Method for determining fineness modulus of sand by utilizing image analysis technology

A technology of image analysis and fineness modulus, which is applied in the research and application of civil engineering materials, and can solve problems such as high labor intensity, low efficiency, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

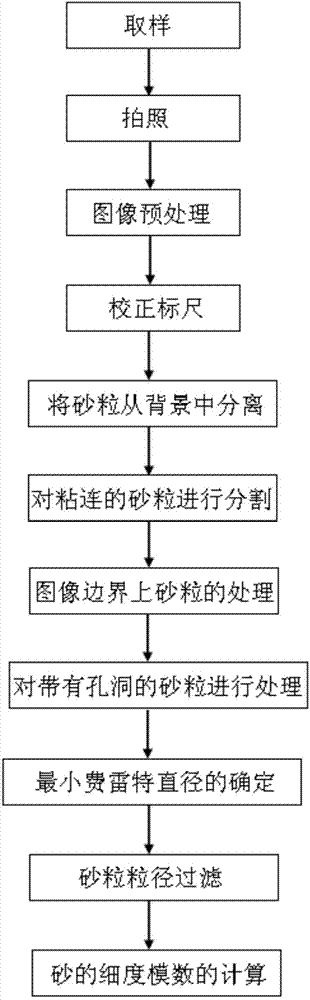

[0045] The fineness modulus measuring method of the sand that the present embodiment relates to specifically comprises the following steps:

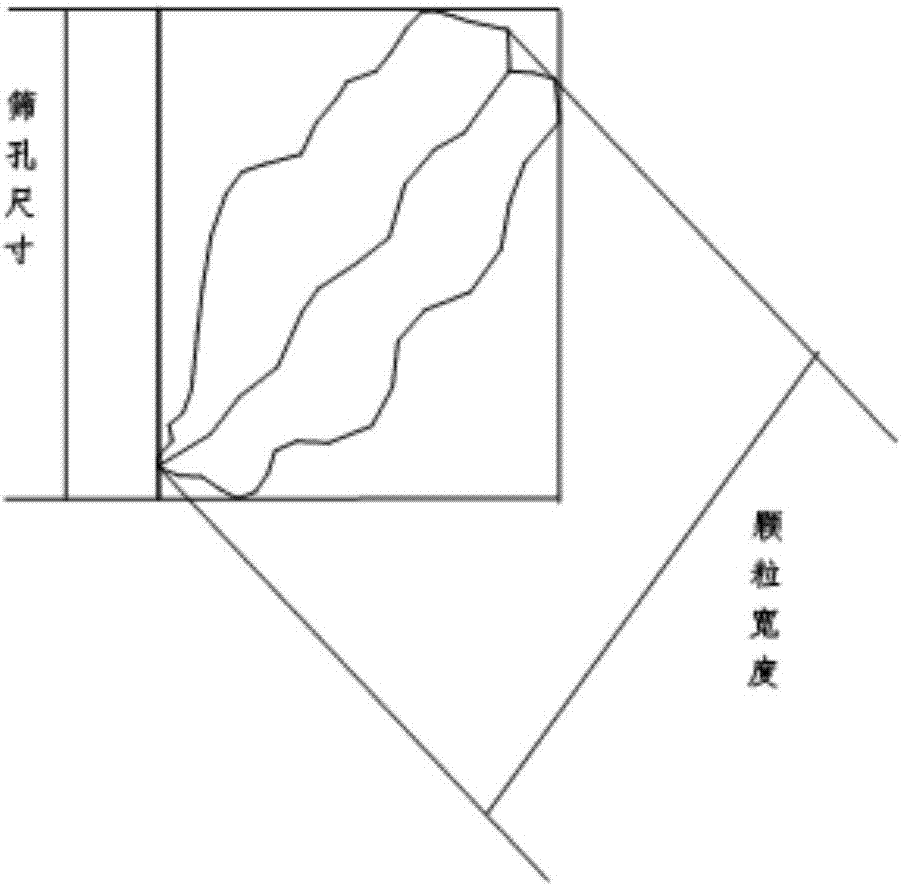

[0046] (1) Sampling: According to the sampling regulations in "Sand for Construction" (GB / T 14684-2011), the sand for calculating the fineness modulus should be sampled through sieve screening. In the actual screening process, as long as the sand grain width The size of the direction is smaller than the diagonal size of the sieve hole, and the sand particles can pass through the sieve hole from the diagonal direction of the sieve hole (such as figure 2 shown), so the nominal particle diameters of sand particles corresponding to sieve holes 9.5mm, 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm and 0.15mm are 10mm, 5.00mm, 2.50mm, 1.25mm, 0.63mm, 0.315 mm and 0.16mm; sand samples with a nominal particle size in the range of 0.16mm-10mm were obtained by sampling and divided into 800ml, then dried in a drying oven to constant weight, and divided into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com