Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Improve self-compacting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

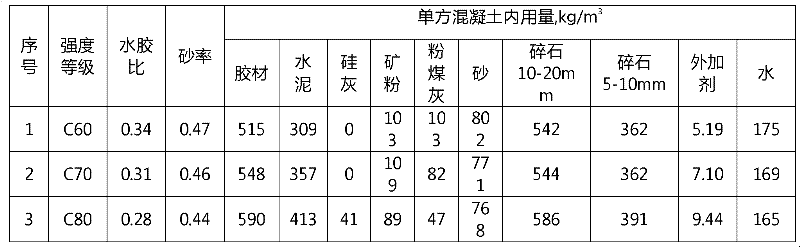

Self-compacting concrete and design method of mixing proportion thereof

The invention relates to the technical field of concrete for building casting, specifically to self-compacting concrete and a design method of the mixing proportion of the concrete. The invention is characterized in that the self-compacting concrete is prepared by uniformly stirring the following raw materials in mixing proportion: 300-400kg / m<3> of cement, 70-150kg / m<3> of fly ash, 70-150kg / m<3> of mineral powder, 0-50kg / m<3> of silicon powder, 750-850kg / m<3> of sand, 850-1050kg / m<3> of stone, 4.4-28kg / m<3> of additive and 150-175kg / m<3> of water. Compared with the prior art, the self-compacting concrete disclosed by the invention has obviously improved flowing property, self-compacting property and durability of the concrete mixture, and is particularly applicable to the engineering structures limited by the construction operation space such as the structures with high casting quantity, large casting depth and height, complex shape, densely arranged reinforcing bars, thin walls, concrete-filled steel tubes and the like.

Owner:HEFEI TIANZHU BAOHE SPECIAL CONCRETE

Sea sand powder concrete

ActiveCN105084837AEasy to fillImprove mechanical propertiesSolid waste managementFiberCopper plating

The invention relates to sea sand powder concrete. The sea sand powder concrete comprises, by weight, 450-750 parts of cement, 250-450 parts of active mineral admixture, 50-150 parts of inert admixture, 850-1400 parts of sea sand, 24-32 parts of high efficiency slushing agents, 145-220 parts of seawater, 2-4 parts of organic fiber and 78-250 parts of copper-bearing steel fiber with the thickness ranging from 0.08 mm to 0.35 mm. According to the sea sand powder concrete, a compact stacking structure principle is adopted, the interior of the concrete is almost seamless in communication channel through optimization of particle size gradation, and a channel of internal ion medium migration is further eliminated through secondary hydration of the active mineral additive, so that the powder concrete obtained by stirring the raw materials through the seawater and the sea sand is ultra-high performance concrete with high durability, corrosion resistance and high mechanic property.

Owner:黄贺明

Highly-antifreezing highly-slump retaining self-compacting C40 concrete

The invention relates to highly-antifreezing highly-slump retaining self-compacting C40 concrete which comprises the following components by kg / m3: 330 parts of cement, 80 parts of granulated blast-furnace slag, 80 parts of fly ash, 830 parts of natural medium sand with a fineness modulus of 2.3-3.0, 920 parts of stone, 4.9 parts of additives, and 160 parts of mixing water; the additive is a modified air-entraining polycarboxylic water reducer, wherein the mixing amount of an air-entraining agent in the polycarboxylic water reducer RP325 is 0.1%, and the mixing amount of the additive for large-scale production is 1.0% of the total amount of gel materials; the air content in the concrete is 5.0%+ / -1.0%; the air-entraining amount in the poured structure from the beginning to the third hour is stabilized within a range of 5.0%+ / -1.0%, and the concrete expansion degree in 3 hours is maintained at 600+ / -50 mm; the number of antifreezing cycle is not less than 150, and the lowest temperature and the highest temperature in the antifreezing cycle are respectively -18 DEG C and 35 DEG C. The concrete of the invention can meet the concrete performance requirements for a skating rink in Shanghai oriental sports center with respect to high slump retaining performance, self-compacting performance, strength performance, high antifreezing performance, and the like.

Owner:TONGJI UNIV +1

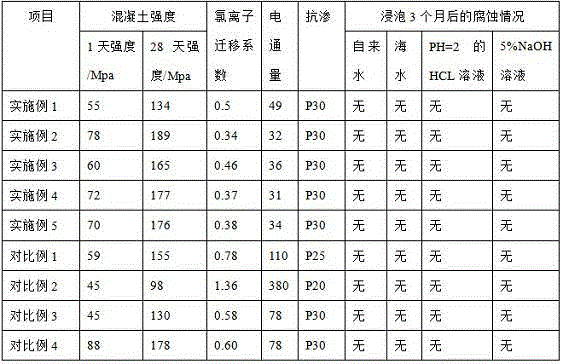

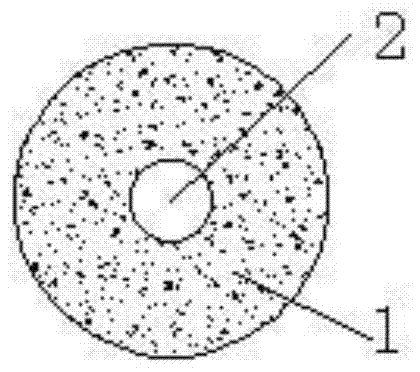

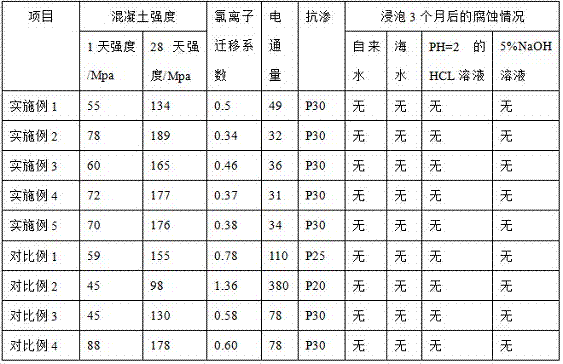

Self-compacting powder concrete for ocean engineering as well as preparation method and application

ActiveCN104876500AExtensive self-compactingImprove self-compactingSolid waste managementCalcium hydroxideUltimate tensile strength

The invention discloses self-compacting powder concrete for ocean engineering as well as preparation method and an application. According to the concrete, coal ash and limestone flour are simultaneously added, the precipitation amount of calcium hydroxide is reduced, and the problem in the prior art that the concrete is poor in corrosion resistance can be solved; moreover, the concrete is doped with nano-scale calcium carbonate and silica fume, so that the self-compacting property of the concrete structure is improved. The comprehensive cost of the concrete is low, the material source is wide, and a great amount of industrial wastes can be doped; the seawater corrosion resistance is good, the self-compacting property is good, the expandability is high, hydration heat is low, the adjusting range of the working expandability is large, the early strength is high, the strength of the concrete is greater than 50Mpa at the first day and greater than 130Mpa at the 28th day, and the self-compacting powder concrete is suitable for different types of ocean engineering.

Owner:黄贺明

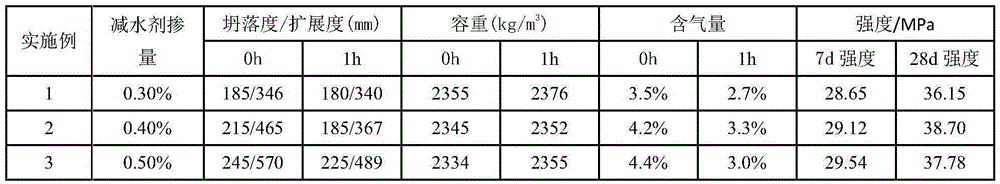

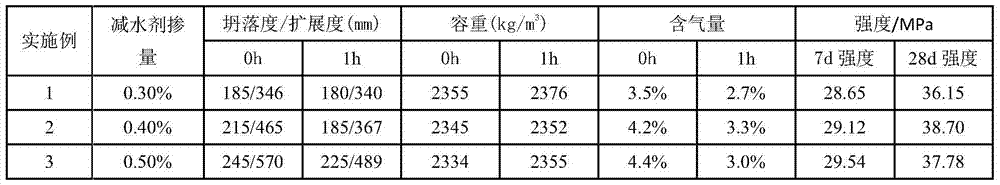

Polycarboxylate water reducer for ultra-compact concrete for nuclear power and preparation method of polycarboxylate water reducer

The invention relates to a polycarboxylate water reducer for ultra-compact concrete for nuclear power and a preparation method of the polycarboxylate water reducer. Every 100 parts of the water reducer comprises components in parts by weight as follows: 50-55 parts of a dispersing ether type polycarboxylate water reducer, 20-25 parts of a slump retaining ether type polycarboxylate water reducer, 3-5 parts of a retarder, 0.01-0.05 parts of a defoaming agent, 1-3 parts of a water retaining agent, 1-2 parts of a shrinkage reducing agent, 0.1-0.3 parts of a preservative and the balance of water. The components are uniformly mixed in parts by weight during preparation. Compared with the prior art, the water reducer has the advantages as follows: concrete workability and liquidity are improved, a temperature peak value and a shrinkage value of the concrete are reduced, the internal porosity of the concrete is reduced, the self-compacting performance and the durability of the concrete are improved and the like; besides, the preparation method is simple, raw material sources are wide, the cost is low, and the water reducer is environment-friendly and has the good application prospect.

