Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Excellent blocking resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Black ink composition, ink set, and image forming method

InactiveUS20130050366A1Excellent blocking resistanceImprove scratch resistanceMaterial nanotechnologyMeasurement apparatus componentsPolymer scienceHue

A black ink composition is provided which suppresses change in hue and can form an image with superior blocking resistance and scratch resistance.The black ink composition for ink jet recording includes a carbon black pigment; at least any one type of colorant pigment which is selected from a magenta pigment and a cyan pigment; a water-soluble polymerizable compound; a polymerization initiator; and water, wherein the average primary particle diameter of the carbon black pigment is 20 nm or more and less than 35 nm, the content ratio of the carbon black pigment with regard to the total mass of all of the pigments is 70 mass % or less, and the total mass of all of the pigments with regard to the total mass of the black ink composition is 4 mass % or less.

Owner:FUJIFILM CORP

Electrostatic image developing toner, toner kit and image forming apparatus

ActiveUS20090123186A1Excellent blocking resistanceLow temperature fixabilityDevelopersElectrographic process apparatusHydrogen atomEther

A toner is provided that comprises a colorant and a binder resin, wherein the binder resin comprises a polyester resin that is prepared by a polycondensation reaction in the presence of at least a titanium-containing catalyst expressed by General Formula (II) or (II), the toner has a volume average particle diameter of 2.0 μm to 10.0 μm and a ratio Dv / Dn within a range of 1.00 to 1.40, in which Dv represents a volume average particle diameter and Dn represents a number average particle diameter,Ti(—X)m(-OH)n General Formula (I)O═Ti(—X)p(-OR)q General Formula (II)in General Formulas (I) and (II), X represents a residue of a mono-alkanolamine of 2 to 12 carbon atoms or a polyalkanolamine from which a hydrogen atom of one hydroxyl group is removed; other hydroxyl group(s) and still other hydroxyl group(s), within the polyalkanolamine molecule that has a directly bonding Ti atom, may polycondense to form a ring structure; other hydroxyl group(s) and still other hydroxyl group(s) may polycondense intermolecularly to form a repeating structure; and the polymerization degree is 2 to 5 in a case of forming the repeating structure; R represents one of a hydrogen atom and alkyl groups of 1 to 8 carbon atoms that may have 1 to 3 ether bonds; “m” is an integer of 1 to 4; “n” is an integer of 0 to 3; the sum of “m” and “n” is 4; “p” is an integer of 1 or 2; “q” is an integer of 0 or 1; the sum of “p” and “q” is 2; and in a case that “m” and “p” is 2 or more, the respective Xs may be identical or different each other.

Owner:RICOH KK

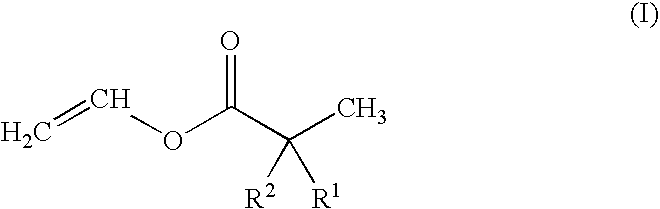

Highly adhesive thermoplastic resin film

ActiveCN102648094AExcellent adhesionSuppression of light interference fringesPrismsConductive layers on insulating-supportsPolyolHigh humidity

Disclosed is a highly adhesive thermoplastic resin film which is substantially free from decrease in adhesion under high temperature high humidity conditions. Specifically disclosed is a highly adhesive thermoplastic resin film which comprises a coating layer on at least one surface of a base film. The highly adhesive thermoplastic resin film is characterized in that the coating layer contains (a) a urethane resin that contains a polycarbonate polyol as a component, and / or a polyester resin that does not substantially contain a carboxylic acid group and has a number average molecular weight of not less than 15,000, and (b) a carbodiimide compound.

Owner:TOYO TOYOBO CO LTD

Chrome-free insulating coating composition and preparation method and oriented silicon steel plate

ActiveCN107190252AEasy to recycleImprove the level ofInorganic material magnetismQuartz/glass/vitreous enamelsOrganic acidMolybdate

The invention provides a chrome-free insulating coating composition and a preparation method and an oriented silicon steel plate. The coating composition comprises the following components of, by weight, 100 parts of phosphate solutions, 1-5 parts of molybdate, 50-150 parts of silica sols, 3-13 parts of selenium dioxide, 1-10 parts of metallic oxide and / or metal hydroxide, 5-15 parts of organic acid, 1-6 parts of boric acid and 100-300 parts of water. The preparation method of the composition comprises the steps that the phosphate solutions, the boric acid and the water are added; the selenium dioxide and the organic acid are sequentially added; and the metallic oxide and / or metal hydroxide and the molybdate are added, then the silica sols are added, and the composition is obtained. The oriented silicon steel plate comprises a pedestal and a chrome-free insulating coating formed on the surface of the pedestal, and the chrome-free insulating coating is obtained by coating the chrome-free insulating coating composition on the surface of the pedestal. The chrome-free insulating coating has extremely high interlayer resistance, surface hardness and surface tension and shows the excellent magnetic property improved effect.

Owner:WUHAN YUANRONG TECH CO LTD

Aqueous copolymer dispersions with improved blocking resistance

ActiveUS20070282049A1Fast dryingExcellent blocking resistanceEmulsion paintsVinyl esterCarboxylic acid

The invention relates to new, aqueous secondary copolymer dispersions, to a process for preparing them and to their use for producing high-grade coatings, especially for wood. The dispersions comprise a copolymer (P) synthesized from a mixture of free-radically polymerizable monomers (M) comprising (M1) cycloaliphatic esters of acrylic and / or methylacrylic acid and also (M2) vinyl esters of aliphatic carboxylic acids.

Owner:COVESTRO DEUTSCHLAND AG

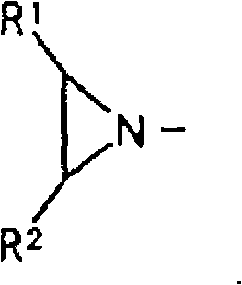

Antistatic coating agent

InactiveCN101538435AGood antistaticExcellent coating performanceSynthetic resin layered productsElectrically-conductive paintsSolventChemistry

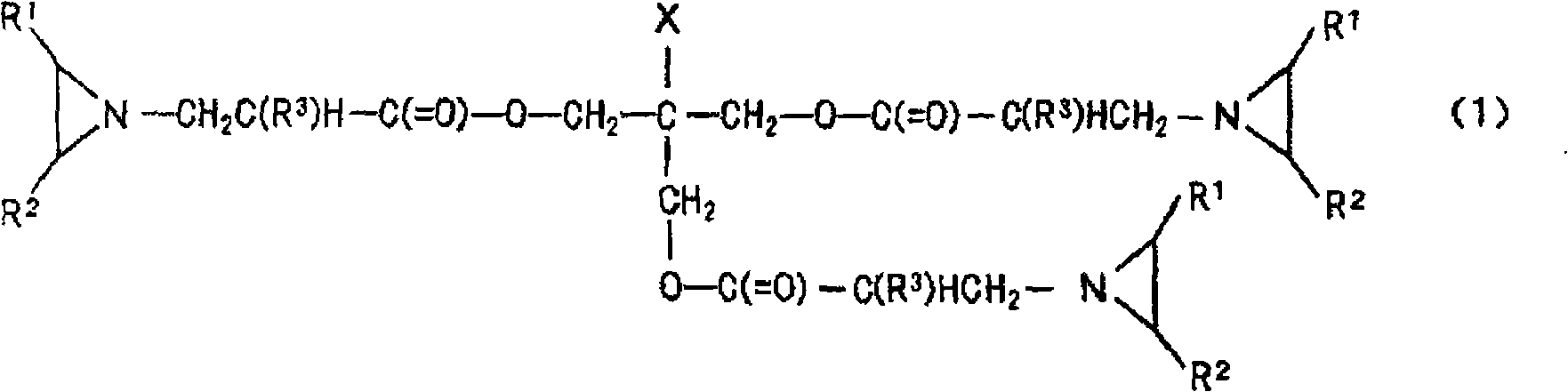

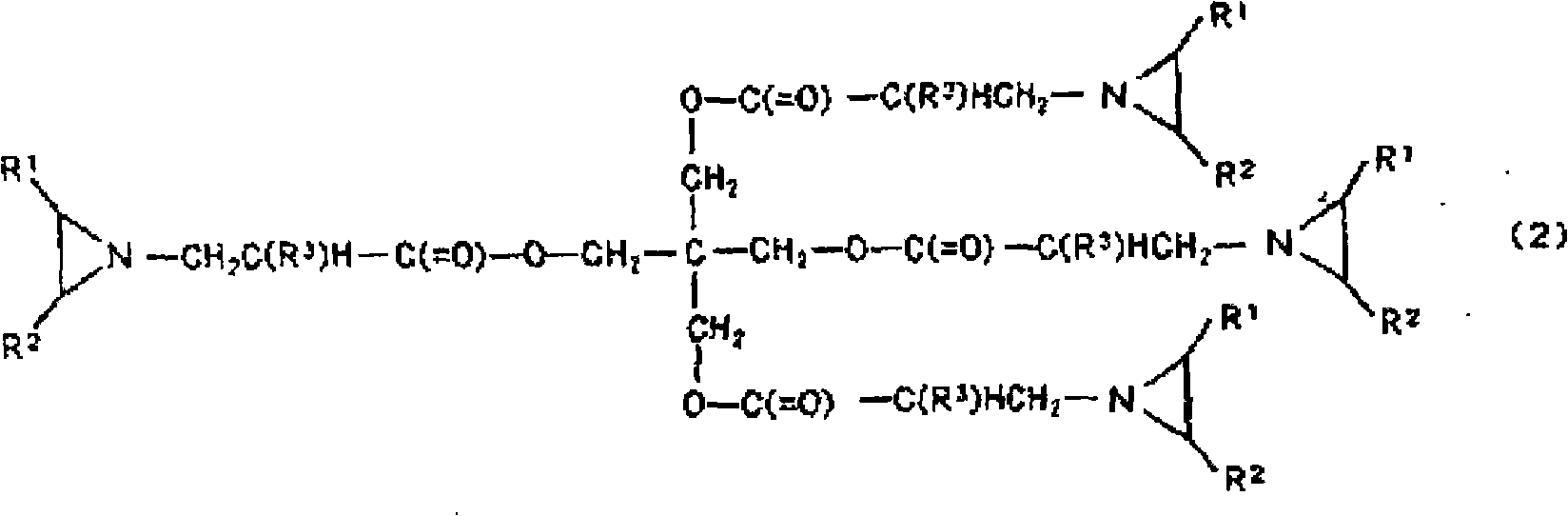

The present invention provides a novel coating agent with an excellent antistatic property, solvent resistance and adhesive resistance. The antistatic coating agent contains acroid resin (A) having carboxylate anion group, a polyfunctional aziridine compound (B) and a Pi conjugated conductive polymer (C) containing hetero atoms.

Owner:ARAKAWA CHEM IND LTD

Laminated polyester film

InactiveCN1457297AImprove adhesionHigh transparencyDuplicating/marking methodsSynthetic resin layered productsGlass transition pointCarboxylic acid

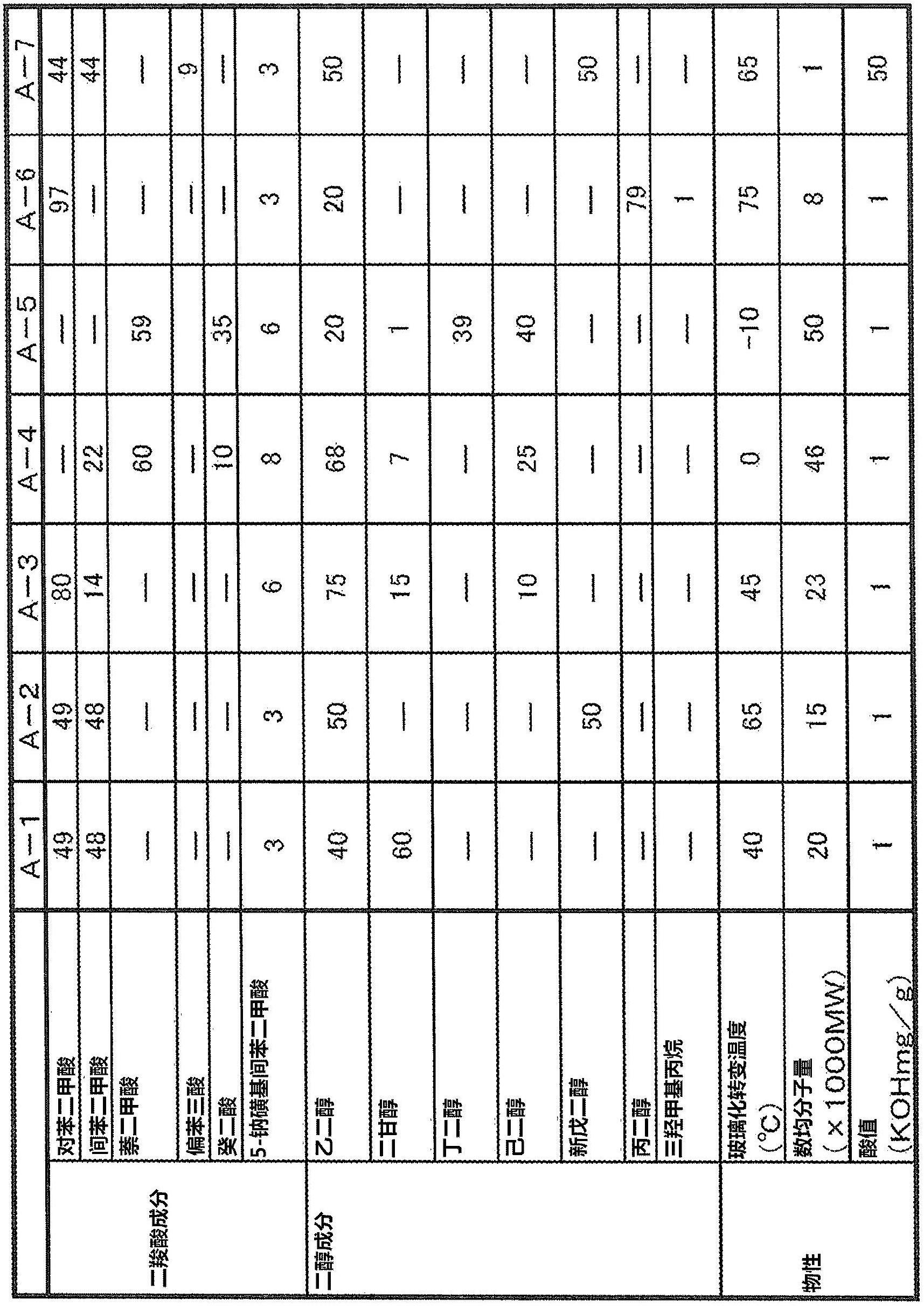

Provided is a laminated polyester film, in which a laminated layer comprising two types of polyester resins having different glass transition points from each other is formed on at least one side of polyester film wherein the two types of polyester resins are composed of a polyester resin (A) having a glass transition point of from 60 DEG C to 100 DEG C, and a polyester resin (B) having a glass transition point of from 0 DEG C to 60 DEG C and the polyester resin (B) contains a specified component, and a dicarboxylic acid component having a sulfonic acid metal base is set as a specified ratio in entire dicarboxylic acid components in the polyester resins (A) and (B), satisfies adhesiveness to various types of coating materials which has conventionally been incompatible and, further, satisfies anti-blockingproperties,transparency,scratch resistance and the other properties.

Owner:TORAY IND INC

Multilayered film and container

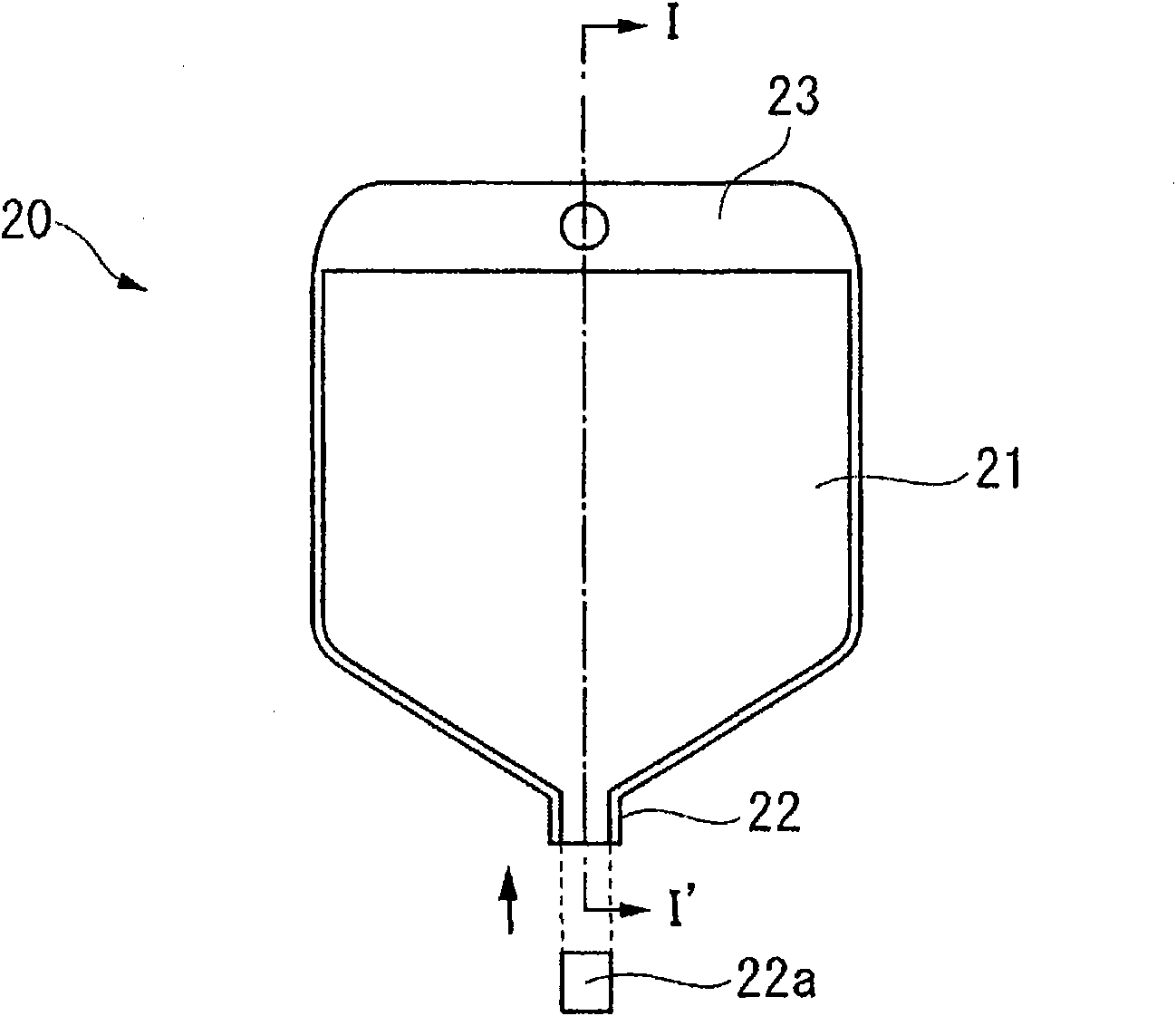

InactiveCN1330588AImprove heat resistanceExcellent blocking resistanceMedical devicesDomestic containersElastomerHigh density

A multilayered film comprising five layers in which the first, third and fifth layers are made of an ethylene . alpha -olefin copolymer having a density of 0.930 to 0.950 g / cm<3> and the second and fourth layers are made of a mixed resin comprising 35 to 55% by weight of polypropylene having a density of 0.900 to 0.930 g / cm<3>, 40 to 60% by weight of ethylene . alpha -olefin elastomer having a density of 0.860 to 0.900 g / cm<3>, and 2 to 8% by weight of high-density polyethylene having a density of 0.955 to 0.970 g / cm<3>; and a container made of the film (bag for infusion fluid, etc.) . The multilayered film and the container are useful in medical applications.

