Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

653results about How to "Reduce heat of hydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

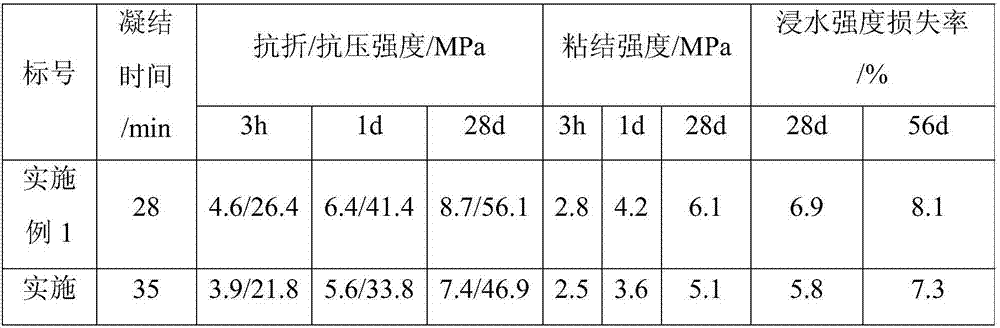

Phosphate cement based patching material and preparation method thereof

The invention relates to a phosphate cement based patching material and a preparation method thereof. The patching material is prepared from the following ingredients in parts by weight: 100 parts of magnesium phosphate cement, 20 to 40 parts of mineral admixtures, 120 to 140 parts of fine aggregates, 0.5 to 1 part of water glass, 0.5 to 1 part of fiber and 20 to 30 parts of water. The preparation method is characterized in that the raw materials are proportionally weighed; magnesium oxide, monopotassium phosphate and composite retarders are firstly stirred and mixed; then, the magnesium phosphate cement is obtained; then, the mineral admixtures and the fine aggregates are added; after uniform stirring, the water glass, the fiber and the water are added; stirring is performed for 3 to 4 minutes by a stirring machine; the phosphate cement based patching material is obtained. The prepared phosphate cement based patching material by the invention has the advantages that the coagulation time is about 30 minutes; the restoration time is short; the construction is not influenced; the restoration effect is obvious; the application requirement of fast patching the damaged road surface is met; the phosphate cement based patching material is applicable to fast restoration projects of cement concrete pavements.

Owner:WUHAN UNIV OF TECH

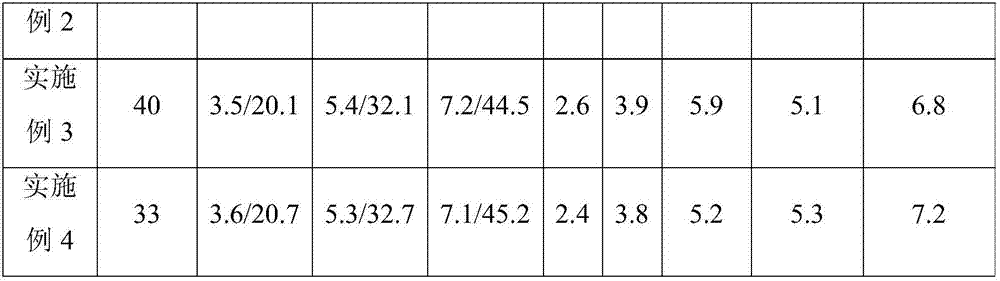

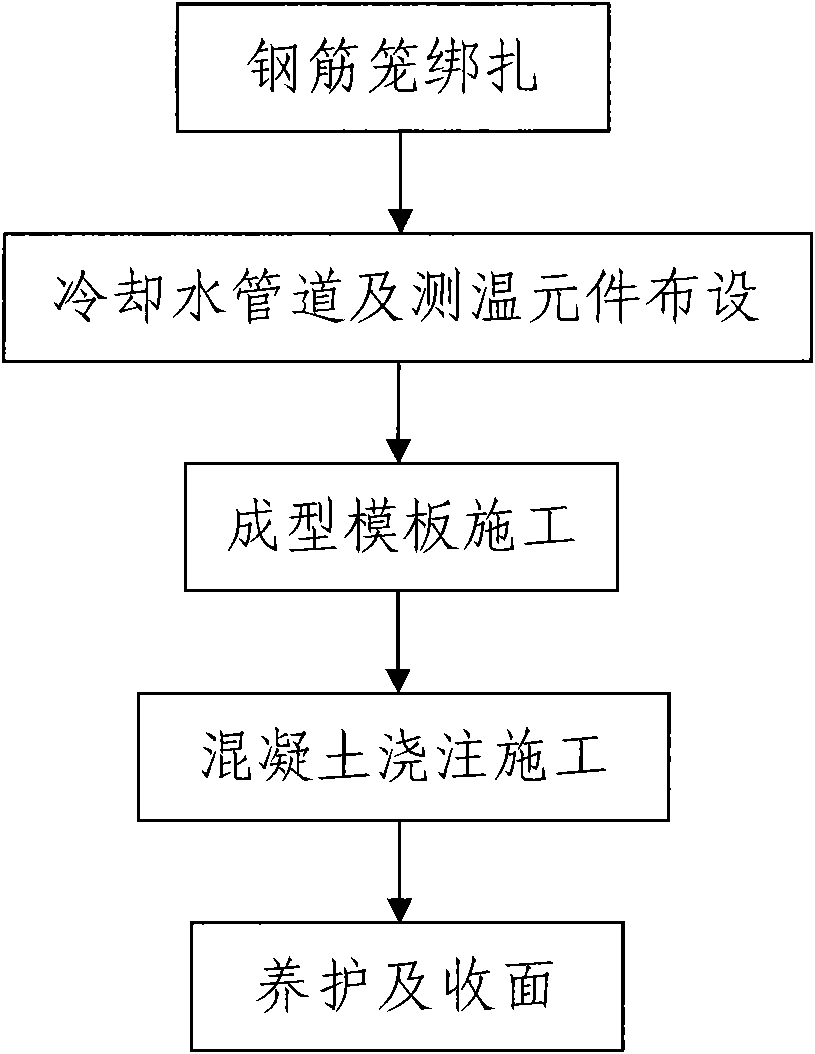

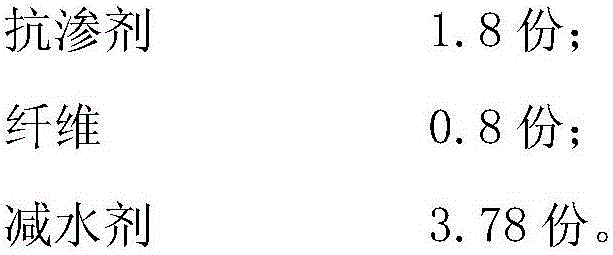

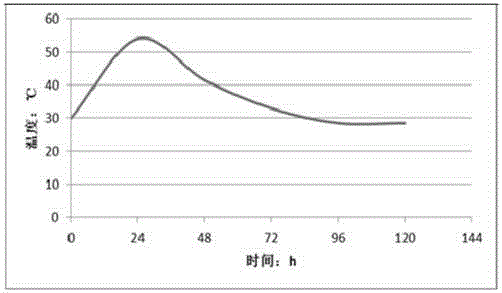

Construction method of large-volume concrete bearing platform with one-time pouring in winter

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and the surface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

Ready-mixed concrete with phosphorus slag powder

InactiveCN101798207AImprove impermeabilityReduce heat of hydrationSolid waste managementSolid waste disposalTensile strainReady mixed concrete

