Concrete Composite Water Reducer

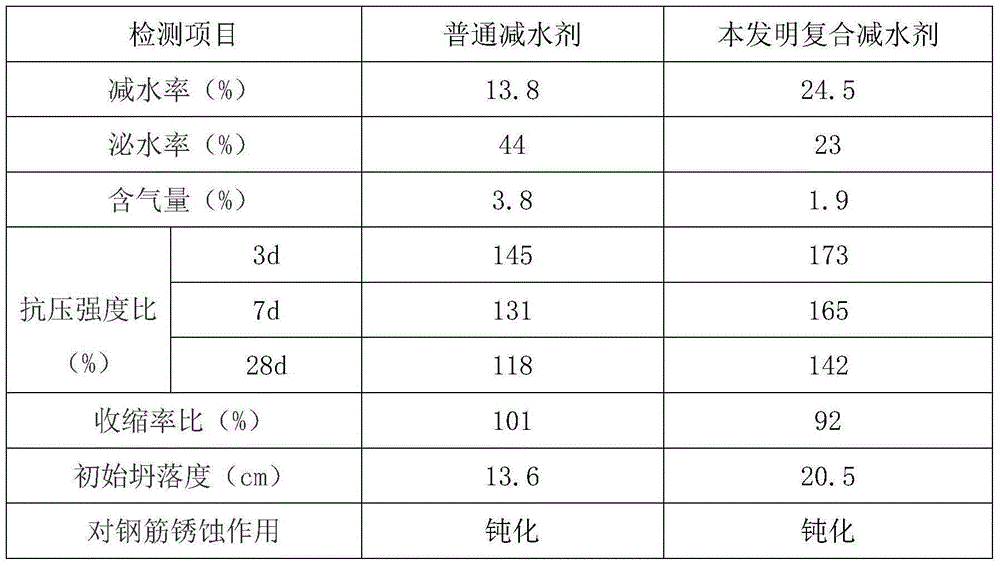

A composite water reducing agent and concrete technology, applied in the field of concrete admixture, can solve the problems of large dosage, poor plasticizing effect, poor water reducing performance, etc., achieve good plasticizing effect, increase slump, and improve cohesion Efficacy of sexuality and ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A concrete composite water reducer, which is made by mixing the following raw materials by weight (kg): p-aminobenzenesulfonate-sulfonated acetone-formaldehyde condensate 40, β-naphthalenesulfonate formaldehyde condensate 30, petroleum sulfonic acid Salt 16, Calcium Lignosulfonate 12, Aminotriethanol 8, Sulfonate Water-based Polyurethane 12, Zinc Phosphate 8, Ash Calcium Powder 6, Polyvinylpyrrolidone 9, Sodium Phosphate 4, Cinder 6, Triterpenoid Saponin 5, Allylthiourea 3, rhamnolipid 3.5, isooctyltriethoxysilane 2.5, additive 5.5;

[0010] The preparation method of described auxiliary agent is as follows: a, get the raw material of following weight (kg): activated magnesia 10, tuff micropowder 10, desulfurization ash 12, melamine urea-formaldehyde resin 16, microporous calcium silicate 8, polyisobutylene 9, tertiary Ethylene carbonate 5, 2-methyl-2,4-pentanediol polyoxypropylene polyoxyethylene ether 3, sodium pentachlorophenolate 2, cocoic acid monoethanolamide 4, bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com