Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

309 results about "Tetralin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetralin (1,2,3,4-tetrahydronaphthalene) is a hydrocarbon having the chemical formula C₁₀H₁₂. It is a partially hydrogenated derivative of naphthalene. It is a colorless liquid that is used as a hydrogen-donor solvent.

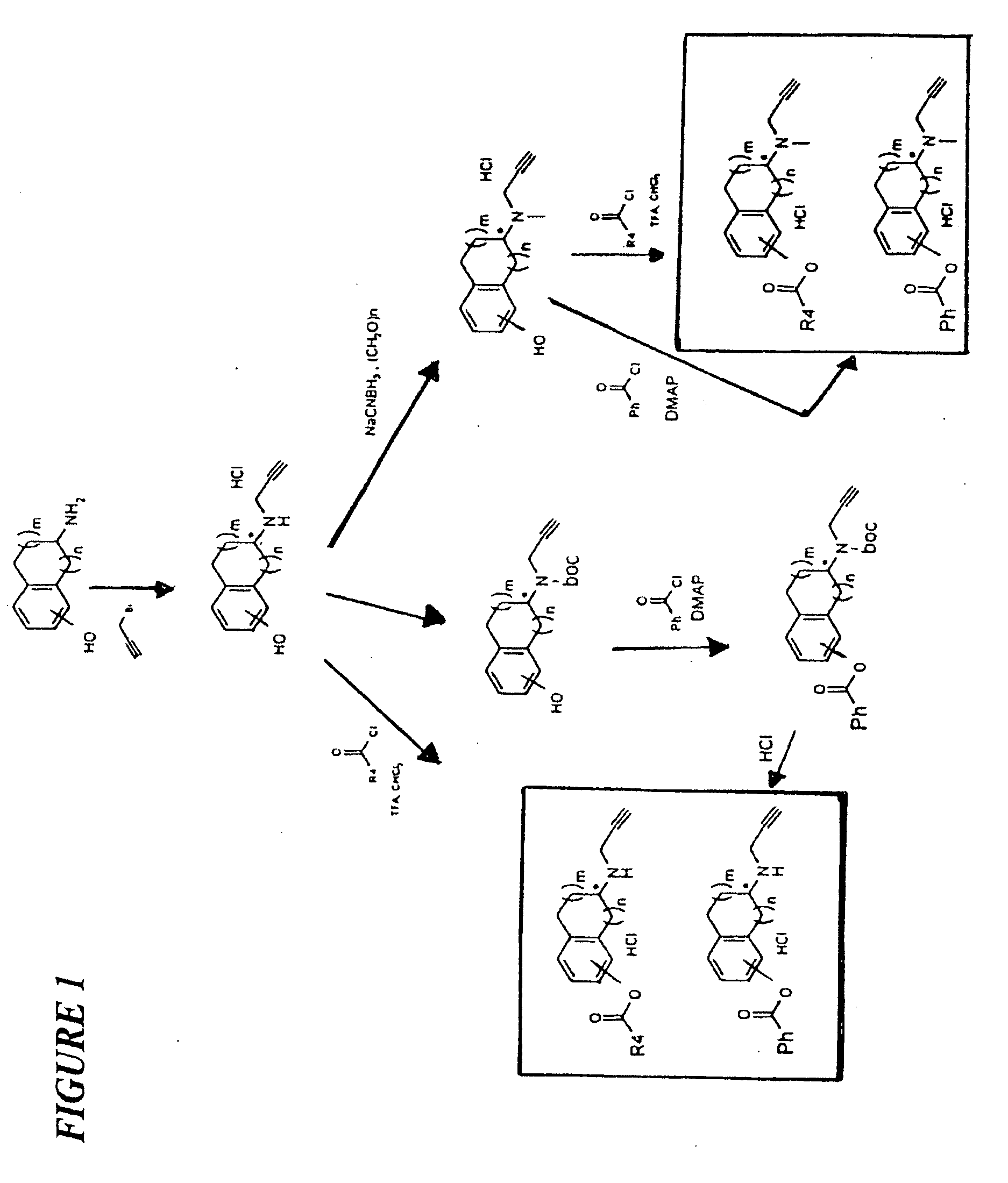

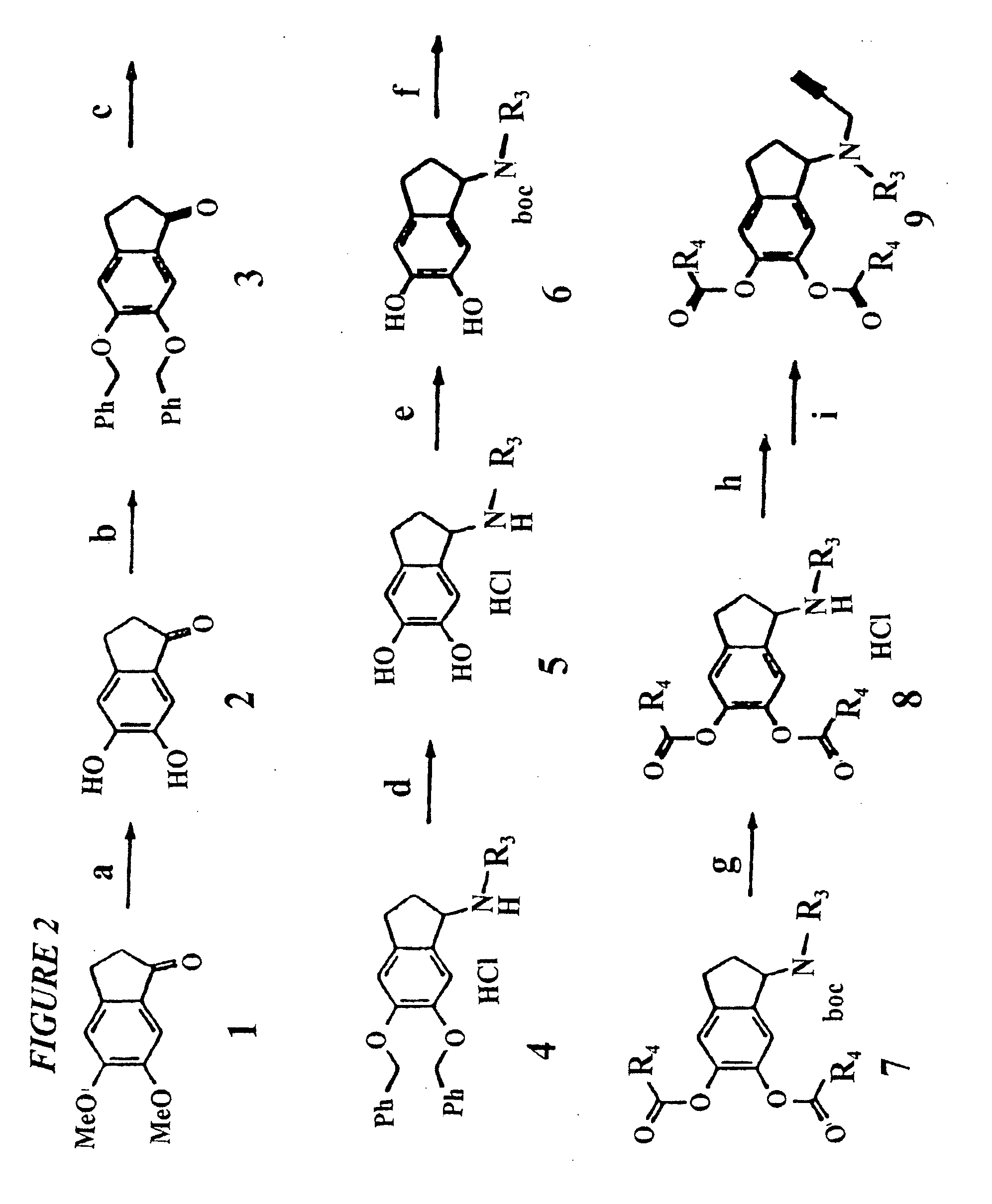

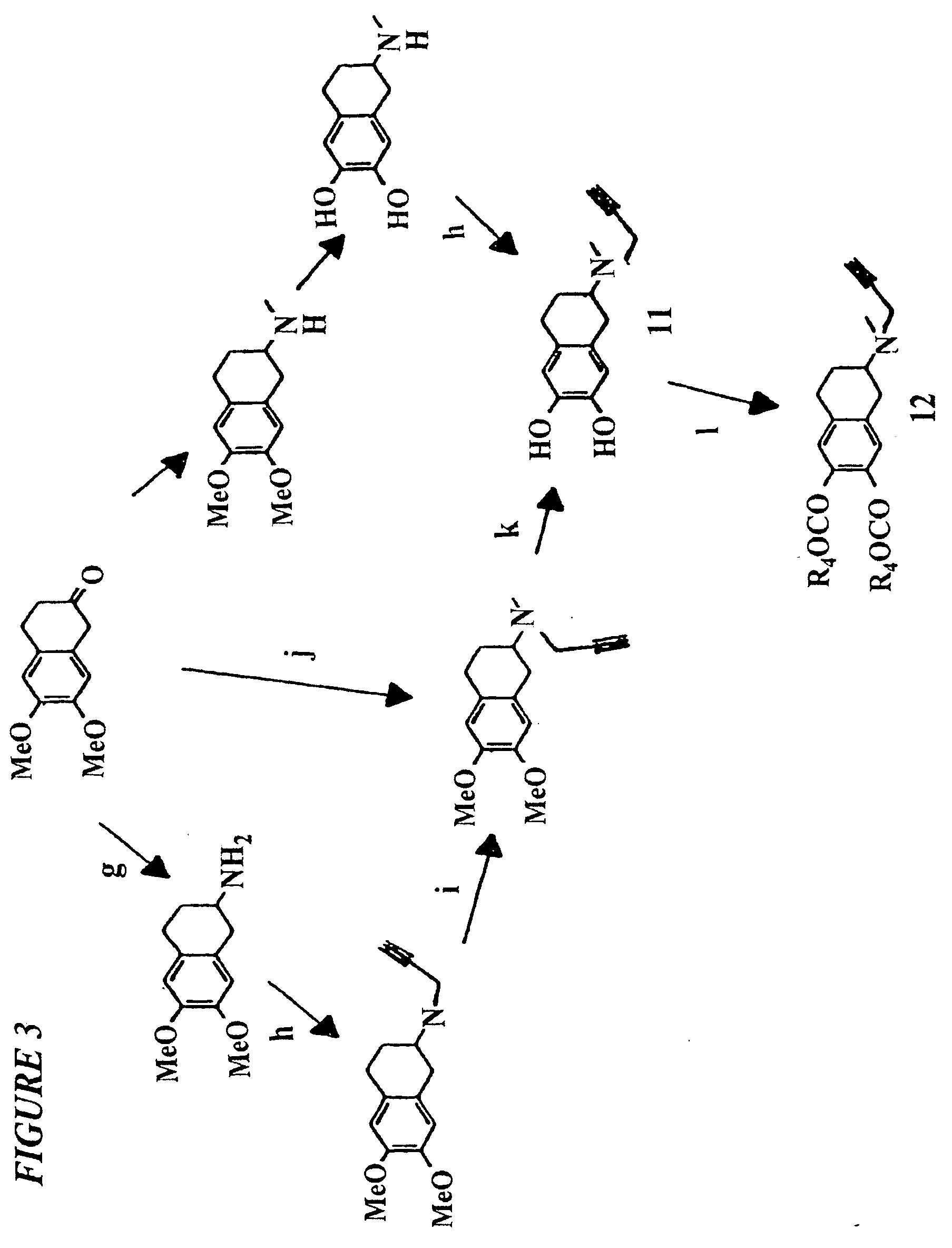

Propargylamino indan derivatives and propargylamino tetralin derivatives as brain-selective mao inhibitors

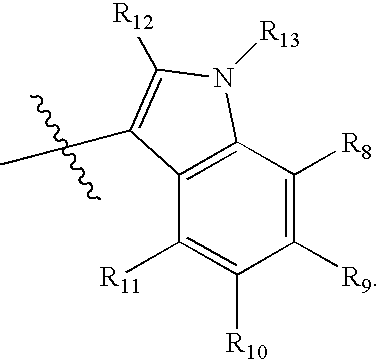

The subject invention provides derivatives of propargylamino indan (PAI) and propargylamino tetralin that selectively inhibit monoamine oxidase (MAO) in the brain, having the structure:wherein R1 is OC(O)R9 and R2 is H,wherein R9 is branched or unbranched C1 to C6 alkyl, aryl, or aralkyl, orR1 is OC(O)R4 and R2 is OC(O)R4,wherein R4 is branched or unbranched C1 to C6 alkyl, aryl, aralkyl or NR5R6,wherein R5 and R6 are each independently H, C1 to C8 alkyl, C6 to C12 aryl, C6 to C12 aralkyl or C6 to C12 cycloalkyl, each optionally substituted;wherein R3 is H or C1 to C6 alkyl;wherein n is 0 or 1; andwherein m is 1 or 2,or a pharmaceutically acceptable salt thereof. Additionally, the subject invention provides methods of treating neurological disorders using these compounds, uses of these compounds for the manufacture of medicaments for treating neurological disorders and processes for synthesis of these compounds.

