Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172 results about "Phenyl phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phenyl phosphate is an aryl phosphate resulting from the mono-esterification of phosphoric acid with phenol.

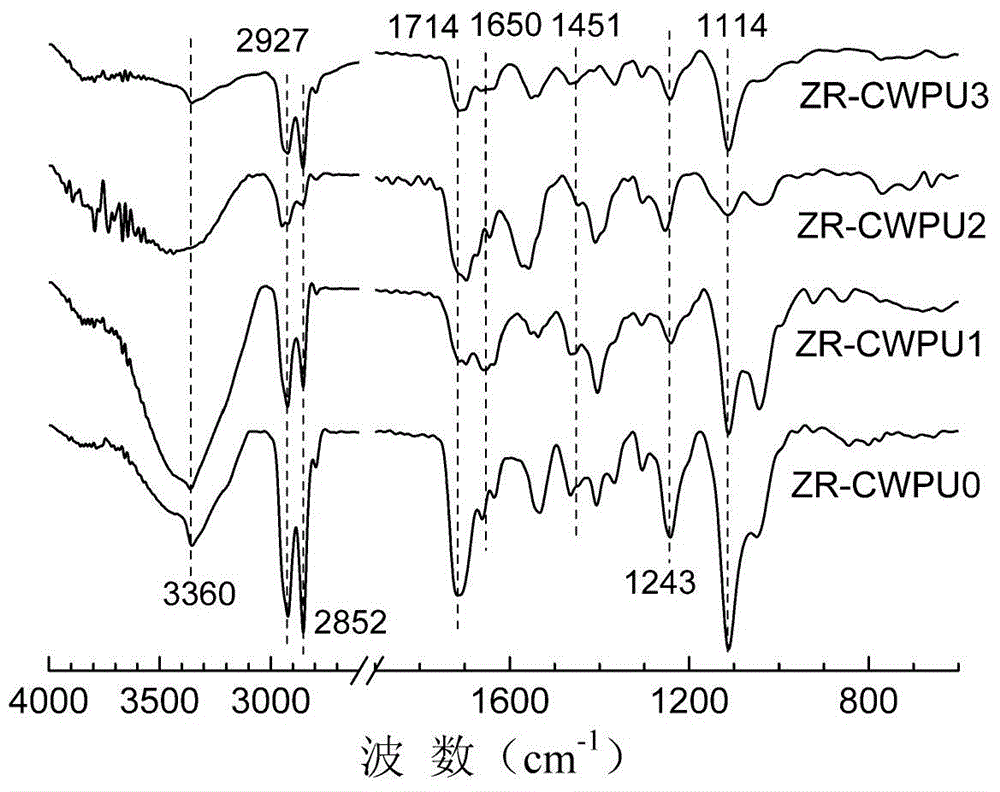

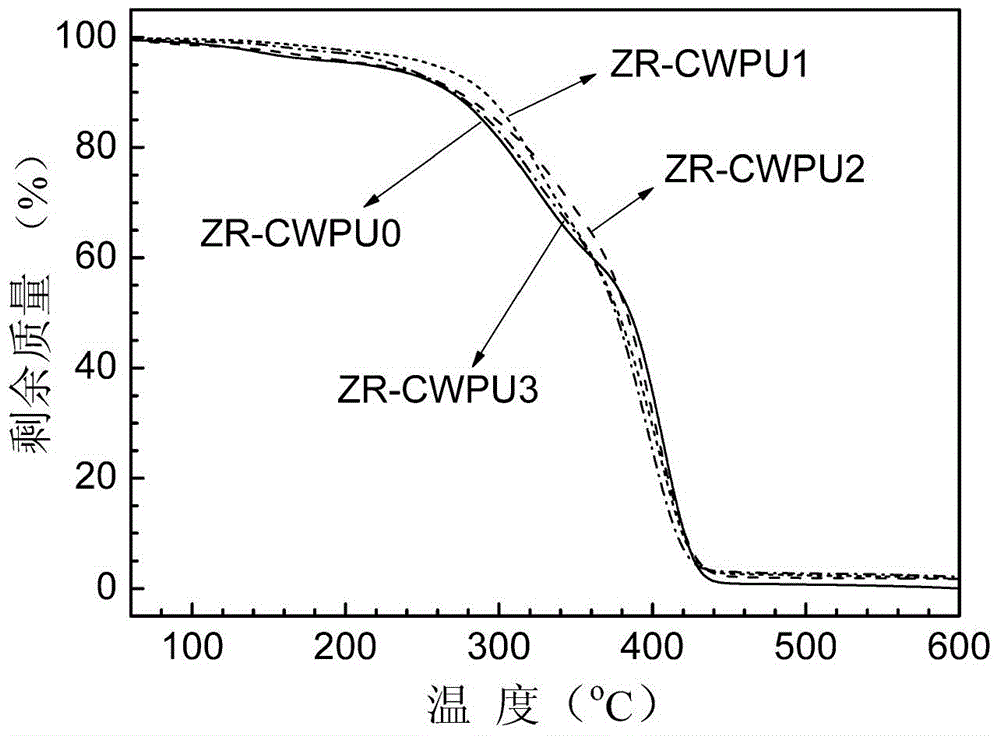

Method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and/or phenyl phosphate groups

InactiveCN104592475ANon-corrosive generationEvenly distributedGroup 5/15 element organic compoundsPolymer scienceAlcohol

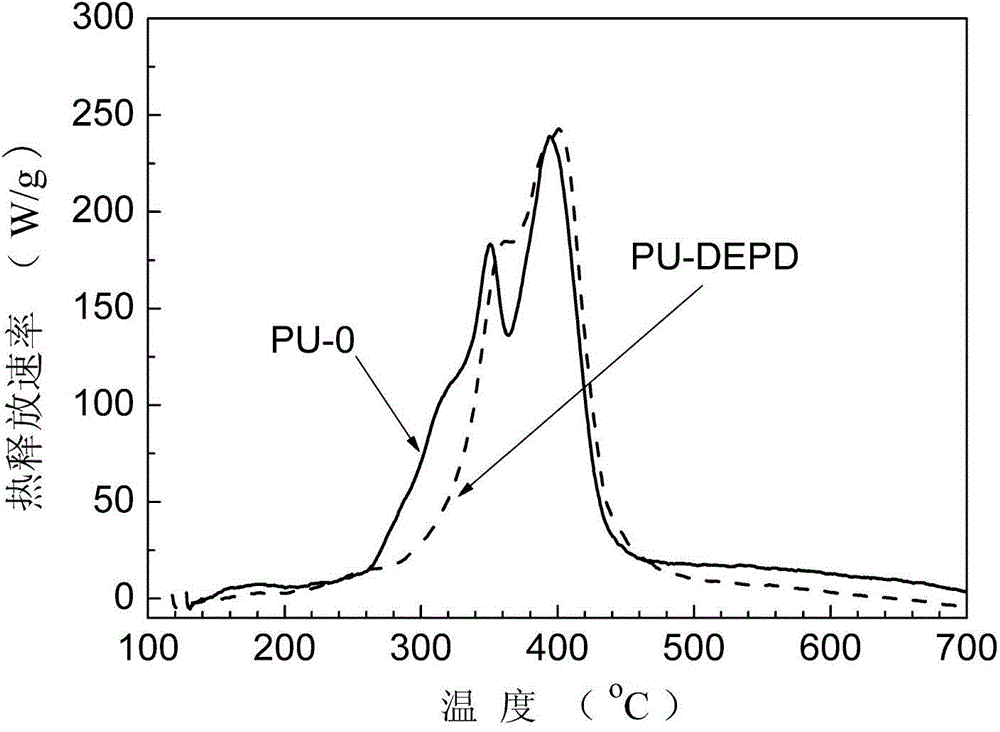

The invention discloses a method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and / or phenyl phosphate groups. The method is characterized by comprising the following step of reacting dihydric alcohol as a reactant which contains phosphaphenanthrene and / or phenyl phosphate groups and of which the hydroxyl groups are symmetric with diisocyanate, macromolecular dihydric alcohol, anionic or cationic hydrophilic chain extender and the like to synthesize flame-retardant waterborne polyurethane. According to the method, since flame-retardant dihydric alcohol is used as one of chain extenders, flame-retardant dihydric alcohol ca partially or totally substitute other small molecular chain extenders, phosphorus-containing flame-retardant groups are controllable in content and difficult to migrate and are evenly distributed, and the flame-retardant property of waterborne polyurethane can be enduringly retained. According to the structural characteristics of selected flame-retardant dihydric alcohol, by virtue of one and a combination of two or more of flame-retardant groups, phosphorus in the flame-retardant groups can be alone located at a main chain, side chains or simultaneously located at the main chain and the side chains of the polyurethane molecule chain as desired so as to meet the requirements of different flame-retardant properties or other properties such as mechanics, toughness and plasticity.

Owner:UNIV OF SCI & TECH OF CHINA

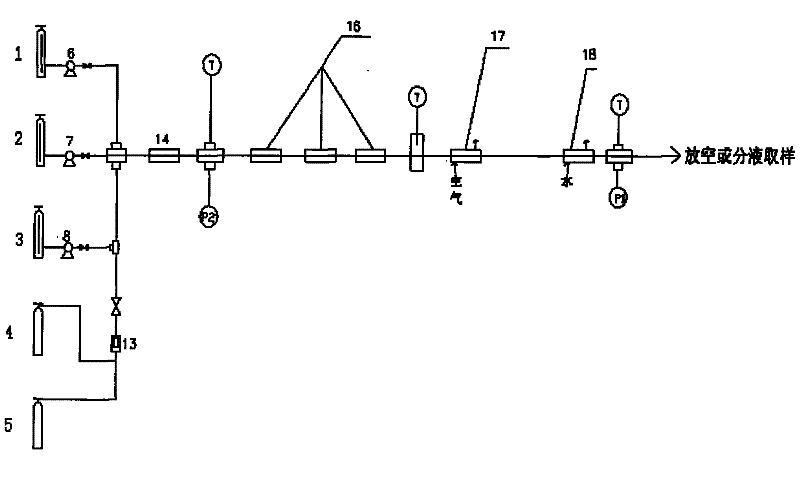

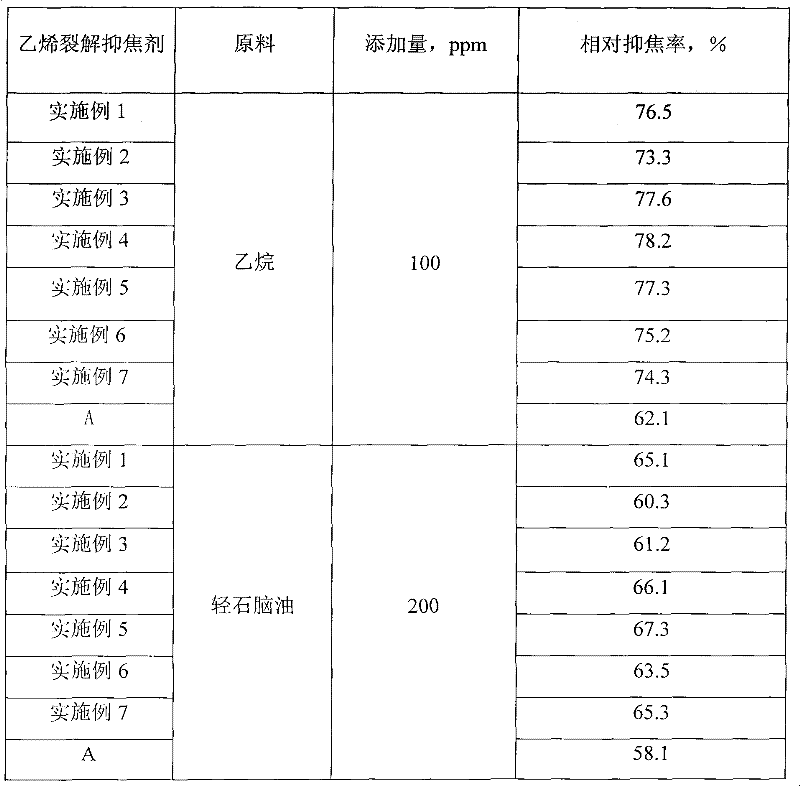

Coke inhibitor for ethylene cracking

ActiveCN101747927AAlleviate cokingGood focus reduction effectThermal non-catalytic crackingPhenyl phosphateSolvent

The invention relates to coke inhibitor for ethylene cracking, which comprises the following component by weight percentage: 20% to 60% of sulfur-containing compound, 5% to 10% of passivator, 1% to 10% of film-forming agent, 5% to 15% of polymerization inhibitor, 1% to 10% of decoking agent and 25% to 45% of solvent, wherein the sulfur-containing compound is particularly dialkyl disulfide, dialkyl sulfide, di-alkylphenol sulfide, diphenyl sulfide, diphenyl disulfide, thiophene or thioxene; and the passivator is particularly triphenyl phosphate, triethyl phosphate, di-octyl-phenyl-phosphate, tributyl phosphate, thiophosphate trilaurate, diethyl-phosphorodi-thioate or triacyl piperidine phosphate, and the passivator is preferably triphenyl phosphate or di-octyl-phenyl-phosphate. The coke inhibitor of the invention for ethylene cracking is capable of effectively relieving the coking condition of an ethylene cracking tube, ensuring the good coke-inhibiting effect, obviously increasing the operation cycle of cracking and reducing the air-decoking time. Therefore, the coke inhibitor of the invention has wide applicable range in the coke inhibition of gaseous light dydrocarbon and naphtha.