Owner:OTSUKA PHARM FAB INC

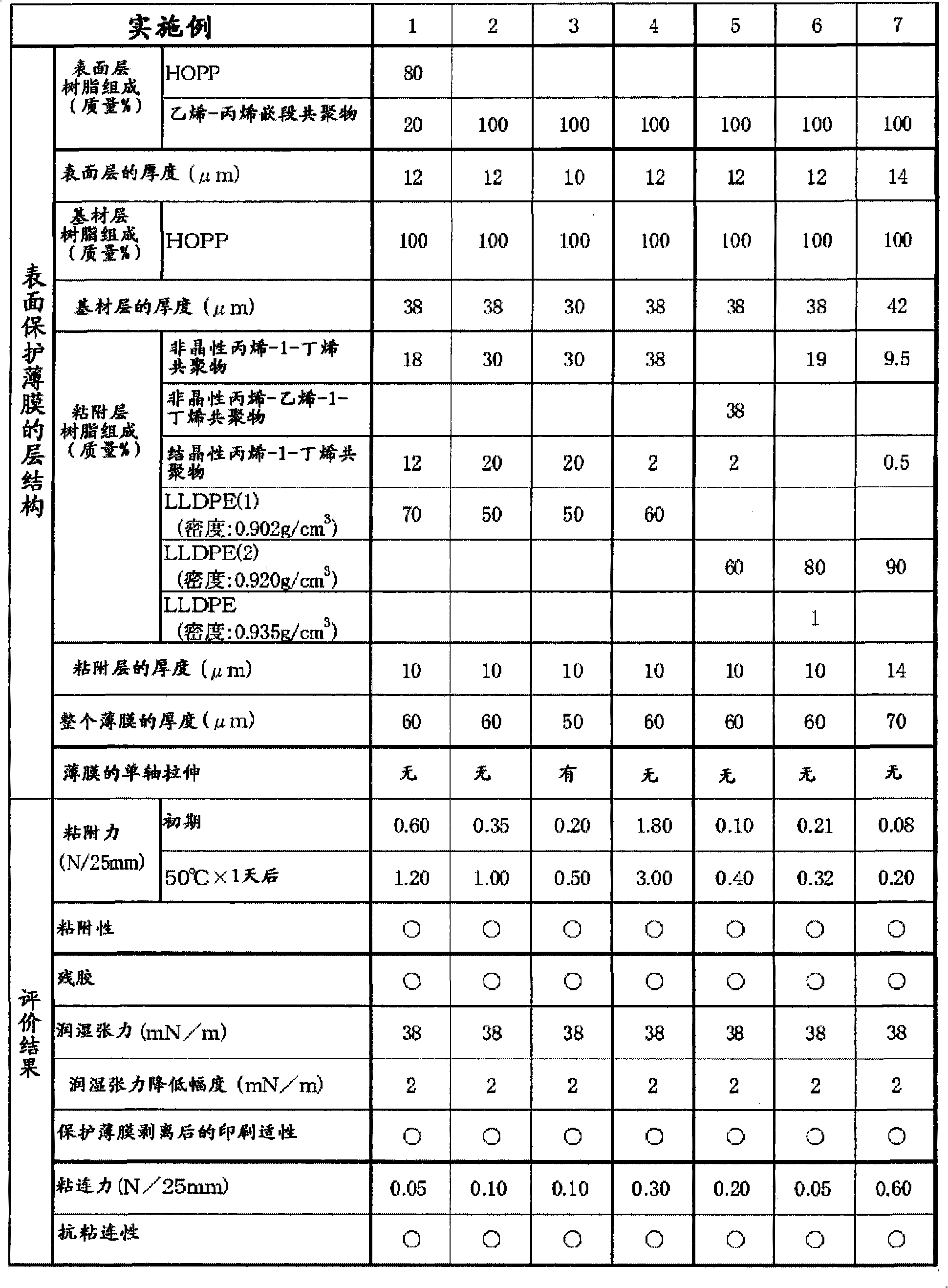

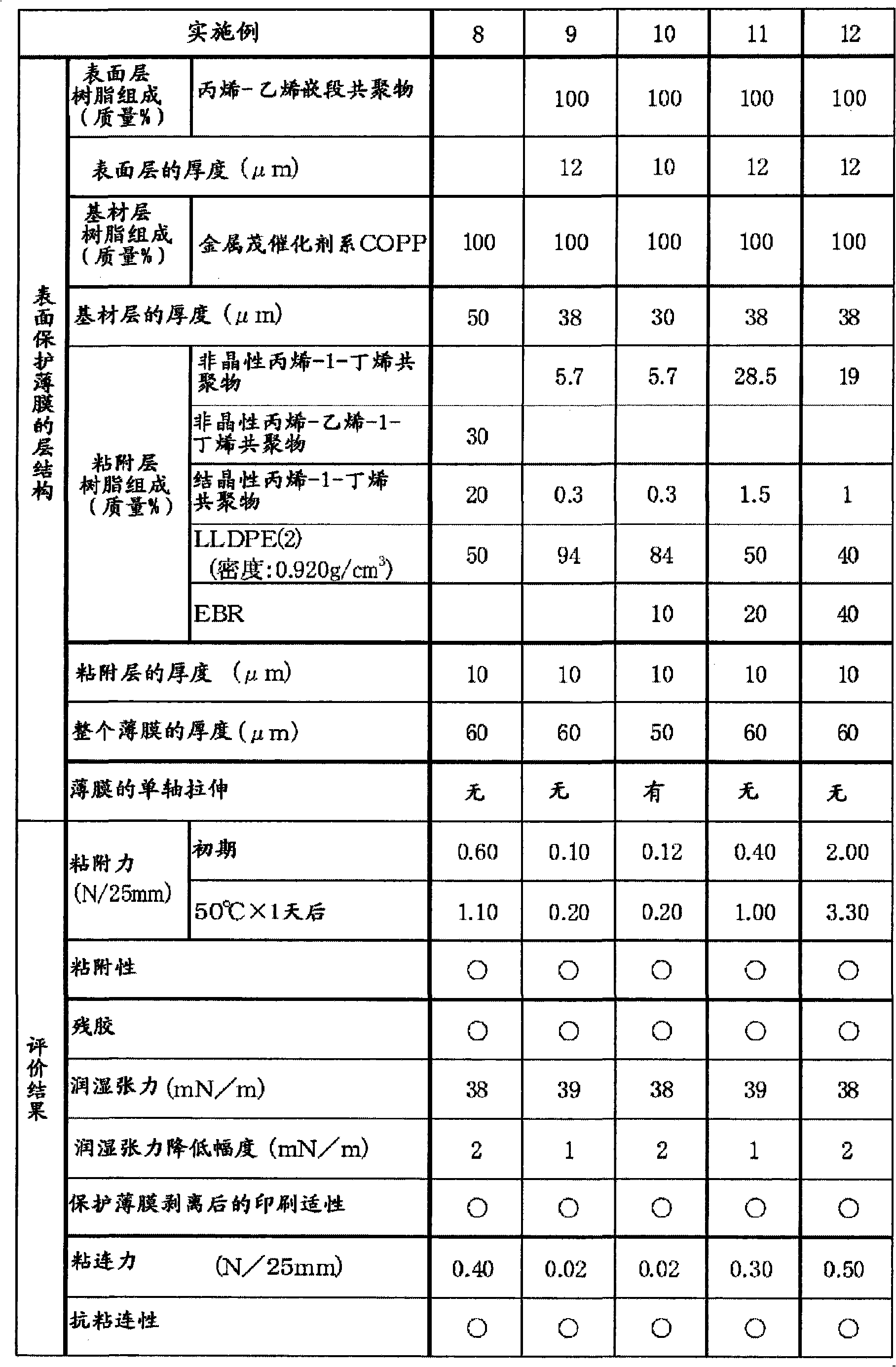

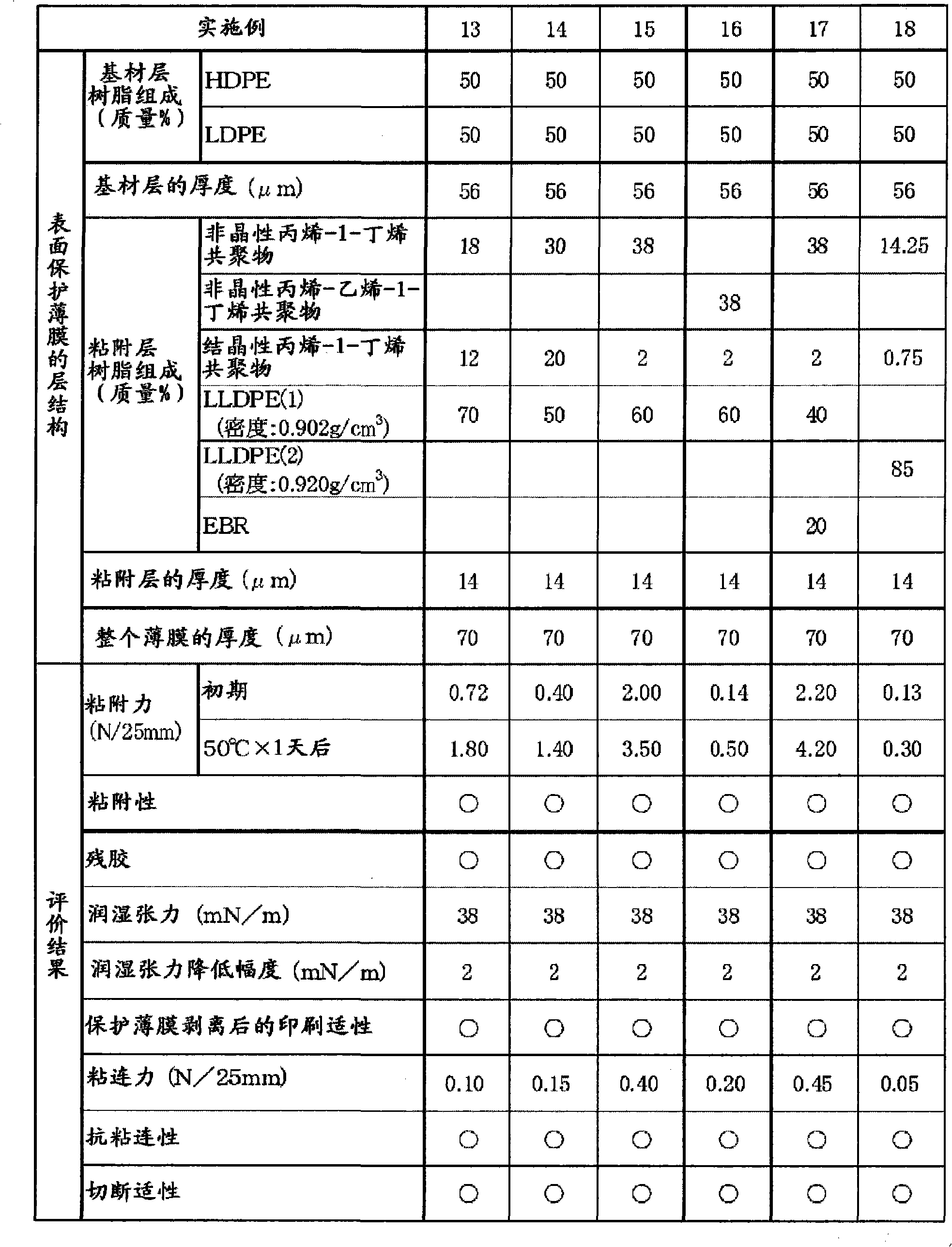

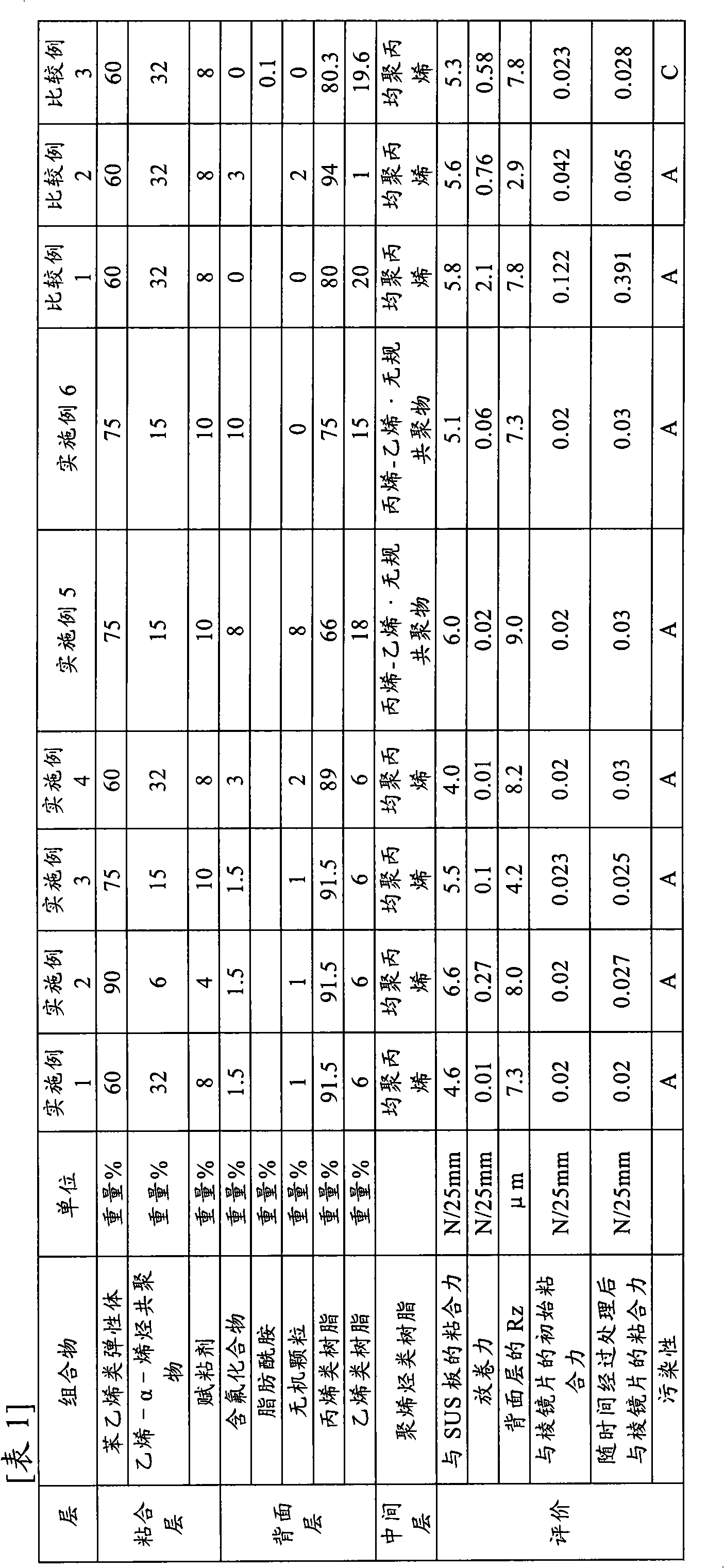

Surface protective film

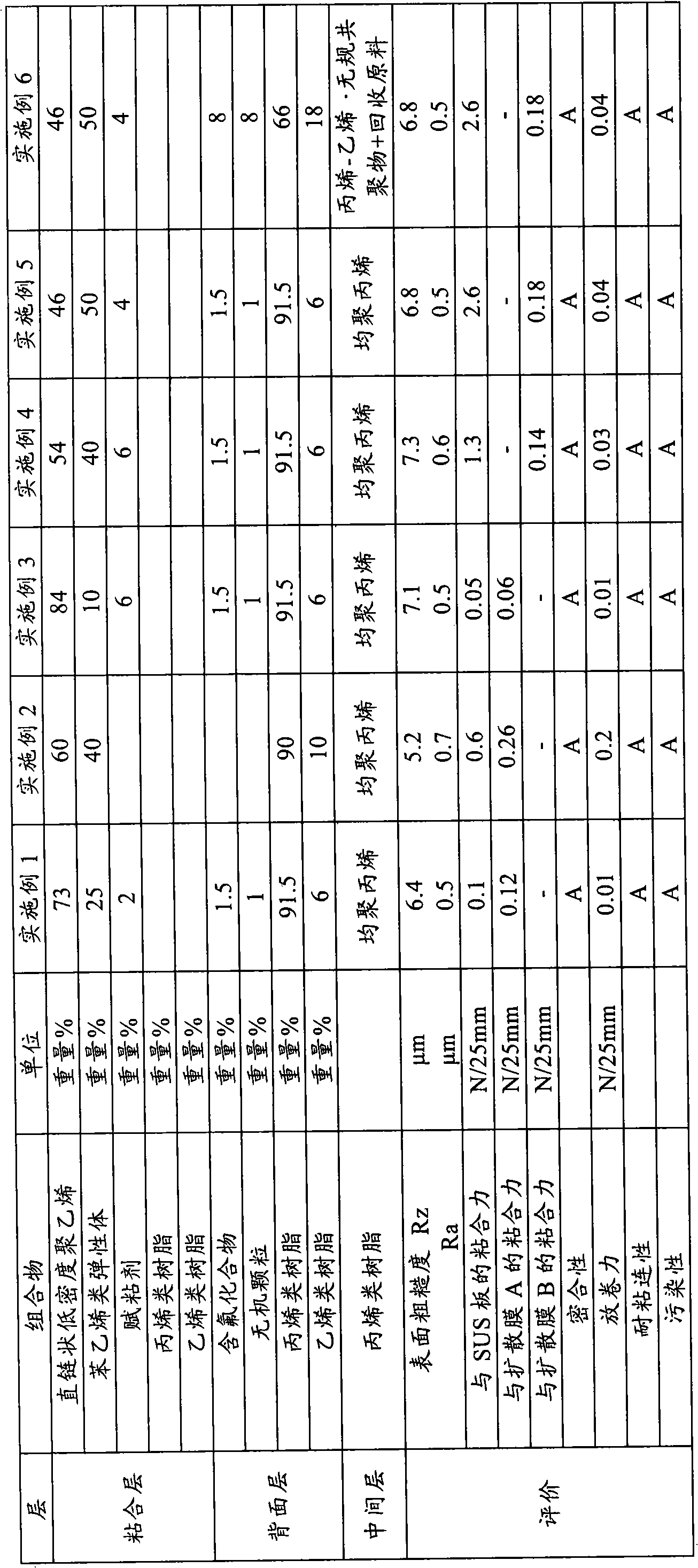

ActiveCN102834263AProper adhesive propertiesEasy to slideFlexible coversWrappersLow-density polyethyleneElastomer

The present invention provides a surface protective film which has proper adhesion property even for an adherend having a rough surface, which is excellent in sliding property of a back surface and is excellent also in anti-blocking property and unwinding characteristic (unwinding tension is reduced, no wrinkle or damage occurs even upon the attaching to the adherend, and the easy and high-speed attachment is made possibly). The surface protective film of the present invention comprising a three-layer composite form consists of an adhesive layer, a middle layer and a back surface layer, wherein the adhesive layer consists of a straight chain-form low density polyethylene 35 to 90 wt.%, a styrenic elastomer 5 to 50 wt.% and a tackfier <= 15wt.%, the middle layer consists mainly of a propylenic resin and the back surface layer is composed mainly of a propylenic resin constituting the middle layer and / or different propylenic resin, and the back surface layer has a surface roughness of >= 3 [mu] m by a ten-point mean roughness(Rz).