Owner:TEVA PHARMA IND LTD

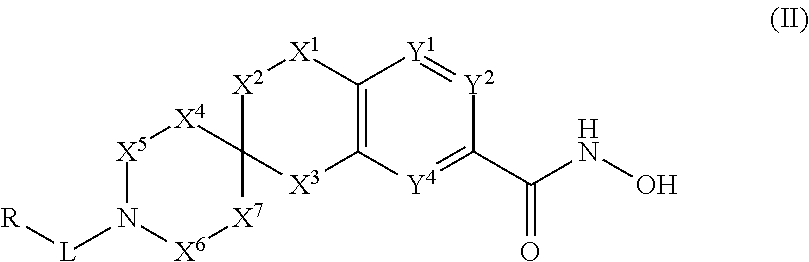

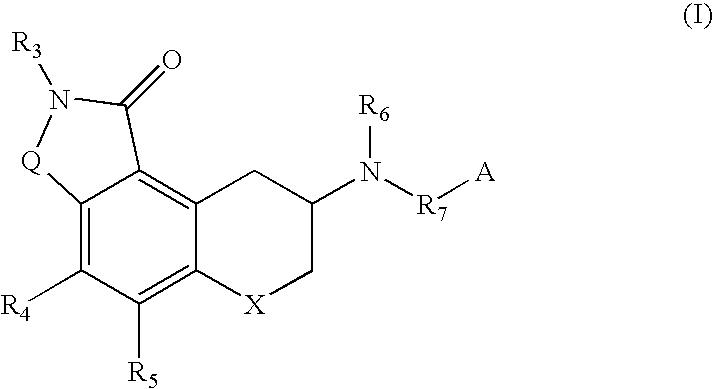

3-spirocyclic-6-hydroxamic acid tetralins as HDAC inhibitors

The present invention is directed to inhibitors of histone deacetylases (HDACs) such as HDAC6 and HDAC11, and their use in the treatment of diseases such as cell proliferative diseases (e.g., cancer), neurological (e.g., neurodegenerative disease or neurodevelopmental disease), inflammatory or autoimmune disease, infection, metabolic disease, hematologic disease, or cardiovascular disease.

Owner:VALO HEALTH INC

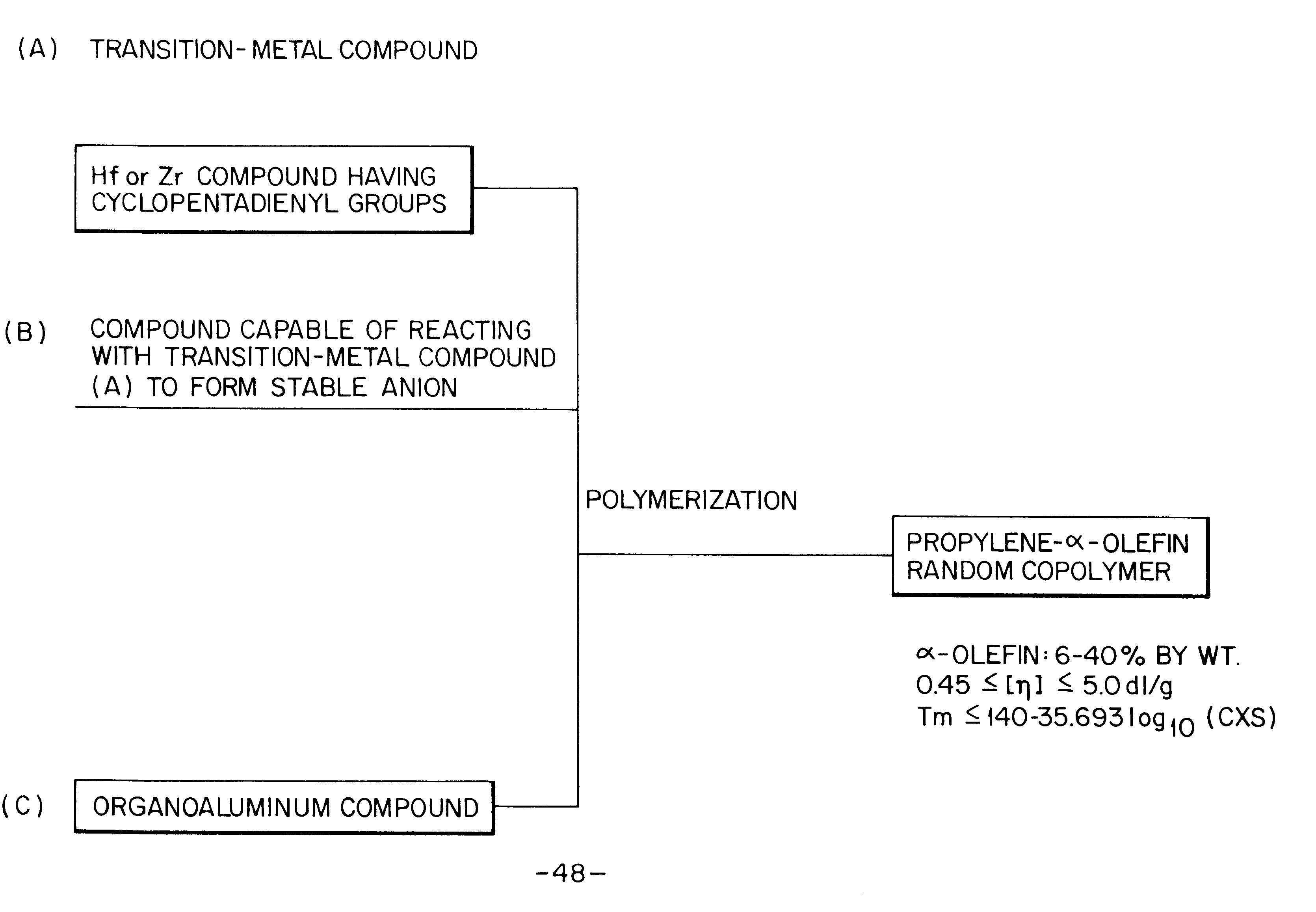

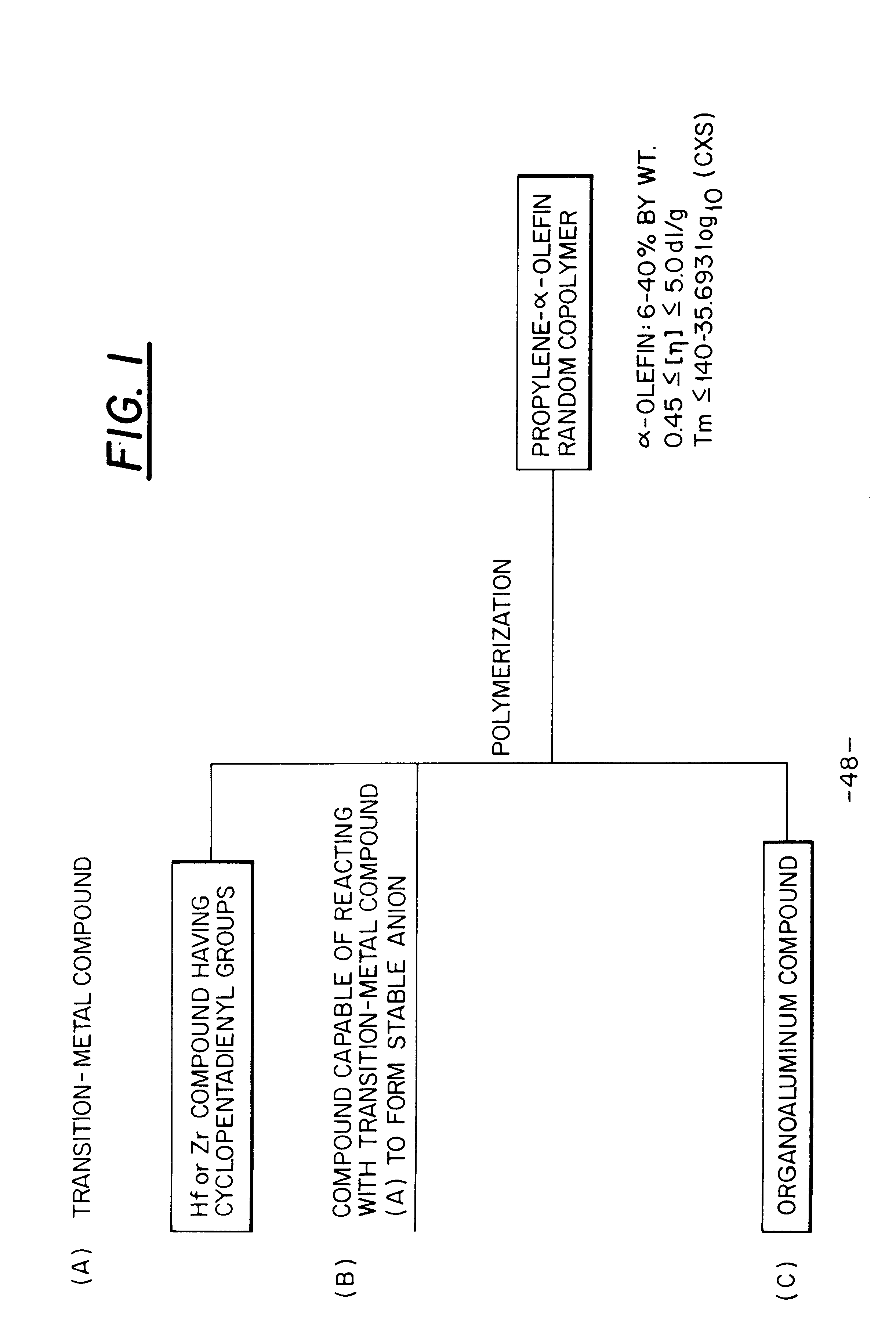

Propylene random copolymer and film laminate thereof

InactiveUS6214952B1Excellent blocking resistanceHigh transparencySynthetic resin layered productsThin material handlingElectricityTetralin

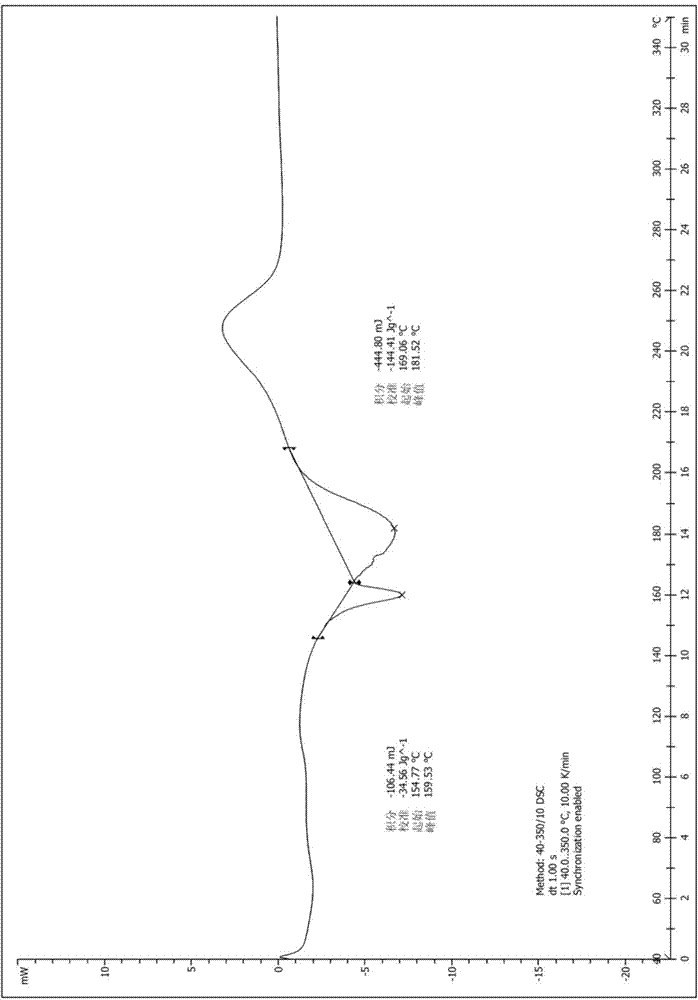

A propylene random copolymer and a film laminate thereof is described having excellent blocking resistance and transparency and substantially maintaining favorable low-temperature heat-sealing properties after corona discharge treatment. The propylene random copolymer of the invention includes a propylene component and an alpha-olefin component having 4 to 10 carbon atoms, wherein the content of the alpha-olefin component is in the range of about 6% to about 40% by weight, the intrinsic viscosity [eta] measured in tetralin at 135° C. is not lower than about 0.45 dl / g and not higher than about 5.0 dl / g, and the melting point (Tm) measured by a differential scanning calorimeter and the content of 20° C. xylene soluble fraction (CSX) fulfill a relationship of

Owner:SUMITOMO CHEM CO LTD

3-spiro-7-hydroxamic acid tetralins as HDAC inhibitors

The present invention is directed to inhibitors of histone deacetylases (HDACs) such as HDAC6, and their use in the treatment of diseases such as cell proliferative diseases (e.g., cancer), neurological (e.g., neurodegenerative disease or neurodevelopmental disease), inflammatory or autoimmune disease, infection, metabolic disease, hematologic disease, or cardiovascular disease.

Owner:VALO HEALTH INC

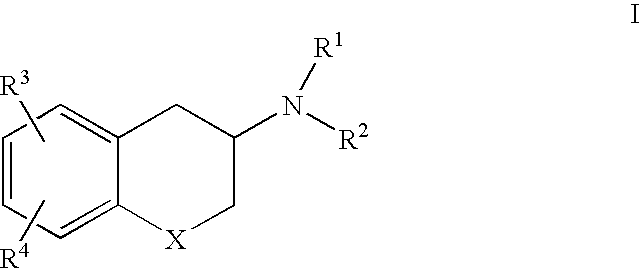

3-Amino chroman and 2-amino tetralin derivatives

3-Amino chroman and 2-amino tetralin derivatives and compositions containing such compounds are disclosed. Methods of using the 3-amino chroman and 2-amino tetralin compounds and compositions containing such compounds in the treatment of serotonin disorders, such as depression and anxiety, are also disclosed.

