A kind of permeable concrete and its construction technology

A technology of permeable concrete and construction technology, which can be applied to cohesive pavement paved on site, roads, and sustainable waste treatment. Increase water permeability, maintain ecological balance, and adjust the effect of urban microclimate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A permeable concrete of the present invention comprises the following components by weight: 1410kg of stones, 52kg of sand, 608.64kg of cement, 32.03kg of silica fume, 160.17kg of water, 4.16kg of water reducing agent, wherein the particle size of the stones is 5-15mm, apparent density 2700Kg / m 3 , Bulk density 1410Kg / m 3 ; The cement is P.O42.5R ordinary Portland cement, density 3100Kg / m 3 ;Sand is river sand, fineness modulus 2.6-2.8, density 2600Kg / m 3 ; The purity of silicon powder is not less than 98%, and the density is 2700Kg / m 3 ; The water reducer is a polycarboxylic acid type water reducer.

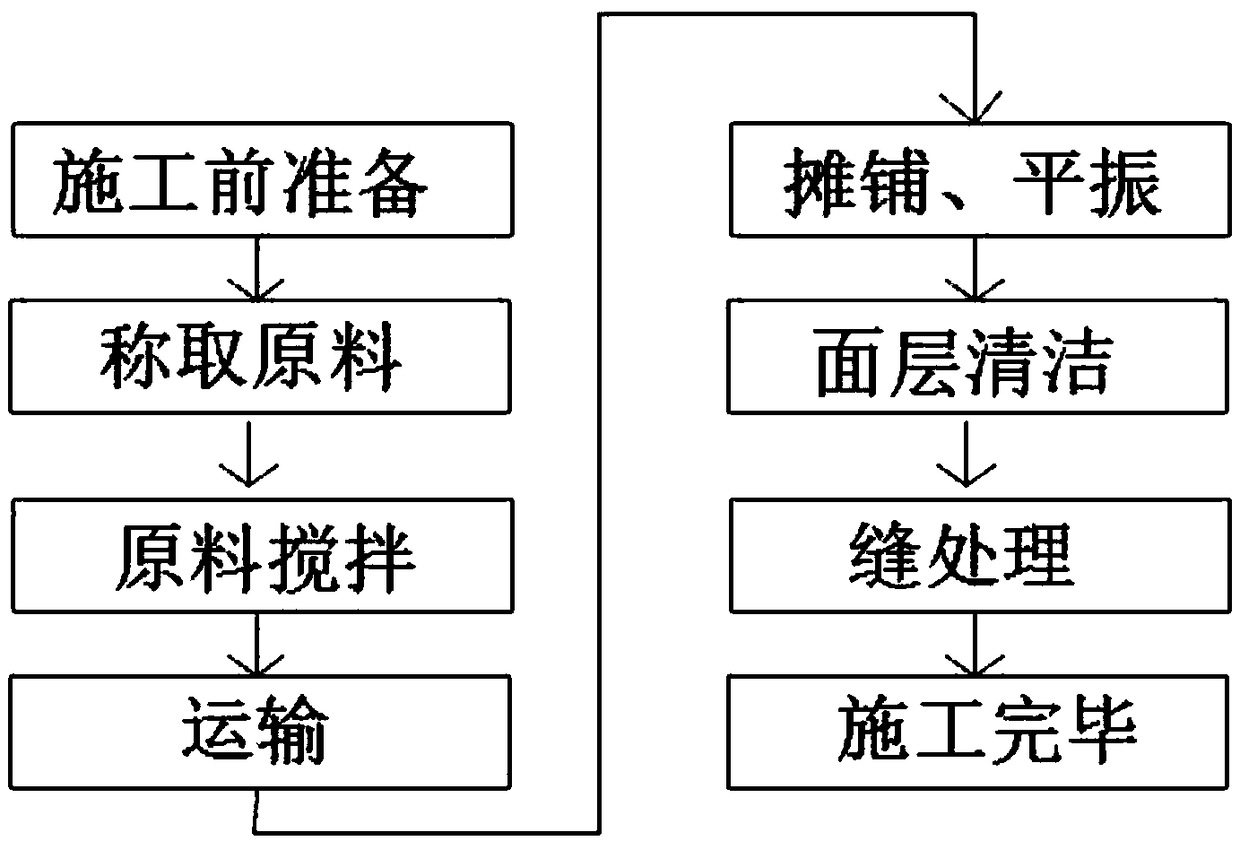

[0025] Such as figure 1 As shown, the construction technology of this kind of permeable concrete is:

[0026] 1) Preparation before construction: check and accept the base layer, and set up the mold after the inspection results meet the requirements to ensure that the thickness, verticality, drainage slope, etc. of the base layer meet the design requirements; The su...

Embodiment 2

[0037] A permeable concrete of the present invention comprises the following components by weight: 1410kg of stones, 52kg of sand, 488.07kg of cement, 60.32kg of silica fume, 148.07kg of water, 10.97kg of water reducer, wherein the particle size of the stones is 5-15mm, apparent density 2700Kg / m 3 , Bulk density 1410Kg / m 3 ; The cement is P.O42.5R ordinary Portland cement, density 3100Kg / m 3 ;Sand is river sand, fineness modulus 2.6-2.8, density 2600Kg / m 3 ; The purity of silicon powder is not less than 98%, and the density is 2700Kg / m3 ; The water reducer is a polycarboxylic acid type water reducer.

[0038] The construction technology of this kind of permeable concrete is as follows:

[0039] 1) Preparation before construction: check and accept the base layer, and set up the mold after the inspection results meet the requirements to ensure that the thickness, verticality, drainage slope, etc. of the base layer meet the design requirements; The surface of the structural l...

Embodiment 3

[0050] A permeable concrete of the present invention comprises the following components by weight: 1410kg of stones, 52kg of sand, 497.07kg of cement, 60.32kg of silica fume, 144.49kg of water, 11.56kg of water reducer, wherein the particle size of the stones is 5-15mm, apparent density 2700Kg / m 3 , Bulk density 1410Kg / m 3 ; The cement is P.O42.5R ordinary Portland cement, density 3100Kg / m 3 ;Sand is river sand, fineness modulus 2.6-2.8, density 2600Kg / m 3 ; The purity of silicon powder is not less than 98%, and the density is 2700Kg / m 3 ; The water reducer is a polycarboxylic acid type water reducer.

[0051] The construction technology of this kind of permeable concrete is as follows:

[0052] 1) Preparation before construction: check and accept the base layer, and set up the mold after the inspection results meet the requirements to ensure that the thickness, verticality, drainage slope, etc. of the base layer meet the design requirements; The surface of the structural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com