Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

295 results about "Fineness modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

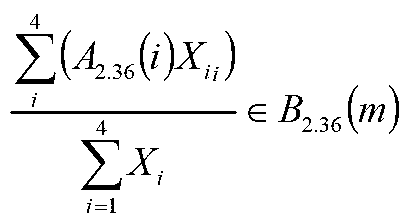

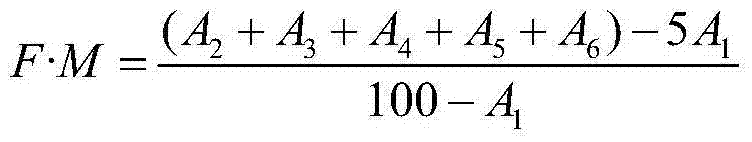

The Fineness modulus (FM) is an empirical figure obtained by adding the total percentage of the sample of an aggregate retained on each of a specified series of sieves, and dividing the sum by 100. The sieve sizes are 0.15 mm, 0.3 mm, 0.6 mm, 1.18 mm, 2.36 mm, 4.75 mm, 9.5 mm, 19.0 mm, 38.1 mm and larger increasing in the ratio of 2:1. The same value of fineness modulus may therefore be obtained from several different particle size distributions. In general, however, a smaller value indicates a finer aggregate. Fine aggregates range from a FM of 2.00 to 4.00, and coarse aggregates smaller than 38.1 mm range from 6.50 to 8.00. Combinations of fine and coarse aggregates have intermediate values.

Lightweight concrete compositions

A lightweight cementitious composition containing from 10 to 90 volume percent of a cement composition, from 10 to 90 volume percent of particles having an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.03 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3, and from 10 to 50 volume percent of sand and / or other fine aggregate, where at least a portion of the sand and / or fine aggregate has a fineness modulus of less than 2; where the sum of components used does not exceed 100 volume percent, and where after the lightweight cementitious composition is set it has a compressive strength of at least 1700 psi as tested according to ASTM C39 after seven days. The cementitious composition can be used to make concrete masonry units, construction panels, road beds and other articles.

Owner:SYNTHEON HLDG SPA +1

Cement-based self-leveling mortar

The invention relates to cement-based self-leveling mortar, which is prepared from the following raw materials in percentage by weight: 35 to 40 percent of No.425 ordinary portland cement, 10 to 15 percent of No.42.5 rapid hardening sulphoaluminate cement, 15 to 18 percent of heavy calcium carbonate, 0.45 to 1 percent of high polymer, 0.15 to 0.3 percent of water reducing agent, 0.15 to 0.3 percent of early strength agent, 0.15 to 0.3 percent of retarder, 0.15 to 0.3 percent of thickener and the balance of fine river sand with the fineness modulus of 1.2 to 1.5. Compared with other traditional cement self-leveling mortar, the self-leveling mortar has the characteristics of higher fluidity, higher leveling property, high early strength and the like.

Owner:CHENGDU JIAXIN TECH

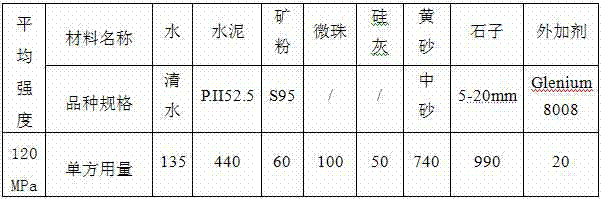

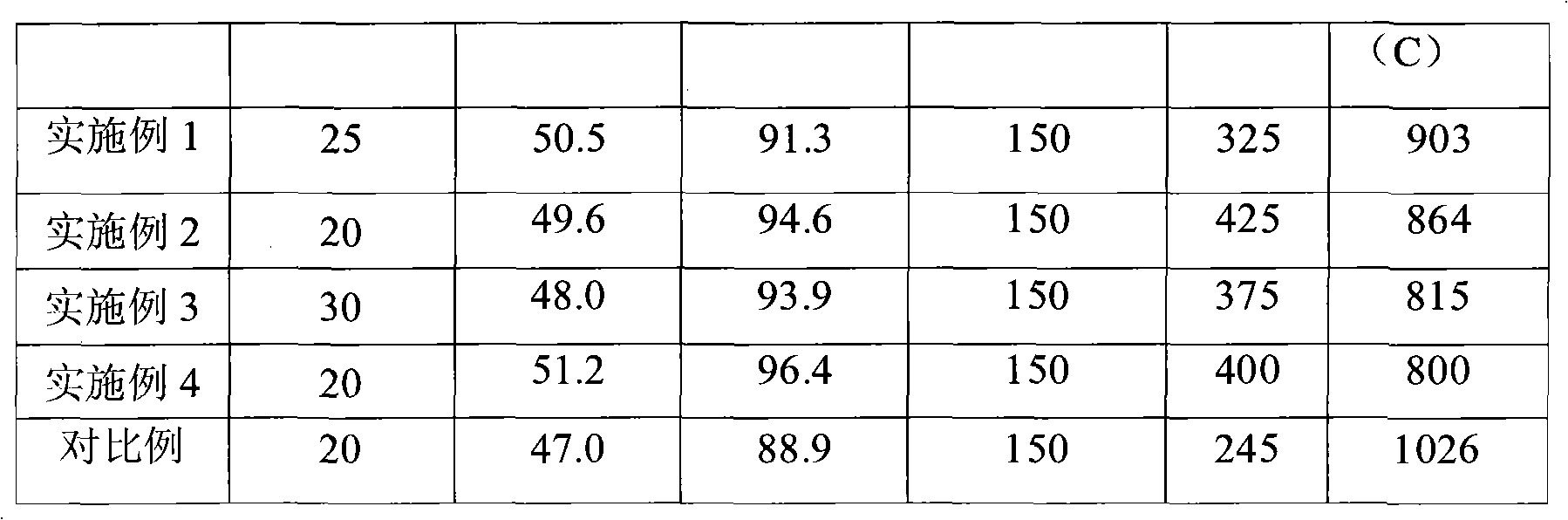

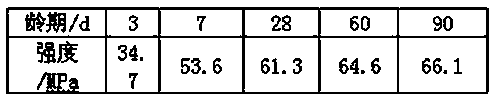

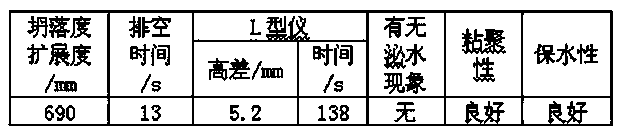

Low-viscosity easy-to-pump ultrahigh-strength concrete with average strength of 120MPa

ActiveCN103613348ALow viscosityEase of pumping performance requirementsHigh strength concreteMicrosphere

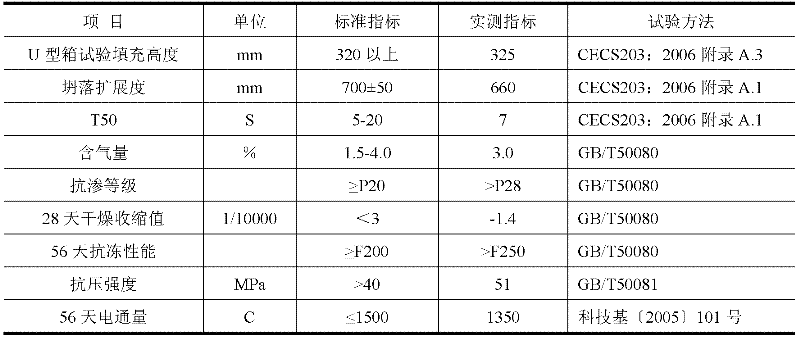

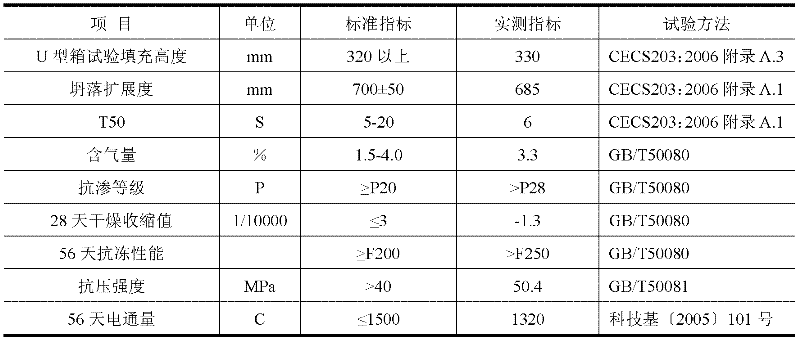

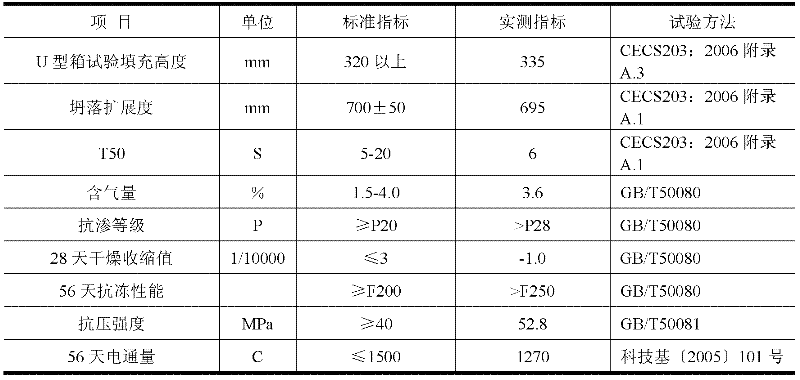

The invention relates to low-viscosity easy-to-pump ultrahigh-strength concrete with average strength of 120MPa. The concrete comprises the following components at single-prescription dosage ratio of kg / m<3>: 400-440 parts of cement, 40-60 parts of silica fume, 60-80 parts of slag micro powder, 100-120 parts of microspheres, 700-750 parts of natural sand with fineness modulus of 2.8-3.2, 980-1,000 parts of stone, 19.5-22.75 parts of additive and 130-135 parts of mixing water, wherein the additive is a polycarboxylate-type high-performance water reducing agent Glenium 8008 and has high water reducing rate, strong viscosity reducing property and high slump retaining property; the expansion degree of the ultrahigh-strength concrete is kept at 700+ / -50mm within 4 hours, the back taper time is controlled at 3-8 seconds, the viscosity is kept at 28-35Pa.s, and ultrahigh pumping of 300m and higher is easy to realize. The concrete provided by the invention can meet the performance requirements for ultrahigh concrete pumping of 500m and higher in terms of high slump retaining property, self-compaction property, strength property, low-viscosity property and the like.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +1

