Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Meet pumping requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

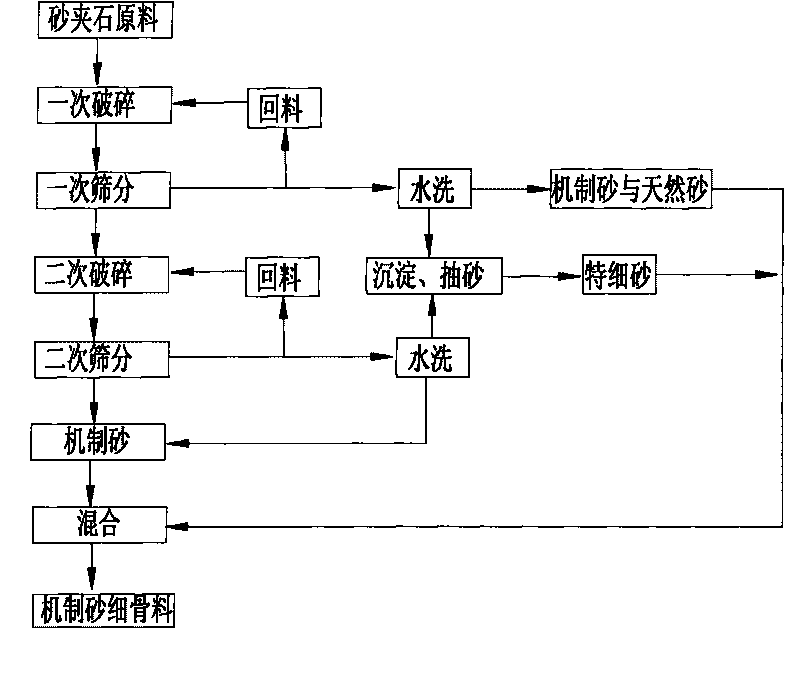

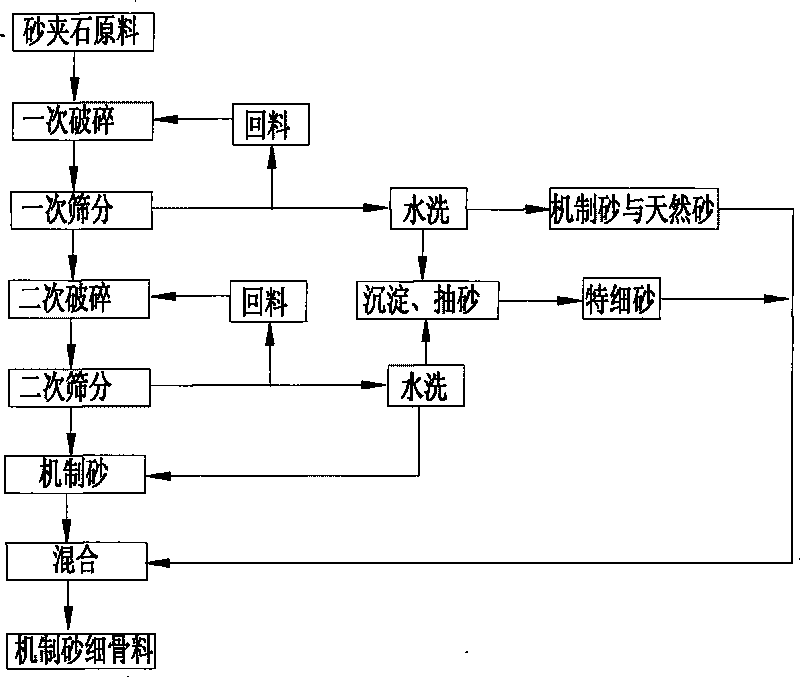

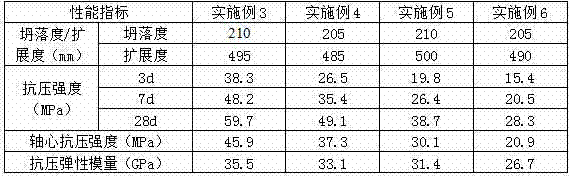

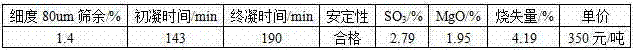

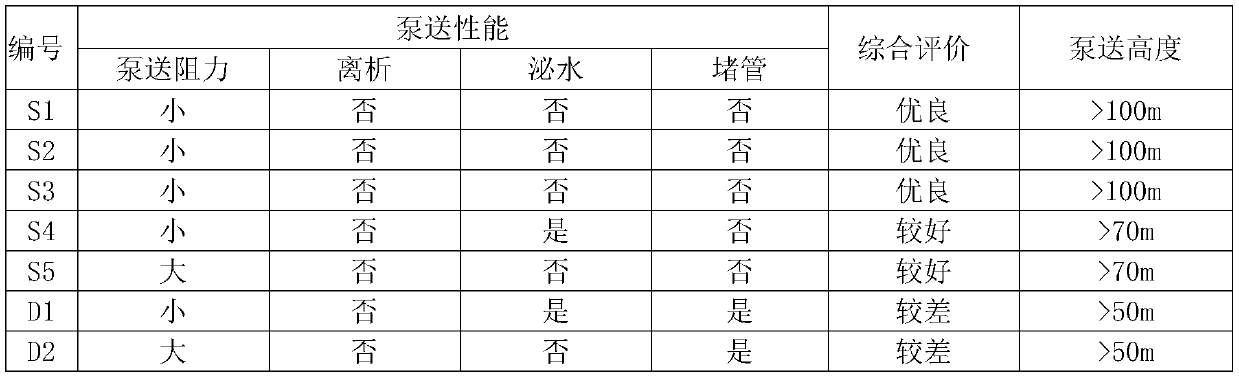

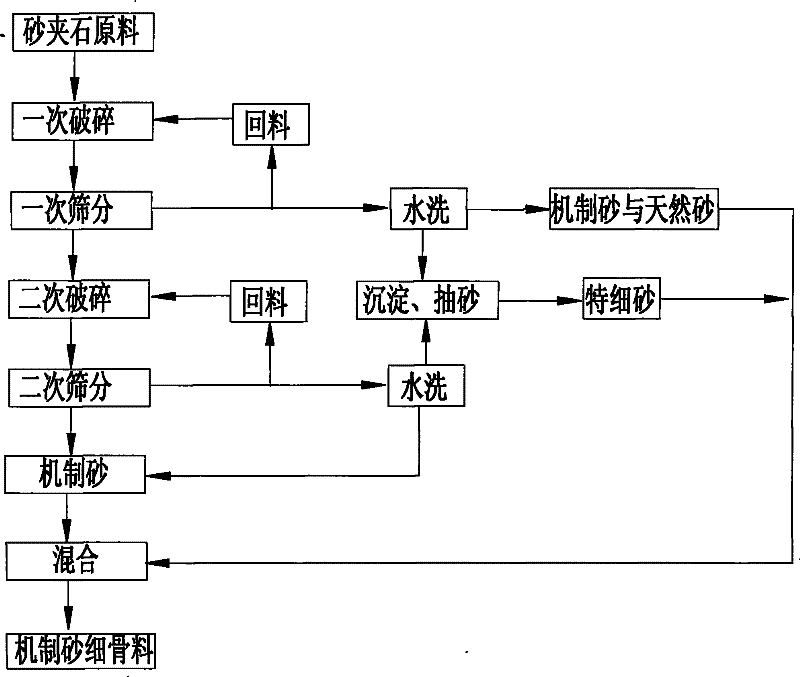

Preparation method of machine-made sand fine aggregate

ActiveCN101708968AMeet pumping requirementsEasy constructionGrain treatmentsFineness modulusDirect production

The invention discloses a preparation method of fine aggregate in concrete, specially relating to a preparation method of machine-made sand fine aggregate. The method adopts sand preparing technology; when preparing machine-made sand fine aggregate, the machine-made sand is combined with special fine sand with smallest grain diameter to produce the machine-made sand fine aggregate with certain fineness modulus. The method overcomes the deficiency that in traditional technology, the fineness modulus of the machine-made sand fine aggregate can not be accurately regulated and controlled, and the method of the invention can directly produce the machine-made sand fine aggregate satisfying premixed concrete pumping as well as construction and easy performance requirements.

Owner:CHONGQING NO 3 CONSTR

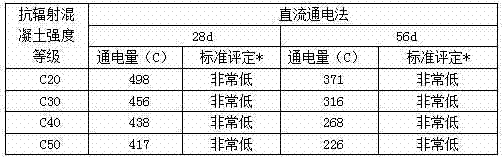

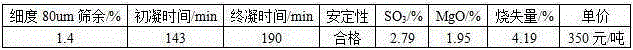

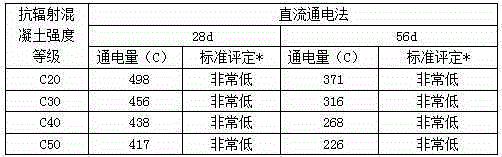

Barite anti-radiation pump concrete

The invention discloses barite anti-radiation pump concrete. The concrete comprises the following components: cement, water, barite powder, barite sand, barite, synergist and admixture according to a ratio of [340-450]:[110-170]:[75-150]:[1000-1400]:[1800-2000]:[2-4]:[7-19]. According to selection of raw materials and design of the ratio, the anti-radiation concrete which is high in density and high in liquidity and can be used for pumping is obtained.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

