Coke inhibitor for ethylene cracking

A technology of ethylene cracking and decoking agent, which is applied in the field of oil refining additives. It can solve the problems that it is difficult to achieve the purpose of coke cleaning and descaling, and achieve the effects of good coke suppression, improved operation cycle and alleviating coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

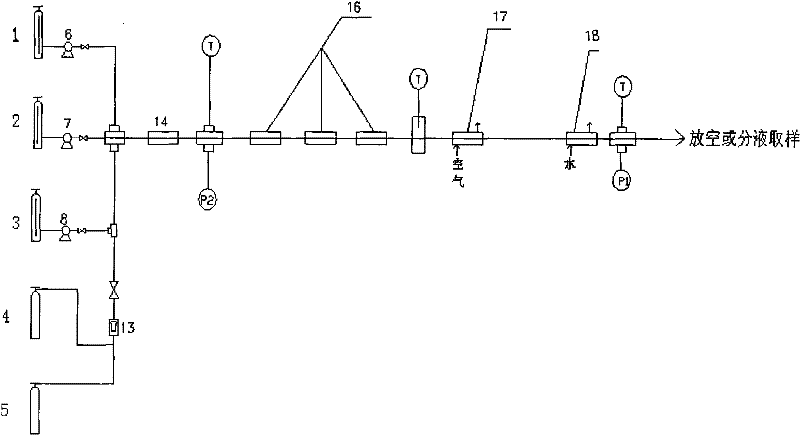

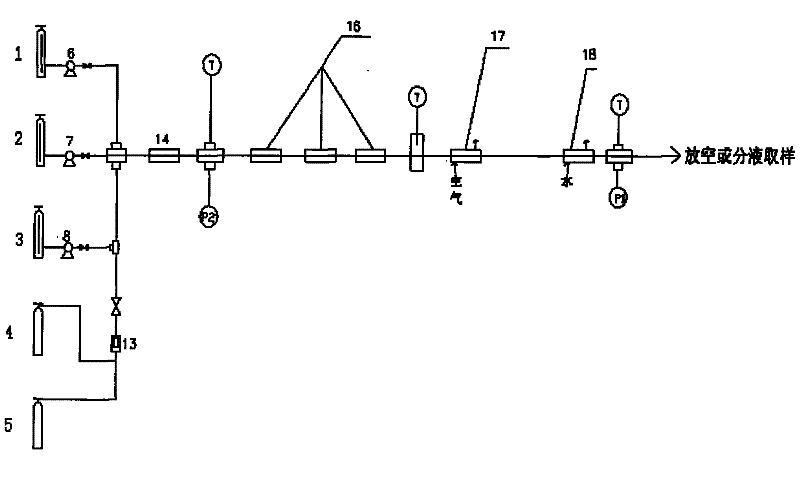

Image

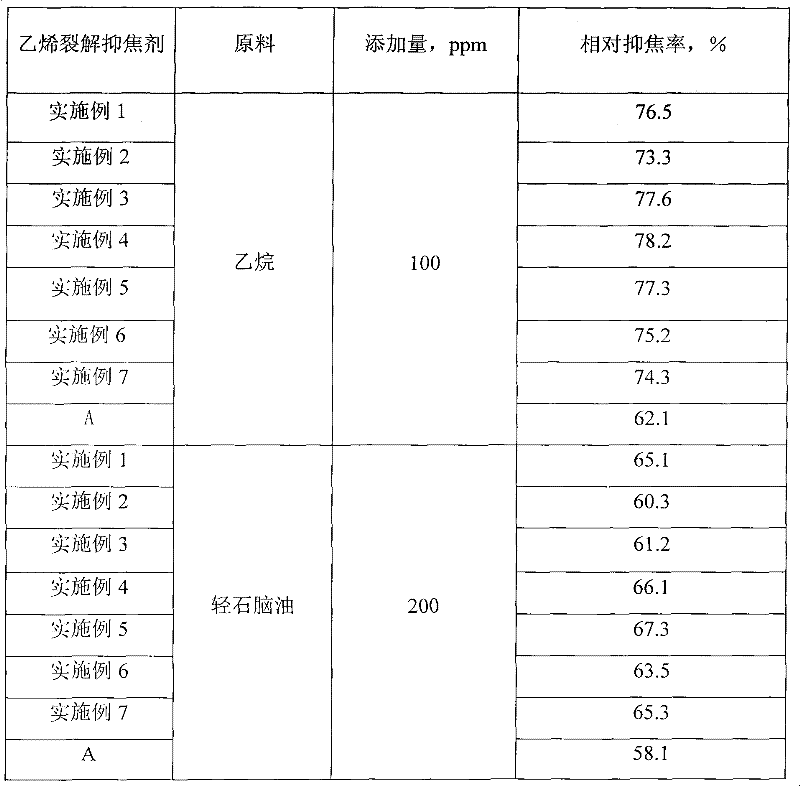

Examples

Embodiment 1

[0023] Example 1 Ethylene cracking scorch inhibitor consists of 25% dimethyl disulfide, 10% triphenyl phosphite, 10% polydiethylsiloxane, 15% p-tert-butylcatechol, high alkali value (TBN> 250mgKOH / g) magnesium alkyl salicylate 3% and C10 heavy aromatic hydrocarbon solvent 37%.

Embodiment 2

[0024] Example 2 Ethylene cracking scorch inhibitor consists of 55% diphenyl disulfide, 5% dioctylphenyl phosphate, 1% polydimethylsiloxane, 5% hydroquinone, calcium alkyl salicylate ( Abbreviated as T109) 9% and tetralin 25%.

Embodiment 3

[0025] Example 3 Ethylene cracking scorch inhibitor consists of thiophene 35%, triacylpiperidine phosphate 7%, polymethylphenylsiloxane 5%, diethylhydroxylamine 13%, Mannich benzylamine 4% and methylnaphthalene 36% composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com