Machine-made sand concrete and preparation process thereof

A technology for machine-made sand and concrete, applied in the field of concrete production, can solve the problems affecting the workability of concrete, limited quantity, etc., and achieve the effects of improving fluidity, slump retention, water retention, and excellent dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

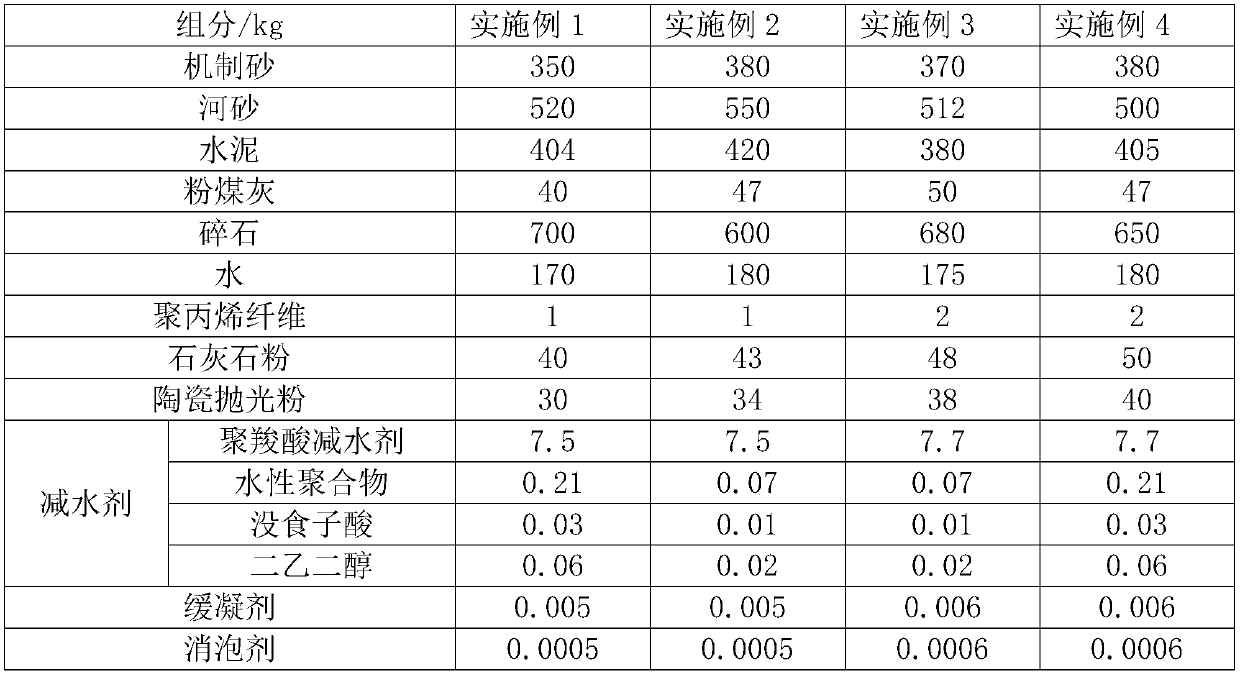

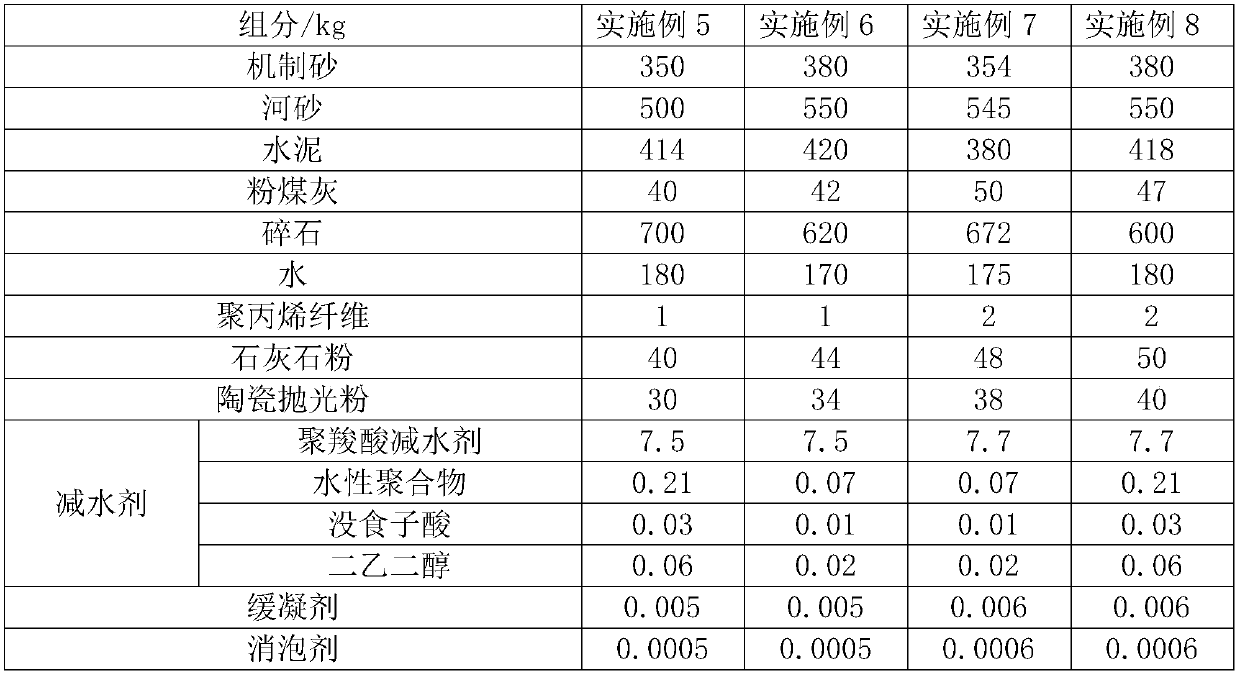

Embodiment 1

[0039] Machine-made sand concrete includes the following components: 350kg machine-made sand, 520kg river sand, 404kg cement, 40kg fly ash, 700kg gravel, 170kg water, 1kg polypropylene fiber, 40kg limestone powder, 30kg ceramic polishing powder, 7.8kg water reducer , 0.005kg retarder and 0.005kg defoamer;

[0040] The water reducer includes 7.5kg polycarboxylate water reducer, 0.21kg water-based polymer, 0.03kg gallic acid, and 0.06kg diethylene glycol.

[0041] Among them, the fly ash is selected from the fly ash modified by dolomite. The specific modification treatment steps include mixing dolomite, silica and fly ash in a weight ratio of 1:1:7, adding water and stirring evenly, so that dolomite and silica are coated on the surface of fly ash particles, and then Calcined at 920°C, kept for 1 hour, then quenched.

[0042] The production process of waterborne polymers includes:

[0043] (1) Dissolve 4 parts of hydrogen peroxide and 8 parts of water completely to obtain the ...

Embodiment 2

[0053] Machine-made sand concrete includes the following components: 380kg machine-made sand, 550kg river sand, 420kg cement, 47kg fly ash, 600kg gravel, 180kg water, 1kg polypropylene fiber, 43kg limestone powder, 34kg ceramic polishing powder, 7.6kg water reducer , 0.005kg retarder and 0.005kg defoamer;