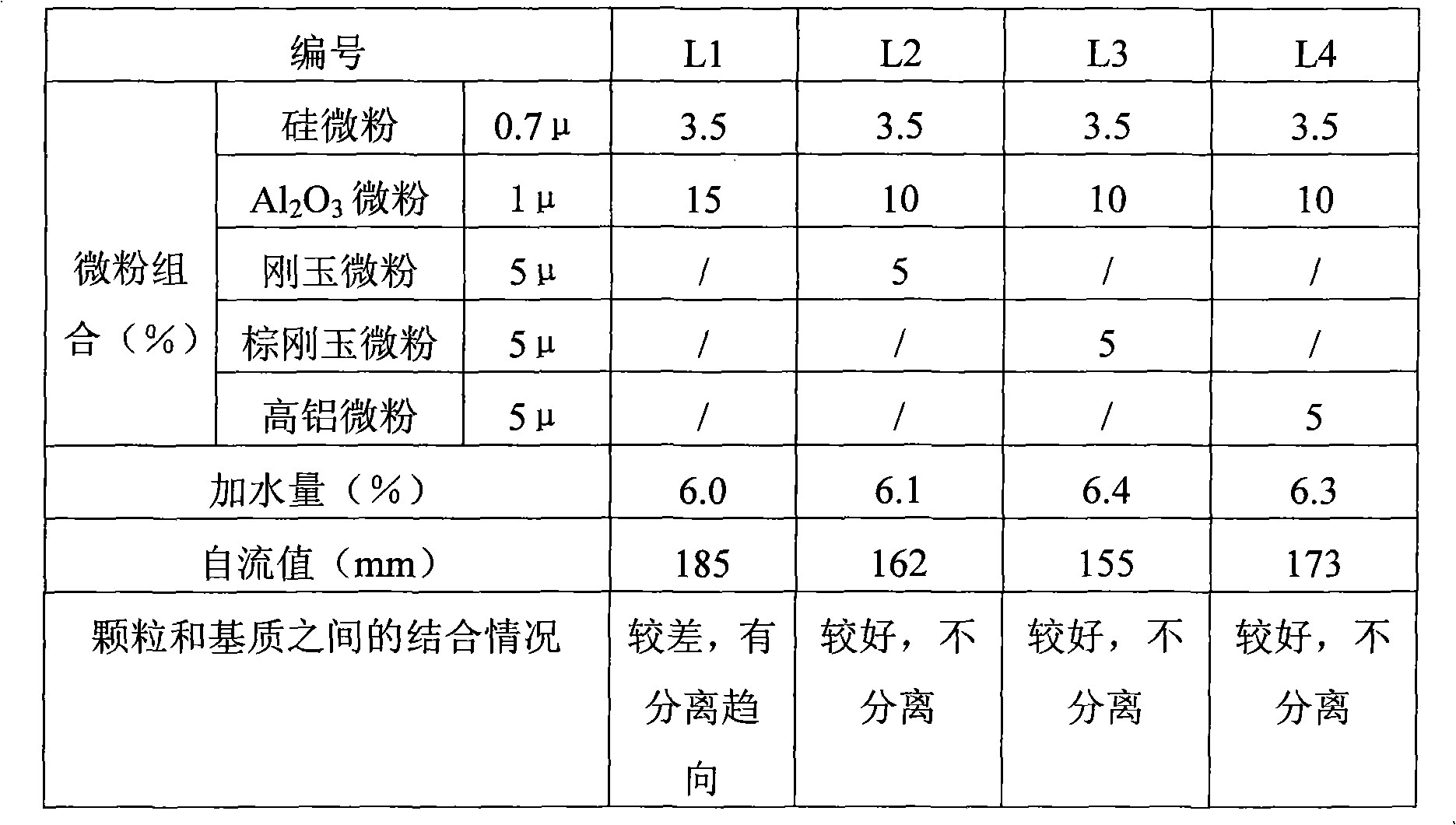

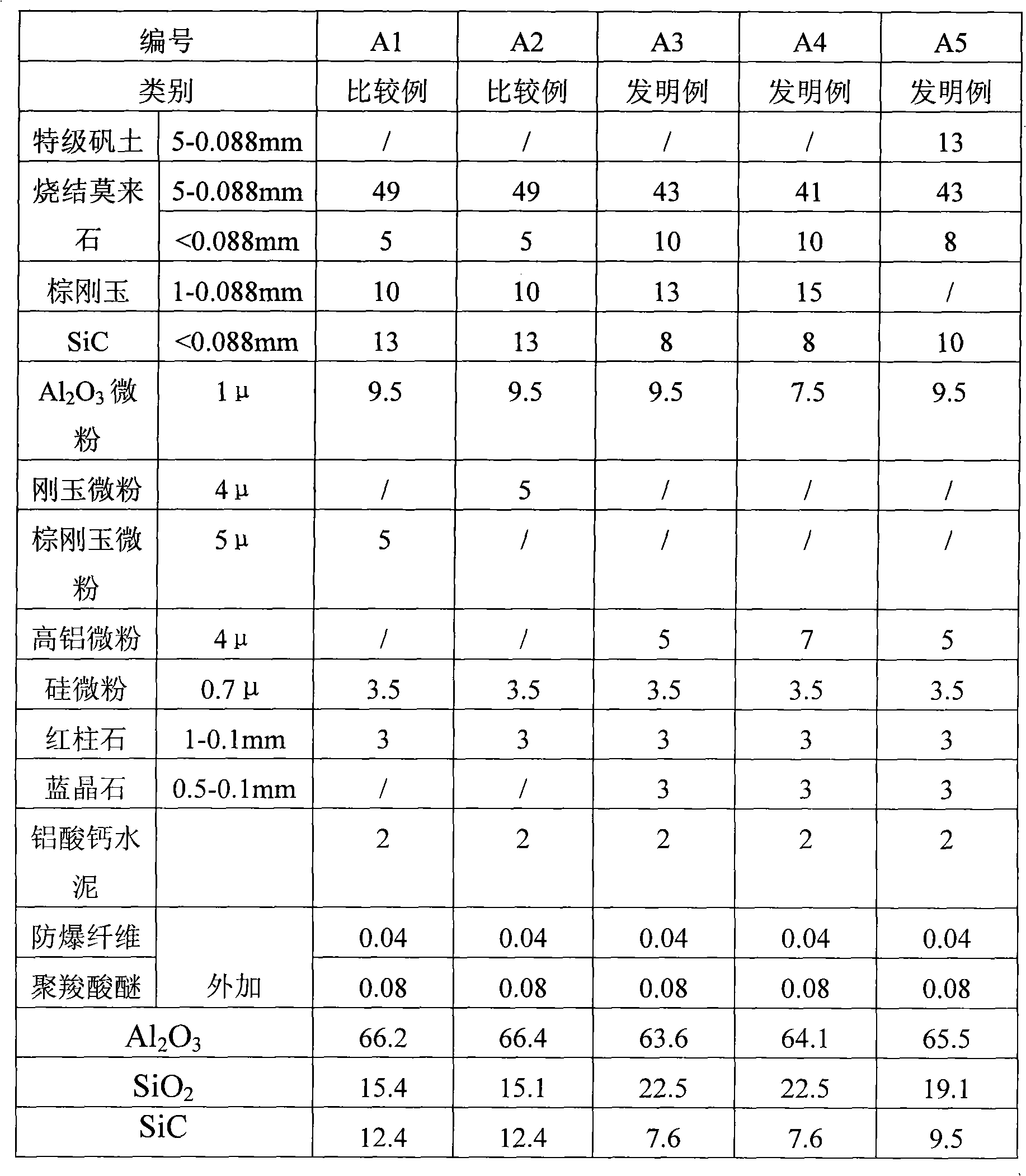

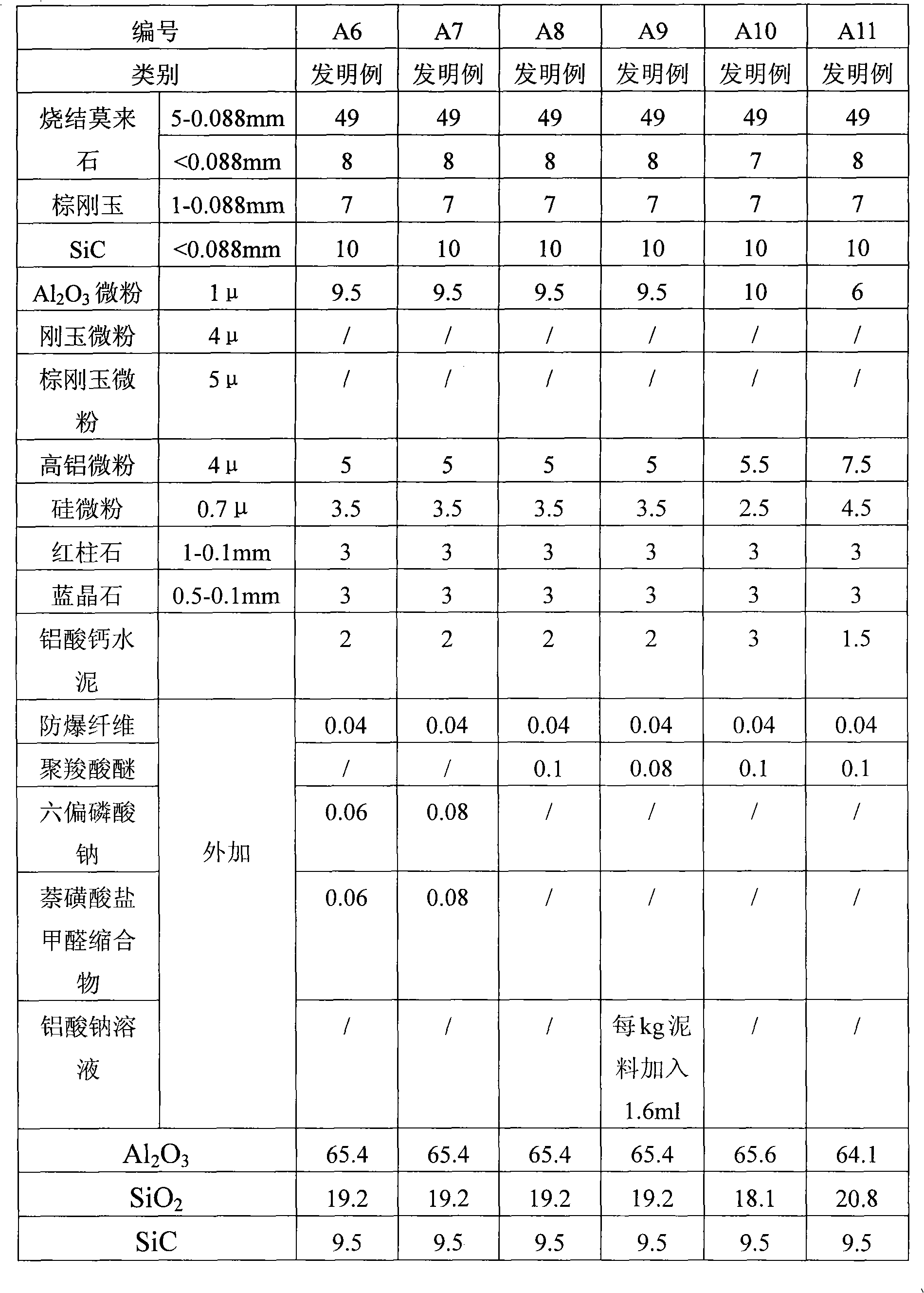

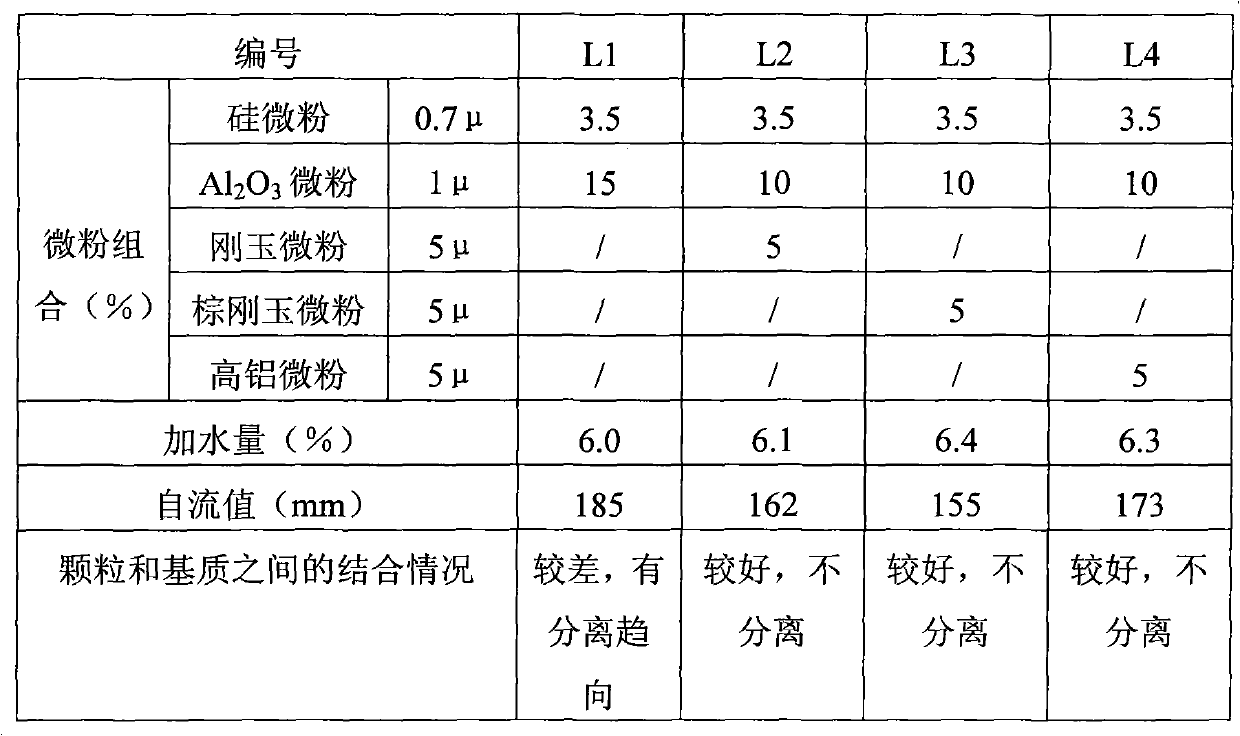

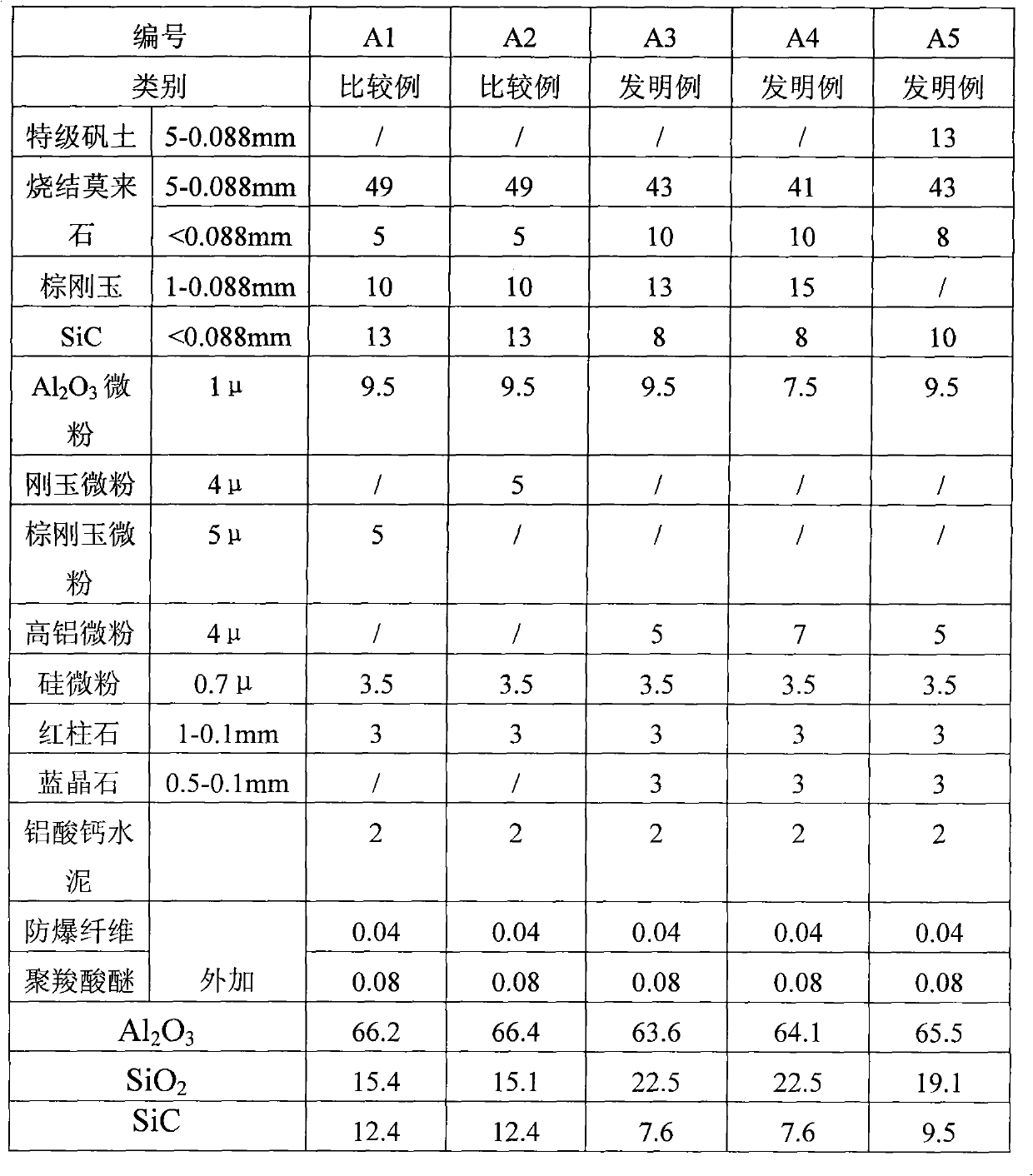

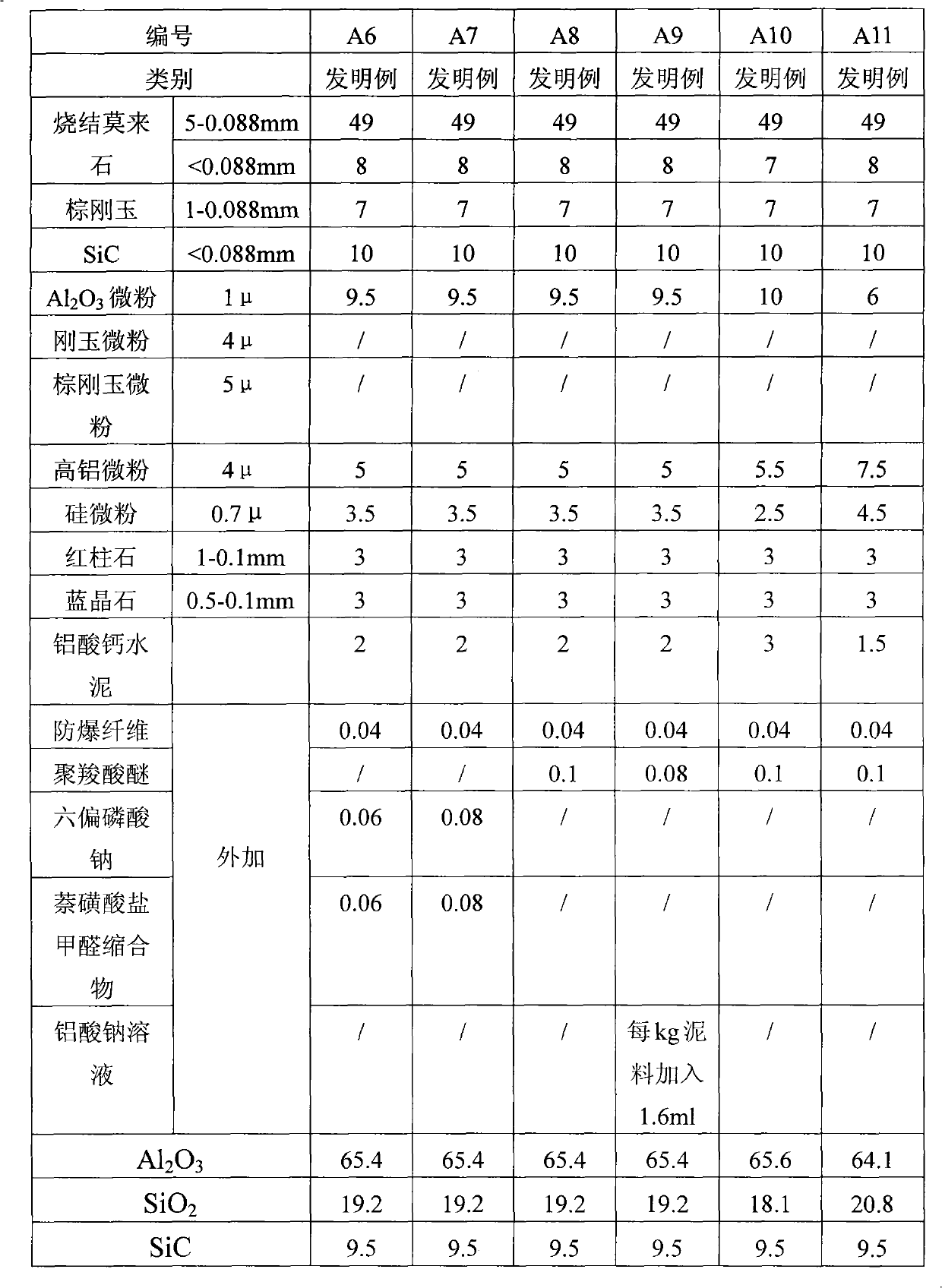

Al2O3-SiO2-SiC-based jet material for foundry ladle

The invention relates to an Al2O3-SiO2-SiC-based refractory material, in particular to an Al2O3-SiO2-SiC-based jet material for wet jet construction of a foundry ladle. The Al2O3-SiO2-SiC-based jet material for the foundry ladle comprises the following components in percentage by weight: 45 to 65 percent of sintered mullite, 5 to 15 percent of SiC, 7 to 18 percent of brown aluminium oxide or special-grade alumina, 5 to 10 percent of Al2O3 super-micro powder, 4 to 8 percent of high-aluminum micro powder, 2 to 5 percent of silicon micro powder, 1.5 to 3 percent of calcium aluminate cement, and 6 percent of balance. The granularity of the Al2O3 super-micro powder is leas than or equal to 2 microns; the purity of Al2O3 in the high-aluminum micro powder is more than or equal to 88 percent, and the granularity is less than or equal to 5 microns; and the purity of SiO2 in the silicon micro powder is more than or equal to 92 percent, and the granularity is less than 1 micron. The balance comprises 3 percent of andalusite and 3 percent of cyanite. The jet material has high strength and good thermal shock stability and corrosion resistance, and ensures good self-flowing property and pumping property.