Owner:TORAY ADVANCED FILM CO LTD

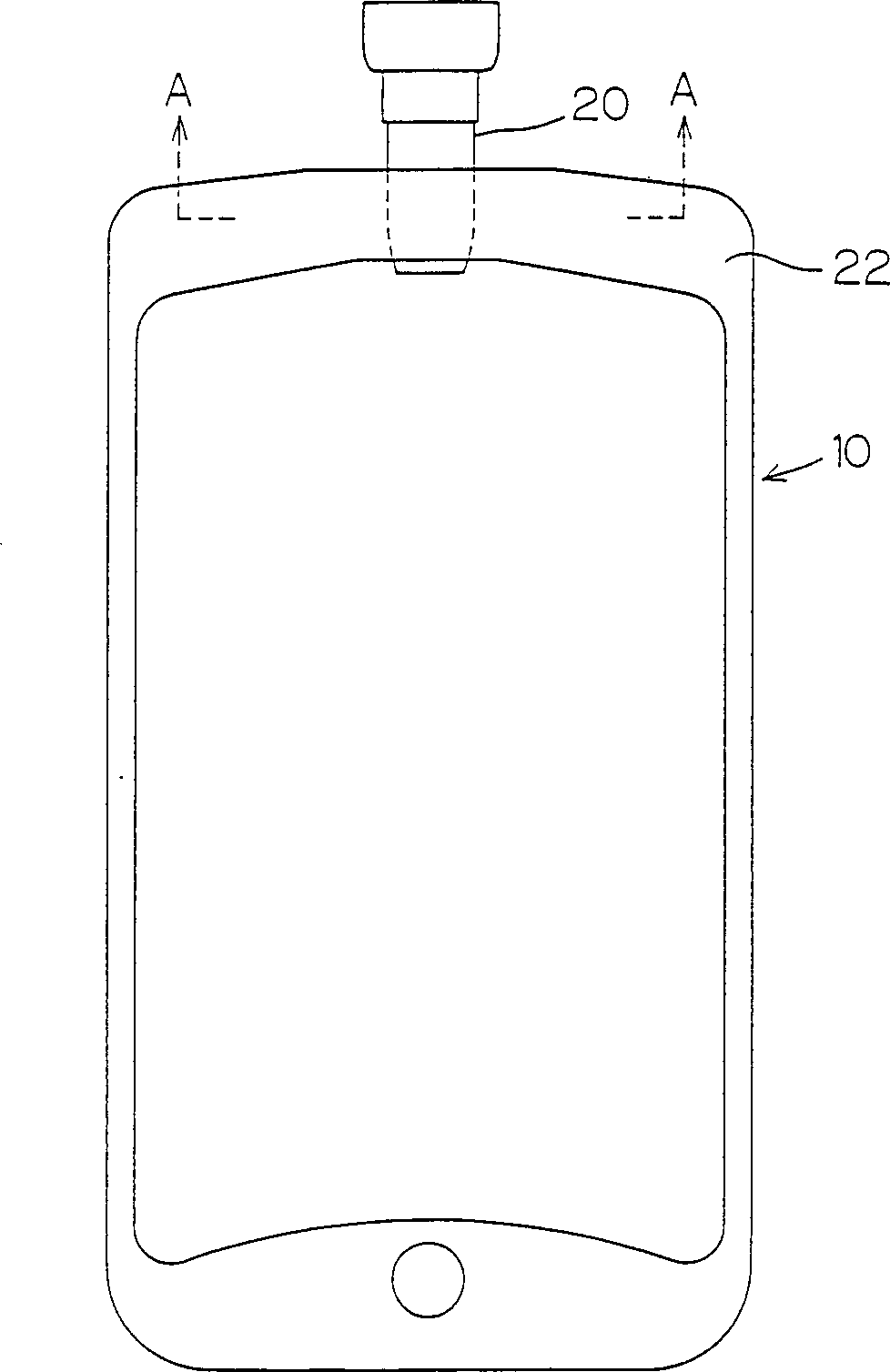

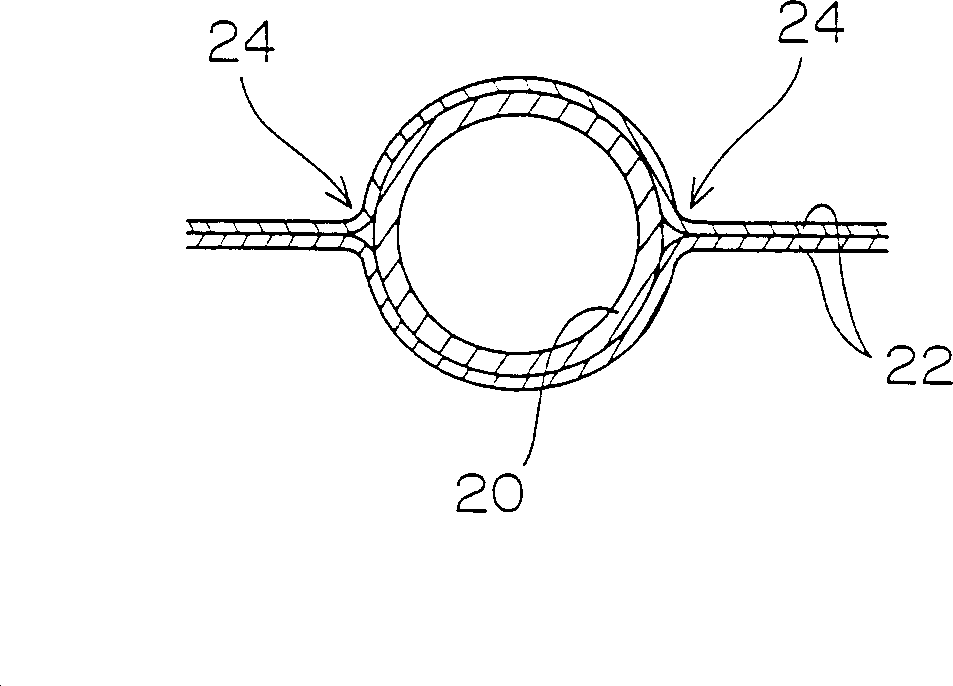

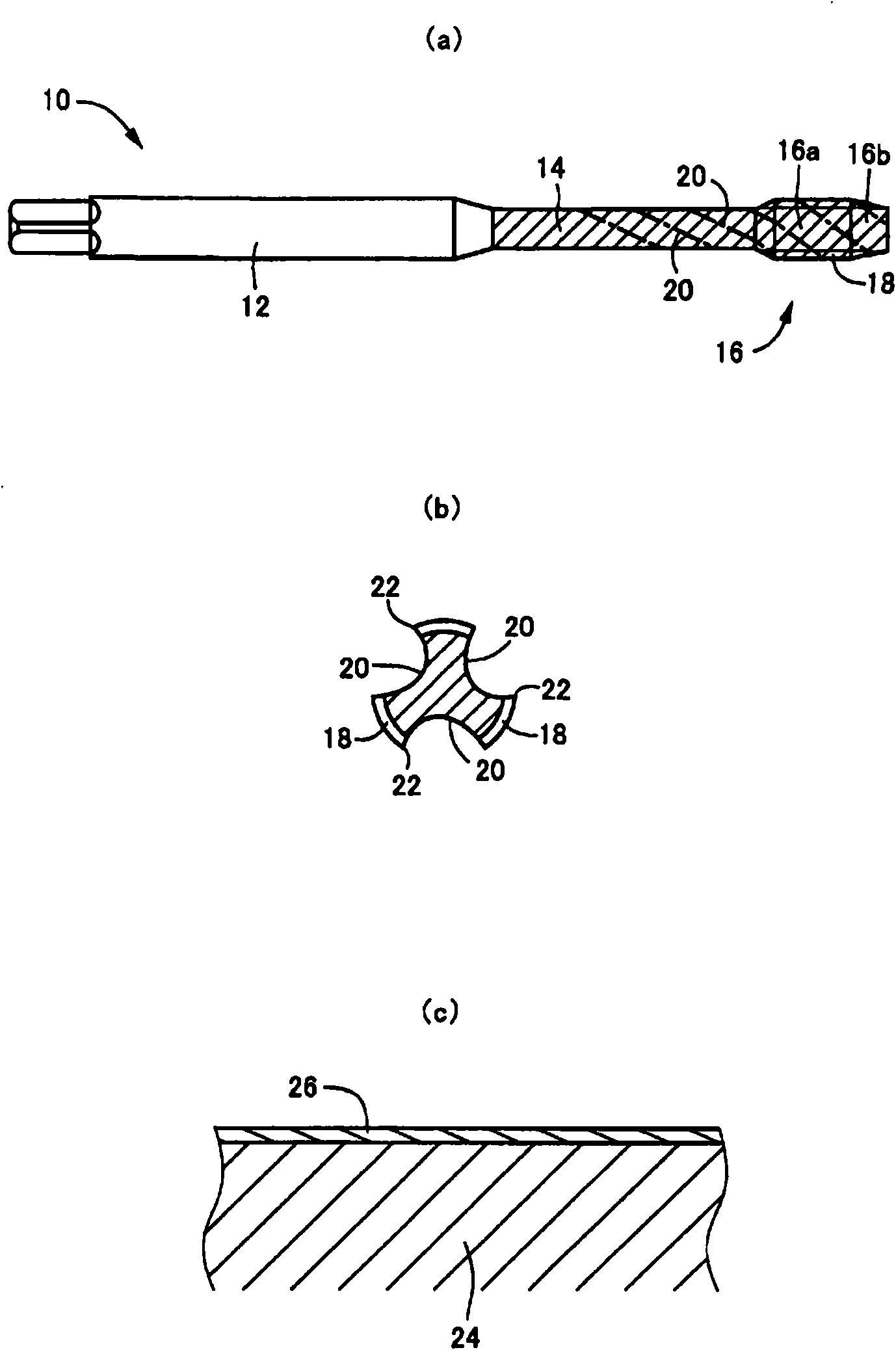

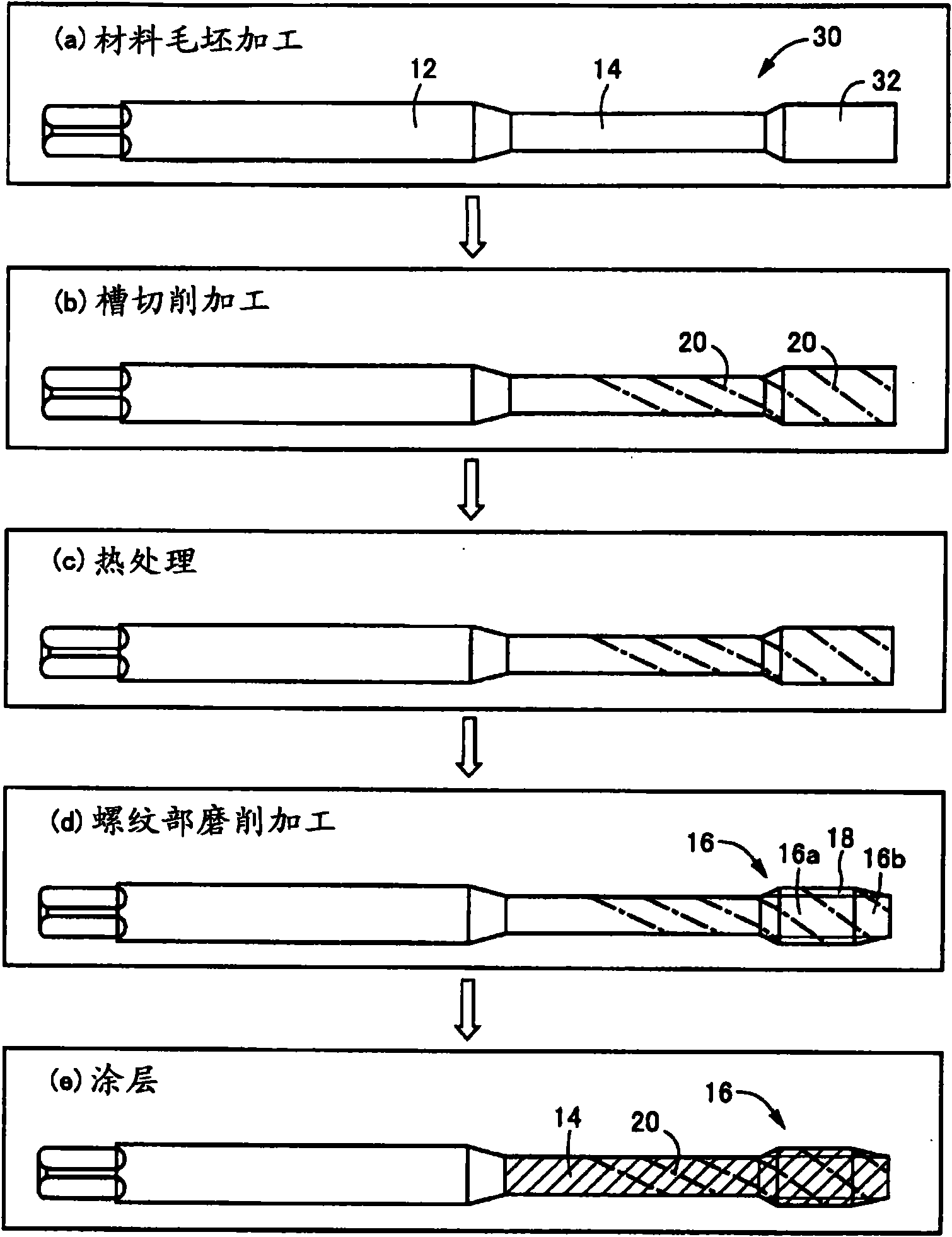

Tap covered with hard coating, and process for manufacturing the same

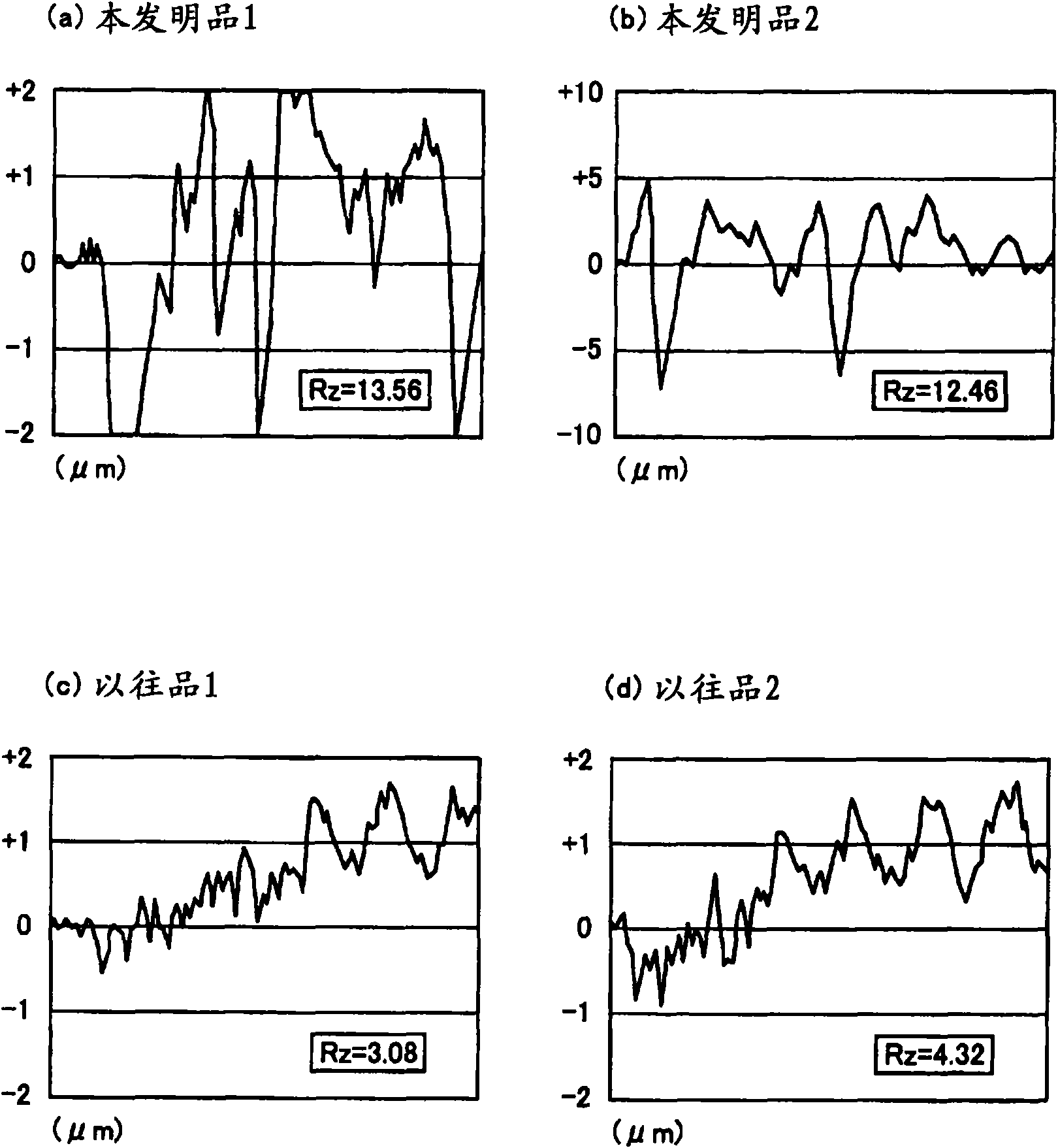

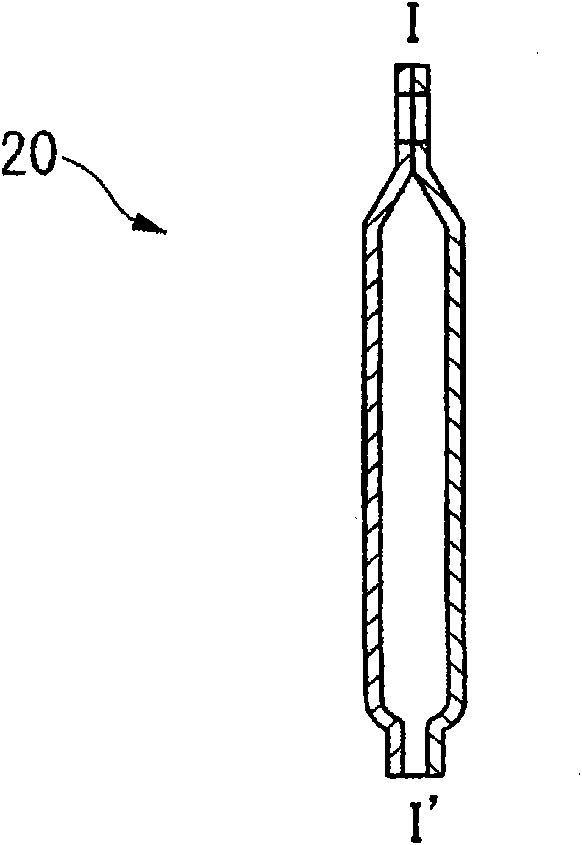

ActiveCN101626861AInhibition of entanglementAvoid breakingThread cutting toolsVacuum evaporation coatingSurface roughnessEngineering

With respect to a tap covered with hard coating, to even in tapping machining of mild steel, etc., facilitate curling of chips so as to inhibit any entanglement thereof, thereby attaining not only enhancement of tool life duration but also continuous operation of tapping machining. ¢MEANS FOR SOLVING PROBLEMS! Not only is twist groove (20) formed by cutting machining, but also screw part (16) is provided by grinding machining performed after heat treatment. The surface of the screw part (16) including the twist groove (20) formed by cutting machining is covered with hard coating (26), so that the surface roughness of twist groove (20) in the state of being covered with the hard coating (26) falls within the range of 6.3 to 25 ¢mu!m in terms of maximum height (Rz). Accordingly, even in the tapping machining of mild steel, etc., curling or segmentalization of chips would be facilitated by the unevenness of the groove surface when the chips are guided by the twist groove (20) and ejected on the side of shank (12). Therefore, entanglement on the tap (10) per se or holders would be inhibited.