Owner:金浦新材料股份有限公司

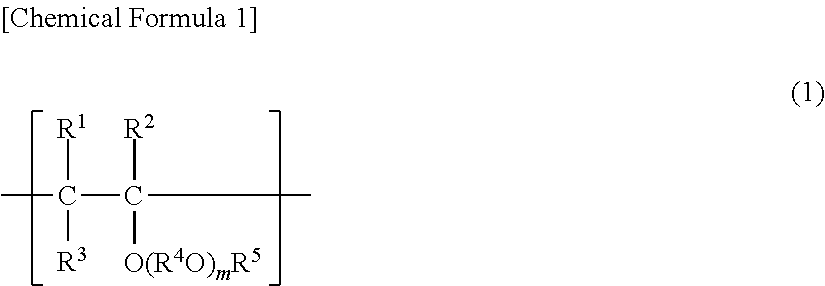

Preparation method of low-hydration-heat polycarboxylate water reducing agent

The invention discloses a preparation method of a low-hydration-heat polycarboxylate water reducing agent. Unsaturated carboxylic acid or unsaturated carboxylic acid anhydride performs acidylation andesterification with alcohol amine and a compound A to simultaneously prepare unsaturated monomers with acidamide groups, unsaturated monomers with amino groups and unsaturated monomers with benzene rings and phosphate groups; then, co-polymerization is performed by excessive unsaturated carboxylic acid or unsaturated carboxylic acid anhydride, unsaturated sulphonate and polyether big monomers during acidylation and esterification; acylamide groups, amino groups, phosphate groups, carboxylate groups, sulphonate groups, polyether lateral chains and benzene rings are introduced into molecular structures, so that the product has a high initial water reducing rate. The molecular structures of the water reducing agent prepared by the preparation method comprise ester groups, phenyls and phosphate groups; the ester groups hydrolyze under the basic condition of the concrete; carboxyls with the water reducing function and hydroxy phenyl phosphate groups with the hydration heat reducing function are gradually released; the concrete hydration heat can be effectively reduced.

Owner:KZJ NEW MATERIALS GROUP CO LTD

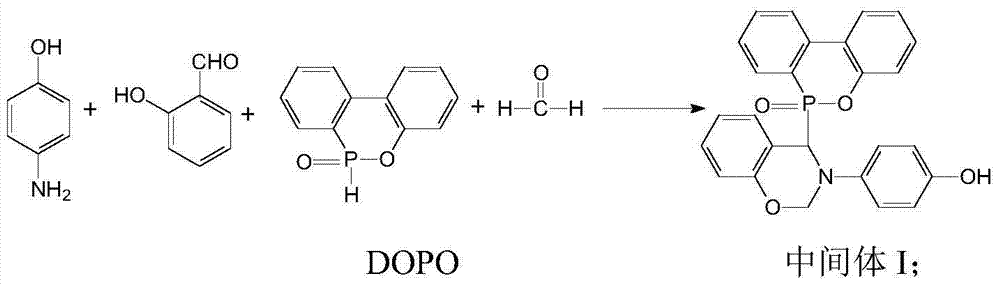

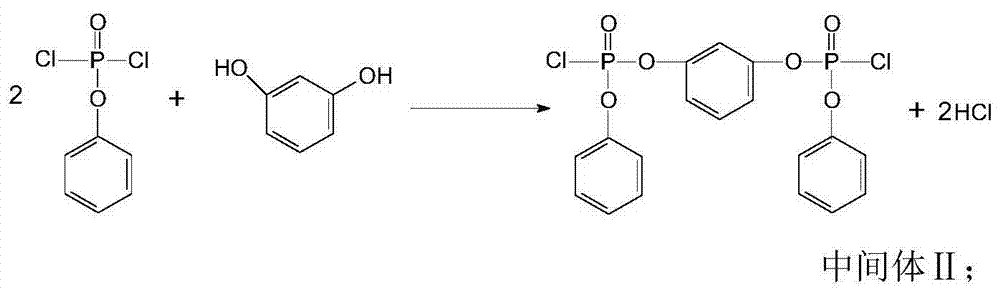

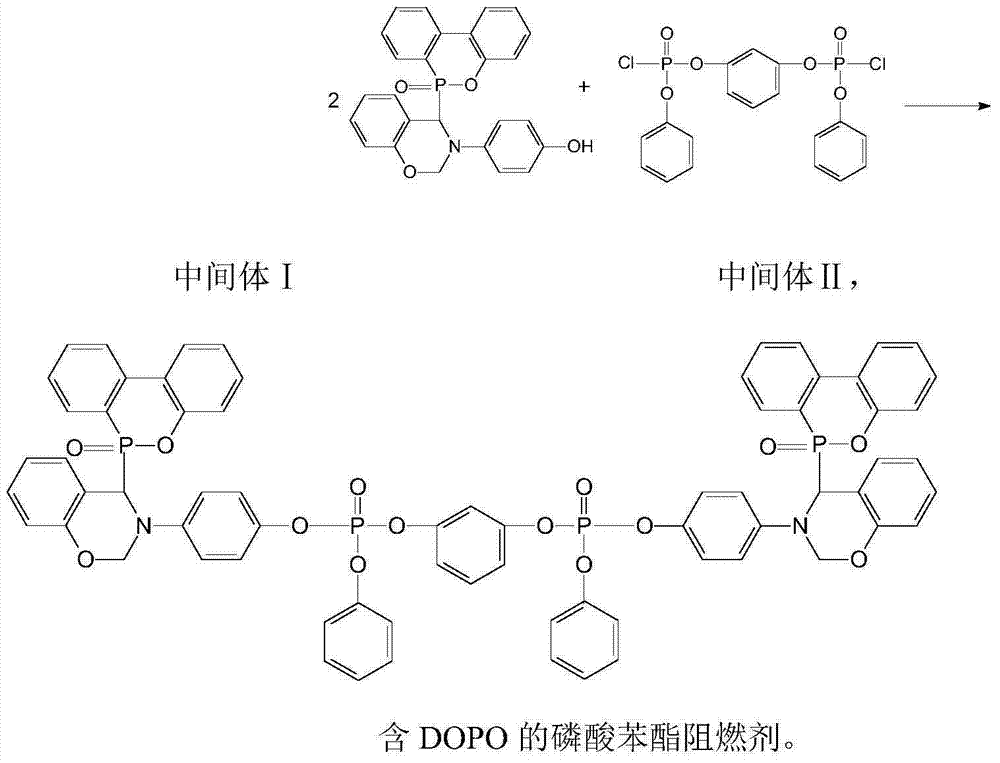

Phenyl phosphate flame retardant containing DOPO, and preparation method and application thereof

InactiveCN104774343AImprove heat resistanceHigh temperature char formation rateGroup 5/15 element organic compoundsDecompositionBenzaldehyde

Preparation method and application of a phenyl phosphate flame retardant containing DOPO. The method is as below: under the action of methanol, reacting 4-amino phenol, 2-hydroxy benzaldehyde, DOPO and formaldehyde in one pot to synthesize an intermediate I; reacting phenyl dichlorophosphate and resorcinol to synthesize an intermediate II (resorcinol bisphenoxyl phosphoryl chloride); and reacting the intermediate I and intermediate II to obtain a white solid which is the phenyl phosphate flame retardant containing DOPO. The initial decomposition temperature of the flame retardant was about 363, and the rate of residual carbon was 49% at 468, 800, and the flame retardant had good thermal stability, high residual carbon ratio and good flame retardant effect, which can be used for the non halogen flame retardant of polypropylene and ABS.