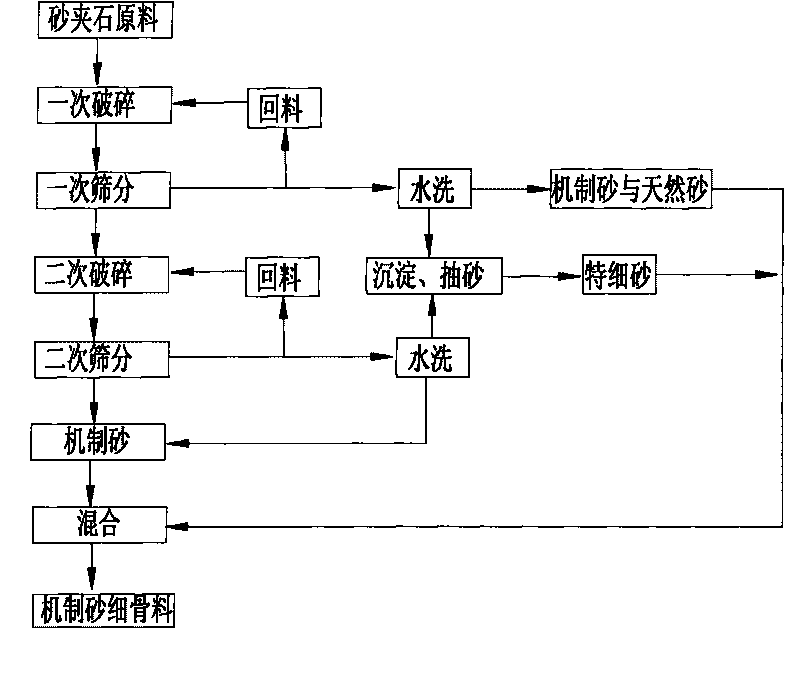

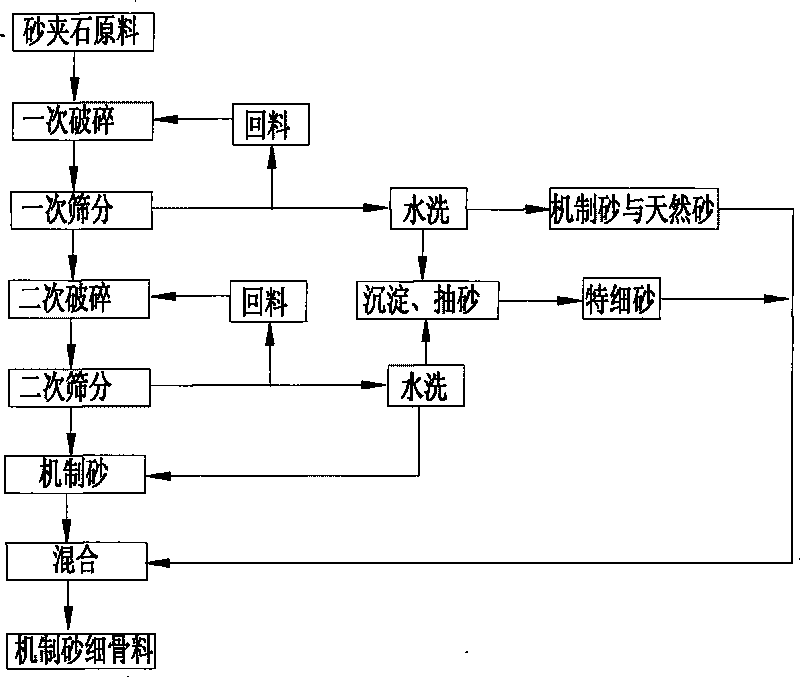

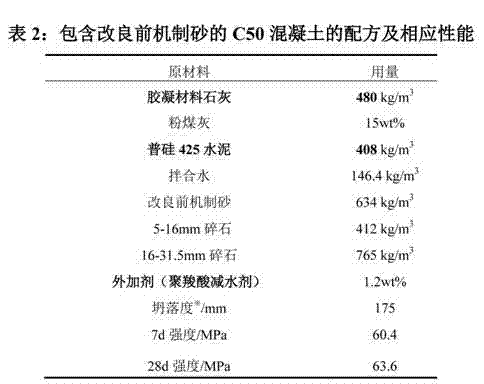

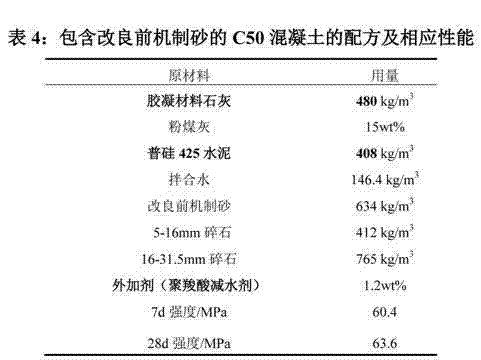

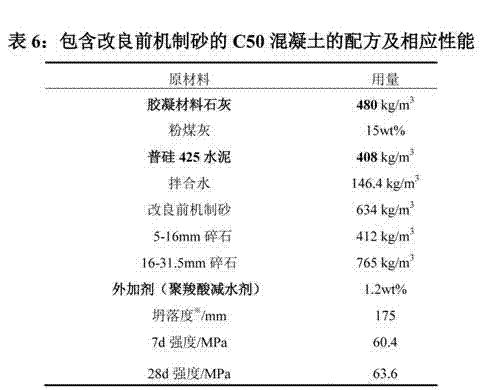

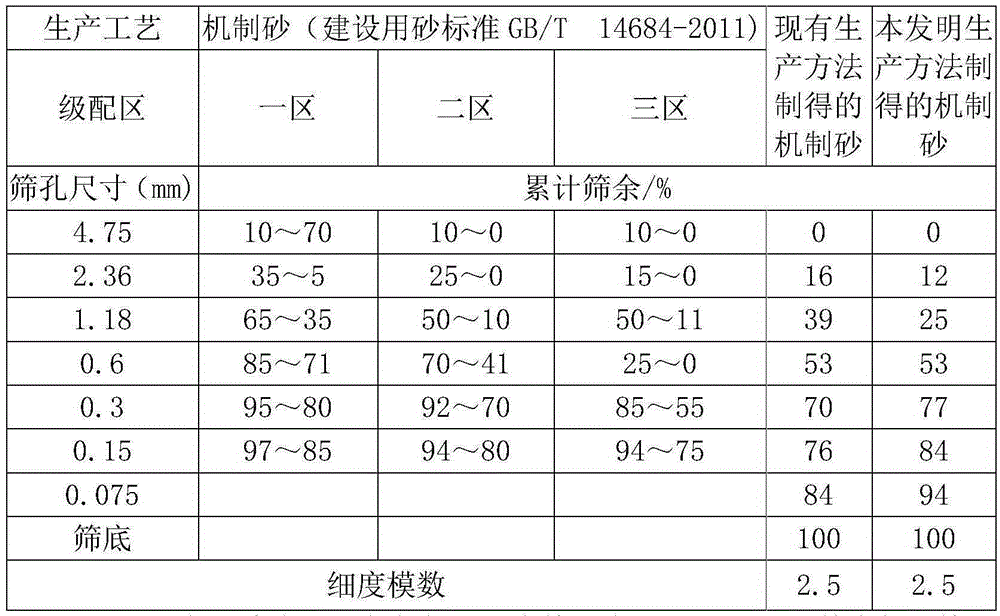

Preparation method of machine-made sand fine aggregate

ActiveCN101708968AMeet pumping requirementsEasy constructionGrain treatmentsFineness modulusDirect production

The invention discloses a preparation method of fine aggregate in concrete, specially relating to a preparation method of machine-made sand fine aggregate. The method adopts sand preparing technology; when preparing machine-made sand fine aggregate, the machine-made sand is combined with special fine sand with smallest grain diameter to produce the machine-made sand fine aggregate with certain fineness modulus. The method overcomes the deficiency that in traditional technology, the fineness modulus of the machine-made sand fine aggregate can not be accurately regulated and controlled, and the method of the invention can directly produce the machine-made sand fine aggregate satisfying premixed concrete pumping as well as construction and easy performance requirements.

Owner:CHONGQING NO 3 CONSTR

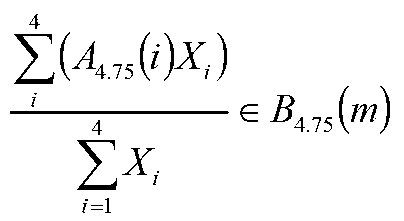

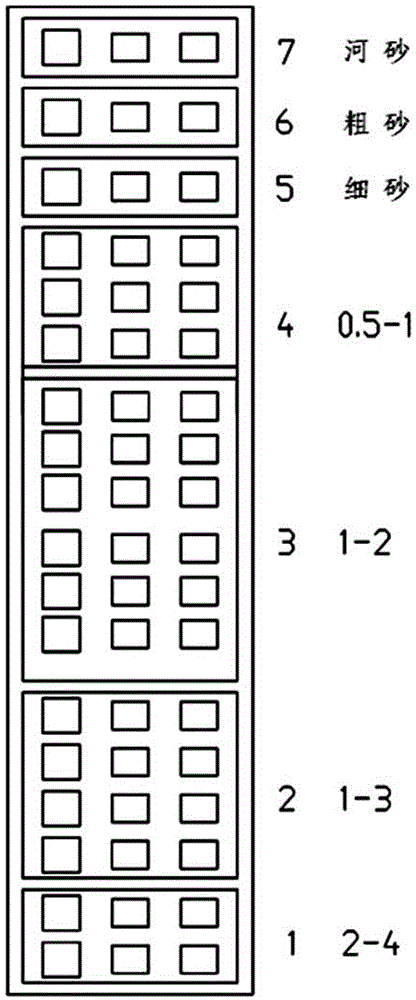

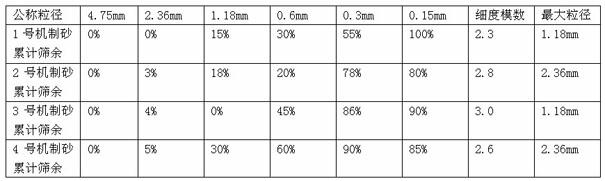

Preparation method of machine-made sand capable of replacing natural sand

The invention relates to a preparation method of machine-made sand capable of replacing natural sand. The machine-made sand is mixed by four or more than four kinds of sand in different specifications as semi-finished products under constraint of graduation, content of mountain flour, clay lump content and fineness modulus of sand for buildings. The method is helpful for recycling waste resources and has the advantages of low comprehensive cost, simpleness in operation, environment-friendly process, large-scale continuous production and the like. The technical quality of the product fully meets the standard of sand for buildings and can completely replace natural sand, so that the machine-made sand can be widely applied to the field of concrete for buildings such as bridges, roads, tubular piles and buildings.

Owner:NANJING UNIV OF TECH +1

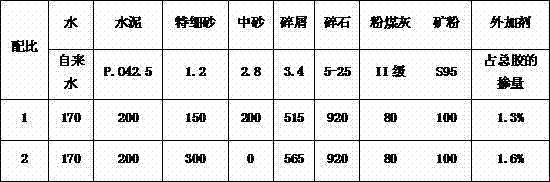

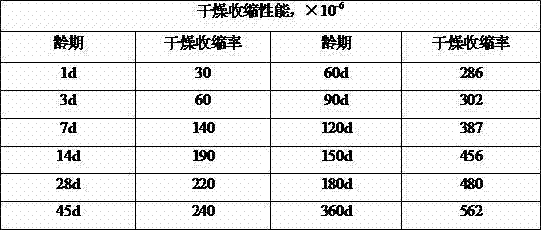

Self-compacting concrete for rapid transit railway III-type plate ballastless tracks and preparation method of self-compacting concrete

The invention discloses a self-compacting concrete for rapid transit railway III-type plate ballastless tracks and a preparation method of the self-compacting concrete. The self-compacting concrete can effectively eliminate bleeding in a pouring process, has low contractibility rate and good durability, and is beneficial to improving of pavement quality of track plates and prolonging of service life of the ballastless tracks. The self-compacting concrete is prepared by stirring and mixing cement, sand, stone, an expanding agent, a water reducing agent, a shrinkage reducing agent, a thickening agent, a water reducing agent, a collapse preventing agent and water as raw materials, wherein the raw materials comprise the following components in parts by weight: 100 parts of common silicate 425# cement, 11 parts of an expanding agent, 38.5 parts of coal ash, 20.5 parts of mineral powder, 261-277 parts of sand with fineness modulus of 2.4-2.8, 235-251 parts of stone with a grain size of 5-10mm, 0.04 part of a thickening agent, 56-60 parts of water, 1.3 parts of a shrinkage reducing agent, 2.3 parts of a water reducing agent and 0.37 part of a collapse preventing agent.

Owner:中铁八局集团第四工程有限公司

Precast concrete pile and manufacturing method thereof

The invention provides a precast concrete pile and a manufacturing method thereof. The precast concrete pile is obtained by mounting concrete into a mold mounted with a reinforcement cage framework, closing the mold, tensioning the mold, centrifugally shaping the mold, curing the mold by steam at a normal pressure; releasing the mold and curing the concrete by steam at a high pressure; raw materials of the concrete comprise a cementing material, a fine aggregate, a coarse aggregate, an admixture and water, wherein the fine aggregate is a machine-made sand or a mixture of the machine-made sand and a natural sand; the percentage of the machine-made sand in the fine aggregate by weight is 5-100%; the machine-made sand is obtained by mechanically crushing stone raw materials, such as mine tailings, industrial tailings and the like, screening the crushed stone raw materials in a graded way and removing dust from the screened stone raw materials; fineness modulus of the machine-made sand is 2.3-3.8; grain gradation of the machine-made sand meets requirements on an area 1 or an area 2 of a standard sand; and stone powder content of the machine-made sand is 2-8 wt%. According to the invention, the concrete cost is reduced and resource utilization rate is increased; and the used machine-made sand has the advantages of low silt content and controllable stone powder content, so that the performance of the precast concrete pile is improved.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Highly-antifreezing highly-slump retaining self-compacting C40 concrete

The invention relates to highly-antifreezing highly-slump retaining self-compacting C40 concrete which comprises the following components by kg / m3: 330 parts of cement, 80 parts of granulated blast-furnace slag, 80 parts of fly ash, 830 parts of natural medium sand with a fineness modulus of 2.3-3.0, 920 parts of stone, 4.9 parts of additives, and 160 parts of mixing water; the additive is a modified air-entraining polycarboxylic water reducer, wherein the mixing amount of an air-entraining agent in the polycarboxylic water reducer RP325 is 0.1%, and the mixing amount of the additive for large-scale production is 1.0% of the total amount of gel materials; the air content in the concrete is 5.0%+ / -1.0%; the air-entraining amount in the poured structure from the beginning to the third hour is stabilized within a range of 5.0%+ / -1.0%, and the concrete expansion degree in 3 hours is maintained at 600+ / -50 mm; the number of antifreezing cycle is not less than 150, and the lowest temperature and the highest temperature in the antifreezing cycle are respectively -18 DEG C and 35 DEG C. The concrete of the invention can meet the concrete performance requirements for a skating rink in Shanghai oriental sports center with respect to high slump retaining performance, self-compacting performance, strength performance, high antifreezing performance, and the like.

Owner:TONGJI UNIV +1

Self compact concrete

The invention relates to self compact concrete, and belongs to the technical field of constructional engineering materials. The self compact concrete comprises the following components by weight: concrete 250-300 kg / m<3>, pulverized fuel ash 120-200 kg / m<3>, coarse aggregate 820-950 kg / m<3>, fine aggregate 700-850 kg / m<3>, water reducer 5-12 kg / m<3>, and water supply volume 145-160 kg / m<3>; the particle size of the coarse aggregate is 5-25 mm, and the fineness modulus of the fine aggregate is 2.5-2.8. The optimal proportion of the self compact concrete is concrete 290 kg / m<3>, pulverized fuel ash 160 kg / m<3>, coarse aggregate 891 kg / m<3>, fine aggregate 754 kg / m<3>, and water reducer 5.29 kg / m<3>. Compared with the prior art, the self compact concrete has the advantages that concrete consumption is about 35-55 kg / m<3>, the varieties of additives and admixtures are few, the preparation is simple, and the cost can be lowered to 30 yuan / m<3> at least.