Owner:OSG

Epoxy resin composition for optical semiconductor device, and lead frame for optical semiconductor device, encapsulation type optical semiconductor element unit and optical semiconductor device each obtainable by using the epoxy resin composition

InactiveUS20160111611A1Warpage suppressionMoldability is degradedDiffusing elementsSemiconductor/solid-state device detailsEpoxyCarboxylic acid

An optical semiconductor device includes a metal lead frame including first and second plate portions, an optical semiconductor element mounted on the metal lead frame, and a reflector provided around the optical semiconductor element. A material for the reflector is an epoxy resin composition containing: (A) an epoxy resin; (B) a curing agent; (C) a white pigment; (D) an inorganic filler; and (E) at least one of a carboxylic acid and water. Components (C) and (D) are present in a total proportion of 69 to 94 wt % based on the amount of the overall epoxy resin composition, and the component (E) is present in a proportion of 4 to 23 mol % based on the total amount of the components (B) and (E). The resin composition has a higher glass transition temperature, and is excellent in moldability and blocking resistance and substantially free from warpage.

Owner:NITTO DENKO CORP

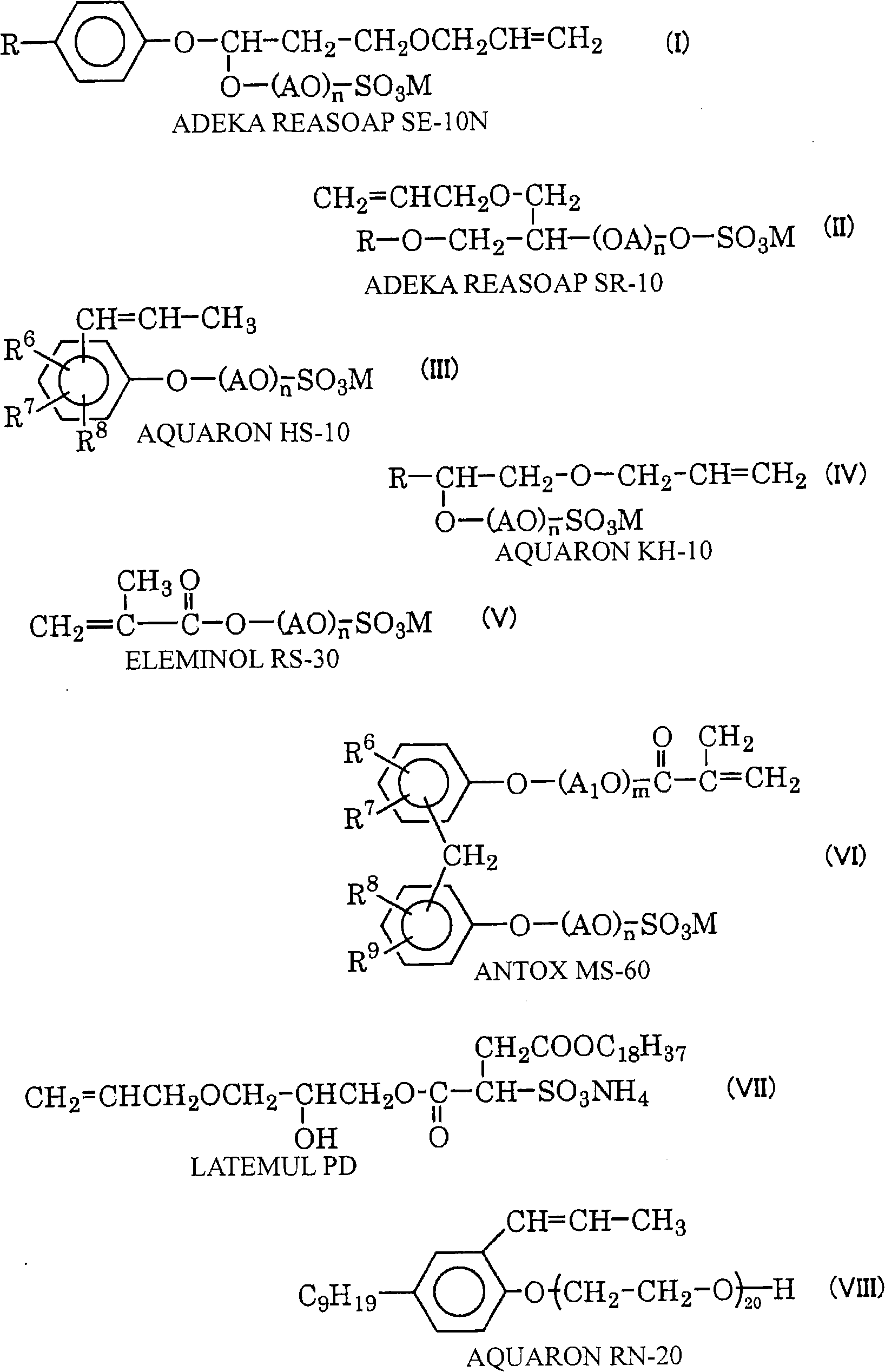

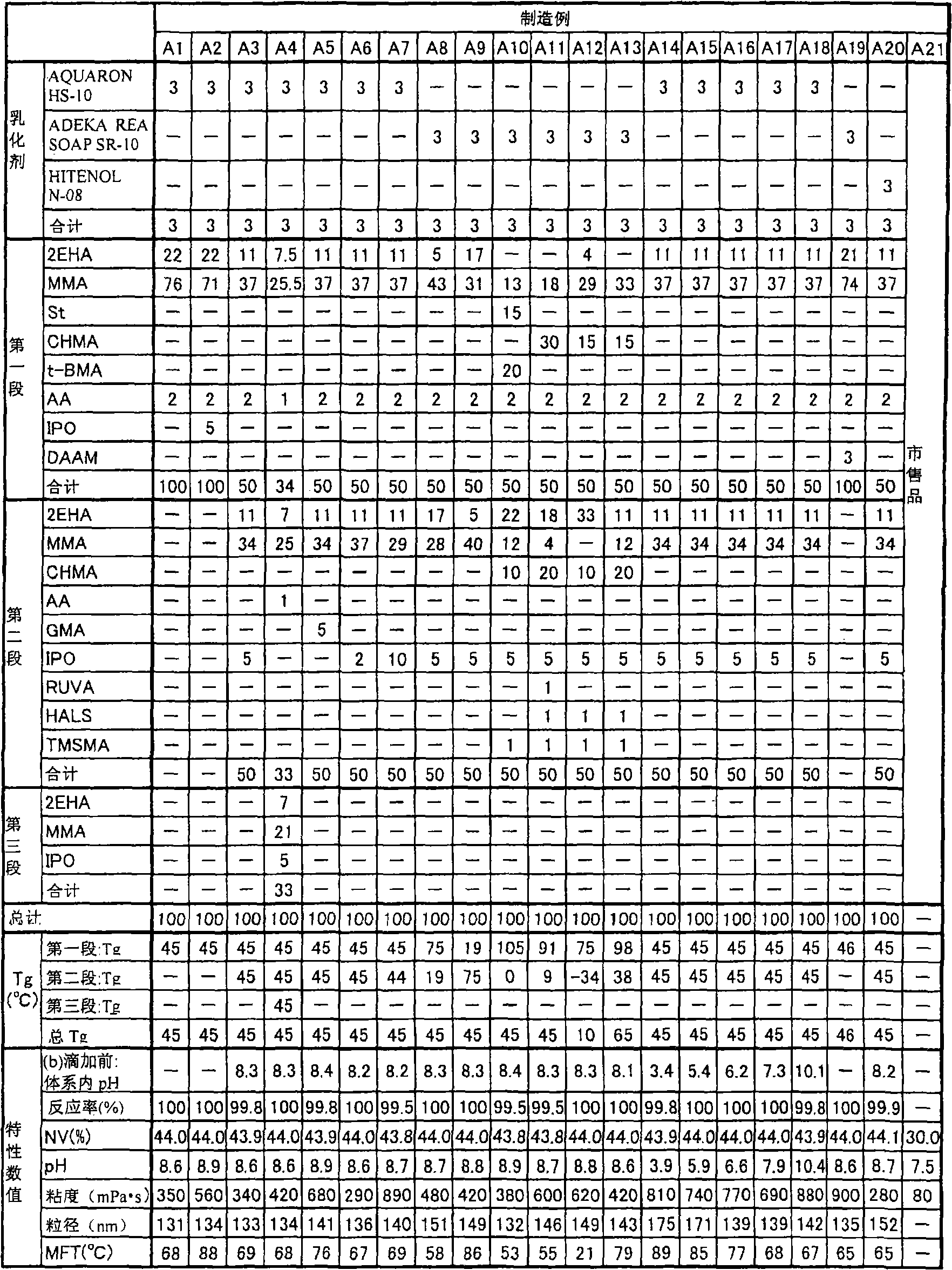

Aqueous coating resin composition

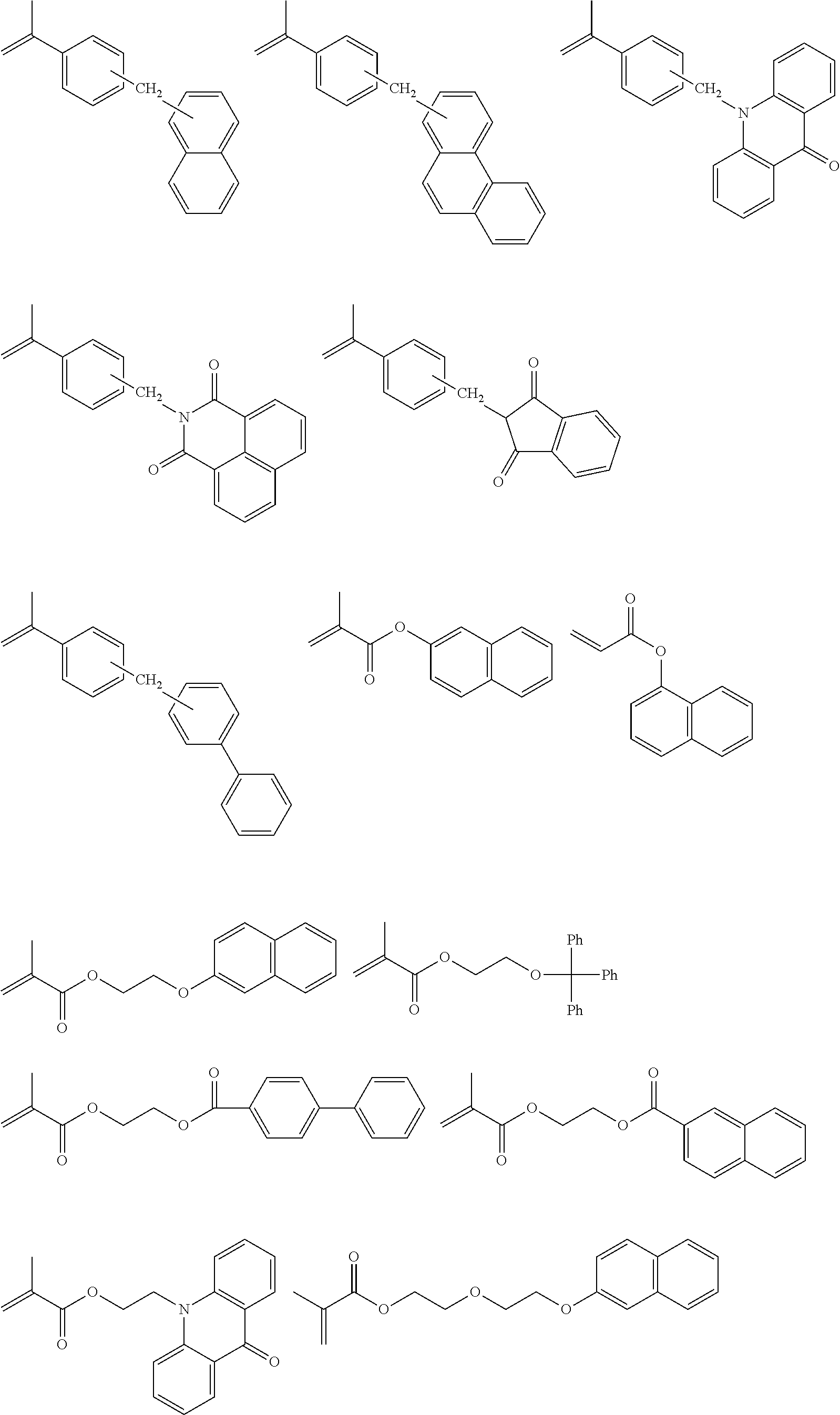

The invention provides an aqueous coating resin composition capable of forming a coating film which is improved in weather resistance, resistance to hot water whitening, frost damage resistance and blocking resistance without impairing excellent film performance and which exhibits excellent stain resistance over a long period just after application, particularly in the outdoors, especially, an aqueous coating resin composition which is favorably usable as a clear coating material requiring higher stain resistance and higher resistance to hot water whitening than those of pigment-containing coating materials. An aqueous coating resin composition which comprises a (meth)acrylic emulsion (A) obtained by emulsion polymerization and a water-soluble resin (B) as the essential components, characterized in that the (meth)acrylic emulsion (A) and the water-soluble resin (B) are ones capable for forming a crosslinked structure.

Owner:NIPPON SHOKUBAI CO LTD

4-methyl-1-pentene polymer, resin composition containing 4-methyl-1-pentene polymer, masterbatch thereof, and formed product thereof

ActiveUS20110165416A1Excellent mold releasabilityExcellent blocking resistanceFilm/foil adhesivesSynthetic resin layered productsMasterbatchSolvent

[Object] To provide a resin composition with excellent mold releasability and blocking resistance.[Solution] A resin composition containing a 4-methyl-1-pentene polymer includes 0.01 to 10 parts by mass of a 4-methyl-1-pentene polymer (B) per 100 parts by mass of at least one resin (A) selected from the group consisting of thermoplastic resins and thermosetting resins, wherein the 4-methyl-1-pentene polymer (B) has (B1) an intrinsic viscosity [η] of 0.01 or more but less than 0.50 dl / g measured at 135° C. in a decalin solvent.

Owner:MITSUI CHEM INC

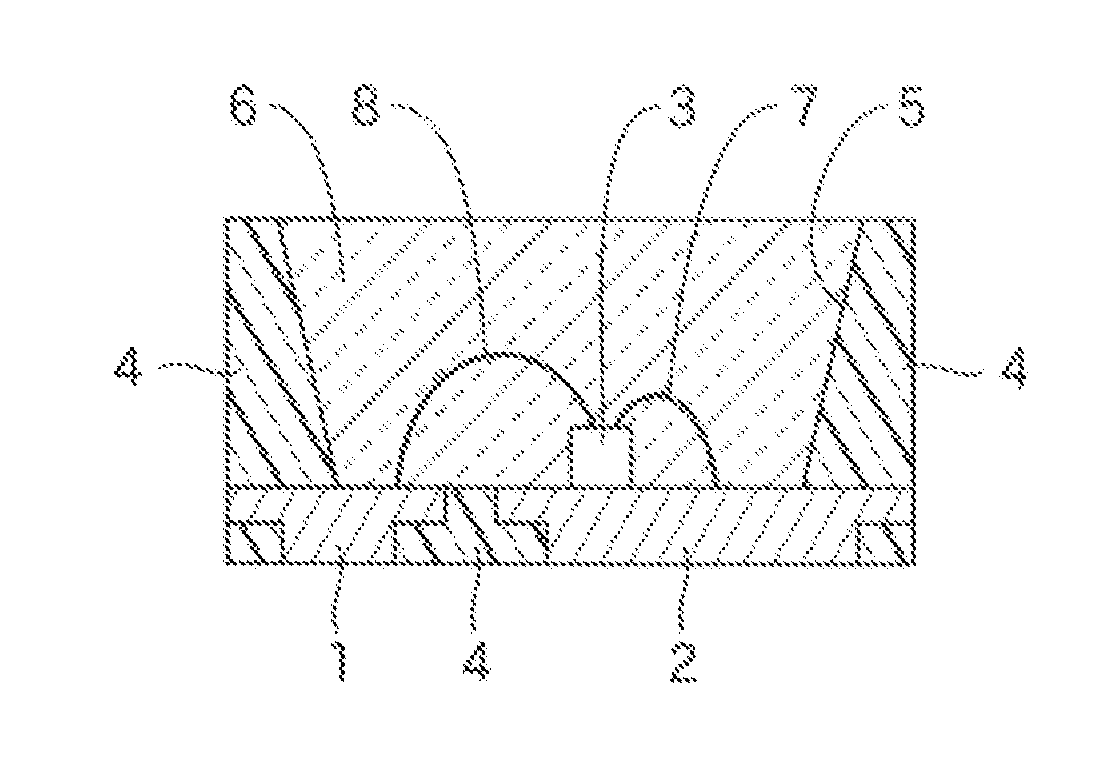

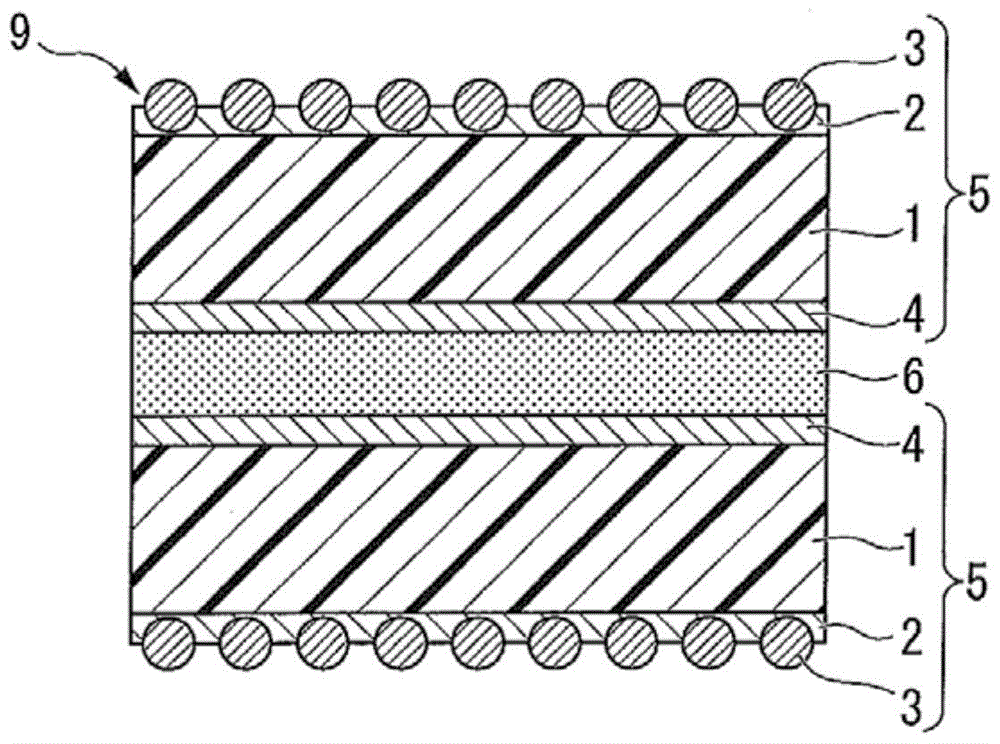

Release film having excellent peelability

ActiveCN105950041AExcellent peelabilitySmall peeling forceSynthetic resin layered productsCellulose adhesivesPolymer sciencePeel force

The present invention provides a release film excellent in peelability. The release film has a small peeling force, which is not liable to increase with a lapse of time even in a state that the release film adheres to an adhesive layer; the transfer of a silicone component to the adhesive layer is less, and the adhesive force of the adhesive layer to which the film adheres is not reduced. The release film excellent in peelability is characterized in that a release agent layer (4) having a thickness of 0.4 to 2 [mu]m and containing a silicone-based release agent is provided on one surface of a base film (1), and an adhesive resin layer (2) containing inorganic fine particles and / or polymer particles as fine particles (3) are arranged on the other surface of the base film; the fine particles (3), the adhesive resin layer (2) and the release agent layer (4) satisfy the following conditions (1) and (2): (1) the volume reference average particle size of the fine particles (3) is more than twice the thickness of the release agent layer (4); (2) the thickness of the adhesive resin layer (2) is in the range of 25 to 60% of the volume reference average particle size of the fine particles (3).