Owner:WYETH

Ethylene based polymer composition and film

An ethylene based polymer composition comprising the following component (A) and the following component (B) wherein the content of the component (B) is 0.5 to 20 parts by weight per 100 parts by weight of the component (A):Component (A): an ethylene based polymer satisfying all of the following requirements (a1) to (a3):(a1) the density is 890 to 925 kg / m3,(a2) the melt flow rate (MFR) is 0.1 to 10 g / 10 minutes,(a3) the flow activation energy (Ea) is 50 kJ / mol or more,Component (B): an ethylene-α-olefin copolymer satisfying all of the following requirements (b1) to (b3):(b1) the density is 890 to 925 kg / m3,(b2) the intrinsic viscosity [η] measured in a tetralin solution is 4 to 15 dL / g,(b3) the flow activation energy (Ea) is less than 50 kJ / mol.

Owner:SUMITOMO CHEM CO LTD

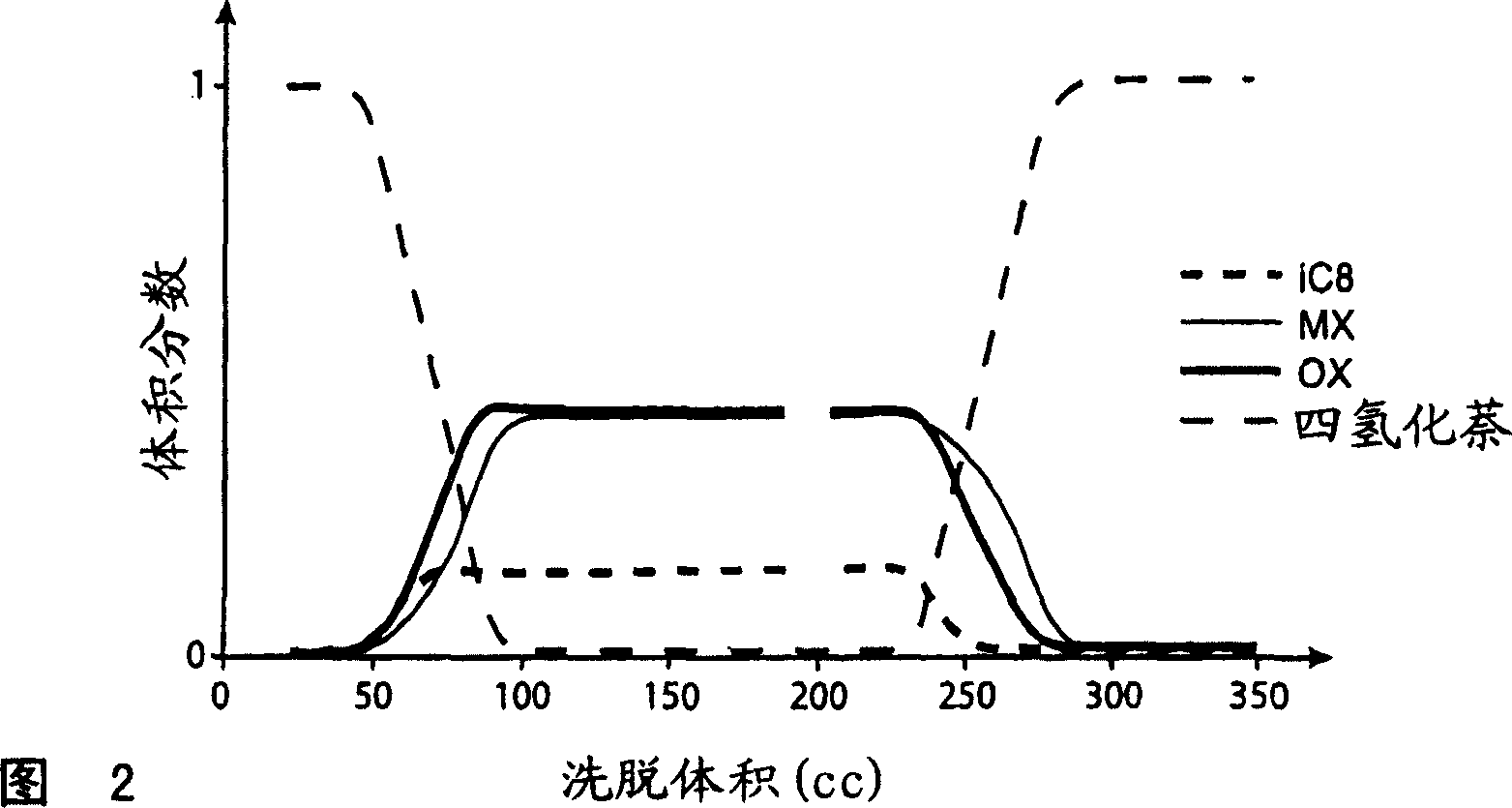

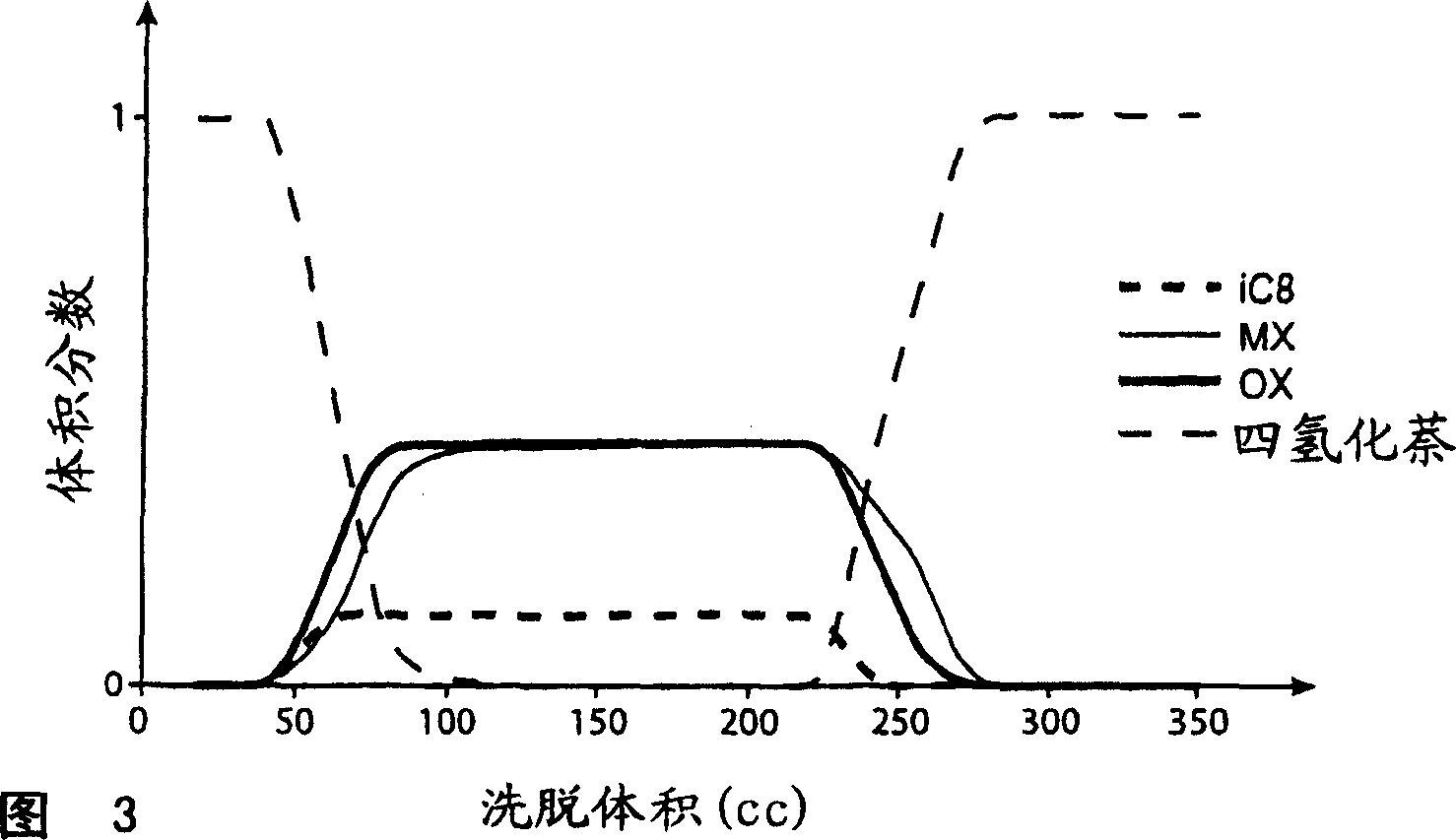

Process for separating meta-xylene from a feed of aromatic hydrocarbons

Owner:INST FR DU PETROLE

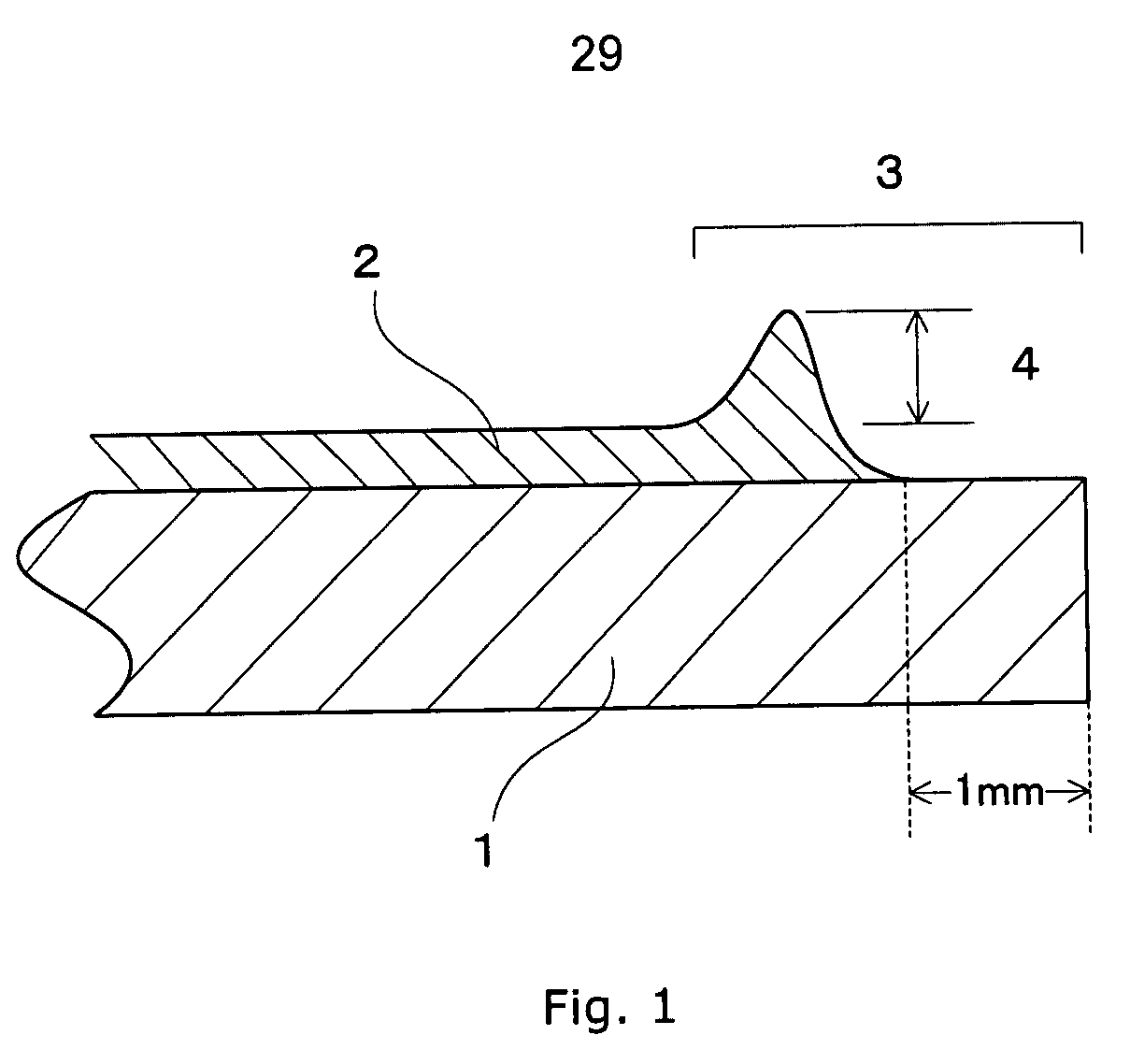

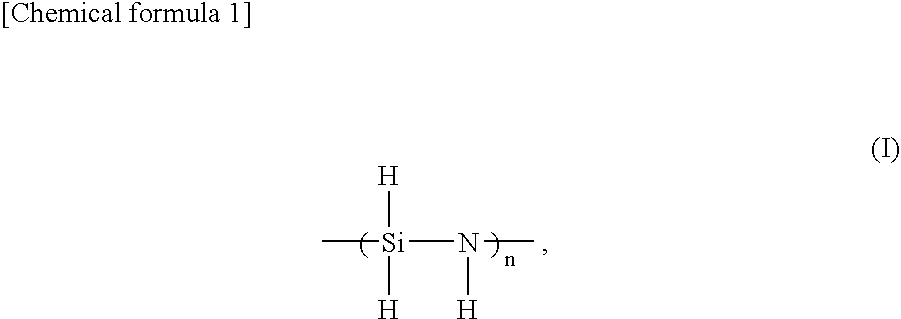

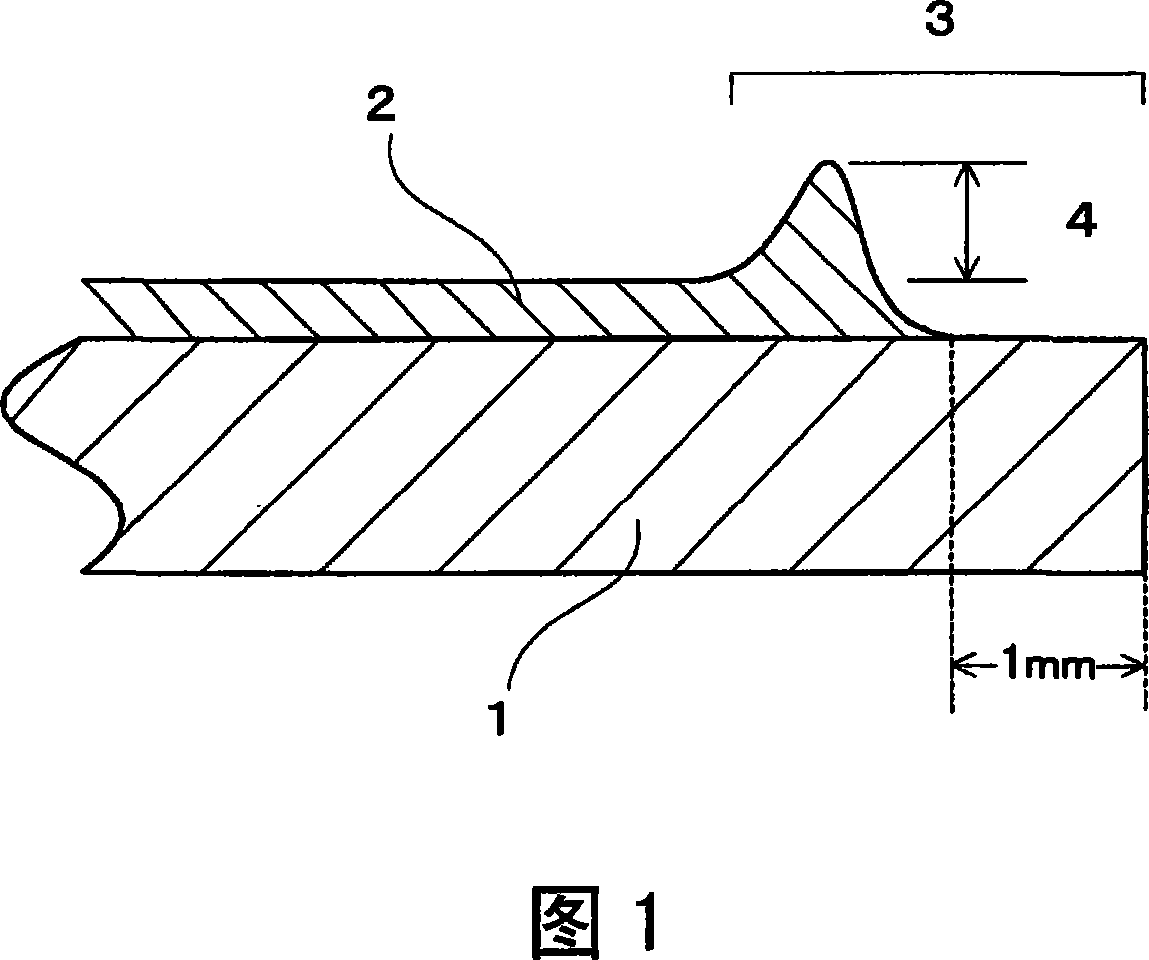

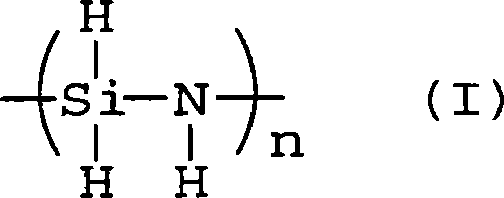

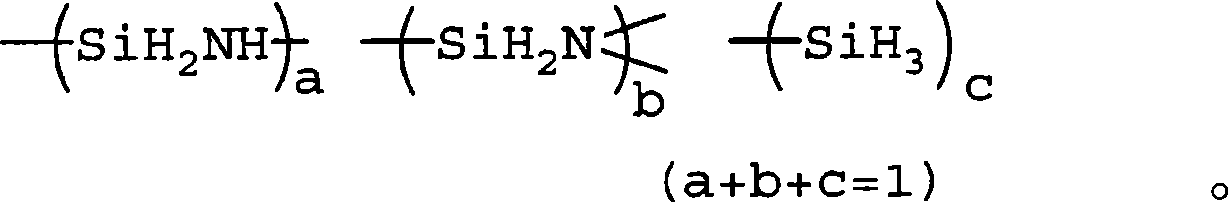

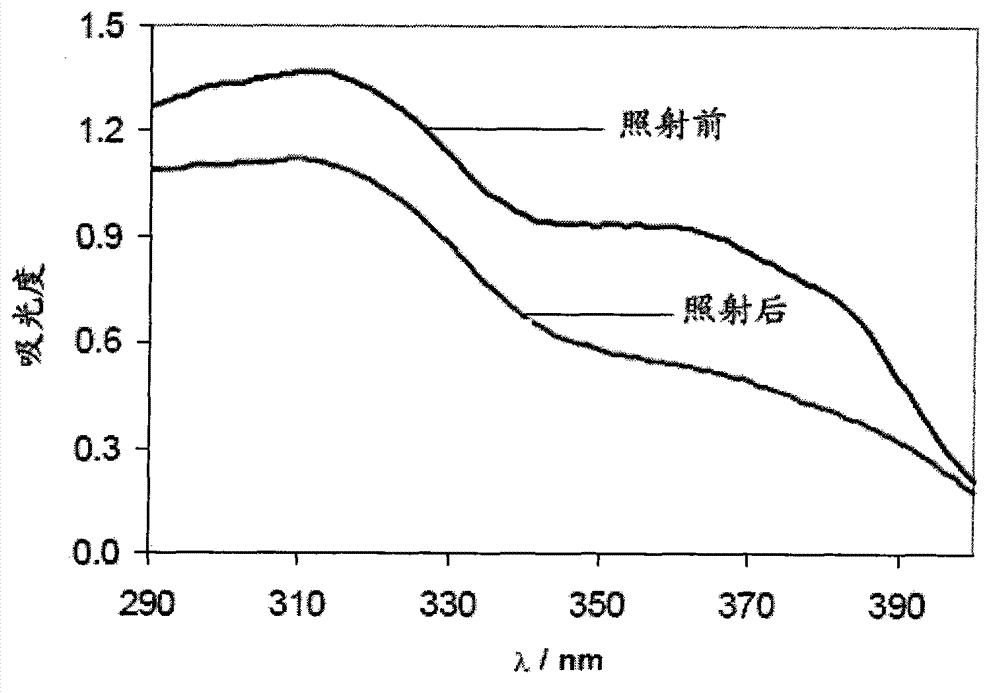

Polysilazane-Treating Solvent and Method for Treating Polysilazane by Using Such Solvent

InactiveUS20080102211A1Good edge cut part shapeImprove solubilityOrganic chemistryChemical paints/ink removersTetralinAlicyclic Hydrocarbons

Owner:MERCK PATENT GMBH

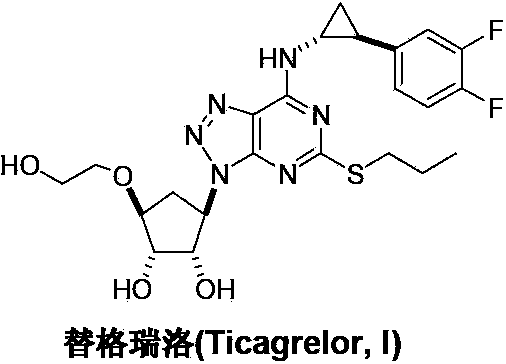

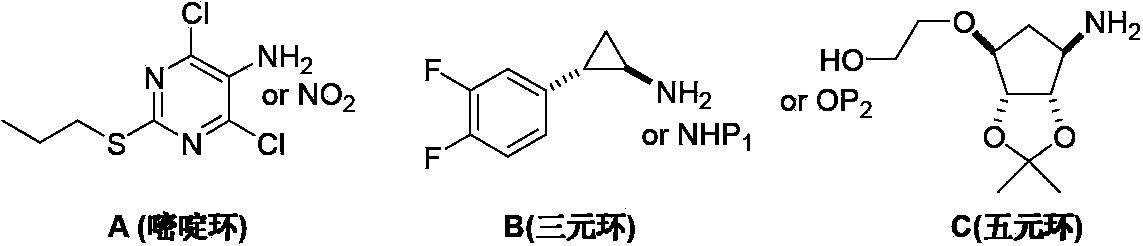

Method for preparing ticagrelor

ActiveCN103360396AReduce usageEasy to prepareOrganic chemistryBulk chemical productionAcetic acidTicagrelor

The invention discloses a method for preparing ticagrelor, which comprises the following steps of by taking 1-[(3aR,4S,6R,6aS)-[[2,2- dimethyl-tetralin-4H-cyclopentadiene-1,3-dioxo heterocyclelane-4-oxygroup] ethyl acetate-6-base]-5-amidogen-4-formamido-1,2,3- triazole(II) as the raw material, sequentially carrying out cyclizing, replacement, condensation and reduction reactions, and removing the protecting group, so as to prepare the ticagrelor. The method is concise, environment-friendly and economic, has high chemical and chirality purity, and provides the new preparation method of ticagrelor industrialized production.