Owner:TONGJI UNIV

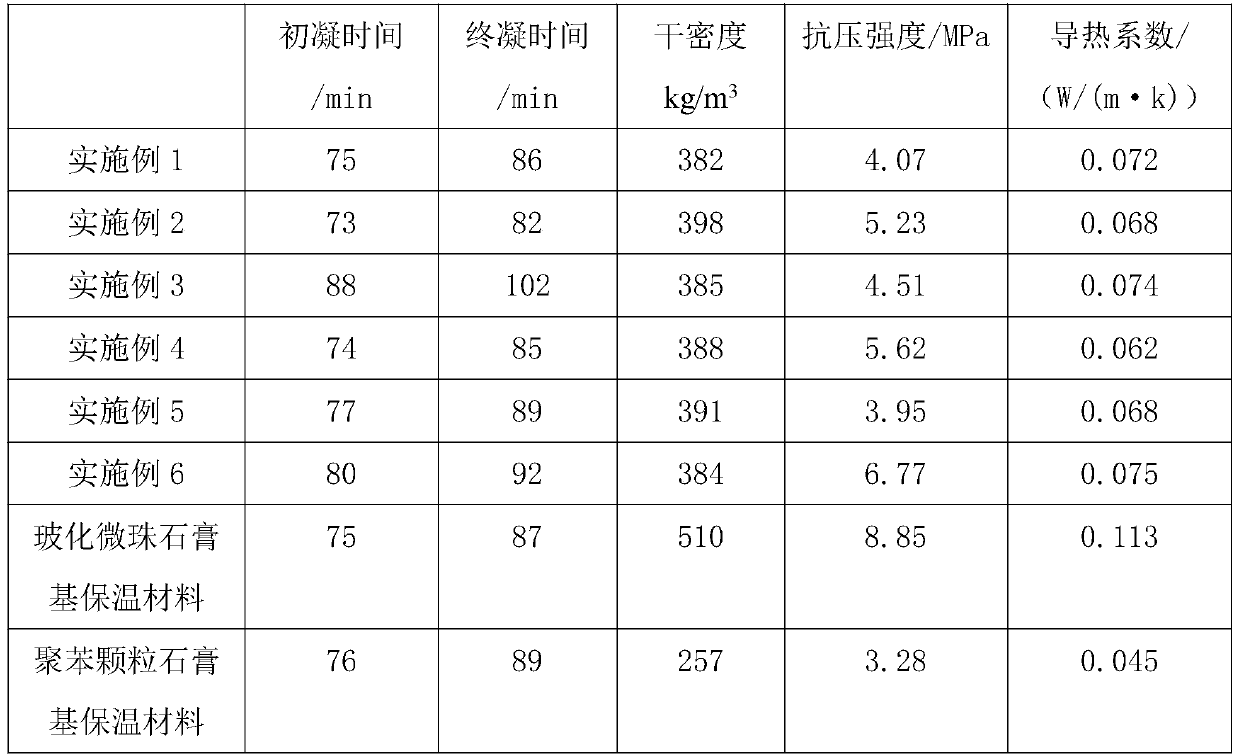

Gypsum-based composite lightweight thermal-insulation mortar and preparation method thereof

The invention provides gypsum-based composite lightweight thermal-insulation mortar. The mortar comprises, by weight, 60-80 parts of gypsum powder, 1-2 parts of polyphenyl granules, 10-15 parts of glazed hollow beads, 5-10 parts of cement, 1-2 parts of redispersible latex powder, 0.2-0.6 part of a water-retaining agent, 0.2-0.6 part of a gypsum retarder, 0.3-0.8 part of a water reducer, 0.2-0.8 part of polypropylene fiber and 60-80 parts of water. The glazed hollow beads and the polyphenyl granules are mixed by selecting a proper grain composition and then combined with semi-hydrated gypsum, apreparation mode is simple, the consumption of a gel material is reduced, the cost is low, the dry density is reduced, the mortar is high in anti-cracking performance, low in shrinkage deformation, high in ductility and good in construction performance, the self-compactness is good, and the heat preservation performance is excellent.

Owner:NANJING UNIV OF TECH

Ladle permanent lining and manufacturing method thereof

ActiveCN103785820AExtended service lifeSolve the problem of seeping steelMelt-holding vesselsBrickRefractory

The invention relates to a ladle permanent lining and a manufacturing method of the ladle permanent lining, and belongs to the technical field of ferrous metallurgy ladle lining fireproof material. The ladle permanent lining is laid on the inner wall of a shell (6) of a ladle and sequentially comprises a ladle bottom permanent lining (1), a ladle wall permanent lining (3) and a ladle nozzle permanent lining (10) from bottom to top. The ladle permanent lining is characterized in that the ladle permanent lining is manufactured by minimum-inflation artesian flow castable in a segmented casting mode, an overall casting forming die is not used, and the ladle permanent lining and a bricked working lining are constructed synchronously. The technological process of repairing and laying the ladle lining is simplified, the problem that in the prior art, the bricked working lining leaks steel because the high-aluminum artesian flow castable shrinks in the hardening process is solved, compared with the prior art, the service life of the ladle working lining is prolonged by 150 furnace round-200 furnace round, and the cost of ladle fireproof material is reduced by over 15%.

Owner:LAIWU IRON & STEEL GRP

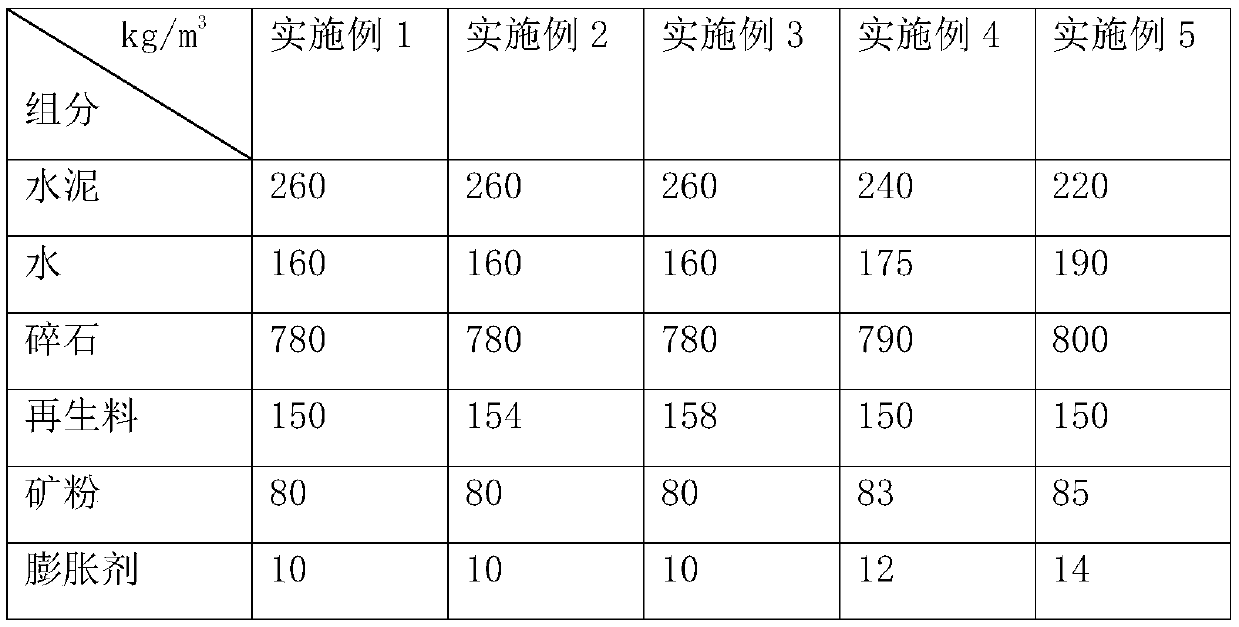

Recycled self-compacting concrete and preparation method thereof

The invention discloses recycled self-compacting concrete and a preparation method thereof. The recycled self-compacting concrete comprises the following components in parts by weight: 220 to 260 parts of cement, 160 to 190 parts of water, 780 to 800 parts of broken stone, 150 to 158 parts of a recycled material, 80 to 85 parts of mineral powder, 10 to 14 parts of an expanding agent, 720 to 750 parts of sand, 3 to 7 parts of a water reducer, 2 to 10 parts of a viscosity modifier and 110 to 117 parts of coal ash; and the recycled material comprises the following components in parts by weight: 20 to 40 parts of iron tailings, 10 to 20 parts of building waste and 20 to 30 parts of steel slag powder. The recycled self-compacting concrete disclosed by the invention has the advantages of high flowing property, filling property and segregation resistance, and the wastes of steel slag and iron tailings are utilized sufficiently.

