Foam composition with epoxy group structure and preparation method and application thereof

A composition and epoxy-based technology, which is applied in the field of epoxy-based structural foam compositions, can solve the problems such as the decrease of material mechanical strength, and achieve the effects of reducing the weight of the whole vehicle, improving the safety of use and simple processing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

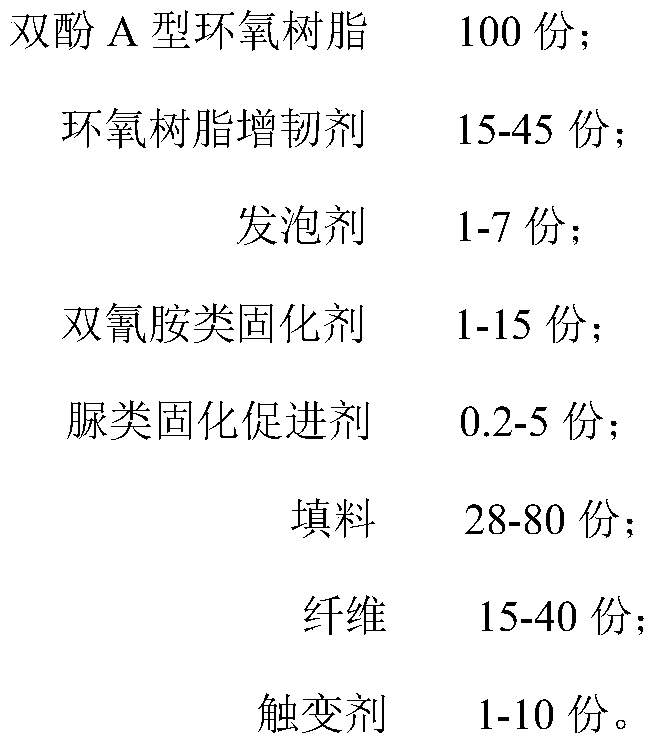

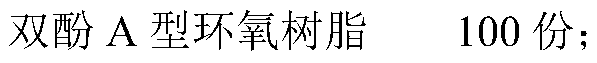

[0047] An epoxy-based structural foam composition, which contains raw materials and parts by weight as shown in Example 1 in Table 1.

[0048] The preparation method of described epoxy-based structural foam composition is:

[0049] Under the condition of 95°C, add bisphenol A type epoxy resin and GB19D epoxy resin toughening agent into the kneader, mix well, process and knead for 20 minutes, then add glass fiber, process and knead for 20 minutes, after mixing evenly, Add AC foaming agent, 093DU120 expanded microspheres, 1250 mesh calcium carbonate, 2000 mesh talc powder, mix well, process and knead for 20 minutes, then add fumed silica, process and knead for 20 minutes, after mixing evenly, add Dyhard100S dicyandiamide to cure agent, UR500 urea curing accelerator, processed and kneaded for 20 minutes, mixed evenly, baked at 170°C for 20 minutes to cure and foam, and then tested the mechanical properties. The results of the mechanical properties test are shown in Table 2.

Embodiment 2

[0051] An epoxy-based structural foam composition, which contains raw materials and parts by weight as shown in Example 2 in Table 1.

[0052] The preparation method of described epoxy-based structural foam composition is:

[0053]Under the condition of 70°C, add bisphenol A type epoxy resin and GB19D epoxy resin toughening agent into the kneader, mix evenly, process and knead for 15 minutes, then add glass fiber, process and knead for 20 minutes, after mixing evenly, Add AC foaming agent, 093DU120 expanded microspheres, 1250 mesh calcium carbonate, 2000 mesh talc powder, mix well, process and knead for 15 minutes, then add fumed silica, process and knead for 20 minutes, after mixing evenly, add Dyhard100S dicyandiamide to cure agent, UR500 urea curing accelerator, processed and kneaded for 15 minutes, mixed evenly, baked at 160°C for 25 minutes to cure and foam, and then tested the mechanical properties. The results of the mechanical properties test are shown in Table 2.

Embodiment 3

[0055] An epoxy-based structural foam composition, which contains raw materials and parts by weight as shown in Example 3 in Table 1.

[0056] The preparation method of described epoxy-based structural foam composition is:

[0057] Under the condition of 80°C, add bisphenol A type epoxy resin and GB17D epoxy resin toughening agent into the kneader, mix evenly, process and knead for 15 minutes, then add glass fiber, process and knead for 20 minutes, after mixing evenly, Add AC foaming agent, 093DU120 expanded microspheres, 1250 mesh calcium carbonate, 2000 mesh talc powder, mix well, process and knead for 20 minutes, then add fumed silica, process and knead for 20 minutes, after mixing evenly, add Dyhard100S dicyandiamide to cure agent, UR200 urea curing accelerator, processed and kneaded for 25 minutes, mixed evenly, baked at 180°C for 30 minutes to cure and foam, and then tested the mechanical properties. The results of the mechanical properties test are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com