Owner:铜陵尚东高新科创有限公司

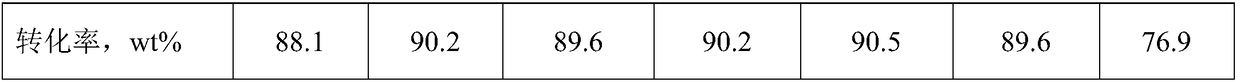

Preparation method of meso-porous alumina and catalytic synthesis of alpha-tetralone

InactiveCN101337186AEasy to recycleImprove conversion rateCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsTetraloneHydrogen

The invention provides a method for preparing cobalt-doped mesoporous alumina by taking a rubber latex as a biological template, and a method for catalytically oxidizing tetralin into tetralone under liquid phase. The invention relates to the method for preparing the cobalt-doped mesoporous alumina by taking the rubber latex as the template, and the method for synthesizing tetralone. The invention aims to develop a method which is used for preparing the cobalt-doped mesoporous alumina by taking the rubber latex as the biological template and a high-conversion and high-selectivity method which is used for catalytically oxidizing tetralin into tetralone under the liquid phase, and comprises the following steps: a mesoporous material is taken as a heterogeneous catalyst, and tetralin is catalytically oxidized into tetralone under the low temperature liquid phase. The experimental results show that the conversion rate of the tetralin reaches 80.3 percent and the selectivity of tetralone reaches 74.5 percent.

Owner:YUNNAN UNIV

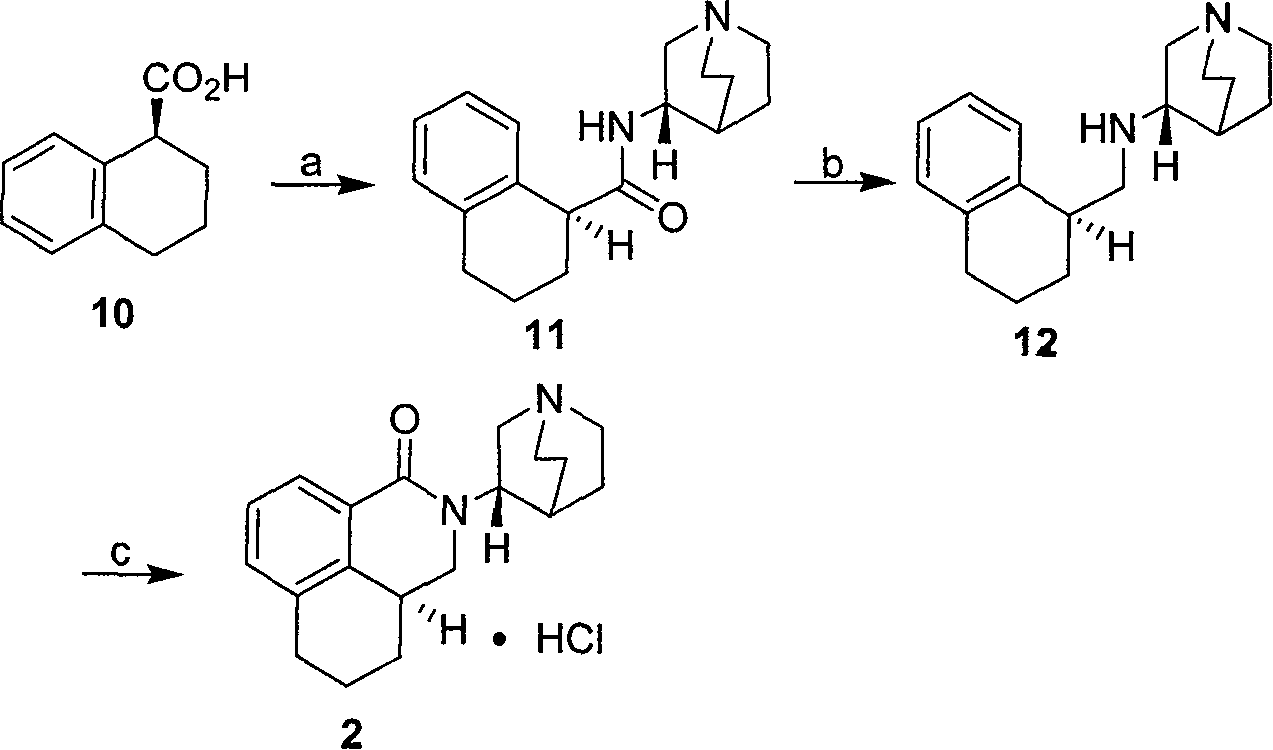

Method for synthesizing palonosetron hydrochloride

The invention discloses a novel synthesis method of palonosetron hydrochloride, which comprises that (1) (S)-tetralin formic acid is reacted with thionyl chloride and (S)-3-amido-quinine cyclic amine, to obtain (S, S)-quinuclidine tetralin formamide, (2), (S, S)-quinuclidine tetralin formamide is reacted with reductant and boron trifluoride diethyl etherate, to obtain (S, S)-tetralin methyl quinine cyclic amine, (3), (S, S)-tetralin methyl quinine cyclic amine is reacted with diphosgene to be added and reacted in boron trifluoride diethyl etherate solution, while the product is added and reacted with alcaine and water, to obtain palonosetron hydrochloride. And the synthesis route is represented as above: a: SOCI2, (S)-3-aminoquinuclidine, b: NaBH4, BF3OEt2, c: BF3OEt2, CICO2CCI3.