Owner:湖北万锦科技有限公司

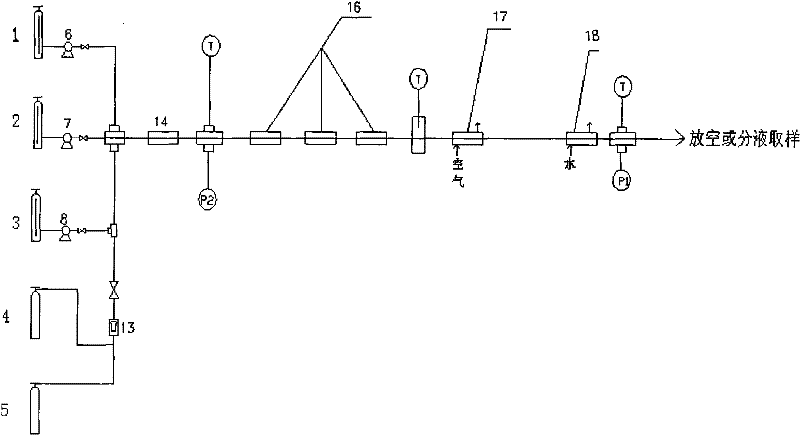

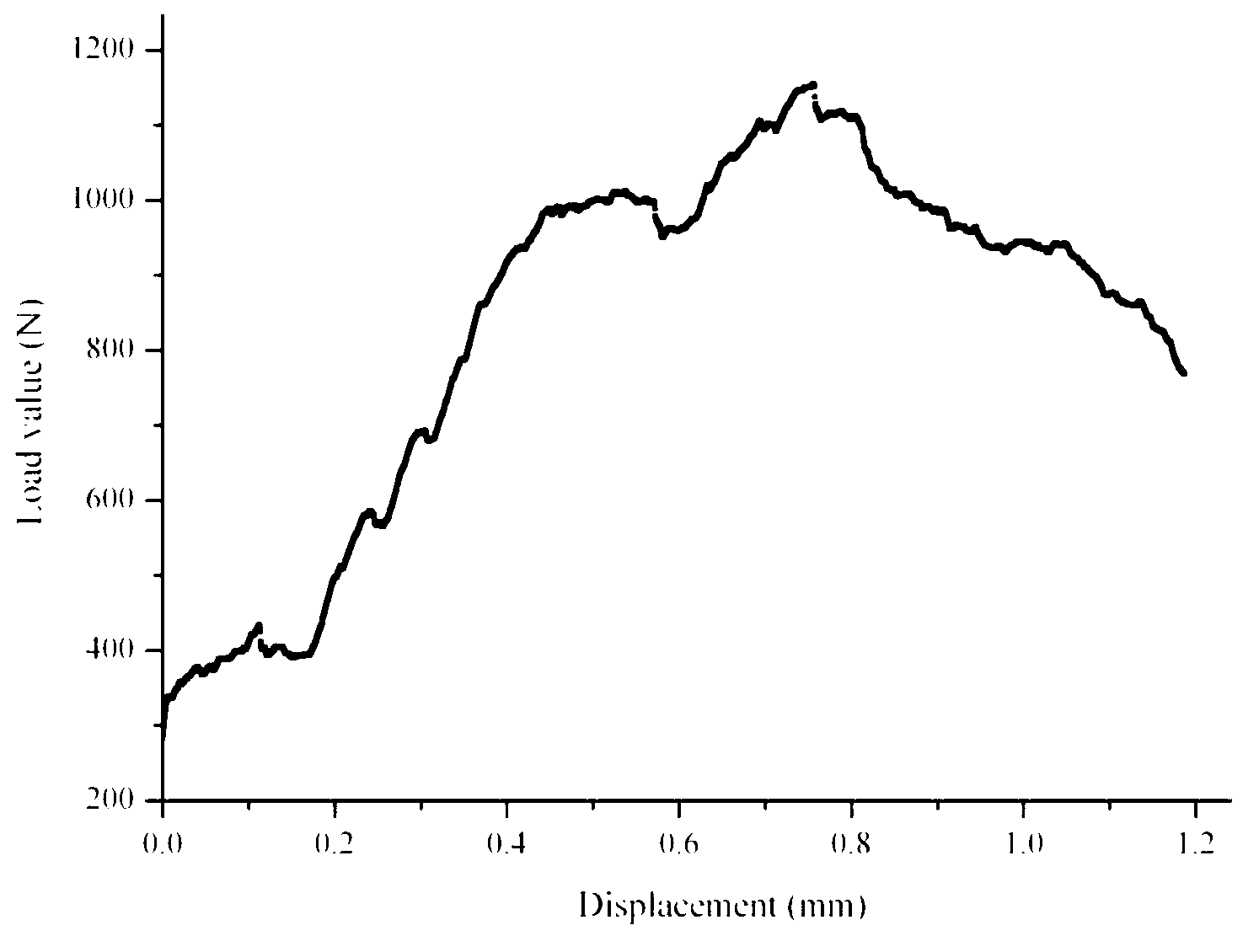

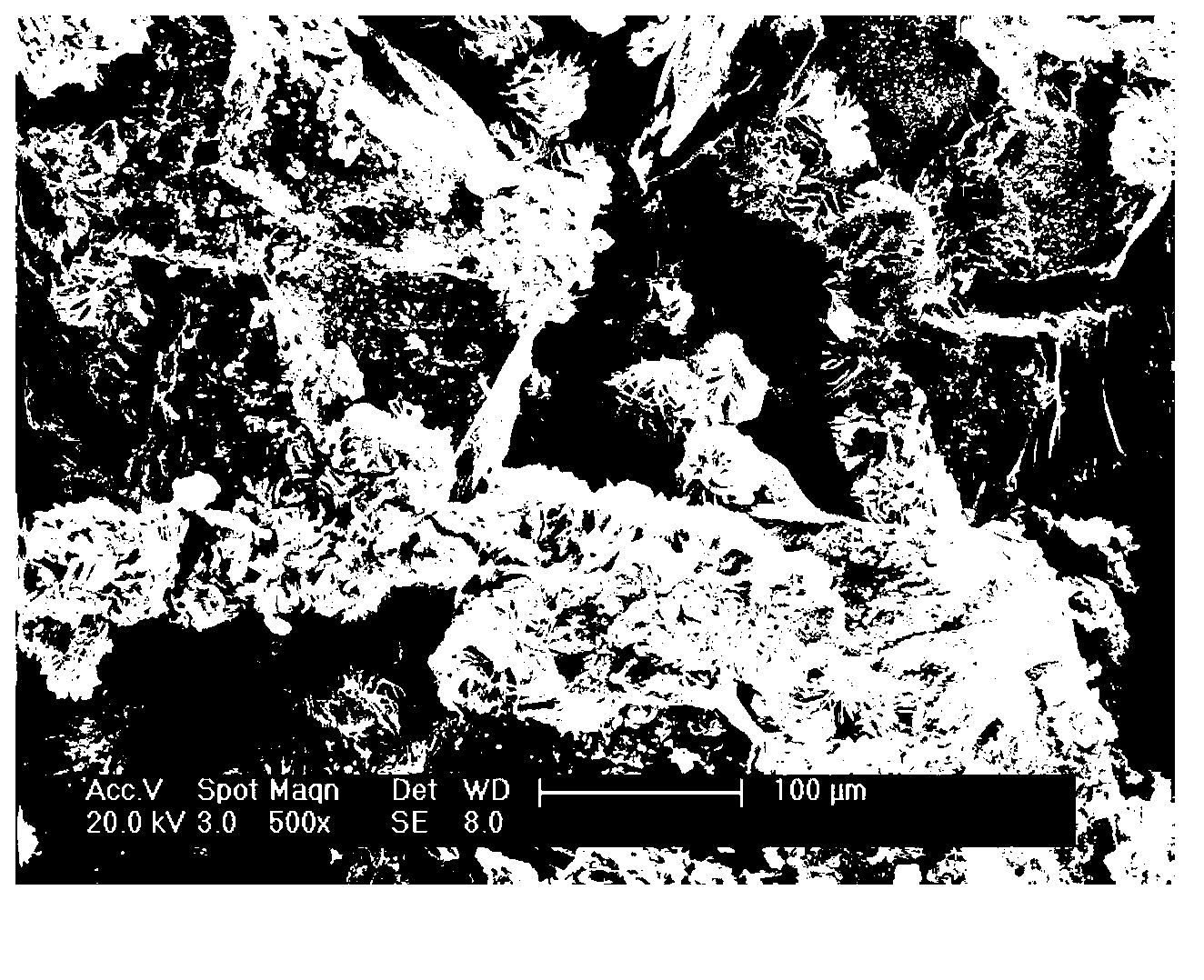

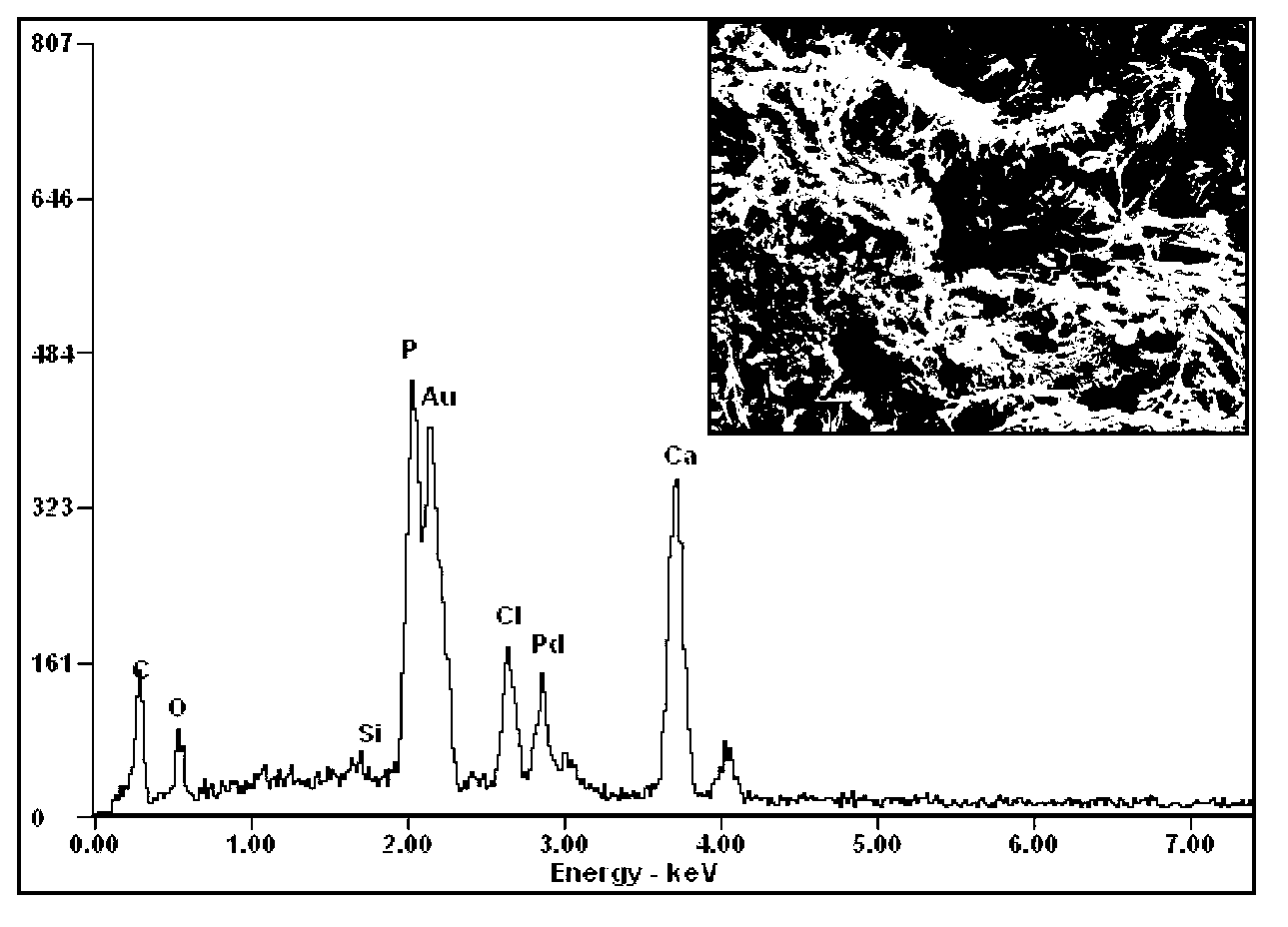

Method utilizing phosphate mineralized bacteria to solidify and loosen loose sand particles

ActiveCN103266592AProtect ecological functionsLess prone to secondary pollutionBuilding constructionsOrganic fertilisersPeristaltic pumpChemical solution

The invention discloses a method utilizing phosphate mineralized bacteria to solidify and loosen loose sand particles. The method comprises the steps that bacillus subtilis is inoculated to beef extract and a peptone culture medium for obtaining bacterial liquid, then disodium phenyl phosphate is added to the prepared bacterial liquid, an anhydrous calcium chloride solution with the concentration of 0.5-1.5mol / L is prepared, 70-90g of sand with two levels of less than 0.15mm and of 0.15-0.30mm is prepared according to the closest Fuller packing method and then loaded into a trial mould with a buffering pad and a sand filter, the bacterial liquid and a chemical solution are respectively poured into the prepared sand in the third step through a peristaltic pump according to a volume ratio of 1:1, the flowing speed of the bacterial liquid is controlled to be 4-6mL / min, the flowing speed of the chemical solution is 10-15mL / min, continuous pouring is carried out for 8-15 days, and the sand with the mould is placed into an oven of 60 DEG C for being conserved for 48h and then taken out and released from the mould. The compressive strength of the sand can reach 1.0MPa.

Owner:SOUTHEAST UNIV

Method for catalyzing gamma-valerolactone to be subjected to ring-opening polymerization by utilizing biomimetic catalyst

The invention provides a method for catalyzing gamma-valerolactone to be subjected to ring-opening polymerization by utilizing a biomimetic catalyst and belongs to the field of biomass high molecular materials. According to the method, the gamma-valerolactone is used as a monomer, the biomimetic catalyst is used as a catalyst and an alcohol compound is used as an initiator, and the gamma-valerolactone is subjected to the ring-opening polymerization in a solvent to obtain poly-gamma-valerolactone; the biomimetic catalyst is one or a mixture of more of a thioureaamide type dihydrogen bond donor catalyst, an aminothiazole type dihydrogen bond donor catalyst and a phenyl phosphate type dihydrogen bond donor catalyst. Compared with a traditional catalyst, the aminothiazole type biomimetic catalyst, the thioureaamide type biomimetic catalyst and the phenyl phosphate type biomimetic catalyst have no metal and the utilization amount is small; the catalysis effect is higher under the action of a dihydrogen bond.

Owner:NANJING UNIV OF TECH

Polyvinyl chloride (PVC) embossed film for using on gypsum board and manufacturing method of PVC embossed film

The invention discloses a polyvinyl chloride (PVC) embossed film for using on a gypsum board and a manufacturing method of the PVC embossed film. The PVC embossed film comprises polyvinyl chloride (PVC powder), epoxidized soyabean oil (ESO), diisooctyl phenyl phosphate (PDOP), dioctyl phthalate (a plasticizer), calcium zinc stabilizer, barium stearate (a stabilizer), nano CaCO3, chromatic color masterbatch (a coloring Material), hydrous aluminum oxide, stearic acid, weather-resistant impact-resistant modifier (a toughener), a plasticizing promoter, an ultraviolet light absorber and an antioxidant. The invention also provides the manufacturing method of the PVC embossed film. The manufacturing method of the PVC embossed film comprises the following steps: taking materials according to the formula; milling; flattening; cooling and trimming edges; coiling; heating; embossing; cooling and trimming edges; coiling; and packaging to obtain a finished product. The PVC embossed film disclosed by the invention has the advantages of temperature resistance, small chromatic aberration, grain elimination resistance, and small shrinkage, and can be easily stretched, and can be easily attached to the gypsum board without wrinkle and without bubble on a pasting surface.

Owner:RONGSHENG SHANGHAI PLASTICS CEMENT

Ultraviolet light-cured phosphorus-nitrogen-containing halogen-free flame retardant and preparation method thereof

ActiveCN101597307AGood fire protectionHigh flame retardant efficiencyFireproof paintsGroup 5/15 element organic compoundsUltraviolet lightsDouble bond

The invention discloses an ultraviolet light-cured phosphorus-nitrogen-containing halogen-free flame retardant and a preparation method thereof. The preparation method is characterized in that: phenyl dichlorophosphate serving as a reaction matrix is reacted with polyalcohol or polyphenol partially acidified by acrylicacid or methacrylic acid; the product of the reaction is reacted with a nitrogen-containing compound with two reactive amino groups to form a yellow, sticky, transparent, liquid and phosphorus-nitrogen-containing substance which is ultraviolet light-cured monomer of which the molecule has an active double bound and phosphorus-nitrogen flame retardant elements; and the ultraviolet light-cured monomer serving as a reactive flame retardant is added into an ultraviolet light-cured resin substrate to form a transparent coating with high flame retarding efficiency through quick curing in ultraviolet light. The ultraviolet light-cured flame-retardant coating generates 34.0 percent of residue under an air condition at 60 DEG C, and 26.3 percent under a nitrogen condition. The maximum release rate of the ultraviolet light-cured flame-retardant coating is 146.6 W / g. The ultraviolet light-cured halogen-free phosphorus-nitrogen-containing flame retardant can be used for inflaming retarding in wood, textile, plastics, metal or circuit boards.

Owner:UNIV OF SCI & TECH OF CHINA

Flame-retardant polystyrene/layered inorganic nanocomposite and preparation method thereof

InactiveCN101665513AHigh flame retardant efficiencyGood fire protectionGroup 5/15 element organic compoundsPolymer sciencePolystyrene

The invention relates to a flame-retardant polystyrene / layered inorganic nanocomposite and a preparation method thereof, which is characterized in that phenyl dichlorophosphate is taken as a reaction matrix for being reacted with polyol or polyphenol which is partially acrylated or partially methacrylated, and then the reaction with a nitrogen-containing compound with a reactive amino group is carried out, thereby obtaining the flame-retardant comonomer which simultaneously has an active double bond and a phosphorus-nitrogen flame-retardant element; the phosphorus-nitrogen monomer and styreneare used for preparing the flame-retardant polystyrene / layered inorganic nanocomposite through the free radical in-situ intercalation polymerization method in the presence of a layered inorganic; a phosphorus-nitrogen-containing flame retardant which is connected with a polymer molecular chain by the chemical bond way has better compatibility with a resin substrate and is more environment-friendly, and the flame retardant has no migration and no loss; the layered inorganic can further improve the thermal stability and the flame-retardant performance of a polymer substrate; and the flame-retardant polystyrene / layered inorganic nanocomposite can be directly prepared into a flame-retardant polystyrene material and can also be prepared into a flame-retardant masterbatch to be added in other plastics.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

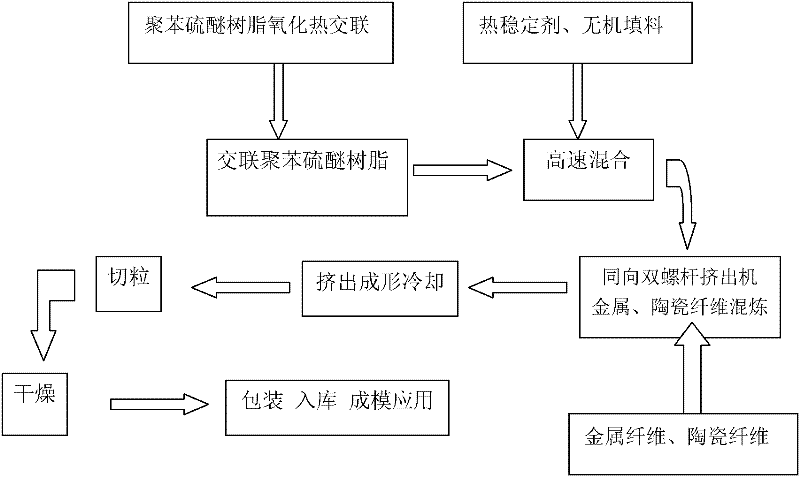

Manufacturing method of polyphenylene sulfide composite heat conduction material for light-emitting diode (LED)

InactiveCN102391647AHeat resistantImprove heat resistanceHeat-exchange elementsHeat conductingMetal fibers

The invention discloses a manufacturing method of a polyphenylene sulfide composite heat conduction material for a light-emitting diode (LED), which adopts the following raw material formulation: 40-60% wt of polyphenylene sulfide resin, 1.5-0.5% wt of heat stabilizer trisnonyl phenyl phosphate, 8-6% wt of nanoscale heat conduction metal fiber materials, 12-7.5% wt of inorganic filling materials,6-4% wt of heat conduction powder materials and 32.5-22% wt of 95% aluminium oxide ceramic fiber. The polyphenylene sulfide composite heat conduction material prepared by the method of the invention has a certain heat-conducting property and good mechanical strength, can be widely used for the fields such as electronic and electric products, war industry, space flight and aviation, electrocommunication and the like which need heat conduction or electronic shielding materials after being molded by injection, and is especially used as the heat conduction material for the LED, so that the heat dispersion performance of the LED in high temperature can be improved, and the service life of the LED can be prolonged.

