A fully recycled recycled FRP reinforced concrete and its preparation method

A technology for reinforcing concrete and glass fiber reinforced plastic, which is applied in the field of concrete materials, can solve the problems of low utilization rate, limited utilization, and shortage of fiberglass fiber reinforced plastic waste resources, and achieves the effect of improving the degree of compaction, reducing the cost, and overcoming the excessive decrease of concrete strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

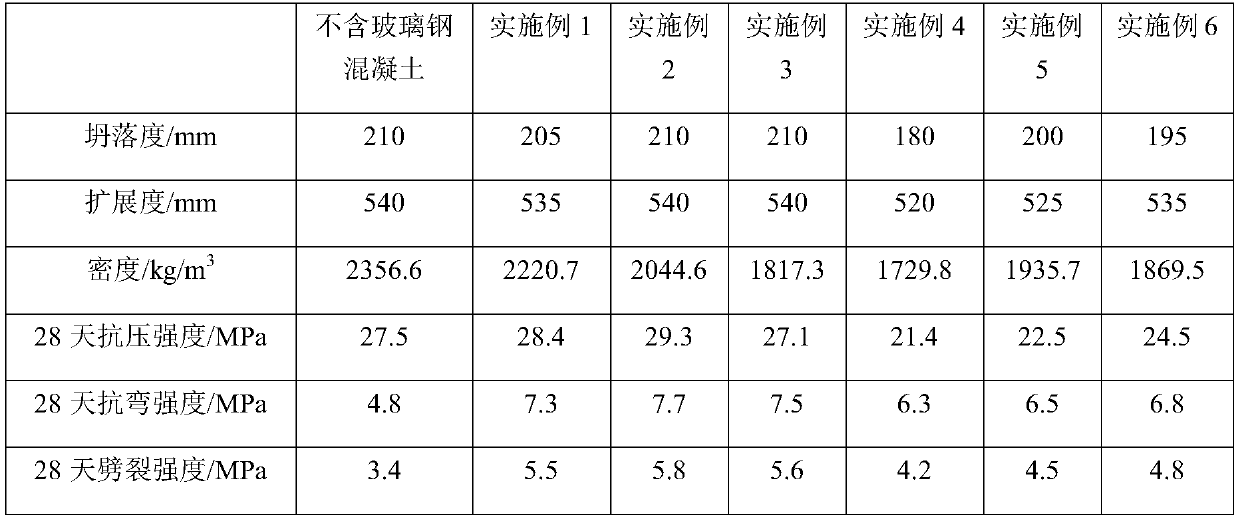

Examples

preparation example Construction

[0047] The preparation method of the above-mentioned fully recycled recycled FRP reinforced concrete, the preparation method comprises the following steps:

[0048] (1) In terms of parts by weight, the above raw materials are divided into four groups, the first group is 2.1-4.9 parts of recycled glass fiber reinforced plastic and 3-3.09 parts of water, the second group is 47.34-57.86 parts of coarse aggregate, ordinary Portland cement 14.4-17.6 parts, 2.7-3.3 parts of fly ash, 0.9-1.1 parts of silica fume, 31.6-36.5 parts of fine aggregate, the third group is 1.35-1.85 parts of water reducing agent and 3-3.09 parts of water, the fourth group is 0.09-0.11 parts of defoamer and 3-3.09 parts of water;

[0049] (2) Put 2.1-4.9 parts of regenerated glass fiber reinforced plastics and 3-3.09 parts of water in the first group into an ultrasonic cleaning machine for pretreatment for 30 minutes.

[0050] (3) For the second group, 47.34-57.86 parts of coarse aggregate, 14.4-17.6 parts ...

Embodiment 1

[0054] In this embodiment, a kind of fully recycled recycled FRP reinforced concrete, in parts by weight, the composition and content of the concrete are respectively:

[0055] P.O 42.5 Ordinary Portland cement 14.9 parts;

[0056] 2.8 parts of fly ash;

[0057] 0.95 parts of silica fume;

[0058] 32.1 parts of fine aggregate;

[0059] Coarse aggregate 48.35 parts;

[0060] 2.1 parts of recycled fiberglass;

[0061] 0.095 parts of defoamer;

[0062] 1.39 parts of water reducing agent;

[0063] 9.06 parts of water.

[0064] The specific surface area of P.O 42.5 ordinary Portland cement is 3.41m 2 / g, the density is 3.15g / cm 3 , the standard consistency water consumption is 26.8%, the initial setting time is 50min, the final setting time is 350min, the calcium oxide content is 55.1%, the silicon dioxide content is 8.59%, the aluminum oxide content is 9.92%, and the 3-day flexural strength is 4MPa, 3-day compressive strength is 18MPa, 28-day flexural strength is 8MPa, ...

Embodiment 2

[0080] In this embodiment, a kind of fully recycled recycled FRP reinforced concrete, in parts by weight, the composition and content of the concrete are respectively:

[0081] Ordinary Portland cement 15.6 parts;

[0082] 2.8 parts of fly ash;

[0083] 0.97 parts of silica fume;

[0084] 33.4 parts of fine aggregate;

[0085] Coarse aggregate 49.6 parts;

[0086] 3.7 parts of recycled fiberglass;

[0087] 0.1 part of defoamer;

[0088] 1.49 parts of water reducing agent;

[0089] 9.18 parts of water.

[0090] The selection of the material species in this implementation is the same as in Example 1.

[0091] The preparation method of the fully recycled recycled FRP reinforced concrete in this embodiment is:

[0092] (1) In parts by weight, the above raw materials are divided into four groups, the first group is 3.7 parts of recycled FRP and 3.06 parts of water, the second group is 49.6 parts of coarse aggregate, 15.6 parts of ordinary portland cement, fly ash 2.8 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com