Recycled self-compacting concrete and preparation method thereof

A technology of self-compacting concrete and recycled materials, applied in the field of concrete, can solve the problems of environmental secondary pollution, occupation of land resources, waste of natural resources, etc., and achieve the effects of protecting the living environment, solving environmental impacts, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

[0042] In the following preparation example, the polypropylene fiber is selected from the polypropylene fiber whose article number is JBX04 sold by Hebei Shenpeng Chemical Co., Ltd., and the epoxy resin is selected from the E-20 epoxy resin sold by Shenzhen Yoshida Chemical Co., Ltd., and the polyacrylamide is selected from Renqiu Shuoda Chemical Co., Ltd. sells polyacrylamide model SD-1200.

preparation example 1

[0043] Preparation Example 1: Heat 5kg of epoxy resin to 140°C, add 10kg of construction waste and 10kg of steel slag powder, mix thoroughly, place in an environment of 40°C for drying, and pulverize into powder, mix the powder with 20kg of iron tailings, 10kg of hollow Mix glass microspheres and 2kg polypropylene fiber evenly, add to 10kg polyacrylamide emulsion, stir evenly, and dry at 45°C; the particle size of iron tailings is 5mm, and the bulk density is 1500kg / m 3 , the apparent density is 2500kg / m 3 , the steel slag powder has an apparent density of 450m after iron removal, crushing, ball milling, and screening 2 / kg steel slag powder, polyacrylamide emulsion is made by mixing polyacrylamide and water with a mass ratio of 1:30, the particle size of hollow glass microspheres is 15μm, and the density is 0.1g / cm 3 , The average particle size of construction waste ≤ 2mm.

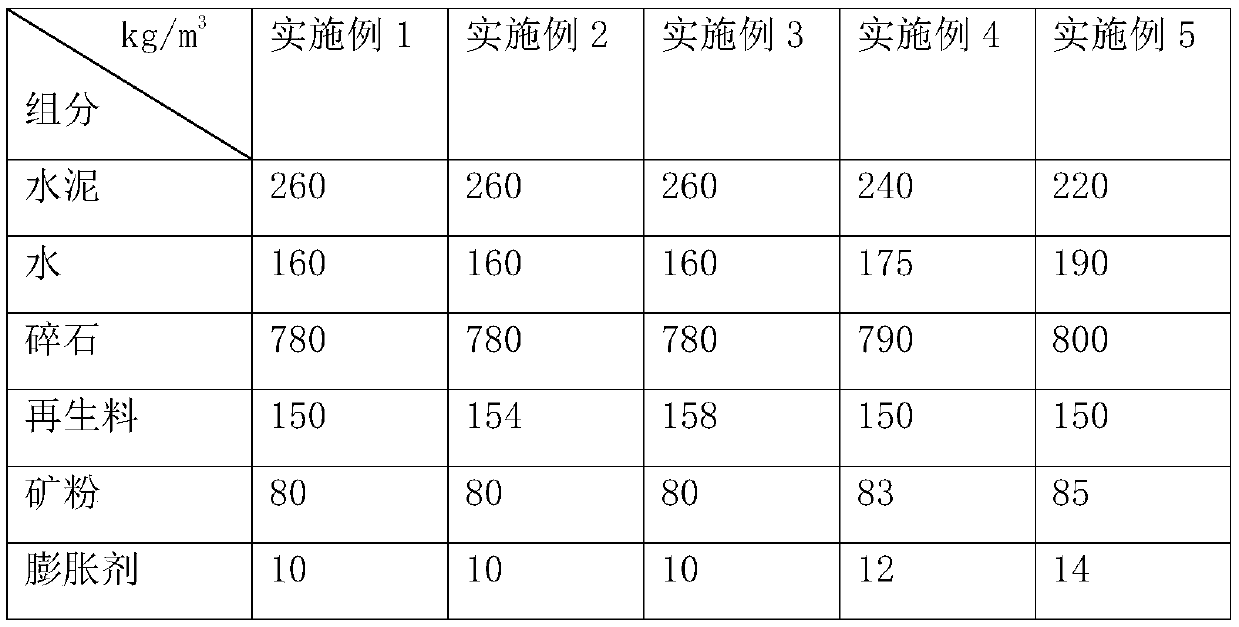

[0044] The raw material ratio of recycled material in table 1 preparation example 1-3

[0045]

preparation example 2

[0046] Preparation Example 2: According to the ratio in Table 1, heat 8kg of epoxy resin to 145°C, add 15kg of construction waste and 13kg of steel slag powder, mix thoroughly, place in an environment of 5°C for drying, and pulverize into powder, and mix the powder with 30kg of iron tailings, 13kg of hollow glass microspheres, and 4kg of polypropylene fibers were mixed evenly, added to 13kg of polyacrylamide emulsion, stirred evenly, and dried at 48°C; the particle size of the iron tailings was 8mm, and the bulk density was 1650kg / m 3 , the apparent density is 2800kg / m 3 , the steel slag powder has an apparent density of 500m after iron removal, crushing, ball milling, and screening 2 / kg steel slag powder, polyacrylamide emulsion is made by mixing polyacrylamide and water with a mass ratio of 1:40, the particle size of hollow glass microspheres is 23μm, and the density is 0.1g / cm 3 , The average particle size of construction waste ≤ 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com