Owner:KUNMING UNIV OF SCI & TECH

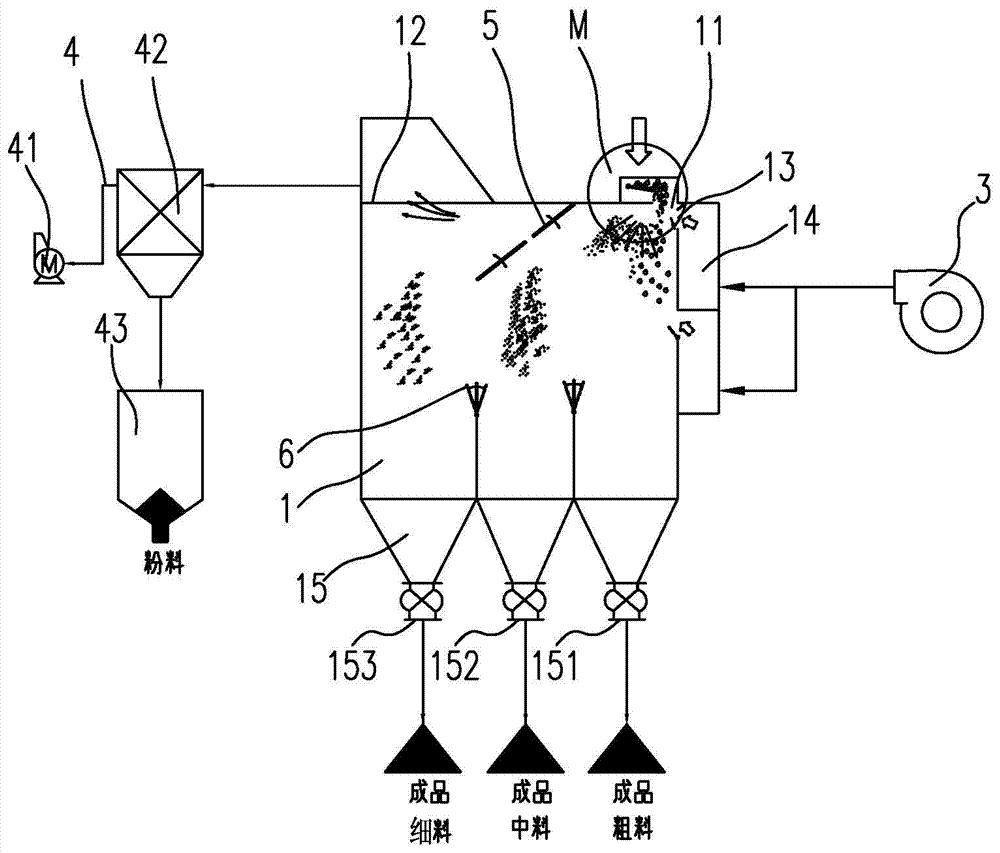

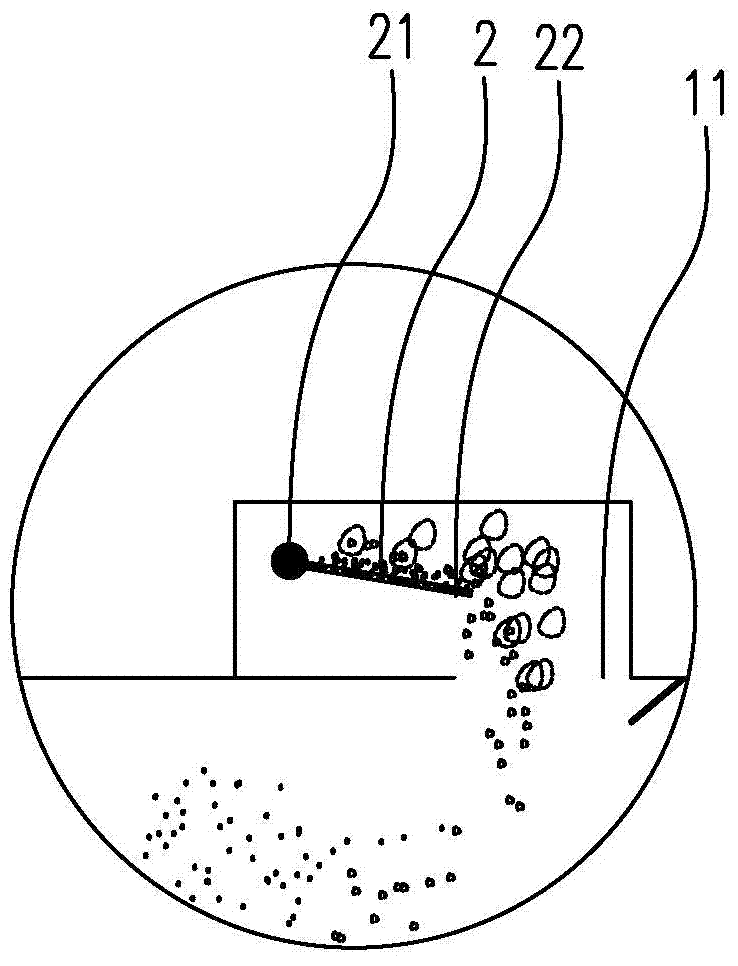

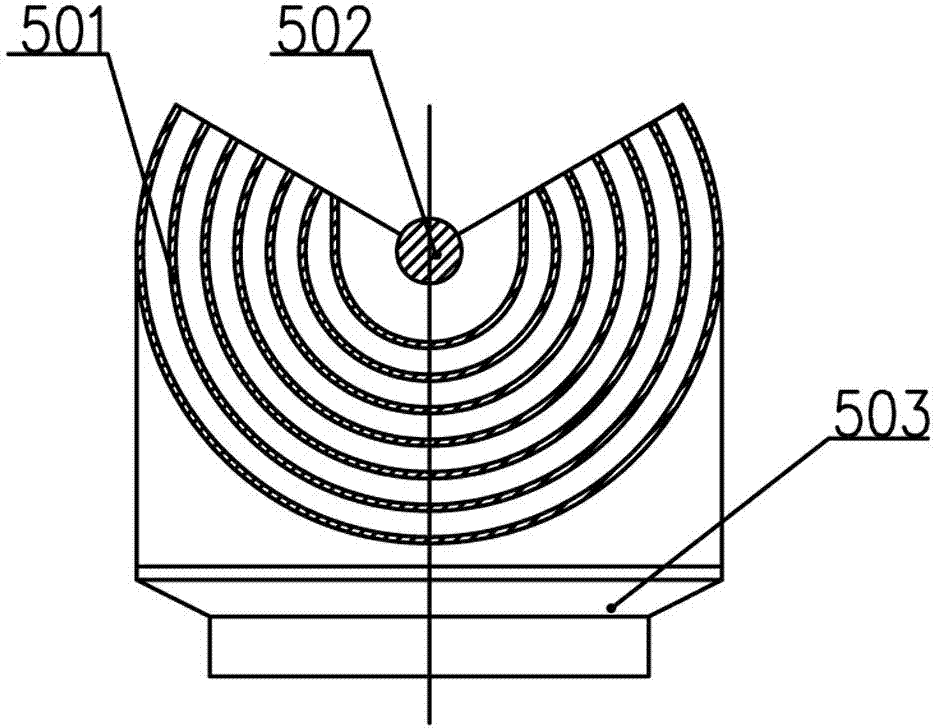

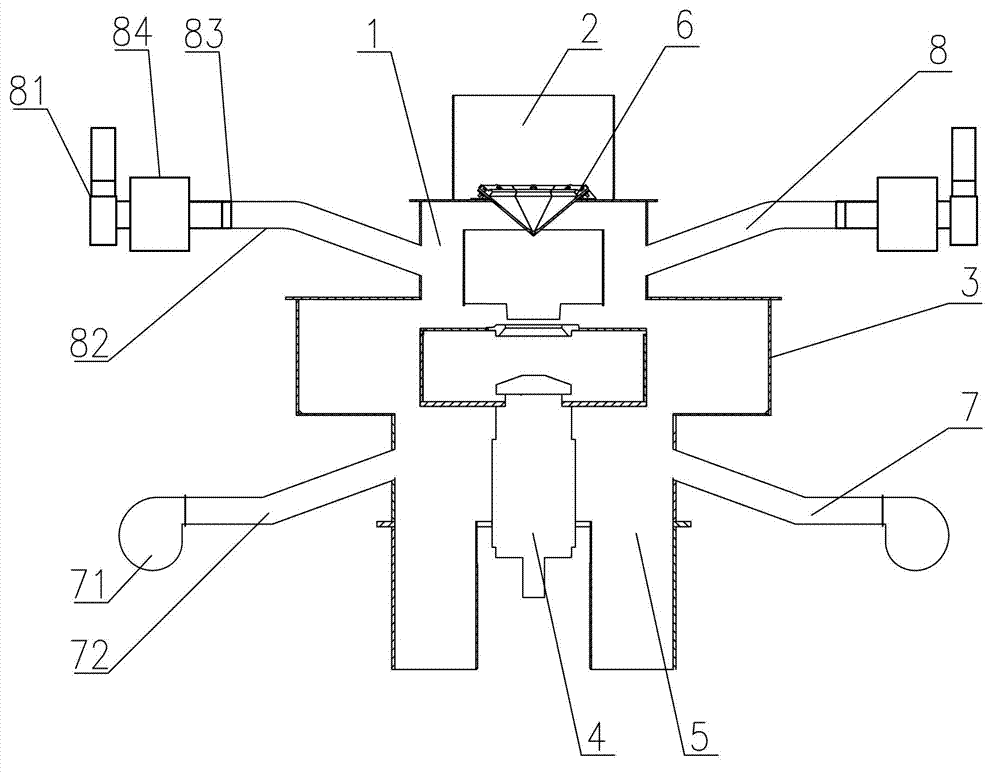

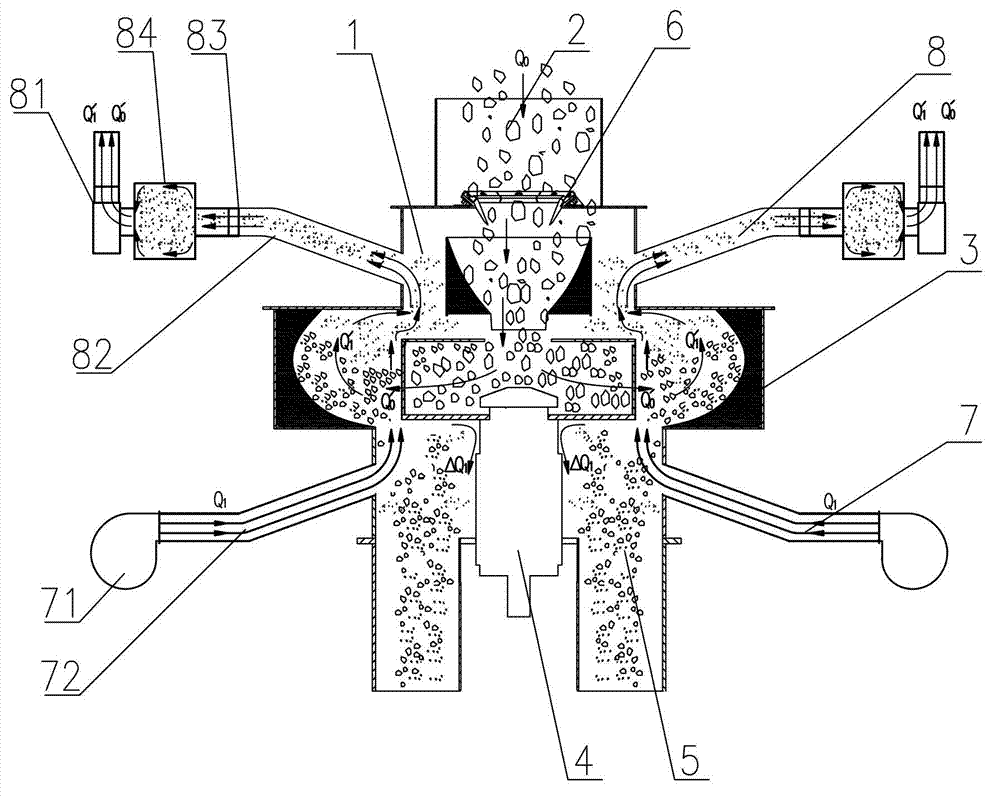

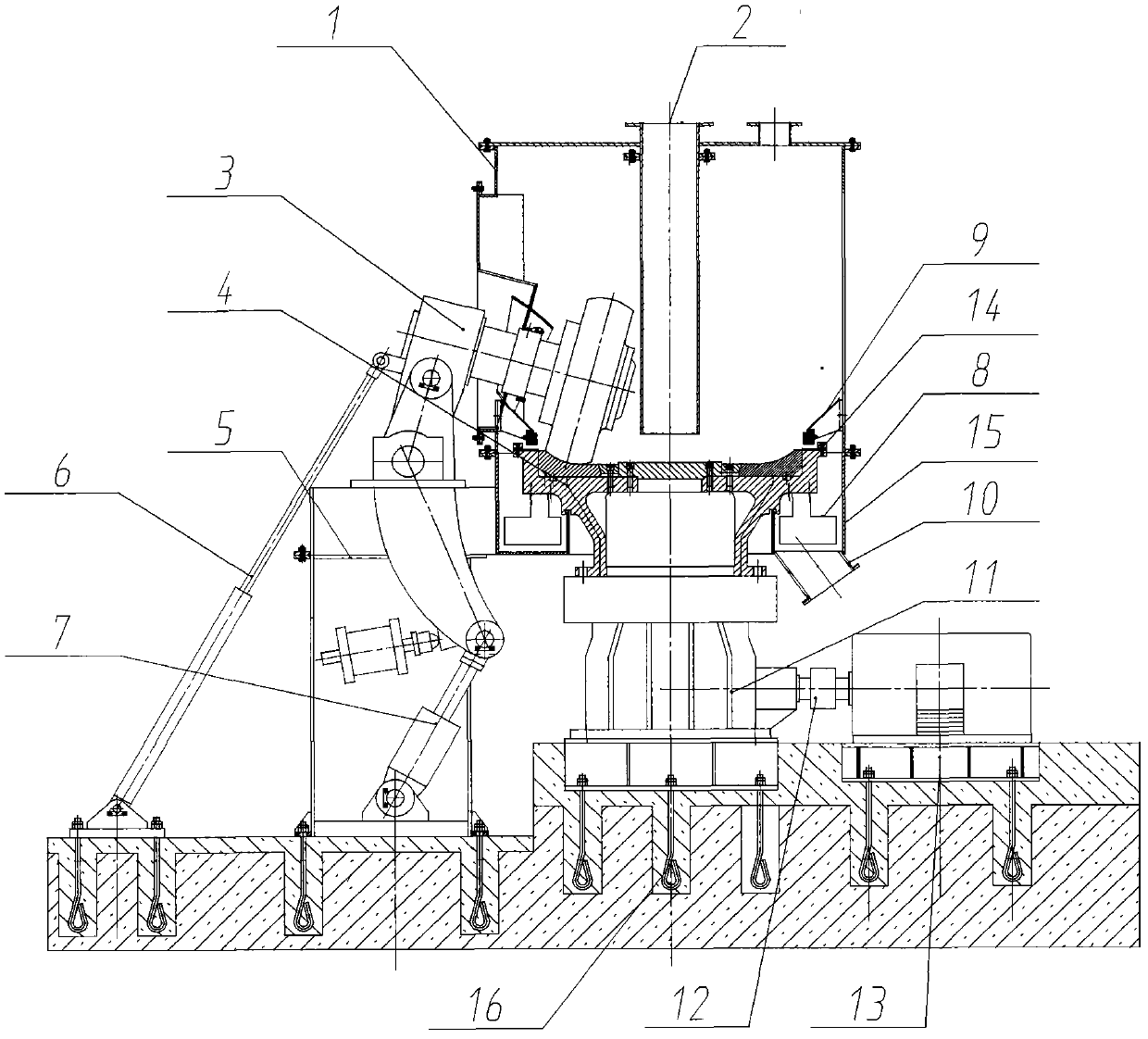

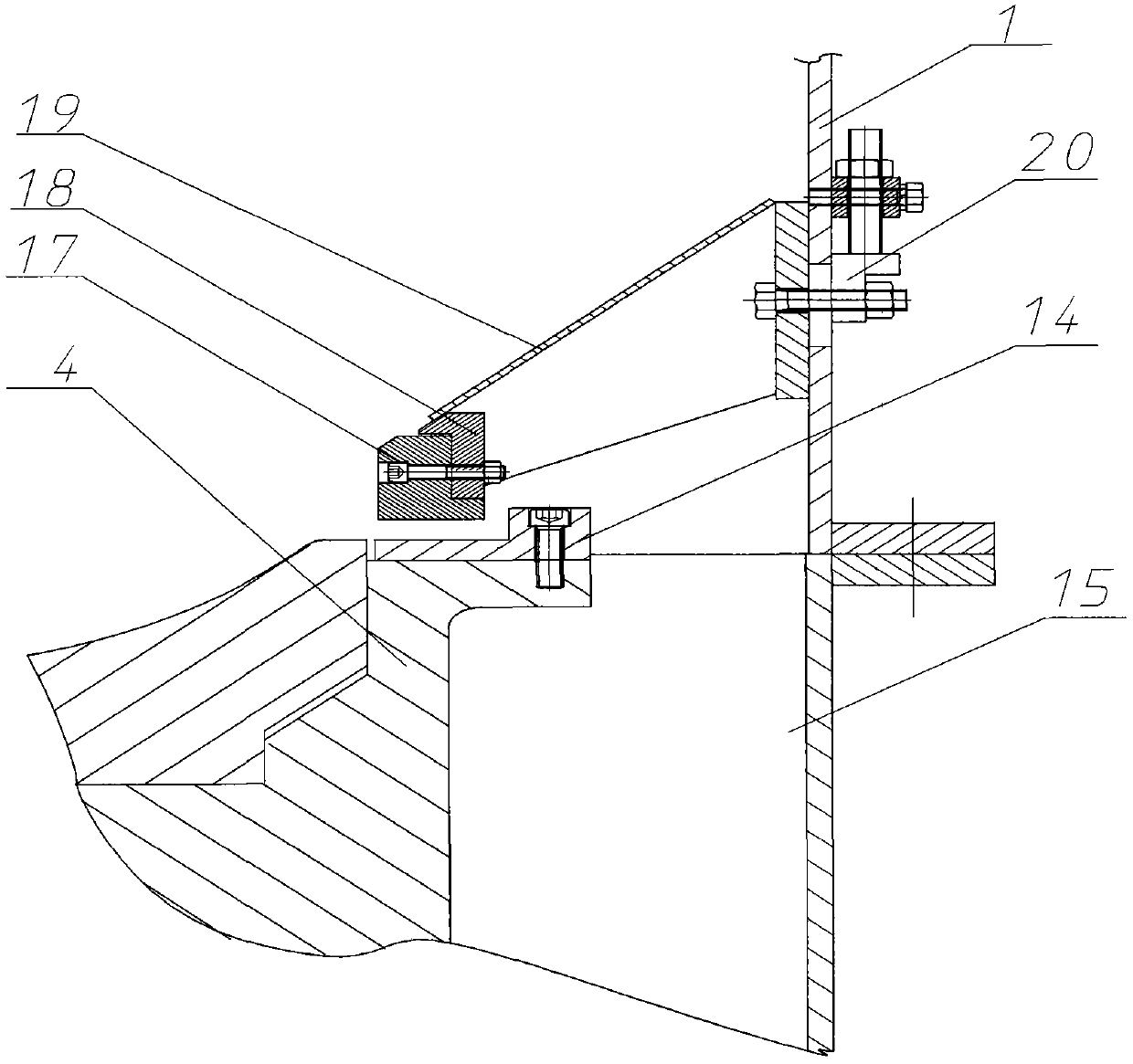

Wind power sand selecting device with adjustable product fineness modulus

InactiveCN103894343AControl granularitySolve the problem of uneven gradation and high powder contentGas current separationFineness modulusEngineering

The invention relates to the technical field of sand making devices, in particular to a wind power sand selecting device with an adjustable product fineness modulus. The wind power sand selecting device comprises a wind selecting bin, a wind supplying device, a dust removing device and a wind board. The wind selecting bin is provided with a feeding port, wind inlets, a dust removing opening and discharging ports. The number of the wind inlets is at least two, and the wind inlets are formed below the feeding port and distributed in the longitudinal direction, the number of the discharging ports is at least two, and the discharging ports are formed in the bottom of the wind selecting bin. The wind supplying device is communicated with the wind selecting bin through the wind inlets and used for supplying wind into the wind selecting bin, and strong wind supplied by the wind supplying device inclines towards the dust removing opening from the feeding port. The wind board is connected above the discharging ports inside the wind selecting bin in a pivoting mode and can rotate around a pivot to adjust the angle of the strong wind. The dust removing device is communicated with the wind selecting bin through the dust removing opening. According to the wind power selecting device with the adjustable product fineness modulus, grading is more accurate, the proportion between fine material and rough material can be controlled, and the product fineness modulus can be controlled.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL +1

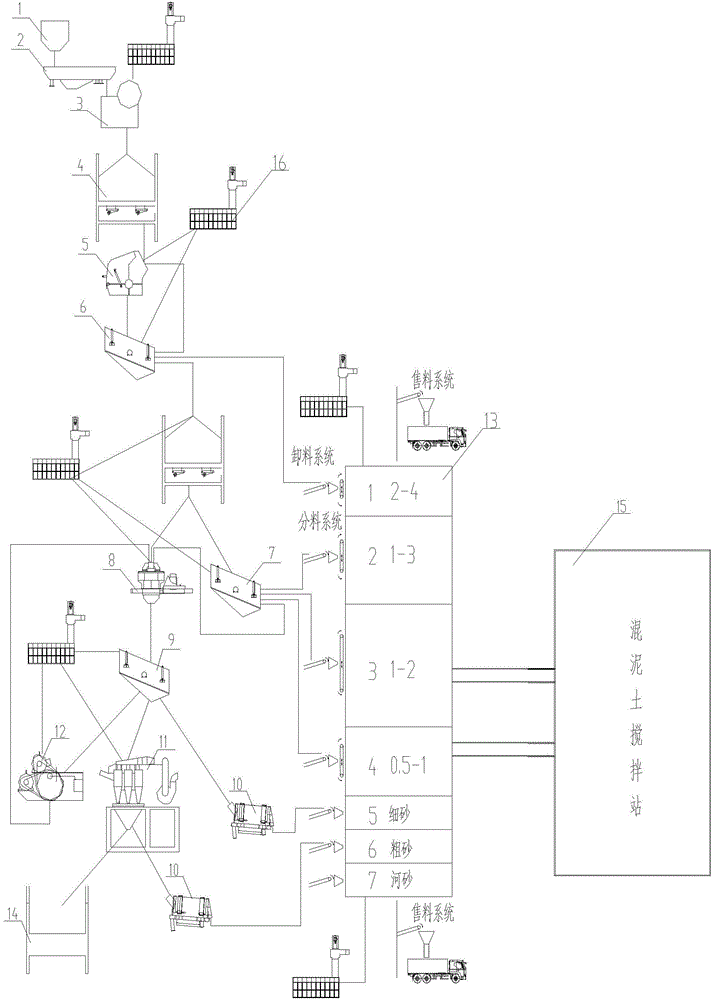

Production system and production method of machine-made gravels

The invention relates to a production system and a production method of machine-made gravels. The production system comprises a feed hopper, a feeding machine, an early crushing system and a medium crushing system, wherein the feed hopper is used for delivering an aggregate into the feeding machine; the early crushing system is used for early crushing the aggregate; the medium crushing system is used for crushing the aggregate again; a gravel making machine for further crushing the aggregate is arranged behind the medium crushing system; a first screen is