Owner:FUJIMORI KOGYO CO LTD

Surface protection film

InactiveCN101909887ANo adhesionExcellent blocking resistanceFilm/foil adhesivesSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention relates to a surface protection film which is to be applied to the surfaces of building materials, various resin plates for use in electrical and electronic fields, glass plates, metal plates and so on for the purpose of protecting the adherends from scratching, contamination or the like in storage, transportation, or post-processing. A surface protection film which little stains the surface of an adherend and is excellent in fabricability is provided by using, as the main resin component constituting the pressure-sensitive adhesive layer of the film, a resin blend which comprises an amorphous a-olefin polymer and a linear low-density polyethylene at a specific ratio or which comprises an amorphous a-olefin polymer, a linear low-density polyethylene, and a crystalline ethylene / a-olefin copolymer at a specific ratio.

Owner:DIC CORP

Pre-treatment liquid and ink set

ActiveCN111565936AExcellent adhesionExcellent blocking resistanceDuplicating/marking methodsInksPolymer scienceActive agent

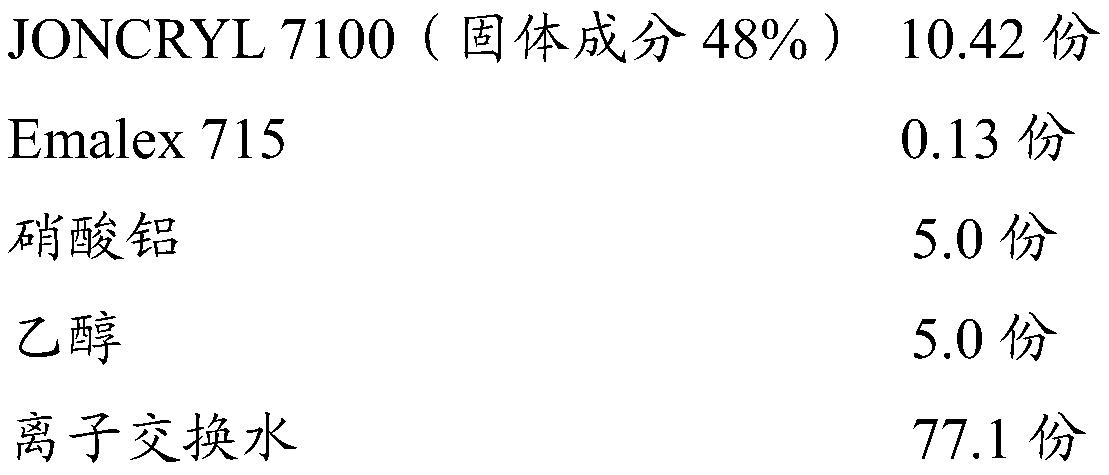

This pre-treatment liquid can be used together with an aqueous inkjet ink containing a pigment and water, and contains resin fine particles (A), a surfactant (B), a coagulant (C) and water. The surfactant (B) contains a polyoxyalkylene alkyl ether (b-1). The coagulant (C) contains a polyvalent metal salt and / or a cationic polymer compound which has a moisture absorption rate of 75 mass% or less ata temperature of 40 deg C and a relative humidity of 80%.

Owner:TOYO INK SC HOLD CO LTD +1

Multilayered body for medical containers and medical container

ActiveCN101903002AGood jointImprove heat resistanceSynthetic resin layered productsPharmaceutical containersPolyolefinHeat resistance

It is intended to provide a multilayered body for medical containers in which the innermost layer made of a cyclic polyolefin is well adhered to another layer without resorting to an adhesive and which is excellent in heat resistance and, in the case of being in a film shape, also excellent in blocking resistance, and a medical container which is made of the above multilayered body for medical containers and shows little deterioration in characteristics such as transparency and peeling strength even after sterilized with high pressure steam or the like.

Owner:HOSOKAWA YOKO CO LTD

Alcohol-based printing ink composition

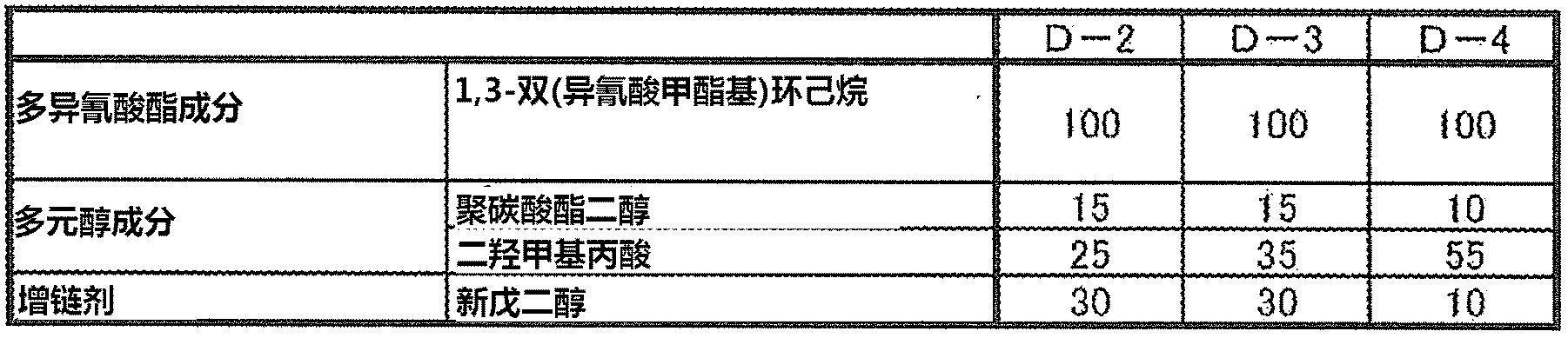

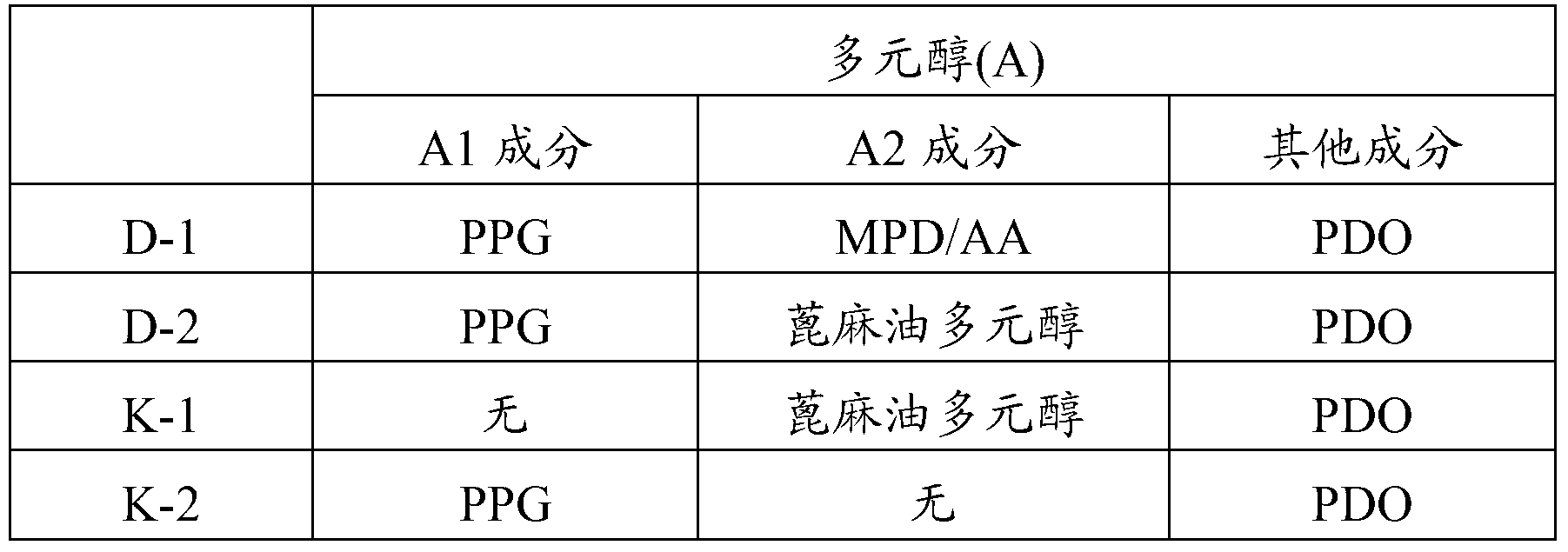

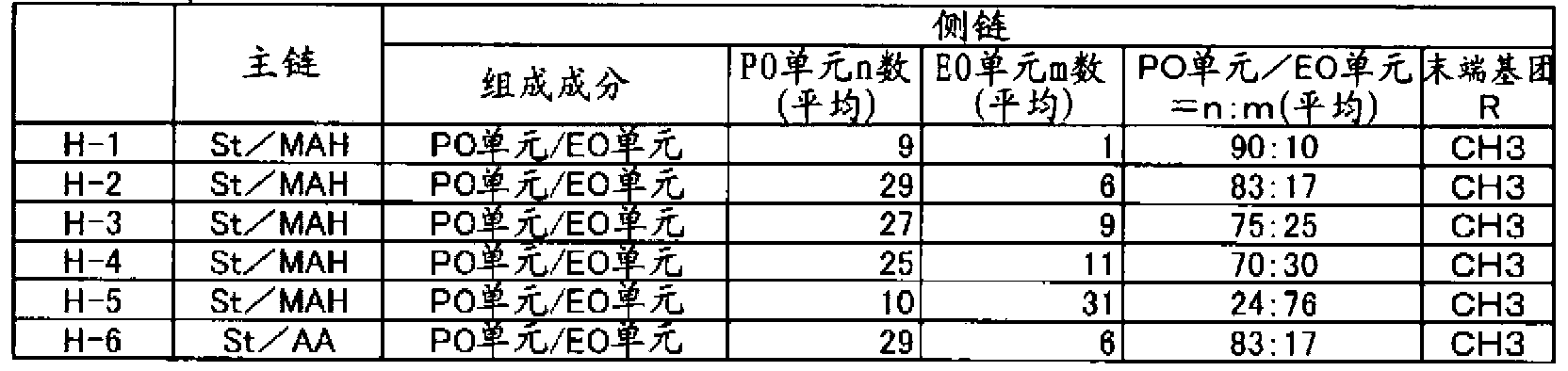

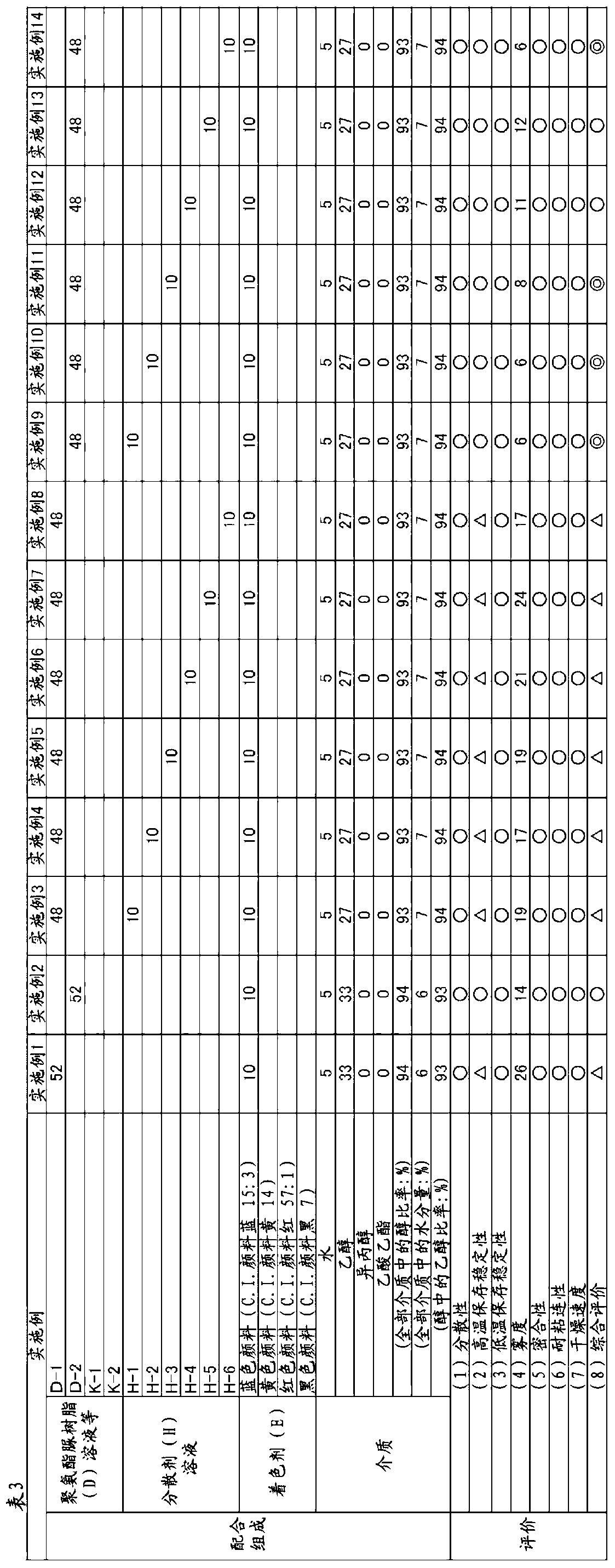

An alcohol-based printing ink composition which contains: a polyurethane urea resin (D) that is obtained by having a polyol (A), a diisocyanate (B) and a chain extender (C) react with each other; a coloring agent (E); and an alcohol (F) and water as media. The alcohol-based printing ink composition is characterized in that the polyol (A) contains a polyether polyol (A1) and a polyester polyol (A2) and 75% by weight or more of the alcohol (F) is contained in 100% by weight of the total media.

Owner:TOYO INK SC HLDG CO LTD +1

Hard coat film and optically functional film

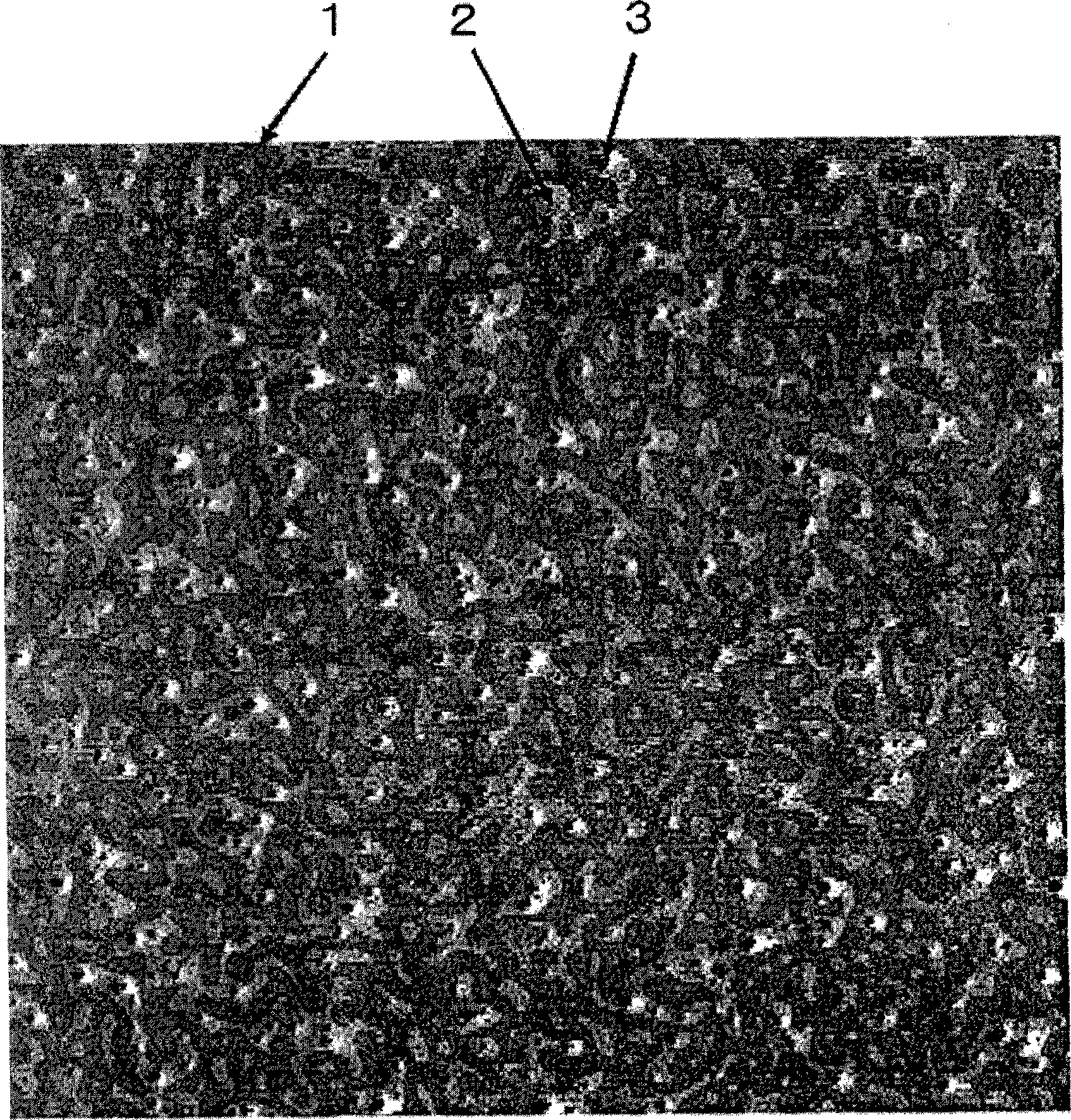

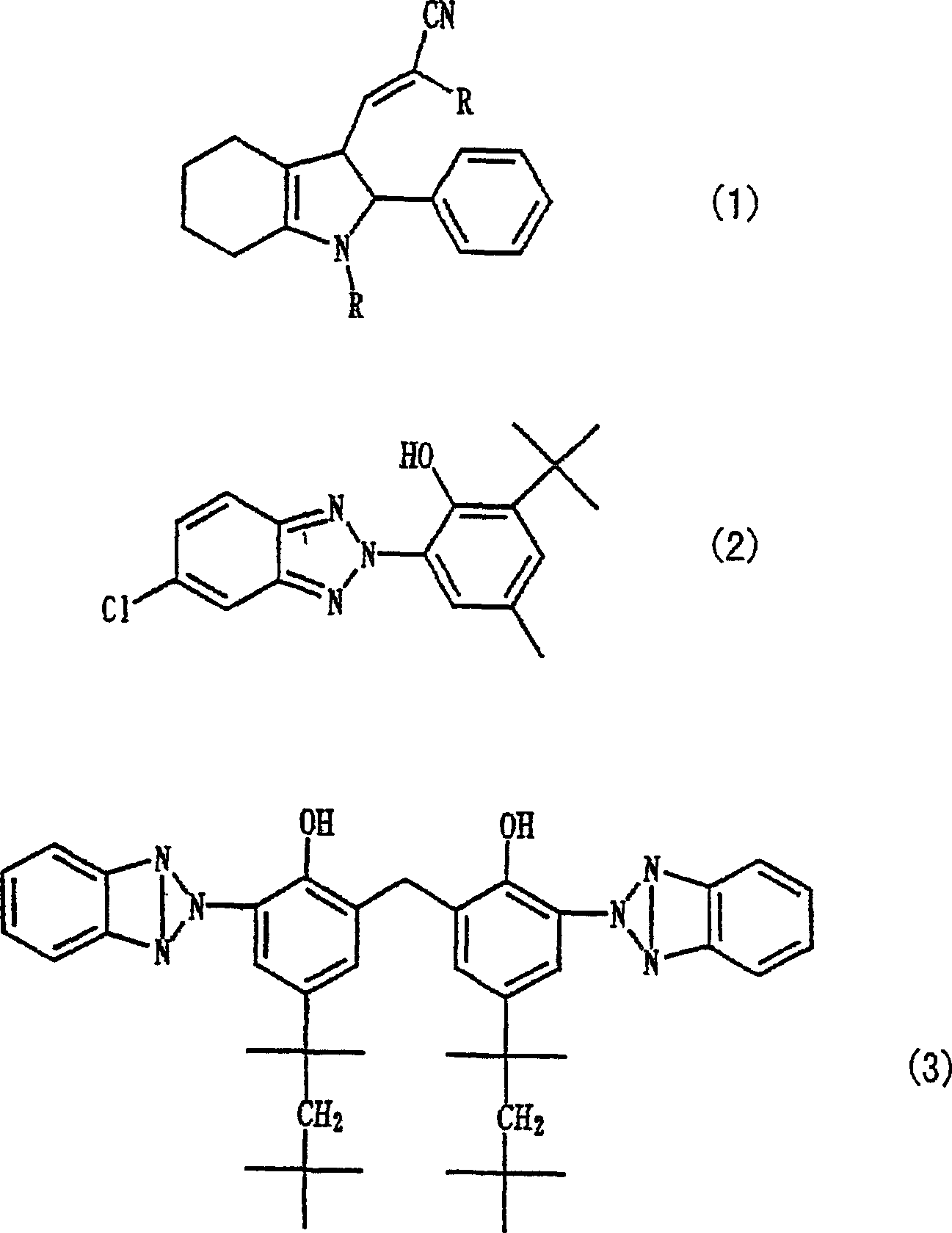

ActiveCN101460308AImprove adhesionHigh hardnessSynthetic resin layered productsNanotechnologyMicroparticleScanning probe microscopy

A hard coat film having an adherence modifying substratum film consisting of adherence modifying layer (B) containing copolymerized PEs and PU superimposed on one major surface or both major surfaces of thermoplastic resin film (A) and having, superimposed on the surface of the adherence modifying layer (B) on either one major surface of the substratum film, hard coat layer (C) containing inorganic microparticles, characterized in that the adherence modifying layer (B) has a micro phase separation structure or nano phase separation structure of PEs phase and PU phase, and that when a cut plane of the hard coat film is observed in a phase measurement mode by the use of a scanning probe microscope, the ratio of area of PU phase of adherence modifying layer (B) in the zone from interface of the adherence modifying layer (B) with the hard coat layer (C) to a depth of 20 nm is in the range of 30 to 60%.