Owner:BAOSHAN IRON & STEEL CO LTD

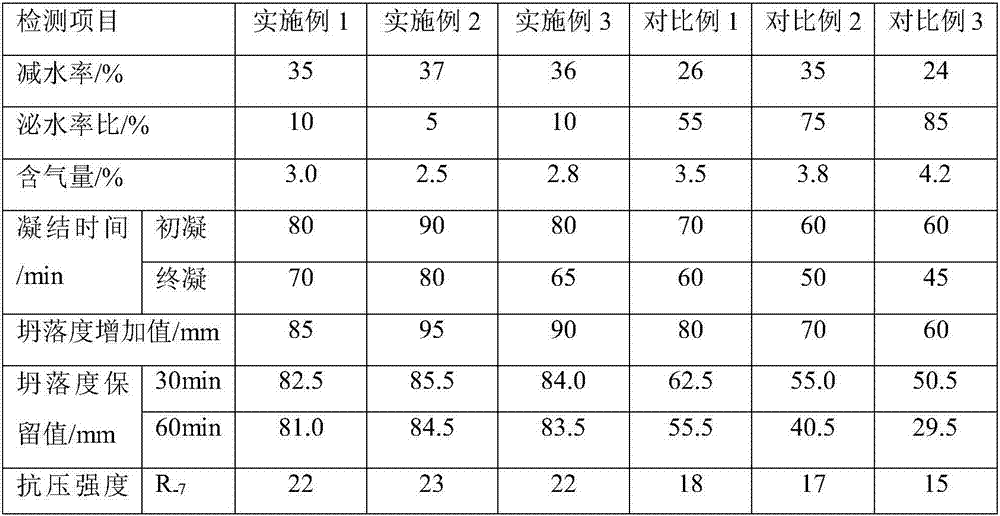

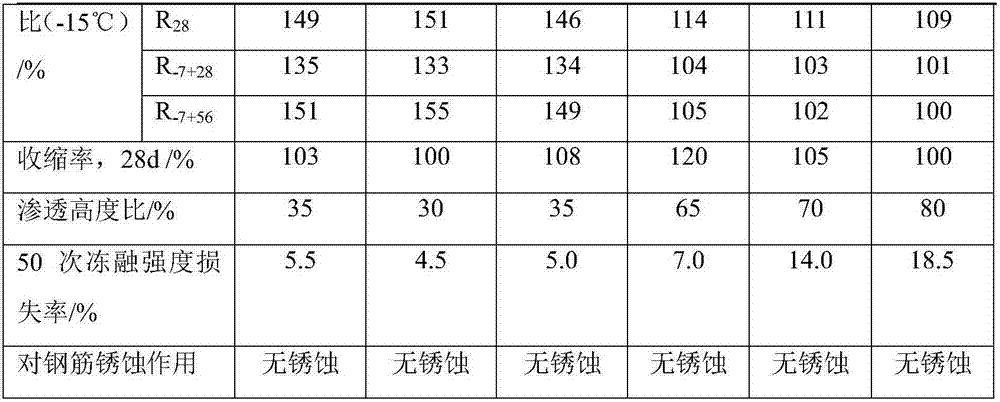

Antifreeze anticorrosion durable concrete and preparation method thereof

The invention discloses an antifreeze anticorrosion durable concrete. The concrete comprises the following components, by weight, 500 parts of a gelling material, 700-715 parts of medium sand, 1050 parts of broken stone, 164 parts of water and 10.56-18 parts of a water reducer, wherein the gelling material comprises 54-56wt% of cement and 44-46wt% of powder A; and the powder A comprises the following components: 30-35wt% of slag, 20-25wt% of zeolite, 35-40wt% of coal ash, 5-10wt% of long bluestone and 0-7wt% of quicklime. The invention also discloses a preparation method of the concrete. The preparation method comprises the following steps: 1, weighing raw materials of the components of the powder A according to above proportions, crushing by an ultrafine mill, and uniformly mixing; 2, weighing raw materials of the components of the concrete according to above proportions; 3, sequentially adding ordinary Portland cement, the powder A, the medium sand and the broken stone to a concrete stirring device, and stirring for 2-3min to fully and uniformly mix; and 4, slowly adding well weighed water and the well weighed water reducer to the obtained mixture while stirring, and continuously stirring for 1-2min to obtain the concrete. The concrete of the invention is high performance concrete which can resist strong sulfate corrosion, strong chloride corrosion, freeze-thaw cycles and drying and wetting cycles.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

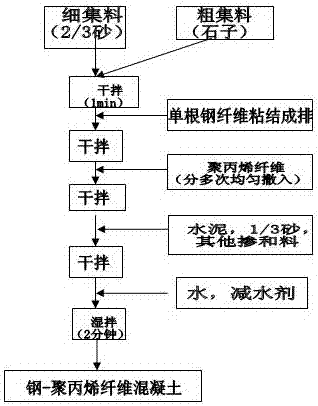

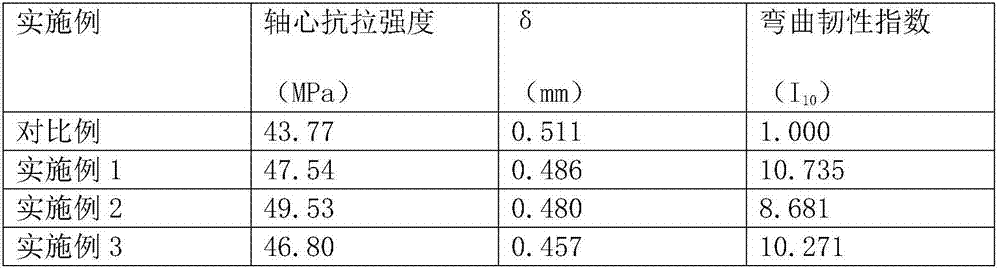

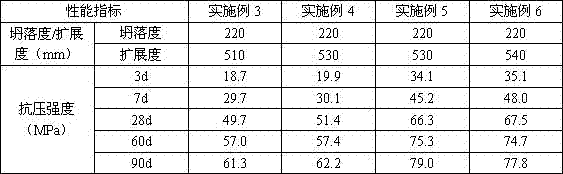

High-performance expanded hybrid fiber concrete material for wet joints, and preparation method thereof

The invention provides a high-performance expanded hybrid fiber concrete material for wet joints, and a preparation method thereof. According to the present invention, based on the practical problems of the wet joint in the whole simply supported-continuous structure system, high-strength hybrid fiber reinforced concrete is used as a joint material to provide the hybrid effect at different levels and different load applying stages so as to well inhibit and restrict the development of cracks, wherein the development of the concrete micro-crack is limited by releasing the concentrated force of the micro-crack in the concrete with Durafibers, the development of the macro-crack is limited by steel fibers, and by mixing the Durafibers and the steel fibers, a variety of mechanical properties of the whole concrete can be improved in the case of the low doping volume, such that the concrete can have characteristics of high bending resistance, high toughness, high impermeability, high fatigue resistance and the like so as to prevent the occurrence of diseases.

Owner:WUHAN UNIV OF TECH

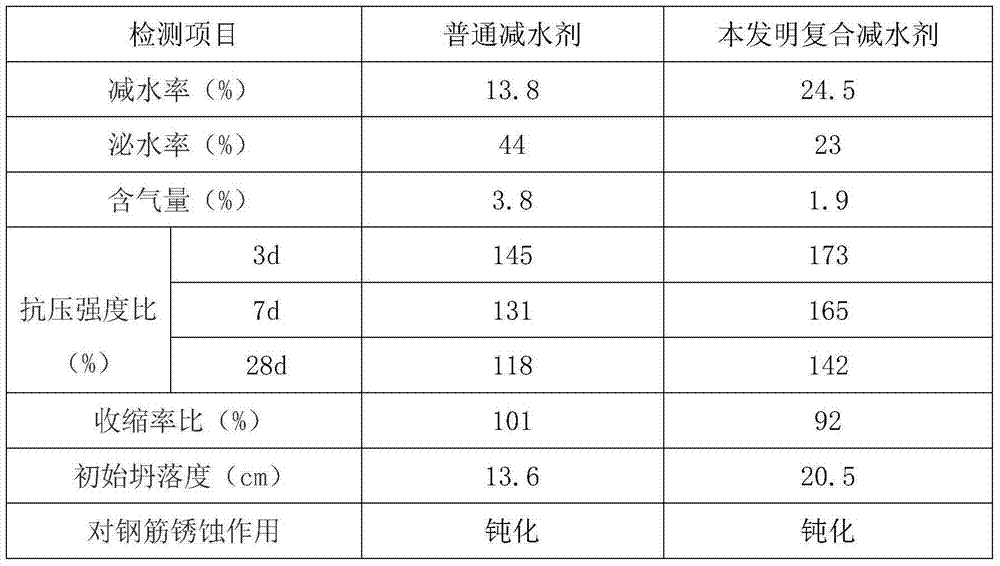

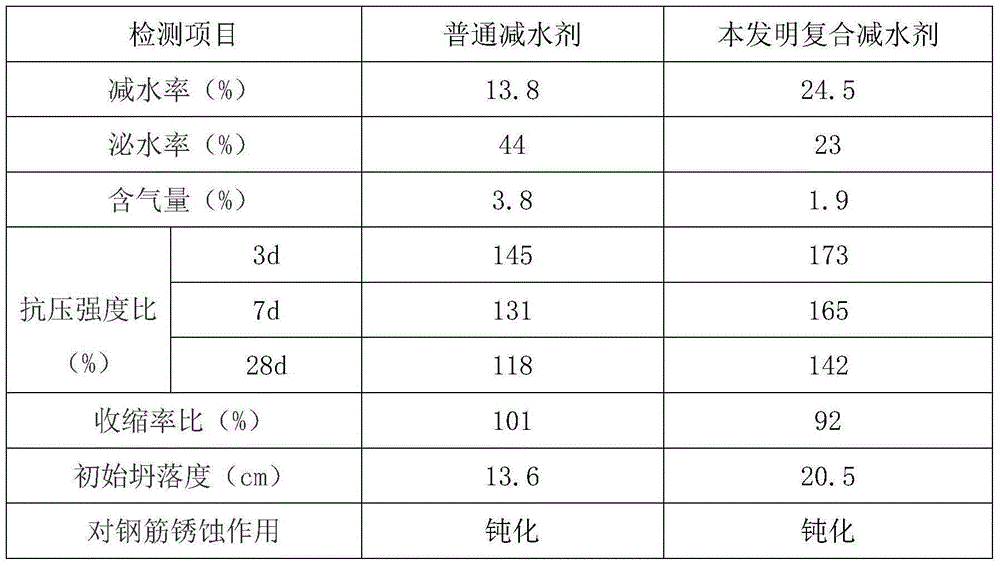

Concrete composite water reducing agent

The invention discloses a concrete composite water reducing agent which is prepared by mixing the following raw materials in parts by weight: 35 to 45 parts of para amino benzene sulfonate-sulfonated acetone-formaldehyde condensates, 25 to 35 parts of Beta-naphthalene sulfonate formaldehyde condensates, 15 to 20 parts of mahogany petroleum sulfonate, 10 to 15 parts of calcium lignosulphonate, 5 to 10 parts of triethanolamine, 8 to 14 parts of sulfonate-type waterborne polyurethane, 6 to 12 parts of zinc phosphate, 5 to 10 parts of ash calcium powder, 5 to 10 parts of polyvinylpyrrolidone, 3 to 6 parts of sodium metasilicate, 4 to 8 parts of coal residue, 3 to 6 parts of triterpenoid saponin, 2 to 4 parts of allylthiourea, 2.5 to 4.5 parts of rhamnolipid, 2 to 3 parts of isooctyl triethoxy silane and 4 to 7 parts of auxiliaries. The adding amount of the water reducing agent is low, i.e., the adding amount of the water reducing agent only accounts for 0.4% to 0.8% of the mass of concrete. The water-reducing rate of the water reducing agent can reach up to 20% to 25%. The water reducing agent has a good plasticizing effect, so that the slump of the concrete is obviously increased, and the cohesiveness and the workability of the concrete are improved, wherein the slump of the concrete can be increased by above 180mm, thereby conforming to the requirement of concrete pumping.