arranged behind the gravel making machine and is used for outputting the aggregate meeting a first particle size section; the aggregate not meeting the first particle size section is shaped by a gradation adjustment system and then returned to the gravel making machine; and all modules are connected with one another by virtue of an aggregate conveying system. By adopting the production system and the production method of the machine-made gravels, the output of the machine-made gravels meeting a required fineness modulus can be improved by controlling reasonable gradation, and the quality of the machine-made gravels is improved by reducing the content of flat and elongated particles by the gravel making machine.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

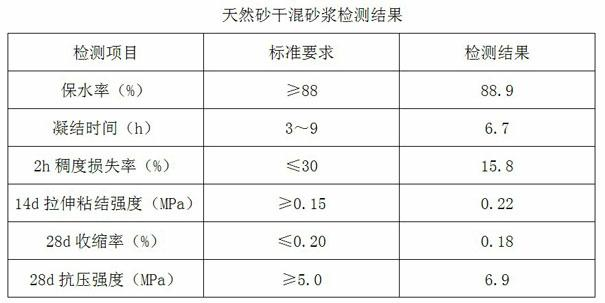

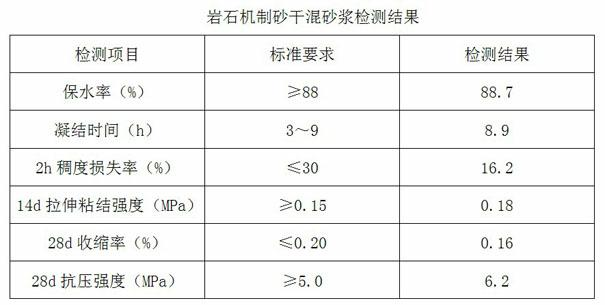

Dry-mixed mortar

The invention discloses a dry-mixed mortar, which comprises the following components in parts by weight: 120 parts of cement, 700 to 800 parts of scree artificial sand, 80 parts of coal ash and 4 parts of additive, wherein the scree artificial sand is made of broken scree through a sand making machine or other sets of equipment; and the fineness modulus of the scree artificial sand is 2.3 to 3.0. The raw material of the dry-mixed mortar is the scree artificial sand; the particle shape and the grading of the scree artificial sand are high, and the moisture content is low, so that the scree artificial sand can be used for preparing the dry-mixed mortar without being dried; and moreover, the hardness of the scree artificial sand is greater than that of rock artificial sand, so that the dry-mixed mortar is low in cost and high in quality and has obvious economic benefit.

Owner:SICHUAN SHENGZHONG ENERGY SAVING TECH

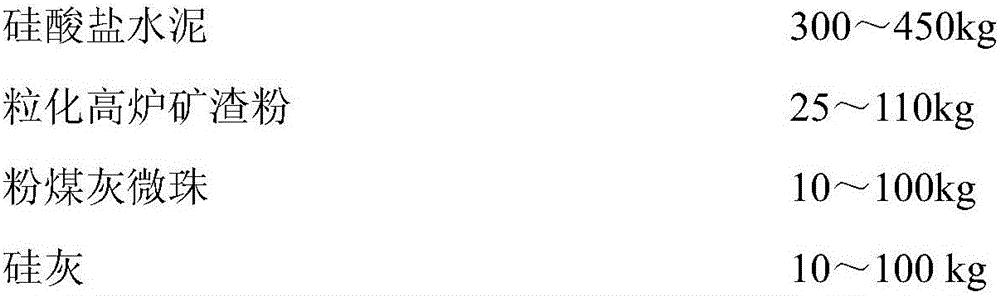

Curing-free PHC pipe pile concrete

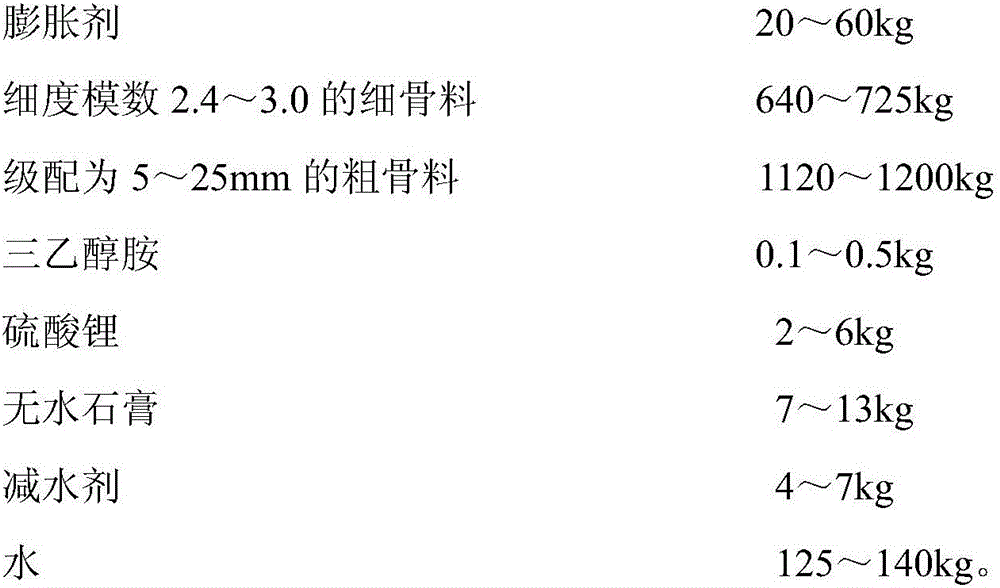

The invention discloses a curing-free PHC pipe pile concrete. Production raw materials of every cubic meter of the concrete comprise 300-450kg of portland cement, 25-110kg of granulated blast-furnace slag powder, 10-100kg of fly ash microspheres, 10-100kg of silica fume, 20-60kg of an expanding agent, 640-725kg of fine aggregates with the fineness modulus of 2.4-3.0, 1120-1200kg of coarse aggregates with the granular composition of 5-25mm, 0.1-0.5kg of triethanolamine, 2-6kg of lithium sulfate, 7-13kg of anhydrous gypsum, 4-7kg of a water reducer, and 125-140kg of water. The concrete is used for producing PHC pipe piles, and can reach the demolding strength requirement of the curing-free PHC pipe piles and the strength requirement of C80 concrete at normal temperature in a short time.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +3