Owner:TOYOBO CO LTD

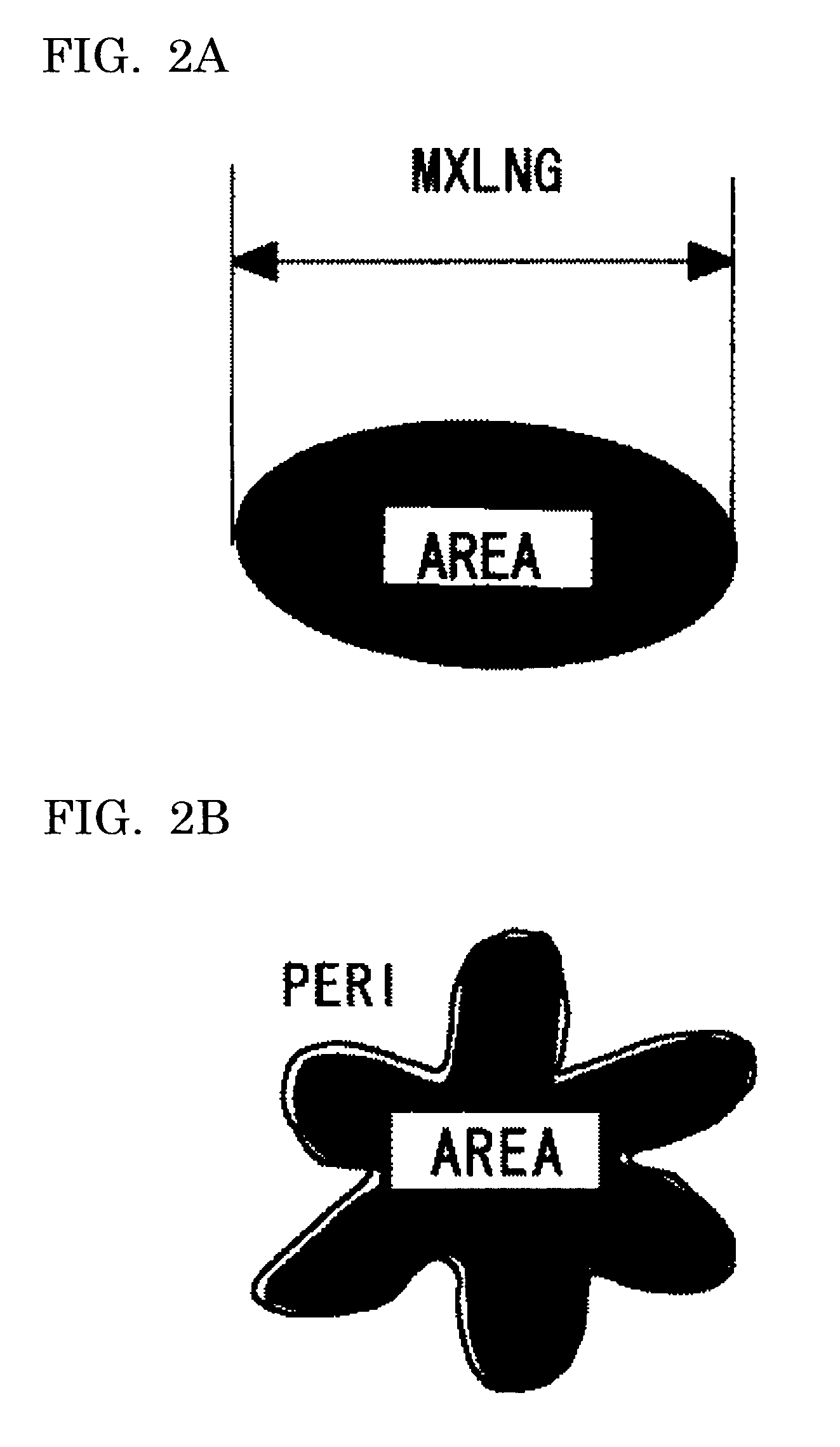

Heat-shrinkable polyester film and heat-shrinkable polyester film roll

A heat-shrinkable polyester-based film, characterized in that it exhibits a heat-shrinking percentages in (A) a warm water of 70 DEG C and (B) warm water of 85 DEG C of (A) 10 to 50 % in the maximum shrinkage direction and (B) 75 % or more in the maximum shrinkage direction and 10 % or less in the direction orthogonal to the maximum shrinkage direction, (C) the difference in heat-shrinking percentages DeltaX (%) representing X0 - X10 is 10 to 20 %, wherein X0 (%) represents the heat-shrinking percentage in the maximum shrinkage direction in a warm water of 95 DEG C and X10 (%) represents the heat-shrinking percentage of a film having been heat-shrunk by 10 % in the maximum shrinkage direction in a warm water of 95 DEG C, (D) the three-dimensional surface roughness SDeltaa of 0.008 to 0.04 and (E) the three-dimensional surface roughness SRz of 0.6 to 1.5 mum. The heat-shrinkable polyester-based film exhibits good accomplishment of shrinkage, the reinforcement function for the resulting shrink-coated container and good resistance to blocking and is also excellent in workability in film making and processability, even when it is used for full labeling. Further, the present invention provides a heat-shrinkable polyester-based film capable of absorbing ultraviolet rays and a heat-shrinkable polyester-based film roll which exhibits uniform heat-shrinking characteristics over the whole of a long film.

Owner:TOYOBO CO LTD

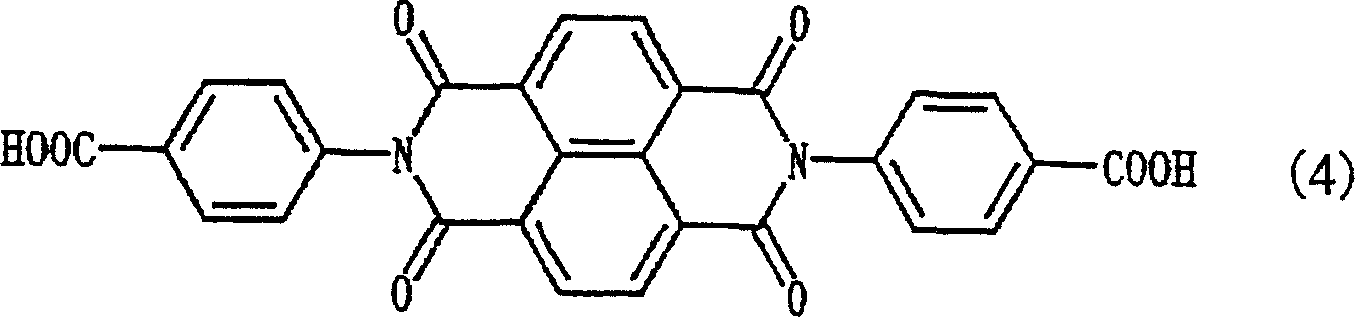

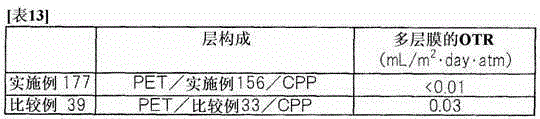

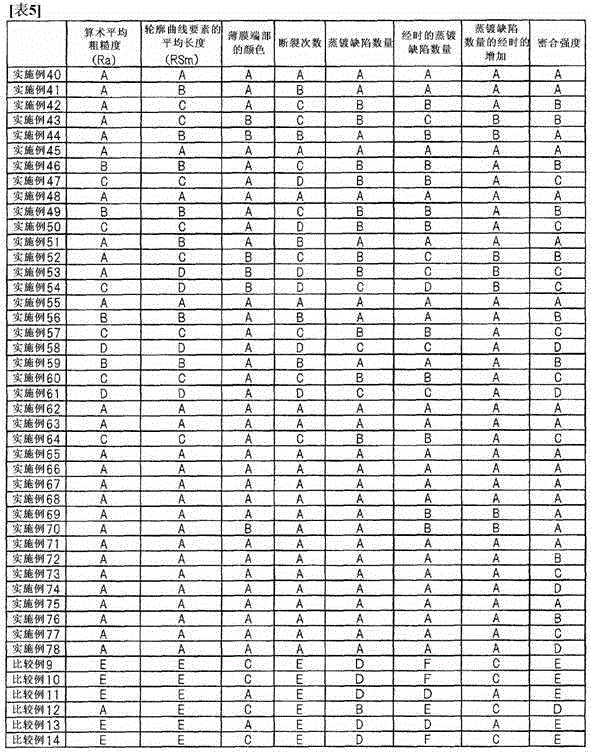

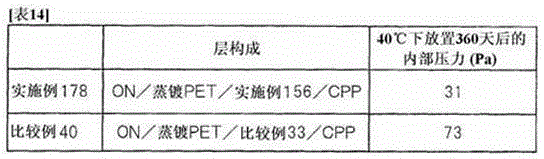

Ethylene-vinyl alcohol copolymer-containing resin composition, film, laminate, packaging material, vacuum heat-insulating body, film production method, and laminate production method

ActiveCN105308117AHigh bonding strengthExcellent gas barrier performanceFlexible coversWrappersPolymer scienceKetone

The purpose of the present invention is to provide a resin composition having excellent external appearance properties after melt molding, such as color of a film end section (roll end section), etc., and having excellent film breakage resistance, blocking resistance, deposition defect-suppressing properties, and adhesion strength of a deposition layer. The present invention is a resin composition containing an ethylene-vinyl alcohol copolymer, inorganic particles, and a C3-8 aliphatic carbonyl compound. The inorganic particle content thereof is 50-5,000 ppm. The aliphatic carbonyl compound is at least one type selected from a group comprising a saturated aldehyde, an unsaturated aldehyde, and a saturated ketone. The aliphatic carbonyl compound content is 0.01-100 ppm. The metal elements configuring the inorganic particles are ideally at least one type selected from a group comprising silicon, aluminum, magnesium, zirconium, cerium, tungsten, and molybdenum.

Owner:KURARAY CO LTD

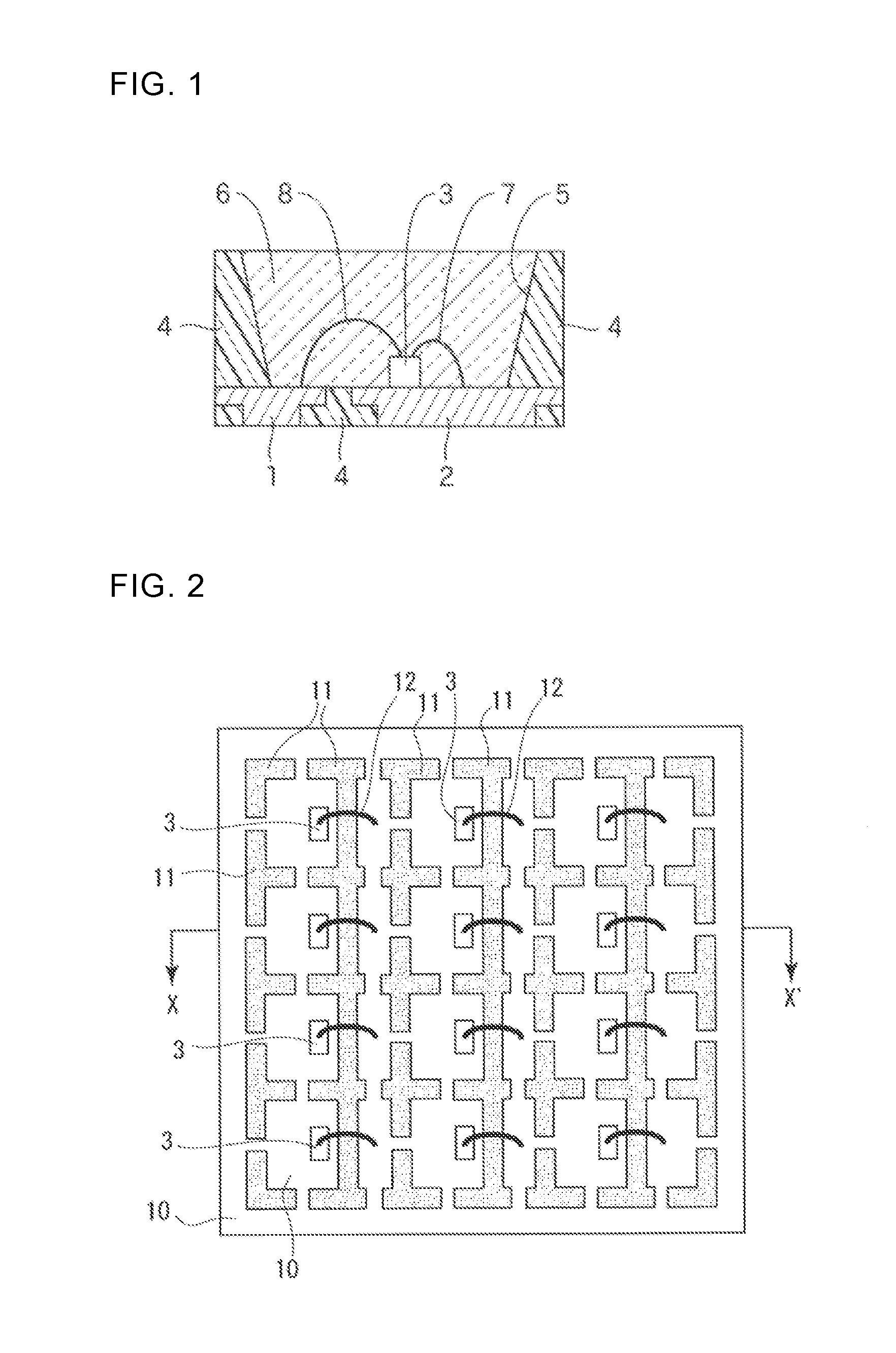

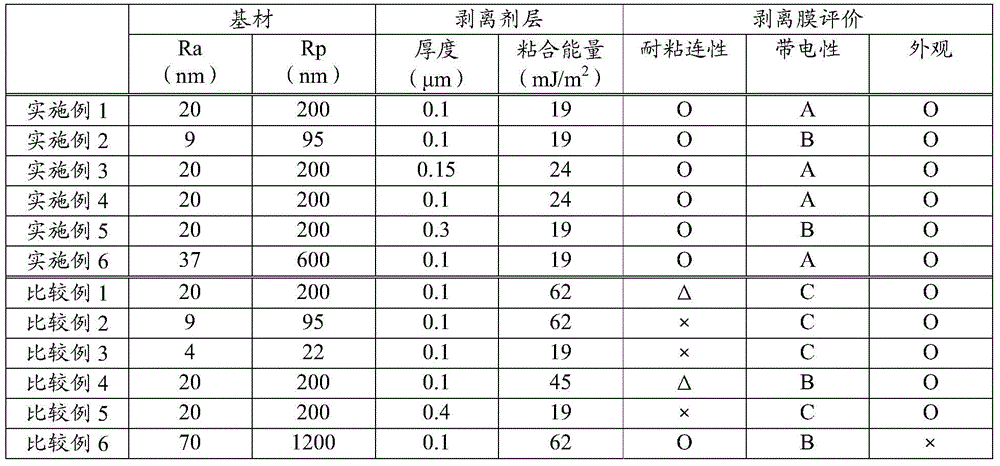

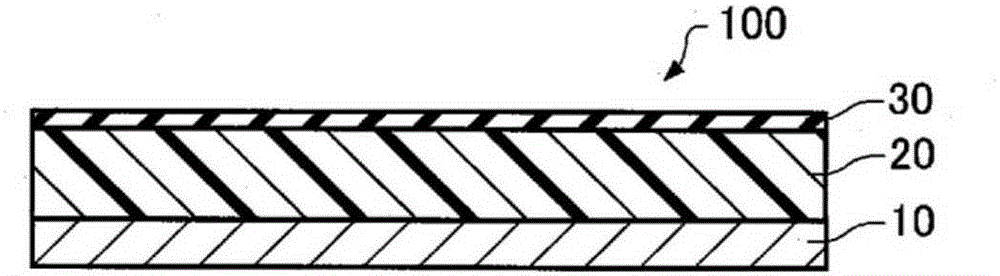

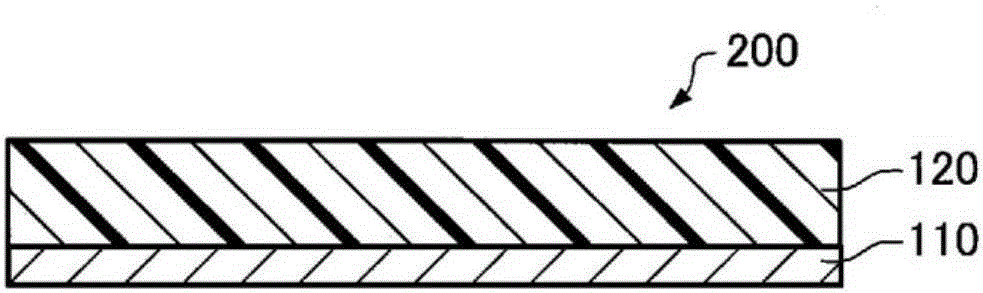

Release film and manufacturing method of release film

InactiveCN105838274AExcellent blocking resistanceSmoothFilm/foil adhesivesPolyesterPolymer chemistry

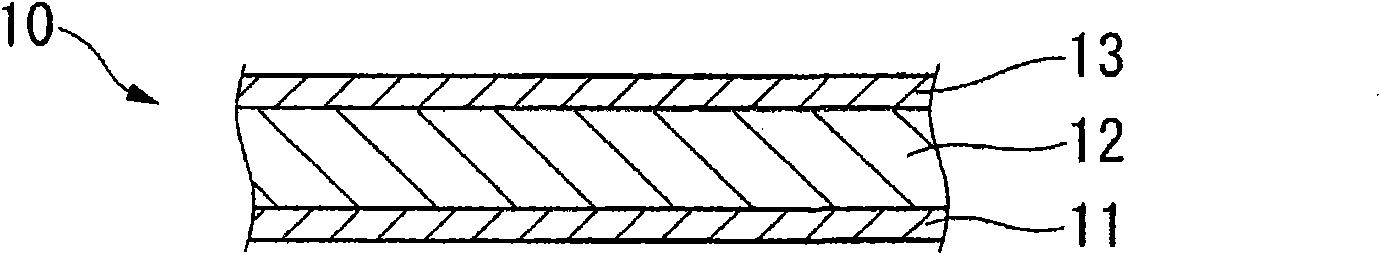

The invention provides a release film with excellent smoothness and anti-adhesion performance, and a manufacturing method of the release film. The release film (1) includes a base material (11) formed by a polyester film, and a release agent layer (12) which is coated on a surface (11a) of the base material (11) to form a composition; the arithmetic mean roughness (Ra) is greater than 5 nm and less than 40 nm, and the maximum rise height (Rp) is greater than 50 nm and less than 1000 nm; the thickness of the release agent layer (12) is greater than 0.05 [mu]m and less than 0.35 [mu]m; adhesion energy of the release agent layer (12) is greater than 15 mJ / m2 and less than 35 mJ / m2, wherein the adhesion energy is calculated by using a force curve measured by an interatomic force microscope.

