Repeating blasthole sealing gun and use method thereof

A blasting hole and blocking gun technology, which is applied in blasting and other directions, can solve problems such as coal dust and gas explosions, affecting blasting effects, and damage to detonating equipment, achieving rapid shallow hole plugging, convenient gas source introduction, and improving construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

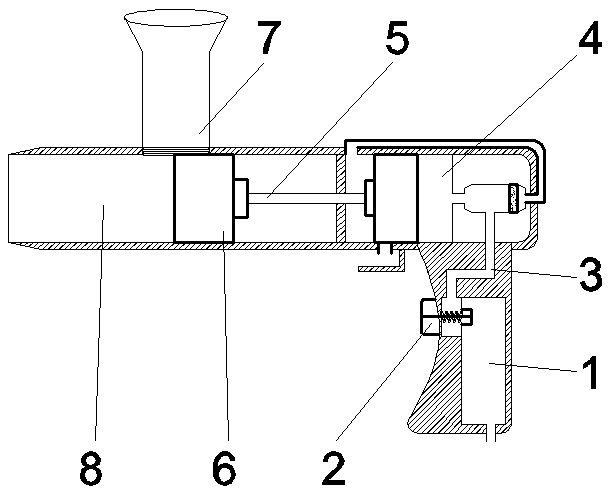

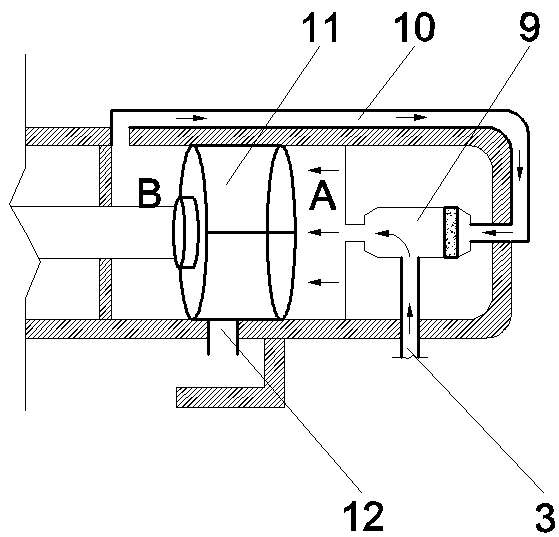

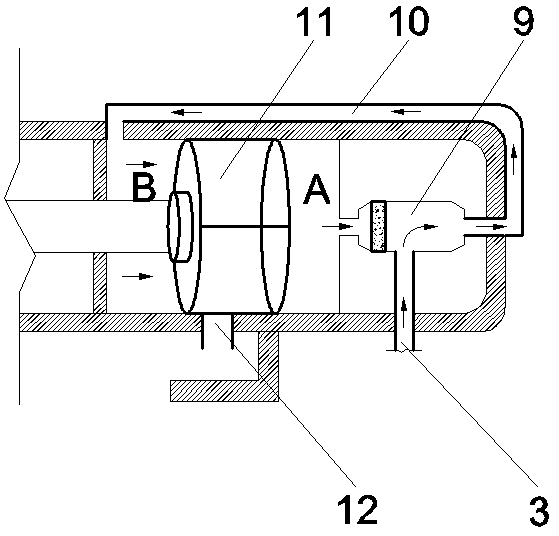

[0025] The invention relates to a continuous-firing gun hole sealing gun, which is composed of an air supply handle, a firing gun chamber and a feed bin.

[0026] The air supply handle mainly includes an air storage chamber 1, an air valve switch assembly 2, and an air delivery channel 3. The air inlet at the lower end of the air storage room 1 can be connected to a high-pressure air pipe, and the upper end of the side part is connected to the air delivery channel 3. The gas valve switch 2 is placed at the connection; the gas valve switch assembly 2 is composed of a switch button, a connecting spring, and a sealing ring. The switch button, the sealing ring is reset under the tension of the connecting spring, and the sealing ring is made of elastic plastic material; the other end of the gas transmission channel 3 is connected to the cylinder assembly 4 of the firing gun bore.

[0027] The firing gun chamber is mainly composed of a cylinder assembly 4, a piston rod 5, and a stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com