Lightweight aggregate concrete and preparation method thereof

Owner:北京东方建宇混凝土科学技术研究院有限公司

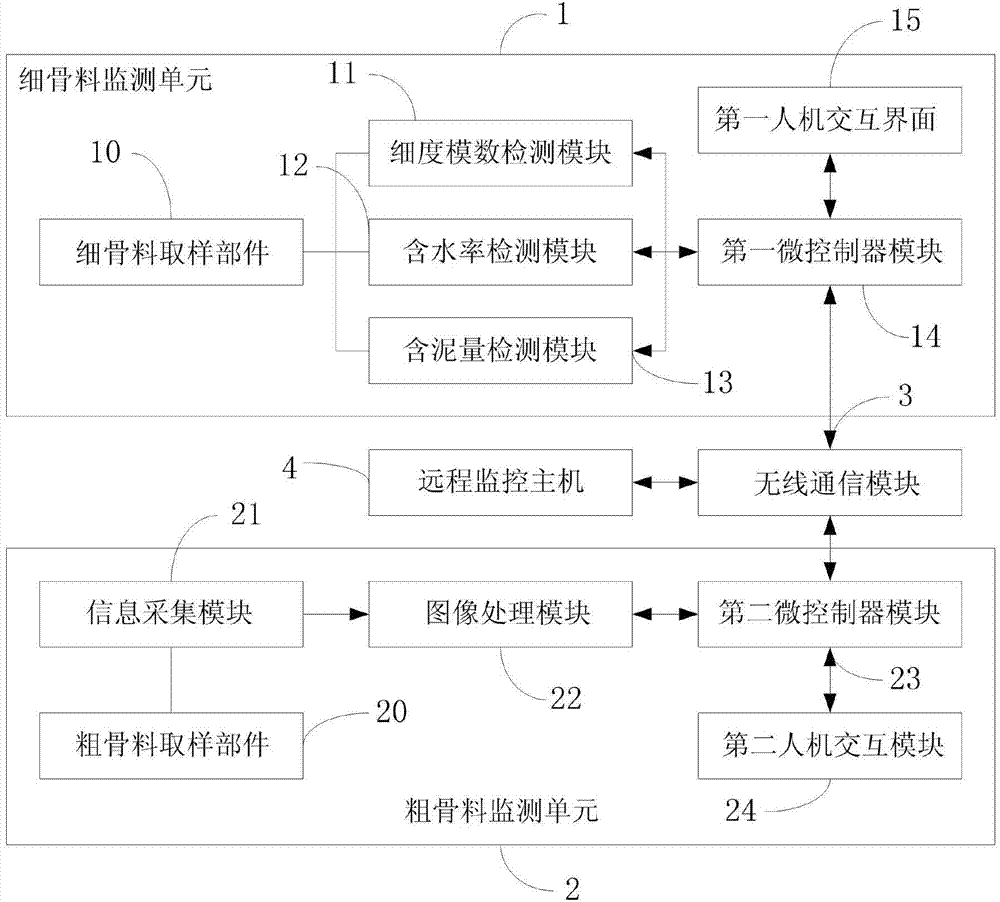

Intelligent monitoring system for gravel aggregate quality

InactiveCN104853168AImprove accuracyImprove timelinessClosed circuit television systemsSpecific gravity measurementFineness modulusInteraction interface

The invention provides an intelligent monitoring system for gravel aggregate quality. The system comprises a fine aggregate monitoring unit, a coarse aggregate monitoring unit, a wireless communication module and a long-distance monitoring host, wherein the fine aggregate monitoring unit comprises a fine aggregate sampling component, a fineness modulus detecting module, a moisture content detecting module, a silt content detecting module, a first human-computer interaction interface and a first microprocessor module; the coarse aggregate monitoring unit comprises a coarse aggregate sampling component, an information collecting module, an image processing module, a second human-computer interaction module and a second microprocessor module. The intelligent monitoring system provided by the invention comprises two online monitoring systems for the gravel aggregate quality, and one system is used for performing intelligent online detection of fine aggregate quality indexes such as the fineness modulus, moisture content and silt content, and the other system is used for performing intelligent online detection of oversize-undersize content of coarse aggregate to substitute daily manual inspection in the laboratory, thereby improving accuracy and timeliness of quality tests of the existing aggregate processing system.

Owner:CHINA THREE GORGES UNIV

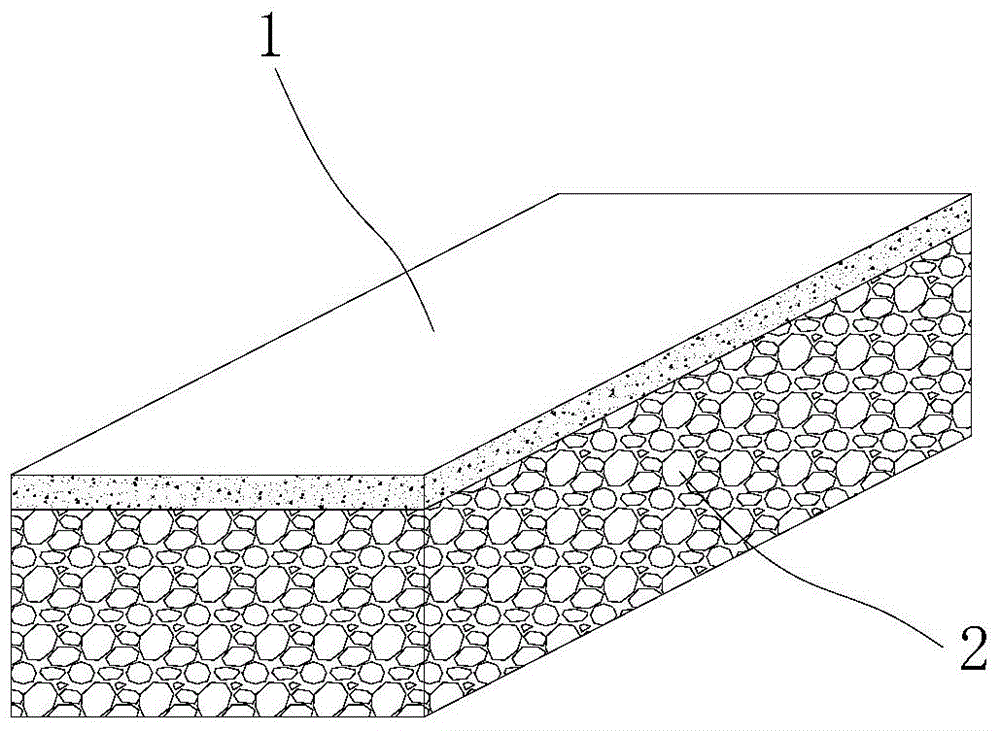

Imitated stone environment-friendly concrete road brick and making method thereof

ActiveCN104891888ACan express its own textureGood flexibilitySingle unit pavingsEnvironmental resistanceEpoxy

The invention relates to an imitated stone environment-friendly concrete road brick which comprises a surface layer and a base layer. The surface layer comprises, by weight, 5-30% of cement, 70-95% of at least one of quartz sand, granite broken sand and tailing sand and 5-30% of one of ethylene vinyl acetate, acrylic resin and waterborne epoxy resin, and the base layer comprises 3-10% of cement, 0-20% of mineral powder, 0-10% of coal ash, 10-50% of coal ash slag, 10-40% of iron ore dressing bits of 1.0-3.0% in fineness modulus and 35-50% of iron ore dressing bits of 2-10mm in grain diameter. The invention further relates to a making method of the road brick. The making method includes that an original producing, stirring and feeding sequence is adjusted, a binder is completely used to replace water for the surface layer, and a stirring process is improved specially. After a new material is used, feasibility of production links like stirring, material distributing, mould press-forming and demoulding is realized by technical means like changing feeding sequence and increasing stirring time. Compared with conventional surface layer mortar, the new surface layer is higher in flexibility and better in waterproofness, alkali efflorescence of cement products is inhibited, sand is protruding in texture, and the road brick has imitated stone effect integrally.

Owner:爱尔建材(天津)有限公司

High-fluidity pumping ceramsite concrete and preparation method thereof

The invention provides high-fluidity pumping ceramsite concrete and a preparation method thereof. A formula of the concrete comprises cement, coal ash, water, fine aggregate, limestone flour, pumping aid, ceramsites, ceramic sand, redispersable emulsion and hydroxypropyl methyl cellulose. The method comprises the following steps: reasonably selecting respective raw materials and usage thereof according to a unit weight of concrete to be prepared, soaking the ceramsites to a saturated water absorption state in advance, then mixing with other raw materials, and stirring to prepare the ceramsite concrete. By controlling the grain size of the ceramsites and a fineness modulus of the fine aggregate, the redispersable emulsion and hydroxypropyl methyl cellulose are cooperatively added to promote the cementation of the cementing materials such as the cement, the coal ash and the limestone flour with the ceramsites, and the cohesiveness and water retaining property of the concrete are increased, and the problems of easy floating, layering and separation of the ceramsites in the ceramsite concrete are effectively solved, moreover, separation and layering of the ceramsites can be effectively avoided by using the ceramsite concrete produced according to the invention, and slump loss in a material transporting and waiting process is obviously reduced.

Owner:重庆富普新材料有限公司

Ultrahigh-performance concrete and preparation method and application thereof

The invention discloses an ultrahigh-performance concrete and a preparation method and application thereof; the ultrahigh-performance concrete is characterized by being made from, by weight, 800-900 parts of cement, 250-300 parts of a mineral admixture, 1100-1200 parts of fine aggregate, 150-160 parts of fine steel fiber, 0.5-1.5 parts of a viscosity-reducing polycarboxylate superplasticizer, 80-90 parts of an expander, and 150-250 parts of clean water, wherein the fine aggregate is river sand 2.3-3.1 in fineness modulus, the mineral admixture comprises silica fume and level-I flyash, and the viscosity-reducing polycarboxylate superplasticizer is greater than 30% in water reducing rate; the ultrahigh-performance concrete is high in strength, the raw materials are widely resourced, the technique is reliable, the cost is relatively low, and the construction process is simple.

Owner:CCCC SECOND HARBOR ENG

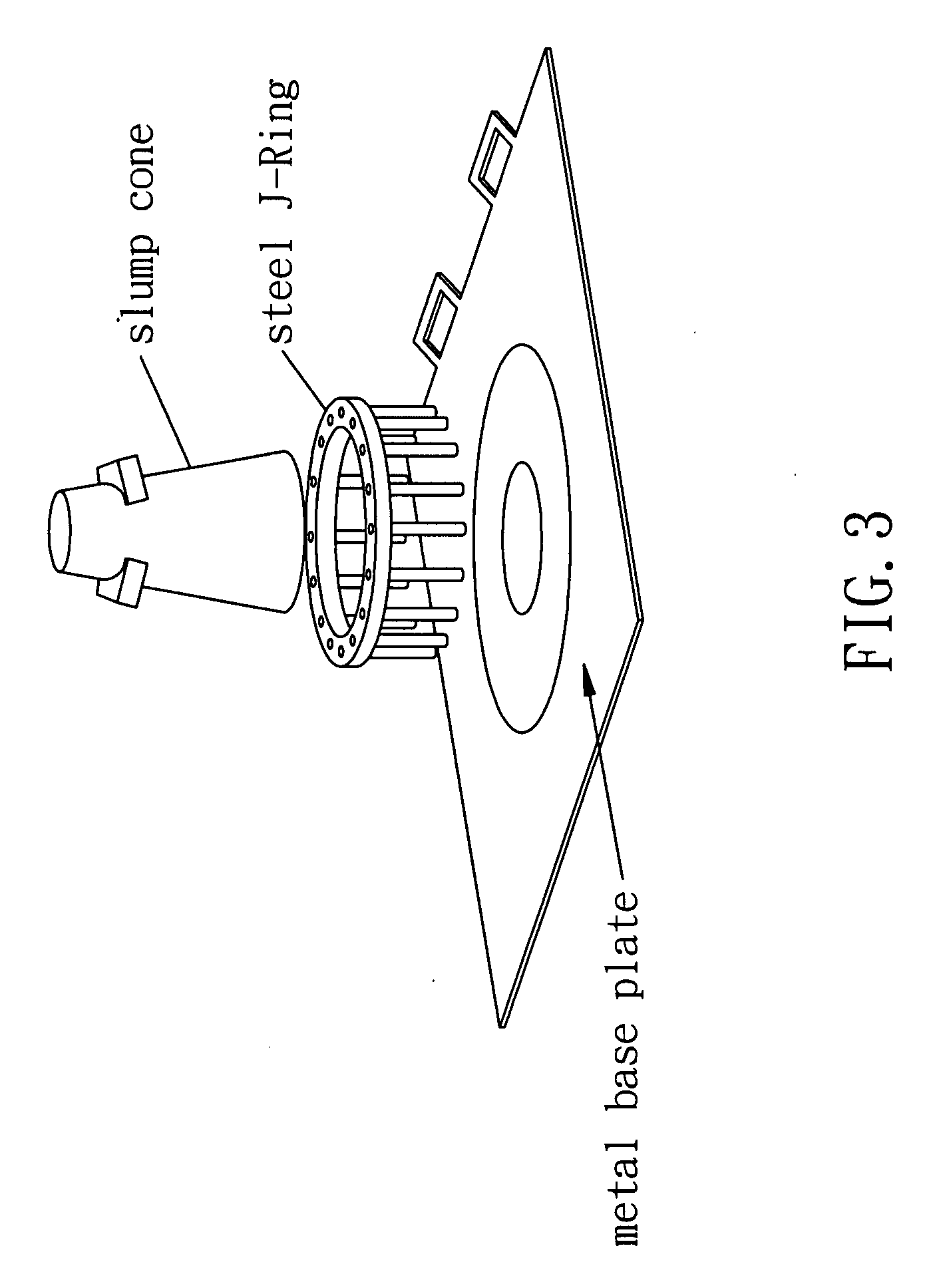

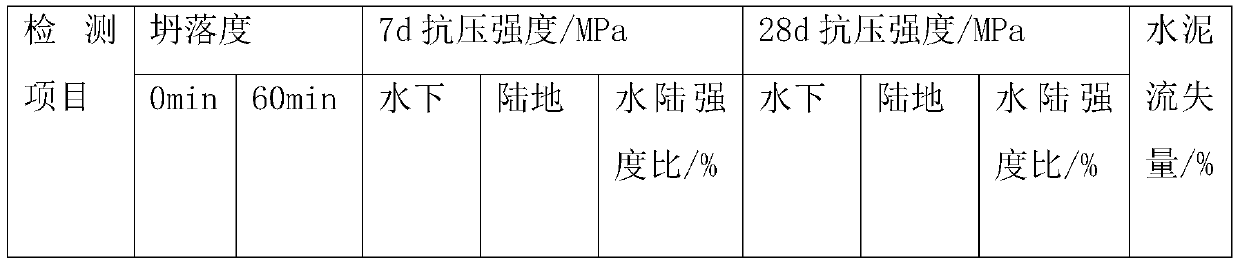

Non-dispersible concrete for underwater and underground construction

InactiveUS20080257221A1Low costImprove pore structureSolid waste managementCoatingsFineness modulusSuperplasticizer

A non-dispersible concrete for underwater and underground construction is disclosed, whose composition primarily comprises: coarse aggregate in a range of from 600 to 1200 kgw / m3; fine aggregate 500 to 1100 kgw / m3, with a fineness modulus (F.M.) in a range of from 2.2 to 3.2; powder 300 to 700 kgw / m3; mixing water 140 to 300 kgw / m3; and cohesion-enhancing admixture (for example, polyacrylamide, PAA) whose solid content is 0.1 to 5.0 wt % of the powder. In addition, a SCC for underwater and underground construction is also developed and has excellent property of self-consolidation (its test value is 400 to 750 mm in slump flow spread test) and an appropriate compressive strength (between 14 to 70 MPa), so as can be widely applied to underwater and underground construction, whose composition further includes superplasticizer with solid content 0.1 to 3.0 wt % of the powder. Also, it covers: water to binder ratio (W / B) of 0.22 to 1.00, paste volume 0.25 to 0.60 m3, and water / powder volume ratio 0.5 to 2.95.