Owner:LINTEC CORP

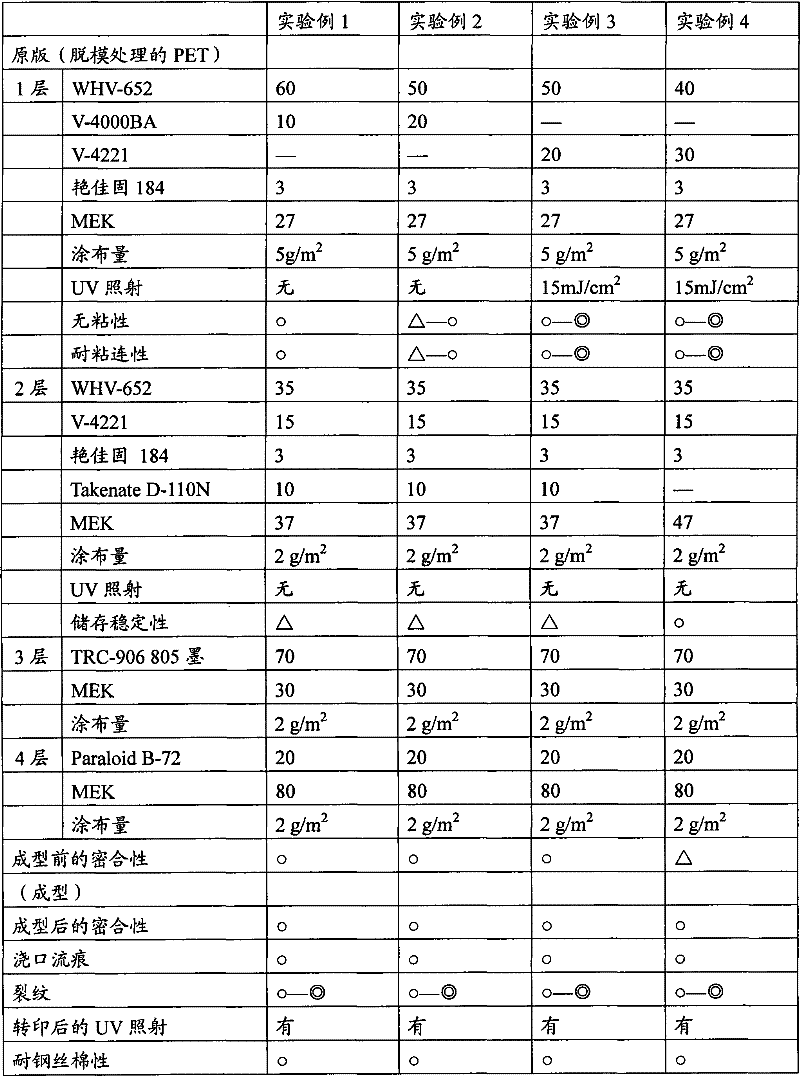

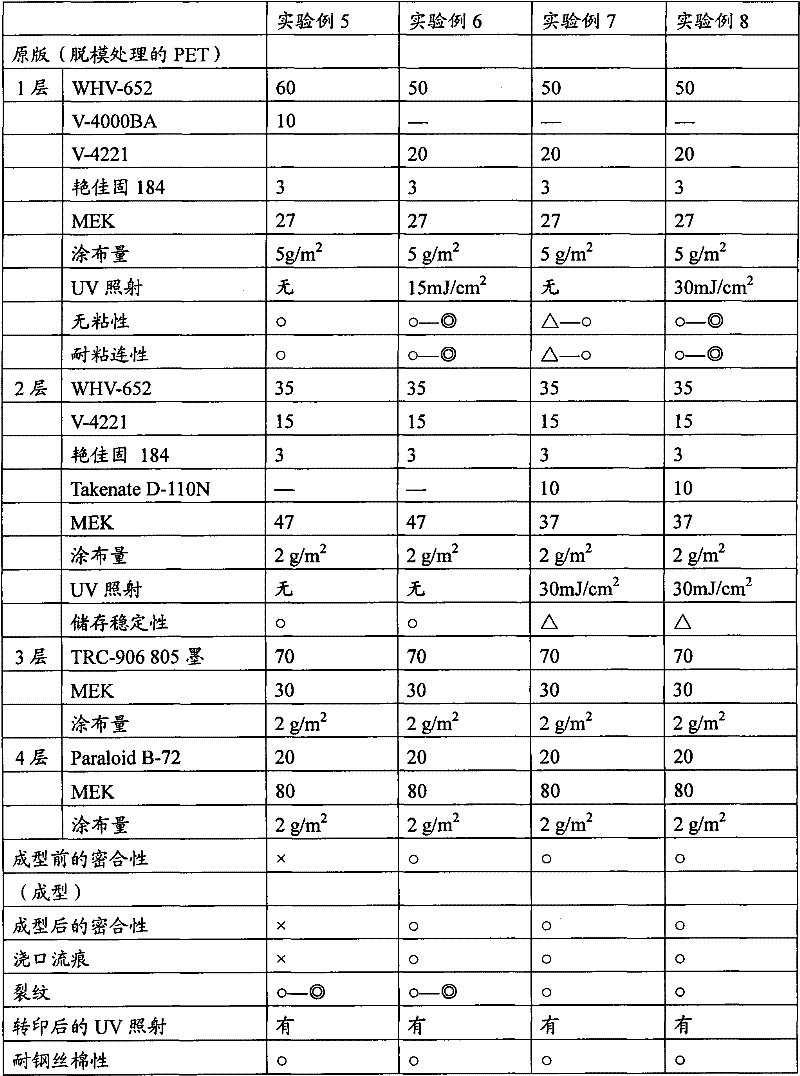

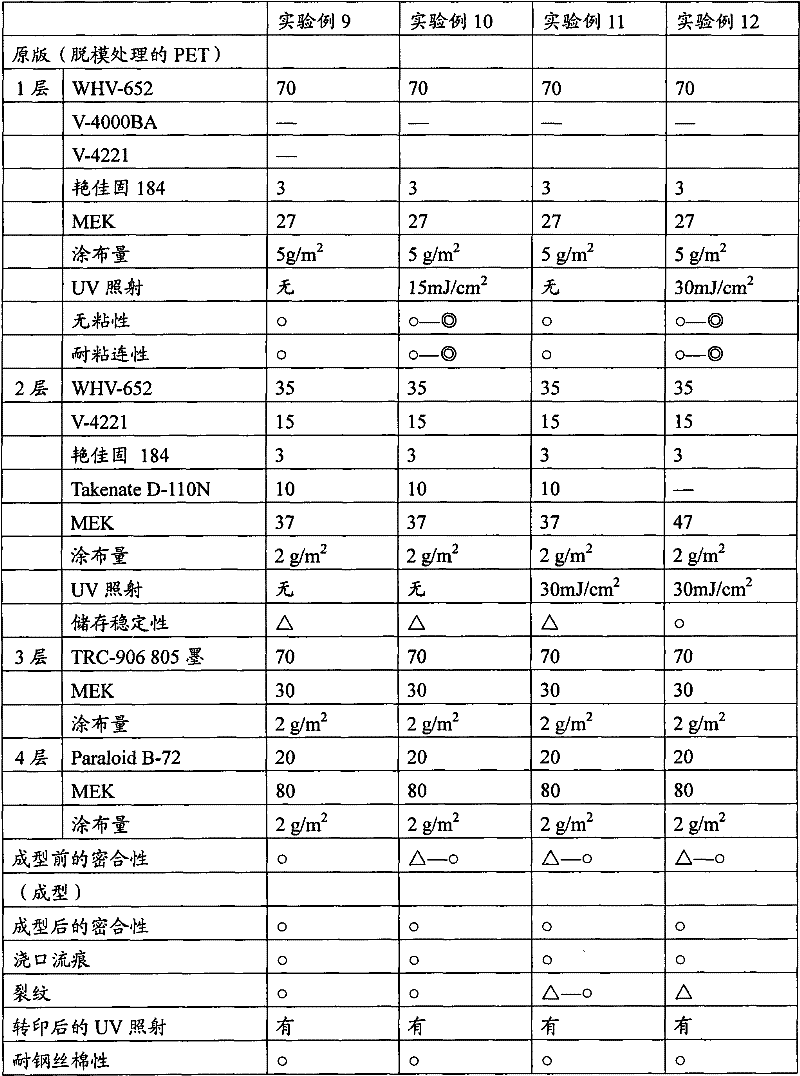

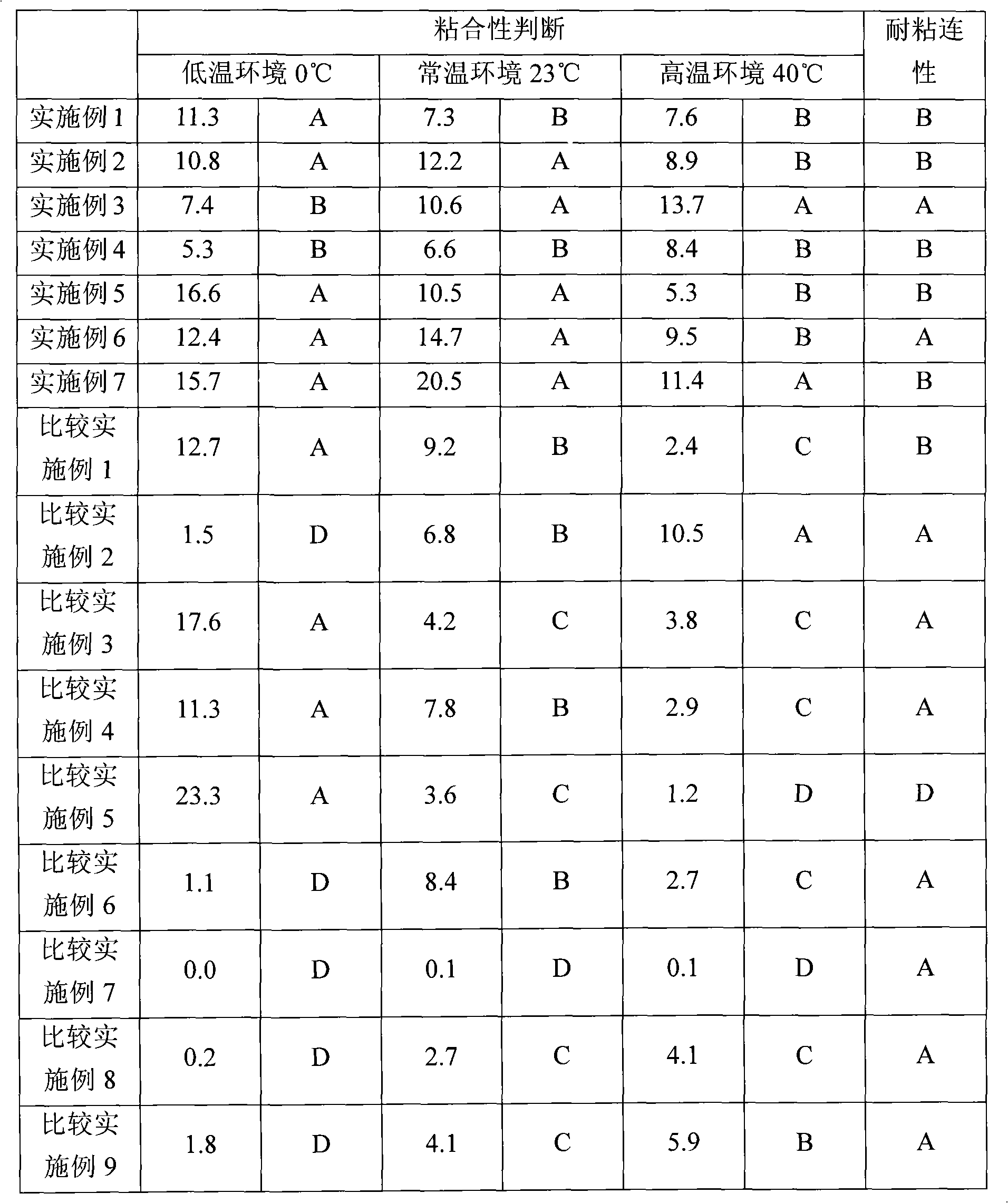

Active energy ray curing transfer sheet and manufacture method thereof

ActiveCN102673211AExcellent adhesionExcellent surface hardnessSynthetic resin layered productsCoatingsHeat resistancePolymer chemistry

The invention provides a transfer sheet for active energy ray curing intra-mold forming and a manufacture method thereof, wherein the transfer sheet has excellent adhesion resistance and sealing performance and heat resistance during forming. The transfer sheet for active energy ray curing intra-mold forming is characterized in that primer agent composites are used for half-curing, wherein the primer agent composites contain active energy ray curing crylic acid acrylic ester resin with hydroxyl and (methyl) acryloyl groups and / or active energy ray curing carbamic acid ester acrylic ester resin and polyisocyanate compounds; or active energy ray curing crylic acid acrylic ester resin and / or active energy ray curing carbamic acid ester acrylic ester resin curing hard coating and / or curing primer coating are used for half curing.

Owner:DIC CORP

Thermosensitive adhesive material

InactiveCN101343519AExcellent blocking resistanceAdhesive enoughNitrile polymer adhesivesEster polymer adhesivesVitrificationAcrylonitrile

An object of the present invention is to provide a thermosensitive adhesive material which is superior in blocking resistance when not active and which has adequate adhesion in a wide temperature range to a target with little smoothness such as corrugated fiberboard. Specifically, the present invention relates to a thermosensitive adhesive material including a support, and a thermosensitive adhesive layer provided on one surface of the support, the thermosensitive adhesive layer containing as essential components a thermoplastic resin and a hot-melt material that melts when heated, wherein the thermoplastic resin contains as a main component a (meth)acrylic copolymer in which acrylonitrile, a monomer component, occupies 5% by mass to 20% by mass of all monomer components, and wherein the glass transition temperature of the copolymer is in the range of -70 DEG C. to -30 DEG C.

Owner:RICOH KK

Composition for electricity storage devices, slurry for electricity storage devices, electrode for electricity storage devices, separator for electricity storage devices, and electricity storage device

ActiveCN105247717AExcellent blocking resistanceAvoid position shiftHybrid capacitor separatorsHybrid capacitor electrodesElectricityLiquid medium

Provided is a composition for electricity storage devices, which is able to produce an electrode or separator that has excellent blocking resistance, while being capable of effectively preventing positional shift when the electrode and the separator are laminated (namely, exhibiting adequate blocking performance). A composition for electricity storage devices according to the present invention contains a binder, a blocking inhibitor and a liquid medium, and is characterized in that if M1 (parts by mass) represents the content of the binder and M2 (parts by mass) represents the content of the blocking inhibitor, M1 and M2 satisfy the relation 1< M1 / M2< 4,000.