Owner:四川瑞安特电子技术有限公司

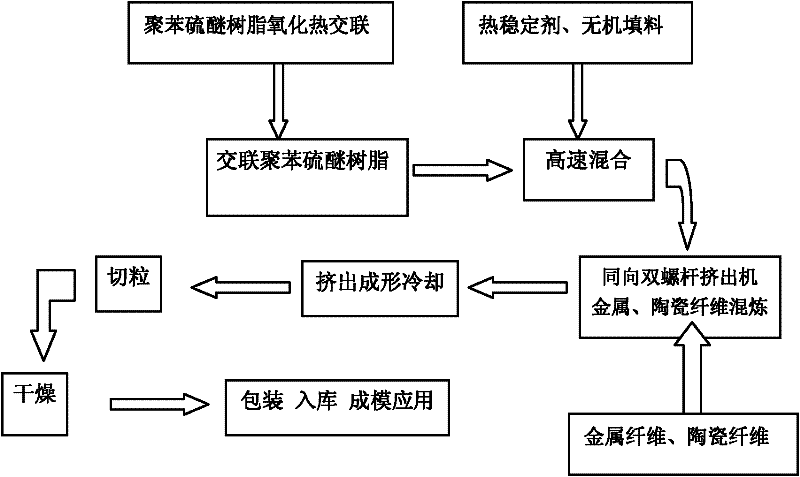

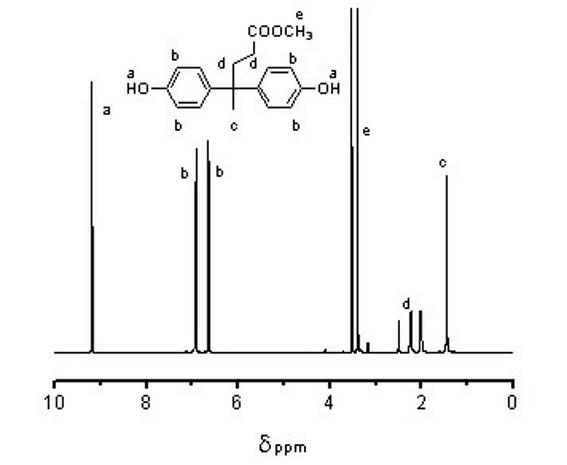

Phosphate ester polymer intumescent flame retardant and preparation method thereof

InactiveCN102417596AImprove thermal stabilityIncrease char formationGroup 5/15 element organic compoundsPhosphoric Acid EstersPolymer science

The invention discloses phosphate ester polymer intumescent flame retardant and a preparation method thereof. Polyhydroxyl acid compound serves as raw materials, and carboxyl is protected by esterification; and in the presence of phase transfer catalyst, with an interfacial polymerization method that esterified polyhydroxyl compounds, such as diphenolic acid methyl ester and phenyl dichlorophosphate, serve as main raw materials, an obtained intermediate polymer comprises a polyhydroxyl acid methyl ester and phenyl dichlorophosphate reaction unit. The synthesis method has the advantages of simple technology and cheap and abundant raw materials, is easy to operate and is suitable for industrial production; and the reaction is easy. The intermediate polymer and amido compound carry out esteramine solution reaction under the action of the catalyst to obtain the intumescent flame retardant. The flame retardant does not contain halogens and belongs to the environmentally-friendly flame retardant. The structural general formula (III) of the phosphate ester polymer intumescent flame retardant is showed as follows.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

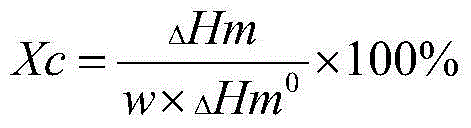

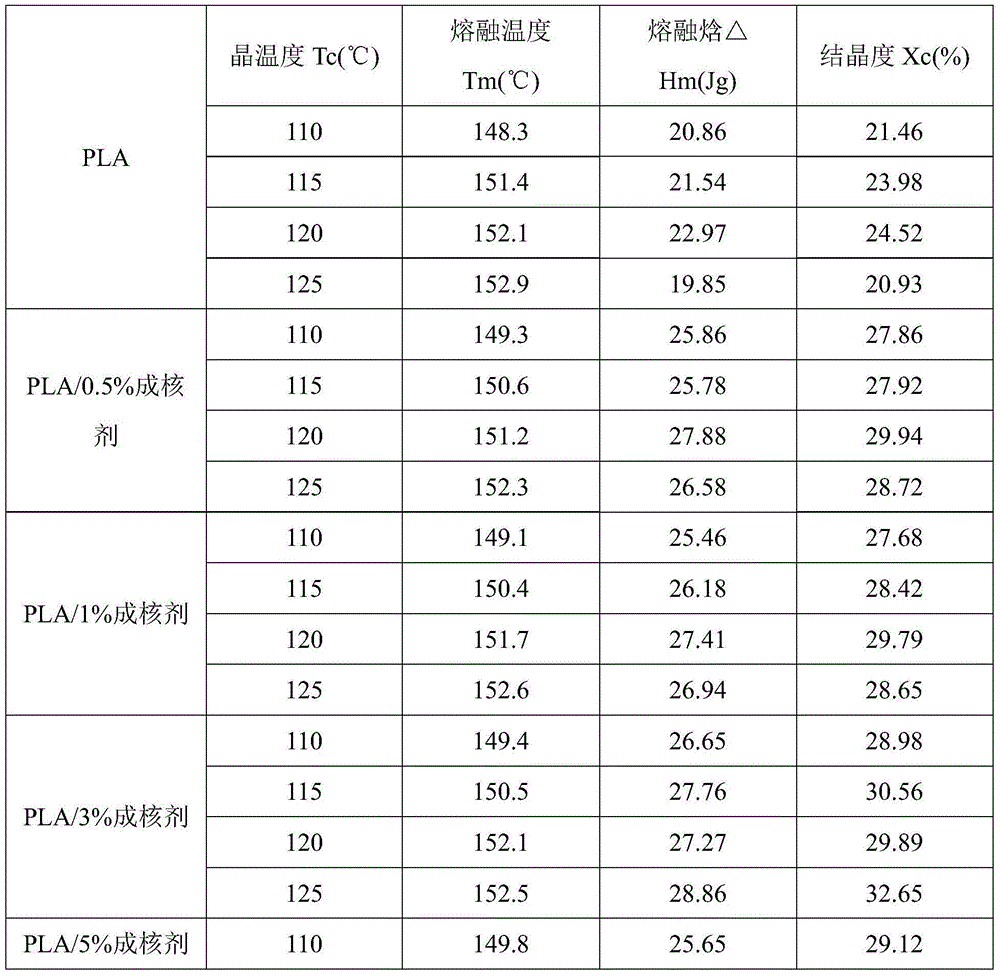

Method for modifying fast-crystallization high-crystallinity polylactic acid

The invention discloses a method for modifying fast-crystallization high-crystallinity polylactic acid, and provides fast-crystallization high-crystallinity polylactic acid prepared by taking a phenyl phosphate nucleating agent and polylactic acid as main raw materials. The method comprises the following steps of firstly preparing a high-crystallinity nucleating agent by utilizing raw materials, namely phosphenylic acid, chloride, alkali and the like; then adding experimental raw materials, namely the nucleating agent, the polylactic acid and the like, to an HAAKE torque rheometer according to a polymer crystallizing principle for blending so as to prepare a sample. According to the method, the obtained modified polylactic acid is reduced in crystallization temperature to 109 DEG C and enhanced in crystallinity by about 107% in a crystallization process, and the half-crystallization time of the modified polylactic acid is reduced by about 15 times compared with the half-crystallization time of pure polylactic acid.

Owner:常州龙骏天纯环保科技有限公司 +1

Radiation-resistance high-elastic resilience polyvinyl chloride composition and preparation method thereof

The invention relates to a radiation-resistance high-elastic resilience polyvinyl chloride composition and a preparation method thereof, which relates to the technical field of plastic processing. The polyvinyl chloride composition comprises the following mixed component: polyvinyl chloride resin, plasticizer and nitrile-butadiene rubber powder. The plasticizer is mixture of dioctyl phthalate andtri-isopropylated phenyl phosphate ester at a weigh ratio of (70:30)-(30:70). The amount of the plasticizer is 80-130 weight parts provided that amount of polyvinyl chloride resin is 100 weight parts. The mass percentage of acrylonitrile in the nitrile-butadiene rubber powder is 31-35%, and the average particle size of the nitrile-butadiene rubber powder is 0.2-1 mm. The amount of the nitrile-butadiene rubber powder is 10-50 weight parts provided that amount of polyvinyl chloride resin is 100 weight parts. The preparation method comprises mixing the components containing polyvinyl chloride resin, plasticizer and nitrile-butadiene rubber powder, and melting.

Owner:CHINA PETROLEUM & CHEM CORP +1

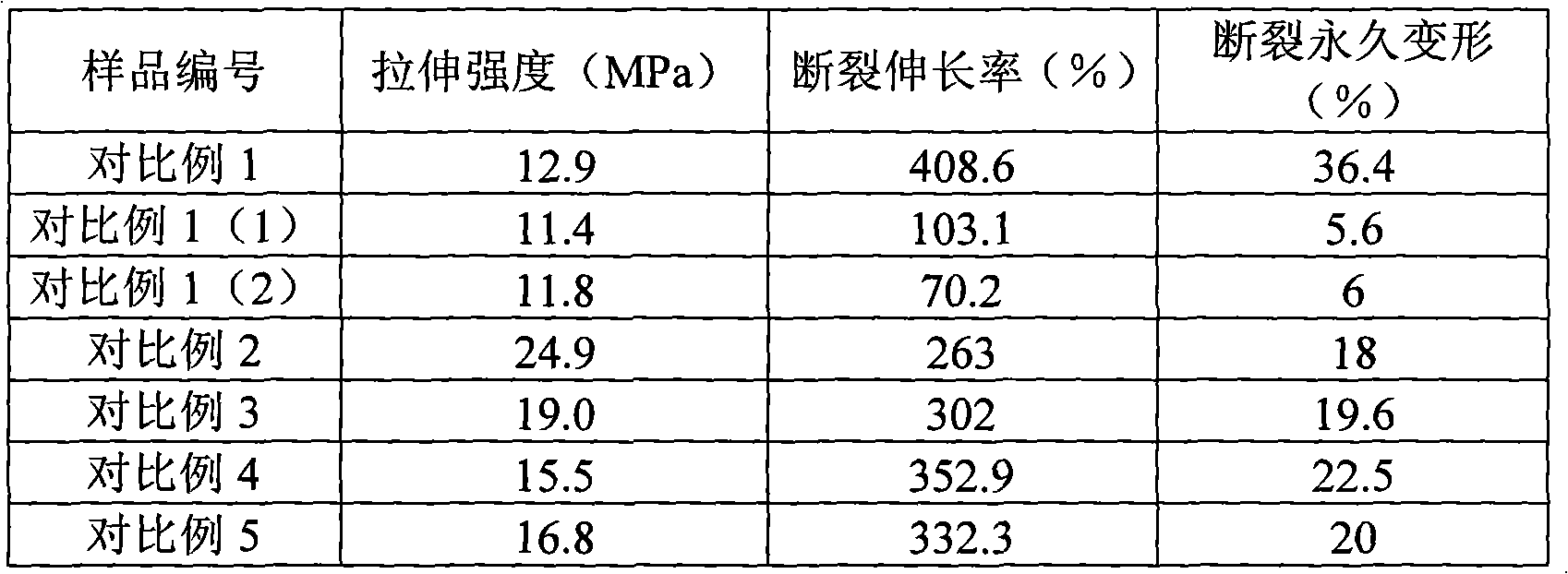

Flame-retardant glycol containing phenyl phosphate-based symmetrical structure and preparation method thereof

InactiveCN104592297AHas flame retardant propertiesRegular structureGroup 5/15 element organic compoundsEthyl acetateTetrahydrofuran

The invention discloses reaction-type flame-retardant glycol containing a phenyl phosphate-based symmetrical structure and a preparation method thereof. The preparation method is characterized by comprising the following steps: reacting phenyl dichlorophosphate with dihydric alcohol in a tetrahydrofuran or ethyl acetate solution in the presence of triethylamine, placing the tetrahydrofuran or ethyl acetate solution of dihydric alcohol and triethylamine into an ice-water bath, stirring and dropwise adding the tetrahydrofuran or ethyl acetate solution of phenyl dichlorophosphate; and filtering a precipitate and then removing the solvent in the filtrate to obtain the product with a structural general formula specified in the description, wherein n is an integer ranging from 2 to 6. According to the preparation method disclosed by the invention, micromolecular dihydric alcohol is introduced in the phenyl dichlorophosphate group in a manner of chemical bonding, so that the obtained dihydric alcohol molecular structure contains both the phenyl dichlorophosphate group and two hydroxyl groups with symmetrical structures and same reaction activity, and can partially or completely replace the micromolecular dihydric alcohol without a flame-retardant characteristic, so that the prepared polymer material has a flame-retardant characteristic; the raw materials in the preparation method disclosed by the invention are easily available, synthesis and post-treatment processes are simple, the cost is low, and the yield can achieve more than 90%.

