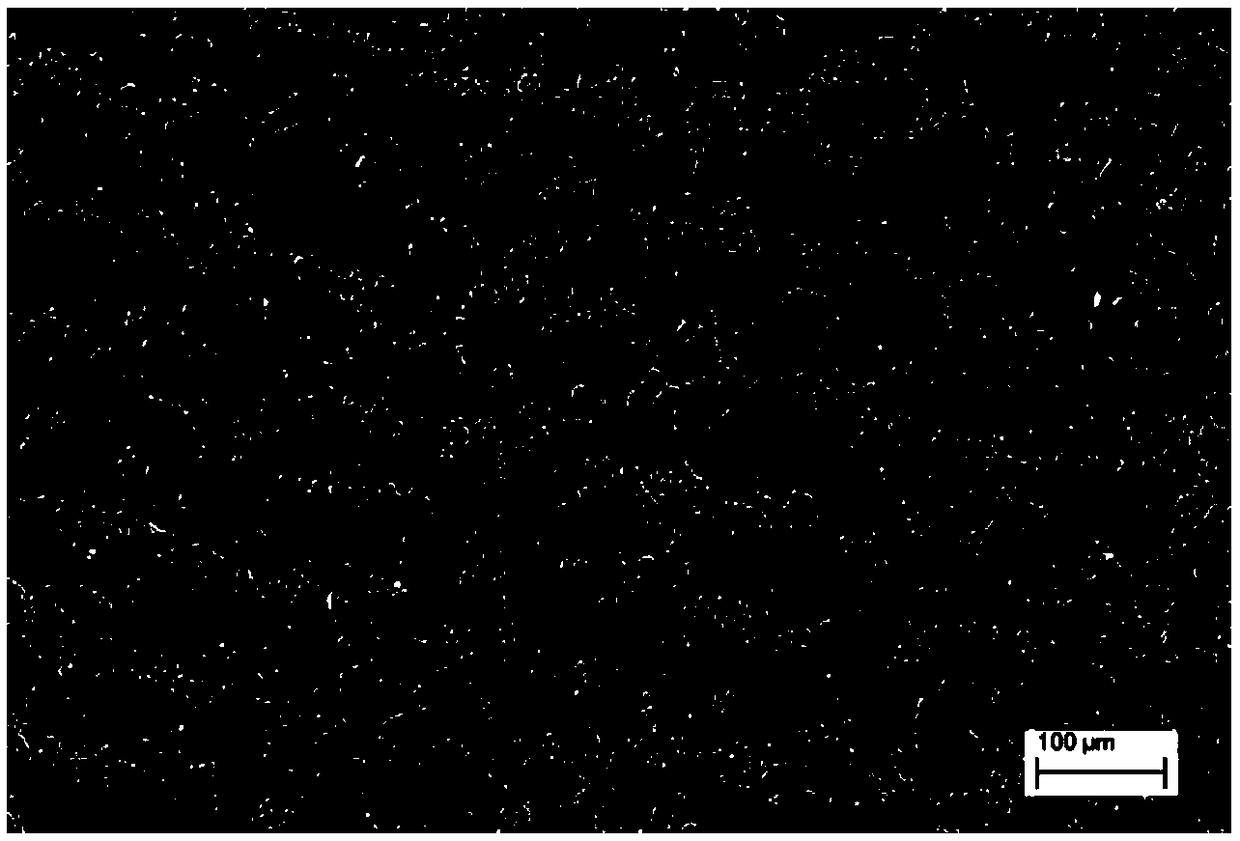

Aluminum alloy sheet and production method thereof

InactiveCN105925858AExcellent formability and mechanical propertiesImproved coiling performanceChemical compositionHardness

The invention discloses a 6016-series aluminum alloy sheet for a vehicle body and a production method thereof. The aluminum alloy sheet comprises the following chemical components in percentage by mass: 1.0-1.5% of Si, 0-0.50% of Fe, 0-0.20% of Cu, 0-0.20% of Mn, 0.25-0.60% of Mg, 0-0.10% of Cr, 0-0.10% of Zn, 0-0.10% of Ti, and the balance of Al. The production method comprises the steps of batching-smelting-converter-furnace side refining-standing-casting-sawing-surface milling-ingot homogenization-hot rolling-intermediate annealing-cold rolling-electrospark frosting-finished product cold rolling-solid solution quenching-drawing correction-Ti / Zr passivation-preageing-finished product coiling. The aluminum alloy sheet can provide a high-grade vehicle body sheet to users, improves the yield in punching, reduces the vehicle manufacturer cost, improves the formability and the baking hardness of aluminum alloy sheets, and is broad in market prospect and prominent in economic benefit.

Owner:SHANDONG NANSHAN ALUMINUM +1

Graphene concrete and preparation process thereof

The invention relates to graphene concrete and a preparation process thereof and solves technical problems of poor durability and proneness to corrosion of concrete in the prior art. The graphene concrete is prepared from, by weight, 150-220 parts of cement, 150-220 parts of sea sand, 225-330 parts of gravels, 5-18 parts of lignosulfonate, 40-100 parts of water, 10-40 parts of silicon powder, 15-45 parts of coal ash, 2-5 parts of graphene, 3-6 parts of oxidized graphene, 1-2.5 parts of magnesium powder, 2-12 parts of polypropylene fibers, 5-15 parts of carbon fibers and 0.5-1 part of ethyleneglycol. The graphene concrete is widely applied to the field of building materials.

Owner:山东昇昀国际贸易有限公司

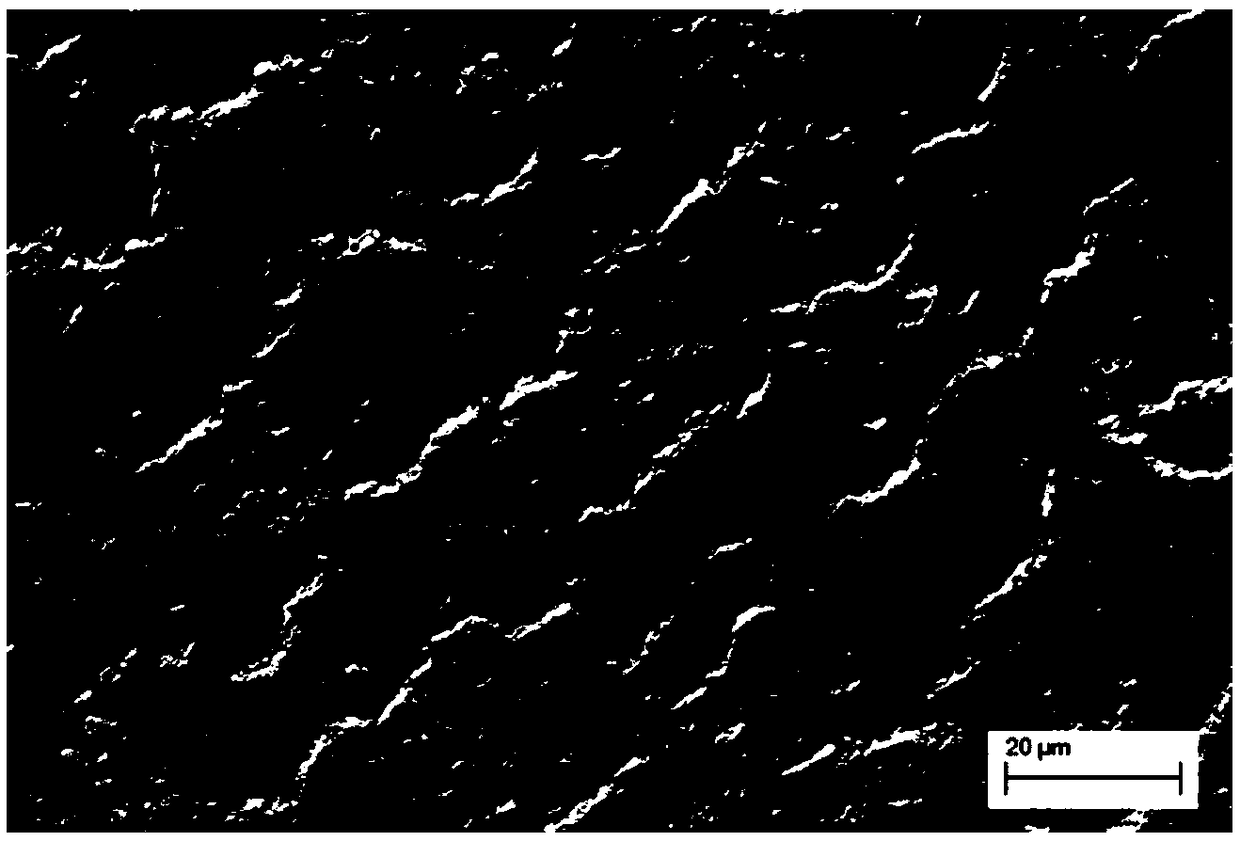

Silicon carbide reinforced metal matrix composite with micro orientated structure and preparation method thereof