Owner:西安新意达建筑制品有限公司

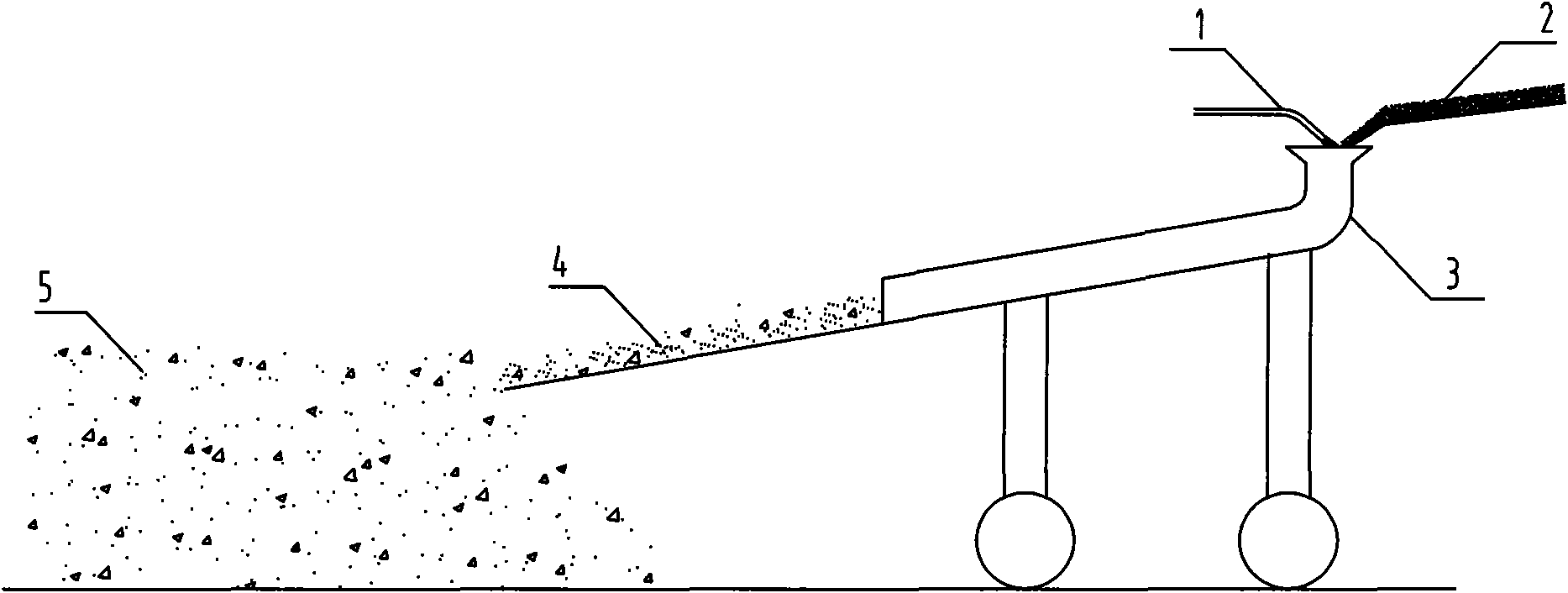

Construction method of gunite concrete

InactiveCN101624826AIncrease mechanical bite forceGuaranteed uniformityFoundation engineeringBuilding material handlingMechanical indexIncomplete mixing

The invention discloses a construction method of gunite concrete, comprising the following steps: adopting normal pure cement paste consisting of water and cement or mixed cement paste consisting of water and cement mixed with fly ash, which is provided by a high-speed stirring slurrying device; respectively injecting dynamic gravel mixed material of a free falling body or respectively injecting dynamic sand and aggregate of the free falling body via a slurry transmission device; injecting cement paste and dynamic gravel mixed material or dynamic sand and aggregate to cause that the mixture enters a mixed conveyor entrance in an imperfect-mixing state; after stirred into even mixed material, directly sending the mixed material into a cabin via the gravity of the mixed material or sending the mixed material into a cabin via a mixed material sending device for vibrating and pouring into concrete. The invention combines concrete mixing, transporting and pouring technology into a whole, directly pours in site to continuously perform concrete construction, which simplifies concrete construction technology; the invention has few in-site construction devices, convenient operation, quick pouring, low cost and short construction period, effectively strengthens various mechanical indexes of concrete and obviously improves construction efficiency.

Owner:沈阳乾玉水利有限公司

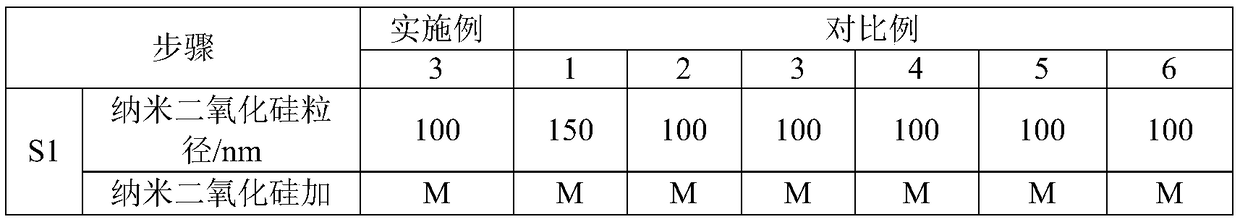

Preparation method of nano-silica compacted concrete

The invention discloses a preparation method of nano-silica compacted concrete. The preparation method comprises the following steps: preparing nano-silica of which the surface is coated with nano-alumina into a nano-silica aqueous solution with the concentration of 0.05 to 0.5 mol / L and injecting the nano-silica aqueous solution into an electrolytic cell; putting a concrete specimen with built-insteel bars into the electrolytic cell, connecting the steel bars into a power supply cathode, arranging an auxiliary anode parallel to the concrete specimen outside the concrete specimen and connecting the auxiliary anode into a power supply anode; under the condition of 0 to 4 DEG C, applying 6 to 96 V / cm impressed voltage between the power supply cathode and the power supply anode in the S3 andthen electrifying. According to the method disclosed by the invention, by taking the nano-silica as a raw material and applying an external electric field, the nano-silica enters pores of the concrete through electrophoresis drive; by utilizing C-S-H gel generated through reacting the nano-silica solution with calcium hydroxide, the pores in the concrete are filled to obtain compacted concrete, and further the durability of the concrete is improved.

Owner:HOHAI UNIV

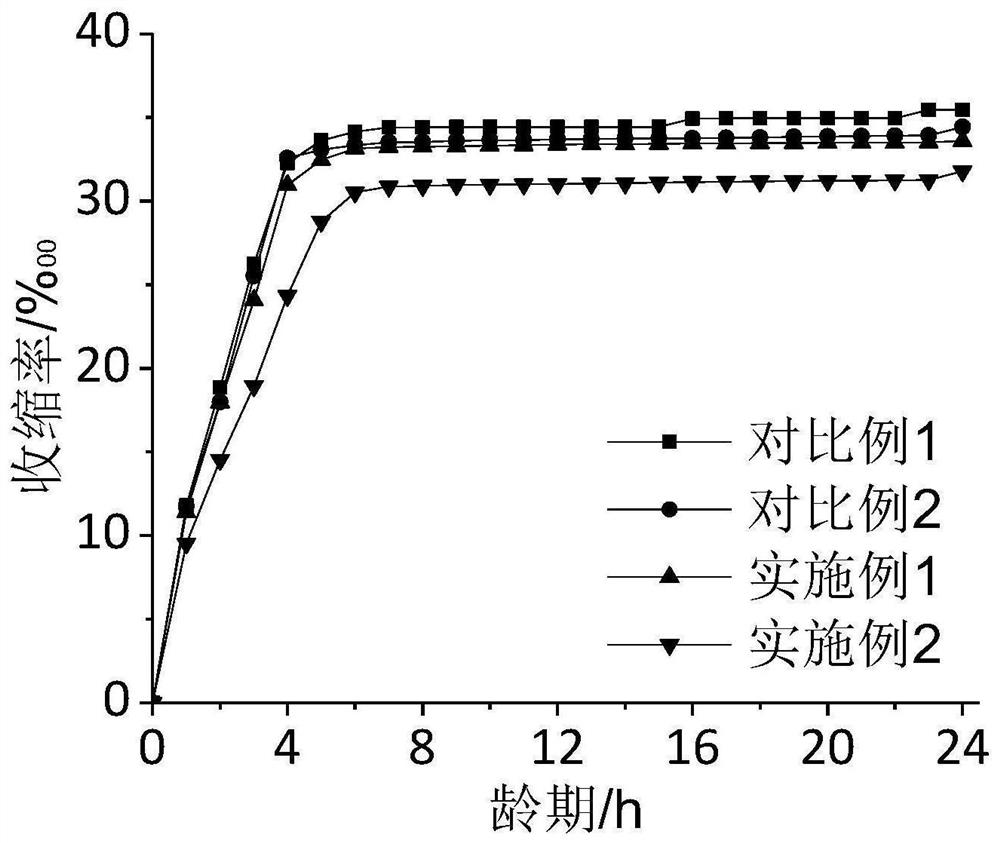

Low-shrinkage 3D printing concrete co-doped with lignin fibers and preparation method of low-shrinkage 3D printing concrete

ActiveCN113372074ASmall shrinkage deformationImprove early crack resistanceAdditive manufacturing apparatusSolid waste managementFiberAluminate

The invention discloses low-shrinkage 3D printing concrete co-doped with lignin fibers and a preparation method of the low-shrinkage 3D printing concrete. The concrete comprises the following components: high belite sulphoaluminate cement, ordinary Portland cement, lignin fibers, a UEA expanding agent, silica fume, quartz sand, water and an additive. The lignin fibers are applied to the 3D printing concrete for the first time, the effects of internal curing and fiber toughening are achieved, shrinkage deformation of the 3D printing concrete in all ages can be effectively reduced, the early-stage cracking resistance is improved, the interlayer bonding performance of the 3D printing concrete is effectively improved, and meanwhile the humidity balance of a concrete material can be adjusted. The high belite sulphoaluminate cement and the ordinary Portland cement are mixed according to a proper proportion to serve as a cementing material of the 3D printing concrete. The printability of the concrete can be optimized and the early strength of the concrete can be improved due to the characteristics of quick setting and early strength of the high belite sulphoaluminate cement, and the shrinkage deformation of the 3D printing concrete in the later period can be reduced due to the characteristic of low shrinkage.