Owner:UNIV OF SCI & TECH OF CHINA

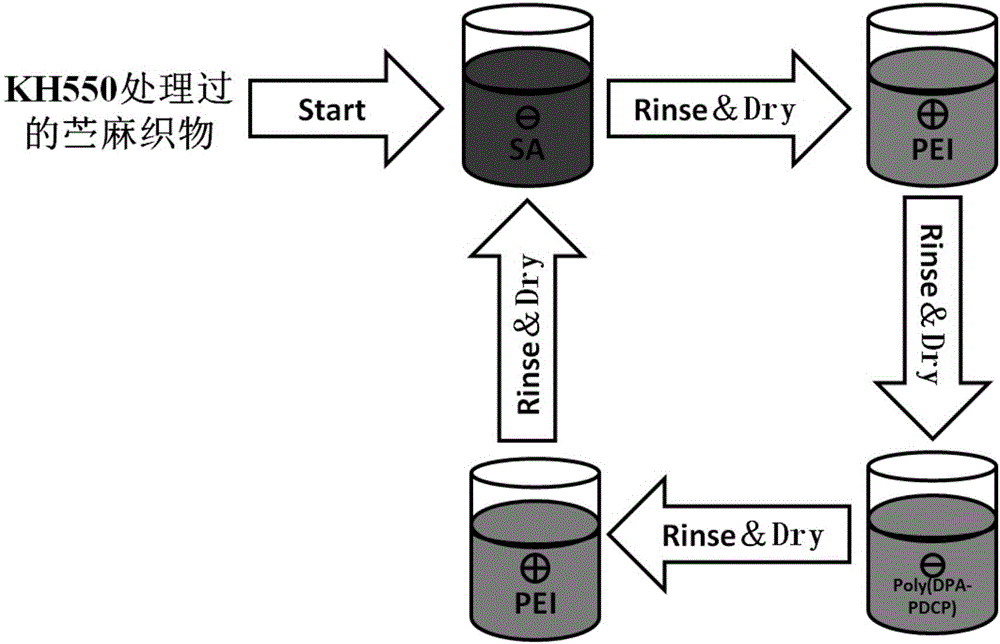

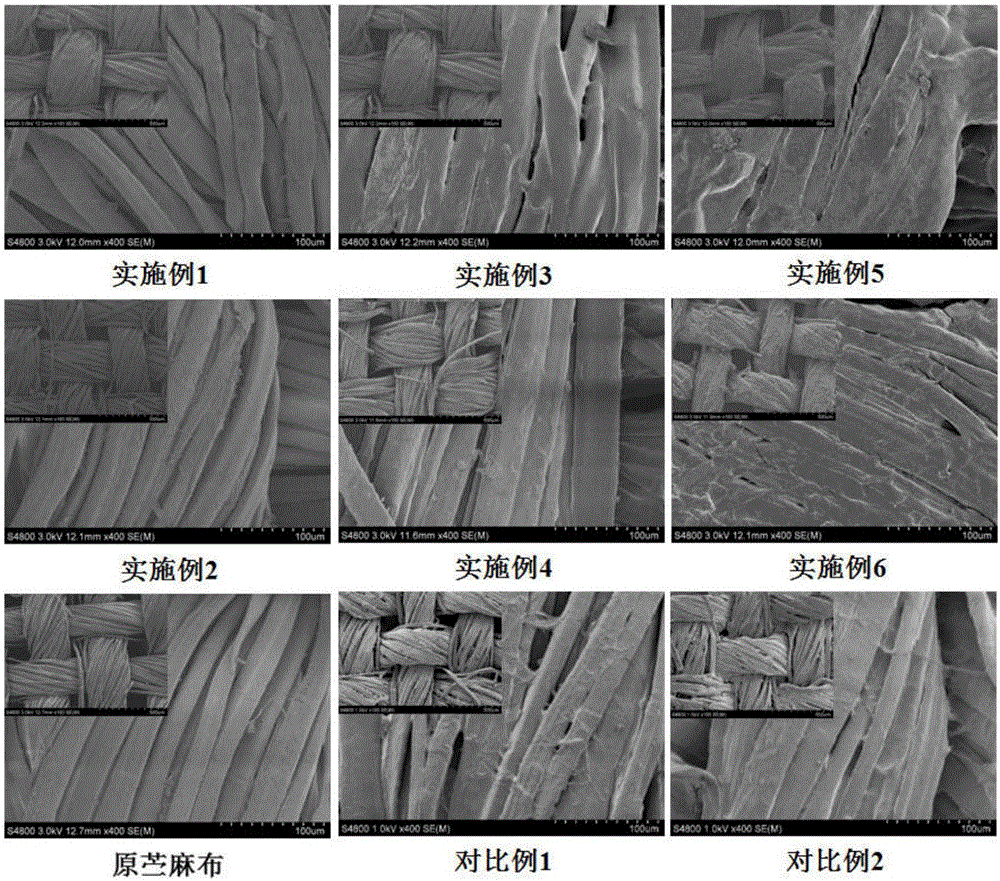

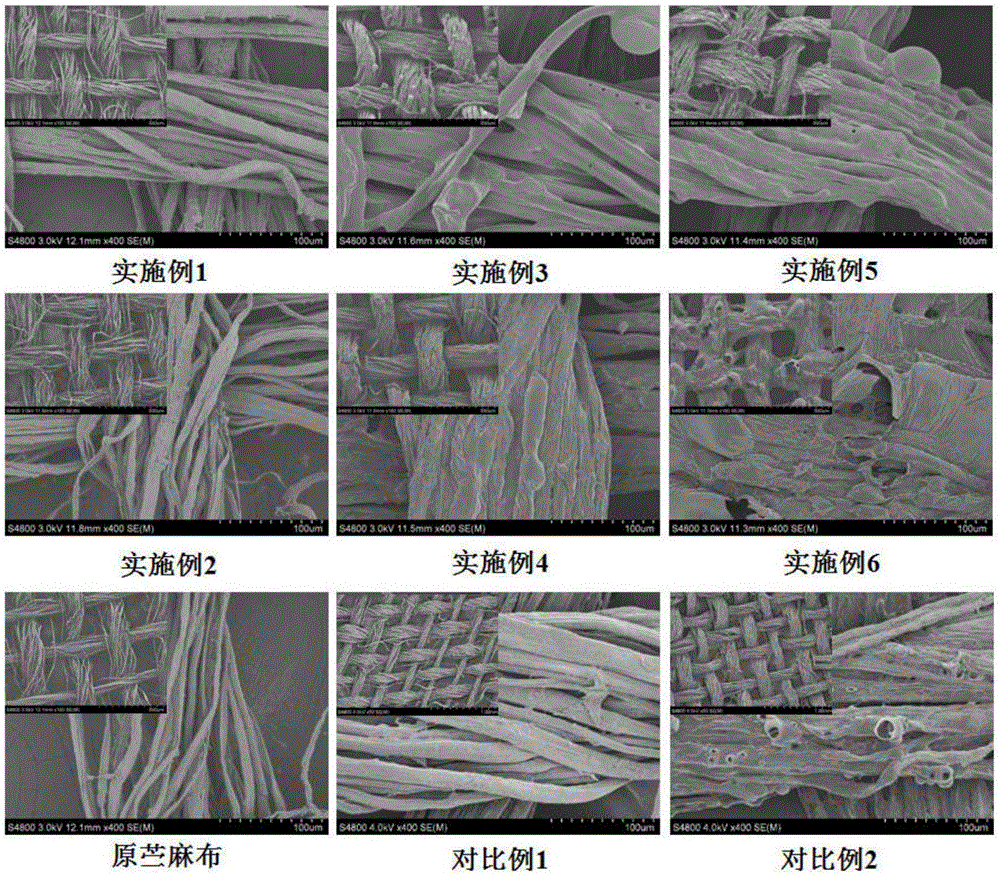

Polyacetylimine/polydiphenolic acid phenyl phosphate/sodium alginate three-component flame-retardant modified ramie fabric and preparation method thereof

ActiveCN107524009AImprove flame retardant performanceComplete shapeVegetal fibresPhenyl phosphateFire retardant

The invention provides a PEI (Polyacetylimine) / poly(DPA-PDCP) (Polydiphenolic Acid Phenyl Phosphate) / SA (Sodium Alginate) layer-by-layer self-assembled flame-retardant modified ramie fabric. A flame-retardant modification layer consists of 1-10 SA / PEI / poly(DPA-PDCP) / PEI layers or poly(DPA-PDCP) / PEI / SA / PEI layers. The preparation method of the ramie fabric comprises the following steps: soaking a ramie fabric in a KH550 solution, drying, soaking in an SA solution, a PEI solution, a poly(DPA-PDCP) solution and a PEI solution in sequence, performing flame-retardant coating assembling treatment, and cleaning and drying after each time of soaking; and repeating the process till 1-10 four-layer flame-retardant coatings are assembled on the surface of the ramie fabric. When the method is compared with a PEI / poly(DPA-PDCP) double-component flame retardant coating, the adsorption capacity of the fabric coating is greatly increased due to introduction of a third component SA, the assembling number can be reduced while the flame retardant modification effect is improved, the assembling treatment time is shortened to a certain extent, the flexibility and stability of the method are further improved, and the cost is lowered.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

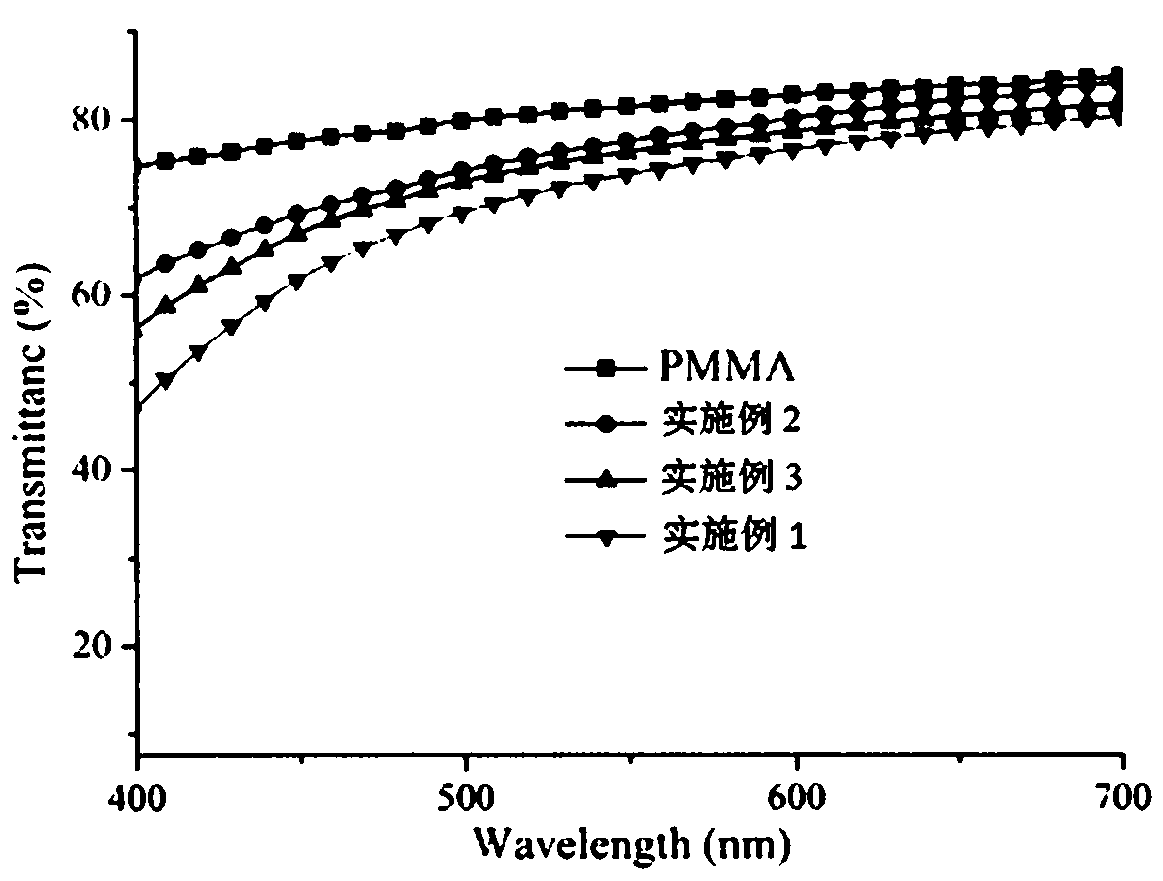

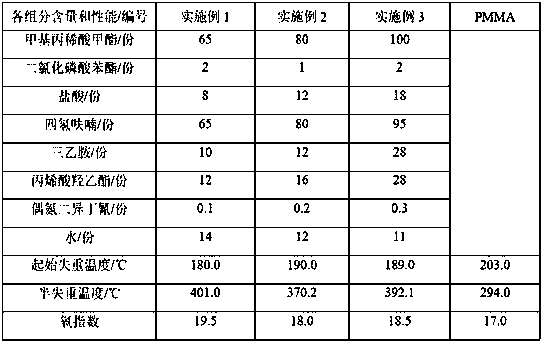

Flame retardant organic glass and preparation method thereof

The invention belongs to the technical field of organic glass materials, and relates to a flame-retardant organic glass and a preparation method thereof. The flame-retardant plexiglass of the present invention is prepared from the following raw materials in parts by weight: 60-100 parts of methyl methacrylate, 1-2 parts of phenyl phosphate dichloride, 5-20 parts of hydrochloric acid, and 60 parts of tetrahydrofuran ‑100 parts, 10‑30 parts of triethylamine, 10‑30 parts of hydroxyethyl acrylate, 0.1‑0.5 parts of azobisisobutylcyanide and 5‑20 parts of water. The invention adds a synthetic flame retardant to make the outer carbon layer of the flame-retardant plexiglass very dense and smooth, which reduces the overflow of flammable gas and plays the role of heat and oxygen insulation, improves the flame-retardant performance, and improves the thermal stability. performance while maintaining good transparency.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

High CTI value halogen free flame-retardant reinforced PBT composite material and preparation method thereof

