Barite anti-radiation pump concrete

A technology for pumping concrete and barite, applied in the field of barite anti-radiation pumping concrete, to achieve the effects of mechanized construction, simple structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

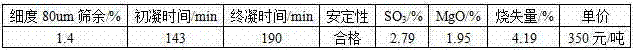

Embodiment 1

[0039] A barite anti-radiation pumping concrete, the concrete is based on the component unit kg / m 3 The mixing ratio is: cement: water: barite powder: barite sand: barite: synergist: admixture = [340~450]: [110~170]: [75~150]: [1000~1400 ]: [1800~2000]: [2~4]: [7~19]. The apparent density of the obtained concrete is 3700-3850kg / m3, and the 28d compressive strength reaches 25-65MPa. It has good slump / expansion suitable for pumping and pouring, and has good resistance to gamma rays and neutron rays. shielding effect.

Embodiment 2

[0041] A kind of barite anti-radiation pumping concrete, said concrete is according to the component unit kg / m 3 The mixing ratio is: cement: water: barite powder: barite sand: barite: synergist: polycarboxylate additive = [340~400]: [140~163]: [85~100]: [1155~1345]: [1857~1957]: [2~4]: [7.6~14.6]. The apparent density of the obtained concrete is 3750-3800kg / m 3 , 28d compressive strength of 28-60MPa has a good slump / expansion suitable for pumping pouring, and has a good shielding effect on gamma rays and neutron rays.

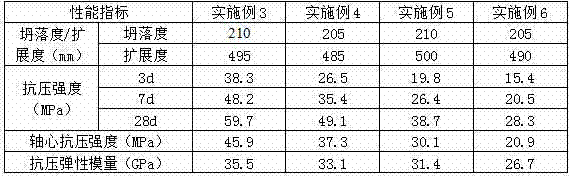

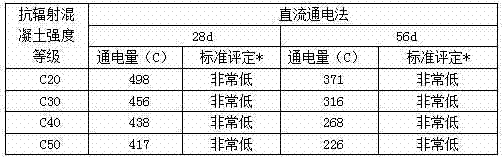

Embodiment 3

[0043] A barite anti-radiation pumping concrete, the proportion of the concrete raw materials by weight is: 400 parts of cement, 140 parts of water, 100 parts of barite powder, 1155 parts of barite sand, 1988 parts of barite, synergistic 2.4 parts of agent, 14.6 parts of polycarboxylate additive. The available slump / expansion is 210mm / 495mm, and the apparent density is 3752kg / m 3 , 28d C50 grade radiation-resistant pumped concrete with a compressive strength of 59.7MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com