The invention relates to a ready-mixed concrete with phosphorus slag powder, which is characterized in that the composition ratio and the weight ratio comprise the following parts: 120-150 parts of cement, 100-250 parts of phosphorus slag powder, 0-120 part(s) of fly ash, 0.5-20 part(s) of water reducing agent, 0-0.5 part of air entraining agent, 0-0.02 part of water retention agent, 50-17000 parts of coarse aggregate, 20-9000 parts of fine aggregate and 100-300 parts of water. The invention takes the industrial waste residue i.e. the phosphorus slag powder as the admixture part of the concrete to replace the cement to dope in the ready-mixed concrete, thereby reducing the use amount of the cement, uses the retarding characteristic of the phosphorus slag to reduce the gelled material cost of the concrete and the manufacture cost the of concrete pumping aid, simultaneously gives full play to the characteristic of the phosphorus slag so as to reduce the hydration heat and the adiabatic temperature rise of the concrete, decreases the elasticity modulus and improves the ultimate tensile strain capacity of the concrete, the strength growth rate is high, and the durability is significantly improved; and the invention can changes the waste into the valuable and turns the harmful into the beneficial.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Sea sand powder concrete

ActiveCN105084837AEasy to fillImprove mechanical propertiesSolid waste managementFiberCopper plating

The invention relates to sea sand powder concrete. The sea sand powder concrete comprises, by weight, 450-750 parts of cement, 250-450 parts of active mineral admixture, 50-150 parts of inert admixture, 850-1400 parts of sea sand, 24-32 parts of high efficiency slushing agents, 145-220 parts of seawater, 2-4 parts of organic fiber and 78-250 parts of copper-bearing steel fiber with the thickness ranging from 0.08 mm to 0.35 mm. According to the sea sand powder concrete, a compact stacking structure principle is adopted, the interior of the concrete is almost seamless in communication channel through optimization of particle size gradation, and a channel of internal ion medium migration is further eliminated through secondary hydration of the active mineral additive, so that the powder concrete obtained by stirring the raw materials through the seawater and the sea sand is ultra-high performance concrete with high durability, corrosion resistance and high mechanic property.

Owner:黄贺明

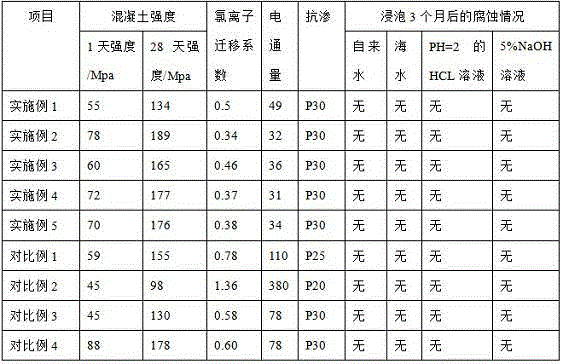

Concrete with ultra-large volume, high strength and low hydration heat

The invention relates to concrete with ultra-large volume, high strength and low hydration heat. The concrete comprises the following components in parts by weight (cube dosage kg / m3): 200-260 parts of cement, 100-160 parts of mineral powder, 80-100 parts of fly ash, 740-800 parts of fine aggregate, 1010-1050 parts of coarse aggregate, 4.0-5.0 parts of additive and 155-165 parts of water. The concrete with ultra-large volume, high strength and low hydration heat can be used to effectively reduce the hydration heat, greatly reduce the cracking risk of the large-volume concrete from the source and increase the engineering quality.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +5

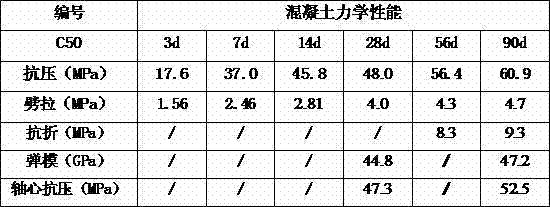

High early strength and high corrosion resistant Portland cement and preparation method thereof

ActiveCN106082724AReduce tricalcium contentExtended service lifeClinker productionMass ratioPortland cement

Belonging to the field of cement production and also relating to the field of building materials, the invention provides a high early strength and high corrosion resistant Portland cement and a preparation method thereof. The high early strength and high corrosion resistant Portland cement is mainly applied to engineering projects in complex marine environments and the west harsh environments. The high early strength and high corrosion resistant Portland cement is characterized by containing, by weight percentage, 60%-90% of a high iron and low calcium cement clinker mineral component, 2%-10% of an auxiliary functional component, 5%-25% of an auxiliary cementitious component, and 3%-7% of industrial gypsum. The high iron and low calcium cement clinker mineral component is mainly prepared from high iron and low calcium Portland cement clinker and high iron and low calcium Q phase cement clinker in a mass ratio of 5-15:1. The cement not only has strong seawater erosion resistance and high early strength, but also has the characteristics of low shrinkage and low hydration heat.

Owner:WUHAN UNIV OF TECH

Compounding process of concrete hydration reducer

InactiveCN1810703AReduce heat of hydrationAdiabatic temperature rise is beneficialSolid phasesChemistry

The concrete hydration heat reducer is compounded with one kind of material selected from starch grafted polyacrylate, hydroxyl acetic acid-lactic acid copolymer, modified starch, polymethylamide, polymethyl formacrylate, polyalkyl acrylonitrile and ethyl cellulose, and through dissolving in water, reaction at 5-55 deg.c, water phase-solid phase separation after reaction to obtain the solid phase concrete hydration heat reducer. The material has molar ratio to water of 1 to 1-50. The product can reduce hydration heat of cement obviously, reduce the early adiabatic temperature raise of concrete, reduce temperature raise rate to lag the peak temperature time by about 6 days, make the concrete possess excellent heat stability, less initial stage temperature stress and less cracks.

Owner:CCCC SECOND HARBOR ENG +1

Preparation method of low-hydration-heat polycarboxylate water reducing agent

The invention discloses a preparation method of a low-hydration-heat polycarboxylate water reducing agent. Unsaturated carboxylic acid or unsaturated carboxylic acid anhydride performs acidylation andesterification with alcohol amine and a compound A to simultaneously prepare unsaturated monomers with acidamide groups, unsaturated monomers with amino groups and unsaturated monomers with benzene rings and phosphate groups; then, co-polymerization is performed by excessive unsaturated carboxylic acid or unsaturated carboxylic acid anhydride, unsaturated sulphonate and polyether big monomers during acidylation and esterification; acylamide groups, amino groups, phosphate groups, carboxylate groups, sulphonate groups, polyether lateral chains and benzene rings are introduced into molecular structures, so that the product has a high initial water reducing rate. The molecular structures of the water reducing agent prepared by the preparation method comprise ester groups, phenyls and phosphate groups; the ester groups hydrolyze under the basic condition of the concrete; carboxyls with the water reducing function and hydroxy phenyl phosphate groups with the hydration heat reducing function are gradually released; the concrete hydration heat can be effectively reduced.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Self-compacting powder concrete for ocean engineering as well as preparation method and application

ActiveCN104876500AExtensive self-compactingImprove self-compactingSolid waste managementCalcium hydroxideUltimate tensile strength

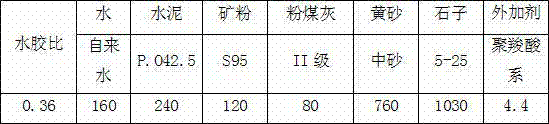

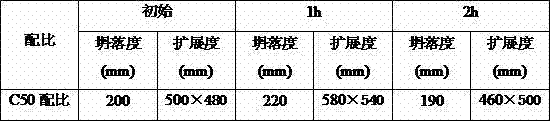

The invention discloses self-compacting powder concrete for ocean engineering as well as preparation method and an application. According to the concrete, coal ash and limestone flour are simultaneously added, the precipitation amount of calcium hydroxide is reduced, and the problem in the prior art that the concrete is poor in corrosion resistance can be solved; moreover, the concrete is doped with nano-scale calcium carbonate and silica fume, so that the self-compacting property of the concrete structure is improved. The comprehensive cost of the concrete is low, the material source is wide, and a great amount of industrial wastes can be doped; the seawater corrosion resistance is good, the self-compacting property is good, the expandability is high, hydration heat is low, the adjusting range of the working expandability is large, the early strength is high, the strength of the concrete is greater than 50Mpa at the first day and greater than 130Mpa at the 28th day, and the self-compacting powder concrete is suitable for different types of ocean engineering.

