Machine-made sand production system, and production method and application thereof

A production system and production method technology, applied in the field of machine-made sand production, can solve the problems of machine-made sand particle gradation and uncontrollable dust content, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

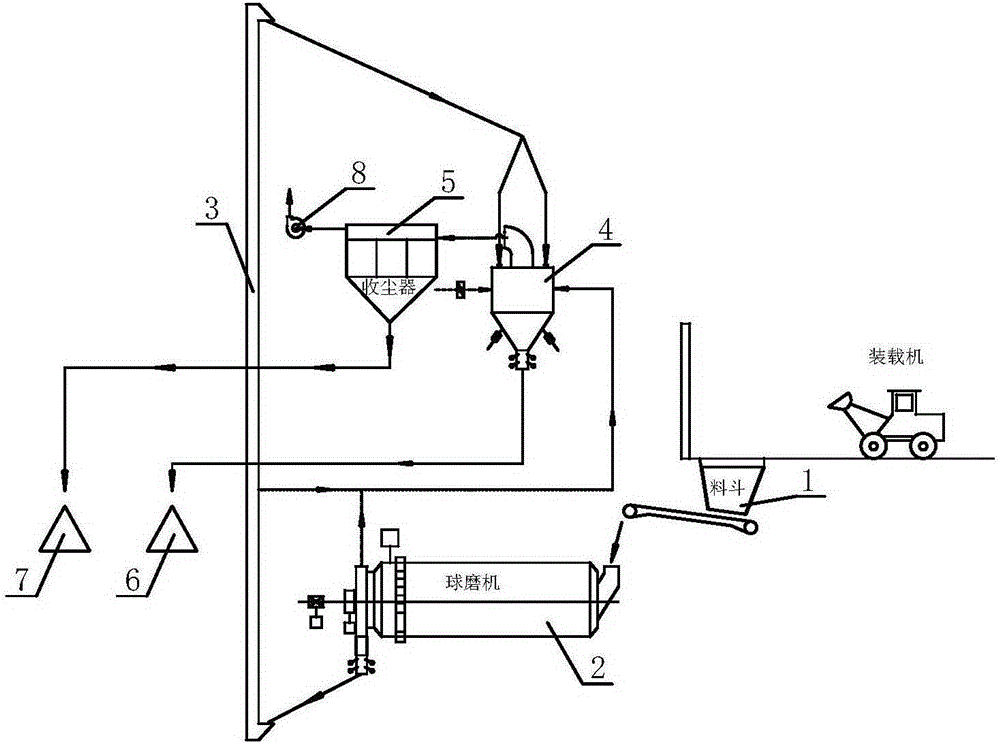

[0031] figure 1 Shown is a schematic structural diagram of the machine-made sand production system of the present invention, including a hopper 1, and a ball mill 2 for grinding materials, and a connecting belt for transferring the materials in the hopper 1 to the ball mill 2, which is used for screening the materials obtained by the ball mill 2. The powder separator 4 is used to transfer the output of the ball mill 2 to the hoist 3 of the high-efficiency powder separator 4, and is used to receive the machine-made sand warehouse 6 for receiving the discharge of the high-efficiency powder separator 4; the air outlet of the high-efficiency powder separator 4 is connected to a Dust collector 5, the air outlet of dust collector 5 is connected with dust collection fan 8; the discharge port of dust collector 5 is connected with dust collection fine powder storehouse 7; connected to the air inlet. The ball mill 2 is a horizontal ball mill. The cylinder of the horizontal ball mill us...

Embodiment 2

[0046] The machine-made sand production system of this embodiment is the same as that of Embodiment 1. The ball mill 2 is a horizontal ball mill. The cylinder of the horizontal ball mill used in this embodiment has a diameter of 2.2 m and a length of 6.5 m. The supplier of the high-efficiency powder separator 4 For Shangrao Machinery Factory, the model is HES-30.