Owner:JAU WEN CHEN

Method for improving gradation of machined sand

The invention discloses a method for improving gradation of machined sand, which adopts any one or two processes: gradation feeding: doping stone dust with the particle size of 0-4.75mm into gravel with the particle size of 9.5-19mm or 19-37.5mm, and adding into a sand maker to make sand; two-stage doping: mixing and doping machined sand with the particle size of 0-4.75mm and machined sand with the particle size of 0-2.36mm; and industrial residue doping: doping industrial residue into machined sand with the particle size of 0-4.75mm. By adjusting the feeding gradation (adding part of stone dust 15-35%), the throughput rate of the fine particles in the finished product machined sand of the 1.18mm sieve is increased by 3-15%; by mixing a small amount of fine machined sand with the maximum particle size of 2.36mm with common machined sand, the fineness modulus of the machined sand can be adjusted, and the machining gradation curve can be optimized; and the industrial residue is doped into the machined sand at a certain ratio to enhance the fine particle content in the machined sand, thereby achieving the goal of improving the gradation of machined sand.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG +1

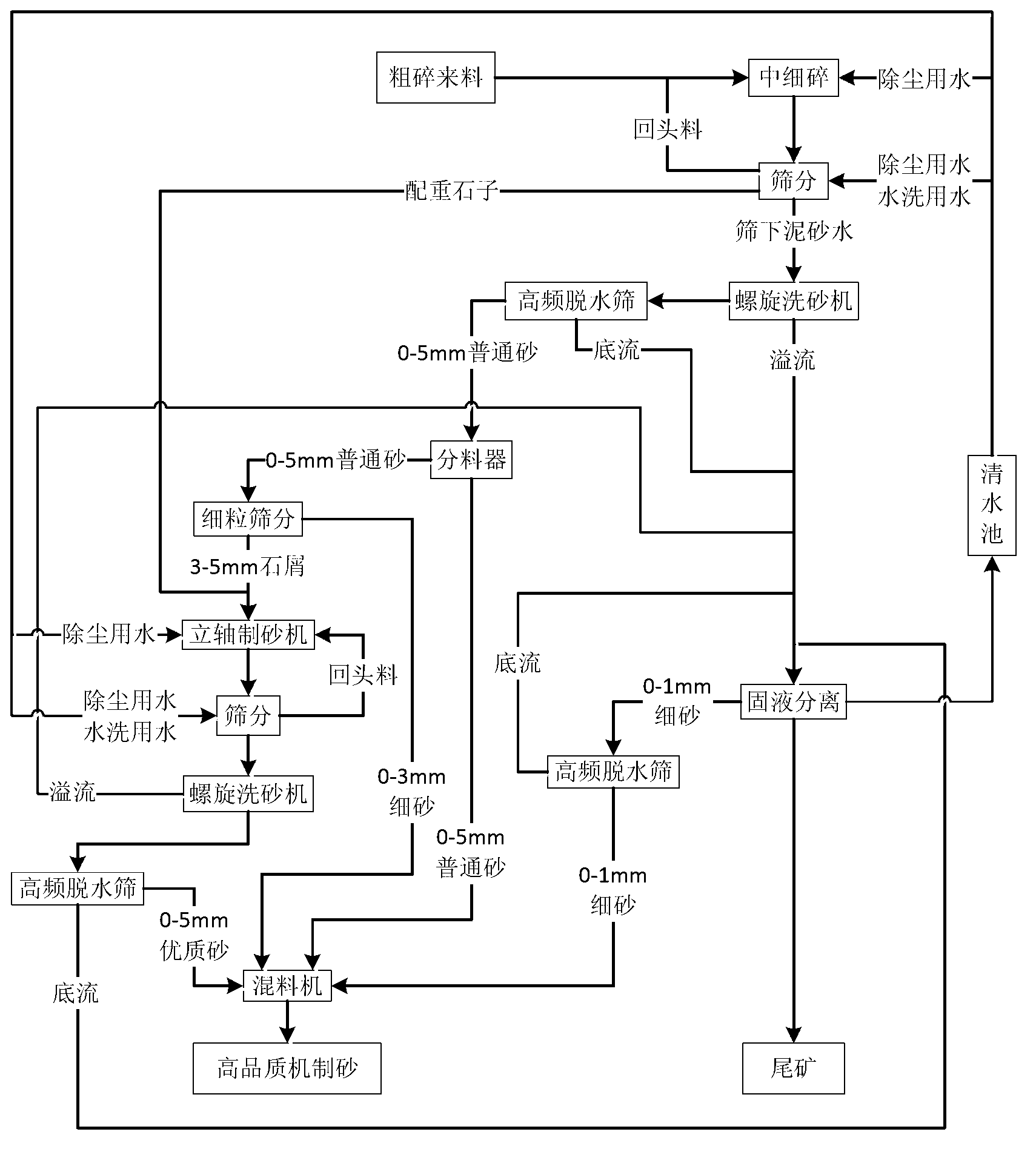

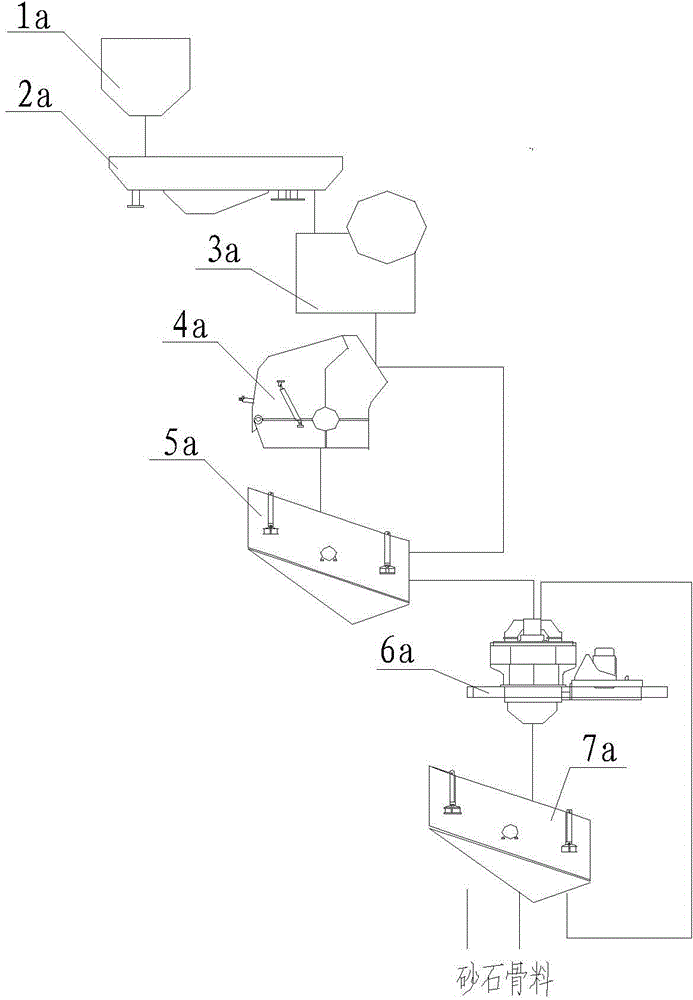

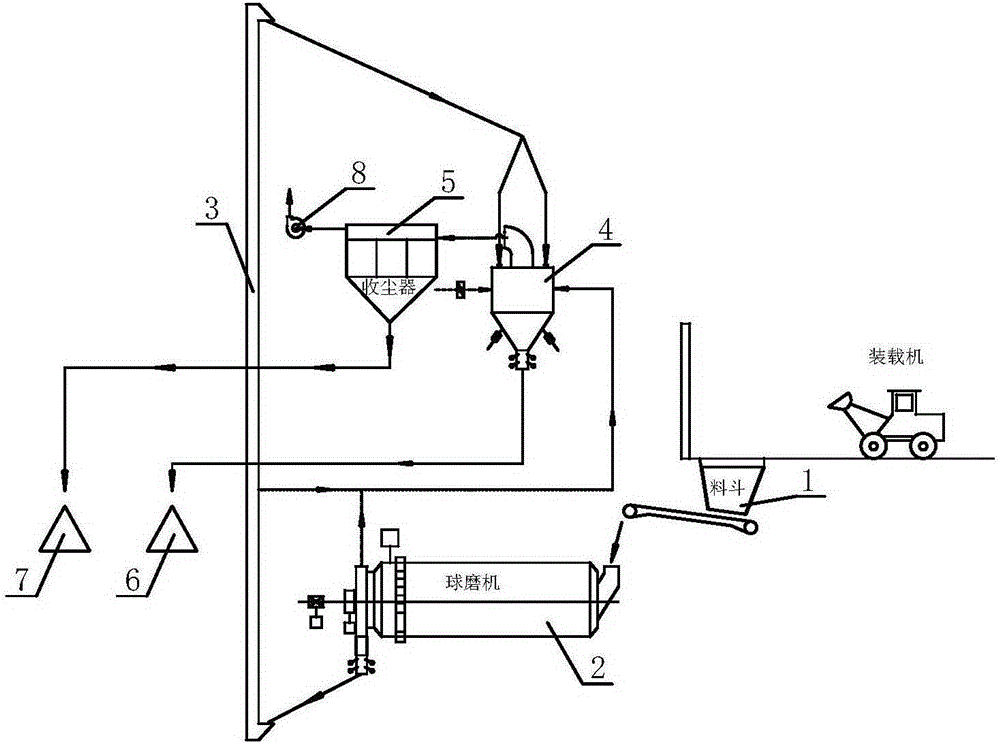

Machine-made sand production system, and production method and application thereof

The invention provides a machine-made sand production system, and a production method and application thereof. The machine-made sand production system comprises a hopper, and also comprises a ball mill for milling materials, a connection belt for conveying a material in the hoper to the ball mill, an efficient power separator for screening the material obtained from the ball mill, an elevator for transmitting the material discharged from the ball mill to the efficient powder separator, and a machine-made sand bin for receiving the material discharged from the efficient powder separator. The production method for the machine-made sand comprises performing ball milling crushing on a stone material and performing efficient winnowing on the material. The beneficial effects comprise that the made machine-made sand is controllable in fineness modulus, that is, the purpose of adjusting the discharge fineness of the machine-made sand by adjusting the ratio of large and small steel balls in the ball mill and the feed amount of crushed stone particles, and also machine-made sand and limestone powder with ideal grain gradation can be obtained by adjusting the material-spreading-plate rotation speed of the efficient powder separator, and the problems that machine-made sand is uncontrollable in grain gradation and dust content in the prior art are effectively solved.

Owner:重庆富普新材料有限公司

No-residual slurry forming technology of centrifugal tubular pile

The invention provides a no-residual slurry forming technology of a centrifugal tubular pile. In a preparation step for producing aggregate, the coarse aggregate is 5-20mm continuously-graded broken stone, and the particles below 10mm account for over 40% of the total mass of the coarse aggregate; the fine aggregate is sand in the II region, the fineness modulus is 2.2-2.8, and the particles below 0.3mm account for less than 20% of the total mass of the fine aggregate; a tackifier is added to a step of concrete stirring, and the stirring time is not longer than 1min after adding the tackifier; the time from the stirring end to the centrifugation start is controlled within 10-15min; and in a centrifugal forming step, the centrifugation speed and time are properly controlled. The technology provided by the invention solves the problem that residual slurry is generated by centrifugation in the production of a tubular pile, improves the utilization rate of material, reduces consumption, realizes clean production, and protects the sanitation of a tubular pile production field and the environment around the factory relatively well.