Owner:SHENZHEN NEPTUNUS PHARM CO LTD

Processing method of waste plastic

ActiveCN108456328AExpand the scope of recyclingImprove conversion ratePlastic recyclingCatalytic pyrolysisMolecular sieve

The invention discloses a processing method of waste plastic. The method comprises the following steps: adding the waste plastic, a modified catalyst and a reaction solvent into a catalytic pyrolysisreactor, so as to be uniformly mixed, and then performing catalytic pyrolysis reaction. The modified catalyst adopts a modifier oxide modified HZM-5 and HY composite molecular sieve, a modifier is selected from one or more in Sn, Fe, Ti and Zn, and the reaction solvent adopts a mixture of tetrahydronaphthalene and n-hexadecane. The conditions of the catalytic pyrolysis reaction are as follows: thereaction temperature is 150 to 300 DEG C; the reaction time is 120 to 240 minutes; the reaction is performed under stirring; the stirring speed is 600 to 1000 revolutions per minute; hydrogen is fedduring reaction; hydrogen partial pressure is 4 to 7MPa. The method obviously reduces the catalytic pyrolysis temperature of waste plastic on the promise of guaranteeing a high conversion rate, and saves energy.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

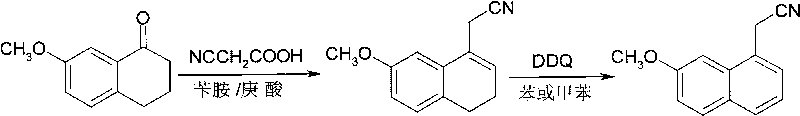

Method for synthesizing (7-methoxy-1-naphthyl) acetonitrile

ActiveCN101723855AReduce the introductionReduce stepsCarboxylic acid nitrile preparationOrganic compound preparationTetralinSynthesis methods

The invention relates to a method for synthesizing (7-methoxy-1-naphthyl) acetonitrile, which prepares the (7-methoxy-1-naphthyl) acetonitrile by taking 7-methoxy tetralin-1-ketone as a main initial raw material and performing dehydrated acetonitrile synthesis and dehydrogenated aromatization in turn, wherein a single reaction solvent is adopted in the step of a two-step reaction, and the two-step reaction adopts a one-pot process. The synthesis method has mild reaction conditions and simple process operations and has the overall yield of over 94 percent.

Owner:JIANGSU YUXIANG CHEM

Oxygen-absorbing resin composition and oxygen-absorbing molded article using same and multilayer body, container, injection-molded article and medical container using these

ActiveUS20140308405A1Improve performanceImprove adhesionBottlesDomestic containersPolyesterHigh humidity

A novel oxygen-absorbing resin composition is not responsive to a metal detector, produces no odor after absorption of oxygen and has excellent oxygen-absorbing performance, and an oxygen-absorbing molded article, and a multilayer body, container, injection-molded article and medical container. Further provided are an oxygen-absorbing resin composition etc. having excellent oxygen-absorbing performance in a wide range of humidity conditions from low to high humidity. The oxygen-absorbing resin composition is an oxygen-absorbing resin composition containing a polyester compound and a transition metal catalyst, in which the polyester compound has at least one constituent unit having a tetralin ring. Furthermore, the oxygen-absorbing molded article of the present invention is formed by molding the oxygen-absorbing resin composition into a film form or a sheet form. Moreover, the multilayer body, container, injection-molded article, medical container, etc. of the present invention are obtained by using the oxygen-absorbing resin composition of the present invention.

Owner:MITSUBISHI GAS CHEM CO INC

Naphthalene compounds

Compound of formula (I): wherein: T represents alkylene, A and B together form a naphthalene, dihydronaphthalene, or tetrahydronaphthalene group, R represents hydrogen, hydroxy, R' or OR', R' being as defined in the description, G1 represents halogen, a radical R1 or a group -O-CO-R1, R1 being as defined in the description, G2 represents a group selected from: X, R2 and R21 being as defined in the description, and medicinal products containing the same which are useful in the treatment of a condition related to the melatoninergic system.

Owner:LES LAB SERVIER

Polysilazane-treating solvent and method for treating polysilazane by using such solvent

ActiveCN101111575AImprove solubilityPerformance is not affectedLiquid surface applicatorsNitrogen compoundsTetralinAliphatic hydrocarbon

The present invention relates to a polysilazane treatment solvent which has excellent solvency and stability, has no influence on the performance of the substrate and polysilazane as the bottom layer, has a good cutting edge shape, and is highly safe to the human body of. The processing solvent contains a solvent selected from the group consisting of tetralin, p-menthane, p-cumylmethane, α-pinene, 1,8-cineole and mixtures thereof, and also relates to a process using the solvent Polysilazane treatment method. The solvent may also contain a solvent selected from the group consisting of aliphatic hydrocarbons, alicyclic hydrocarbons, and mixtures thereof.

Owner:MERCK PATENT GMBH

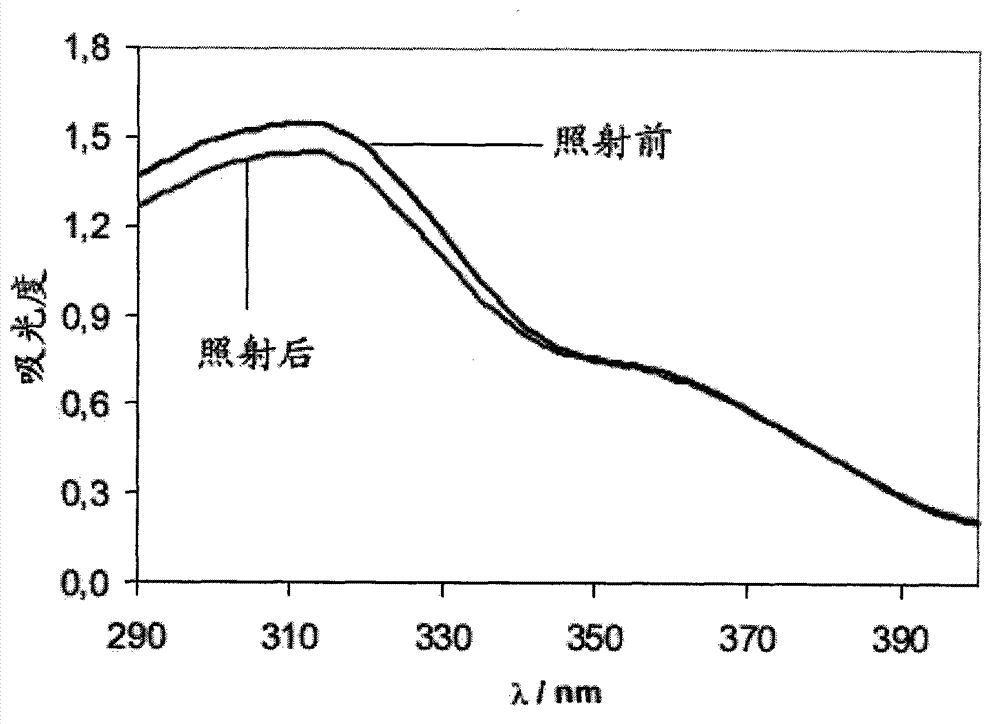

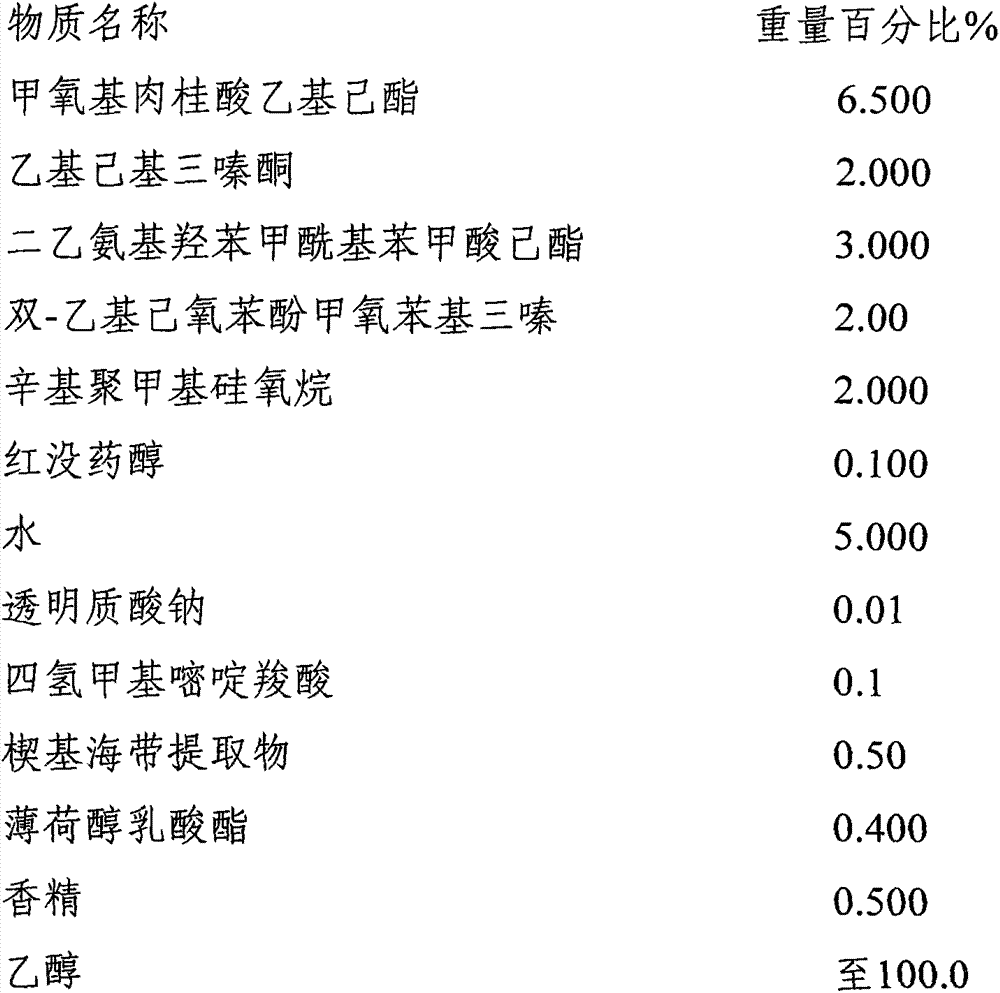

Sunscreen composition and preparation method thereof

InactiveCN103083203APrevent sunburnIdeal full band protectionCosmetic preparationsToilet preparationsTetralinUltraviolet

The invention relates to a sunscreen composition (namely, Solarex-3, Solarex-3Complex or triple sunscreen compositions) which comprises 2-10wt% of methoxy cinnamic acid ester, 0.1-6wt% of ethylhexyl triazinone, 0.1-6wt% of lignocainehy droxybenzoyl hexyl benzoate, 0.1-6wt% of bis-ethylhexyloxyphenol methoxyphenyl triazine, 0.001-0.2wt% of sodium hyaluronate, 0.001-1.0wt% of tetralin methyl pyrimidine carboxylic acid, 0.01-2wt% of LAMINARIA OCHROLEUCA, and effective quantity of cosmetically acceptable carriers. The invention further relates to the preparation method of the composition. The composition disclosed by the invention is prepared based on the principle of the harm of ultraviolet rays to human bodies, has the characteristics of light stability and broad spectrum sunscreen, can improve ultraviolet ray immunity of skin, and can prevent the ultraviolet rays from hurting the human bodies more comprehensively.