[0054] The water reducer includes 7.5kg polycarboxylate water reducer, 0.07kg water-based polymer, 0.01kg gallic acid, and 0.02kg diethylene glycol.

[0055] Among them, the fly ash is selected from the fly ash modified by dolomite. The specific modification treatment steps include mixing dolomite, silica and fly ash in a weight ratio of 1:1:7, adding water and stirring evenly, so that dolomite and silica are coated on the surface of fly ash particles, and then Calcination at 930°C, heat preservation for 1 hour, then quenching.

[0056] The production process of waterborne polymers includes:

[0057] (1) Dissolve 5 parts of hydrogen peroxide and 8 parts of water complete...

Embodiment 3

[0067] Machine-made sand concrete includes the following components: 370kg machine-made sand, 512kg river sand, 380kg cement, 50kg fly ash, 680kg gravel, 175kg water, 2kg polypropylene fiber, 48kg limestone powder, 38kg ceramic polishing powder, 7.8kg water reducer , 0.006kg retarder and 0.0006kg defoamer;

[0068] The water reducer includes 7.7kg polycarboxylate water reducer, 0.07kg water-based polymer, 0.01kg gallic acid, and 0.02kg diethylene glycol.

[0069] Among them, the fly ash is selected from the fly ash modified by dolomite. The specific modification treatment steps include mixing dolomite, silicon dioxide and fly ash in a weight ratio of 1:1:8, adding water and stirring evenly, so that dolomite and silicon dioxide are coated on the surface of fly ash particles, and then Calcined at 940°C, kept for 1 hour, then quenched.

[0070] The production process of waterborne polymers includes:

[0071] (1) Dissolve 6 parts of hydrogen peroxide and 8 parts of water comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com