Graphene-base concrete resist and application thereof

A graphene and graphene technology, applied in the field of graphene-based concrete resist, can solve problems such as ignoring the corrosion resistance of sulfate radicals, achieve significant economic benefits, inhibit gel decomposition, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

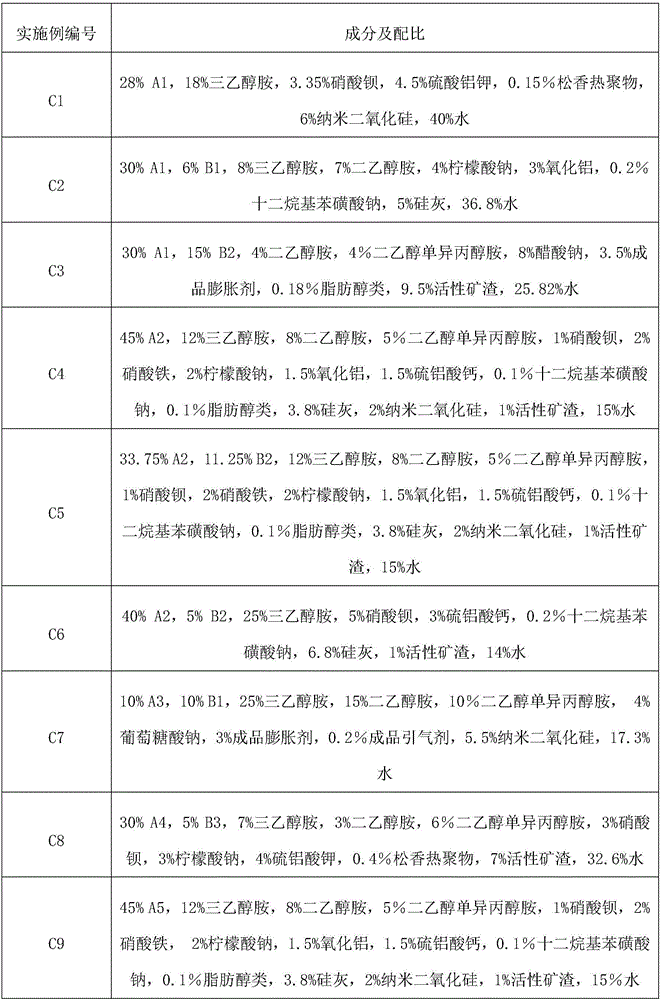

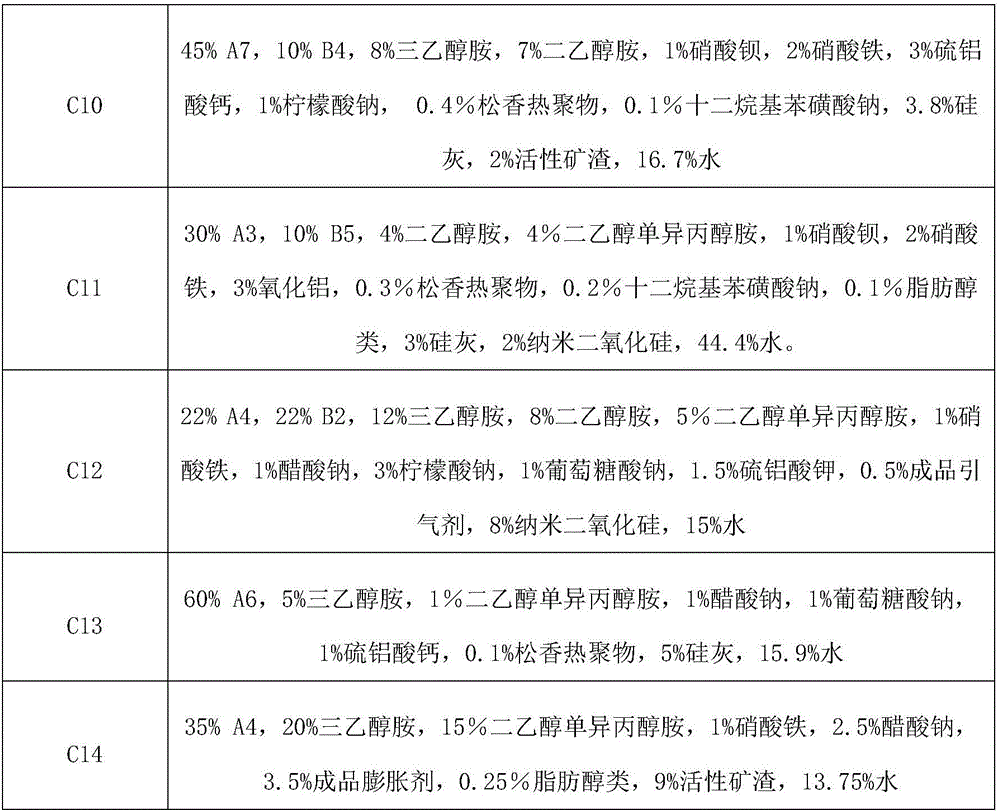

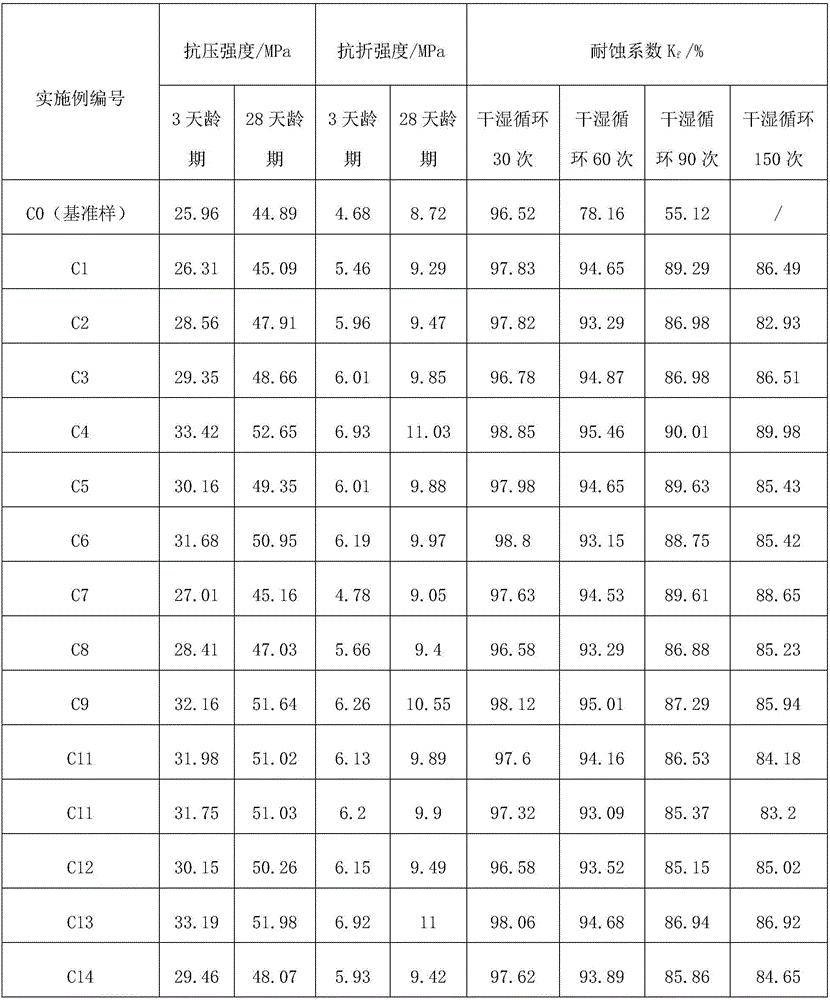

Examples

Embodiment 1

[0065] 1) After stirring 100g of graphene oxide and 30L of deionized water evenly, ultrasonically disperse for 80min (ultrasonic power is 200W) to obtain a uniformly dispersed graphene oxide aqueous suspension;

[0066] 2) Place a mixture of 200 g of maleic anhydride and 400 mL of water in a water bath at 60° C., heat and stir for 50 min to obtain maleic acid. Take the graphene oxide aqueous suspension in step 1) and slowly add it dropwise to the maleic acid in step 2), and react for 60 minutes under heating in a water bath at 80°C to obtain maleic acid-modified graphene oxide;

[0067] 3) Add 200 g of triethanolamine dropwise to the maleic acid-modified graphene oxide solution in step 2), and react for 100 min under heating in a water bath at 80° C. After the reaction is completed, filter the reactant, and then use deionized water to After washing and repeated filtration to neutrality, functionalized graphene oxide was obtained, marked as A1.

Embodiment 2

[0069] 1) After stirring 100g of graphene oxide and 200L of deionized water evenly, ultrasonically disperse for 100min (ultrasonic power is 250W) to obtain a uniformly dispersed graphene oxide aqueous suspension;