Owner:MENTHOLATUM (CHINA) PHARM CO LTD

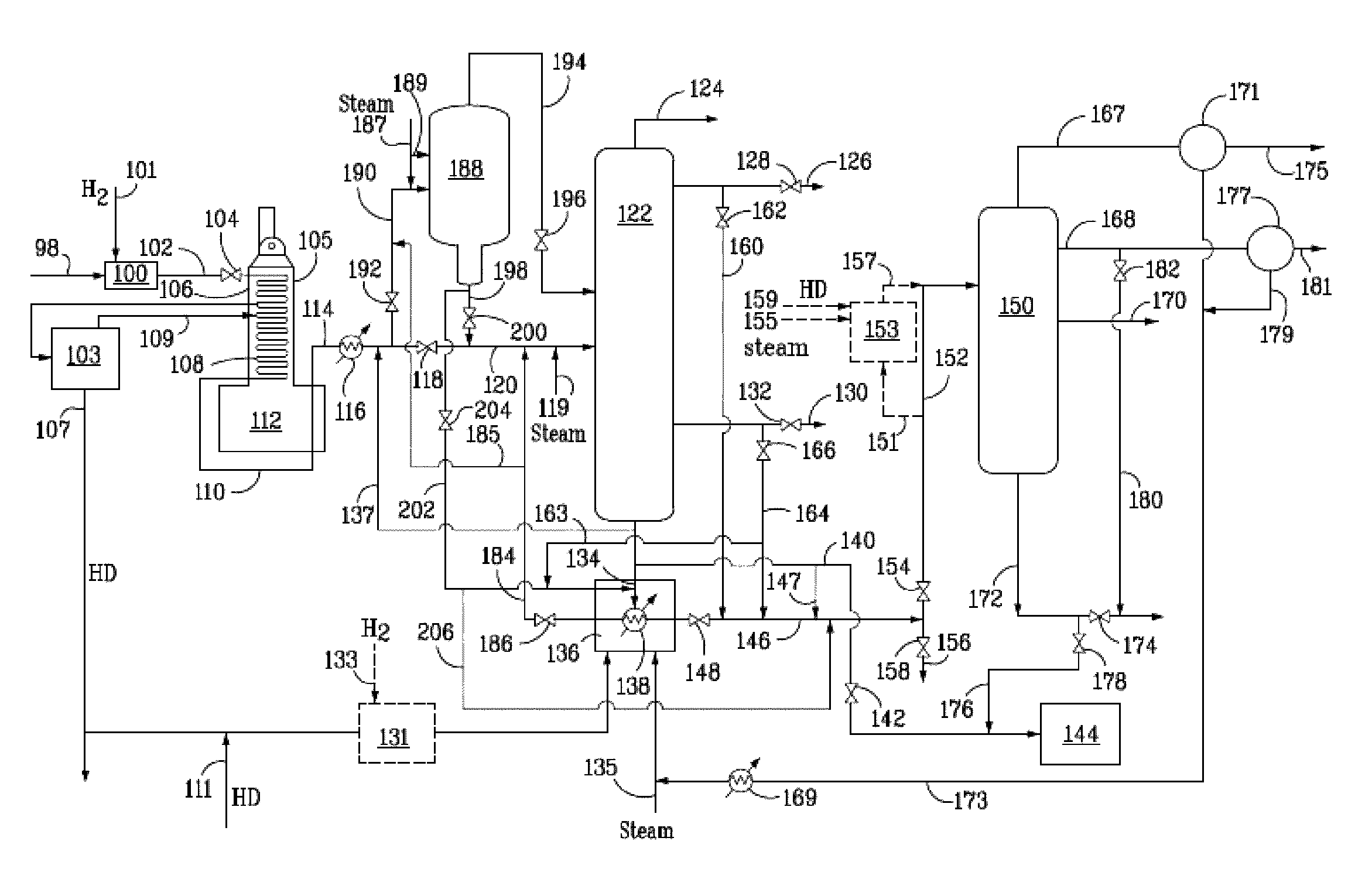

Process and apparatus for upgrading steam cracker tar using hydrogen donor compounds

ActiveUS8197668B2Efficiently managing introductionIncrease percentageThermal non-catalytic crackingTreatment with plural serial cracking stages onlyThermodynamicsTetralin

A process and apparatus are provided for upgrading steam cracker tars from steam crackers. The invention also relates to a steam cracking process and apparatus for reducing yields of tars produced from steam cracking while increasing yields of higher value products by heating steam cracker tar, in the presence of hydrogen donor compounds, e.g., tetralin. The hydrogen donor compounds can be provided in a hydrogen donor-rich hydrocarbon stream, e.g., light cycle oils, or low sulfur vacuum tower bottoms. The treated tar can be separated into gas oil, fuel oil and tar streams.

Owner:EXXONMOBIL CHEM PAT INC

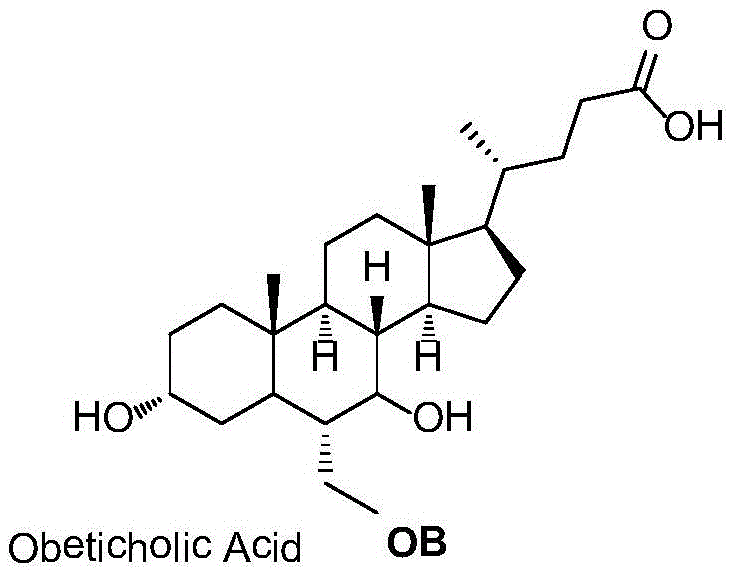

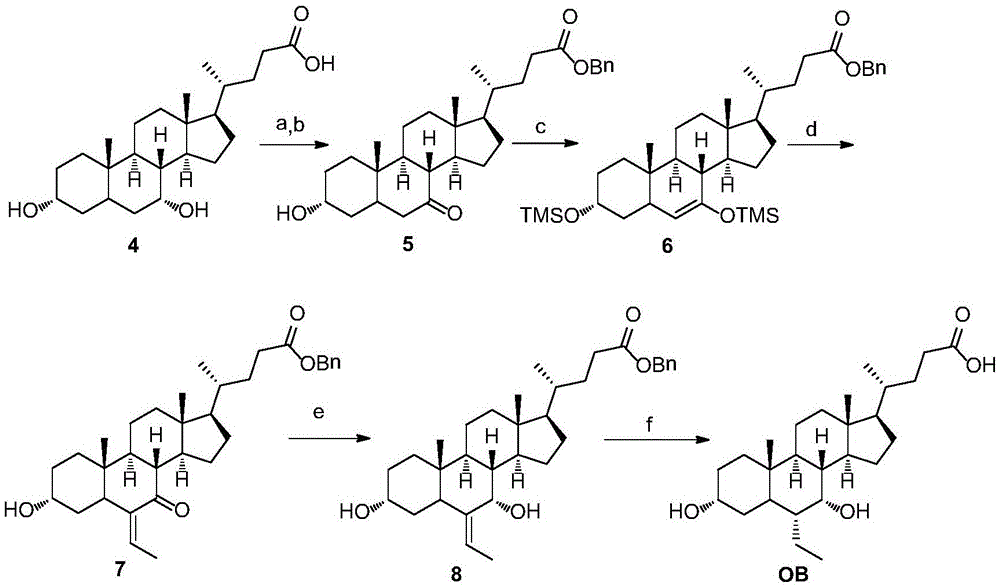

Preparation method for obeticholic acid and intermediate thereof

The invention relates to a preparation method for obeticholic acid and an intermediate thereof. The intermediate 3alpha-hydroxy-6alpha-ethyl-7-keto-5beta-cholanic acid is obtained by subjecting 3alpha-hydroxy-6-ethylidene-7-keto-5beta-cholanic acid benzyl ester compounds to a reaction under the action of a catalyst and a hydrogen donor. The catalyst is selected from Pd / C or PtO2 or Raney Ni. The hydrogen donor is selected from cyclohexene or cyclohexadiene or tetrahydronaphthalene. According to the method, the yield is high, the stereoselectivity is high, safety is good, the reaction condition is mild, and the method is applicable to industrial production.

Owner:NANJING GRITPHARMA CO LTD +1

Tetraline derivatives as ghrelin receptor modulators

The present invention is related to compounds of formula (I),or a therapeutically suitable salt or prodrug thereof, the preparation of the compounds, compositions containing the compounds and the use of the compounds in the prevention or treatment of disorders regulated by ghrelin including anorexia, cancer cachexia, eating disorders, age-related decline in body composition, weight gain, obesity, and diabetes mellitus.

Owner:ABBVIE INC

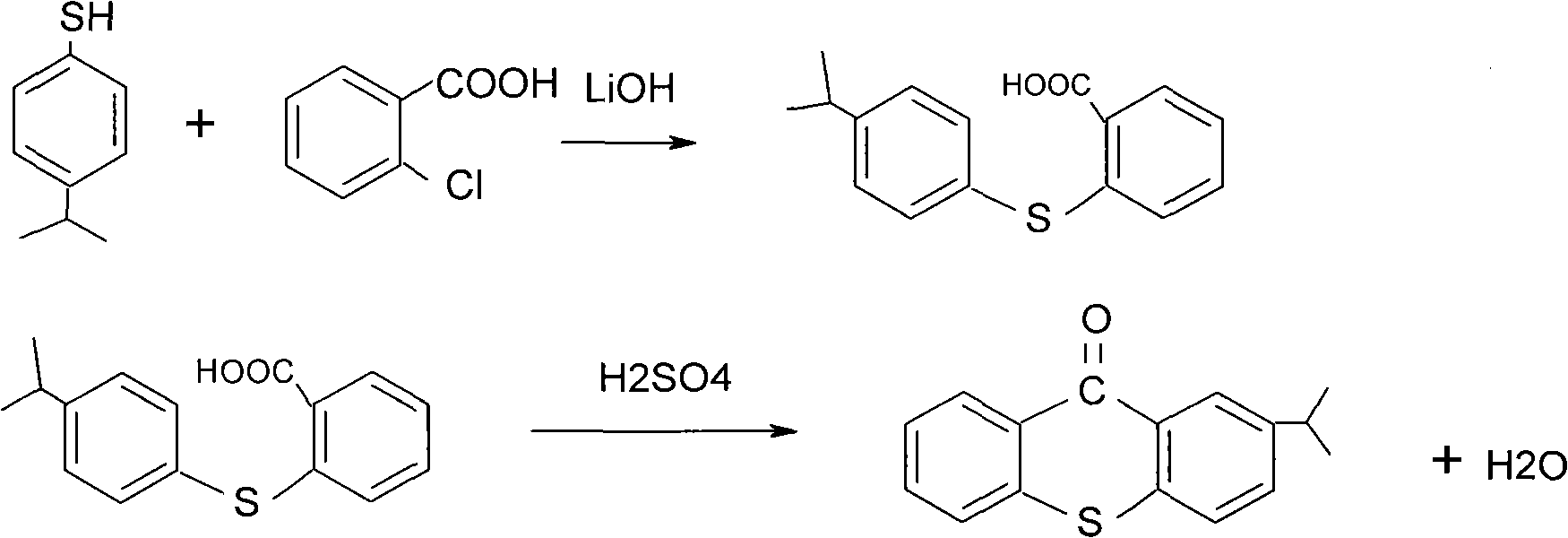

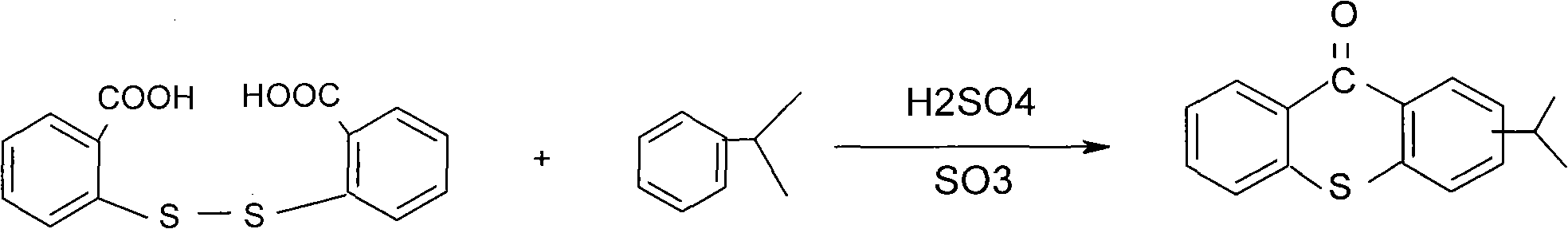

Preparation process of 2-isopropylthioxanthone

InactiveCN101570534AReduce manufacturing costIncrease productivityOrganic chemistryCalcium hydroxideTetralin

The invention relates to a preparation process of 2-isopropylthioxanthone of light trigger, in particular to a process for preparing 2-isopropylthioxanthone by using 4-isopropylbenzenethiol and 2-chlorobenzoic acid as the main raw material through the reaction steps of condensation, exsolution, neutralization, cyclization, hydrolyzation, recrystallization, and the like. The preparation process is characterized in that the 4-isopropylbenzenethiol and the 2-chlorobenzoic acid are used as the raw materials and are condensed by using tetraline as solvent under the alkaline (lithium hydroxide) condition, the mol ratio of the 4-isopropylbenzenethiol, the 2-chlorobenzoic acid and the lithium hydroxide is 1:1-1.5:2-2.5, and preference for 1:1.05:2.1; the condensation temperature is 180-190 DEG C, the product is prepared by the reaction steps of exsolution, neutralization, cyclization, hydrolyzation, recrystallization, and the like after the reaction is performed for 6h. The invention has easily obtained raw materials, can improve the performability of the process, can greatly lower the production cost because the produced lithium hydroxide of the side product can be sold through the treatment and has high purity of produced products without isomer.