Owner:FUJIAN DADI CONCRETE PILE

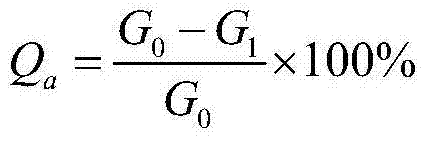

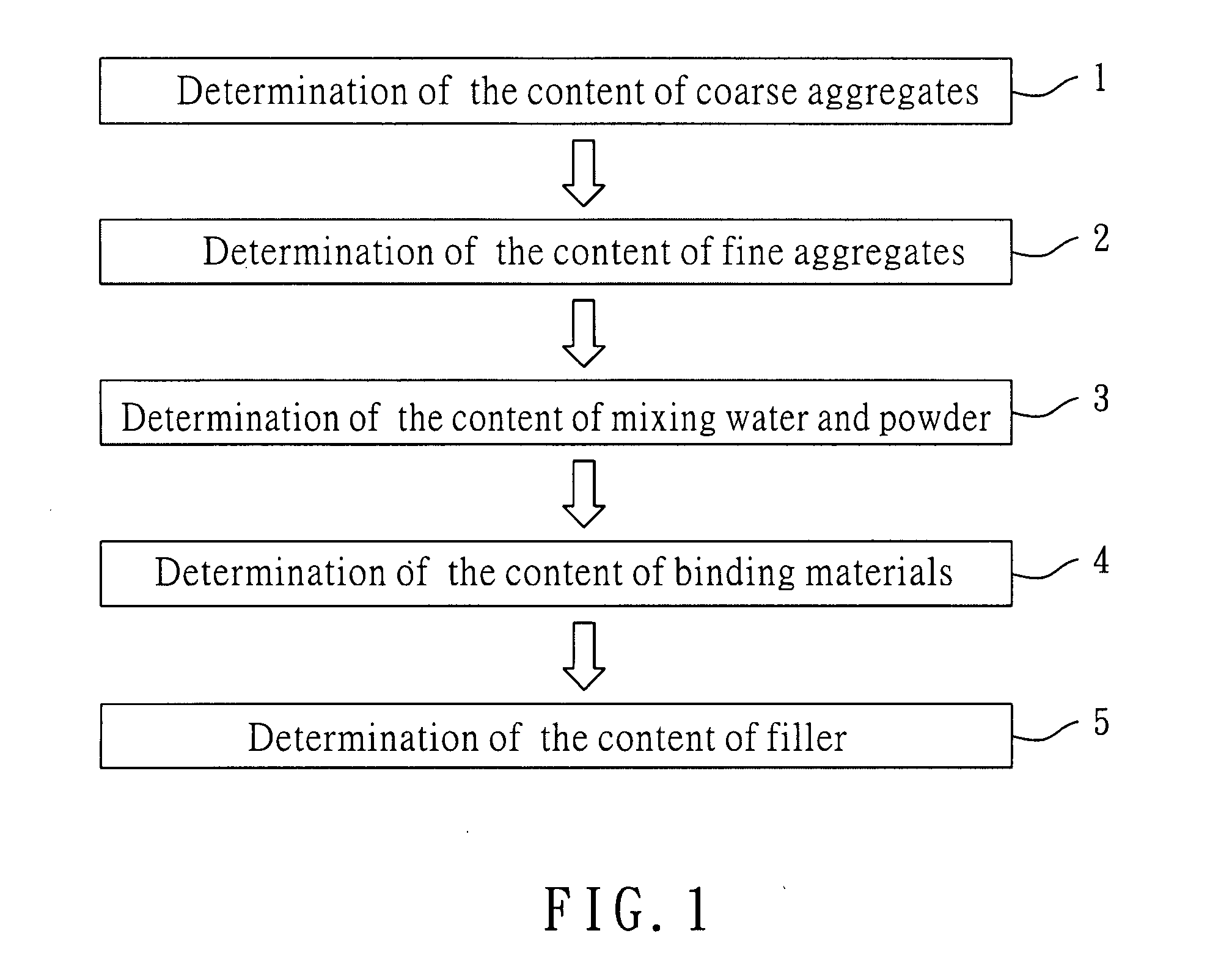

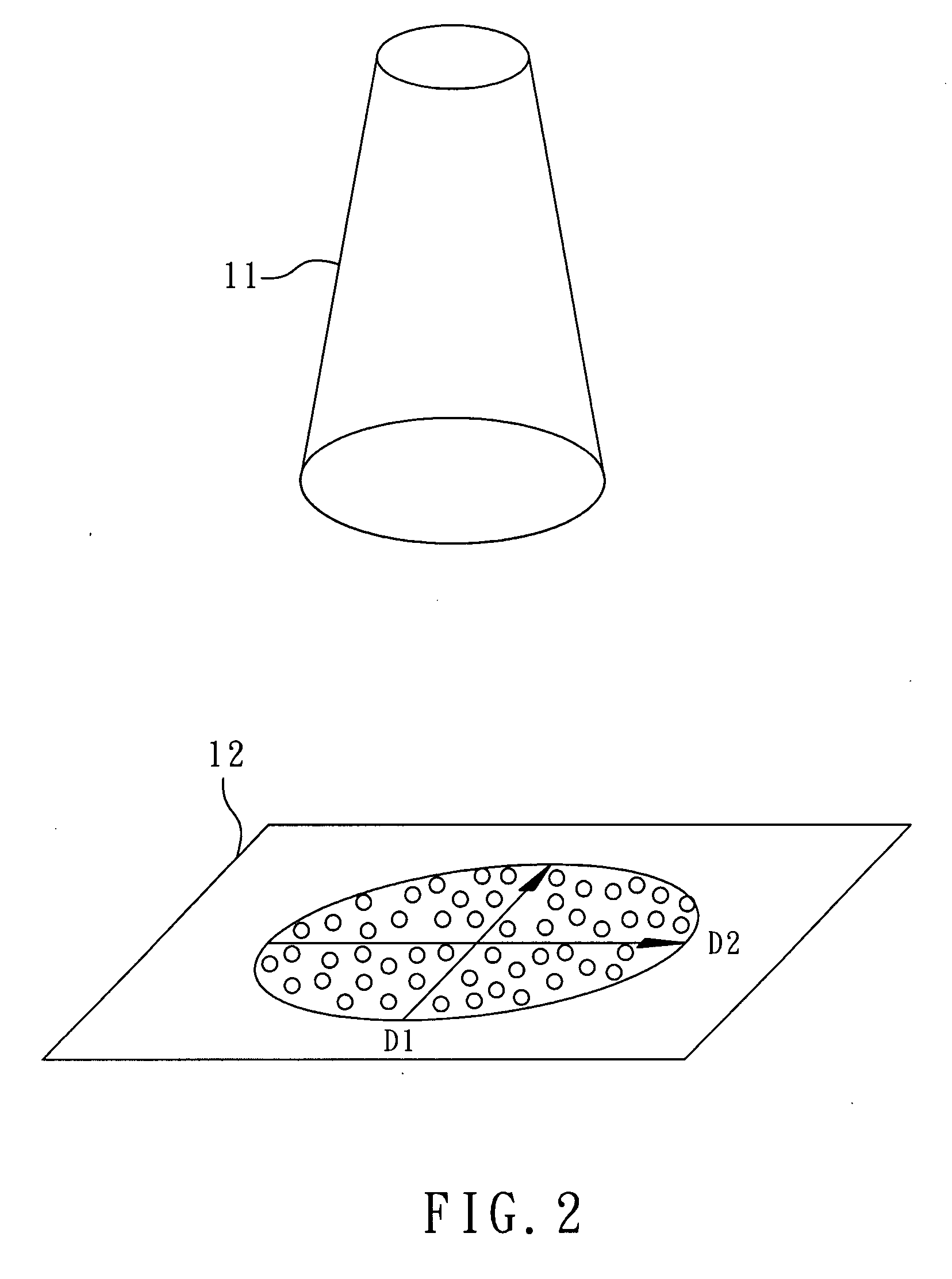

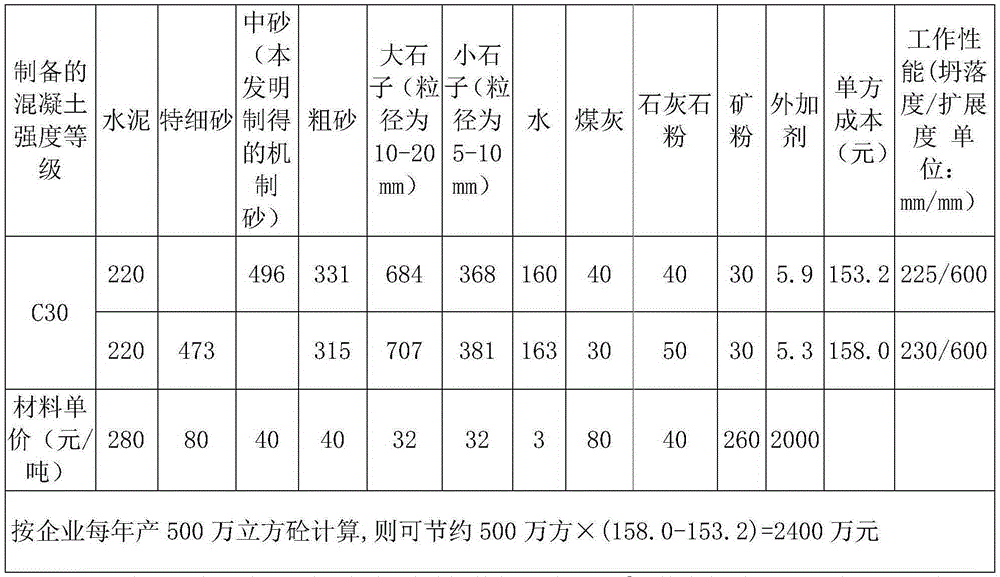

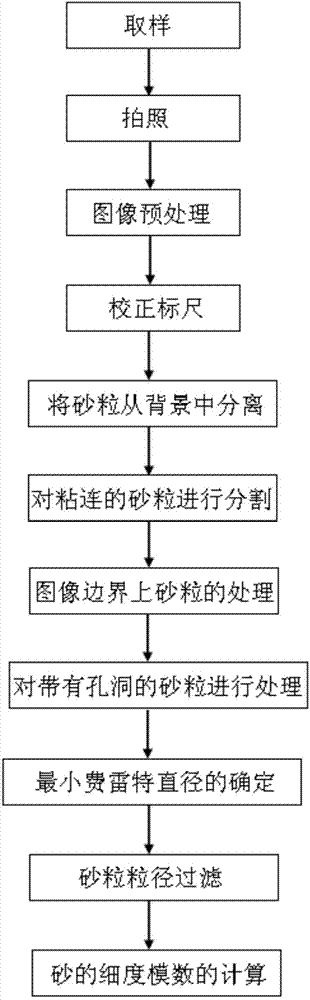

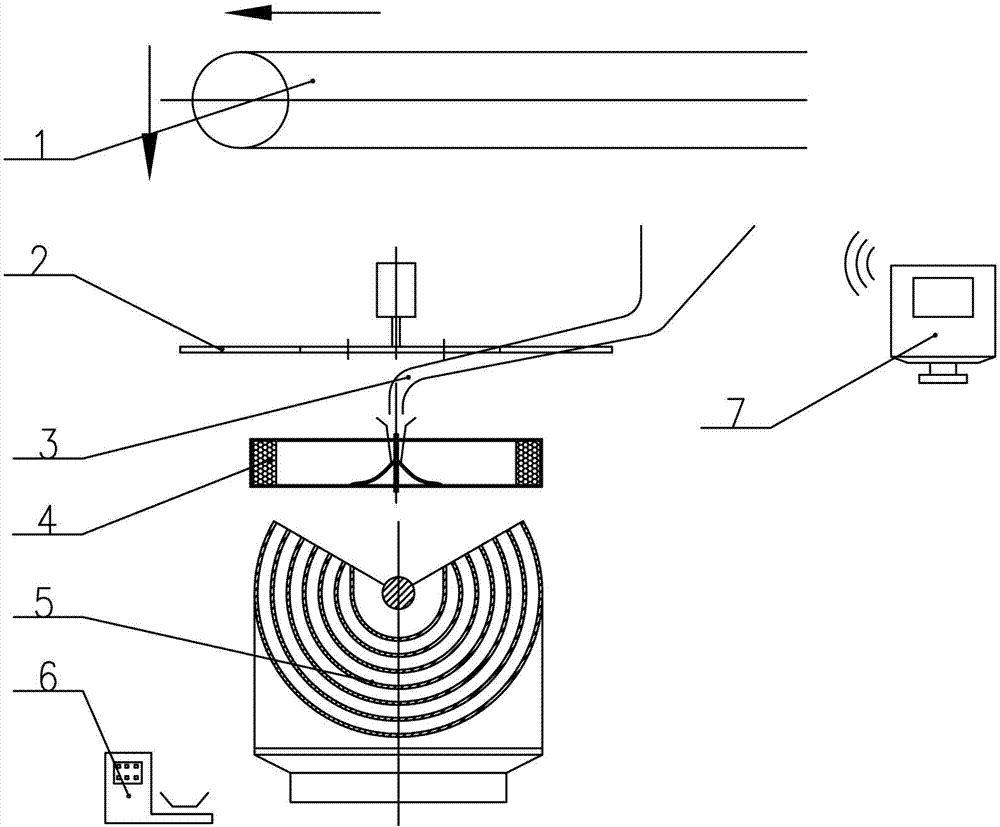

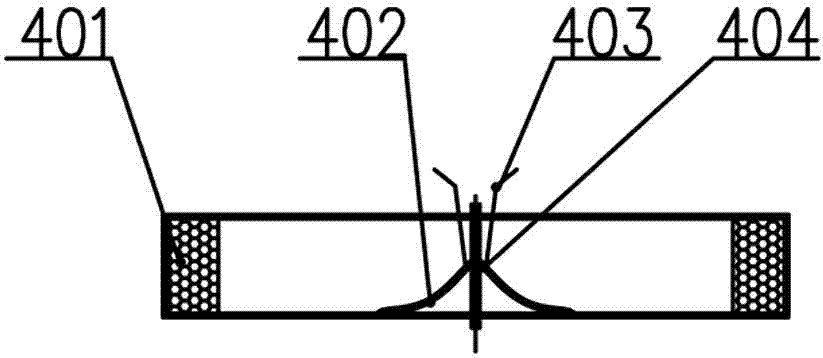

Method for determining fineness modulus of sand by utilizing image analysis technology

InactiveCN104502245AAvoid weighingGuaranteed accuracyImage analysisParticle size analysisImaging analysisFineness modulus

The invention belongs to the technical field of research and application of civil engineering materials and relates to a method for determining the fineness modulus of sand by utilizing an image analysis technology. The method comprises the eleven specific steps: sampling, photographing, preprocessing images, calibrating a scale, separating sand grains from the background, dividing the adhered sand grains, treating the sand grains on the image boundary, treating the sand grains with holes, determining the minimum Ferrette diameter, carrying out grain-diameter filtering on the sand grains and calculating the fineness modulus of the sand. The method has the advantages that the image analysis method is adopted for calculating the fineness modulus of the sand for the first time, and the criterion that the volume ratio and the weight ratio is equal is applied, so that the weighing process of the sand is avoided; the minimum Ferrette diameter is adopted as the equivalent grain diameter of the sand which can be sieved, so that the accuracy of determined data is better guaranteed; and the method is novel in design, reliable in principle, simple in operation, scientific in calculation, accurate in data, low in cost and high in automation degree.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