The invention relates to a silicon carbide reinforced metal matrix composite with a micro orientated structure and a preparation method thereof. The composite consists of silicon carbide with a volumefraction of 5-90% and metal, and has the micro orientated structure which is expressed as oriented arrangement of the silicon car bide in a metal matrix. The preparation method of the composite comprises the following steps of: firstly preparing water-based slurry containing silicon carbide powder; processing the slurry by utilizing freeze casting and vacuum freeze drying to obtain a green body with an orientated porous structure; compressing the green body and removing organic matters in the green body; carrying out sintering to obtain an oriented porous skeleton of silicon carbide; and finally infiltrating the skeleton by utilizing liquid metal bath, and carrying out solidification and cooling to obtain the silicon carbide reinforced metal matrix composite with the micro orientated structure. The composite has excellent properties such as light mass, high intensity, wear resistance and high-temperature creep resistance, the micro structures and properties of the composite can be effectively controlled through adjusting the preparation process, and the composite has considerable application prospect when serving as a structural material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Wide-temperature range and high-efficiency soft ferrite material, magnetic core preparation method and application

ActiveCN108558385AEffective dopingControl microstructureInorganic material magnetismInductances/transformers/magnets manufactureVolumetric Mass DensityHigh effectiveness

The invention provides a wide-temperature range and high-efficiency soft ferrite material, a magnetic core preparation method and the application. Through optimized selection of a main formula and effective doping, the wide-temperature range and high-efficiency soft ferrite material is developed; by a multi-stage equilibrium atmosphere sintering method, the density, the crystal grain size and theporosity of the ferrite material and distribution of the ferrite material inside and between crystal grains are controlled, so that the microstructure of the ferrite material is more effectively controlled, and main characteristic parameters of the material are guaranteed to be harmonious and unified; ui of a final product can reach 3400, the core loss at 25-120 DEG C is 350mW, the core loss at 100 DEG C is 250mW, the L value stably reaches +3.5% in the temperature range of -40 DEG C to 85 DEG C, and the overall loss level is reduced by 8-13.8% in a relatively wide temperature range; the hightemperature Bs of the final product is also greatly improved, the final product has excellent inductance stability under a wide-temperature range condition, and the production cost is reduced by 20% or above.

Owner:湖北华磁电子科技有限公司

Method for improving processing property of FeCrNiAl-based high-entropy alloy

The invention belongs to the fields of metal material processing and heat treatment and relates to a method for improving the processing property of FeCrNiAl-based high-entropy alloy. An optimizing treatment process comprises high-temperature homogenization, forging and annealing, and particularly comprises the following steps: maintaining homogenizing treatment at 1200 to 1300 DEG C for 3 to 20 hours; performing forging with the deformation quantity of 1:9 to 1:5, wherein the forging deformation rate is not more than 10 s<-1>; and performing periodic annealing at the temperature of 1100 to 1250 DEG C and performing furnace cooling to room temperature. After the above optimizing treatment, high-entropy alloy avoids crack and cracking phenomena in cold and hot processing, a stable hot processing area is obviously enlarged and the processing property is significantly improved. Through high-temperature long-time heat insulation, high-temperature forging and periodic annealing process, thedefects of bulky arborescent structure, component segregation and micropores in the cast-state high-entropy alloy are effectively eliminated, so that the plasticity and the toughness of the high-entropy alloy are improved and the processing property can be optimized.

Owner:ANYANG INST OF TECH +1

Phase conversion pouring preparation process and forming device for inorganic porous ceramic tubular membrane

InactiveCN104707489ASimple equipmentThe preparation process and equipment are simpleSemi-permeable membranesSulfonePorous pipe

The invention discloses a phase conversion pouring preparation process and a forming device for an inorganic porous ceramic tubular membrane. The preparation process comprises the steps of preparing a ceramic casting solution, forming a film in a phase conversion manner and completely solidifying the film. Ceramic powder, N-methyl-2-pyrrolidinone, polyvinylpyrrolidone and polyether sulfone are uniformly mixed to obtain the casting solution according to a given ratio; then the casting solution is defoamed and then injected into the forming device, and the demolding and formation can be realized in a solidification bath; finally the film is completely solidified in the solidification bath to obtain a ceramic film green body. The process has the characteristic that the phase conversion process is combined with a pouring forming process to realize the preparation of a ceramic film tube. Compared with a traditional extrusion forming and pouring process, the process is low in cost, easy to operate and capable of meeting the requirements for preparing a porous tube, an asymmetric hole gradient structural tube, a specially-shaped tube or a multichannel tube.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