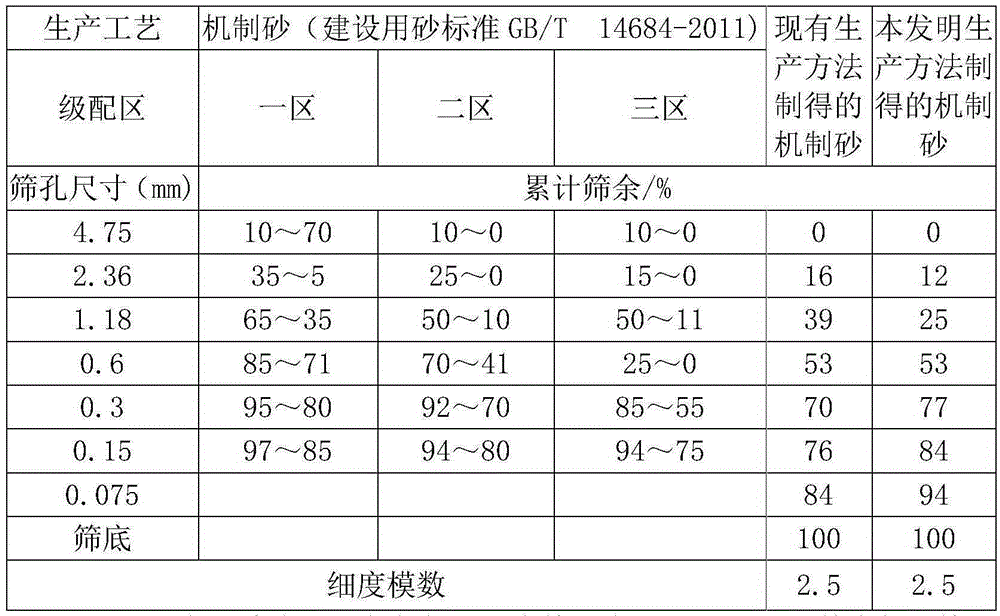

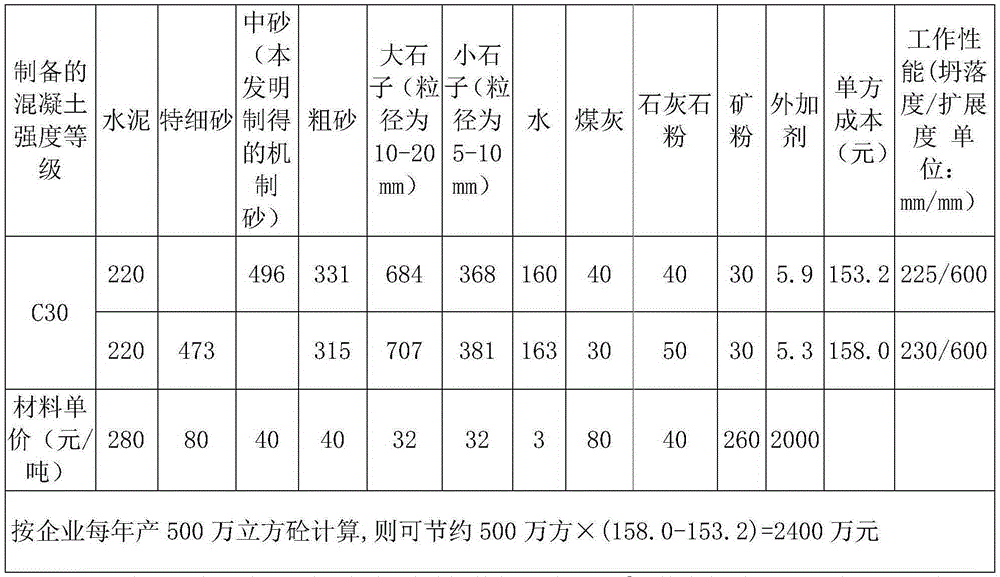

[0047] The operation process of the machine-made sand production system of the present invention is as follows: the loader puts the stones with a particle size ≤ 5mm obtained by upstream pretreatment into the hopper 1, and the materials in the hopper 1 are sent to the ball mill 2 through the conveyor belt, and the ball mill 2 is a horizontal ball mill. , the diameter of the cylinder is 2.2m, and the length is 6.5m. The steel ball inside the ball mill 2 performs ball milling on the stone material. The material fineness modulus at the outlet of the ball mill is 2.2-2.6, and the material enters through the screen at the...

Embodiment 3

[0053] The machine-made sand production system of this embodiment is the same as that of Embodiment 1. The ball mill 2 is a horizontal ball mill. The cylinder of the horizontal ball mill used in this embodiment has a diameter of 1.8 m and a length of 13 m. The supplier of the high-efficiency powder separator 4 is Shangrao Machinery Factory, the model is HES-30.

[0054] The operation process of the machine-made sand production system of the present invention is as follows: the loader puts the stones with a particle size ≤ 5mm obtained by upstream pretreatment into the hopper 1, and the materials in the hopper 1 are sent to the ball mill 2 through the conveyor belt, and the ball mill 2 is a horizontal ball mill. , with a diameter of 1.8m and a length of 13m. The steel balls inside the ball mill 2 mill the crushed stones. The material fineness modulus at the outlet of the ball mill is 2.2-2.6. The machine 3 and the elevator 3 send the material into the high-efficiency powder sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com