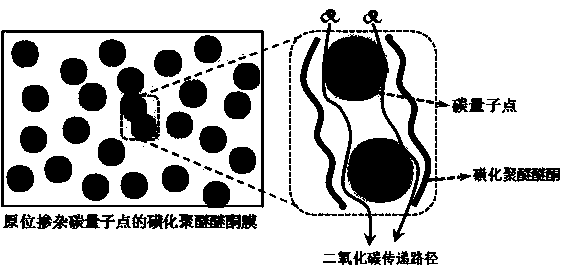

SPEEK (Sulfonated Polyether Ether Ketone) mixed matrix membrane with in-situ doped carbon quantum dots as well as preparation method and application thereof

A sulfonated polyether ether ketone and mixed matrix membrane technology, applied in chemical instruments and methods, separation methods, membrane technology and other directions, can solve the problems of low gas permeability and high crystallinity, achieve low cost and easy availability of raw materials, improve Penetration, the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: The preparation method of the sulfonated polyether ether ketone composite film doped with carbon quantum dots in situ according to the present invention, the steps are as follows:

[0032] (1) Take a porous polysulfone membrane with a molecular weight cut-off of 6000 as a supporting membrane, soak it in a 2% ethylenediamine aqueous solution at 30°C for 72 hours, wash and dry it for later use.

[0033] (2) Sulfonated polyether ether ketone composite material doped with carbon quantum dots in situ: Polyvinyl alcohol and polyether ether ketone are dried in a vacuum drying oven at 80°C for 24 to remove residual moisture. Add the dried solid mixture of polyether ether ketone to polyvinyl alcohol with a mass ratio of 99.75%: 0.25% to the concentrated sulfuric acid solution (the mass ratio of solid mixture to concentrated sulfuric acid is 1:10), at a temperature of 25°C Under the conditions, after mechanical stirring at 250rpm for 6h, the temperature was raised to 60°C a...

Embodiment 2

[0036] Embodiment 2: The method for preparing the sulfonated polyether ether ketone composite film doped with carbon quantum dots in situ according to the present invention, the steps are as follows:

[0037] (1) Take a porous polysulfone membrane with a molecular weight cut-off of 6000 as a supporting membrane, soak it in a 2% ethylenediamine aqueous solution at 30°C for 72 hours, wash and dry it for later use.

[0038] (2) Sulfonated polyether ether ketone composite material doped with carbon quantum dots in situ: PVA and polyether ether ketone are dried in a vacuum drying oven at 80°C for 24 hours to remove residual moisture. Add the dried solid mixture of polyether ether ketone to polyvinyl alcohol with a mass ratio of 99.50%:0.50% to the concentrated sulfuric acid solution (the mass ratio of solid mixture to concentrated sulfuric acid is 1:10), at a temperature of 25°C Under the conditions, after mechanical stirring at 250rpm for 6h, the temperature was raised to 60°C and reac...

Embodiment 3

[0041] Example 3: The method for preparing the sulfonated polyether ether ketone composite film doped with carbon quantum dots in situ according to the present invention, the steps are as follows:

[0042] (1) Take a porous polysulfone membrane with a molecular weight cut-off of 6000 as a supporting membrane, soak it in a 2% ethylenediamine aqueous solution at 30°C for 72 hours, wash and dry it for later use.

[0043] (2) Sulfonated polyether ether ketone composite material doped with carbon quantum dots in situ: PVA and polyether ether ketone are dried in a vacuum drying oven at 80°C for 24 hours to remove residual moisture. Add the dried solid mixture of polyether ether ketone to polyvinyl alcohol with a mass ratio of 99.00%:1.00% to the concentrated sulfuric acid solution (the mass ratio of solid mixture to concentrated sulfuric acid is 1:10), at a temperature of 25°C Under the conditions, after mechanical stirring at 250rpm for 6h, the temperature was raised to 60°C and reacted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com