The invention relates to a PBT composite material, in particular to a high CTI value halogen free flame-retardant reinforced PBT composite material and a preparation method thereof. The PBT composite material comprises the following components in parts by weight: 48-64 parts of PBT, 20-30 parts of glass fibre, 16-22 parts of flame retardant, 0.1-0.5 part of CTI synergist, 0.3-0.8 part of anti-oxidant, and 0.5-0.8 part lubricant; wherein the flame retardant is prepared by comprising one or more components comprising methyl phenyl phosphate, methyl phenyl phosphate ester and methyl phenyl phosphite ester; the CTI synergist is prepared by comprising at least one of components comprising calcium oxide, magnesium oxide, and barium oxide; the anti-oxidant is prepared by comprising 1010 or 168; and the lubricant is prepared by comprising at least one of the components comprising EBS, oxidized lignite wax and oxidized polyethylene wax. The PBT composite material has the advantages of high CTI, environmental protection, high performance and the like.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

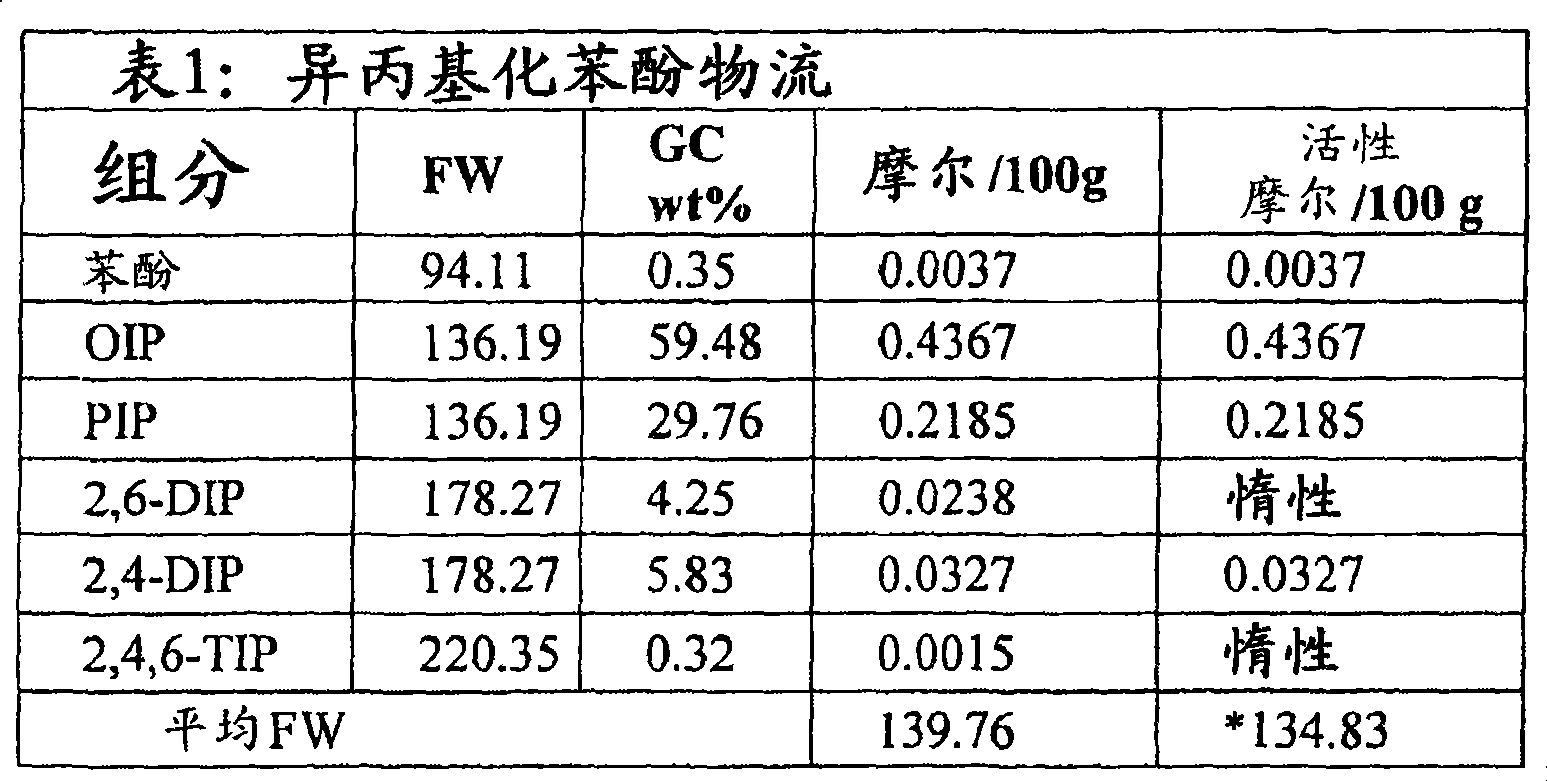

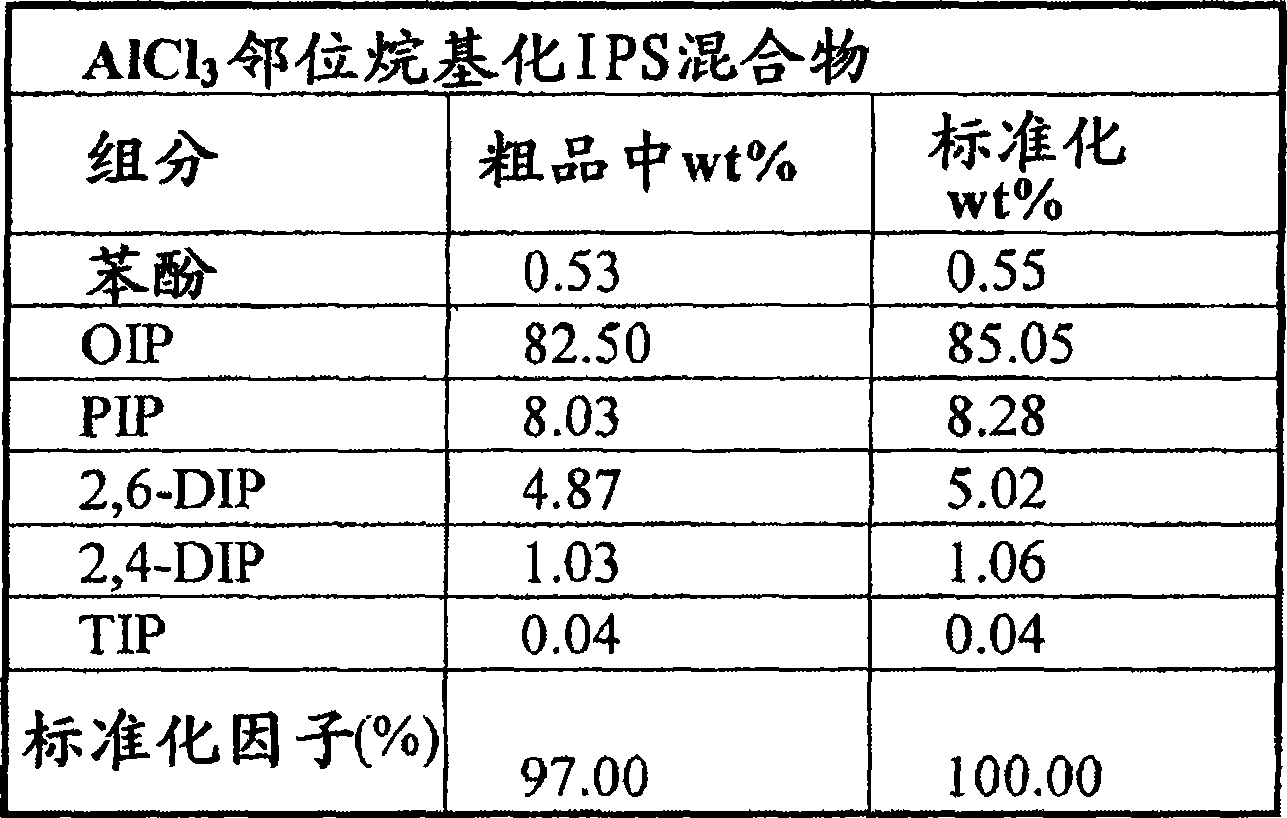

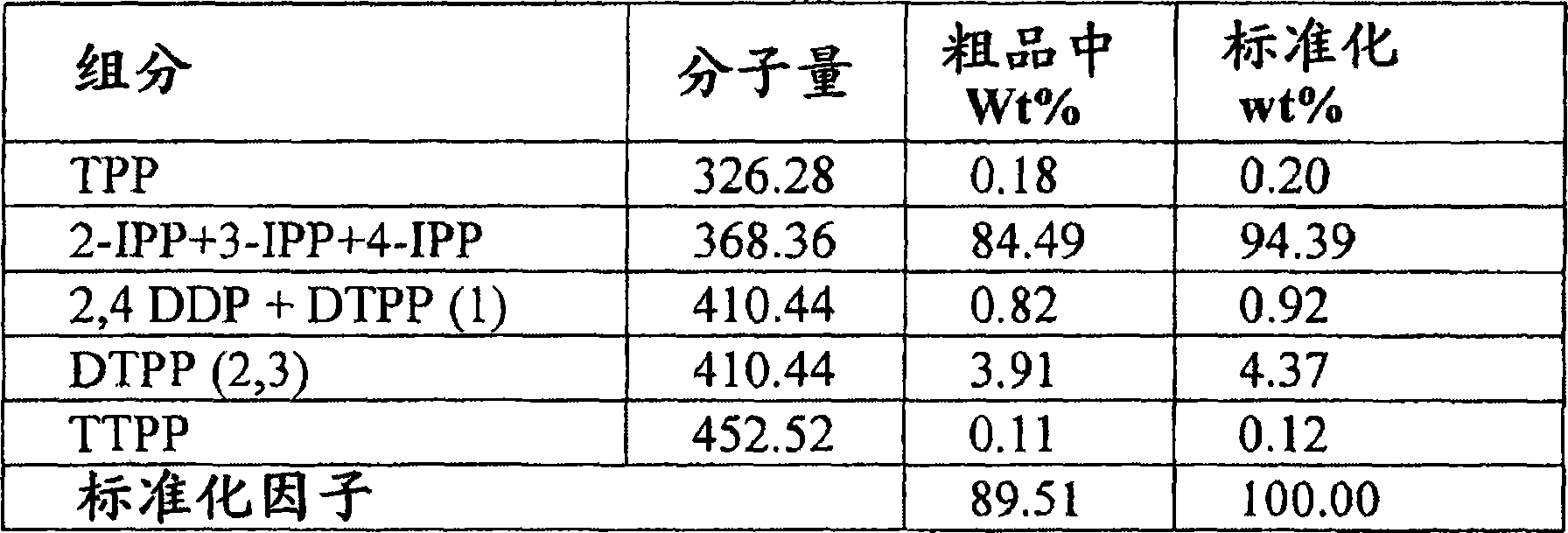

Use of low triphenylphosphate, high phosphorous content isopropyl phenyl phosphates as flame retardants in polyurethane or polyisocyanurate foams

The present invention relates to the use of low triphenyl phosphate, high phosphorous content aryl phosphates with high ortho alkylation as flame retardants in polyurethane or polyisocyanurate foams or polyurethane or polyisocyanurate foam formulations.

Owner:HICKORY SPRINGS MFG

Biomass oil suitable for modifying thermosetting resin and preparation method thereof

ActiveCN105860428AEasy to prepareMild reaction conditionsLiquid carbonaceous fuelsHydrocarbon oils treatmentDistillationSalicylic acid

The invention discloses biomass oil suitable for modifying thermosetting resin and a preparation method thereof. The biomass oil is prepared from the following raw materials in parts by weight: 150-350 parts of biomass briquette, 280-520 parts of reaction medium A, 30-120 parts of reaction medium B, 5-20 parts of catalyst C, 2-8 parts of catalyst D and 2-9 parts of neutralizing agent, wherein the reaction medium A is one or more of methanol, ethanol, butanol and glycerin; the reaction medium B is one or more of ethyl acetate, acetone, toluene and petroleum ether; the catalyst C is one or more of phenolsulfonic acid, p-toluenesulfonic acid, benzenesulfonic acid, phenyl phosphate and salicylic acid; the catalyst D is one or more of inorganic acids; and the biomass oil is prepared by the steps of charging, heating for reacting, cooling, separation and distillation. With relatively good quality indexes, the biomass oil does not need secondary processing and can be directly applied to the modification of thermosetting resin; and moreover, the preparation method is simple, the reaction conditions are mild, and the production cost is reduced.

Owner:四川景文材料科技有限公司

Low pressure resistant polyethylene terephthalate resin and producing method thereof

A low-pressure-resisting polypara-formate ethylene glycol ester resin contains isophthalic acid, ethylene glycol, diglycol, catalyst, stabilizer and p-phthalic acid; catalyst is antimony or cellulose antimony or Germanic oxide, stabilizer is phosphoric acid or poly-phosphoric acid or phosphorous acid or tri-methyl phosphate or tri-phenyl phosphate. The process is carried out by beating, esterification reacting, polymerization reacting, dicing, pre-crystallizing, crystallizing, solid-phase polymerizing, and fluidized cooling to obtain final product. It costs low and can be used to produce soda beverage bottle.

Owner:新疆维格瑞生物科技有限公司

High temperature resistance flaming-retardant silicone rubber cable material for electric power and preparing method thereof

InactiveCN104945916AImprove flame retardant performanceImprove high temperature resistanceRubber insulatorsTetrabromobisphenol AWear resistant

The invention discloses a high temperature resistance flaming-retardant silicone rubber cable material for electric power and a preparing method thereof. The high temperature resistance flaming-retardant silicone rubber cable material for the electric power is formed by following raw materials, by weight, 120-140 parts of methyl vinyl silicone rubber, 10-20 parts of chloroprene rubber, 8-12 parts of polyethylene glycol terephthalate, 4-5 parts of tri methylol propane tri methacrylate, 8-10 parts of magnesium hydrate, 40-50 parts of dicyclohexyl terephthalate, 6-7 parts of vinyl trimethoxy silane, 4-6 parts of NDZ-401 titanate coupling agents, 6-8 parts of organic antimony stabilizer, 5-7 parts of antioxygen, 50-60 parts of nano calcium carbonate, 8-10 parts of diisooctyl phenyl phosphate, 11-13 parts of tetrabromo-bisphenol A, 6-9 parts of polyoxyethylene polyoxy hydramine amidogen ether, 6-8 parts of demethyl siloxane, 4-5 parts of antimonous oxide, 7-9 parts of calcium stearate, 7-10 parts of carbon monofluoride and 8-12 parts of nanometer titania. According to the synergistic effect of the added antimonous oxide and chlorine elements of the chloroprene rubber, the flaming retardant property of the methyl vinyl silicone rubber is enhanced, due to the added polyethylene glycol terephthalate, the diisooctyl phenyl phosphate and the tetrabromo-bisphenol A, the high temperature resistant property of the silicon rubber is improved, the wear resistant property and the machining performance are improved at the same time, and the flexibility of the cable is improved.

