Curing-free PHC pipe pile concrete

A PHC pipe pile and concrete technology, applied in the field of concrete materials, can solve the problems of the adverse effect of the PHC pipe pile concrete durability, the adverse effect of the concrete compressive strength, the cracks of the PHC pipe pile concrete, etc. Excellent effect, small radius effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments are listed below to further illustrate the present invention. It should be understood that the examples are not intended to limit the protection scope of the present invention.

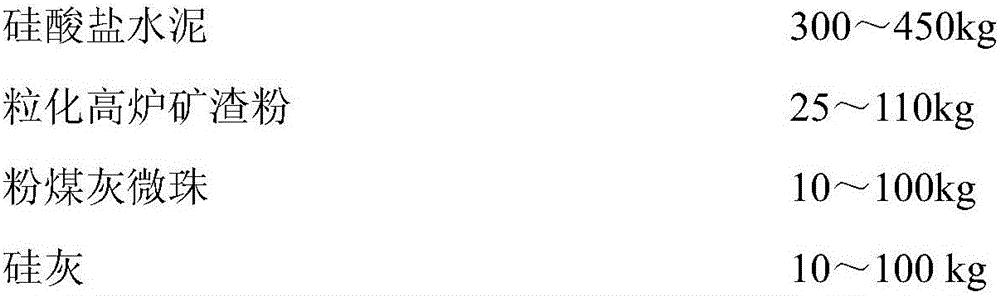

[0030] Examples of raw materials

[0031] (1) Cement: Portland cement with strength grade 52.5 type II

[0032] (2) Slag powder: S115 grade granulated blast furnace slag powder

[0033] (3) Fly ash microbeads: the water demand ratio is 80%, and the 7-day activity index is 85%.

[0034] (4) Silica fume: the specific surface area is 18500m 2 / kg, the activity index for 28 days was 96%.

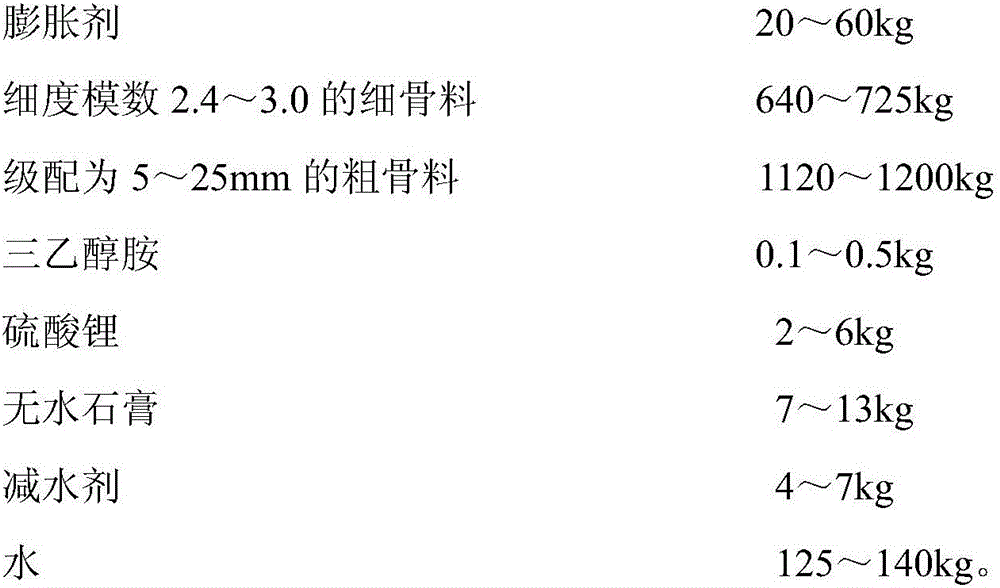

[0035] (5) Expansion agent: adopt ZY expansion agent produced by Beijing Xinzhongyan Building Materials Technology Co., Ltd., with an alkali content of 0.30wt%, a chloride ion content of 0.005wt%, and a 7-day limit expansion rate in water of 0.028%.

[0036] (6) Fine aggregate (sand): medium sand with a fineness modulus of 2.7, a mud content of 0.5 wt%, and a mud content of 0.2 wt%.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Electric flux | aaaaa | aaaaa |

| Diffusion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com