Owner:江苏金海宁新型建材科技有限公司

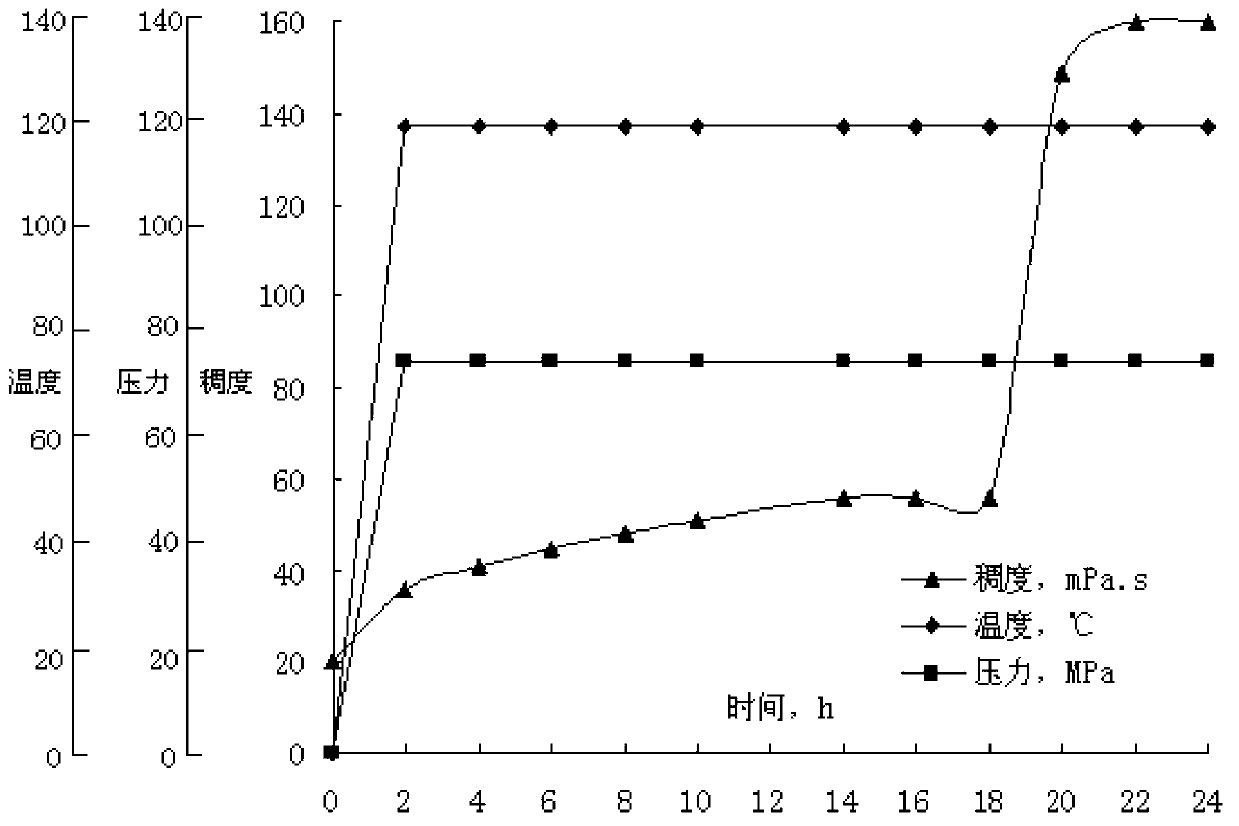

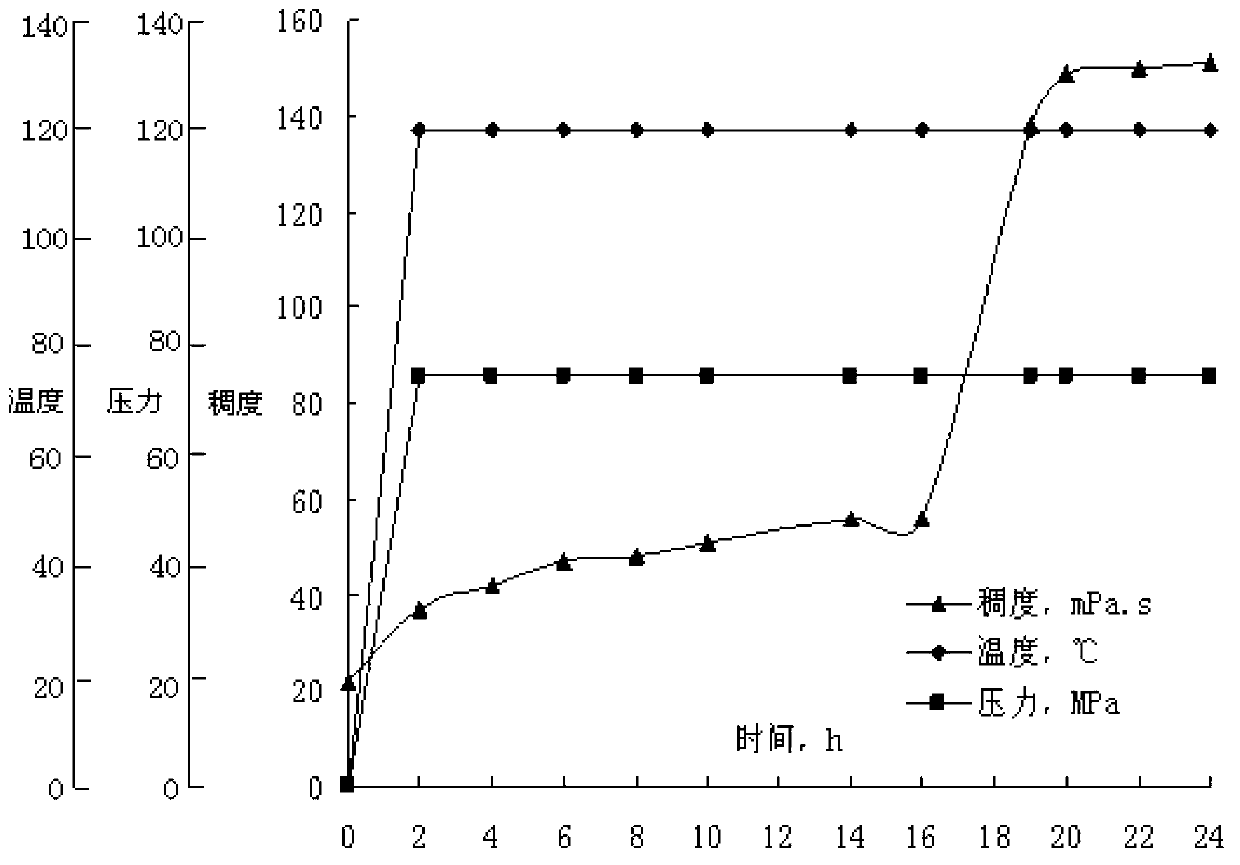

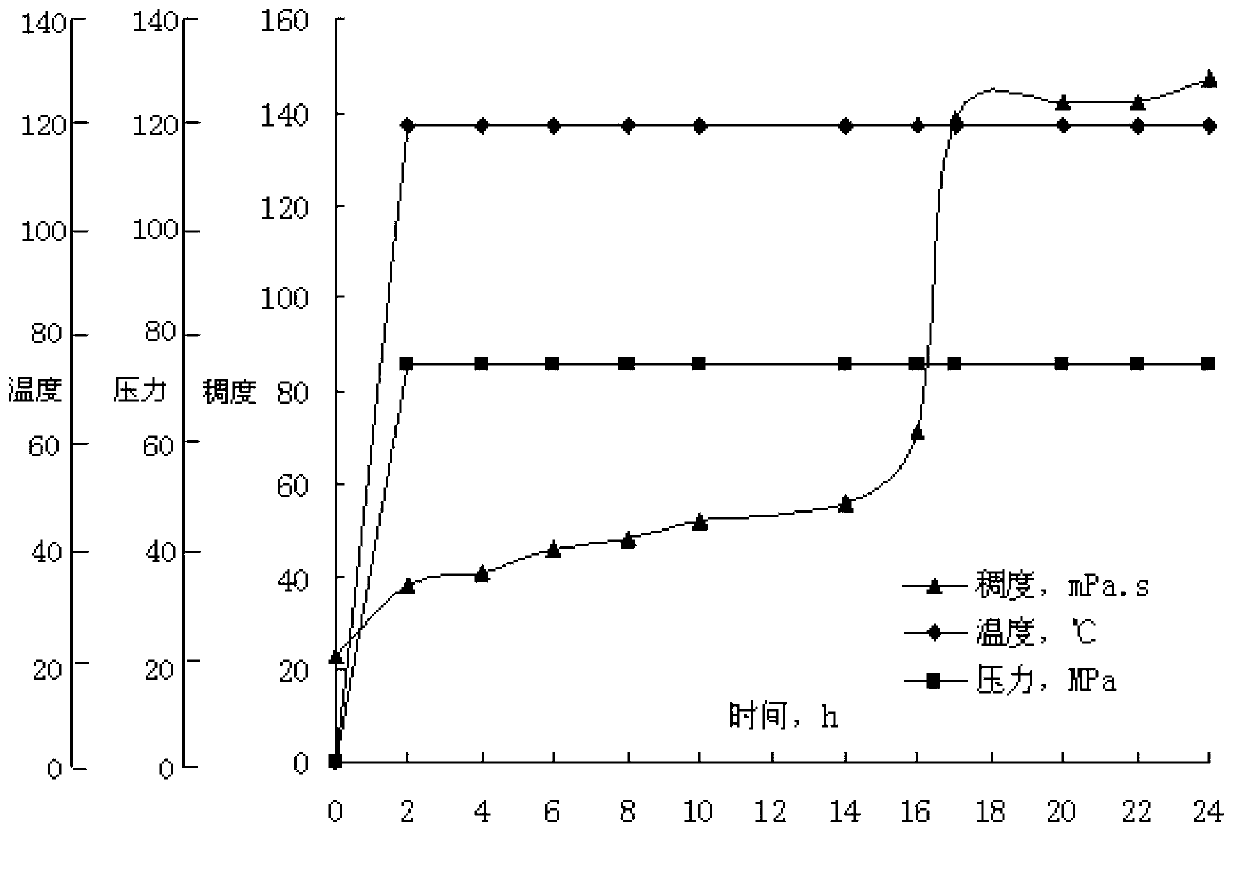

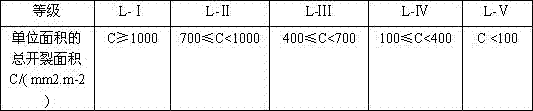

Heat-resistant and salt-resistant profile controlling agent and preparation method thereof

ActiveCN102994057AGood temperature and salt resistanceAdjustable densityDrilling compositionMaterials scienceSlurry

The invention discloses a heat-resistant and salt-resistant profile controlling agent, comprising waste slurry, a slurry curing agent, a strength modifier, a dispersant, a retarder and water. Based on the weight of the waste slurry as 100%, the profile controlling agent comprises 6-12 wt% of the slurry curing agent, 6-12 wt% of the strength modifier, 0.1-1.5 wt% of the dispersant, 0.02-0.15 wt% of the retarder and 6-12 wt% of water. The invention also relates to a preparation method of the heat-resistant and salt-resistant profile controlling agent. The heat-resistant and salt-resistant profile controlling agent is obtained by the steps of adding the slurry curing agent, the strength modifier, the dispersant, the retarder and water in the waste slurry, based on the weight of the waste slurry, and standing for 66-78 hours. The invention also provides an application of the waste slurry in preparing the heat-resistant and salt-resistant profile controlling agent.

Owner:CHINA PETROLEUM & CHEM CORP

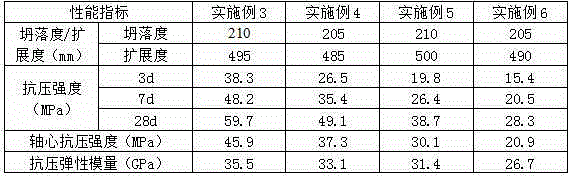

High-performance lithium slag pump concrete

The invention discloses high-performance lithium slag pump concrete. The proportion of mixture of the concrete is cement:water:mineral powder:fly ash:lithium slag:sand:gravel:synergist: additive being (340-520):(165-200):(0-50):(0-50):(40-150):(700-850):(1,000-1,100):(2-3.5):(7-12) according to the component unit of kg / m<3>. By means of selection of the raw materials and design of proportioning, the high-performance lithium slag concrete which is good in working performance, mechanical performance and durability and can be used for pumping is obtained.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

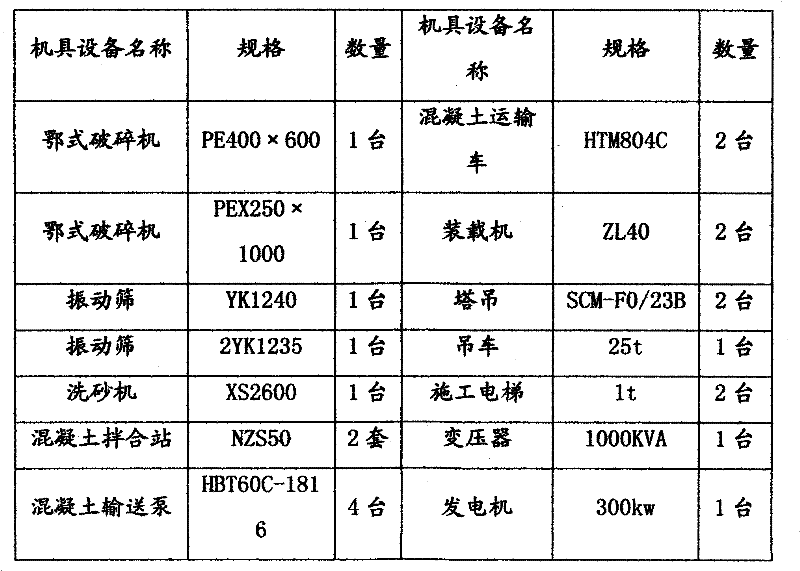

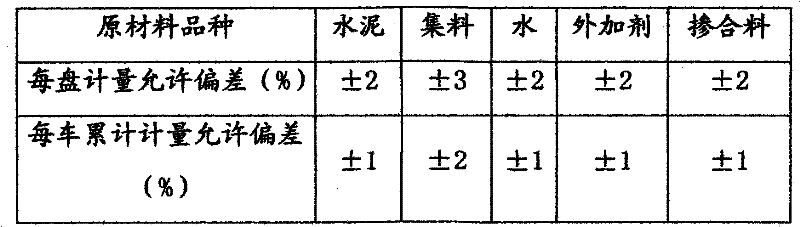

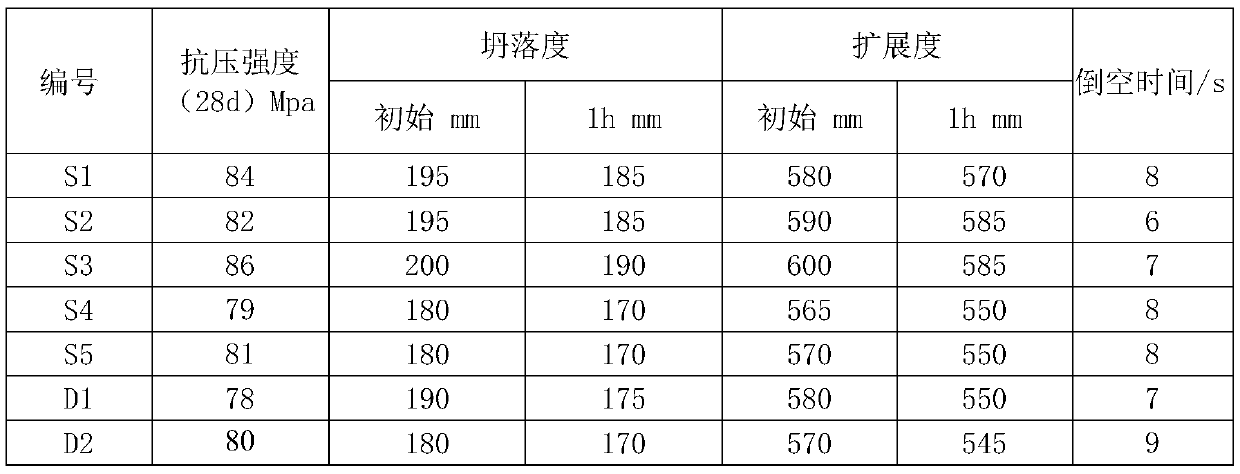

Mixture for preparing C55 high-intensity ultra-high-pumping concrete

The invention discloses a mixture for preparing C55 high-intensity ultra-high-pumping concrete, which comprises cement, river sand, mechanism sand, broken stone, water and additional additives. The slump of the concrete prepared from the mixture is 180 to 220mm, the expansion degree is greater than 500, and the air content is 2 percent to 4 percent. The work performance such as water preserving performance, cohesiveness, flowability and the like of the mixture of C55 high-intensity ultra-high-pumping concrete is good. The slump loss of the prepared concrete is small, the machine outlet slump is controlled to be 180 to 220mm, the expansion degree is greater than 500mm, the slump after 1h is not less than 180mm, and the expansion degree is also not smaller than 500mm. The air is properly led through the additional additives, so the air content of the concrete is controlled to be 2 percent to 4 percent, the pumpability of the concrete is good, and the pumping requirement is met. The initial setting time of the concrete is about 7 hours, and the concrete construction casting interruption time limit requirement can be perfectly met.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

Anti-crack pumping concrete, and preparation method and pumping method thereof

InactiveCN110746159AChoose simpleWide variety of sourcesBuilding material handlingSuperplasticizerCarboxylic acid

The invention discloses an anti-crack pumping concrete, and a preparation method and a pumping method thereof, and belongs to the field of concrete preparation. The anti-crack pumping concrete comprises, by weight, 380-420 parts of cement, 1050-1210 parts of coarse aggregates, 630-675 parts of fine aggregates, 58-72 parts of fly ash, 40-78 parts of S95-grade mineral powder, 45-60 parts of silica fume, 0.8-5 parts of a polypropylene fiber, 12.5-15.1 parts of a polycarboxylate superplasticizer and 128-136 parts of water. The water-cement ratio is controlled to be 0.28-0.34; the water-binder ratio is controlled to be 0.23-0.27, the fly ash accounts for 10-13% of the total amount of all cementing materials, the mineral powder accounts for 7-14% of the total amount of all the cementing materials, the silica fume accounts for 7-11% of the total amount of all the cementing materials, the ratio of the fly ash to the mineral powder is controlled to be 1.2-1.68, and the sand rate is controlled to be 0.3-0.39. The anti-cracking pumping concrete has a high strength, and can meet the pumping requirement of 100 m superhigh-rise building construction.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Preparation method of machine-made sand fine aggregate

ActiveCN101708968BMeet pumping requirementsEasy constructionGrain treatmentsFineness modulusMaterials science

Owner:CHONGQING NO 3 CONSTR

Slump loss resistant concrete pumping aid

The invention discloses a slump loss resistant concrete pumping aid, which is prepared from the following raw materials in parts by weight: 20 to 30 parts of naphthalene high efficient water reducer, 8 to 12 parts of diethanol isopropanol amine maleate, 5 to 7 parts of glycerol carbonate, 3 to 5 parts of triethylamine, 0.2 to 0.6 part of dimethyl silicone oil, 3 to 7 parts of retarder, 0.1 to 0.3 part of fatty alcohol polyoxyethylene ether, and 40 to 60 parts of water. The provided slump loss resistant concrete pumping aid has the advantages that the properties of the naphthalene high efficient water reducer are obviously improved through diethanol isopropanol amine maleate, glycerol carbonate, and triethylamine. The concrete prepared therefrom has the advantages that the durability is good, the slump loss resistant performance is strong, water secretion is prevented, the slump loss is little, good workability and pumping property of concrete are effectively maintained, the pumping requirements can be met, and the pumping aid is suitable for various cements and generates good economic benefits and social benefits.