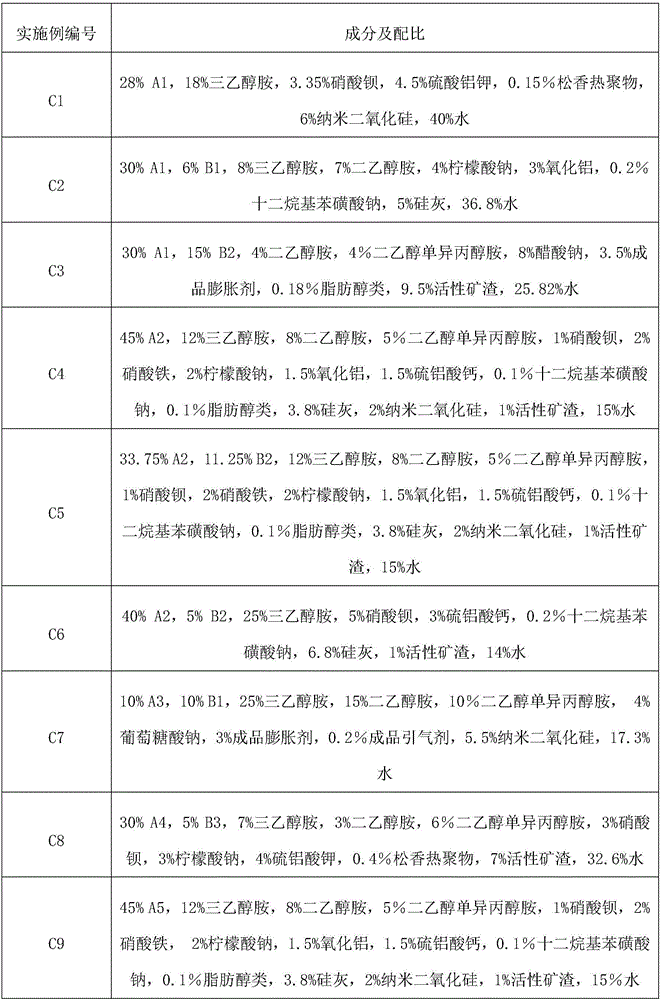

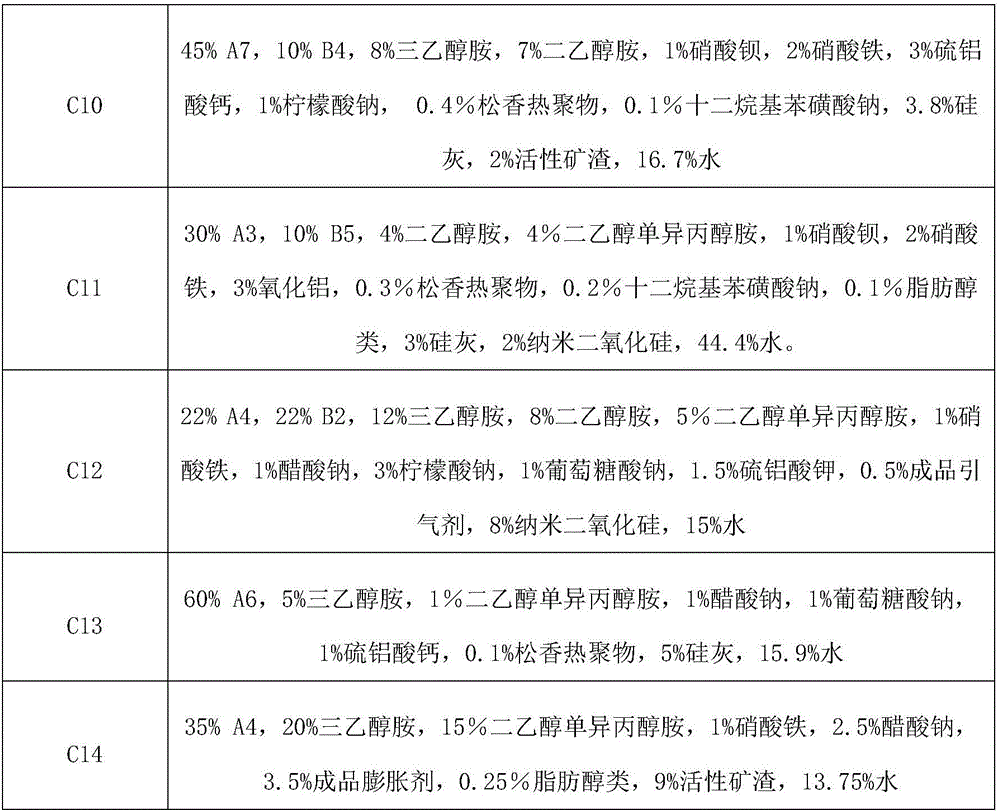

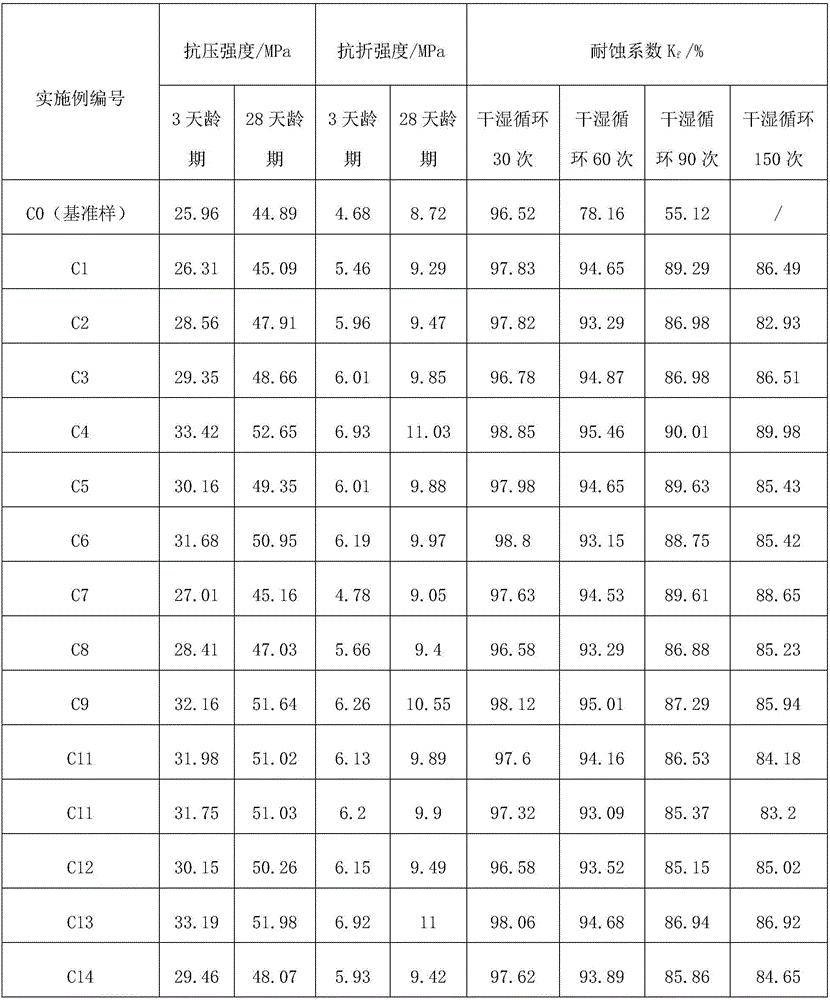

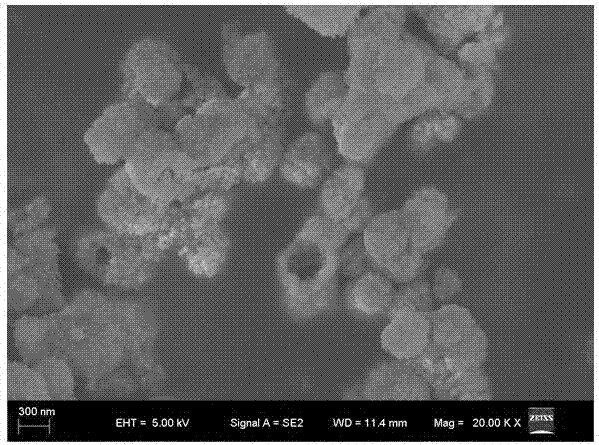

Graphene-base concrete resist and application thereof

ActiveCN106746829ADifficult to disperseHinder crystallization expansion reactionInorganic saltsSocial benefits

The invention discloses a graphene-base concrete resist and a preparation method thereof, a functionalized graphene oxide and a preparation method thereof, and a functionalized graphene and a preparation method thereof. The graphene-base concrete resist comprises the following raw materials in parts by weight: 20-60 parts of graphene carbon material, 10-50 parts of alcamine compounds, 2-8 parts of inorganic salt, 1-6 parts of expanding agent, 5-10 parts of filler, 0.1-0.5 part of air entraining agent and 5-50 parts of water. The graphene carbon material is graphene oxide or a graphene oxide-graphene mixture. The experimental research indicates that when the graphene concrete resist is used, the sulfate attack resistance coefficient of the concrete can reach 0.82 or above, thereby obviously prolonging the service life of the concrete material, and bringing in obvious economic benefits and social benefits.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

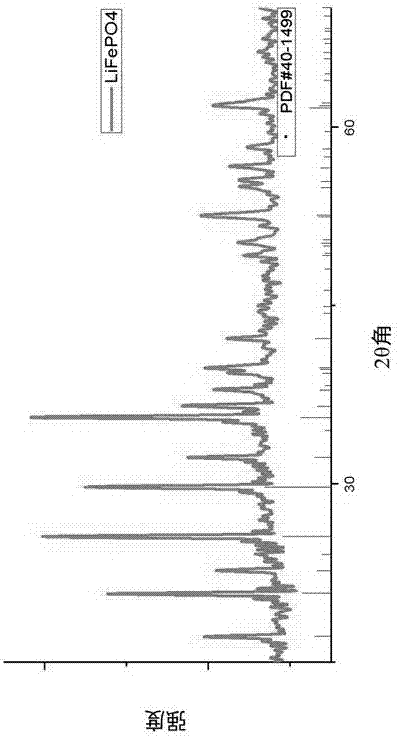

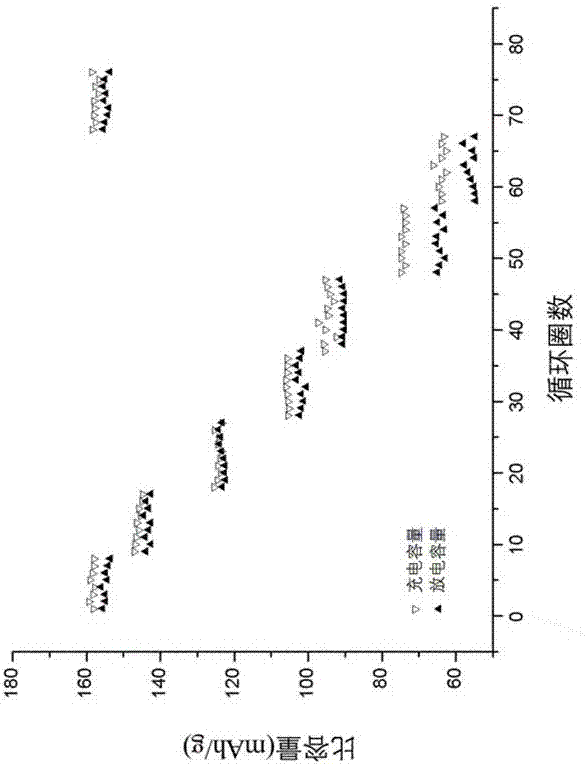

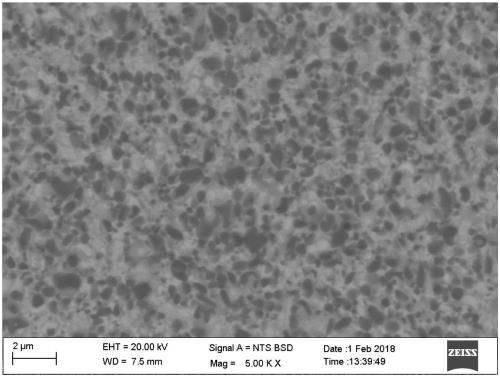

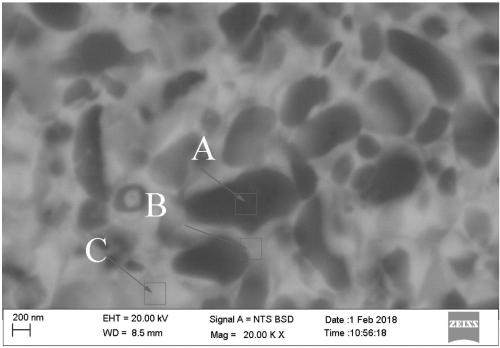

Preparation method of carbon-coated lithium iron phosphate hollow nanospheres

The invention discloses a preparation method of carbon-coated lithium iron phosphate hollow nanospheres and belongs to the technical field of lithium-ion battery materials. Polyethylene glycol 600 and deionized water are mixed, the obtained mixture is mixed with phosphoric acid and lithium hydroxide monohydrate for a reaction, and a lithium phosphate precursor is obtained; the lithium phosphate precursor is mixed with ethylene glycol and ferrous chloride tetrahydrate, ultrasonic treatment is performed for 30 min, the obtained mixture is placed in an autoclave to be subjected to a sealed heating reaction, and lithium iron phosphate hollow nanospheres are prepared; the lithium iron phosphate hollow nanospheres are dipped in a sucrose aqueous solution, the dipped lithium iron phosphate hollow nanospheres are dried and calcined in a nitrogen atmosphere, and the carbon-coated lithium iron phosphate hollow nanospheres are obtained. Nano spherical lithium phosphate is taken as a self-sacrifice template, a template removal step is omitted during preparation, the method adopts a convenient process, the microstructure of lithium iron phosphate can be effectively controlled, and high-purity lithium iron phosphate hollow nanospheres can be obtained.

