High-performance roadway wall back filling layer material taking pretreated phosphogypsum as aggregate

A technology of backfilling and phosphogypsum is applied in the field of high-performance roadway backfilling material, which can solve the problems of inability to accurately control the strength of the backfilling material, inability to reduce the cost of storage and transportation, and complicated storage and transportation conditions. , to achieve the effect of strong applicability and practicability, simple and easy operation process, and reduced transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

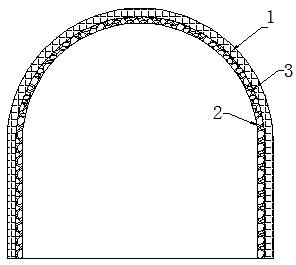

[0047] This embodiment provides a high-performance roadway wall backfill material with pretreated phosphogypsum as the aggregate. The specific proportions used are: the proportions of pretreated phosphogypsum, slag, and ground carbide slag are respectively 75%, 20%, and 5% of the total solid mass, water accounts for 35% of the total filling layer material mass, and the bone-to-glue ratio is 3:1.

Embodiment 2

[0049] This embodiment provides a high-performance roadway wall backfill material with pretreated phosphogypsum as the aggregate. The specific proportions used are: the proportions of pretreated phosphogypsum, slag, and ground carbide slag are respectively 70%, 20%, and 10% of the total solid mass, water accounts for 35% of the total filling material mass, and the bone-to-cement ratio is 2.3:1.

Embodiment 3

[0051] This embodiment provides a high-performance roadway wall backfill material with pretreated phosphogypsum as the aggregate. The specific proportions used are: the proportions of pretreated phosphogypsum, slag, and ground carbide slag are respectively 70%, 25%, and 5% of the total solid mass, water accounts for 35% of the total filling material mass, and the bone-to-glue ratio is 2.3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com