Owner:HEBEI UNIV OF TECH +1

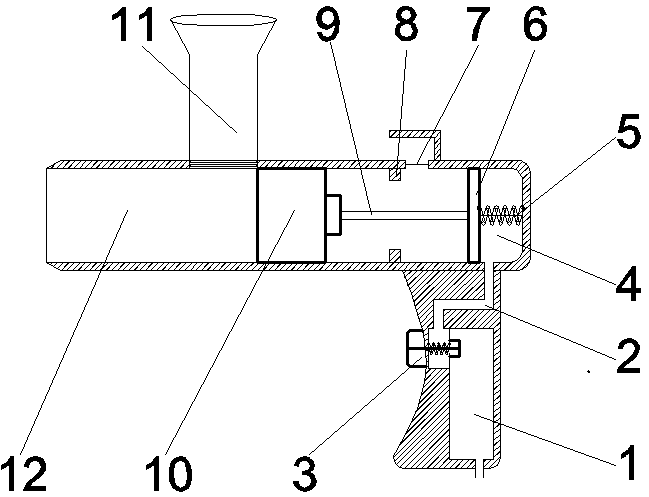

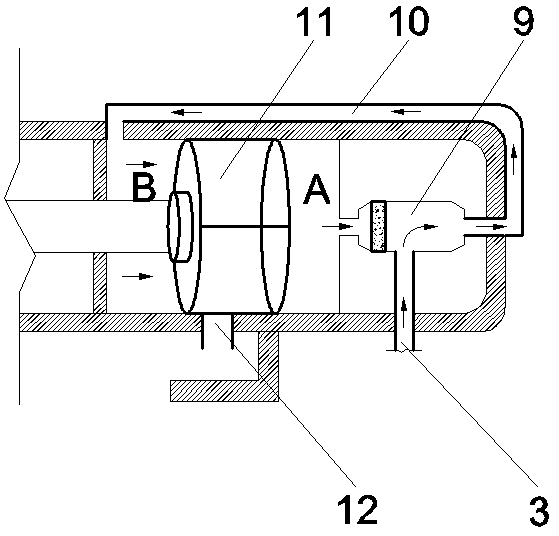

Pellet type blast hole plugging gun and use method

The invention discloses a pellet type blast hole plugging gun and a use method. The pellet type blast hole plugging gun structurally consists of an air supply handle, a shooting chamber and a storagebin; an air inlet is formed in the lower end of an air storage chamber in the air supply handle; an opening in the left end of the air storage chamber is connected with an air conveying hole channel;an air valve switch is placed at the connecting part of the air storage chamber and the air conveying hole channel; the other end of the air conveying hole channel is connected with the shooting chamber; and a piston rod in the shooting chamber is connected with a piston and an impact disc. During the implementation, a gun muzzle stretches into a blast hole, the air inlet is connected with a high-pressure air pipe, and after a switch is pressed down, the piston makes reciprocating motion under the action of a reverse drawing spring and compressed air to drive the impact disc to impact a charging hopper to discharge a tamping plug, and the stemming tamping plug falls in and rushes into the blast hole at a high speed, so that the purpose of high compactness plugging is achieved. By taking the compressed air as a power source, the pellet type blast hole plugging gun is simple to operate and is safe and portable, and contributes to solving the problem that an existing blast hole is difficult to plug; and compared with manual filling, the construction efficiency is improved substantially.

Owner:SHANDONG UNIV OF SCI & TECH

Underwater dispersion-resistant concrete additive for building

The invention discloses an underwater dispersion-resistant concrete additive for a building. The underwater dispersion-resistant concrete additive is prepared from the following components in parts byweight: 1 to 2 parts of methylcellulose, 1 to 2 parts of hydroxypropyl methyl starch, 2 to 5 parts of zeolite powder, 10 to 15 parts of stearic acid, 10 to 12 parts of naphthalene-based superplasticizer, 1 to 2 parts of sepiolite fibers, 3 to 5 parts of polyacrylamide, 1 to 3 parts of polyvinyl alcohol, 3 to 5 parts of sodium aluminate, 20 to 22 parts of polycarboxylate superplasticizer, 63 to 73parts of water, and 10 to 12 parts of polyacrylamide. By adopting the underwater dispersion-resistant concrete additive, the cohesiveness, the mobility, the dispersion resistance and the self-compacting performance of the concrete can be comprehensively improved, so that a mixture is not isolated and dispersed, is self-leveled and self-compacted without being vibrated, the water on the original poured surface can be extruded, after the mixture is cured, and the mixture has good adhesion with the surface of the original concrete surface; and the methylcellulose and the polyacrylamide are usedas the anti-scattering agent, so that the concrete has good cohesiveness and water scouring resistance.

Owner:徐州巨龙新材料科技有限公司

Inorganic penetration waterproof agent

The invention discloses an inorganic penetration waterproof agent and belongs to the technical field of building materials. According to the inorganic penetration waterproof agent, nano ferroferric oxide is used as a raw material, and glycidyl methacrylate and divinylbenzene are added to carry out emulsion polymerization, so as to obtain a polymer magnetic microsphere; the inner part of concrete is filled with crystals, the self-compaction performance of the concrete is improved and the effect of protecting and repairing cracks on the surface of the concrete is realized; methyltriethoxysilaneand vinyltriethoxysilane are used as main raw materials and a silicon resin additive is obtained; the adhesion force can be improved and a hydrophobic network is formed and is filled into a gap, so that the binding force with a concrete matrix is improved; triethanolamine is introduced and N atoms exist in triethanolamine molecules; a covalent bond is formed through the N atoms and metal ions andcomplexing is carried out, and the density of the concrete is increased, so that the waterproof performance is improved. By adopting the inorganic penetration waterproof agent, the problems of a current penetration waterproof agent that the waterproof performance is poor and the self-repairing capability is poor, and the current penetration waterproof agent and the concrete are subjected to earlyreaction in a penetration process are solved.

Owner:翟琳

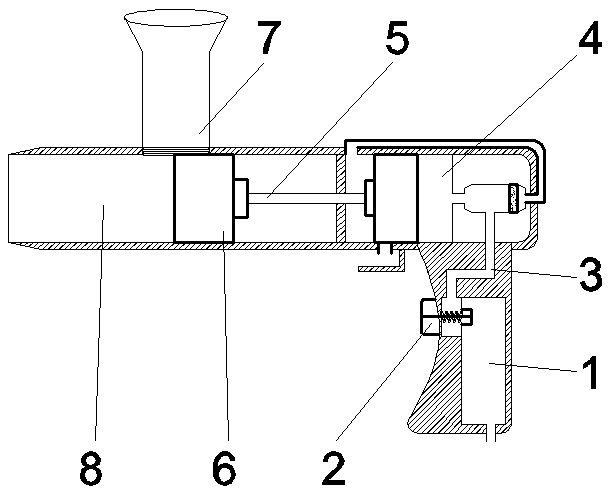

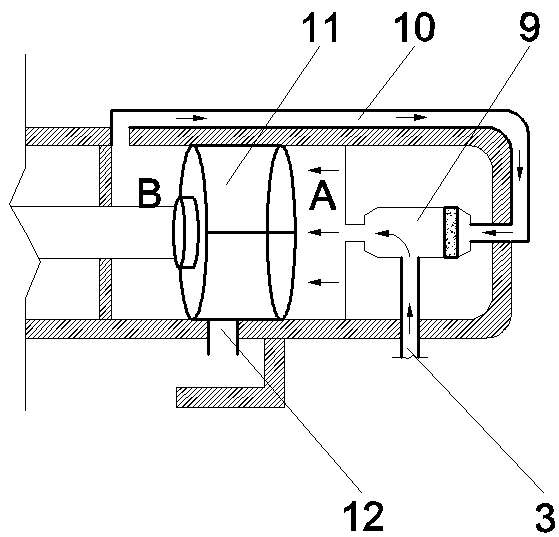

Repeating blasthole sealing gun and use method thereof

The invention discloses a repeating blasthole blocking gun and a use method thereof. The repeating blasthole blocking gun is structurally composed of an air supply handle, a firing gun barrel and a stock bin. The air supply handle comprises an air storage chamber, an air valve switch assembly and an air delivery hole channel, a lower end air inlet of the air storage chamber is connected with a high-pressure air pipe, a left end opening of the air storage chamber is connected with the air delivery hole channel, and an air valve switch is arranged at the joint. The other end of the air deliveryhole channel is connected into an air cylinder assembly of the firing gun barrel, the air cylinder assembly comprises a front section for arranging a piston and a rear section for arranging a distributing valve, and the front section uses a piston rod to connect the piston to a bump disk. During use, a muzzle extends into a blasthole to be connected with the high-pressure air pipe, an air cylinderis driven to reciprocate continuously by compressed air, and at the same time, the bump disk impacts a material entering cylinder to enable gun mud to fall in and the gun mud enters the blasthole ata high speed, so that the purpose of blocking the blasthole with high compactness is achieved. According to the repeating blasthole blocking gun and the use method thereof, rapid filling of the blasthole is realized, the labor intensity of workers is reduced, the blocking compactness is high, and the application prospects are broad.