Owner:CHANGZHOU CITY WUJIN DISTRICT KAILIDA ELECTRONICS

Extreme pressure lubricating metal cutting fluid

InactiveCN106244295AImprove the lubrication effectExcellent extreme pressure lubricityAdditivesFatty alcoholOleic Acid Triglyceride

The invention discloses an extreme pressure lubricating metal cutting fluid, which comprises the following raw materials by weight: 20-50 parts of cycloalkyl silicone oil, 5-15 parts of a modified anionic surfactant, 2-6 parts of borax, 3-6 parts of diethanolamine, 1-5 parts of boric acid, 2-6 parts of heptanoic acid, 3-6 parts of oleic acid, 1-4 parts of polyoxyethylene stearyl phosphate, 2-5 parts of polyoxyethylene phenyl phosphate, 1-3 parts of maleic anhydride, 2-6 parts of dodecyl ammonium benzene sulfonate, 3-5 parts of sodium alkylsulfonate, 1-4 parts of fatty alcohol polyoxyethylene ether, 2-6 parts of sodium benzoate, 3-5 parts of an antifoaming agent, 1-5 parts of methyl benzotriazole, 2-6 parts of an antirust additive, 1-4 parts of an anticorrosive bactericide, and 3-9 parts of water. The metal cutting fluid of the present invention has advantages of excellent extreme pressure lubricating performance, excellent lubricating performance, excellent cooling performance, excellent corrosion resistance, and excellent rust resistance.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

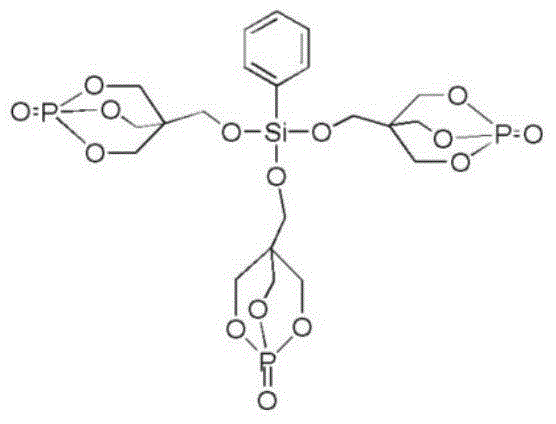

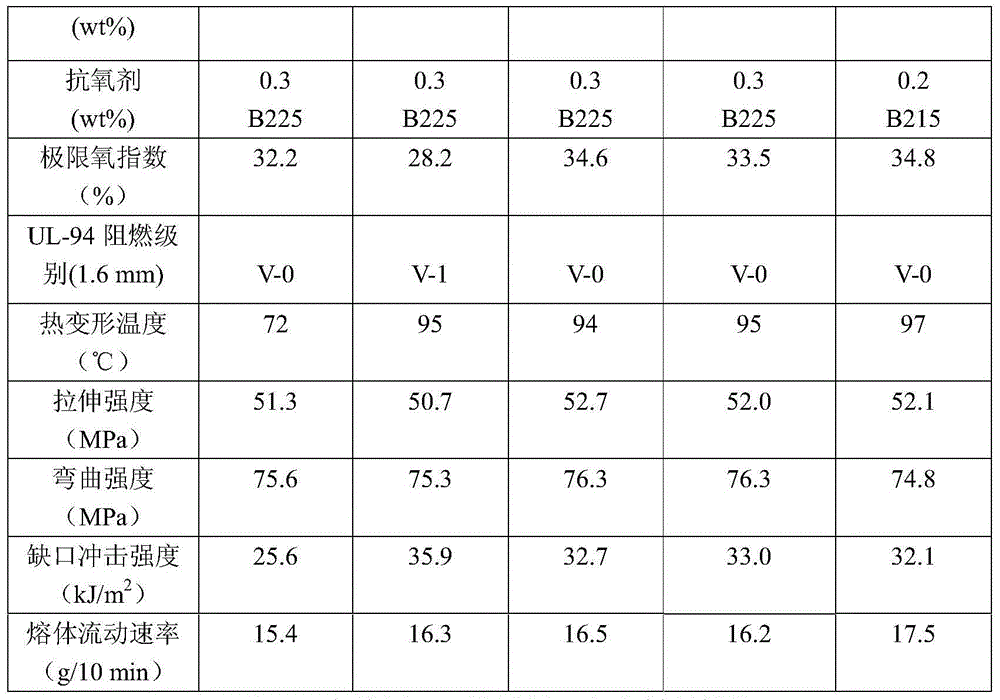

Bicyclic caged phenyl phosphate silicone modified flame-retardant PC/ABS (polycarbonate/acrylnitrile-butadiene-styrene) alloy and preparation method thereof

ActiveCN104530677AHigh flame retardant gradeImprove heat resistanceHeat deflection temperatureAntioxidant

The invention discloses a bicyclic caged phenyl phosphate silicone modified flame-retardant PC / ABS (polycarbonate / acrylnitrile-butadiene-styrene) alloy and a preparation method thereof. The flame-retardant PC / ABS alloy is prepared from the following raw materials in percentage by mass: 55-60% of polycarbonate, 20-25% of an ABS copolymer, 7-9% of phosphate, 5-7% of bicyclic caged phenyl phosphate silicone, 5-7% of a polydimethylsiloxane-styrene-methyl methacrylate copolymer, 0.3-0.5% of an anti-dripping agent and 0.2%-0.4% of an antioxidant. The flame retardant rating of the flame-retardant PC / ABS alloy disclosed by the invention is UL94V-0@1.6mm, the heat deflection temperature is above 92 DEG C, the notched impact strength is above 31kJ / m<2>, and the melt flow rate is above 16g / 10min. The flame-retardant PC / ABS alloy has the advantages of high flame retardant rating, good heat resistance, excellent mechanical properties and good processing fluidity.

Owner:广州广化塑料管道有限公司

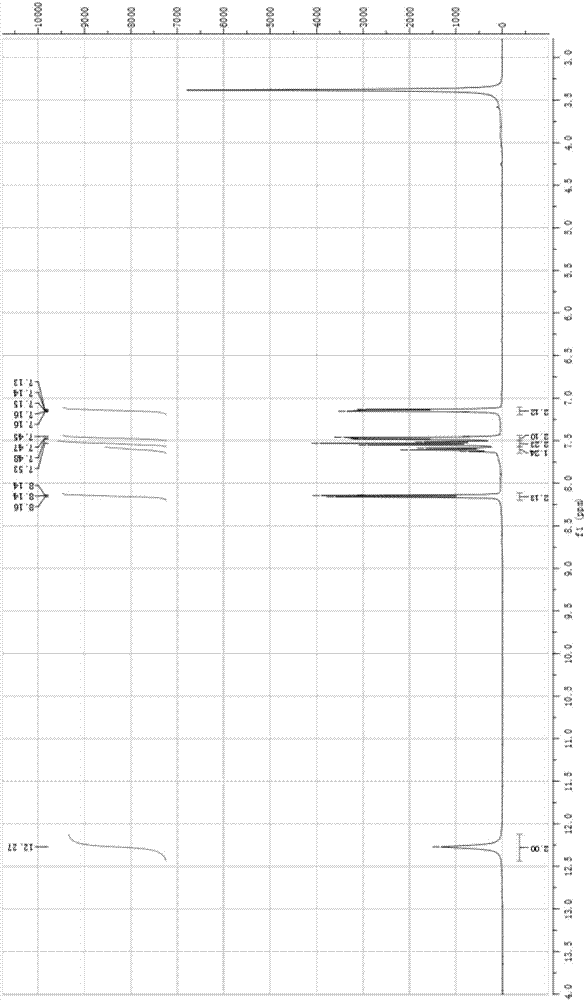

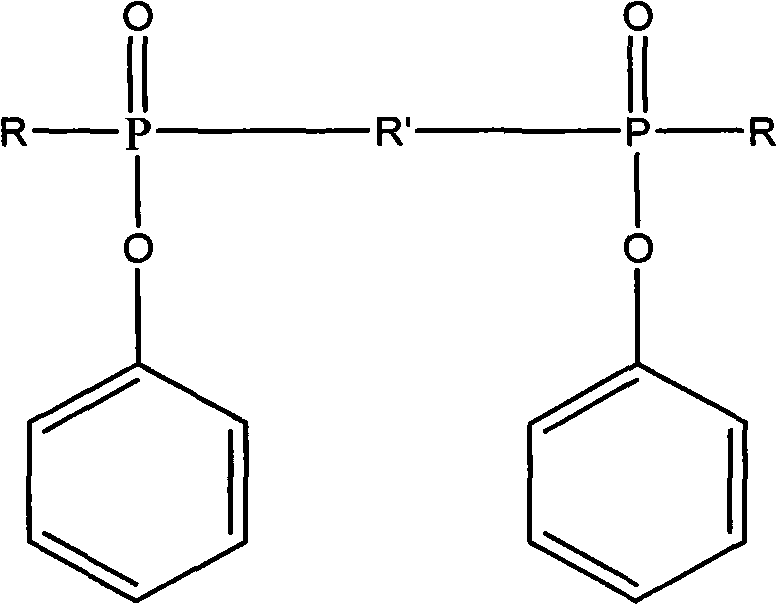

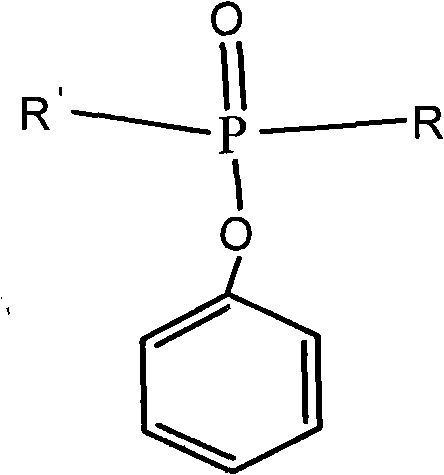

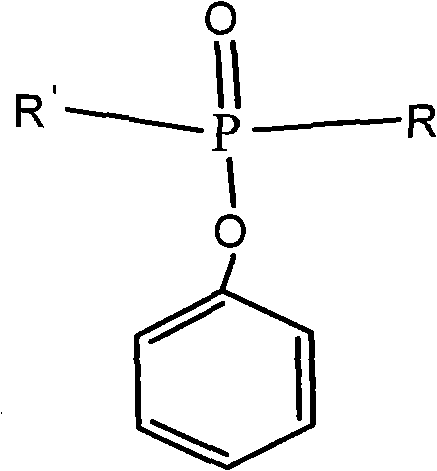

Method for preparation of N-[(S)-(2,3,4,5,6-pentafluorophenoxy)phenoxy phosphoryl]-L-alanine isopropyl ester

ActiveCN104761582ARealize large-scale productionSolution conditionsGroup 5/15 element organic compoundsOrganic solventPhenyl phosphate

The invention discloses a method for preparation of N-[(S)-(2,3,4,5,6-pentafluorophenyloxy)phenoxy phosphoryl]-L-alanine isopropyl ester; the method comprises the steps: first of all, carrying out a reflux reaction of dichloro phenyl phosphate and pentafluorophenol for 5-15 hours in an organic solvent and under an alkaline condition; followed by, cooling the reaction liquid down to room temperature, adding L-alanine isopropyl ester hydrochloride, and carrying out a stirring reaction for 2-8 hours at room temperature; and then carrying out suction filtration, concentrating the filtrate under reduced pressure, and carrying out recrystallization treatment on the concentrated residue. The method can effectively solve the defect problems that a conventional method has harsh reaction conditions, high requirements on equipment, relatively low yield and the like, prepares the high-purity N-[(S)-(2,3,4,5,6-pentafluorophenyloxy)phenoxy phosphoryl]-L-alanine isopropyl ester with simple operation, mild conditions and relatively high yield, and has an important value on achieving scale production of the compound.