Owner:黄贺明

Retarding superplasticizer composition for roller compacted concrete

InactiveCN102659342AVC value loses quicklyVC value loss is smallRoller-compacted concreteSuperplasticizer

The invention relates to a retarding superplasticizer composition for roller compacted concrete, which is prepared from 40-80 percent of barium-containing naphthalene based superplasticizer, 10-30 percent of modified lignosulfonate, 3-7 percent of plastic retaining agent, 5-15 percent of composite retarder, 1-7 percent of layer silicate mineral material, 0.1-0.5 percent of polysiloxane and 0.1-0.2 percent of air entraining agent. The retarding superplasticizer composition does not contain alkali harmful to alkali-aggregate reaction, has a better inhibition effect to the alkali-aggregate reaction, and has the advantages of high water reducing rate, strong VC value retaining capacity, good water retaining property, small bleeding rate, remarkable retarding effect and the like, so that the prepared roller compacted concrete mixture has the characteristics of good workability, small VC value loss, small bleeding rate, long setting time, greatly reduced early hydration heat and delayed occurrence time of a hydration heat peak, so as to have better construction property, mechanical property and durability.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

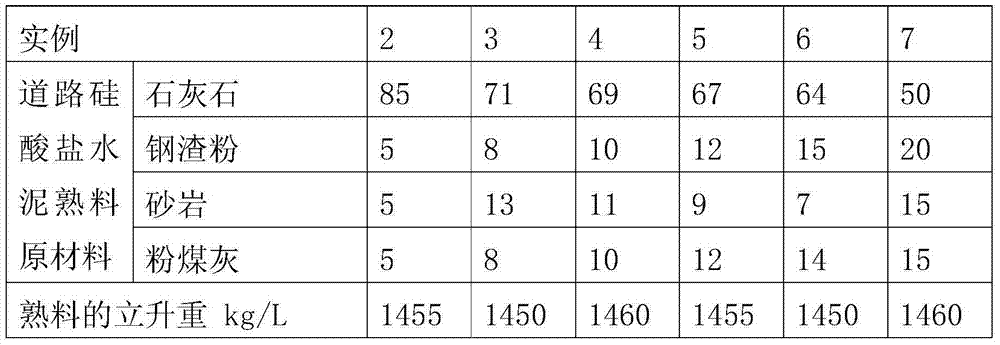

Road silicate cement clinker and preparation method thereof

InactiveCN104496228AImprove flexural performanceImprove wear resistanceCement productionHigh fractureShrinkage rate

The invention relates to road silicate cement clinker and a preparation method thereof. The preparation method for the road silicate cement clinker comprises the following steps: grinding and roasting a cement raw material, wherein the cement raw material consists of the following substances in parts by weight: 50-85 parts of lime stones, 5-20 parts of steel slag powder, 5-15 parts of sandstones and 5-15 parts of coal ash. The preparation method can be used for recycling the steel slag, grinding the steel slag into powder after drying, and adopting the prepared steel slag powder as a cement production raw material to prepare road silicate cement clinker with low heat and high fracture resistance, so that the sintering quality of the clinker can be effectively improved after the steel slag powder is added. On the basis of meeting the technical requirements specified in the road silicate cement national standards, the road silicate cement clinker can be used for improving the fracture resistance and wear resistance of the cement, and lowering the hydration heat evolution and the dry shrinkage rate.

Owner:CHINA BUILDING MATERIALS ACAD

Phosphorous slag activation modifier

InactiveCN1457937ALow costImprove grinding effectSolid waste managementSolid waste disposalPhosphorous acidNitrate

The phosphorous slag activating modifier is precipitant comprising one or several kinds of oxide, hydroxide, chloride and nitrate of Ca, Mg and Ba, and prepared through crushing. It is added into phosphorous slag to convert the slowly coagulating components in phosphorous slag into insoluble precipitate as stuffing component. The present invention makes it possible to utilize phosphorous slag to produce high-quality and low-cost cement and other building material.

Owner:尹小林

Low-dosage steel fiber modified powder concrete

The invention discloses low-dosage steel fiber modified powder concrete which comprises the following raw materials in parts by weight: 600-1000 parts of cement, 150-300 parts of active mineral admixture, 60-100 parts of inert admixture, 900-1300 parts of sand, 26-35 parts of a water reducing agent, 135-160 parts of water, 30-100 parts of extra-fine steel fibers and 7-12 parts of a corrosion inhibitor. According to the low-dosage steel fiber modified powder concrete, provided by the technical scheme of the invention, the extra-fine steel fibers with the diameters being smaller than 0.13 mm and the lengths being 6-12 mm are adopted for replacing common steel fibers, therefore on the one hand, the mechanical property of the concrete is improved, on the other hand, the additive amount of steel fibers in the concrete is further reduced, and the production cost of the low-dosage steel fiber modified powder concrete is reduced; besides, the low-dosage steel fiber modified powder concrete is relatively low in the wholesale cost, good in the fiber distribution uniformity, high in fracture resistance and shock resistance and is suitable for popularization and application in the constructional engineering industry.