Owner:RIZHAO FEM NEW MATERIAL TECH

Concrete Composite Water Reducer

The invention discloses a concrete composite water reducing agent which is prepared by mixing the following raw materials in parts by weight: 35 to 45 parts of para amino benzene sulfonate-sulfonated acetone-formaldehyde condensates, 25 to 35 parts of Beta-naphthalene sulfonate formaldehyde condensates, 15 to 20 parts of mahogany petroleum sulfonate, 10 to 15 parts of calcium lignosulphonate, 5 to 10 parts of triethanolamine, 8 to 14 parts of sulfonate-type waterborne polyurethane, 6 to 12 parts of zinc phosphate, 5 to 10 parts of ash calcium powder, 5 to 10 parts of polyvinylpyrrolidone, 3 to 6 parts of sodium metasilicate, 4 to 8 parts of coal residue, 3 to 6 parts of triterpenoid saponin, 2 to 4 parts of allylthiourea, 2.5 to 4.5 parts of rhamnolipid, 2 to 3 parts of isooctyl triethoxy silane and 4 to 7 parts of auxiliaries. The adding amount of the water reducing agent is low, i.e., the adding amount of the water reducing agent only accounts for 0.4% to 0.8% of the mass of concrete. The water-reducing rate of the water reducing agent can reach up to 20% to 25%. The water reducing agent has a good plasticizing effect, so that the slump of the concrete is obviously increased, and the cohesiveness and the workability of the concrete are improved, wherein the slump of the concrete can be increased by above 180mm, thereby conforming to the requirement of concrete pumping.

Owner:江苏金海宁新型建材科技有限公司

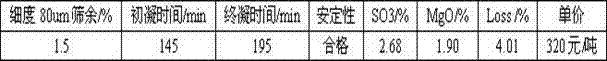

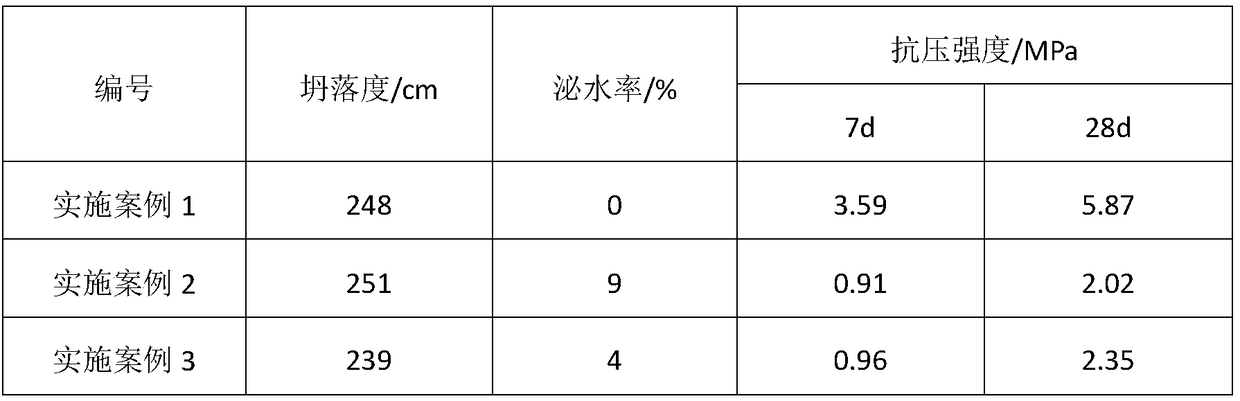

Circulating fluidized bed combustion ash based filling cemented material and preparation method of slurry of circulating fluidized bed combustion ash based filling cemented material

The invention discloses a circulating fluidized bed combustion ash based filling cemented material and a preparation method of slurry of the circulating fluidized bed combustion ash based filling cemented material. The circulating fluidized bed combustion ash based filling cemented material is prepared by taking circulating fluidized bed combustion ash as a cementing material and phosphate tailings as fine aggregates, and using water glass, quick lime and sodium sulfate for composite excitation. The cemented material comprises the following raw materials in percentage by weight: 12-30 percentof the circulating fluidized bed combustion ash, 34-58 percent of the phosphate tailings, 1.1-2.6 percent of the water glass, 2.1-5.2 percent of the quick lime, 0.3-0.7 percent of sodium sulfate and 26-30 percent of tap water. In the circulating fluidized bed combustion ash based filling cemented material, the activity of volcanic ash of the circulating fluidized bed combustion ash is relatively low; and by using the water glass and sodium sulfate, the early compressive strength of the cemented material is remarkably improved; and by adding the quick lime, the later compressive strength of thecemented material is improved. The filling material fully utilizes industrial waste slag, is low in bleeding rate, good in mobility and high in compressive strength, greatly lowers the filling cost and is environmentally friendly.

Owner:CHINA THREE GORGES UNIV

A kind of barite anti-radiation pumping concrete

The invention discloses a barite anti-radiation pumping concrete. The mixing ratio of the concrete according to the weight part is: cement: water: barite powder: barite sand: barite: synergist: admixture = [340 ~450]: [110~170]: [75~150]: [1000~1400]: [1800~2000]: [2~4]: [7~19]. Through the selection of raw materials and the design of the ratio, a radiation-resistant concrete with high density and good fluidity that can be used for pumping is obtained.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

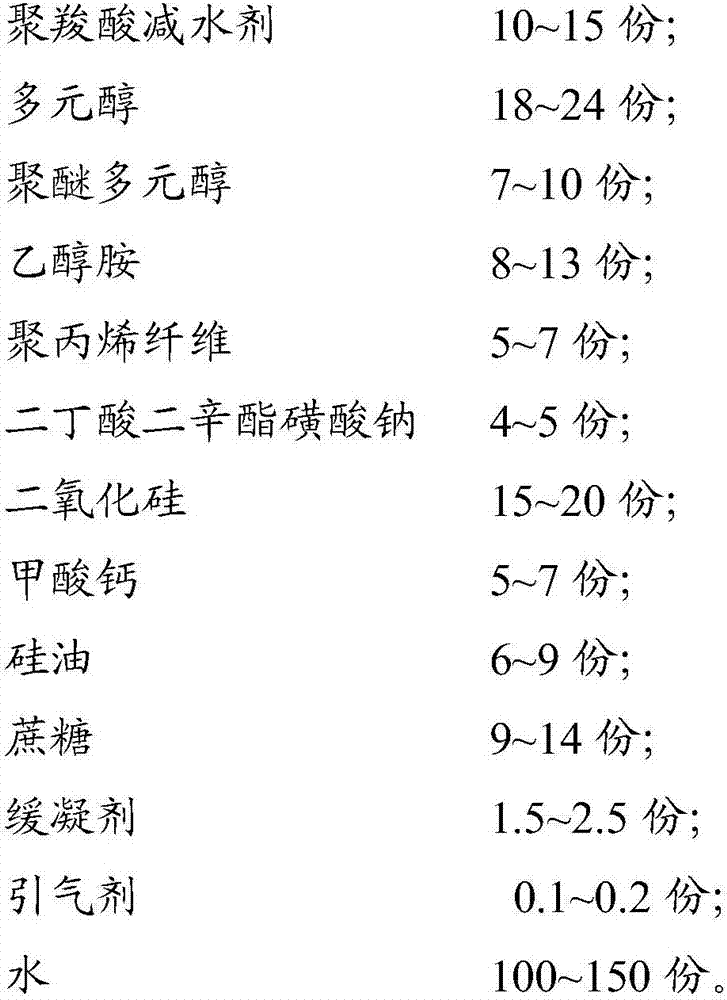

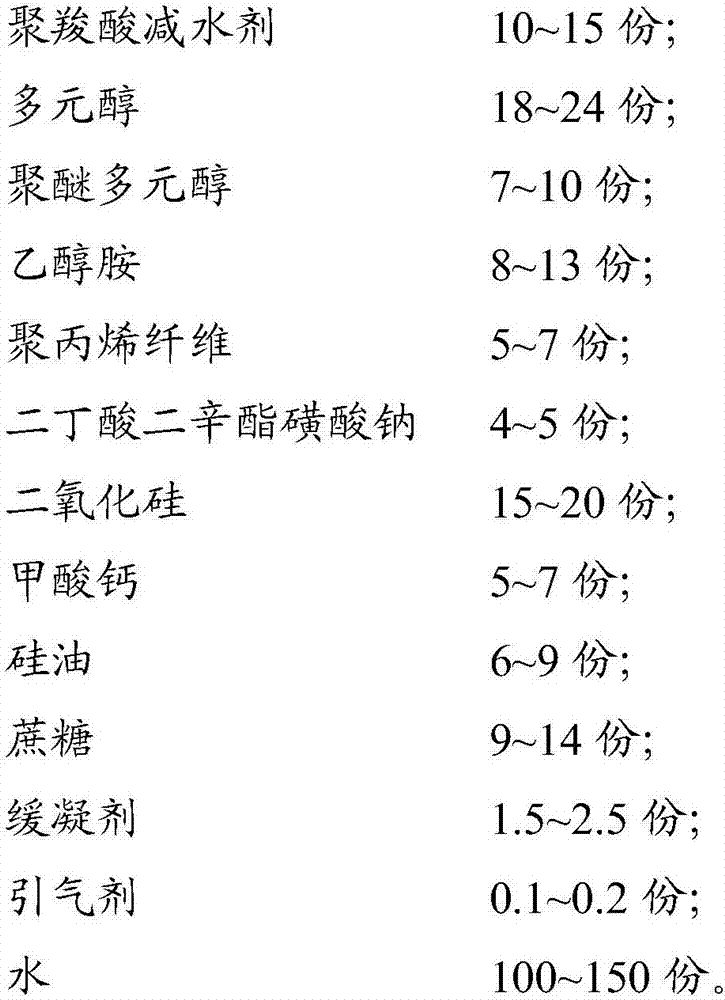

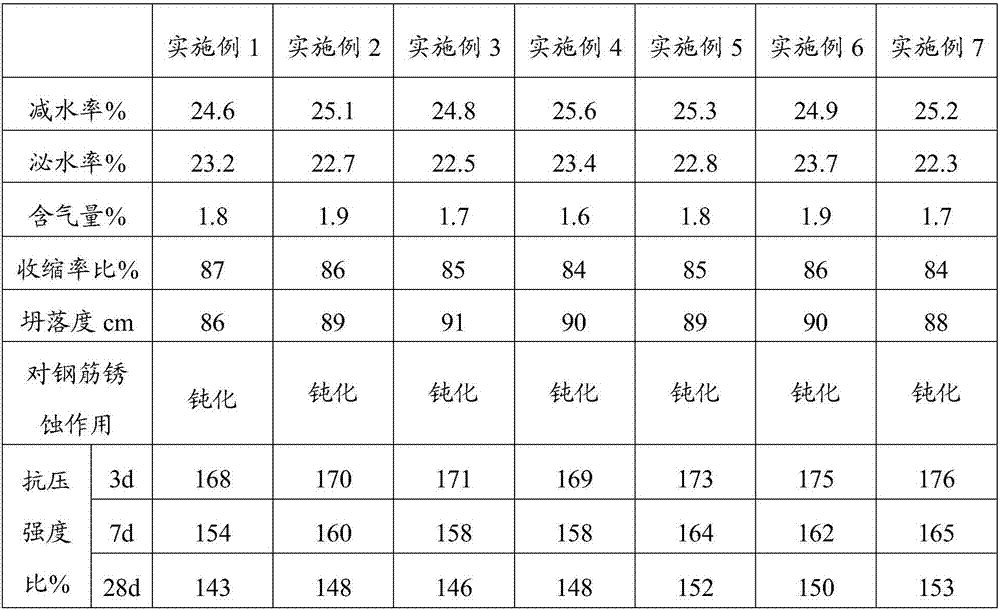

Concrete water reducer and preparation method thereof

The invention discloses a concrete water reducer and a preparation method thereof. The water reducer is prepared from the following raw materials in parts by weight: 10-15 parts of polycarboxylic acidwater reducer, 18-24 parts of polyalcohol, 7-10 parts of polyether polyol, 8-13 parts of ethanolamine, 5-7 parts of polypropylene fibers, 4-5 parts of sodium dibutyl dioctyl sulfonate, 15-20 parts ofsilicon dioxide, 5-7 parts of calcium formate, 6-9 parts of silicone oil, 9-14 parts of saccharose, 1.5-2.5 parts of setting retarder, 0.1-0.2 part of air entraining agent and 100-150 parts of water.According to the concrete water reducer and the preparation method thereof, all the raw materials are in synergism, thus, the mixed amount of the water reducer can be reduced, the water reducing rateis improved, the slump of the concrete can be remarkably improved, the cohesiveness and workability of the concrete are improved, and pumping requirements of the concrete are met; the water reducer disclosed by the invention and a concrete material are used in a combined manner, and the chemical corrosion resistance, durability, fluidity and folding strength of the concrete can be greatly improved, so that the water reducer can be extensively applied to the in-place casting of concrete constructions such as high-rise buildings, wide-span bridges, offshore oil production platforms and nuclearpower plants with requirements on high durability, high fluidity, high strength guarantee rate and the like and commercial concrete.