Owner:SHANDONG UNIV OF SCI & TECH

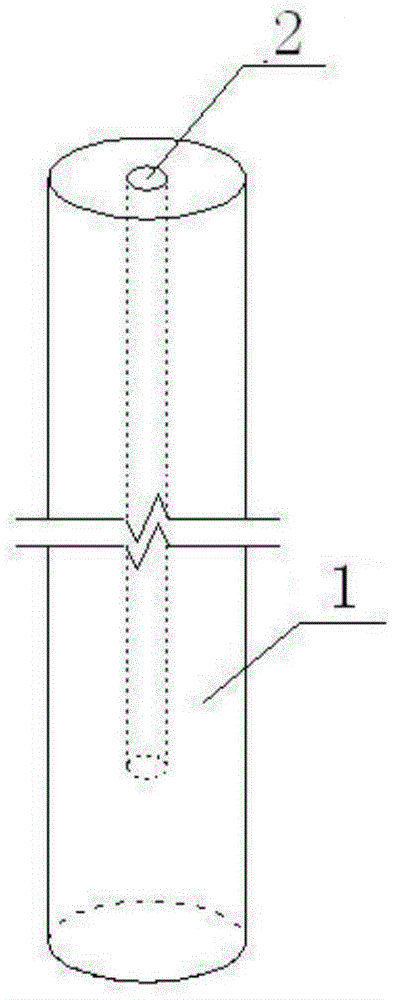

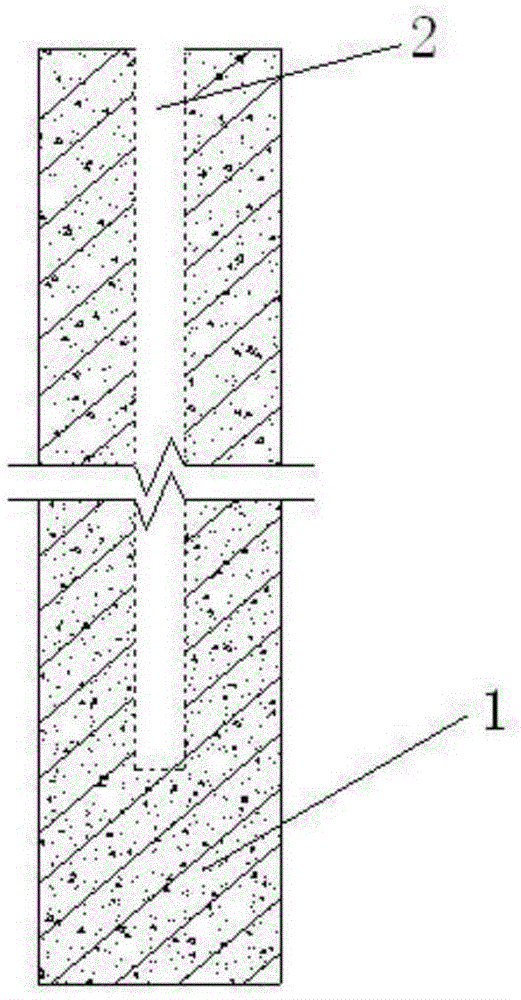

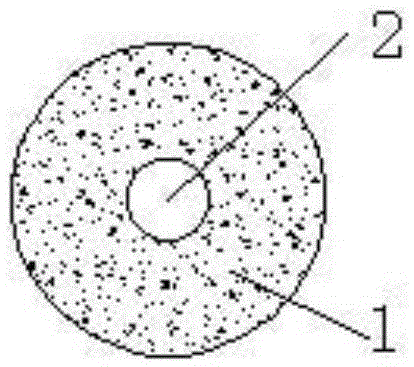

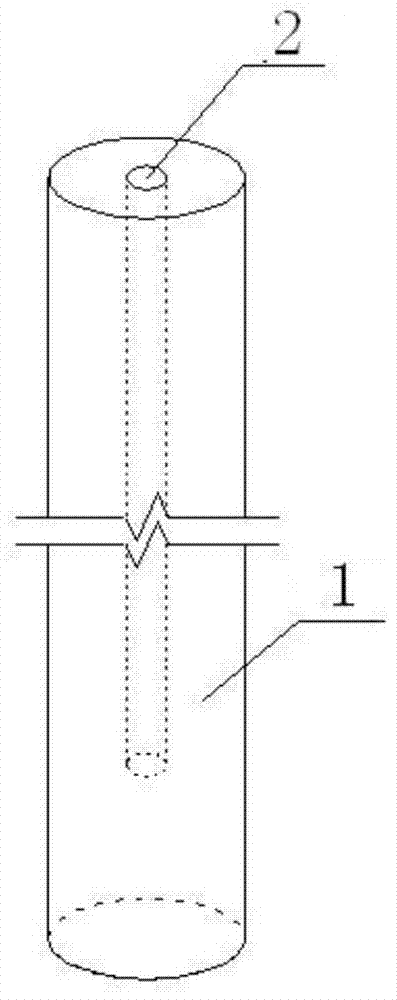

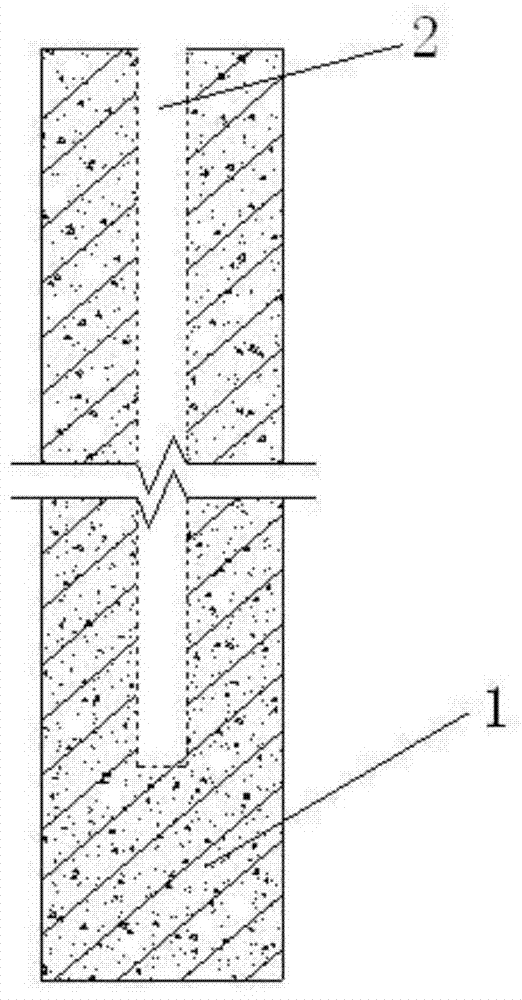

Reinforced concrete pile structure resisting seawater corrosion

ActiveCN105297709AAvoid corrosionImprove self-compactingProtective foundationBulkheads/pilesReinforced concreteOperability

The invention discloses a reinforced concrete pile structure resisting seawater corrosion. A duct not penetrating the bottom of a pile body is arranged in the middle of the pile body of the reinforced concrete pile structure and is filled with liquid which is not soluble in seawater and has a stable source. Compared with an existing reinforced concrete pile structure for improving self compaction and high cracking resistance of reinforced concrete, the reinforced concrete pile structure resisting seawater corrosion is high in operability; compared with an existing pouring technology of self-compaction reinforced concrete in the prior art, a pouring technology of reinforced concrete is more mature and more reliable; and in addition, processes can be obviously reduced, only the duct needs to be reserved when the reinforced concrete is poured, the construction cost can be reduced, corrosion of seawater on the reinforced concrete pile structure can be effectively avoided, and operation is easy.

Owner:GUANGXI UNIV

Polycarboxylate water reducer composition for self-compaction high-workability concrete

The invention discloses a polycarboxylate water reducer composition for self-compaction high-workability concrete. The polycarboxylate water reducer composition is composed of the following components: allyl alcohol polyoxyethylene ether, an unsaturated acid, functional monomers, an oxidizing agent, a reducing agent and a chain transfer agent, wherein the unsaturated acid consists of citric acid,acetic anhydride, acrylic acid and methacrylic acid according to a mass ratio of (1-3):(1-2):(2-3):(5-10), and the functional monomers are nano-diatomaceous earth and sulfonated melamine formaldehyderesin. According to the invention, the water reducer is synthesized by the allyl alcohol polyoxyethylene ether and the unsaturated acid, so that mixing performance of concrete can be improved, meanwhile, steel bars can be prevented from rusting, and the service life of the concrete is prolonged. Mutual reactions between cementing materials can be promoted through the functional monomers, and workability of the concrete is enhanced.