Owner:YANGZHOU UNIV

Multilayer antioxidant high-temperature-resistant SiC/Ta/C/Ta/SiC coating and preparation method thereof

ActiveCN103722849AImproves antioxidant propertiesMitigates differences in coefficient of thermal expansionLayered productsOxidation resistantMicrostructure

The invention discloses a multilayer antioxidant high-temperature-resistant SiC / Ta / C / Ta / SiC coating and a preparation method thereof. The multilayer antioxidant high-temperature-resistant SiC / Ta / C / Ta / SiC coating is formed by laminating SiC layers, Ta layers and C layers, and is characterized in that the laminating sequence is the SiC layer, the Ta layer, the C layer, the Ta layer and the SiC layer, or SiC layer, the Ta layer, the C layer, the Ta layer, the SiC layer, SiC layer, the Ta layer, the C layer, the Ta layer, and the SiC layer, or SiC layer, the Ta layer, the C layer, the Ta layer, the SiC layer, SiC layer, the Ta layer, the C layer, the Ta layer, the SiC layer, SiC layer, the Ta layer, the C layer, the Ta layer and the SiC layer; both sides of the C layer are Ta layers; the innermost layer and the outermost layer are SiC layers; and the Ta layer, the C layer, the Ta layer and the SiC layer are sequentially deposited on the prepared SiC layer with a chemical vapor deposition method so as to obtain the multilayer antioxidant high-temperature-resistant SiC / Ta / C / Ta / SiC coating. According to the coating and the preparation method thereof, the outer SiC layer forms a layer of SiO2 film in a high-temperature aerobic environment, so that diffusion of oxygen atoms can be prevented effectively, and meanwhile, a TaC layer can be formed on a contact surface of the Ta layer and the C layer to further improve the antioxidation performance. Alternate deposition of coatings can effectively relieve differences of coefficients of thermal expansion of the coatings and improve the thermal shock performance of the coatings remarkably, the thickness and lay number of a matrix can be controlled by controlling deposition time and deposition times, and the microstructure of the composite coating can be controlled.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

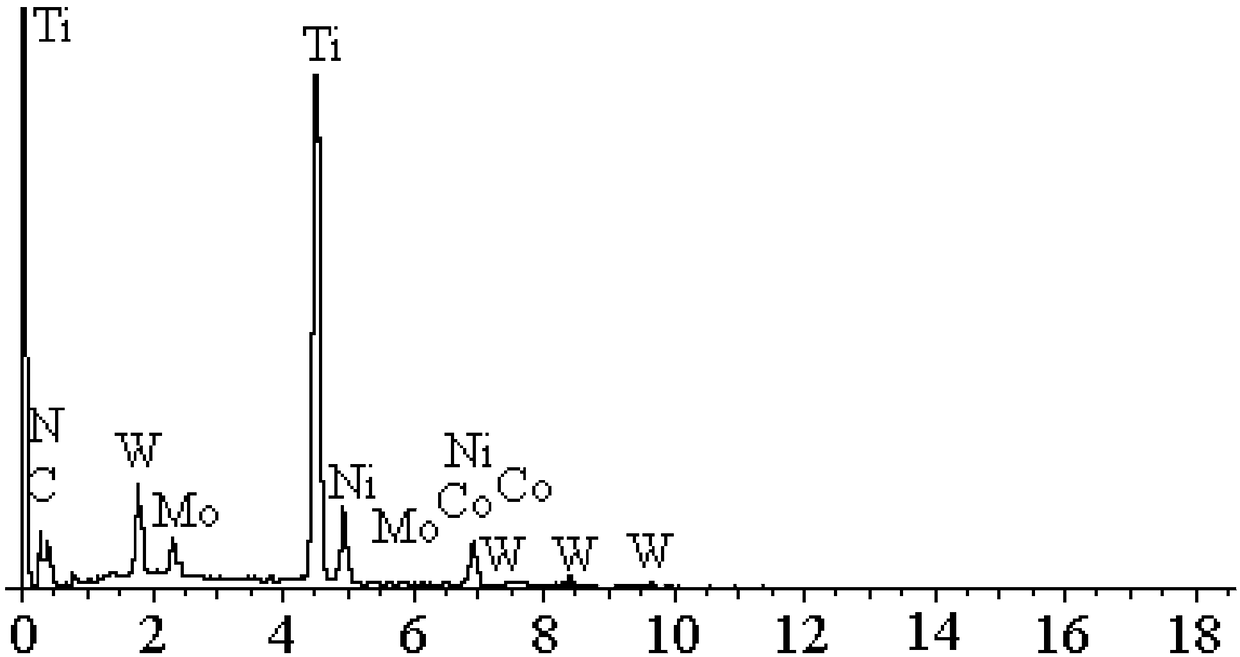

Metal ceramic alloy free of core-ring structure and preparation method thereof

ActiveCN109338193ASmall expansion coefficientRealize microcrystallization interfacial bonding methodMaterials preparationAlloy

The invention relates to the technical field of metal ceramic material preparation, and relates to a metal ceramic alloy free of a core-ring structure and a preparation method thereof. The metal ceramic alloy free of the core-ring structure comprises the following components of, in percentage by weight, 10-55% of Ti (C, N) micron powder, 10-55% of (Ti, M) (C, N) micron powder, 10-55% of Ti (C, N)sub-micron or / and nano powder, 10-55% of (Ti, M) (C, N) sub-micron or / and nano powder, 5-20% of WC, 0-30% of TiC, 0-30% of TiN, 0-20% of Co, 0-20% of Ni, 0-10% of Cr, 0-15% of Mo2C, 0-10% of TaC / NbC,0-2. 5% of VC, 0-5% of Cr2C3, and 0-1.2% of carbon black; the components are prepared into a mixture according to a certain ratio, the mixture is subjected to ball milling, sieving and mould pressingto prepare a blank, and the blank is subjected to sintering and cooling to prepare a metal ceramic material free of the core-ring structure. According to the method, a powder metallurgy method is adopted to prepare the metal ceramic alloy free of the core-ring structure, and the technological difficulty of being not easy to control the thickness of a microcosmic core-ring structure in the preparation process a traditional metal ceramic with core-ring structures is solved.

Owner:ZIGONG CEMENTED CARBIDE CORP

Method for preparing isotropic coke through catalytic carbonization

InactiveCN104293366ALow reaction temperatureShorten the production cycleWorking-up pitch/asphalt/bitumen by chemical meansCoking carbonaceous materialsChemistryCoal

The invention relates to a method for preparing isotropic coke through catalytic carbonization. The method comprises the following steps: by taking coal tar (or coal pitch) as a raw material, adding a certain ratio of lewis acid catalyst, mixing to be uniform, putting the mixture into an autoclave, and performing catalytic carbonization under a certain temperature and pressure, thereby obtaining the isotropic coke. Compared with the traditional process for coking carbon precursors at high temperature through reactions such as thermal initiated free radical polymerization and cracking, the catalytic carbonization method has the advantages that the needed heating temperature is low, and low-cost coal tar (or coal pitch) is selected. Therefore, the manufacturing cost of the isotropic coke is greatly reduced on aspects of the raw materials and the process.

Owner:HUAQIAO UNIVERSITY

Rapid low-temperature preparation method for Y-alpha-SiAlON transparent ceramics

The invention relates to a rapid low-temperature hot-pressing sintering method for transparent Y-alpha-SiAlON ceramics, and belongs to the field of transparent ceramic material preparation. The method comprises the following steps: firstly, batching on the basis of an alpha-SiAlON composition design, preparing ultrafine mixed powder by adopting a planetary ball mill, and preparing the transparent Y-alpha-SiAlON ceramics by utilizing the obtained ultrafine mixed powder by adopting the technologies of high-temperature slow pressurizing and cooling with pressure, high-temperature rapid nitrogen-filling, high-temperature rapid heating and rapid cooling. According to the method, the densification process of the alpha-SiAlON ceramics is greatly promoted by adopting the technology of preparing the transparent Y-alpha-SiAlON ceramics by the ultrafine mixed powder, the sintering time is effectively shortened, the sintering temperature is remarkably reduced, and the rapid low-temperature sintering of the alpha-SiAlON ceramics is realized.