Owner:江苏省中兴化工有限公司

Preparation method of methyl phenyl hydrogen-containing silicone oil for LED packaging adhesive

InactiveCN106478951AAvoid complex processesSingle hydrolysis and condensation processDisiloxaneTetralin

The invention discloses a preparation method of methyl phenyl hydrogen-containing silicone oil for LED packaging adhesive. The method takes methyl phenyl dimethoxy silaneas raw material and hydrochloric acid or acid cationic resin as catalyst, and performs hydrolytic condensation reaction under the heating and stirring condition, and prepares methyl phenyl hydroxyl silicone oil; the prepared methyl phenyl hydrogen-containing silicone oil and tetramethyl tetralin cyclotetrasiloxane (D4H) as raw materials, hexamethyl disiloxane (MM) or hydrogen-containing dual-sealing end (MMH) as the end-capping reagent, and acid cationic resin as the catalyst; the reaction is carried out under the heating and stirring conditions; after finishing the reaction, catalyst is filtered and removed; and then the methyl phenyl hydrogen-containing silicone oil is obtained after depressurizing and distilling the product and removing the low-boiling-point substance. The prepared hydrogen-containing silicone oil is colorless and transparent thick fluid; the light transmittance, refractive index and activated hydrogen content are high, the thermal stability is good; besides, the methyl phenyl hydrogen-containing silicone oil can be used as the LED packaging material.

Owner:SOUTH CHINA UNIV OF TECH

Thermoplastic resin composition and its injection molded article

InactiveUS20050101738A1Good molding effectImprove liquidityFilm/foil adhesivesOrganic dyesElastomerTetralin

Disclosed is a thermoplastic resin composition that contains specific amounts of polypropylene resin (A), elastomer (B), inorganic filler (C) and resin (D) which is composed of 60 to 80% by weight of a first segment which is a propylene homopolymer or a propylene-ethylene random copolymer and has an intrinsic viscosity, measured in tetralin at 135° C., of 5 dl / g or more and 20 to 40% by weight of a second segment which is a propylene homopolymer or a propylene-ethylene random copolymer and has an intrinsic viscosity, measured in tetralin at 135° C., of 0.8 to 1.2 dl / g.

Owner:SUMITOMO CHEM CO LTD

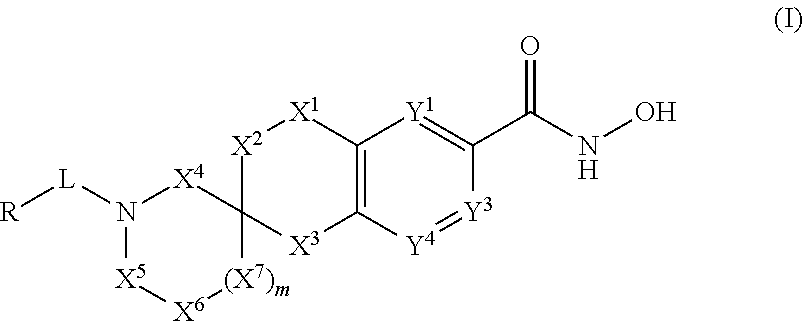

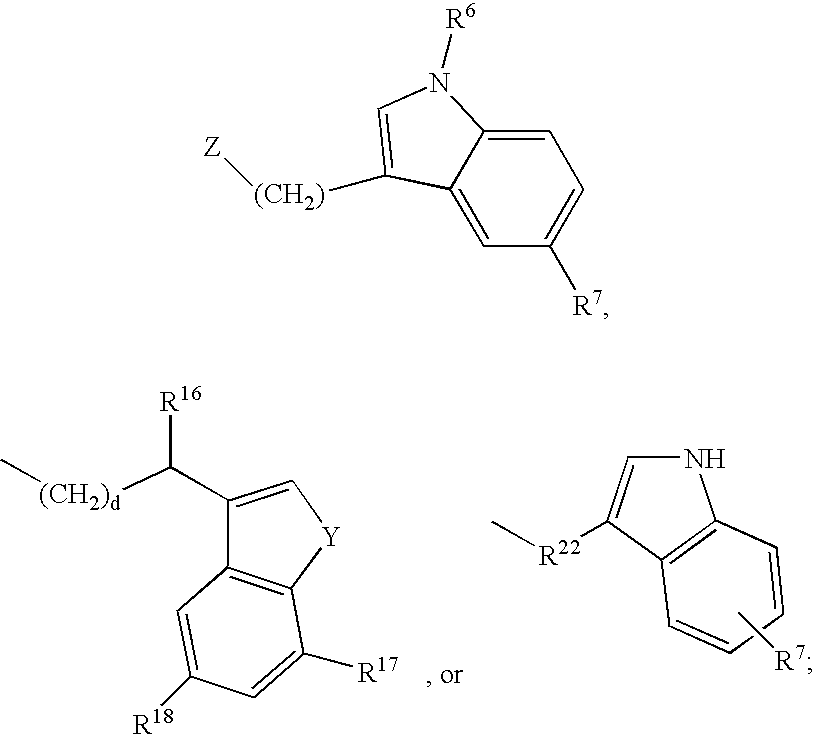

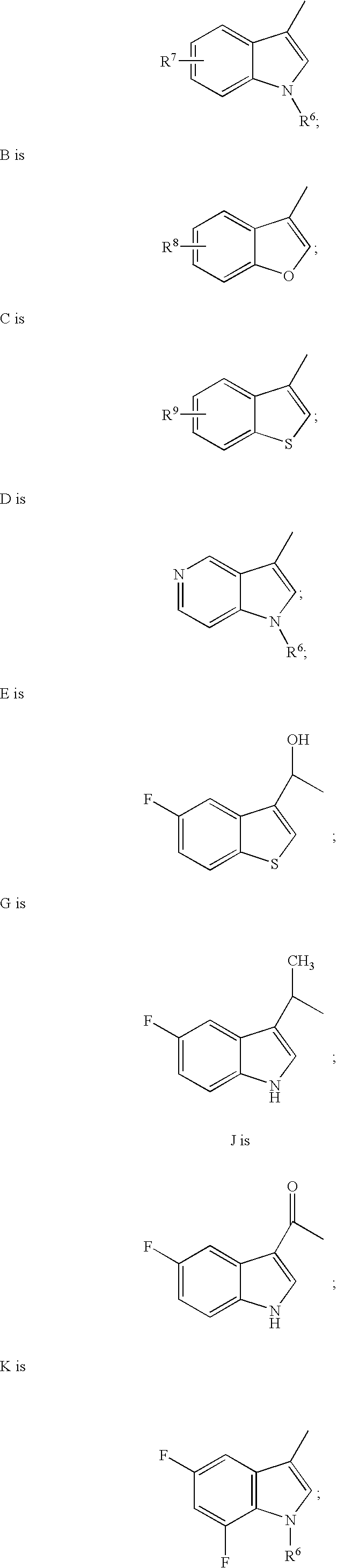

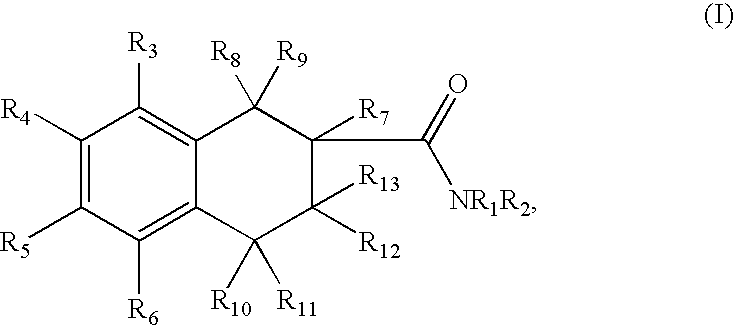

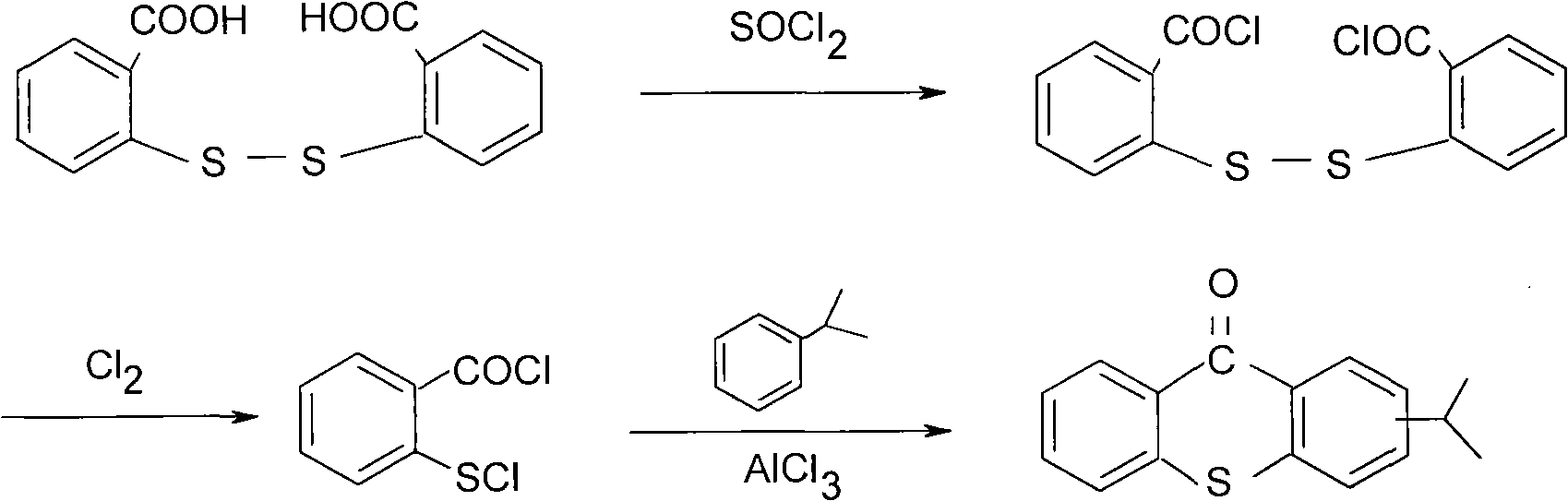

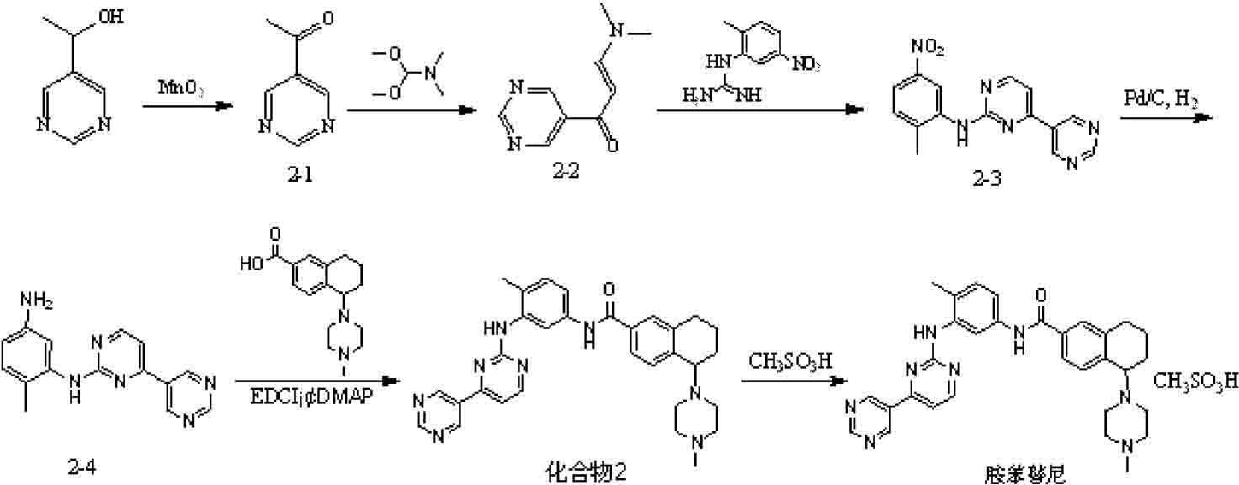

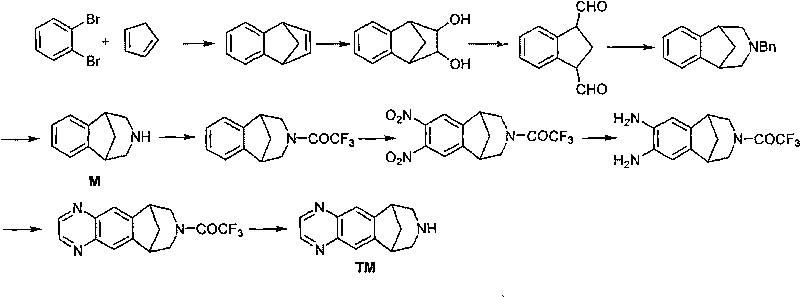

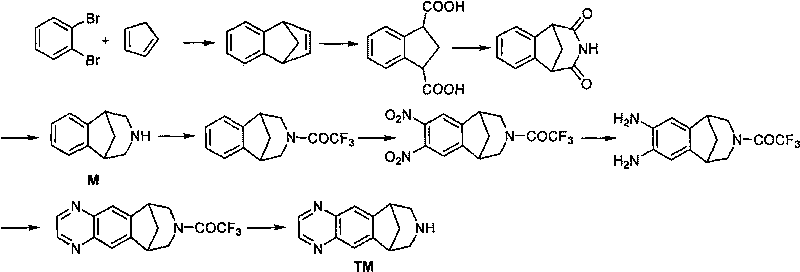

Antineoplastic drug tetrahydronaphthalene amide compound and pharmaceutically acceptable salt thereof, preparation method and application thereof

ActiveCN102295635AGood antitumor activityImprove securityOrganic active ingredientsOrganic chemistryAcute toxicity testingTetralin

The invention relates to new antitumor medicament compounds, namely tetralin amide compounds as shown in a general formula I or pharmaceutically acceptable salts thereof used as an antitumor medicament. The invention also provides a preparation method of the compounds and medicament compositions containing the compounds as well as in vitro and in vivo antitumor effect results and acute toxicity researches thereof. The antitumor medicament, namely tetralin amide compounds obtained by the preparation method, has better antitumor activity and safety, and can be applied to treatment of tumors such as leukemia, lung cancer, colon cancer, ovarian cancer, renal cancer and the like, thus the tetralin amide compounds have wide treatment ranges and also have extremely high application value in the medicine field as antitumor agents.