Owner:武汉优城科技有限公司

Underwater self-compacting concrete and preparation method thereof

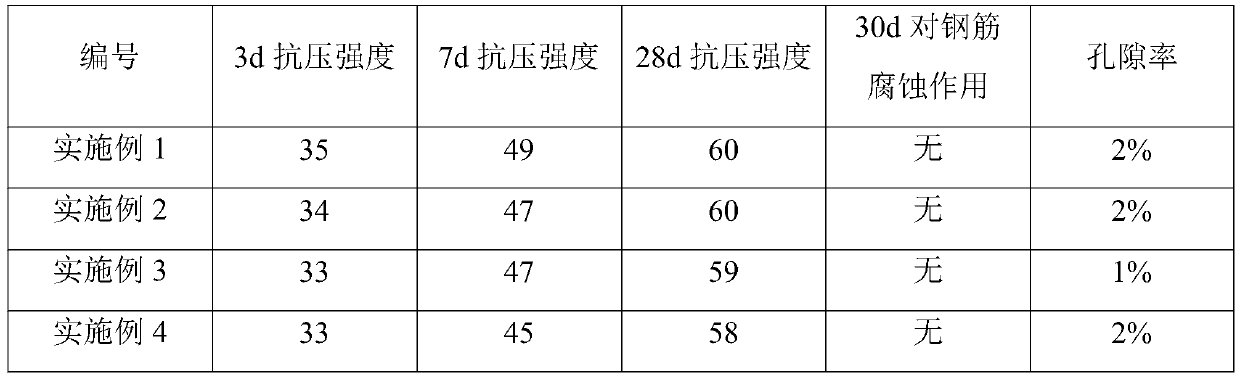

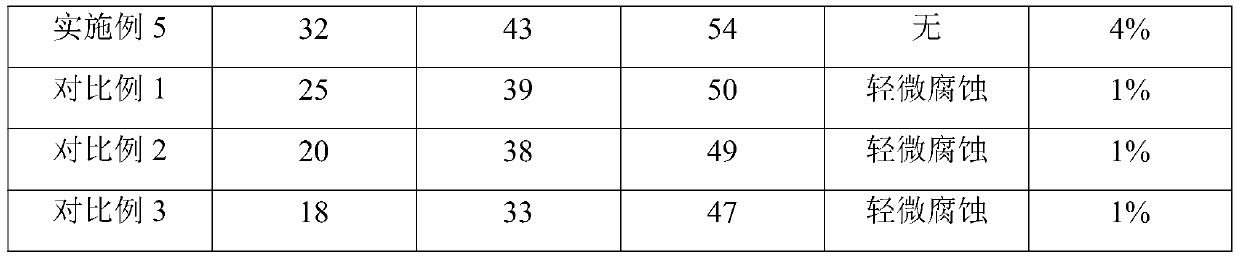

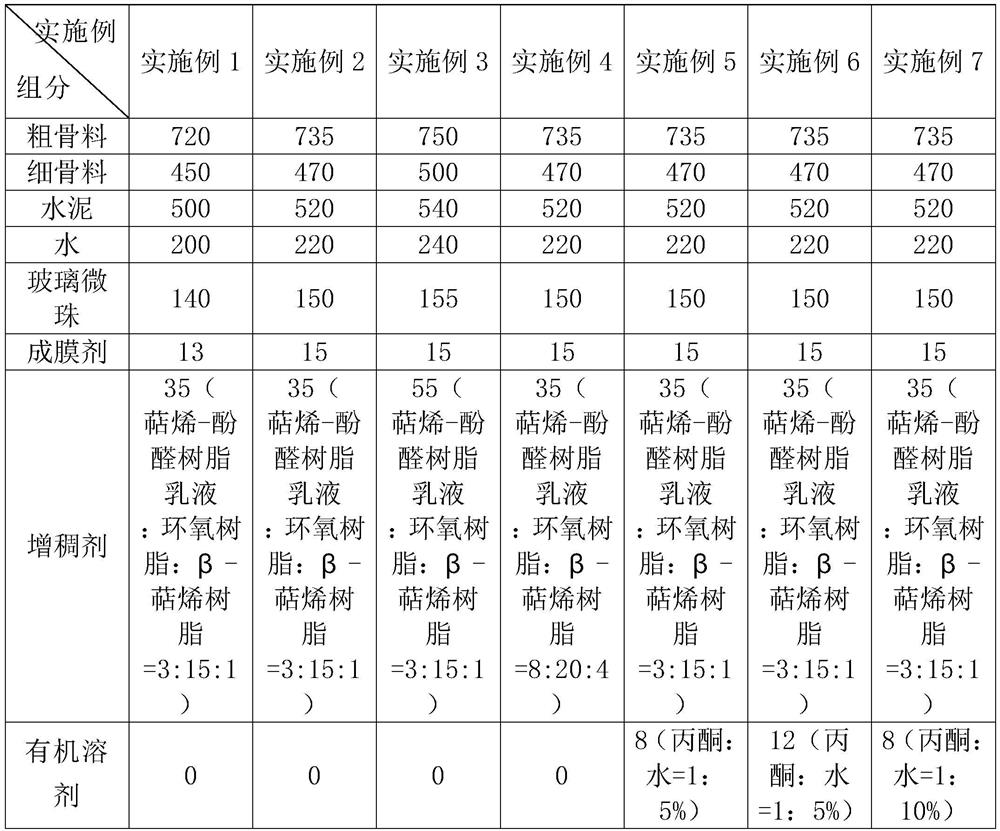

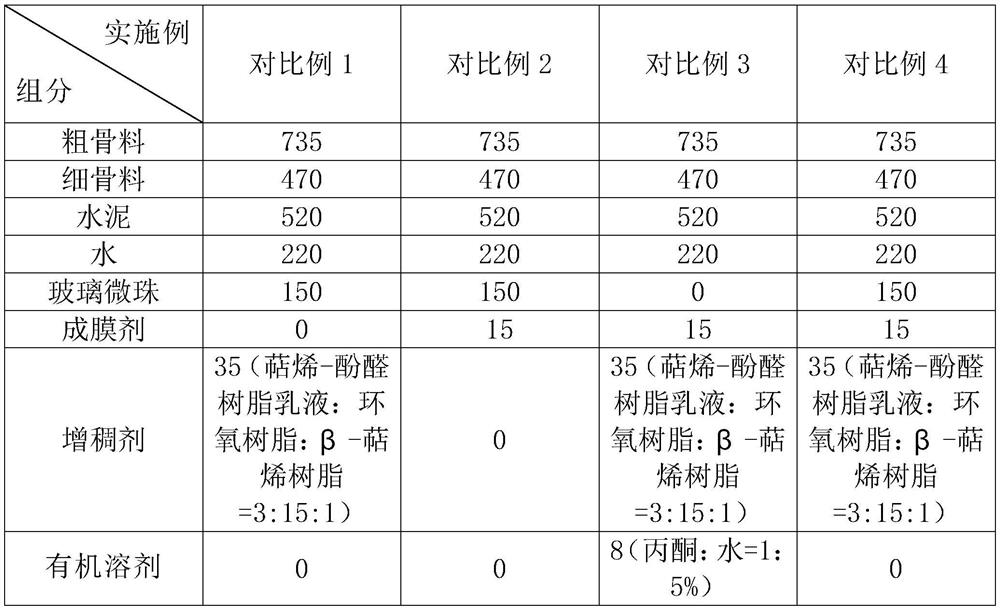

ActiveCN111960740AImprove self-compactingReduce mixing and self-compactingSelf-consolidating concreteFilm-forming agent

The invention discloses underwater self-compacting concrete and a preparation method thereof. The concrete is prepared from components in parts by weight as follows: 720-750 parts of coarse aggregate,450-500 parts of fine aggregate, 500-540 parts of cement, 200-240 parts of water, 140-155 parts of porous microspheres, 13-15 parts of a film-forming agent and 35-55 parts of a thickener, and the thickener comprises terpene-phenolic resin emulsion, epoxy resin and beta-terpene resin. The underwater self-compacting concrete and the preparation method thereof provided by the invention have the advantages that the fluidity is higher, the self-compacting effect is realized, the compactness and the strength are improved, and the underwater self-compacting concrete can be poured underwater and is not easy to disperse.

Owner:宁波新力建材科技有限公司

Production process for producing flow-state self-compacting backfill solidified soil by using solidifying material, application and equipment thereof

PendingCN114716205AReduce shippingReduce the storage areaSolid waste managementEmbankmentsPtru catalystSoil science

The invention discloses a production process, application and equipment for producing flow-state self-compacting backfill solidified soil by using a solidifying material, which comprises the following steps: taking soil, sludge and building residue soil as main solidifying materials, taking a catalyst and a solidifying agent as catalytic materials, taking tailings such as Portland cement, fly ash, phosphogypsum and lithium slag as auxiliary cementing materials, and adding a certain proportion of water, the mixture which has flowability and self-compaction performance and has certain strength and impermeability after being cured is formed, and the mixture can be widely applied to fertilizer groove backfilling, foundation reinforcement, road subgrade backfilling, mine goaf backfilling, municipal pipe gallery backfilling and wall decoration; according to different requirements of component properties of soil and strength of a finished product, the mass percent of each component material is as follows: 70-80% of soil; 5%-10% of a catalyst; 0.05% to 0.10% of a curing agent; 10%-20% of an auxiliary cementing material; the flowability and the water required by the reaction process are met. The material not only has high strength, but also has good flowability and water stability, is convenient to construct, is green and environment-friendly, and has a good application prospect.

Owner:中建三局四川建筑装备有限公司 +1

Self-compacting concrete and preparation method thereof

The invention relates to the technical field of building materials, and particularly discloses self-compacting concrete and a preparation method thereof. The self-compacting concrete is higher in flowability and stronger in compressive strength. According to the technical scheme, the self-compacting concrete is characterized in that every cubic meter of self-compacting concrete is prepared from the following components: 155 to 170 kilograms of water, 350 to 400 kilograms of cement, 700 to 800 kilograms of sand, 960 to 1,000 kilograms of stones, 160 to 200 kilograms of a mineral additive, 5 to7 kilograms of an admixture, 1 to 4 kilograms of ultrafine powder and 2 to 5 kilograms of a modifier. According to the self-compacting concrete and the preparation method thereof, the concrete is prepared by mixing each raw material according to a certain proportion, so that the concrete is endowed with a higher gap passing rate and self-compacting capability, and can freely flow to fully fill aninternal space of a structure to form a uniformly compacted structure; the ultrafine powder is added into the concrete, so that the flowability of the concrete is further improved, and meanwhile, thecompressive strength is strengthened.