Owner:DALIAN MARITIME UNIVERSITY

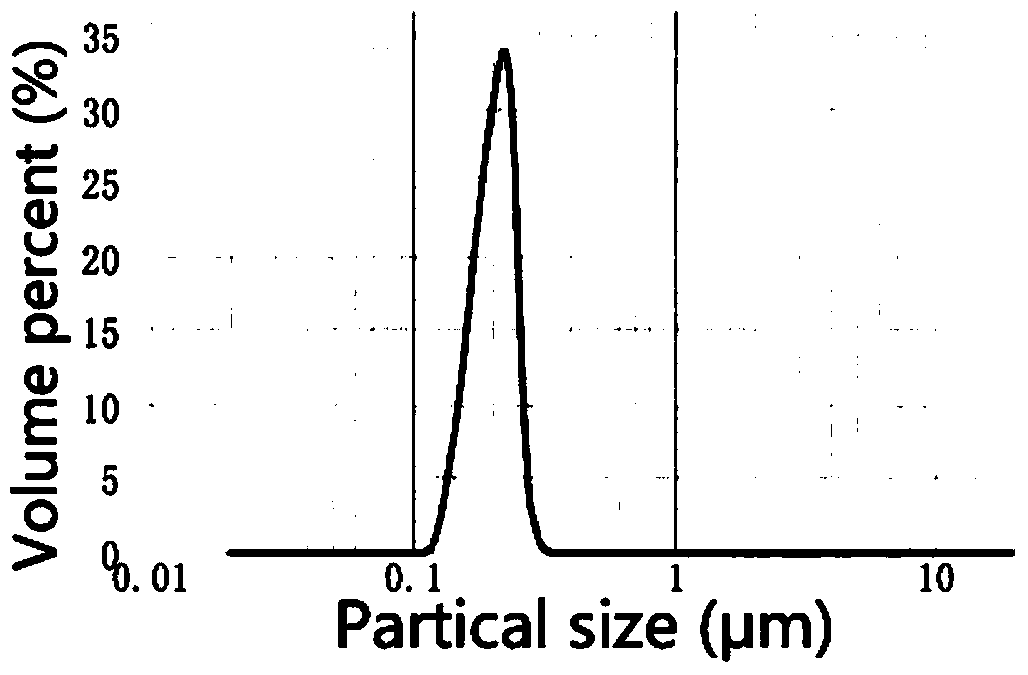

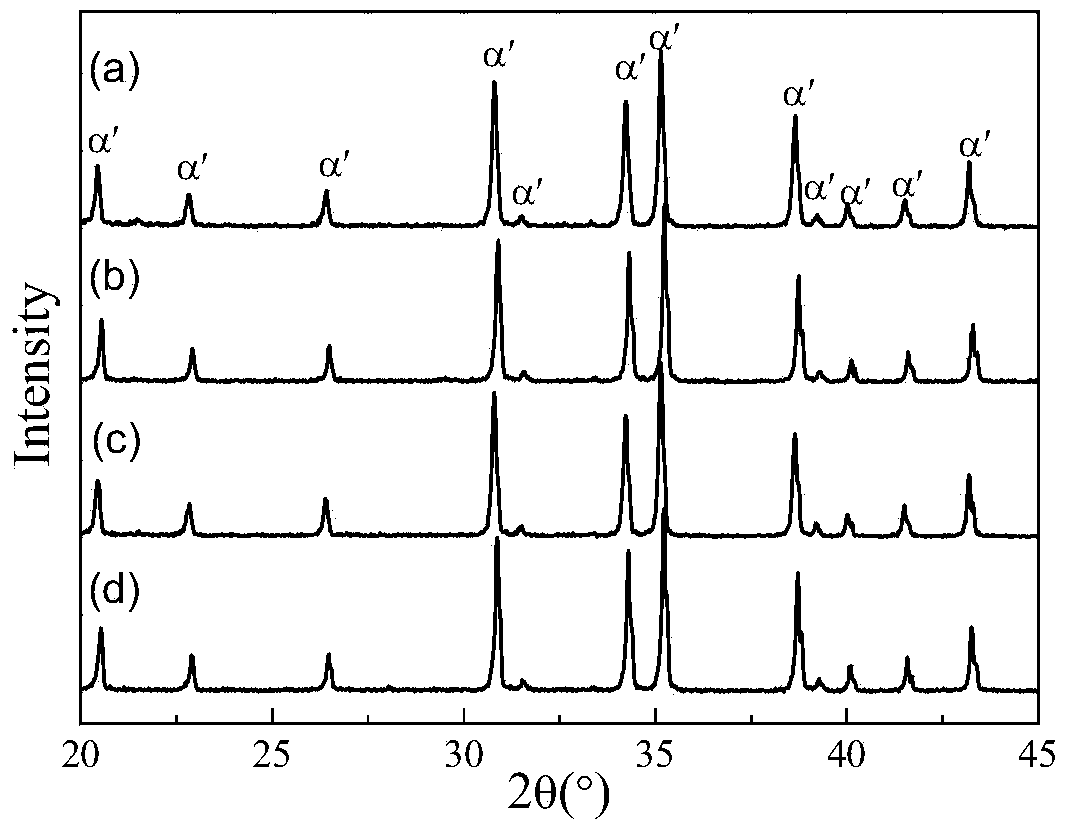

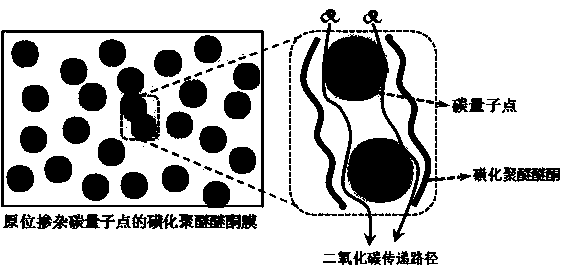

SPEEK (Sulfonated Polyether Ether Ketone) mixed matrix membrane with in-situ doped carbon quantum dots as well as preparation method and application thereof

ActiveCN108745002AImprove free volume fractionHigh crystallinitySemi-permeable membranesGas treatmentSeparation factorPolyether ether ketone

The invention discloses an SPEEK (Sulfonated Polyether Ether Ketone) mixed matrix membrane with in-situ doped carbon quantum dots as well as a preparation method and application thereof. The preparation method comprises the following steps: taking polyvinyl alcohol and polyether ether ketone as raw materials and adding the raw materials in concentrated sulfuric acid, and reacting, thus obtaining an SPEEK composite material with the in-situ doped carbon quantum dots; dissolving the SPEEK composite material into deionized water, thus preparing a membrane casting solution; preparing a functionallayer on the surface of a microporous filter membrane through a coating method, and forming the SPEEK mixed matrix membrane of the in-situ doped carbon quantum dots, the mixed matrix membrane is formed by SPEEK and carbon quantum dots, wherein the carbon quantum dots account for 0.1 to 5.0 percent by mass of the SPEEK.. The preparation method provided by the invention is simple and easy, a prepared functional membrane can be applied to CO2 / N2 gas separation, and higher CO2 permeability and separation factors are obtained.

Owner:TAIYUAN UNIV OF TECH

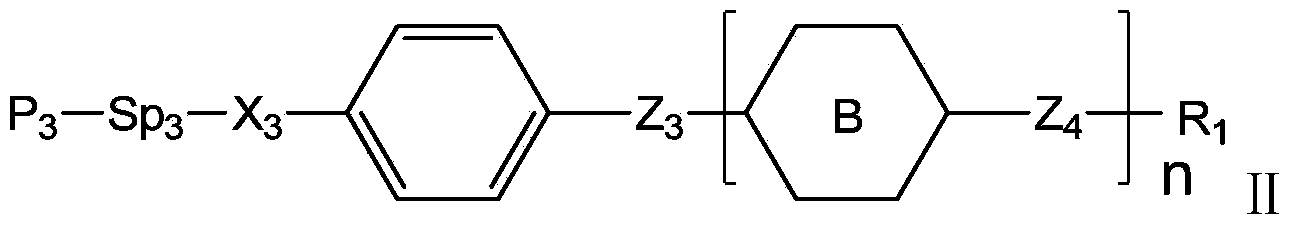

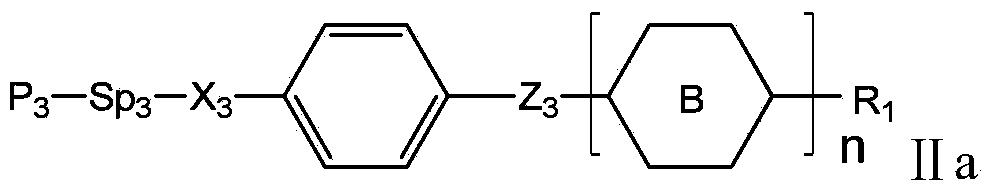

Liquid crystal combination

InactiveCN104099104ASolve the melting pointSolve problems such as refractive indexLiquid crystal compositionsCrystallographyLiquid-crystal display

The invention provides a polymerized liquid crystal combination. According to the polymerized liquid crystal combination, at least one compound containing two polymerizable groups and conforming to a general formula I serves as a first component, and at least one compound containing a polymerizable group and conforming to a general formula II serves as a second component. Compared with other polymer liquid crystal compounds in the prior art, the polymerized liquid crystal combination is low in melting point and large in optical anisotropy and can be used for preparing a phase difference film and improve optical performance of a liquid crystal display.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

Preparation method of fine-grain TA15 titanium alloy foil

ActiveCN113578959AControl microstructureControl mechanical propertiesForging/pressing devicesFurnace typesTitanium alloyMaterials science

