Construction method of gunite concrete

A construction method and concrete technology, applied in the direction of basic structure engineering, architecture, building construction, etc., can solve the problems of expanding equipment, increasing power, increasing mixing time, etc., to improve surface bonding strength, increase mechanical bite force, simplify The effect of the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

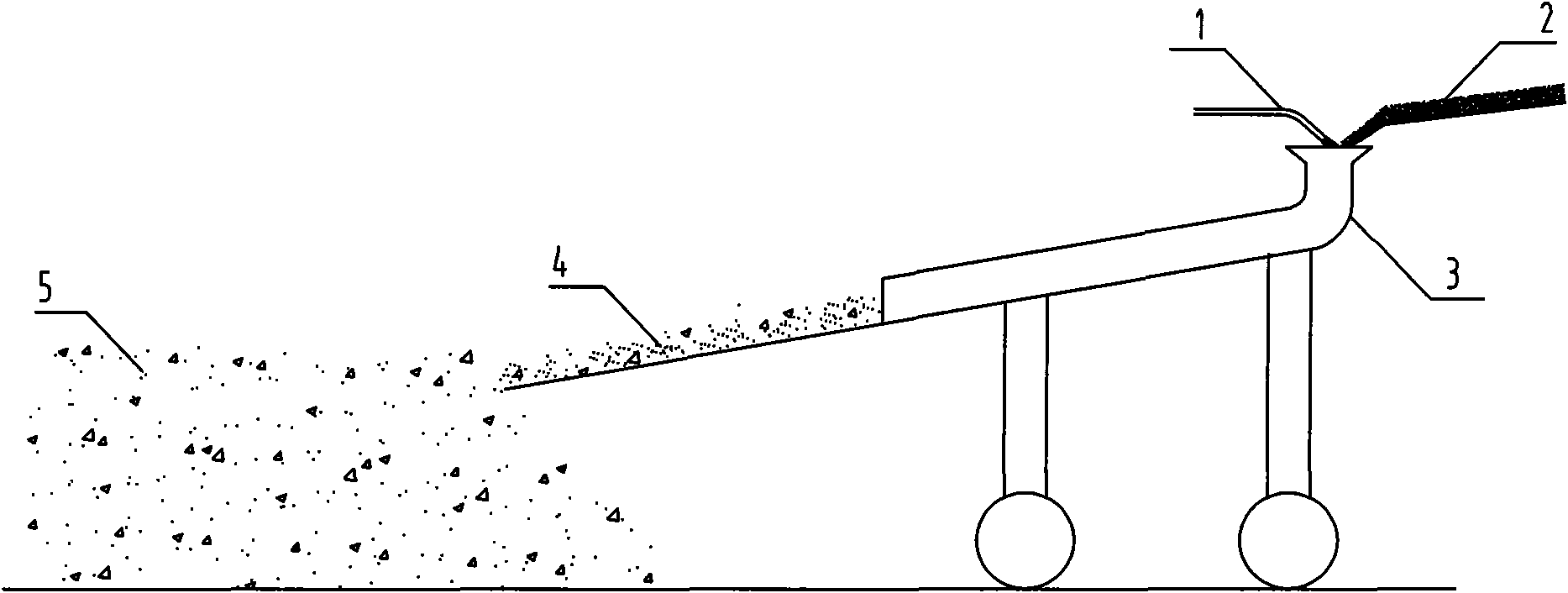

[0028] Example 1: Construction method for pouring shotcrete in foundation pit of large-scale concrete engineering

[0029] For large-scale concrete engineering foundation pit pouring, a conventional high-speed mixing slurry making device can be installed near the foundation pit according to the site, and the water-cement ratio of the prepared slurry should be the concrete water-cement ratio required by the design. The pulping device can provide cement mixed slurry with fly ash, if MgO is required 2 expansion agent, the pulping unit can provide mixed with MgO 2 The high-speed mixer commonly used in pulping equipment, its speed is greater than 1200r / min, and the mixing time is 30s to 50s. The qualified cement slurry is transported to the delivery device in the concrete pouring area through the delivery pipe by the slurry delivery pump. 2 spare. Sand and gravel aggregates can be conveyed by conveyor troughs or conveyor belts. When using two-stage aggregates, the sand and grave...

Embodiment 2

[0030] Embodiment 2: Adopting the construction method of shotcrete gravity dam

[0031] The shotcrete gravity dam is used for construction, and the maximum particle size can be up to 30cm, reducing the amount of cement to reduce the temperature rise of the heat of hydration. It is convenient to use cold water slurrying and aggregate pre-cooling, effectively reducing the storage temperature, and concrete pouring The process effectively prevents the separation of large aggregates. On the construction site, pipeline transportation and mixture delivery devices are used instead of trucks to transport concrete, and simple conventional high-speed mixing and slurrying devices and mixing conveyors 3 are used to replace expensive concrete mixing plants. The construction period can be shortened by 1 / 3 of the time.

Embodiment 3

[0032] Example 3: Construction method of shotcrete in dikes and dams

[0033] In order to reduce the section of the embankment and enhance the anti-scouring or anti-seepage ability, the natural mixture can be selected, and the conveying device 2 is used to spray the grout with the slurry conveying device 1 and then simply mixed and conveyed with the mixing conveyor 3, and rolled to form cement sand and gravel aggregate stone structure. Maximize the use of local materials, save investment, and be durable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com