Owner:南通中厦建筑工程总承包有限公司

Structural glue containing nano material

InactiveCN1216114CGood flexibilityImprove breathabilityEpoxy resin adhesivesPolymer sciencePolysulfide rubber

The structural adhesive containing nano material includes two components, the component A consists of epoxy resin, liquid polysulfide rubber, stuffing and nano SiO2, and the component B consists of modified curing agent, promoter, plasticizier, fine silica powder, fine titania powder, aluminum powder and coupling agent, with the ratio between component A and component B being 0.5-1.5 to 0.5-1.5. The liquid polysulfide rubber can increase the flexibility of the adhesive and the nano material can increase the contact area between the adhesive and adhered body and binding force, improve mechanical performance. The structural adhesive is dense, waterproof, flexible, antiaging, and has high adhering strength, shearing strength, high stability, etc.

Owner:湖南省宏尚土木工程技术有限公司 +1

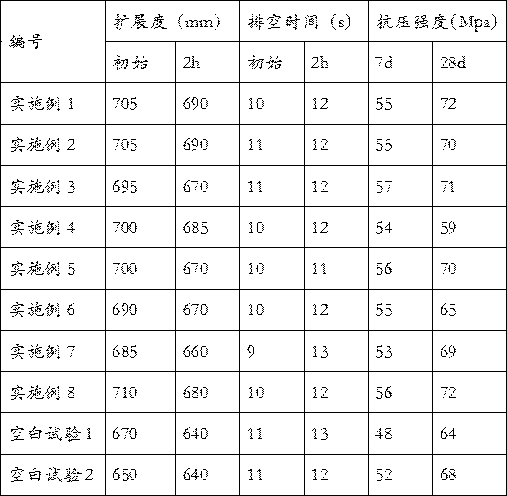

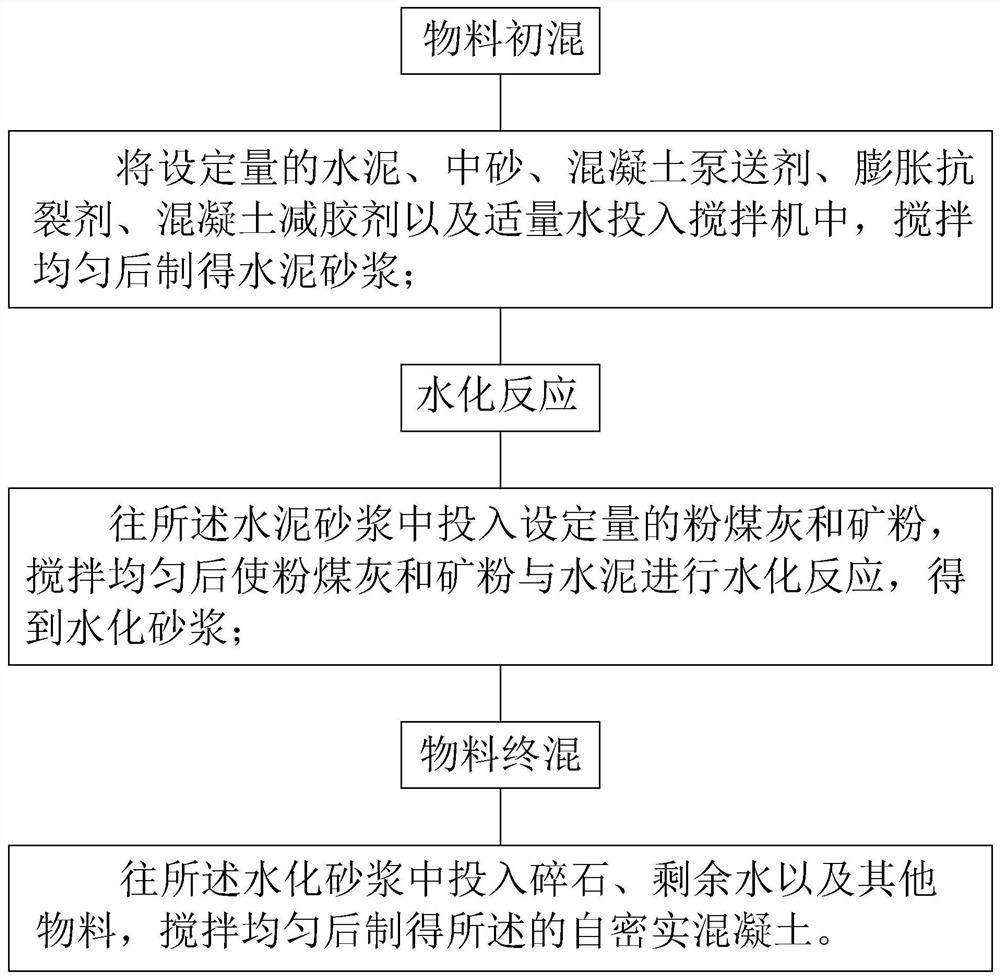

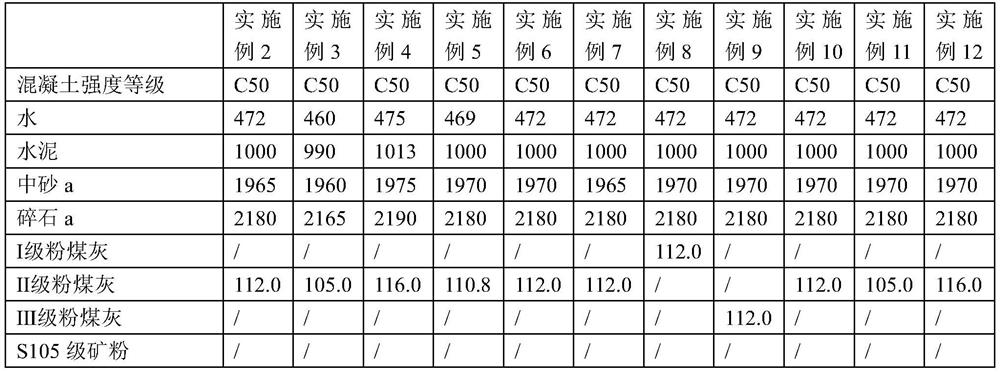

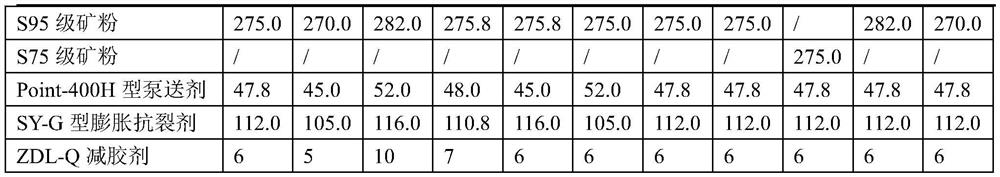

Self-compacting concrete and preparation method thereof

ActiveCN113173758AImprove self-compactingMeet impermeabilitySolid waste managementMineralogyHydration reaction

The invention relates to the technical field of concrete, in particular to self-compacting concrete and a preparation method thereof. The self-compacting concrete is prepared from the following components in parts by mass: 460 to 475 parts of water, 990 to 1013 parts of cement, 1960 to 1975 parts of medium sand, 2165 to 2190 parts of gravel, 105 to 116 parts of fly ash, 270 to 282 parts of mineral powder, 45 to 52 parts of a concrete pumping agent, 105 to 116 parts of an expansion anti-cracking agent and 5 to 10 parts of a concrete glue reducing agent, wherein the fineness modulus of the grain size of the medium sand is 2.4-2.8, and the grain size of the gravel is 5-20 mm; the concrete pumping agent is a Point-400H type pumping agent; and the expansion anti-cracking agent is an SY-G type expansion anti-cracking agent. The self-compacting concrete is prepared through primary mixing of materials, a hydration reaction and final mixing of the materials and has an excellent self-compacting effect; a preparation process is simple; and large-scale preparation of the concrete is facilitated.

Owner:宁波市镇海景联混凝土有限公司

Concrete with performance improved by using BTC (bis-trichloromethyl carbonate) functional admixture

The invention discloses concrete with performance improved by using a BTC (bis-trichloromethyl carbonate) functional admixture. The concrete comprises the following components in parts by mass: 200-320 parts of cement, 60-90 parts of mineral powder, 40-60 parts of fly ash, 680-780 parts of sand, 1060-1100 parts of broken stones, 3.3-4.74 parts of a concrete admixture, 1.92-2.58 parts of the BTC functional admixture and 170 parts of water. The BTC functional admixture can improve the cohesiveness of the concrete, reduce the bleeding and segregability of the concrete and enhance the fluidity of the concrete, so that the service life of a pump pipe is prolonged, the use of a cementing material in the concrete is reduced, the cost of the concrete is lowered, the workability of the concrete is improved, and the concrete is convenient to construct.