The invention discloses a preparation method of fine-grain TA15 titanium alloy foil. The preparation method specifically comprises the following steps of (1) heating a TA15 titanium alloy cast ingot at 1000-1100 DEG C, and then carrying out cogging forging to obtain a plate blank; (2) carrying out heat preservation at 900-960 DEG C, and then carrying out rolling; (3) carrying out heat treatment at 30-50 DEG C above a beta phase transformation point, and then carrying out water quenching cooling; (4) carrying out heating at 900-940 DEG C, and then carrying out rolling; (5) carrying out assembly welding on the obtained blank to obtain a cladding ply-rolling pack; (6) carrying out heating at 900-940 DEG C, and then carrying out rolling for the fourth time; (7) opening the ply-rolling pack, and then carrying out assembly welding on the blank to obtain a cladding ply-rolling pack; (8) carrying out heating at 920-940 DEG C, and then carrying out rolling in a direction perpendicular to the previous rolling direction; (9) carrying out annealing, creep correction, alkali pickling and sanding on the blank to obtain a plate with the thickness of 0.6 mm; (10) shearing the plate, and then carrying out cold rolling multiple times to obtain rolled foil with the thickness ranging from 0.1 mm to 0.2 mm; and (11) carrying out vacuum annealing heat treatment to obtain the finished foil with the thickness ranging from 0.1 mm to 0.2 mm.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

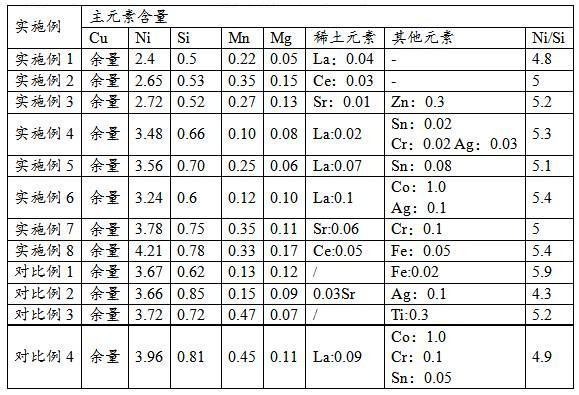

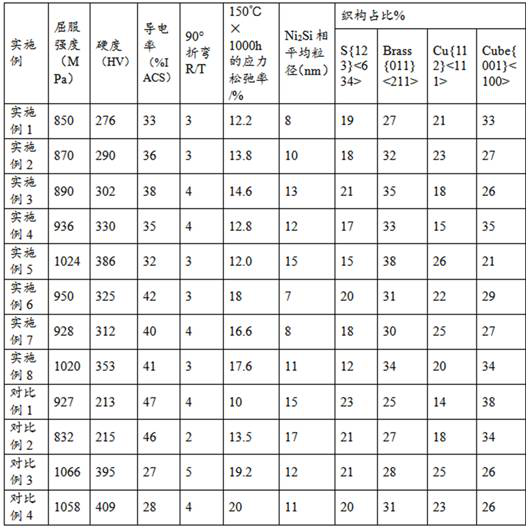

Environment-friendly conductive elastic copper alloy and preparation method thereof and application in connectors

PendingCN112111671AImprove high temperature resistanceAccelerated corrosionConductive materialMetal/alloy conductorsSolution treatmentRare-earth element

The invention belongs to the technical field of non-ferrous metal processing, and provides an environment-friendly conductive elastic copper alloy and a preparation method and application thereof. Thecopper alloy comprises, by weight, 2.0-4.3% of Ni, 0.5-0.85% of Si, 0.05-0.4% of Mn, 0.01-0.2% of Mg, 0.01-1.0% of rare earth element and the balance of Cu. The copper alloy can keep high conductivity while having ultrahigh strength, has the characteristics of being high-temperature-resistant, stress-relaxation- resistant, complex-environment-corrosion-resistant and high in elasticity, is excellent in forming performance and high in reliability, can meet the use requirements of connectors in different application scenes, and is a new generation of alloy material for the connectors. Accordingto the preparation method, the copper alloy is prepared through smelting, casting, hot rolling, primary rolling, intermediate annealing, intermediate rolling, rapid solution treatment, finish rollingand aging treatment, so that the microstructure of the copper alloy can be effectively controlled, and various properties of the copper alloy are guaranteed.

Owner:NINGBO XINGYE SHENGTAI GROUP

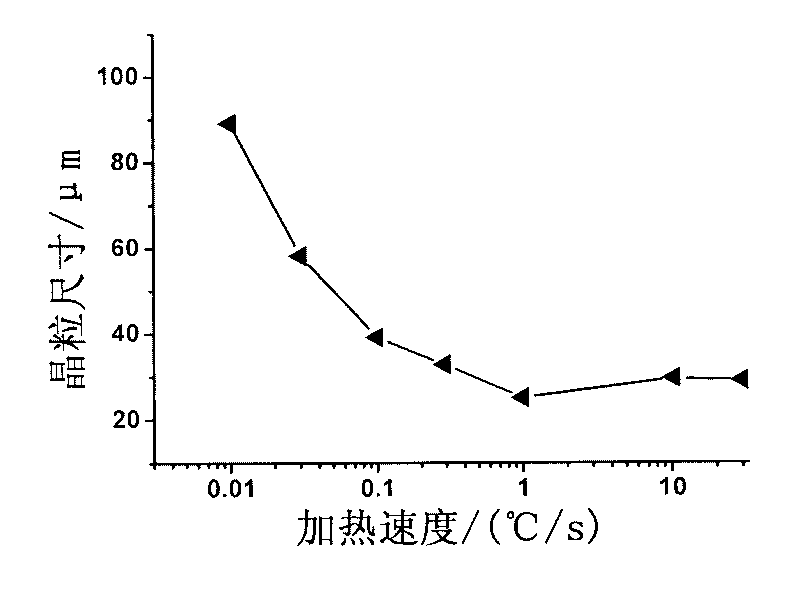

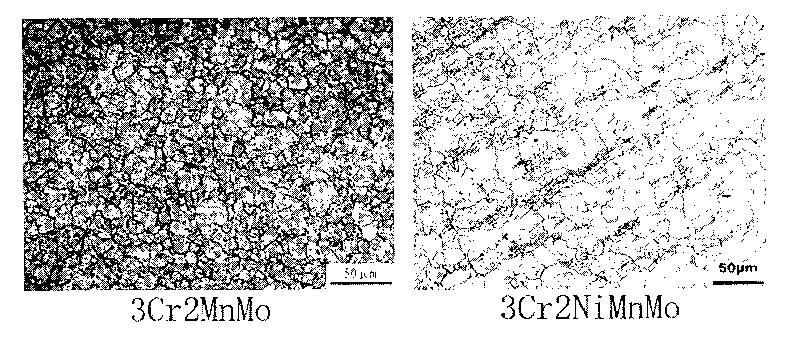

Organization control method of large-size pre-hardening type plastic die steel module

ActiveCN101736139AControl grain sizeControl microstructureHeat treatment process controlSlow coolingHeat treated

The invention relates to an organization control method of a large-size pre-hardening type plastic die steel module for manufacturing plastic products, belonging to the technical field of metallographical organization structure control of alloy steel heat treatment. Aiming at multiple large-size pre-hardening type plastic die steel containing carbon, chromium, manganese and molybdenum or the large-size pre-hardening type plastic die steel containing a small amount of elements of copper, nickel, aluminum, boron, and the like, after steel ingots are forged into a module, cooling is controlled according to the phase change characteristics of the steel, and then heat is preserved in a low-temperature furnace to ensure that the austenite of the module is sufficiently converted; the module is heated again at a proper speed, and after complete austenite, the cooling is controlled; after the temperature of the surface of the module is reduced to 350-200 DEG C, slow cooling is carried out to obtain a bainite or bainite and martensite mixed organization, and the grain size is 5-8 grades; and finally, tempering is carried out within a temperature range of 300-600 DEG C, the hardness is adjusted into a range of 28-38 HRC, and the section hardness difference is smaller than + / -2HRC.