Owner:黄贺明

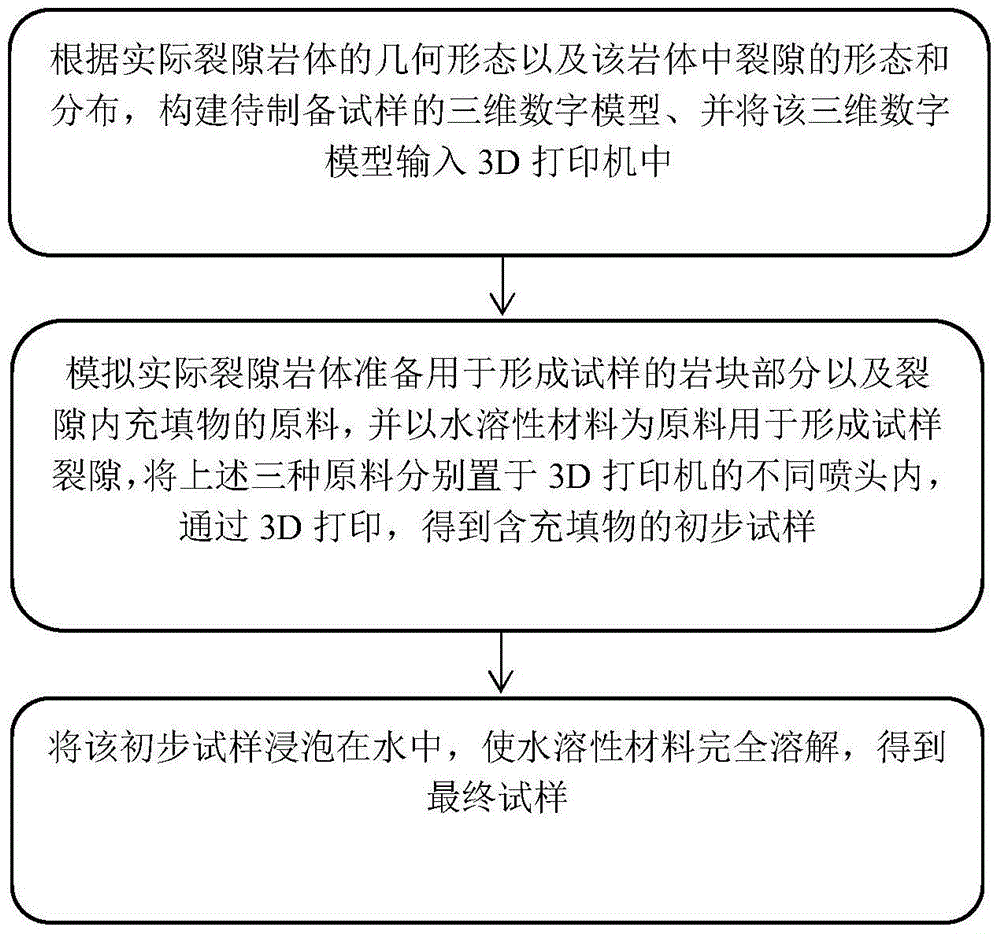

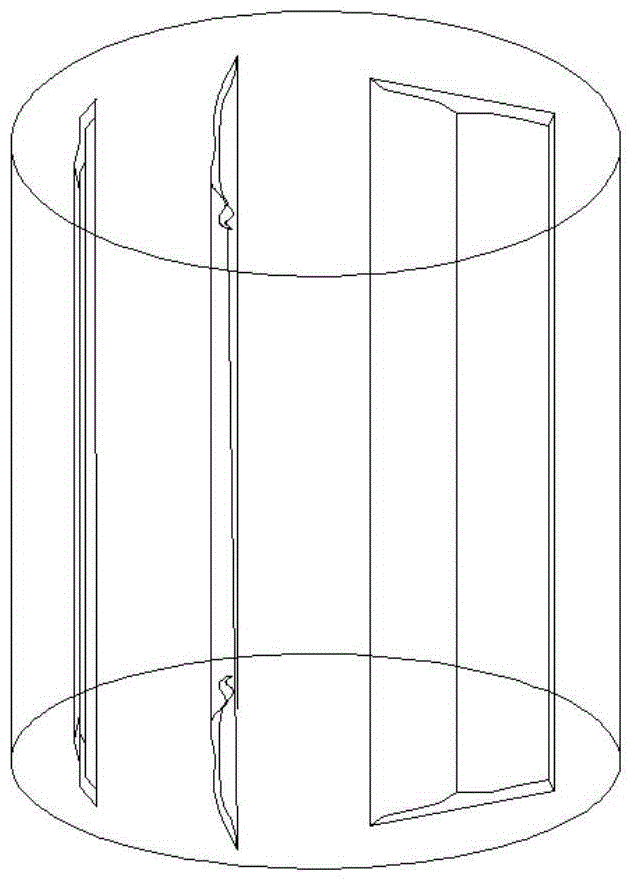

Method for preparing fractured rock mass samples with filler

InactiveCN105675365AReduce heat of hydrationGood shrinkage performancePreparing sample for investigationSpray nozzleWater soluble

The invention discloses a method for preparing a rock mass sample with filling fissures. model, and input the three-dimensional digital model into the 3D printer; (2) simulate the actual fractured rock mass to prepare the rock block part for forming the sample and the raw materials for the crack filling, and use water-soluble materials as raw materials to form the sample The above three raw materials were placed in different nozzles of the 3D printer, and a preliminary sample containing the filling was obtained by 3D printing; (3) The preliminary sample was soaked in water to completely dissolve the water-soluble material to obtain final sample. The invention does not need to use a mold to prepare the sample, and the prepared sample contains fillers, which overcomes the defect in the prior art that powdery solid particles cannot be filled into cracks of the sample to form fillers.

Owner:HOHAI UNIV

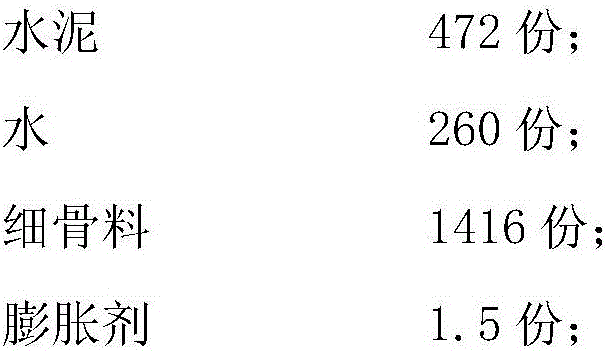

Anti-crack and impervious mortar and preparation method thereof

The invention relates to an anti-crack and impervious mortar and a preparation method thereof, belonging to the technical field of building materials. The anti-crack and impervious mortar is prepared from the following components in parts by weight: 450 to 650 parts of cement, 250 to 270 parts of water, 1200 to 1500 parts of fine aggregate, 1 to 3 parts of an expansion agent, 1 to 3 parts of an impervious agent, 0.4 to 1.2 parts of fiber and 2.5 to 4.5 parts of a water reducing agent. The mortar prepared by using the method provided by the invention has the following advantages: the workability is good; the setting time of the mortar can be controlled by adjusting the usage amount of an additive; the construction time is convenient to be controlled; the construction is easy; by adding materials like anti-crack fiber, the impervious agent and the expansion agent into the mortar, anti-crack and impervious comprehensive performances of the mortar are improved; the engineering durability is effectively improved; and the preparation method for the mortar is simple and convenient to operate, and can be extensively popularized and applied.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR

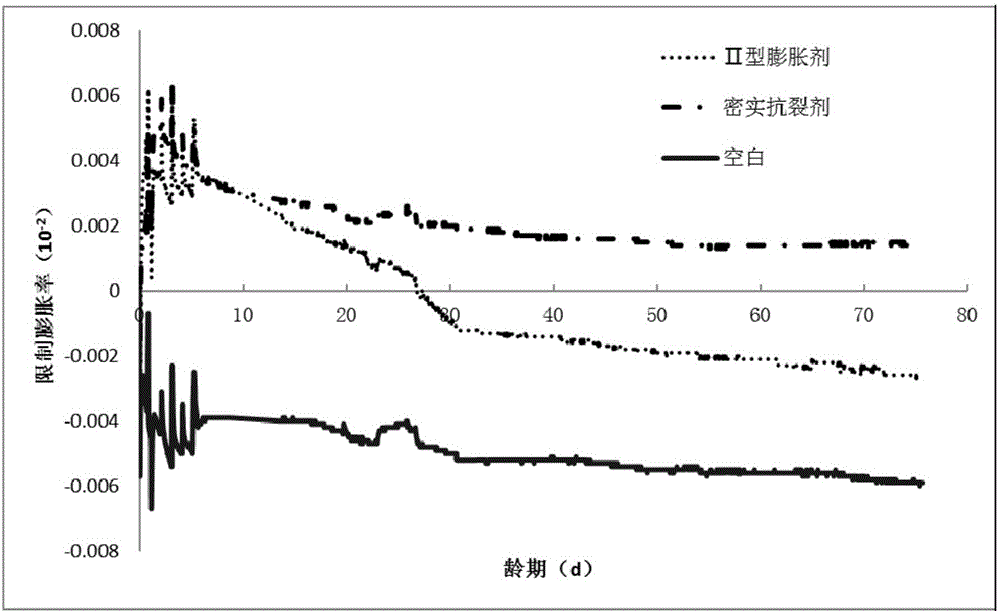

Concrete compaction anti-cracking agent

The invention discloses a concrete compaction anti-cracking agent which comprises 20.0-60.0% of light calcined magnesia, 10.0-30.0% of calcium oxide-calcium sulfoaluminate double-expansion source expanded clinker, 5.0-15.0% of gypsum and 20.0-50.0% of a fine powder material of which the specific surface area is greater than 300m<2> / kg, wherein the sum of the contents of all components is 100% based on the total mass of the concrete compaction anti-cracking agent. The concrete compaction anti-cracking agent can be used in concrete to effectively inhibit shrinkage of the concrete and improve the compactness and the durability of the concrete.

Owner:武汉三源特种建材有限责任公司

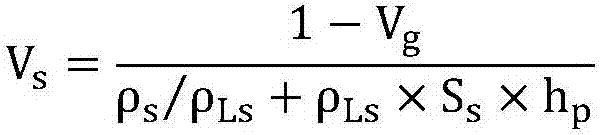

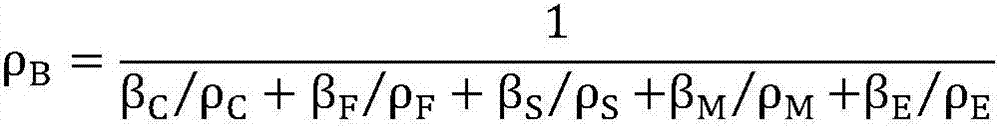

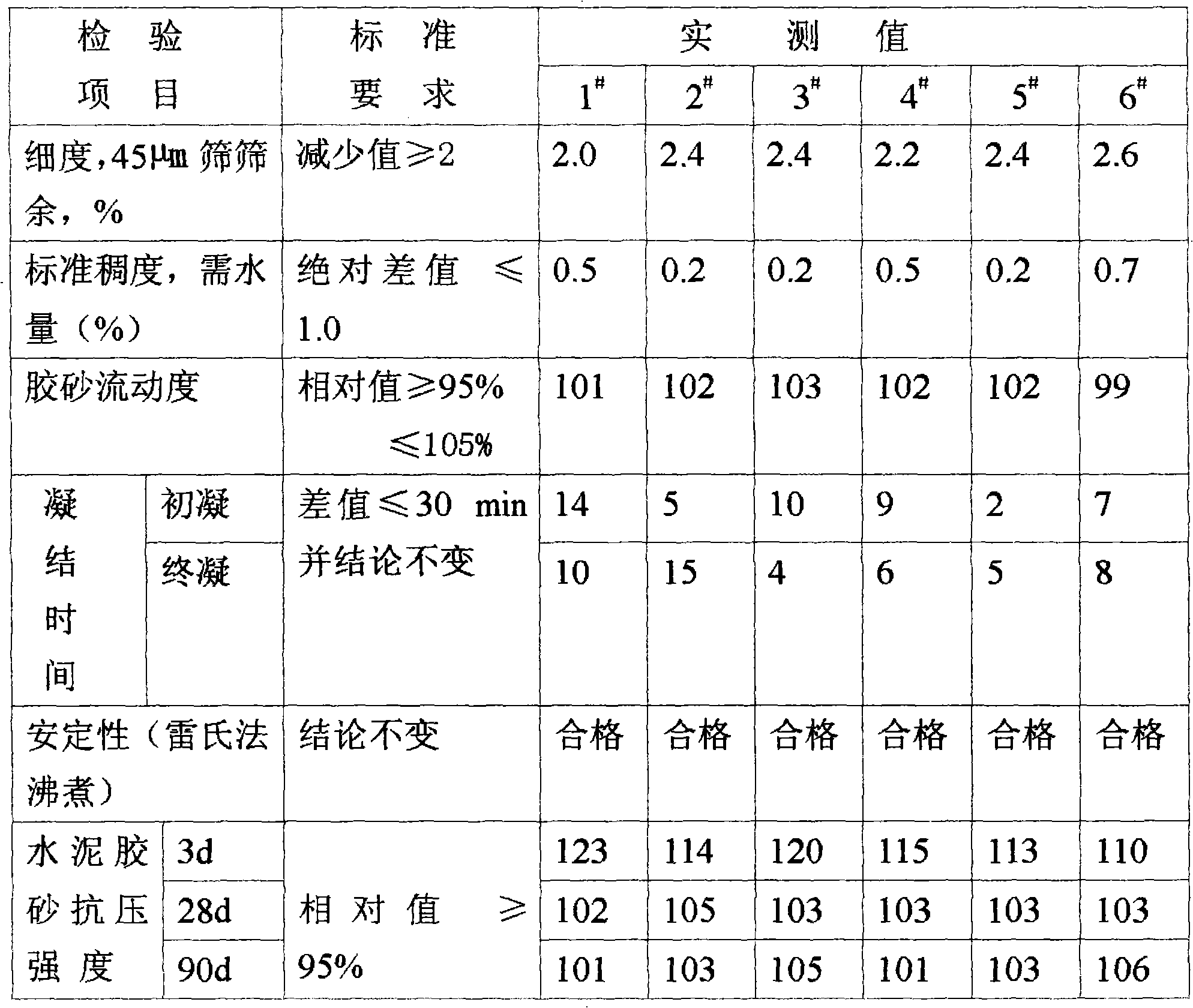

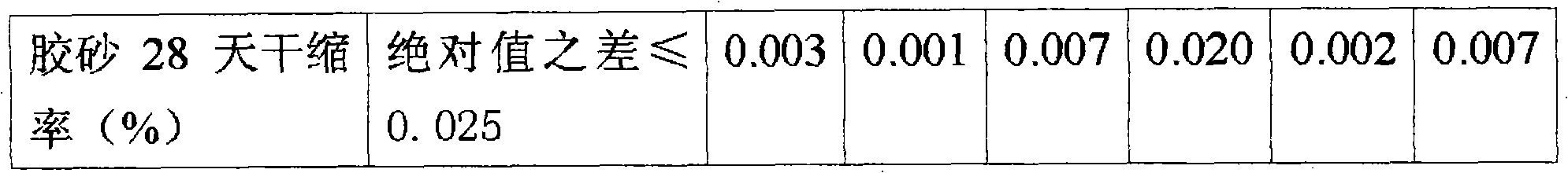

Designing of mix ratio of high-performance recycled concrete

The invention discloses designing of the mix ratio of high-performance recycled concrete. Unlike common concrete, the aggregate of recycled concrete has high porosity and water absorption rate, coarse aggregates of different sources are greatly different in performance, and the particle strength and elastic modulus of the recycled concrete are thus low; so it is impossible for usage of a universally accepted strength formula as a base for designing of the mix ratio of the recycled concrete. Although a variety of strength formulas are brought forward at home and abroad, the strength formulas are all limited and cannot be practically applied since the problem of great difference among the performances of recycled aggregates cannot be handled.