Owner:SHANGHAI DESANO CHEM PHARMA +1

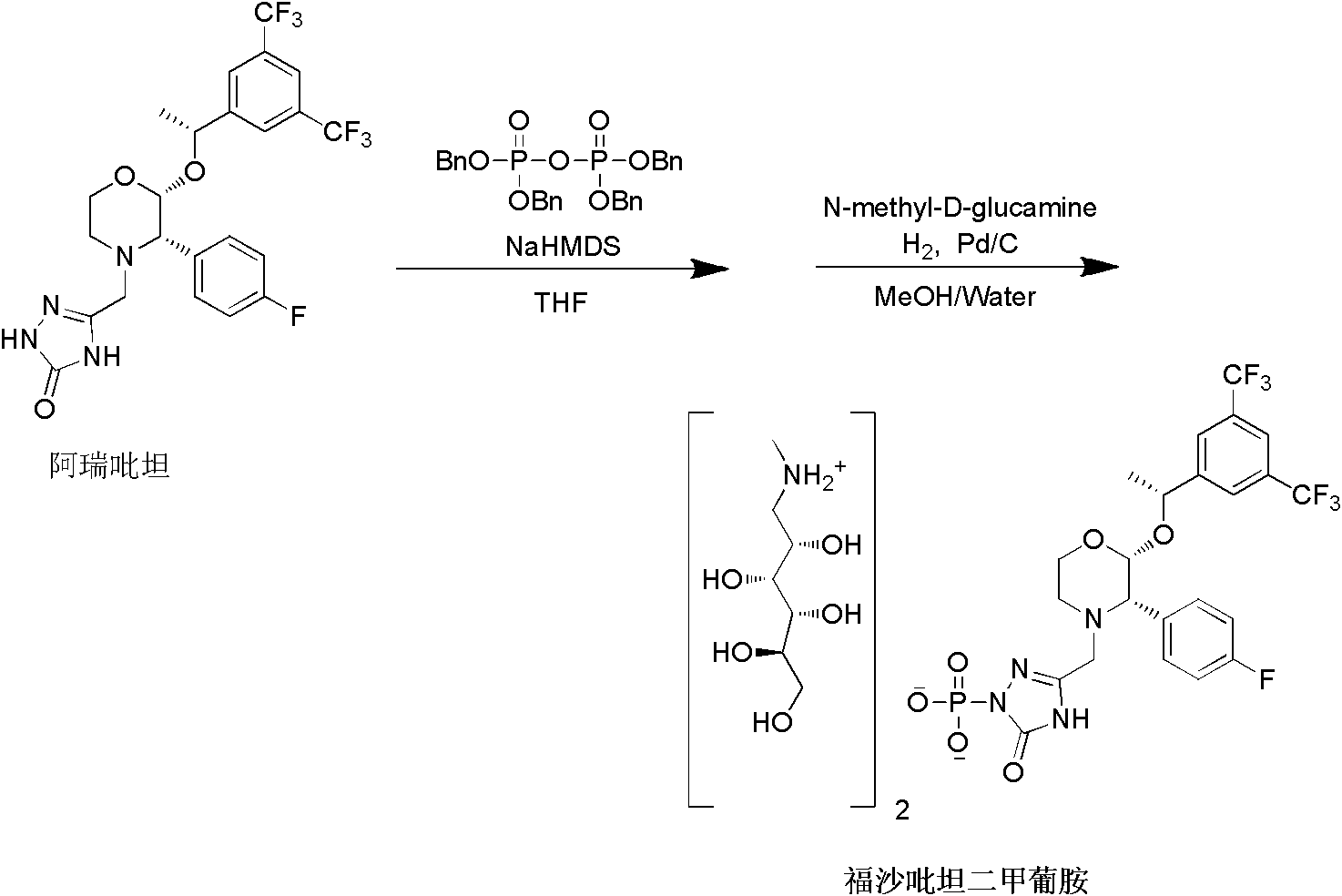

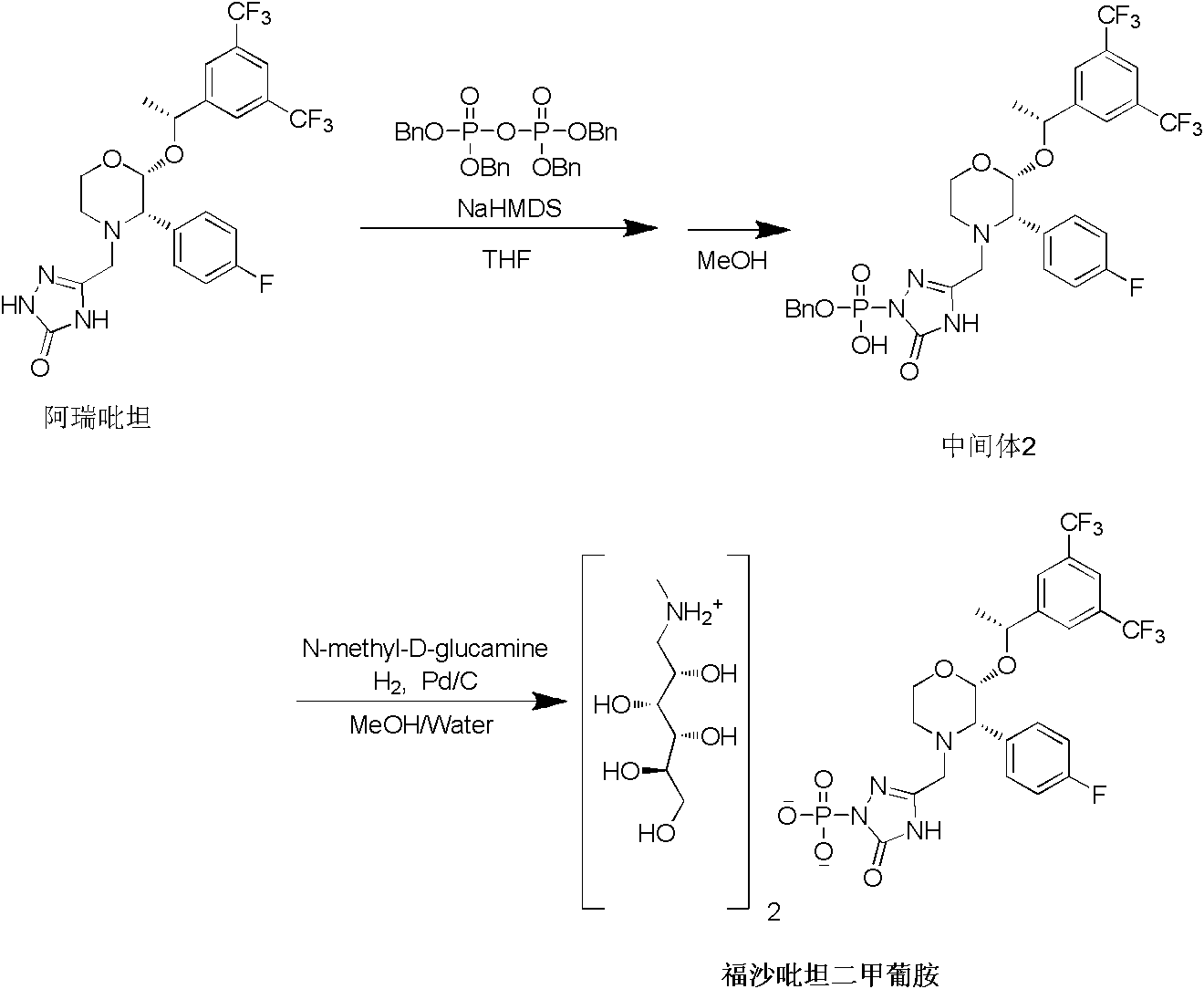

Preparation method for fosaprepitant dimeglumine

InactiveCN103183708ASimple and fast operationMild conditionsGroup 5/15 element organic compoundsTrimethylsilylPhenyl phosphate

The invention provides a preparation method for fosaprepitant dimeglumine. The method comprises the steps of condensation reacting aprepitant and tetrabenzyl pyrophosphate in tetrahydrofuran in presence of bis(trimethylsilyl)sodamide to obtain bis-O-phenyl phosphate; then temperature reacting with methanol to obtain mono-O-phenyl phosphate; and finally obtaining the fosaprepitant dimeglumine through a hydrogenation reaction. The method is simple in operations, mild in conditions, low in cost and high in yield, is suitable for industrialized production and has relatively large application value.

Owner:YANGZIJIANG PHARMA GROUP SHANGHAI HAINI PHARMA

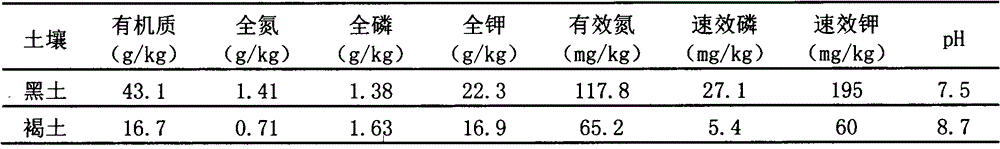

Enzyme preparation composition for improving fertility of soil, and its applications

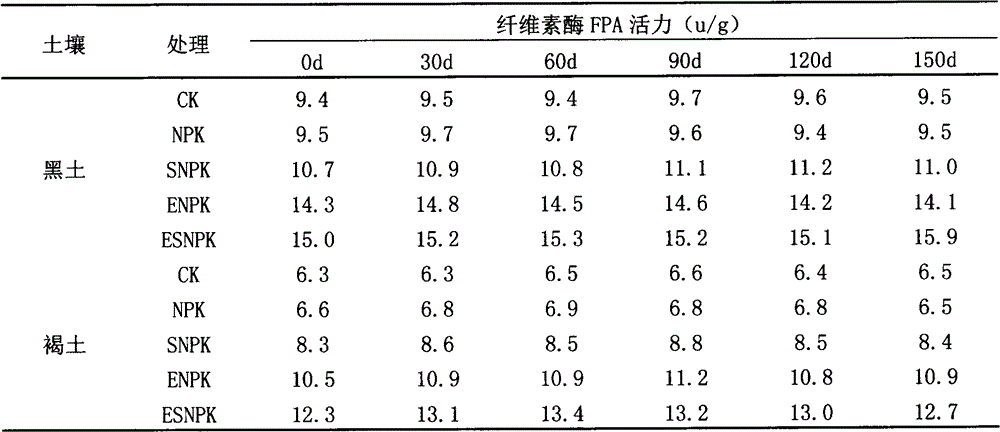

The invention aims to provide an enzyme preparation composition for improving the fertility of soil, and its applications. The enzyme preparation composition is added to fully and accurately decompose organic fertilizers and plant straws to improve the contents of active organic matters in the soil so as to reach soil fertility and sol quality improvement purposes. The enzyme preparation composition provided by the invention can be applied after mixed with the organic fertilizers, inorganic fertilizers and the straws, and can also be sprayed on the surfaces of the organic fertilizers or the straws after dissolved in water with a ratio of the enzyme preparation composition to water being 1:9. The enzyme preparation composition is characterized in that the enzyme preparation composition comprises the components, by enzyme activity, 10000-50000mu / g of cellulase (QB 2583-2003, filter paper activity (FPA)), 1000-3000mg / g of sucrase (3,5-dinitrosalicylic acid colorimetry), 2000-10000mg / g of catalase (potassium permanganate titration method), 500-1000ug / g of soil protease (rancTRH method) and 500-1000mg / g of soil phosphatase (disodium phenyl phosphate colorimetry).

Owner:SUZHOU KUNLAN BIOTECH

Refrigerator working fluid composition and refrigerant oil

ActiveUS20150115194A1Reduce coefficient of frictionLong period of timeHeat-exchange elementsLubricant compositionDiphenyl phosphateWorking fluid

A working fluid composition for a refrigerating machine comprising: a refrigerating machine oil containing at least one lubricating base oil selected from a mineral oil and a synthetic oil, and at least one phosphorus compound selected from a mono(alkylphenyl) diphenyl phosphate having a C3-C5 alkyl group and a di(alkylphenyl) phenyl phosphate having two C3-C5 alkyl groups, wherein a content of the phosphorus compound is 0.01 to 5% by mass based on a total amount of the refrigerating machine oil; and a hydrocarbon refrigerant having 2 to 4 carbon atoms.

Owner:JX NIPPON OIL & ENERGY CORP

Low triphenylphosphate, high phosphorous content isopropyl phenyl phosphates with high ortho alkylation

The present invention relates to low triphenyl phosphate, high phosphorous content aryl phosphates with high ortho alkylation that are suitable for use as flame retardant compositions, processes for their preparation, and their use as flame retardants.

Owner:ALBEMARLE CORP

Use of low triphenylphosphate, high phosphorous content isopropyl phenyl phosphates as flame retardants in polyurethane or polyisocyanurate foams

The present invention relates to the use of low triphenyl phosphate, high phosphorous content aryl phosphates with high ortho alkylation as flame retardants in polyurethane or polyisocyanurate foams or polyurethane or polyisocyanurate foam formulations.

Owner:HICKORY SPRINGS MFG

Chlorinated-esterified polybutadiene rubber modified polyvinyl chloride cable material

The invention discloses a chlorinated-esterified polybutadiene rubber modified polyvinyl chloride cable material which is prepared from the following raw materials: polyvinyl chloride, chlorinated-esterified polybutadiene rubber, modified pyrophyllite, calcined argil, zinc oxide, stearic acid, epoxy resin, polysulfide rubber, triphenyl phosphate, a methyl methacrylate-butadiene-styrol copolymer, epoxy butyl oleate, a thermal stabilizer, polyhydric alcohols, aluminum hydroxide, diisooctyl phenyl phosphate, dilauryl thiodipropionate, a coupling agent, barium stearate and dicumyl peroxide. The chlorinated-esterified polybutadiene rubber modified polyvinyl chloride cable material disclosed by the invention is high in shock strength and good in thermal stability and has excellent flame-retardant, wear-resistant and corrosion-resistant properties.

Owner:无为县华祥电缆材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparation of N-[(S)-(2,3,4,5,6-pentafluorophenoxy)phenoxy phosphoryl]-L-alanine isopropyl ester Method for preparation of N-[(S)-(2,3,4,5,6-pentafluorophenoxy)phenoxy phosphoryl]-L-alanine isopropyl ester](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/2aa91e72-2b25-4b9d-aaae-9d4a77fc70db/BDA0000454418690000011.PNG)

![Method for preparation of N-[(S)-(2,3,4,5,6-pentafluorophenoxy)phenoxy phosphoryl]-L-alanine isopropyl ester Method for preparation of N-[(S)-(2,3,4,5,6-pentafluorophenoxy)phenoxy phosphoryl]-L-alanine isopropyl ester](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/2aa91e72-2b25-4b9d-aaae-9d4a77fc70db/BDA0000454418690000012.PNG)

![Method for preparation of N-[(S)-(2,3,4,5,6-pentafluorophenoxy)phenoxy phosphoryl]-L-alanine isopropyl ester Method for preparation of N-[(S)-(2,3,4,5,6-pentafluorophenoxy)phenoxy phosphoryl]-L-alanine isopropyl ester](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/2aa91e72-2b25-4b9d-aaae-9d4a77fc70db/BDA0000454418690000021.PNG)