[0070] 2) Place a mixture of 200 g of maleic anhydride and 600 mL of water in a water bath at 60° C., heat and stir for 35 min to obtain maleic acid. Take the graphene oxide aqueous suspension in step 1) and slowly add it dropwise to the maleic acid in step 2), and react for 60 minutes under heating in a water bath at 80°C to obtain maleic acid-modified graphene oxide;

[0071] 3) Add 150 g of triethanolamine dropwise to the maleic acid-modified graphene oxide solution in step 2), and react for 60 minutes under heating in a water bath at 80° C. After the reaction is completed, filter the reactant, and then use deionized water After washing, repeat filtration until neutral to obtain a functionalized graphene oxide solution, marked as A2.

Embodiment 3

[0073] 1) After stirring 200g of graphene oxide and 50L of deionized water evenly, ultrasonically disperse for 90min (ultrasonic power is 240W) to obtain a uniformly dispersed graphene oxide aqueous suspension;

[0074] 2) Place a mixture of 600 g of maleic anhydride and 800 mL of water in a water bath at 65° C., heat and stir for 45 min to obtain maleic acid. Take the graphene oxide aqueous suspension in step 1) and slowly add it dropwise to the maleic acid in step 2), and react for 90 minutes under heating in a water bath at 80°C to obtain maleic acid-modified graphene oxide;

[0075] 3) Add 250 g of triethanolamine dropwise to the maleic acid-modified graphene oxide solution in step 2), and react for 100 min under heating in a water bath at 80° C. After the reaction is completed, filter the reactant, and then use deionized water After washing, repeat filtration to neutrality to obtain functionalized graphene oxide, marked as A3.

[0076] 4) 70g dispersant was dissolved in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com