Owner:SHANGHAI UNIV

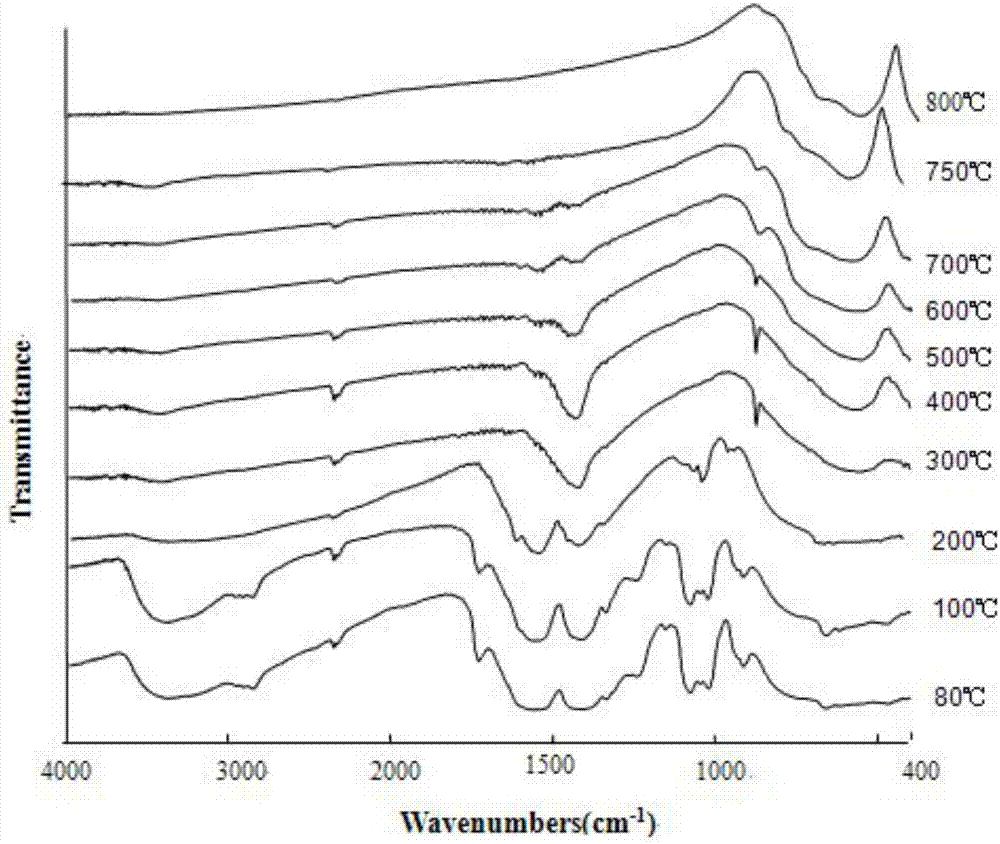

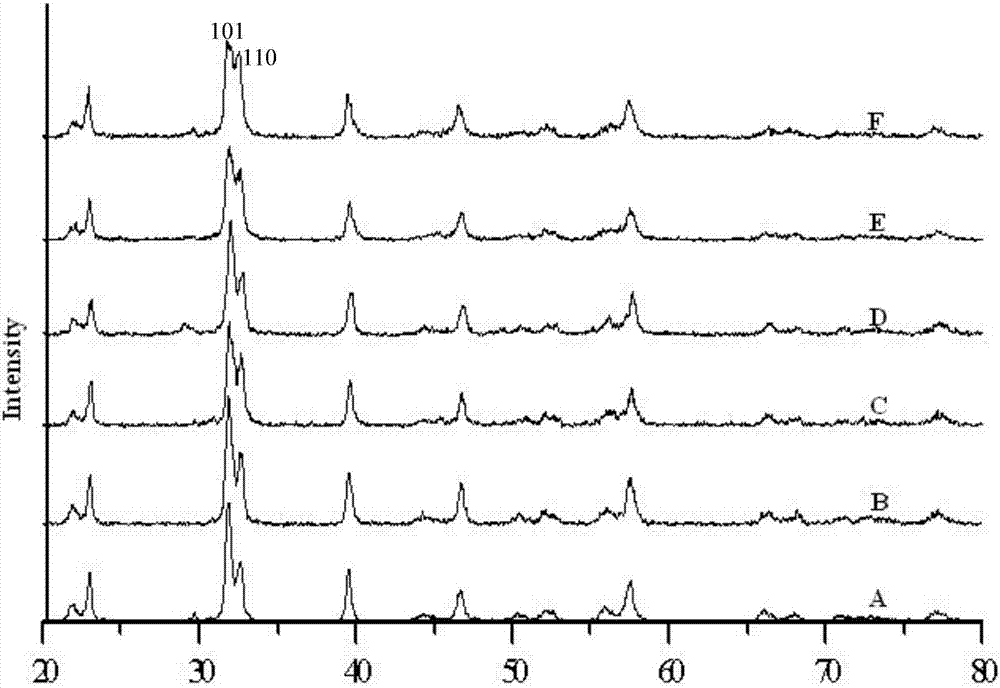

Preparation method of calcium doped lead titanate ceramic fiber

InactiveCN107164841AImprove uniformityMicrostructure is easy to controlFibre chemical featuresFiberHigh density

The invention relates to a preparation method of calcium doped lead titanate ceramic fiber, and the preparation method is characterized by comprising the following specific steps: (1) preparation of stable sol; (2) drawing and drying; (3) decomposition of dry gel fiber; and (4) sintering. The sintering conditions are as follows: the sintering temperature is 750 DEG C, the sintering time is 60min, and the heating rate is 2 DEG C / min. The preparation method has scientific and reasonable design, simple process, easy operation, low cost, and other advantages, the ceramic fiber prepared by the method has high strength, superior performance, smooth surface, high density, low tendency to fragmentation and other advantages, and the method has the advantages of convenient operation and easy implementation, and is a highly innovative preparation method of the calcium doped lead titanate ceramic fiber.

Owner:HEBEI CHEM & PHARMA COLLEGE

Preparation method of 550-650 DEG C high-temperature titanium alloy foil

ActiveCN113578967AControl microstructureControl mechanical propertiesWeight reductionMetal rolling arrangementsIngotTitanium alloy

The invention relates to a preparation method of 550-650 DEG C high-temperature titanium alloy foil. The method specifically comprises the following steps of (1) heating a high-temperature titanium alloy cast ingot at 1100-1200 DEG C, and then carrying out forging to obtain a blank; (2) carrying out heating at 950-1000 DEG C, and then carrying out rolling; (3) carrying out heat treatment at 50-70 DEG C above a beta phase transformation point, and then carrying out water quenching cooling to room temperature to obtain a plate blank; (4) carrying out heating at 950-1000 DEG C, and then carrying out rolling; (5) carrying out assembly welding on the obtained blank to obtain a cladding ply-rolling pack; (6) heating the ply-rolling pack at 950-1000 DEG C, and then carrying out rolling; (7) opening the ply-rolling pack, and carrying out secondary assembly welding on the blank to obtain a cladding ply-rolling pack; (8) heating the ply-rolling pack at 900-950 DEG C, and then carrying out rolling in a direction perpendicular to the previous rolling direction; (9) carrying out annealing, creep correction, alkali pickling and sanding to obtain a plate with the thickness of 0.6 mm; (10) shearing the plate, and then carrying out cold rolling 7-25 times to obtain rolled foil with the thickness of 0.08-0.2 mm; and (11) carrying out vacuum annealing heat treatment to obtain the finished foil with the thickness ranging from 0.08 mm to 0.2 mm.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

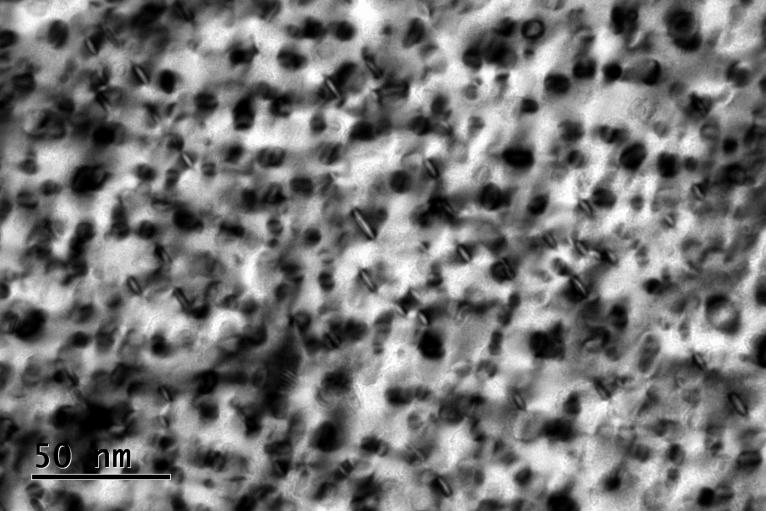

arsenic-removing adsorbent with IB group metal nanoparticles loaded on zinc zirconium composite oxide and preparation method thereof

ActiveCN107551986ALarge specific surface areaHigh removal rateOther chemical processesWater contaminantsCooking & bakingSorbent

The invention discloses an arsenic-removing adsorbent with IB group metal nanoparticles loaded on a zinc zirconium composite oxide and a preparation method thereof. The method comprises the followingsteps: firstly, preparing an IB group metal salt solution, a zinc salt solution and a zirconium salt solution into a mixed metal salt solution; with the deionized water with pre-regulated pH value asa base solution, adding the mixed metal salt solution and a precipitant solution for co-precipitating and controlling an end point pH value within a range of 7-10; ending the dropwise adding, continuously stirring, heating and hydrolyzing the precipitate; centrifugally separating, thereby acquiring a hydrolysis product; washing, centrifuging, drying and baking, thus obtaining the arsenic-removingadsorbent. The arsenic-removing adsorbent prepared according to the invention is high in specific surface area and narrow in pore size distribution; the metal nanoparticles are highly dispersed and loaded onto an amorphous composite oxide carrier, so that the arsenic-removing adsorbent has the characteristics of high removal rate, high adsorption capacity, less dosage, high adsorption rate, and the like; the arsenic-removing adsorbent can be used for deeply treating the low-concentration arsenic pollutants in underground water and surface water and the low-concentration arsenic-bearing industrial wastewater.