Owner:山东天汇科技有限公司

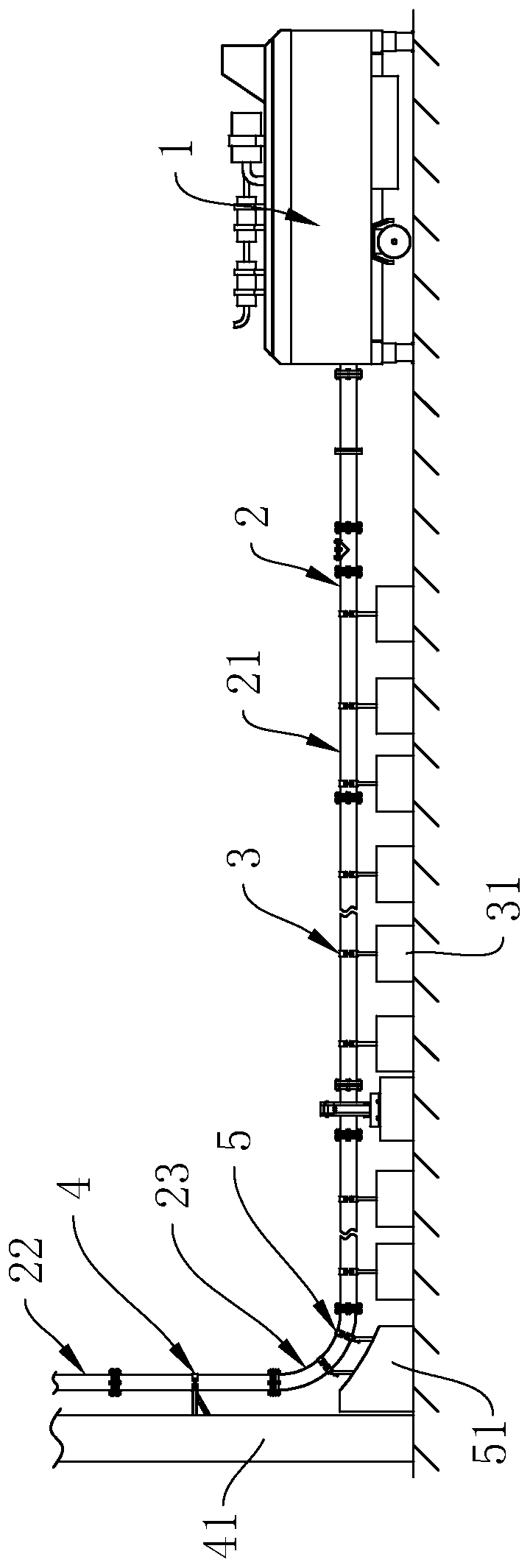

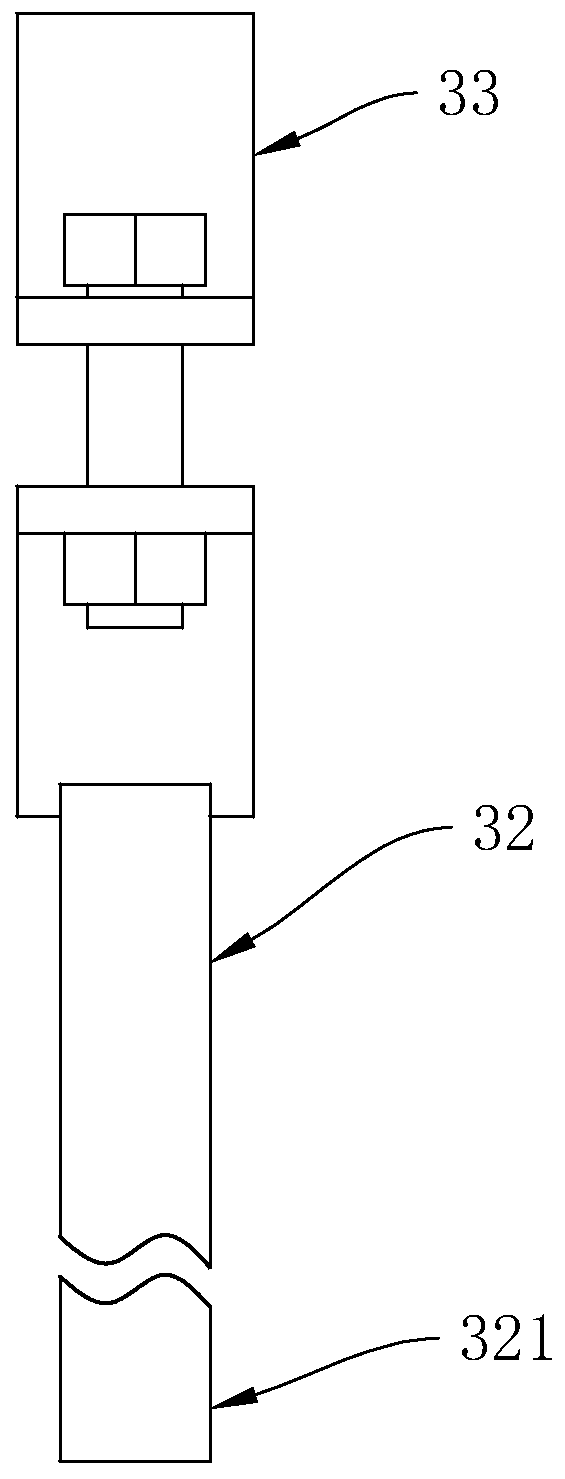

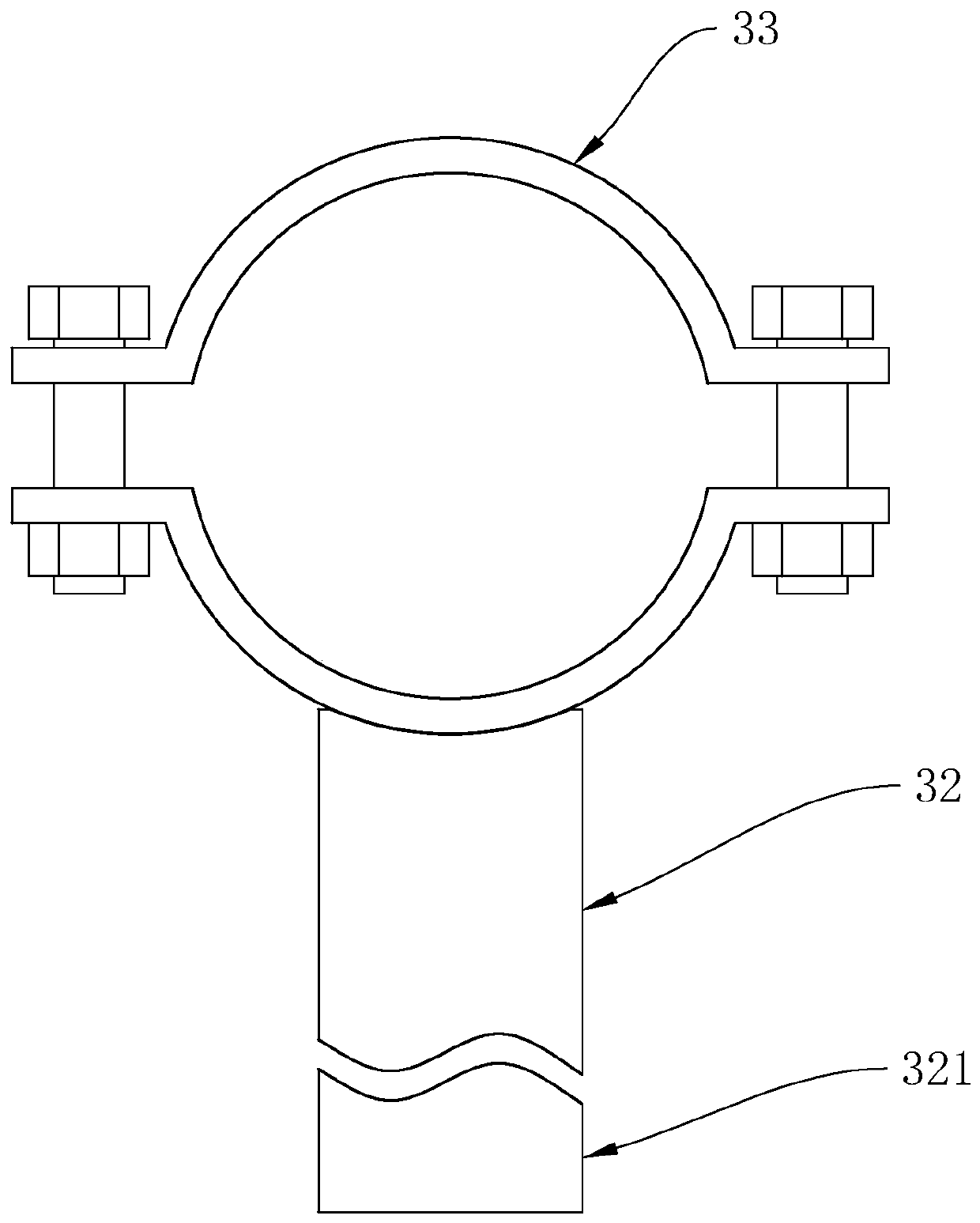

Mounting and fixing structure for super-high-rise pumping pipeline

PendingCN111120733AFull and effective support positioningSupport is adequate and effectivePipe supportsBuilding material handlingPipeFastener

The invention relates to a mounting and fixing structure for a super-high-rise pumping pipeline. The structure comprises the pumping pipeline, a horizontal pipe fixing assembly, a vertical pipe fixingassembly and a bent pipe fixing assembly; the horizontal pipe fixing assembly comprises a horizontal concrete structure I, a supporting part I and a fastening part I, and the two ends of the supporting part I are fixed to the fastening part I and the horizontal concrete structure I correspondingly; the vertical pipe fixing assembly comprises a vertical concrete structure, a supporting part II anda fastening part II, and the two ends of the supporting part II are fixed to the fastening part II and the vertical concrete structure correspondingly; and the bent pipe fixing assembly comprises a horizontal concrete structure II, supporting parts III and a fastening part III, the at least two supporting parts III are arranged, and the two ends of each supporting part III are fixed to the fastening part III and the horizontal concrete structure II. According to the mounting and fixing structure for the super-high-rise pumping pipeline, the pumping pipeline can be firmly fixed, the pumping pipeline is prevented from falling off due to vibration, and the pumping pipeline can be sufficiently and effectively supported, so that the supporting effect is improved, and it is guaranteed that thewhole pumping pipeline meets the super-high-rise pumping requirements.

Owner:重庆华西易通建设股份有限公司

Activator of large doped quantities of levigated slag concrete

This invention discloses an activator used in large-doping-amount finely ground slag concrete. The activator is composed of: gypsum 60-81 wt.%, naphthalin high-performance water reducer 7-10 wt.%, hydroxyl compound 0-0.02 wt.%, surfactant 0-0.002 wt.%, and finely ground slag 9-30 wt.%. The activator can replace 4-6% of cement in large-doping-amount finely ground slag. The concrete added with the activator has such advantages as high mixability, high pumpability, and high volume stability. With the activator, the doping amount of finely ground slag in the concrete can be increased to 70%.

Owner:NANJING RUIDI HIGH TECH

High-performance roadway wall back filling layer material taking pretreated phosphogypsum as aggregate

InactiveCN114180922AThe preparation operation process is simpleLow costAggregate (composite)Land resources

The invention belongs to the technical field of roadway wall back filling layers and solid waste recycling, and discloses a high-performance roadway wall back filling layer material with pretreated phosphogypsum as aggregate. According to the ardealite backfill material, ardealite which is pretreated after being dried for 8 hours at the temperature of 130 DEG C is used as aggregate, slag and carbide slag are added, the mixture is stirred with tap water, and no other additive is added. The ardealite, the slag and the carbide slag pretreated by the aggregate used by the wall back filling layer material respectively account for 65-75%, 20-25% and 5-10% of the total solid mass. The ardealite wall back filling layer manufactured according to the mixing ratio can meet the compressive strength requirement, the fluidity requirement and the water permeability requirement of the wall back filling layer in a roadway composite support system, and has the advantages of being low in cost and easy and convenient to manufacture. Meanwhile, the problem that a large amount of industrial solid wastes such as ardealite and the like are accumulated is solved, land resource pressure is released, contribution is made to environmental protection, and certain practical significance is achieved.

Owner:LIAONING TECHNICAL UNIVERSITY

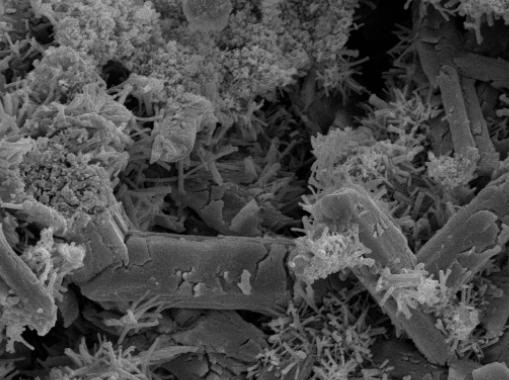

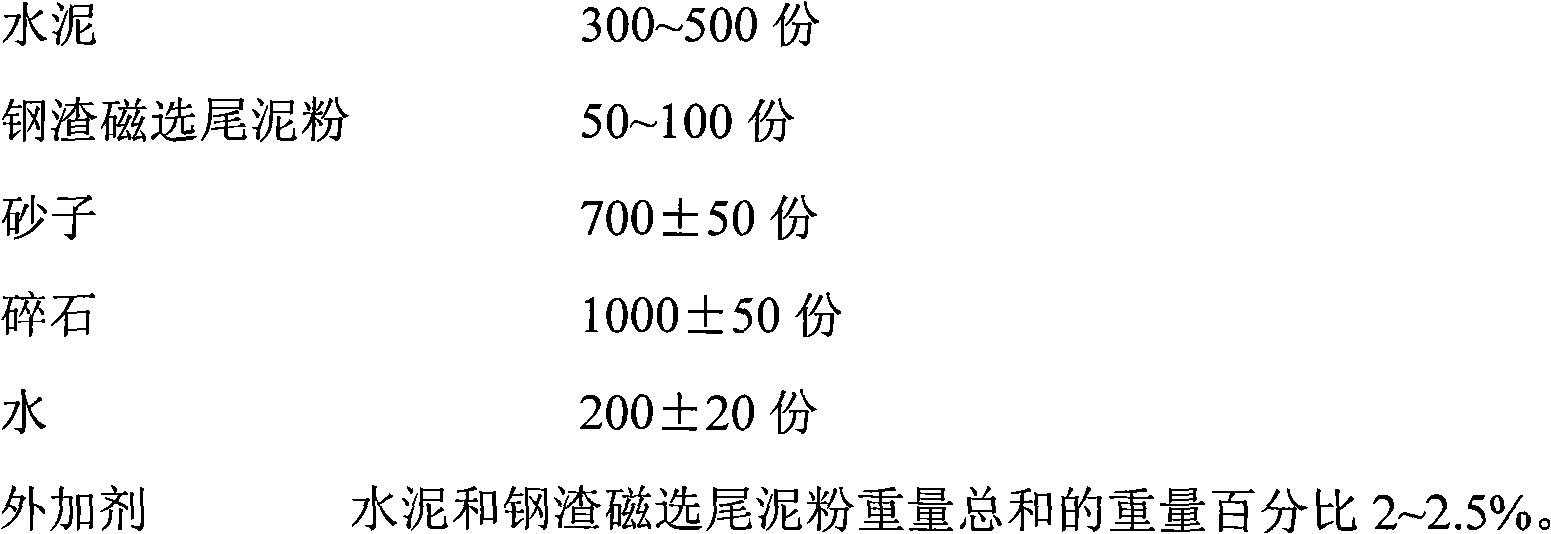

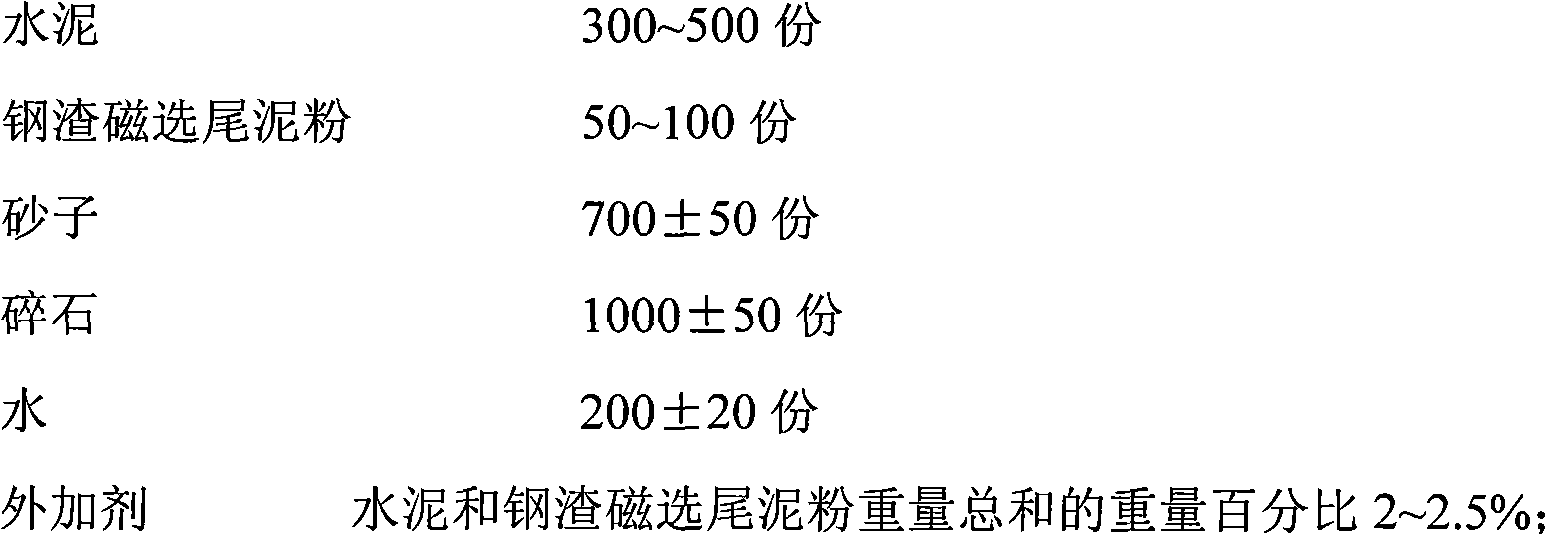

Pump concrete added with steel slag magnetic separation mud powder and preparation method thereof

InactiveCN102060476ASolve the technical problems of volume stabilityMeet pumping requirementsSolid waste managementSlagCrushed stone

The invention relates o the field of premixed concrete building materials, in particular to pump concrete added with steel slag magnetic separation mud powder and a preparation method thereof. Admixtures comprise 300 to 500 weight parts of cement, 50 to 100 weight parts of steel slag magnetic separation mud powder, 700+ / -50 weight parts of sand, 1,000+ / -50 weight parts of gravel and 200+ / -20 weight parts of water; and an additive is 2 to 2.5 percent of the total weight of the cement and the steel slag magnetic separation mud powder. The preparation method comprises the following steps of: stirring and mixing the cement, the steel slag magnetic separation mud powder, the sand and the gravel according to a weight ratio; and adding water and the additive, continuously stirring uniformly, and using the concrete for construction and pouring. The invention has the advantages that: the technical problem of low volume stability of the steel slag mud powder in the concrete is solved; the pump concrete has the fluidity of more than 16cm and the assurance factor of strength of over 99 percent, does not bleed, and has better workability; three-waste pollution is reduced; and the production cost of each cubic meter of concrete can be greatly reduced.

