Pellet type blast hole plugging gun and use method

A blasthole and projectile technology, applied in the field of projectile type blasthole plugging guns, can solve the problems of substandard compactness, time-consuming and laborious manual filling, delaying construction progress, etc. The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

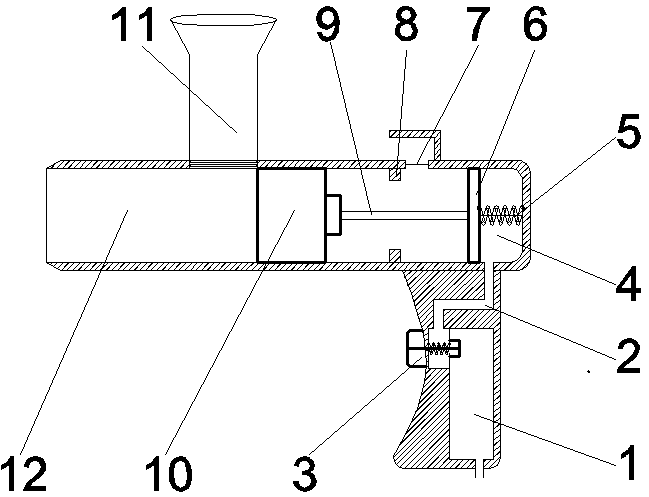

[0023] The invention relates to a bullet-type gun hole plugging gun, which is composed of an air supply handle, a launching gun bore and a feed bin.

[0024] The air supply handle mainly includes an air storage chamber 1, an air transmission hole 2, and an air valve switch assembly 3. The air inlet at the lower end of the air storage chamber 1 can be connected to a high-pressure air pipe, and the opening on the left end is connected to the air transmission hole 2. The gas valve switch 3 is installed; the gas valve switch assembly 3 is composed of a switch button, a connecting spring, and a sealing ring, and the sealing ring is made of elastic plastic material; the other end of the gas transmission channel 2 is connected to the firing gun chamber.

[0025] The launch chamber mainly includes a cylinder system 4, a piston rod 9, and a striker plate 10. In the cylinder system 4, a piston stopper 8 is arranged at the left end, and an exhaust hole 7 is arranged at the upper end near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com