Owner:FUZHOU UNIV

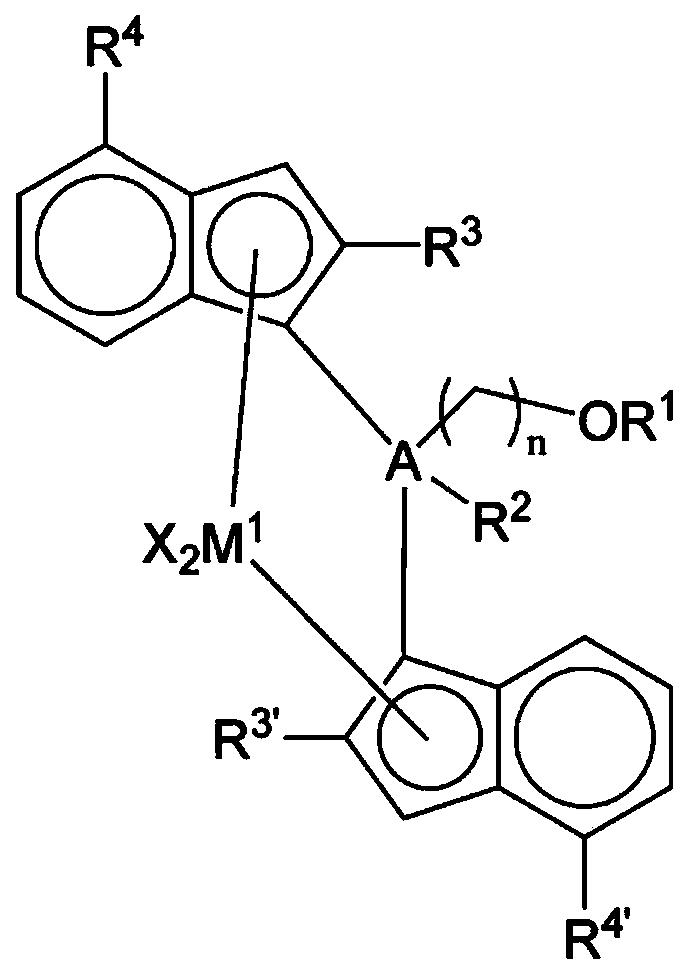

Ansa-metallocene compound and method for preparing supported catalyst using same

ActiveCN104271586AHigh catalytic activityEasy to manufactureOrganic-compounds/hydrides/coordination-complexes catalystsMetallocenesPolyolefinAnsa-metallocene

This disclosure relates to an ansa-metallocene compound of a novel structure that can provide various selectivities and activities to polyolefin copolymers, a preparation method thereof, and a method for preparing polyolefins using the ansa-metallocene compound.

Owner:LG CHEM LTD

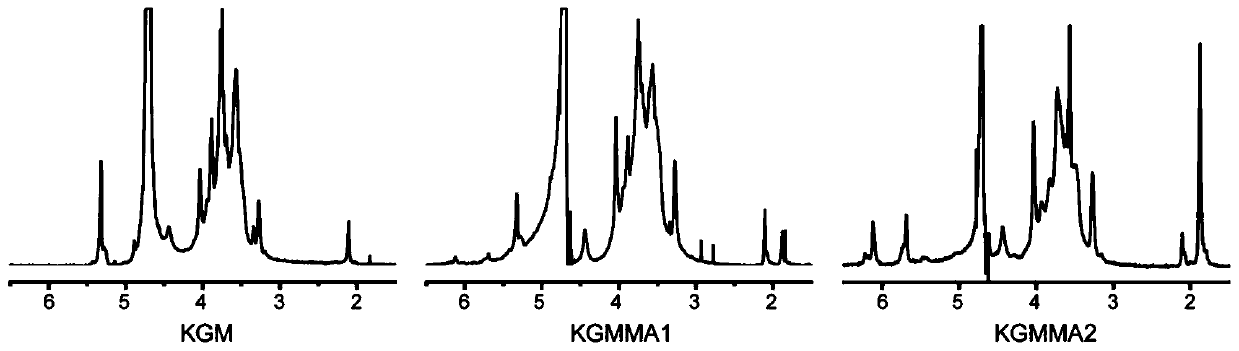

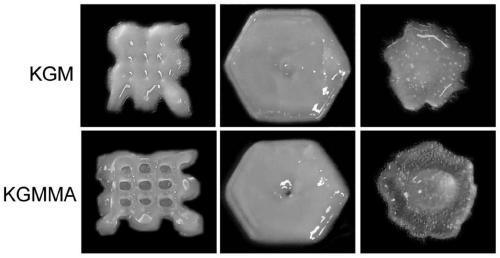

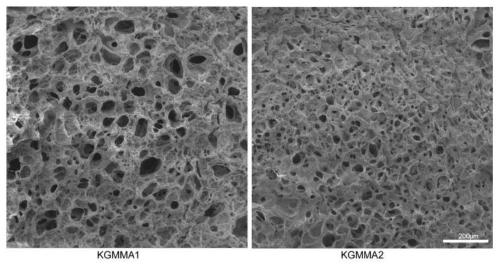

3D printing konjac glue gel stent, preparing method and application

InactiveCN110478529AGood biocompatibilityHigh biosecurityAdditive manufacturing apparatusTissue regenerationPolymer scienceFreeze-drying

The invention discloses a 3D printing konjac glue gel stent, a preparing method and application. Konjac glue gel is methacrylated konjac glue gel. The preparing method includes the following steps ofmodifying a konjac glue gel raw material through methacrylic anhydride, conducting dialysis and freeze-drying to obtain methacrylated konjac glue gel powder, dissolving the methacrylated konjac glue gel powder in PBS with a photoinitiator to obtain hydrogel, combining the obtained hydrogel with chondrocyte for printing through a 3D-Bioplotter system, and then conducting ultraviolet crosslinking toobtain the konjac glue gel stent product. The stent combined with the chondrocyte has the potential for cartilage repair engineering. The 3D printing konjac glue gel stent has the effects of being good in biocompatibility, controllable in material performance, low in cost, wide in source and simple in operation.

Owner:GUANGXI MEDICAL UNIVERSITY

Preparation method of carbon/carbon composite material

The invention belongs to a preparation method of a carbon / carbon composite material, in particular to a method for catalytically carbonizing a compacted carbon / carbon composite material. The preparation method is characterized by comprising the following steps: uniformly mixing carbon fiber reinforcement which is used as a reinforcement phase, coal tar (or other substances containing polycyclic aromatic hydrocarbon such as asphalt) which is used as a soaking agent and lewis acid of a given ratio, placing the mixture into a high-pressure kettle, and catalytically carbonizing the mixture to obtain the carbon / carbon composite material. In order to improve the density of the composite material, the carbon / carbon composite material can be soaked in multiple times so as to be compacted. Compared with the traditional process for compacting the carbon / carbon composite material by virtue of polymerization and splitting decomposition of radicals caused by the heat under the high temperature, the heating temperature needed by the catalytic carbonization method is low; moreover, the coal tar with low cost is selected, so that the manufacturing cost of the carbon / carbon composite material is greatly reduced.

Owner:HUAQIAO UNIVERSITY

Preparation method for silicon dioxide block layer used for I-III-IV compound solar cell

ActiveCN102646756AImprove barrier efficiencyControl microstructureAlkali metal silicate coatingsPhotovoltaic energy generationSilicic acidAcid catalysis

The invention relates to the technical field of a solar cell and provides a preparation method for a silicon dioxide block layer used for an I-III-IV compound solar cell. The preparation method comprises the following steps that: acid catalysis solution of ortho-silicic acid alkyl ester is prepared; the acid catalysis solution of the ortho-silicic acid alkyl ester rests for 0.5-6h, and then NH4OH solution is added into the acid catalysis solution, so as to obtain silica sol; the silica sol is coated on a medium in an isopropanol atmosphere; the medium after being coated with the silica sol is aged continuously in the isopropanol atmosphere for 5-75min and then is soaked into isopropanol solution to be aged, so as to obtain an aged gel membrane; and the aged gel membrane is heated and dried, the heating rate is 10-180 DEG C / s, the aged gel membrane is kept for 10-75min after being heated to the temperature of 150-500 DEG C, so as to obtain the silicon dioxide block layer used for the I-III-IV compound solar cell. The preparation method is simple, thereby being suitable for batch production; moreover, the prepared silicon dioxide block layer used for the I-III-IV compound solar cell can effectively improve the efficiency of the solar cell.

Owner:徐东

Method for preparing porous ceramic green body by combining microemulsion with freeze drying

ActiveCN111559918AControl microstructureControl mechanical propertiesCeramicwareDiphenylmethaneFreeze-drying

The invention relates to a method for preparing a porous ceramic green body by combining microemulsion with freeze drying. The method comprises the following steps: (1) mixing water, an oil phase anda surfactant to obtain an oil-in-water emulsion, wherein the oil phase is preferably selected from at least one of cyclohexane, n-octane, diphenylmethane and cyclopentane; (2) adding ceramic powder, asintering aid, a dispersing agent and a binder into the obtained oil-in-water emulsion, and mixing to obtain ceramic slurry; and (3) carrying out vacuum degassing on the obtained ceramic slurry, pouring the ceramic slurry into a mold, and carrying out freeze curing and freeze drying to obtain the porous ceramic green body.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com