Owner:HUNAN CITY UNIV

Foam concrete containing recycled inorganic lightweight aggregate and preparation method thereof

InactiveCN105777018AHigh strengthSmall shrinkageSolid waste managementCeramicwareBuilding materialWater reducer

The invention discloses foam concrete containing recycled inorganic lightweight aggregate. The foam concrete is prepared from 20-60 parts of cement, 20-60 parts of slag, 0-50 parts of sand, 0.5-3 parts of a water reducer, 0.1-3 parts of fibers, 25-60 parts of water, foam with the addition amount accounting for 1-80% of the total volume of the foam concrete and the recycled inorganic lightweight aggregate with the addition amount accounting for 1-80% of the total volume of the foam concrete, wherein the recycled inorganic lightweight aggregate is obtained by smashing, screening and grading one or more inorganic heat insulation building materials including but not limited to aerated concrete, foam concrete, foamed ceramic and foamed glass. The invention further discloses a preparation method of the foam concrete. The foam concrete containing the recycled inorganic lightweight aggregate has the advantages of being high in strength, small in shrink, free of formwork collapse, good in fluidity, homogeneous, low in cost and the like and is especially suitable for cast-in-situ lightweight walls, roofs, lightweight cement product elements and the like.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD +1

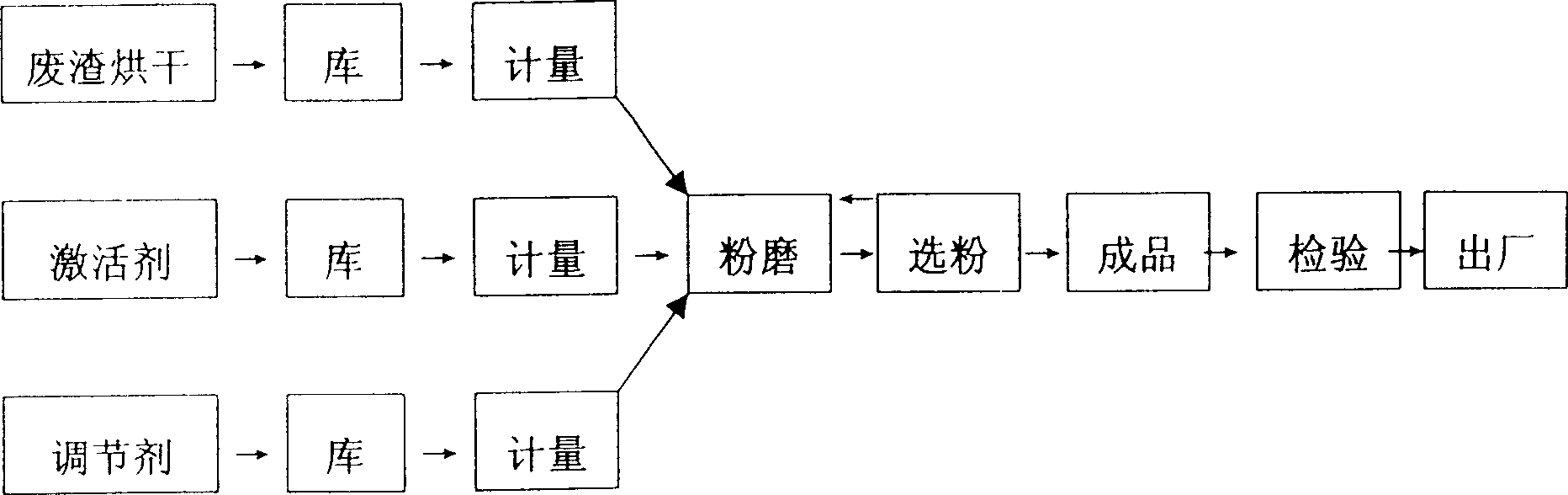

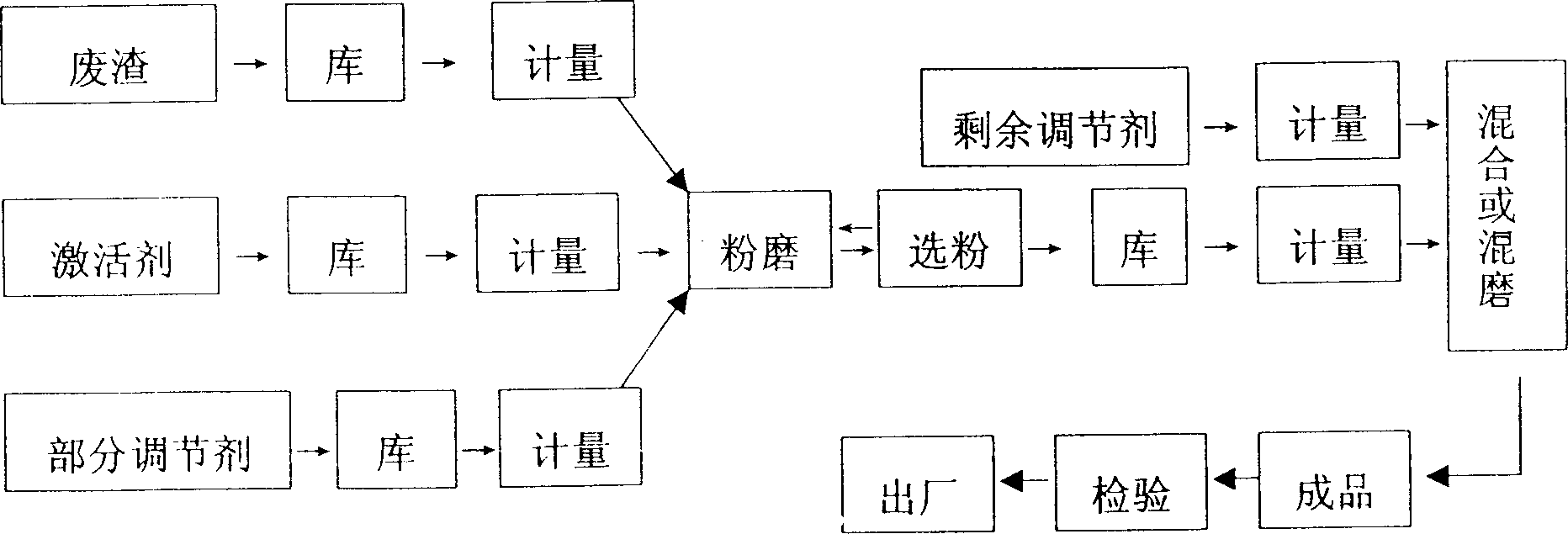

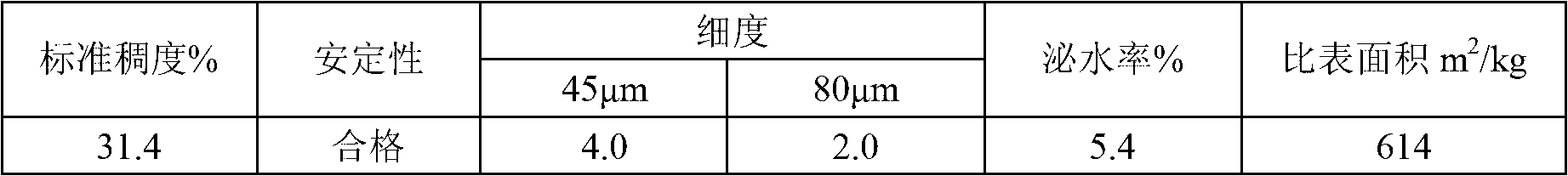

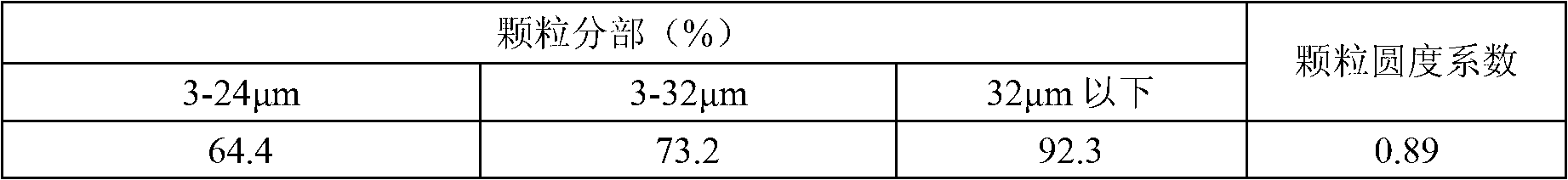

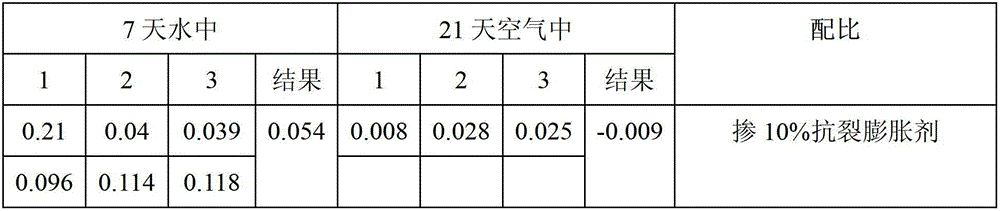

High-performance cement and concrete and their production

InactiveCN1896024AImprove compactnessImprove liquidityCement productionMaterials scienceHeating energy

High-performance cement, concrete and its production are disclosed. The cement consists of industrial fag end, activator, functional regulator and performance regulator, and Bosi specific surface is 300-550m2 / kg. Its advantages include excellent fluidity and endurance, less loss and hydrated heat energy, better density and strength.

Owner:张卫党

Low-carbon high-performance tunnel shotcrete composite cementing material