Owner:ANGANG CONSTR CONSORTIUM

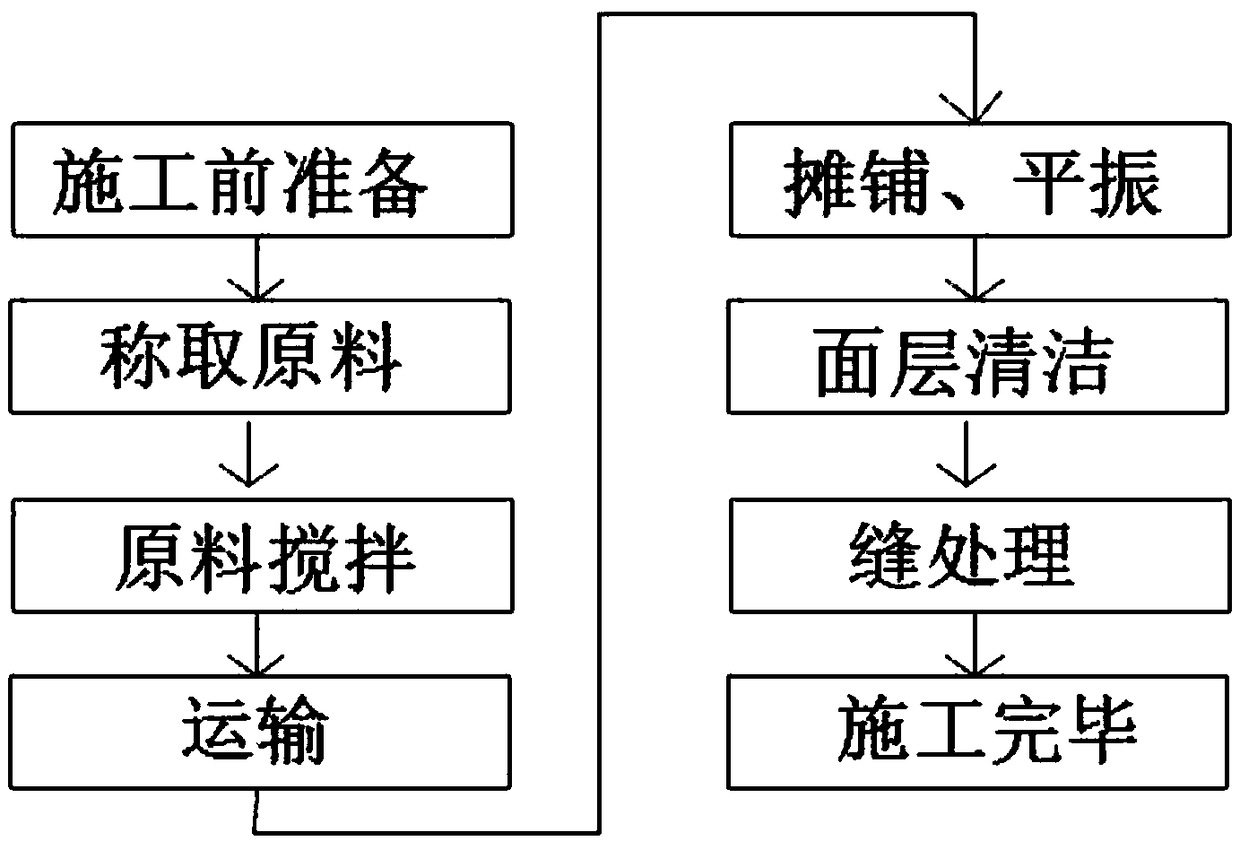

A kind of permeable concrete and its construction technology

ActiveCN106145830BGood water permeabilityRegulate the microclimateIn situ pavingsSolid waste managementRoad surfaceWater reducer

The invention discloses a permeable concrete and a construction process thereof. Stones, cement, sand, silicon powder, water, and a water reducing agent are used as aggregates of the permeable concrete. The construction process is as follows: pre-construction preparation-weighing raw materials-raw material mixing- Transportation-spreading, flat vibration-surface cleaning-seam treatment-construction completed; using the above scheme, the average relative density of permeable concrete of the present invention is 2169Kg / m3, the compressive strength is greater than 35MPa, and the water permeability coefficient of concrete pavement is greater than 1mm / s, the slump can reach more than 120mm, which can meet the pumping requirements when necessary; at the same time, due to the use of aggregates with large particle size and wide application range and the control of silicon rate, the cost is low. This construction process is suitable for permeable concrete pavement , squares, parking lots and other constructions can increase the water permeability of urban pavement while meeting the structural requirements, adjust the urban microclimate and maintain ecological balance.

Owner:GUANGZHOU UNIVERSITY +1

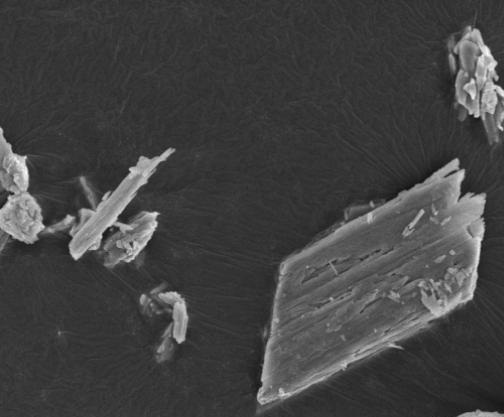

A fully recycled recycled FRP reinforced concrete and its preparation method

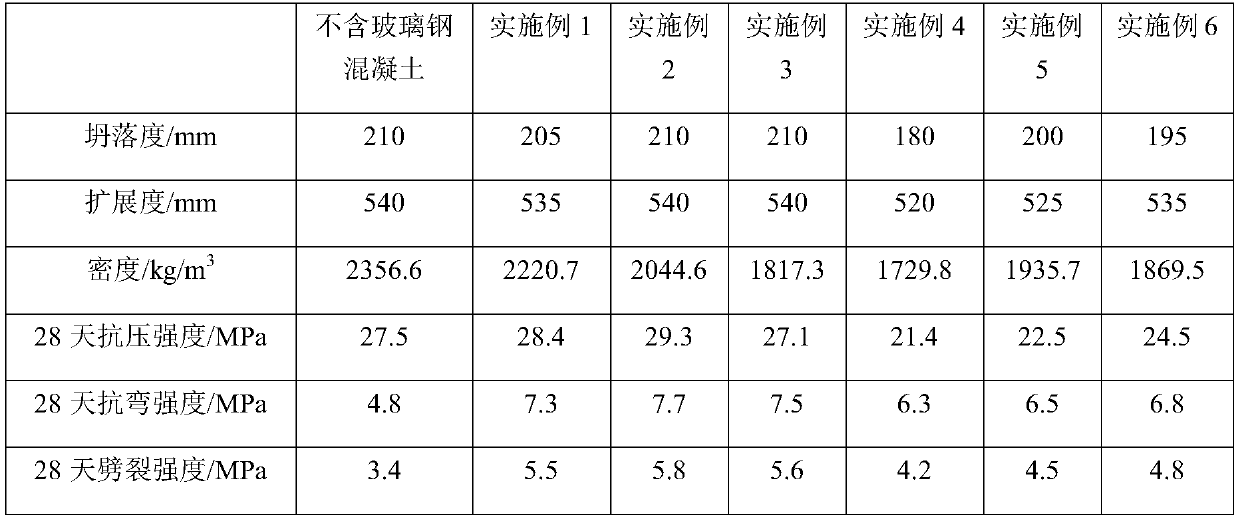

The invention relates to fully recycled regenerated glass fiber reinforced plastic reinforced concrete and a preparation method thereof, wherein the concrete comprises the components in parts by weight: 14.4 to 17.6 parts of ordinary Portland cement, 2.7 to 3.3 parts of fly ash, 0.9 to 1.1 parts of silica fume, 31.6 to 36.5 parts of a fine aggregate, 47.34 to 57.86 parts of a coarse aggregate, 2.1to 4.9 parts of regenerated glass fiber reinforced plastic, 1.35 to 1.85 parts of a water reducing agent, and 9 to 9.27 parts of water. The regenerated glass fiber reinforced plastic comprises regenerated fibers and glass fiber reinforced plastic powder, the content of the glass fiber reinforced plastic powder is not more than 20%, the length of the regenerated fibers is not larger than 10 mm, and the particle size of the glass fiber reinforced plastic powder is not more than 1 mm. The concrete realizes full recycling of the regenerated glass fiber reinforced plastic, has high working performance, meets the pumping requirement, and has good ductility while the strength meets the standard requirement. The concrete solves the problems of shortage of sandstone material resources, limited glass fiber reinforced plastic waste recycling way and low utilization rate, and is beneficial to promoting the practical engineering application of glass fiber reinforced plastic solid wastes in building materials.

Owner:HEBEI UNIV OF TECH

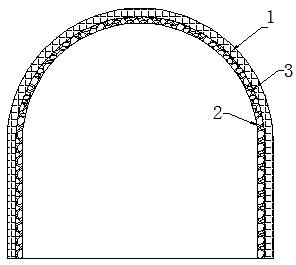

A Configuration Method of Low Shear Strength Grouting Material in Shield Excavation Gap

ActiveCN113788665BSolve the lockMeet performance requirementsUnderground chambersTunnel liningFilling materialsStructural engineering

Owner:BEIJING URBAN CONSTR GROUP +2

Environment-friendly concrete pumping agent and preparation method thereof

InactiveCN112456857AReduce manufacturing costReliable workmanshipHyperbranched polyesterCyclodextrin

The invention discloses an environment-friendly concrete pumping agent which is characterized by comprising the following components in parts by weight: 8-13 parts of sulfobutyl-beta-cyclodextrin sodium, 4-7 parts of 2-chloroethyl sodium sulfonate modified hydroxyl-terminated hyperbranched nano hybrid polymer, 3-5 parts of rosin-based hyperbranched polyester, 10-15 parts of a polycarboxylic acid high-performance water reducing agent, 0.1-0.3 part of a defoaming agent and 45-65 parts of water. The invention further discloses a preparation method of the environment-friendly concrete pumping agent. The environment-friendly concrete pumping agent disclosed by the invention is good in pumping effect, good in water reducing and retarding performance, capable of effectively controlling the slumploss of concrete, high in durability, free of bleeding, good in cement adaptability, stable in quality and environment-friendly in product.

Owner:姚小永

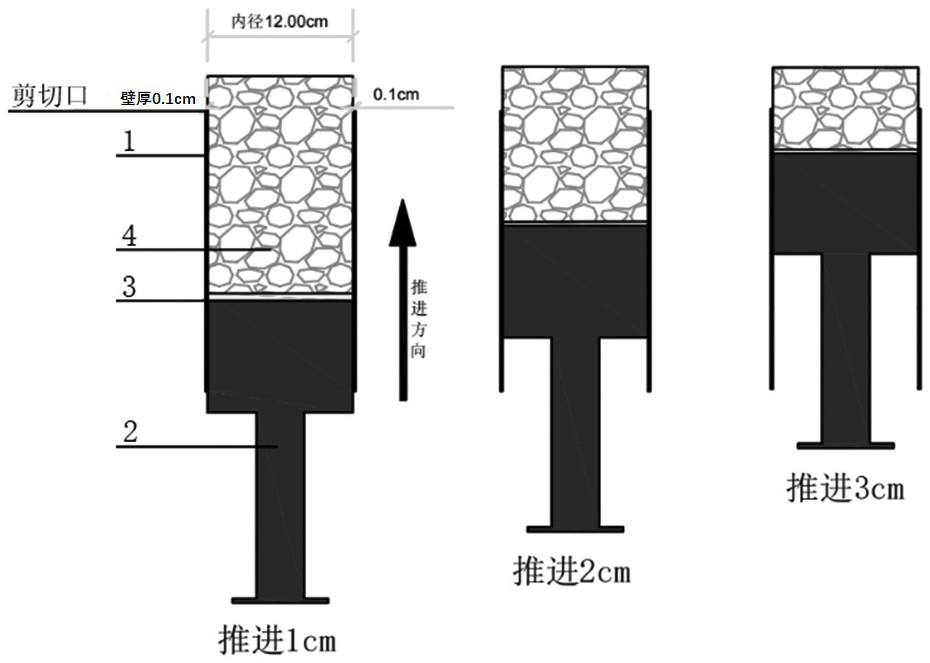

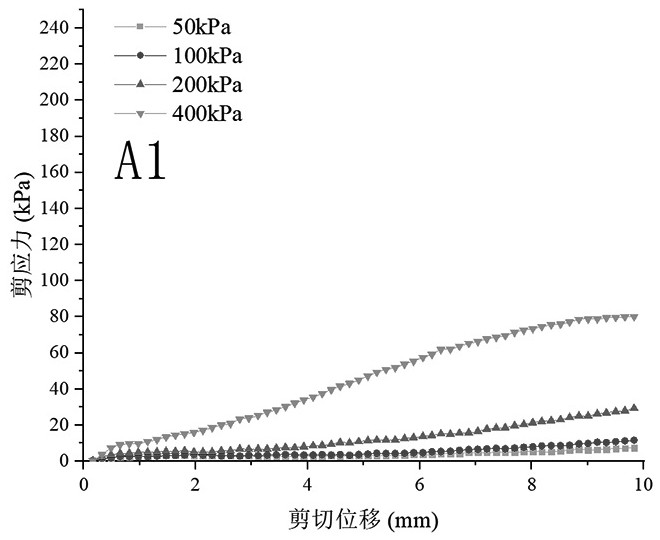

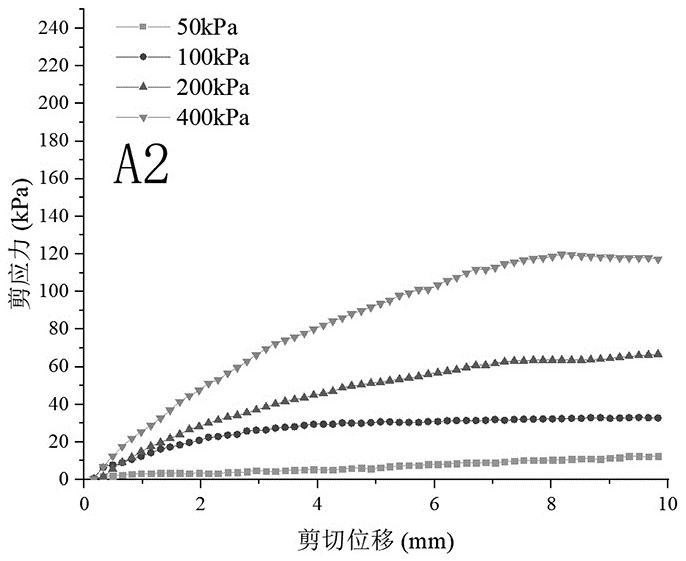

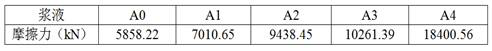

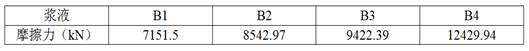

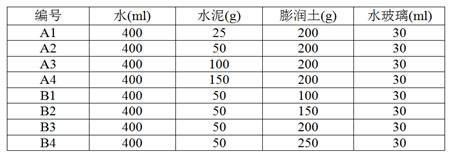

Preparation method of low-shear-strength grouting material for shield excavation gap

ActiveCN113788665ASolve the lockMeet performance requirementsUnderground chambersTunnel liningFilling materialsSlurry

The invention discloses a preparation method of a low-shear-strength grouting material for a shield excavation gap. The preparation method comprises the following steps: selecting a grouting material; preliminarily designing multiple groups of grouting materials with different water cement ratios and multiple groups of grouting materials with different swelling-water ratios; manufacturing a plurality of groups of grouting material test pieces; testing the shear strength of each group of test pieces to obtain the optimal water-cement ratio and the optimal swelling-water ratio of the grouting material; adding bentonite and water into a stirrer according to the optimal swelling-water ratio, conducting stirring, fully and uniformly conducting mixing, conducting standing, and fully conducting swelling; measuring water glass with required baume degree, adding the water glass into expanded bentonite slurry, and uniformly conducting stirring; and adding cement powder, and continuously conducting stirring uniformly to finish the preparation. The filling problem of the excavation gap in shield construction is studied, and the problem that a shield body is locked by a conventional shield body grouting material can be solved; and a novel filling material configuration method is adopted, the pumping requirement in grouting equipment is met, and meanwhile high shear strength is achieved.