Owner:JIANGSU GUANGYA BUILDING MATERIAL

Multifunctional box culvert pipe gallery concrete and preparation method thereof

The invention discloses a multifunctional box culvert pipe gallery concrete and a preparation method thereof. The multifunctional box culvert pipe gallery concrete is prepared from, by weight, 20-25 parts of cement, 8-12 parts of sand, 9-18 parts of aggregate, 5-8 parts of microbeads, 8-15 parts of fly ash, 12-18 parts of zeolite, 4-6 parts of waterborne resin, 0.6-1.5 parts of an expanding agent,1-3 parts of composite fiber, 0.7-2 parts of a water reducing agent component and 12-20 parts of total water. The self-compacting and working performance of concrete can be obviously improved, meanwhile, the self-curing performance is achieved, and vertical cracking of a large-size, ultra-long and thin-wall concrete gallery body structure can be effectively reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

A kind of self-compacting powder concrete for marine engineering and its preparation method and application

ActiveCN104876500BExtensive self-compactingImprove self-compactingSolid waste managementCalcium hydroxideUltimate tensile strength

Owner:黄贺明

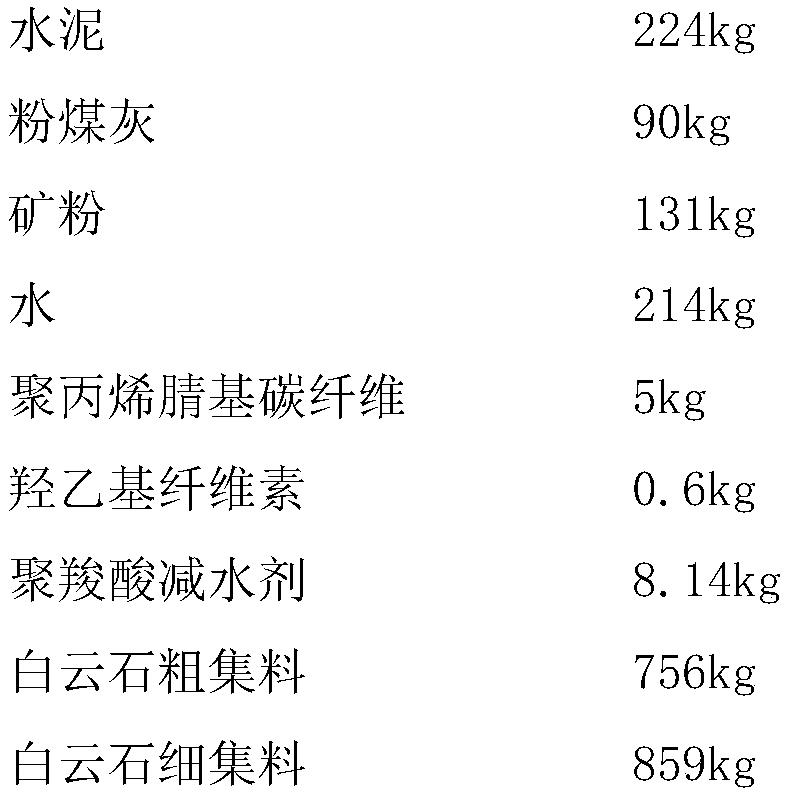

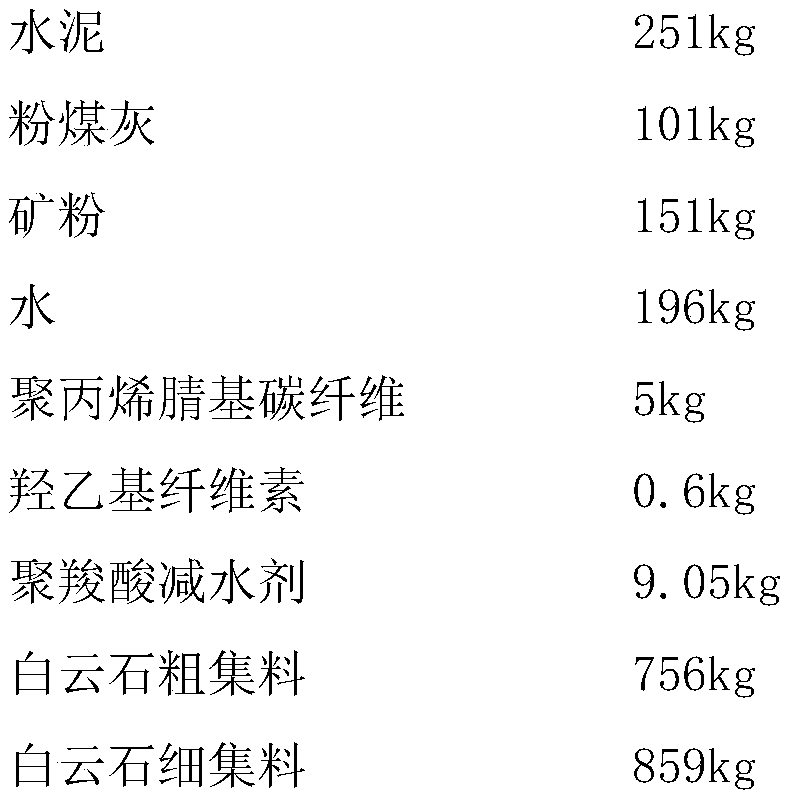

Unfired self-compacting concrete and preparation method thereof

The invention discloses a preparation method of unfired self-compacting concrete, wherein the unfired self-compacting concrete comprises the following production raw materials: cement, a mineral admixture, water, polyacrylonitrile-based carbon fibers, a water reducing agent, dolomite coarse aggregate and dolomite fine aggregate, wherein the per-square mixing amount of the dolomite coarse aggregateis 756 to 810 kg, and the per-square mixing amount of the dolomite fine aggregate is 835 to 859 kg. According to the invention, the self-compactness of the unfired concrete material is remarkably improved, and the unfired property of the material is further improved.

Owner:成都宏基建材股份有限公司

Seawater Corrosion Resistant Reinforced Concrete Pile Structure

ActiveCN105297709BAvoid corrosionImprove self-compactingProtective foundationBulkheads/pilesReinforced concreteCrack resistance

The invention discloses a reinforced concrete pile structure resistant to seawater corrosion. The middle part of the pile body of the reinforced concrete pile structure is provided with a tunnel that does not penetrate the bottom of the pile body, and the tunnel is filled with seawater incompatible and Have a steady source of fluid. The seawater corrosion-resistant reinforced concrete pile structure of the present invention has strong operability compared with the existing reinforced concrete pile structure by improving the self-compacting property and high crack resistance of reinforced concrete, and the pouring technology of reinforced concrete is compared with the existing self-compacting The pouring technology of reinforced concrete is more mature and reliable. And can significantly reduce the process, only need to reserve holes when pouring reinforced concrete, can also reduce the cost of the project, and can effectively prevent seawater from corroding the reinforced concrete pile structure, and is easy to operate.

Owner:GUANGXI UNIV

A kind of sea sand powder concrete

ActiveCN105084837BEasy to fillImprove mechanical propertiesSolid waste managementFiberCopper plating

The invention relates to sea sand powder concrete. The sea sand powder concrete comprises, by weight, 450-750 parts of cement, 250-450 parts of active mineral admixture, 50-150 parts of inert admixture, 850-1400 parts of sea sand, 24-32 parts of high efficiency slushing agents, 145-220 parts of seawater, 2-4 parts of organic fiber and 78-250 parts of copper-bearing steel fiber with the thickness ranging from 0.08 mm to 0.35 mm. According to the sea sand powder concrete, a compact stacking structure principle is adopted, the interior of the concrete is almost seamless in communication channel through optimization of particle size gradation, and a channel of internal ion medium migration is further eliminated through secondary hydration of the active mineral additive, so that the powder concrete obtained by stirring the raw materials through the seawater and the sea sand is ultra-high performance concrete with high durability, corrosion resistance and high mechanic property.

Owner:黄贺明

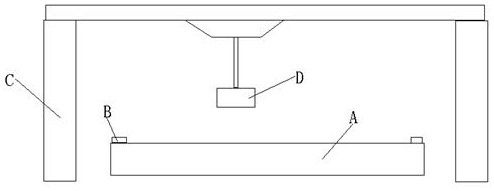

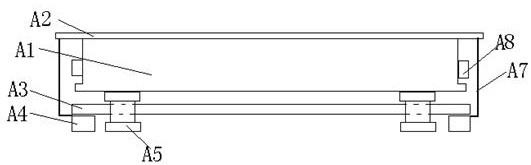

A high-efficiency production line system and production process for laminated panels

ActiveCN110181654BIncrease profitSmall footprintCeramic shaping plantsProcess engineeringManufacturing line

The invention relates to an efficient laminated plate production line system and a production process. The production system is characterized by comprising a plurality of fixed mold tables arranged onthe ground, positioning clamps arranged on the fixed mold tables, and movable distribution devices erected on the two sides of the fixed mold tables, wherein a distribution hopper is hung on each movable distribution device, and the movable distribution devices are used for completing distribution operation. The production process comprises the following steps: 1, preparing of concrete; 2, pouring of the concrete; 3, primary lamination; 4, surface layer treatment; 5, secondary lamination; and 6, demolding and hoisting. According to the laminated plate production line system, the utilization rate of the mold tables is greatly improved, and the occupied area is small. The concrete can reach the demolding condition within 12 hours without need for adopting steam curing.

Owner:烟台红旗瑞弘建材有限公司

Ultra-dense concrete polycarboxylate water reducer for nuclear power and preparation method thereof

The invention relates to an ultra-dense concrete polycarboxylate water reducer for nuclear power and a preparation method thereof. The water reducer includes the following components and parts by weight per 100 parts: 50-55 parts of dispersed ether polycarboxylate water reducer, Slump-preserving ether polycarboxylate superplasticizer 20-25 parts, retarder 3-5 parts, defoamer 0.01-0.05 parts, water-retaining agent 1-3 parts, shrinkage reducing agent 1-2 parts, preservative 0.1- 0.3 parts, water is the balance; during preparation, the components can be mixed uniformly by weight. Compared with the prior art, the water reducing agent of the present invention has the functions of improving the workability of concrete, increasing the fluidity, reducing the peak temperature of concrete, reducing the shrinkage value of concrete, reducing the internal porosity of concrete, improving the self-compacting property of concrete, improving the durability of concrete, etc. The invention has the advantages of simple preparation method, wide source of raw materials, low cost, environmental protection and good application prospect.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com