The invention discloses a low-carbon high-performance tunnel shotcrete composite cementing material. The low-carbon high-performance tunnel shotcrete composite cementing material is used for shotcreting construction of roads, railway tunnels and urban underground engineering. The low-carbon high-performance tunnel shotcrete composite cementing material comprises 40% of cement clinker, 25% of slag powder, 15% of coal ash, 8% of silicon ash and 12% of a mixed material. A preparation method of the low-carbon high-performance tunnel shotcrete composite cementing material comprises the following steps of preparing the above materials of which performances satisfy requirements, respectively grinding cement clinker, a mineral mixture and the mixed material into powder having different specific surface areas, and homogenizing the powder according to a formula ratio by a homogenizer to obtain a target product. Compared with the common portland cement, the low-carbon high-performance tunnel shotcrete composite cementing material has the advantages that a mineral mixture amount is greatly improved; cementing material components are changed; and performances are greatly improved. A clinker doping ratio is reduced and thus carbon emission is reduced; environmental protection is realized; and resources and energy are saved.

Owner:SOUTHWEST JIAOTONG UNIV

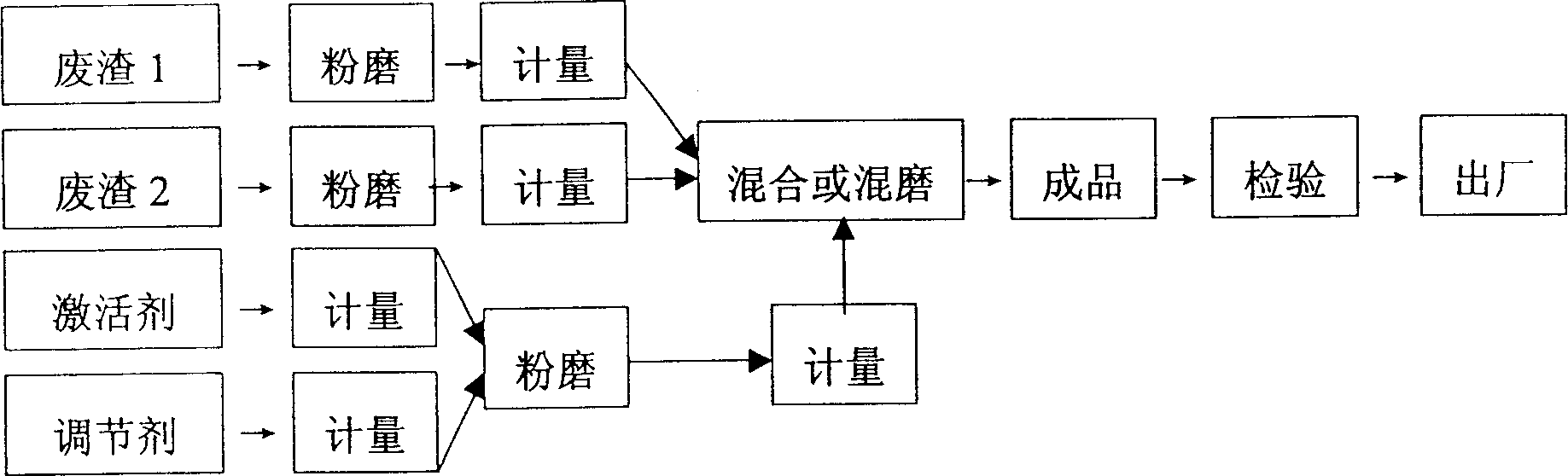

Industrial waste residue activating grinding aid

InactiveCN1451624APromotes hydration activityAchieve clinker effectOther chemical processesSolid waste disposalBiochemical engineeringElectric consumption

An activating grinding aid for industrial waste residues is prepared from catalyst (1-8 wt.%), activating agent (30-80 wt.%), setting regulator (0-20 wt.%), grinding aid (3-12 wt.%) and carrier (3-30wt.%). Its advantages are effective use of industrial waste residues, low electric consumption of grinder, and improve cement performance.

Owner:尹小林

Anti-crack expanding agent and preparation method thereof

ActiveCN102745933AImprove densification performanceImprove waterproof performanceWollastoniteDickite

The invention discloses an anti-crack expanding agent which comprises the following ingredients by weight: 35%-40% of calcium oxide clinker, 15%-20% of gypsum, 30%-35% of dickite, 5%-10% of coal ash and 2%-5% of wollastonite powder, wherein the sum of the weight ratios is 100%. The invention further discloses a preparation method of the anti-crack expanding agent. Compared with the prior art, the anti-crack expanding agent disclosed by the invention has the advantages of being capable of effectively preventing concrete from cracking so as to improve compactness.