Owner:BEIJING URBAN CONSTR GROUP +2

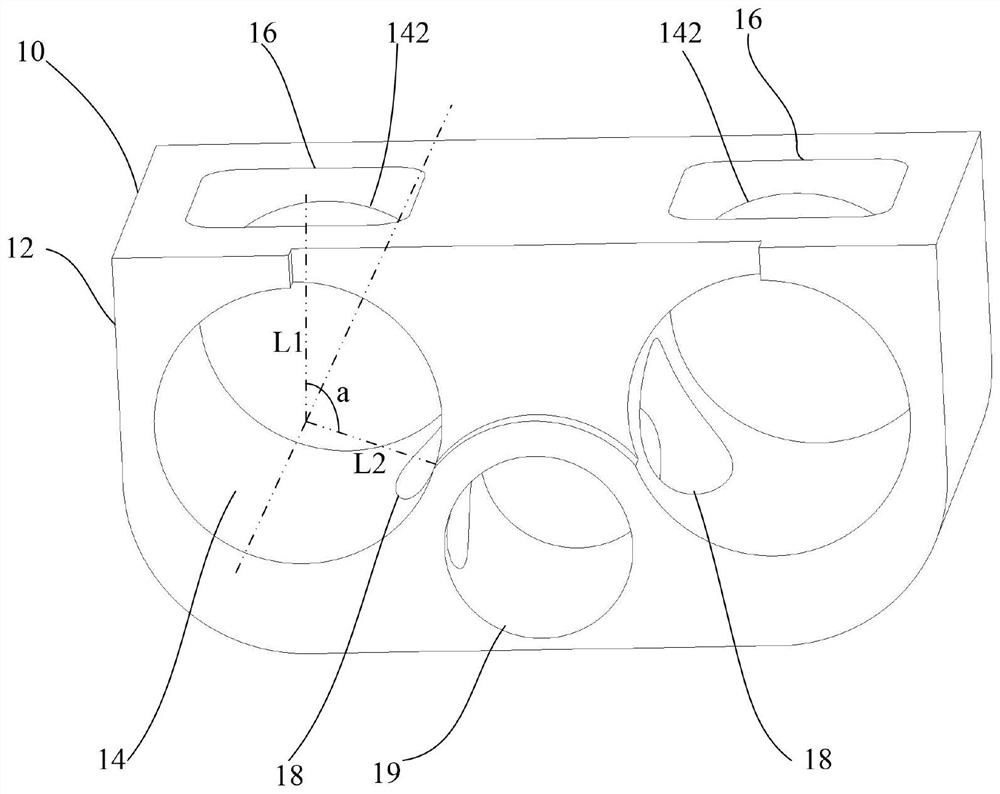

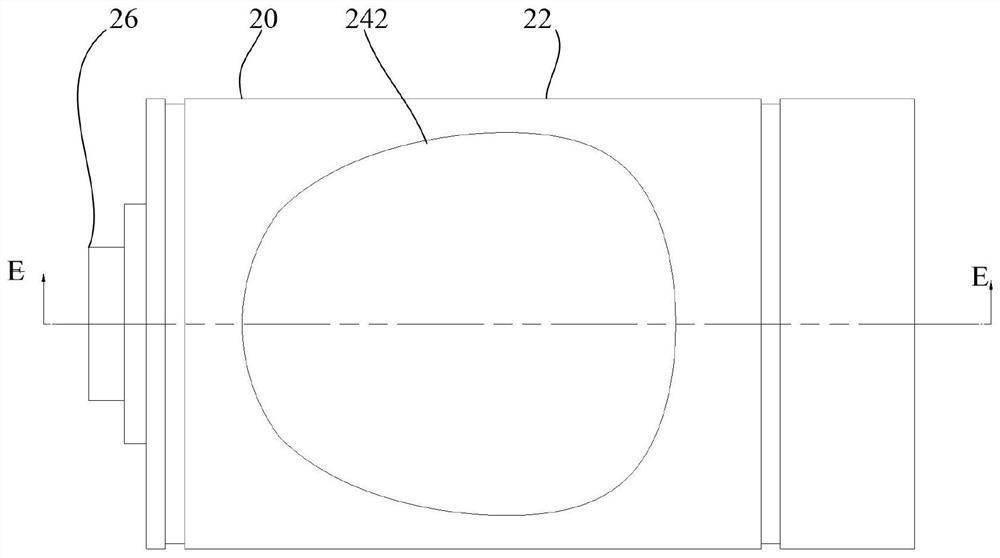

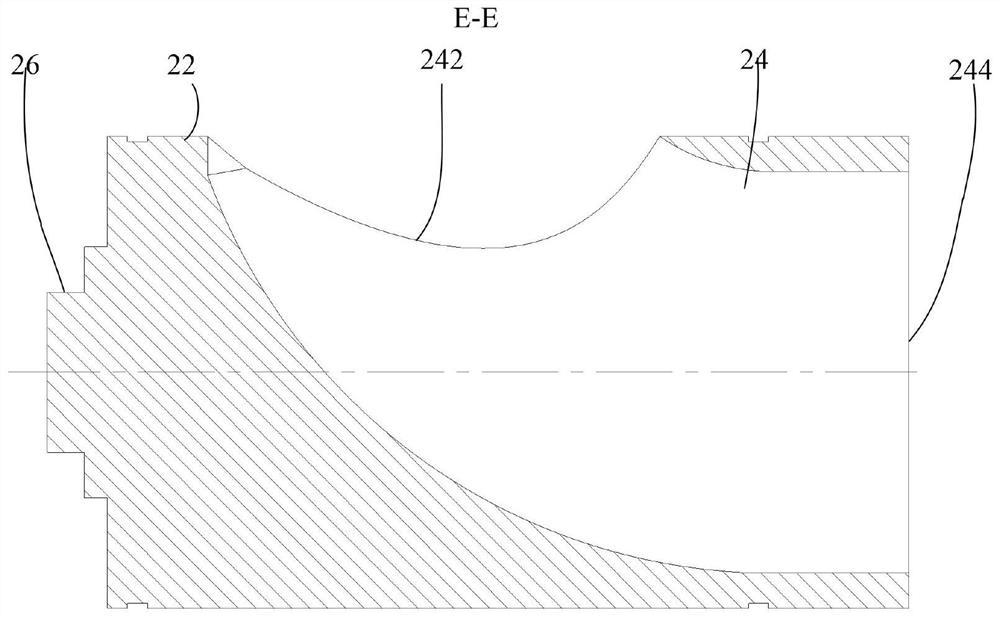

Distribution valve, pumping system and pumping machine

ActiveCN112343812ARealize the commutation functionFulfilling Pumping RequirementsPositive displacement pump componentsPumpsEngineeringMechanical engineering

The invention provides a distribution valve, a pumping system and a pumping machine. A valve body of the distribution valve comprises a valve body, two valve holes, two feeding ports and two discharging ports, wherein the two valve holes are formed in the valve body side by side, and a feeding and discharging port is formed in one end of each valve hole; the two feeding ports are formed in the valve body and communicate with the two valve holes respectively; and the two discharging ports are formed in the valve body and communicate with the two valve holes respectively. According to the technical scheme, the feeding and discharging ports communicate with the feeding ports or the discharging ports by rotating a valve element, so that the reversing function of the distribution valve can be realized, the distribution valve can work stably and efficiently in pumping operation, the requirement for noise reduction is met, and the application range of the distribution valve is enlarged.

Owner:SANY AUTOMOBILE MFG CO LTD

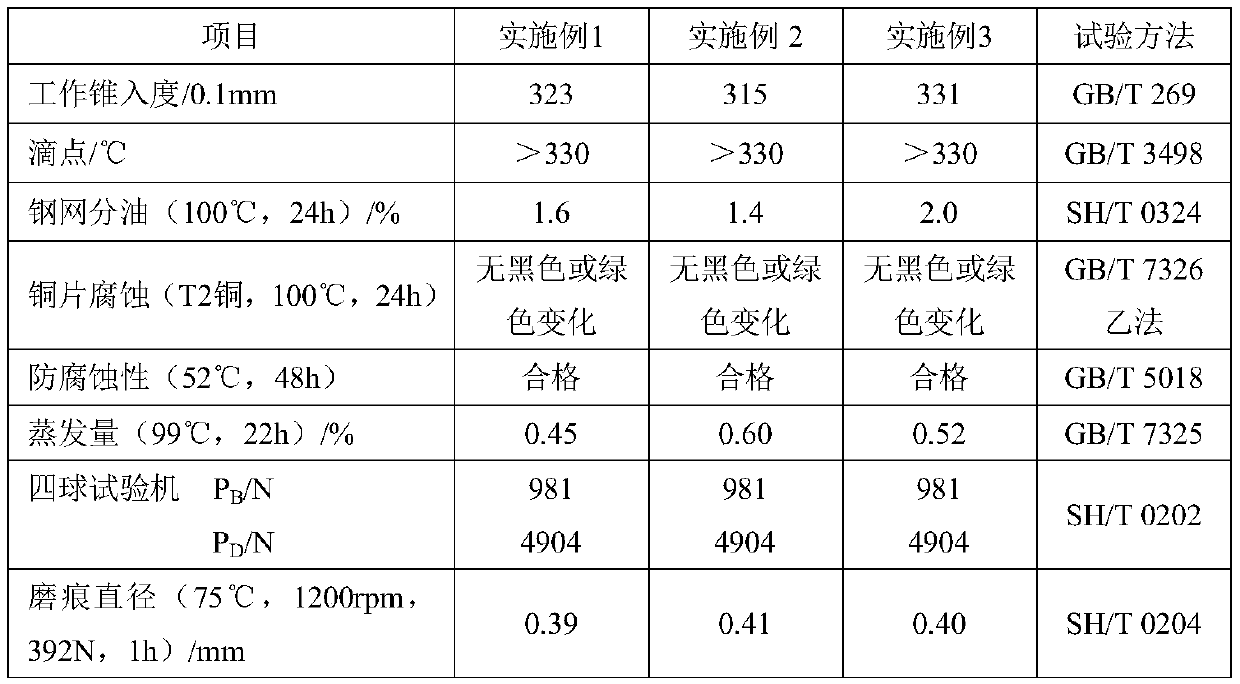

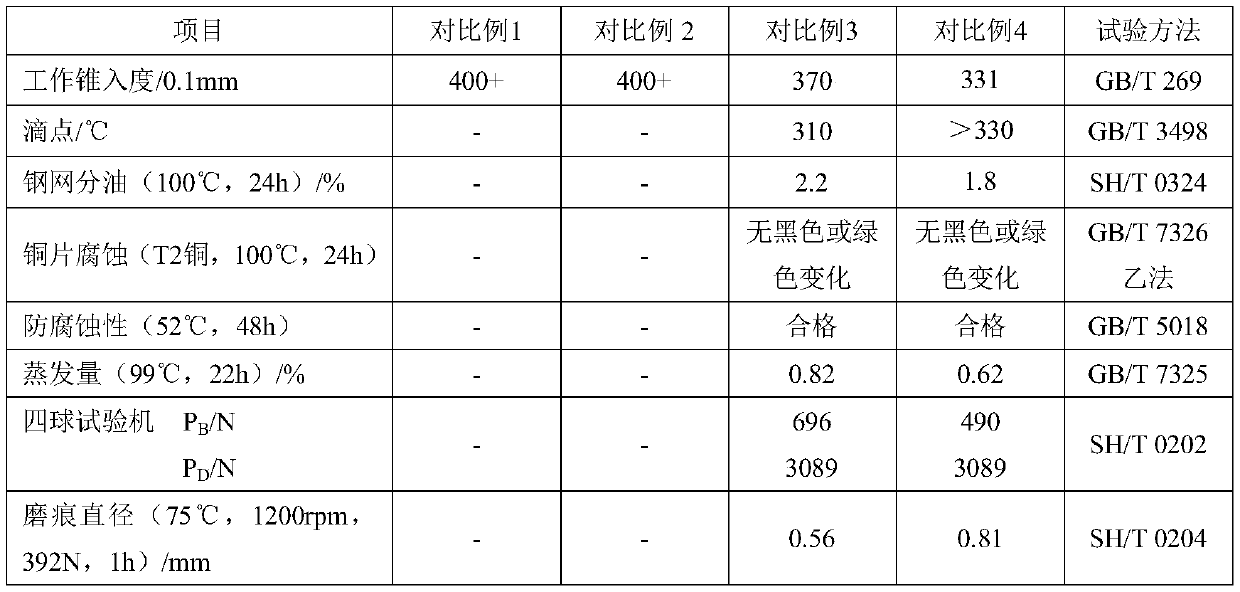

Sintering machine slideway sealing lubricating grease and preparation method thereof

ActiveCN111117729AImprove high temperature resistanceReduce lossesLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to the technical field of lubricating grease, and concretely relates to a special lubricating grease used for an elastic slideway of a sintering machine and prepared by adoptingcomposite calcium sulfonate as a thickening agent, and a preparation method thereof. The lubricating grease comprises, by weight, 50-70% of base oil, 10-15% of alkyl benzene sulfonic acid, 10-15% of calcium hydroxide, 1-4% of boric acid, 5-12% of dodecahydroxy stearic acid, 1-3% of a phase inversion agent and 0.5-1% of an antioxidant. The lubricating grease has excellent high-temperature resistance, excellent lubricating property and extreme-pressure wear resistance, excellent sealing property, excellent colloid stability and excellent pumpability.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Al2O3-SiO2-SiC-based jet material for foundry ladle

The invention relates to an Al2O3-SiO2-SiC-based refractory material, in particular to an Al2O3-SiO2-SiC-based jet material for wet jet construction of a foundry ladle. The Al2O3-SiO2-SiC-based jet material for the foundry ladle comprises the following components in percentage by weight: 45 to 65 percent of sintered mullite, 5 to 15 percent of SiC, 7 to 18 percent of brown aluminium oxide or special-grade alumina, 5 to 10 percent of Al2O3 super-micro powder, 4 to 8 percent of high-aluminum micro powder, 2 to 5 percent of silicon micro powder, 1.5 to 3 percent of calcium aluminate cement, and 6 percent of balance. The granularity of the Al2O3 super-micro powder is leas than or equal to 2 microns; the purity of Al2O3 in the high-aluminum micro powder is more than or equal to 88 percent, and the granularity is less than or equal to 5 microns; and the purity of SiO2 in the silicon micro powder is more than or equal to 92 percent, and the granularity is less than 1 micron. The balance comprises 3 percent of andalusite and 3 percent of cyanite. The jet material has high strength and good thermal shock stability and corrosion resistance, and ensures good self-flowing property and pumping property.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of waste oil scum dehydration treatment process

ActiveCN106267907BImprove liquidityPromote degradationFatty/oily/floating substances removal devicesNon-miscible liquid separationSewagePetroleum

Owner:CHINA PETROLEUM & CHEM CORP

Dirty oil floated oily sludge dewatering treatment method

ActiveCN106267907AImprove liquidityPromote degradationFatty/oily/floating substances removal devicesNon-miscible liquid separationRhamnolipidProcessing cost

The invention discloses a dirty oil floated oily sludge dewatering treatment method, and belongs to the technical field of petroleum waste residue treatment. According to the dirty oil floated oily sludge dewatering treatment method, biosurfactant rhamnolipid is added into dirty oil floated oily sludge continuously for dewatering, wherein adding amount of rhamnolipid is controlled to be 400 to 1000ppm, dewatering temperature is controlled to be 45 to 60 DEG C, pH value is adjusted to 4 to 5, rhamnolipid is uniformed mixed with the dirty oil floated oily sludge via stirring, and an obtained mixture is allowed to stand for 10min to 5h, so that solid floated oily sludge and oil float upwards, and a lower layer is a relatively clear water layer; after demulsification treatment of the dirty oil floated oily sludge with rhamnolipid, dewatering rate is higher than 60 to 70%, obtained concentrated floated oily sludge still possesses excellent fluidity, requirements of pumping are satiasfied, the floated oily sludge is subjected to coking treatment to avoid discharge of the floated oily sludge; processing cost is reduced, environmental protection benefits are achieved, and environment pollution on surrounding areas is reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com