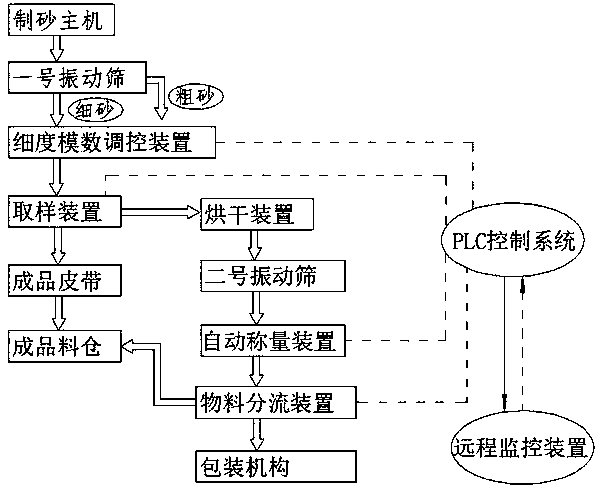

Detection control device and method for fineness modulus

PendingCN108732071AImprove securityReal-time monitoring of fineness modulusParticle size analysisProgramme control in sequence/logic controllersProduction lineShunt Device

The invention discloses a detection control device and method for a fineness modulus. A sampling device, drying equipment, a NO.2 vibration sieve, an automatic weighing device and a packaging mechanism connected through a material shunting device are arranged on the material outlet of the fineness modulus regulation and control device of a sand making production line, wherein the sampling device,the drying equipment, the NO.2 vibration sieve and the automatic weighing device are connected in sequence; in addition, the above equipment is connected with a PLC (Programmable Logic Controller) control system; the sampling device carries out sampling; samples enter and leave the drying equipment to be quickly dried; the NO.2 vibration sieve carries out sieving grading; the automatic weighing device weighs each grade of sand materials; the PLC control system carries out analysis comparison; finally, a comparison result is fed back to the fineness modulus regulation and control device to carry out real-time detection, regulation and control, and in addition, a detection sample is packaged and archived through the packaging mechanism. According to the detection control device, automatic detection can be realized, flexibility is high, the fineness modulus of a finished sand product can be monitored, regulated and controlled in real time, regulation and control accuracy is high, productquality stability is guaranteed, and the quality and the production efficiency of the product are improved.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

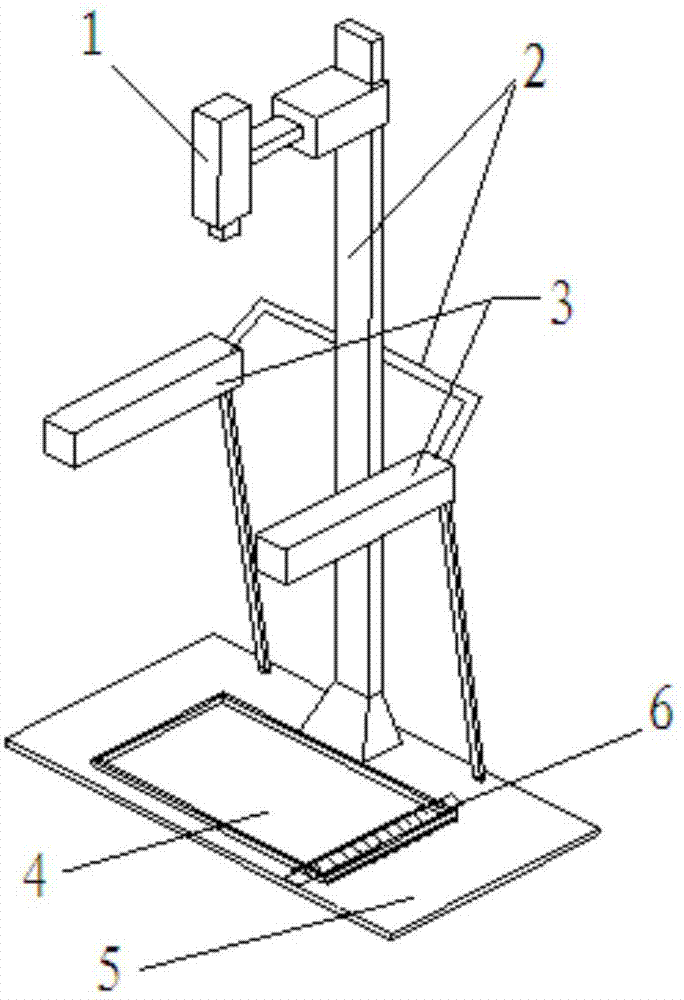

Sandstone aggregate production and detection device

InactiveCN104330324AQuality improvementRealize online detectionWeighing by removing componentProduction lineFineness modulus

The invention discloses a sandstone aggregate production and detection device, which comprises a feeding belt, a material receiving rotary table, a feeding hopper, a dryer and a screening instrument that are disposed from top to bottom in order. A controller is arranged outside the material receiving rotary table, and one side of the screening instrument is provided with a weighing instrument. The controller is used for sending a command signal to control the material receiving rotary table in terms of driving the feeding hopper to rotate together, and the feeding hopper rotates to a position right below the feeding belt discharge port to perform material receiving. The dryer is used for drying the discharged material, and the screening instrument is used for screening the dried material. The device provided by the invention is used for detecting the water content of sandstone aggregate and specific fineness modulus in a concrete sandstone aggregate online production process, is mounted at the discharge port position of a concrete production line, and a rack is fixedly mounted at a corresponding part to maintain the entirety stable and safe. Good sealing ensures that the whole device can carry out effective and high quality detection work in real time in the sandstone aggregate online production process.

Owner:CHINA THREE GORGES UNIV

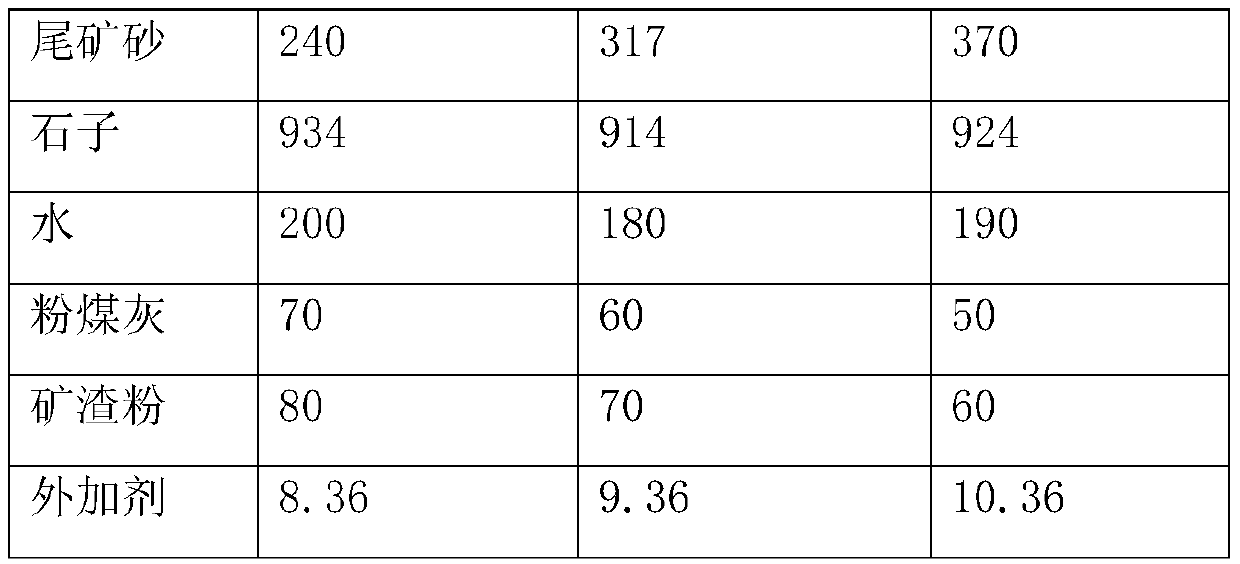

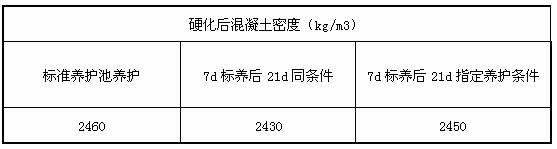

C30 tailing sand concrete and preparation method thereof

The invention discloses a C30 tailing sand concrete and a preparation method thereof. The C30 tailing sand concrete includes cement, sands, tailings sands, broken stones, water, fly ash, slag powder and an admixture; the tailing sands have a fineness modulus of 2.1-2.3 and a mud content of below 5%; the admixture is prepared by mixing a water reducer, a flocculant, a reinforcing component and modified bentonite according to a mass ratio of 1:(0.8-1.2):(4.5-5.5):(0.04-0.06); and the reinforcing component is prepared by mixing triethanolamine, polydimethylsiloxane and modified coal gangue powderaccording to a mass ratio of 1:(0.4-0.6):(1.2-1.5). The C30 tailing sand concrete of the invention has the advantages of good workability, small slump loss, and low dispersibility during underwater construction.

Owner:青岛中建富兴商砼有限公司

High-flow low-shrinkage C30 concrete capable of shielding radiation

The invention relates to high-flow low-shrinkage C30 concrete capable of shielding radiation. The concrete is prepared by mixing cement, mineral powder, fly ash, sand, gravels, additive and water, wherein the concrete comprises the following components in cubic amount kg / m<3>: 220-240 kg / m<3> of cement, 80-125 kg / m<3> of mineral power, 80-35 kg / m<3> of fly ash, 795-820 kg / m<3> of gravels with fineness modulus of 2.3-2.6, 1,000-1,025 kg / m<3> of gravels with maximum particle diameter of not greater than 25 mm, 3.0-4.0 kg / m<3> of additive and 150-155 kg / m<3> of water; the dry density of the concrete is greater than 2,350 kg / m<3>; the content of internal moisture of the concrete is not less than 0.35 percent within all operation time of a structure space cast by using the concrete; the expansion degree of the concrete is 550+ / -75 mm; the contents of cobalt Co, silver Ag and iridium Ir in the cement, the mineral powder and the fly ash are less than 50 ppm respectively; and the contents of europium Eu, samarium Sm, gadolinium Gd, dysprosium Dy and thulium Tm are less than 10 ppm respectively. According to the concrete provided by the invention, shielding can be effectively produced for a proton flow and a neutron flow produced by hospital proton heavy ion equipment; and meanwhile, the concrete has the characteristics of high fluidity and low shrinkage.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +2

Ultrafine mixed sand concrete by using additive

ActiveCN102241495ASolve difficult problems that cannot be used for important projectsSolve the disadvantages of not being beautifulSolid waste managementFineness modulusSlag

The invention relates to an ultrafine mixed sand concrete by using an additive, the concrete comprises cement, slag powder, fly ash, mixed sand, broken stone and the additive, the mixed sand comprises ultrafine mixed sand with fineness modulus of 0.8 - 1.2, medium sand with fineness modulus of 2.3 - 3.0, chips with fineness modulus of 2.8 - 3.6, and the stone flour content in chips is 4% - 8%, methylene blue is less than 1.4. According to the invention, the ultrafine mixed sand concrete solves the problems that the concrete prepared by chips is solid but unaesthetic, the ultrafine sand can not be used for the important projects and the slump loss of the ultrafine mixed sand concrete is large.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +7

Impact crusher capable of adjusting aggregate fineness modulus

ActiveCN102764686AAdjustable fineness modulusAvoid cloggingGrain treatmentsAir volumeFineness modulus

An impact crusher capable of adjusting aggregate fineness modulus comprises a machine case, a feeding device, a crushing cavity, a rotor and a discharge channel, and is characterized in that a discharge opening of the feeding device is provided with a dust shield device for preventing dust from being discharged from the machine case; an airflow forming device is arranged below the crushing cavity, an air guide device is arranged above the crushing cavity; the airflow forming device generates rising airflow in the crushing cavity, the airflow and the meeting dust in the crushing cavity form dust flow, the air guide device forms a negative pressure area above the crushing cavity so as to guide a large amount of dust flow in the negative pressure area, and in this way, the dust can not be discharged from the discharge opening due to the blocking of the dust shield device but only can be discharged from the machine case by the air guide device; the air guide amount of the air guide device is adjustable, and the dust content of the aggregate in the crushing cavity is controlled by adjusting the air guide amount. The dust removing effect and the control of dust content of the crushed aggregate are realized by adjusting the air inlet amount and the air guide amount of the crushing cavity so as to realize the adjustable aggregate fineness modulus.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Dry-method sand manufacturing machine

InactiveCN103341383AEasy to adjustControl stone powder contentGrain treatmentsFineness modulusElectric machinery

The invention relates to the technical field of sand manufacturing equipment, and particularly relates to a dry-method sand manufacturing machine. The dry-method sand manufacturing machine comprises a feeding port, an upper shell, a lower shell, grinding rollers, a grinding disc, a support, an overhauling device, an inner screening device, a working cylinder, a scraper blade, a discharge port, a reduction box, a coupler, a main motor and foundation bolts, wherein the feeding port is arranged in the central position of the upper part of the upper shell, the discharge port is arranged on a bottom plate of the lower shell, the grinding rollers are uniformly distributed on the grinding disc, the inner screening device is fixed on the upper shell through a regulating device, and the support can support the grinding rollers, the upper shell and the lower shell and is connected with a base through the foundation bolts. The dry-method sand manufacturing machine provided by the invention has the advantages that the sand grade is conveniently regulated through regulating the size of grinding force of the grinding rollers and a gap between a moving ring and a static ring, the reasonable fineness modulus is controlled, and the content of mountain flour in machine-made sand is regulated; meanwhile, few needle-shaped and sheet sand is manufactured by the machine under the action of a grinding force and a shear force, and the machine-made sand is good in particle shape; in addition, by virtue of a dry method for manufacturing, the appropriate mountain flour content in machine-made sand is remained, the grade of the machine-made sand is optimized, and meanwhile, the water resource is saved.

Owner:王燕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com