Owner:TIANJIN JINSHENGYUAN SPECIAL BUILDING MATERIALS

Magnesium oxychloride fiber light wallboard

InactiveCN103979921AAvoid the phenomenon of moisture absorption and return to halogenHigh strengthSolid waste managementCompressive resistanceSlag

The invention provides a magnesium oxychloride fiber light wallboard, and relates to the wallboard field in the construction materials. The wallboard is composed of the following components in parts by weight: 40 to 60 parts of magnesium chloride water solution, 20 to 30 parts of magnesium oxide, 0.1 part of fly ash, 0.2 part of slag, 0.5 part of construction waste, 0.1 part of waste ceramic, 2 parts of short glass fiber, 2 parts of straw, 2 parts of saw dust, 3 parts of perlite, and 0 to 2 parts of modifier. The formula of the wallboard comprises industrial and agricultural wastes such as fly ash, slag, mineral slag, construction wastes, broken ceramics, straws, and saw dust, thus the wastes are fully recycled and reutilized, and moreover the using amount of sands and stones is reduced, so the destroy on mountain and river bed is avoided, resources are saved, and environment is protected. The prepared magnesium oxychloride fiber light wallboard has the advantages of good water resisting property, high compressive strength, good freeze resisting performance, good acid / alkali resistant property, no halogen appearance, no scumming, and no deformation.

Owner:四川省元程中博能源开发有限公司

Composite admixture for high strength concrete and preparation method thereof

Belonging to the technical field of building material concrete, the invention in particular relates to a composite admixture for high strength concrete and a preparation method thereof. The composite admixture for high strength concrete is formed by mixing of the following components by weight percentage: 1%-3% of cement clinker, 20%-30% of silica fume, 20%-30% of levigated desulphurization ash, 20%-30% of superfine fly ash, 1%-2% of a plasticizer, 1%-2% of a strength exciting agent, and the balance levigated slag powder. Specifically, the strength exciting agent is formed by mixing of an additive XC, triethanolamine, triisopropanolamine, redispersible latex powder, nano-silica and xanthan gum in a ratio of 1:1.5-3:1.5-3:0.015-0.04:0.8-1.2:0.4-0.6, and the plasticizer is powdery polycarboxylate superplasticizer. The composite admixture adopting the technical scheme of the invention can improve the concrete strength and durability, and is easy to prepare.

Owner:重庆市建筑科学研究院有限公司 +2

Steel slag concrete

The invention relates to steel slag concrete comprising the following components: cement, water, barite sand, stones, sintered pellets, a naphthalene high-efficiency water reducing agent, an expanding agent, and fly ash. The steel slag concrete has the advantages that the steel slag concrete is prepared by mixing the cement, water, the barite sand, the stones, the sintered pellets, the naphthalene high-efficiency water reducing agent, the expanding agent and the fly ash; the sintered pellets and the barite sand enable the density of the concrete to be effectively improved; with the use of the barite sand, the sintered pellets can be prevented from sinking, the separation resistance of the concrete is improved, and the amount of the cement is reduced; the fly ash effectively reduces the hydration heat of the concrete; with adulteration of the naphthalene high-efficiency water reducing agent, the work degree of the concrete is improved, the setting time of the concrete is delayed, the construction difficulty is effectively reduced, and the construction period is greatly shortened; and with reasonable utilization of the industrial waste residue sintered pellets, the energy is effectively saved, the environment is effectively protected, and the production cost is reduced.

Owner:ZHONGTIAN CONSTR GROUP

Metakaolin concrete for oversized structure and mixing proportion designing method

The invention discloses metakaolin concrete for oversized structure and a mixing proportion designing method. The metakaolin concrete is prepared by mixing 1016-1072kg of gravel, 825-848kg of refined machine-made sand, 213-282kg of P.O42.5 cement, 37-43kg of II-grade coal ash, 51-80kg of S75 slag powder, 22-26kg of metakaolin, 22-26kg of I-type UEA expanding agent, 0.6-1.5kg of polypropylene fiber, 6.26-8.13kg of coagulation-delaying polycarboxylate superplasticizer and 163-176kg of water. An aggregate close packing model is adopted, and a designing method based on wrapping and filling gravel gaps through mortar and wrapping and filling refined machine-made sand gaps through binding material slurry is adopted, so that close packing of components of the concrete is realized, improvement on strength and fluidity of the concrete is facilitated, and binding material consumption and system hydration heat can be reduced.

Owner:云南建投绿色高性能混凝土股份有限公司

High efficiency cement composite grinding additive and preparation method thereof

InactiveCN101618955AIncrease incorporationIncrease productionSolid waste managementAluminiteSodium metasilicate

The invention discloses a high efficiency cement composite grinding additive, comprising the following raw materials by weight percent: 10-25% of calcined gypsum, 10-30% of calcined aluminite, 20-40% of sodium metasilicate, 2-4% of triethanolamine, 0.5-2% of polyacrylate, 0.5-3% of dispersant and 20-30% of zeolite powder. The preparation method of the high efficiency cement composite grinding additive comprises the following steps: first selecting raw materials, then dripping liquid raw materials-triethanolamine and polyacrylate TH-1100 with a liquid pump in zeolite powder, then preparing reinforced grinding component with a dry powder mixer, finally adding the reinforced grinding component, calcined gypsum, calcined aluminite, sodium metasilicate and dispersant in a kneader to mix for 20-30min and obtaining the product. The product has prominent grinding aid, and can increase the hourly output of mills by 10-15%, reduce the consumption of electricity, and increase the cement 3-day compression strength and the cement 7-day compression strength by more than 20% and the cement 28-day compression strength by 10-15%.

Owner:葫芦岛市辽西混凝土外加剂有限公司

Preparation and use method of fly ash based mineral polymer

InactiveCN101353232AAvoid pollutionReduce manufacturing costSolid waste managementCement productionGeopolymerSolid content

The invention relates to a preparation for a fly ash-based geopolymer and an application method thereof. The method mainly comprises the following steps: excitant solution and fly ash are mixed and stirred to paste; the paste is injected into a mold frame for molding; the molded product is maintained; the excitant solution is 2mol / L-5mol / L of silicate solution or water glass solution with the solid content to be 25-40% and the modulus to be 1.0-1.5. The preparation and the application method of the fly ash-based geopolymer fully use the industrial waste fly ash, which has the advantages of reducing cost, being favorable for environmental protection, reducing energy consumption and convenient application; the product obtained has the excellent characteristic of geopolymer.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Low heat composite cementing material

InactiveCN102617057AHeat of hydrationSolve the high temperature riseCement productionToxic materialCement paste

The invention provides a low heat composite cementing material, the raw materials of which comprise, by weight: 20-50 parts of cement, 40-70 part of fly ash, 5-25 parts of metakaolin, and 0-8 parts of an exciting agent. The cementing material is prepared by placing the above materials into a material mixer in order, and stirring them for 5-15m at a speed of 60-120 r / m under normal temperature and pressure. Application of the cementing material consists of the steps of: placing 88-97 parts by weight of the cementing material, 3-12 parts by weight of an expanding agent 1.0-1.5 parts by weight of a water reducer, and 24-32 parts by weight of tap water into a cement paste blender for blending based on the speed and procedure prescribed by the national building material industry standard JC / T729-2005: carrying out slow stirring for 117-123s at a rotation speed of 135-145 r / m and a revolution speed of 57-67 r / m, then stopping stirring for 14-16s, and then performing stirring again rapidly for 117-123s at a rotation speed of 275-295 r / m and a revolution speed of 115-135r / m for molding. The material provided in the invention is not only suitable to be used as a building material, and also can be used in backfill grouting, toxic waste curing and other special aspects.

Owner:63653 FORCES PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com