Owner:LIAONING UNIVERSITY

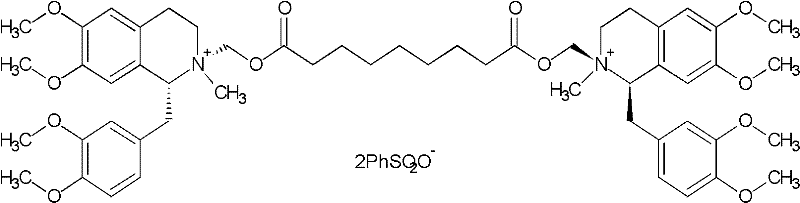

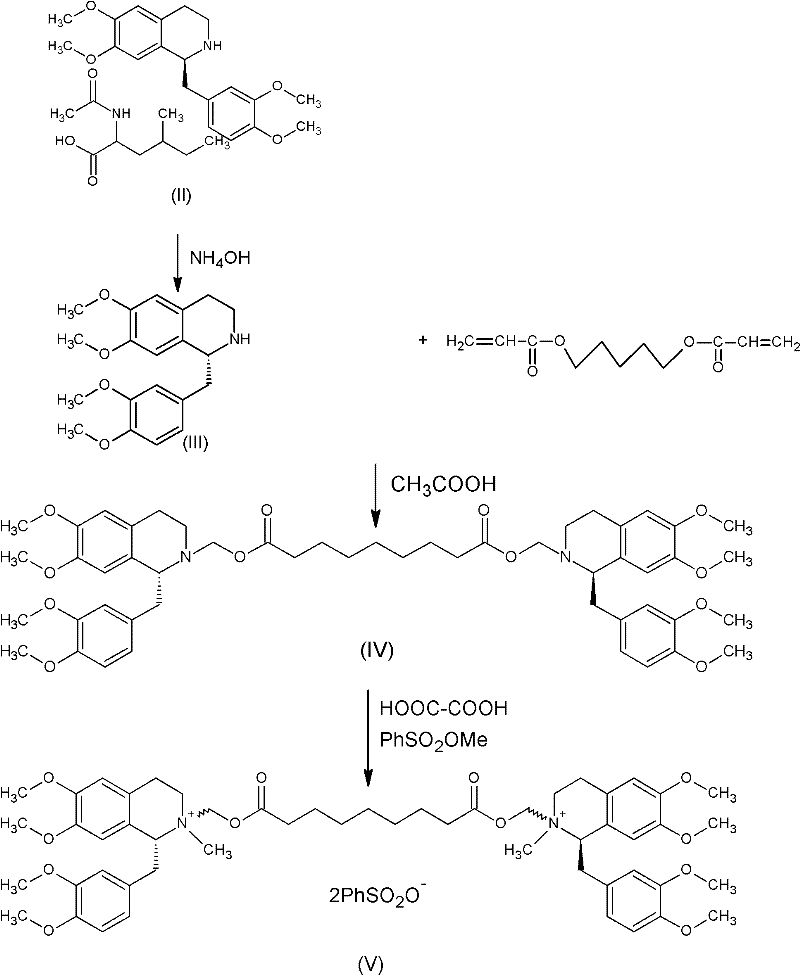

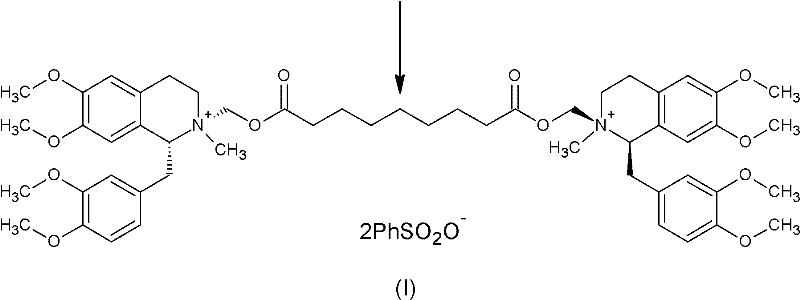

Method for preparing cisatracurium besylate

ActiveCN102249998AQuality improvementHigh purityOrganic chemistryCisatracurium BesylateDiacrylate ester

The invention discloses a preparation method of cisatracurium besylate. The method comprises the following steps: carrying out weal base dissociation on a R-tetrahydropapaverine-N-acetyl-L-leucine salt having a chiral purity of above 99.5% as a starting material so as to obtain R-tetrahydropapaverine; then carrying out a reaction on R-tetrahydropapaverine and 1,5-pentyl glycol diacrylate so as toobtain (1R,1'R)-2,2'-(3,11-dioxo-4,10-dioxa-1,13-subtridecyl) di[1,2,3,4-tetralin-6,7-dimethoxy-1-(3,4-dimethoxyl)benzyl]isoquinoline; after carrying out oxalate refinement and weal base dissociation, carrying out a reaction on (1R,1'R)-2,2'-(3,11-dioxo-4,10-dioxa-1,13-subtridecyl) di[1,2,3,4-tetralin-6,7-dimethoxy-1-(3,4-dimethoxyl)benzyl]isoquinoline and methyl benzenesulfonate so as to prepare1R,1'R-atracurium besilate; and finally, carrying out column chromatography separation on 1R,1'R-atracurium besilate so as to obtain cisatracurium besylate. By using the preparation method, the yieldof cisatracurium besylate can reach 30%, the purity of the product reaches above 98.6%, and single impurity content is below 0.3; and the process is brief, the yield is stable, and the product quality is good, thus the preparation method disclosed by the invention has an industrial application prospect.

Owner:ZHEJIANG XIANJU PHARMA

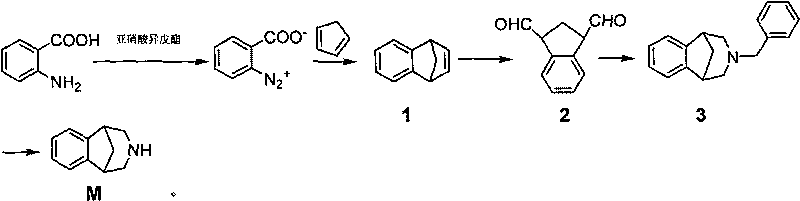

Method for synthesizing Varenicline intermediate 2, 3, 4, 5-tetralin-1, 5-methylene-hydrogen-benzoazepine

The invention relates to a method for synthesizing Varenicline intermediate 2, 3, 4, 5-tetralin-1, 5-methylene-hydrogen-benzoazepine. The method includes the following steps: under the action of catalyst, mixing amyl nitrite with o-aminobenzoic acid solution to generate diazonium salt, then mixing the diazonium salt with cyclopentadiene, and heating to react to generate compound 1; feeding ozone into the solution of compound 1, after complete conversion, adding reducing agent to generate compound 2, then dripping the compound 2 to the mixed solution of triacetoxy sodium borohydride and benzylamine to generate compound 3 by loop closing; and hydrogenating the compound 3 under the action of palladium and carbon for debenzylation and reduction to obtain M intermediate 2, 3, 4, 5-tetralin-1, 5-methylene-hydrogen-benzoazepine. The method has the advantages of greatly simplifying the method for preparing Varenicline intermediate, being simple in production process and safe in operation, well ensuring no harm to the environment and control on production cost, increasing yield and being capable of becoming a process in great industrial production.

Owner:上海立科化学科技有限公司

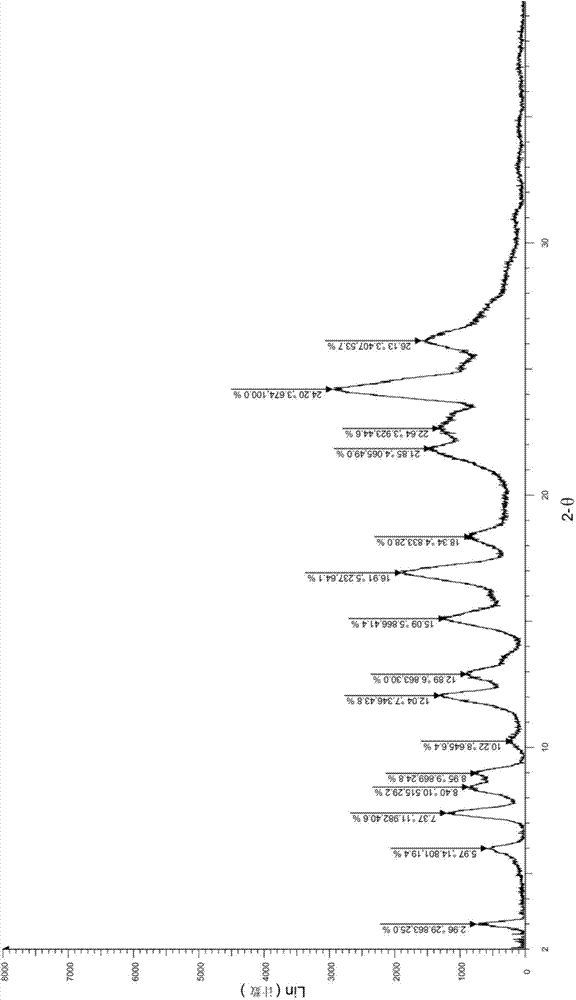

Crystal form of diethanolamine salt of thrombopoietin mimic and preparation method thereof

InactiveCN104844582AImprove stabilityMeet the pharmaceutical requirements for production, transportation and storageOrganic active ingredientsOrganic chemistryFuranThrombopoietin mimetics

The invention relates to a crystal form of a diethanolamine salt of a thrombopoietin mimic and a preparation method thereof. Specifically, the invention relates to a type A crystal of (Z)-5-(2-hydroxy-3-(2-(3-methyl-5-oxo-1-(5,6,7,8-tetralin-2-yl)-1H-pyrazole-4(5H)-idene)hydrazino)phenyl)furan-2-diethanolamine carboxylate (a compound as shown in a formula (I)) and a preparation method thereof. The crystal has an x-ray powder diffraction pattern as shown in a figure 1. The type A crystal of the compound as shown in the formula (I) has good chemical stability and crystal-form stability, uses a crystallization solvent with low toxicity and low residues and can be better applied to clinical treatment.

Owner:JIANGSU HENGRUI MEDICINE CO LTD

Fomula for Joint Synthetic Jet, Rocket, And Diesel Fuel

A synthetic fuel formula using a blend of High Density Synthetic (HDS) (e.g. Decalin and Tetralin), and Low Density Synthetic (LDS) (e.g. Synthetic Paraffinic Kerosene—SPK) is disclosed. This HDS and LDS blend has been shown to be useful as a jet, rocket and diesel fuel of standard density, and under low temperature conditions. The inventions described herein relate to 100% synthetic hydrocarbon fuels derived from various carbonaceous materials such as, but not limited to, biomass, municipal waste, natural gas, and coal. This 100% synthetic fuel can be universally used for both jet and diesel fuels. It meets Joint Battlefield Use Fuel of the Future (J-BUFF), or Single Battlefield Fuel (SBF) strategic requirements. The commercial advantage of the present invention is that it can be prepared from commercial available fuel stocks or co-processed using currently available chemical processes.

Owner:KNIGHT ROY CAMERON +3

Method for preparing intermediate of axitinib and application of intermediate in preparation of axitinib

The invention relates to a method for preparing an intermediate of axitinib and application of the intermediate in preparation of axitinib. The preparation method for the intermediate of axitinib 3-iodine-6-nitro-1-(teralin-2H-pyran-2-base)-1H-indazole comprises the following steps that 6-nitroindazole and 3,4-dihydro-2H-pyran react under the action of catalyst so as to protect perssad tetralin-2H-pyran-2-base at N-H site, and the key intermediate with high yield is obtained through iodination at site 3. The application of the intermediate in preparation of axitinib is as follows: Heck coupled reaction is carried out on the intermediate and 2-vinyl pyridine, then nitro reduction and diazo-reaction for iodination are sequentially carried out, finally, the axitinib is obtained after docking of 2-sulfydryl-N-methyl benzamide and deprotection. The related main initial raw materials are easy to purchase in markets, and the method has high yield and high molecule economic efficiency, is efficient and environment-friendly, and is suitable for industrial mass production.

Owner:湖南欧亚药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com