Owner:株式会社引能仕材料

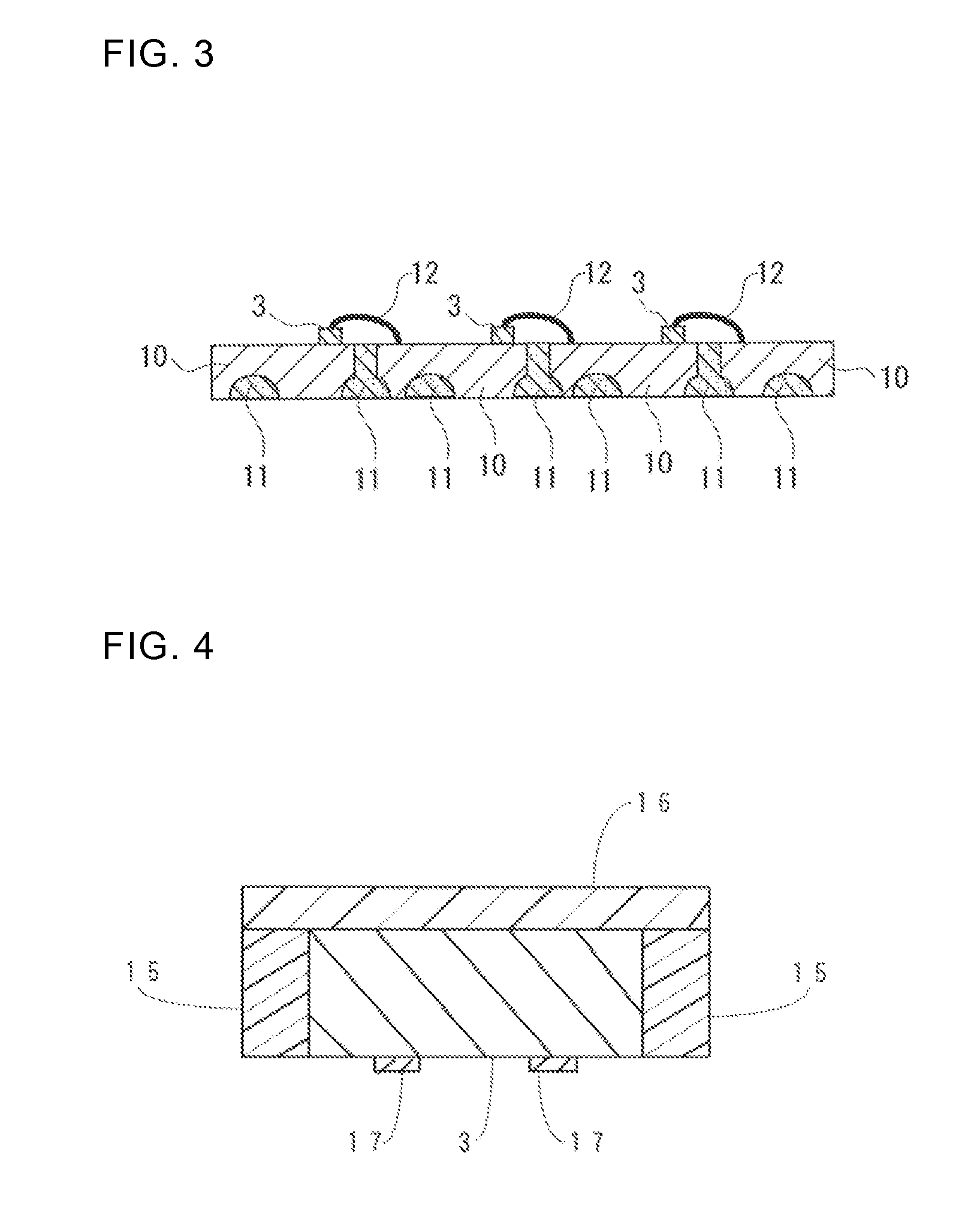

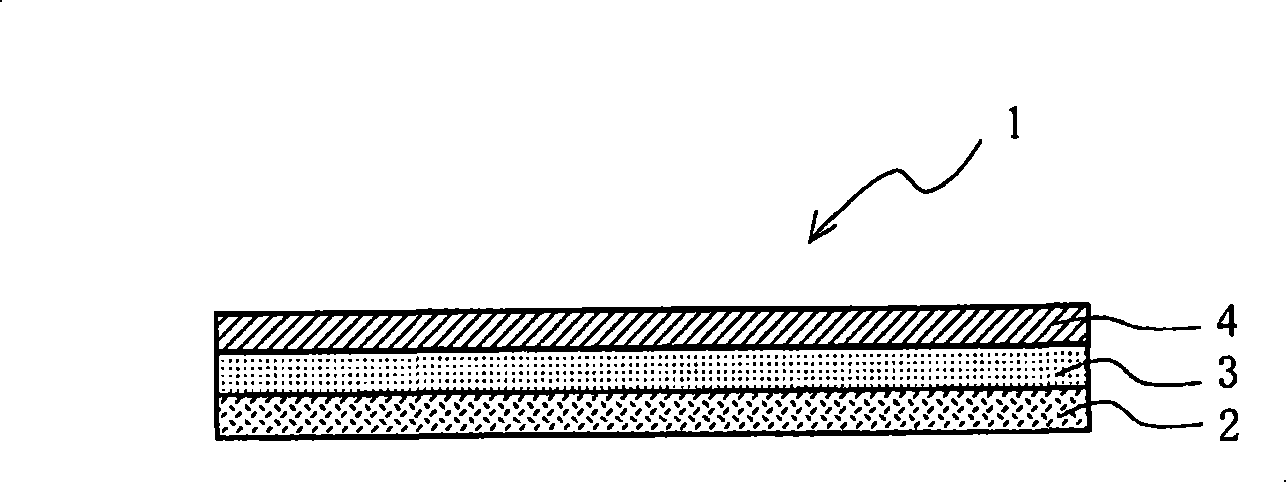

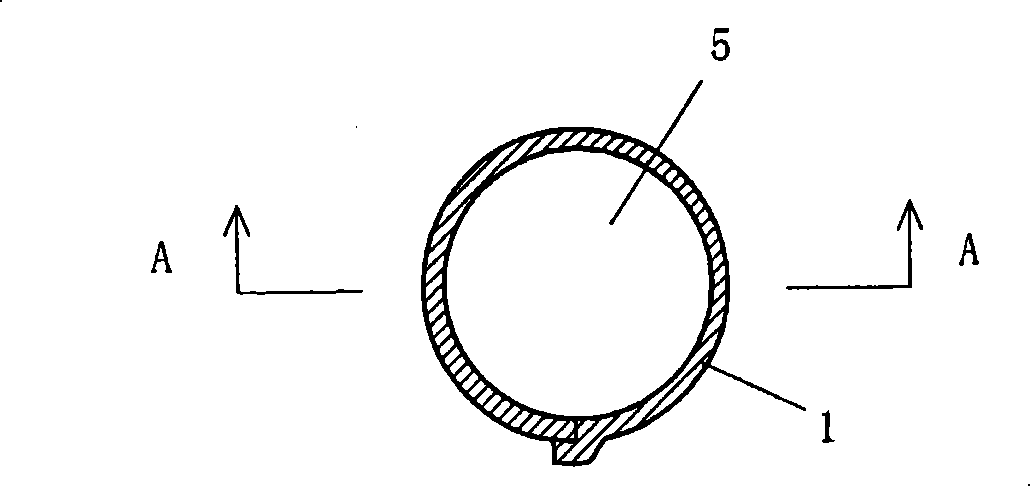

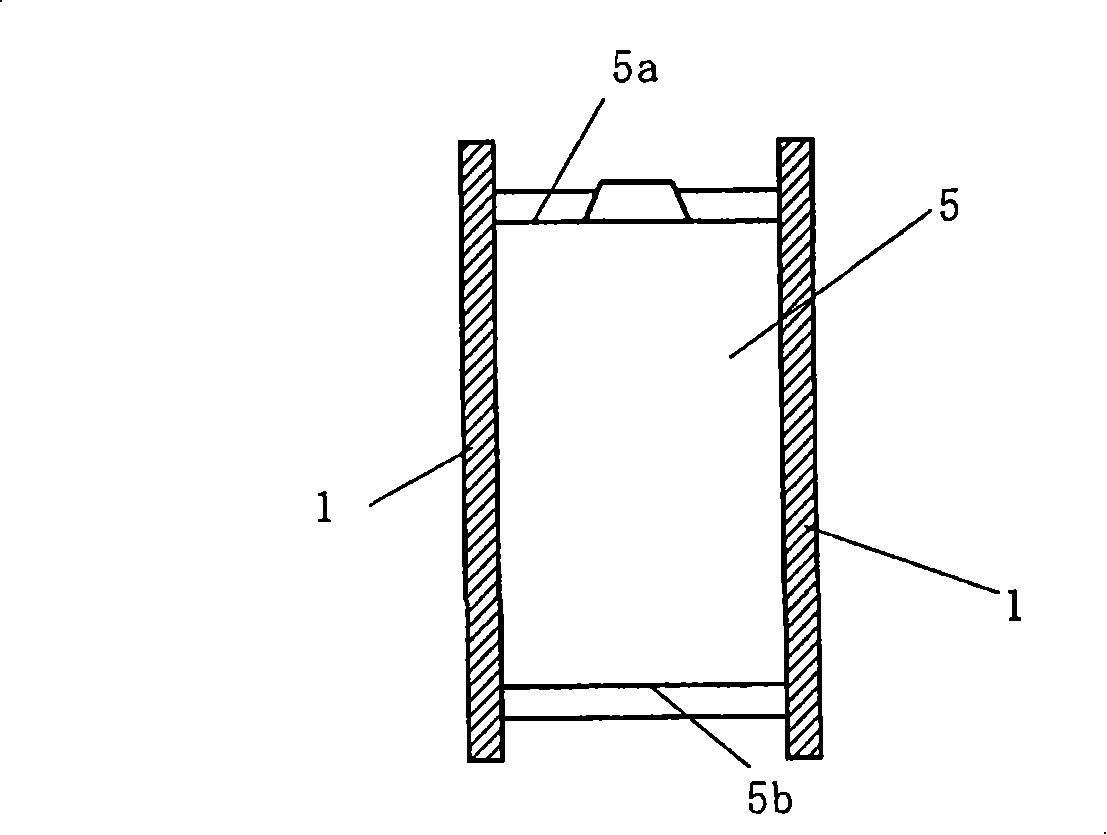

Label for battery casing

InactiveCN101233551AFor long-term storageLow costStampsCell component detailsEmulsionPolymer science

The battery casing label (1) of the present invention includes a heat shrinkable film (2) and a printing layer (3) and an adhesive layer (4) laminated on the heat shrinkable film (2). Layer (4) is made of the following emulsion-type heat-sensitive adhesive, which contains an ethylene-based copolymer with an ethylene content of 66-84% by weight and a melting point of 60-90°C and 10-30% by weight of tackifier. The above-mentioned heat-shrinkable film (2) is preferably a film having a heat shrinkage rate of 10% or more in the main stretching direction when immersed in a glycerin bath at 100° C. for 5 seconds. When the label (1) for battery cases of the present invention is used, it is excellent in low-temperature adhesiveness and blocking resistance, and does not deteriorate over time.

Owner:FUJI SEAL INTERNATIONAL INC

Surface protection film

InactiveCN102844392AEasy to slideExcellent blocking resistanceFilm/foil adhesivesSynthetic resin layered productsRough surfaceElastomer

Provided is a surface protection film which exerts appropriate adhesive properties even to an adherend having a rough surface and which exhibits excellent back surface slidability, blocking resistance, and reeling properties. Specifically, disclosed is a surface protection film which has a laminate structure comprising at least an adhesive layer and a back surface layer, wherein: the adhesive layer is mainly formed from a styrene-based elastomer; the back surface layer is mainly formed from a propylene-based resin containing 0.5 weight% to 10 weight% of a fluorine-containing compound having a polyfluoro-hydrocarbon group and a polyoxyethylene group, and has a 10-point average surface roughness (Rz) of 3[mu]m or more; and the surface protection film has an initial adhesion strength of 1N / 25mm or more in relation to a SUS304 plate, which was subjected to a #320 hair-line processing treatment, and has a reeling strength of 0.5N / 25mm or less when the rolled-up film is being reeled.

Owner:TORAY ADVANCED FILM CO LTD

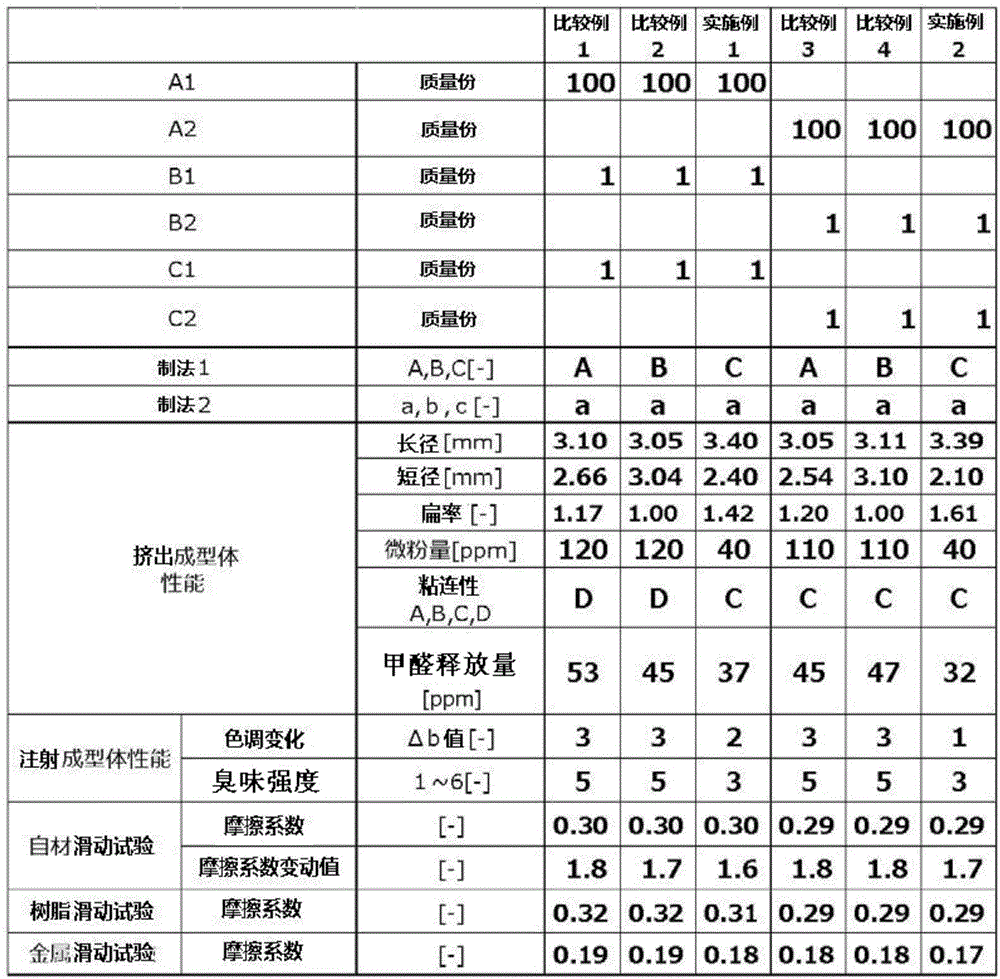

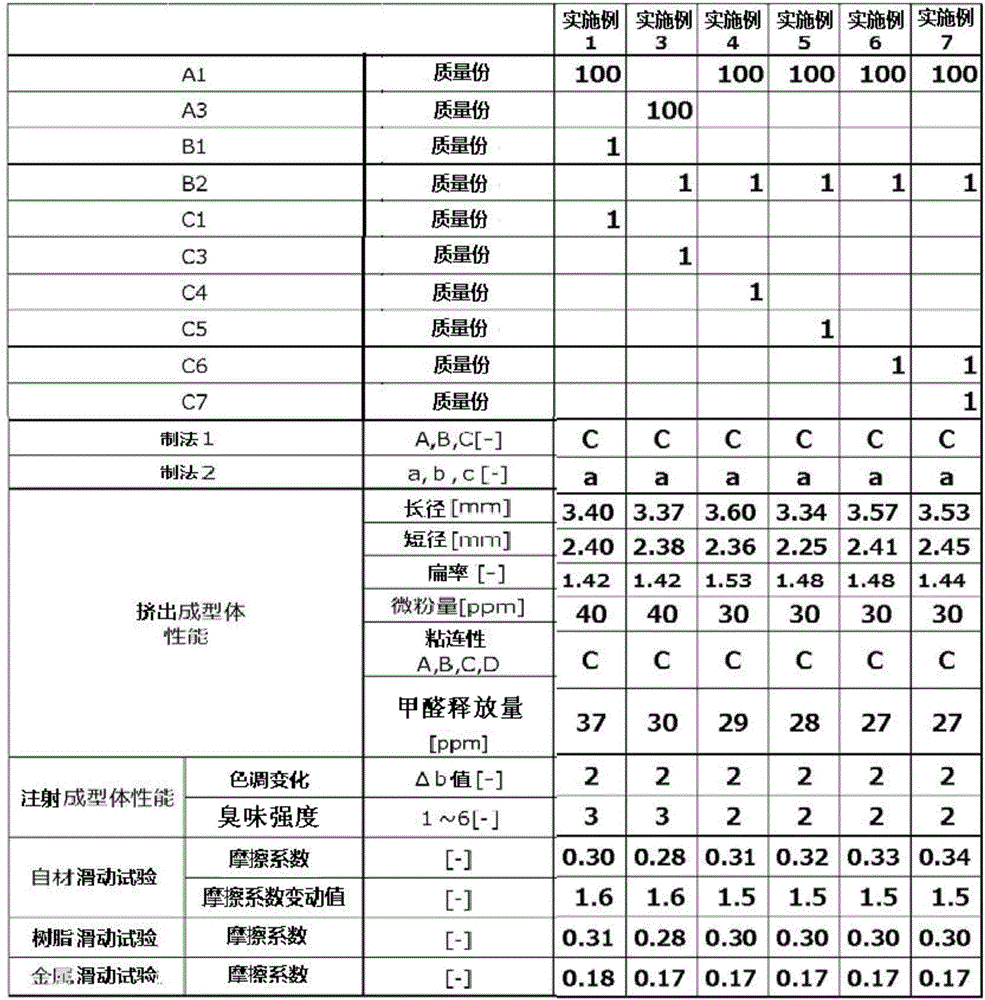

A polyacetal resin molded body

The invention relates to a polyacetal resin molded body, and particularly relates to a polyacetal resin molded body having stable sliding performance, less time-dependent color changes, low odour and excellent adhesion resistance. The polyacetal resin molded body comprises (A) polyacetal resin, (B) lubricating oil and (C) polyolefin. The long diameter of the polyacetal resin molded body is 2.5-4.0 mm, the short diameter is 1.4-2.8 mm, and the oblateness (the ratio of the long diameter to the short diameter) is larger than 1.25. In addition, the polyacetal resin molded body is further molded to obtain a component provided by the invention.

Owner:ASAHI KASEI KK

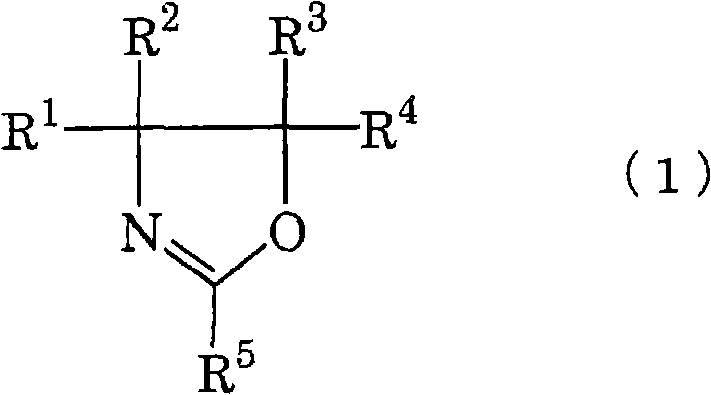

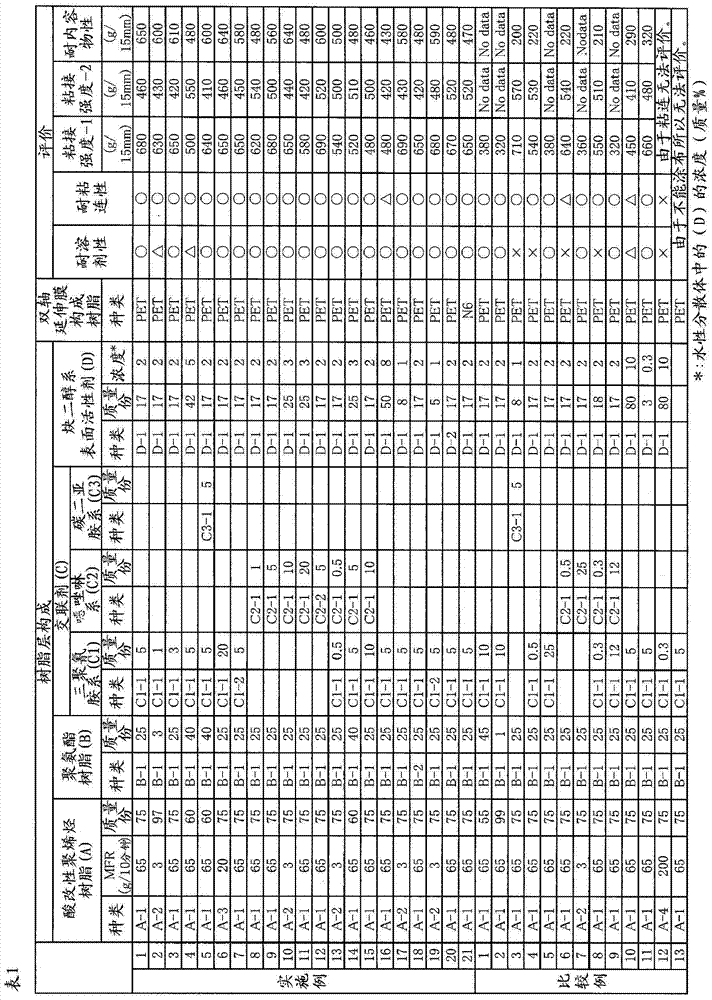

Multilayer film, method for producing same, and aqueous dispersion used for production of same

ActiveCN104520104AExcellent blocking resistanceGood solvent resistanceLiquid surface applicatorsDomestic sealsPolyolefinMelamine

A multilayer film that is obtained by forming a resin layer, which contains (A) an acid-modified polyolefin resin, (B) a polyurethane resin, (C) a crosslinking agent and (D) an acetylene glycol surfactant, on at least one surface of a biaxially stretched film. This multilayer film is characterized in that: the crosslinking agent (C) contains (C1) a melamine-based crosslinking agent and / or (C2) an oxazoline-based crosslinking agent; the mass ratio of component (A) to component (B) ((A) / (B)) is from 60 / 40 to 97 / 3; the total amount of component (C1) and component (C2) or respective amounts of component (C1) and component (C2) are 1-20 parts by mass per 100 parts by mass of the total amount of component (A) and component (B); and the amount of component (D) is 5-50 parts by mass per 100 parts by mass of the total amount of component (A) and component (B).

Owner:UNITIKA LTD

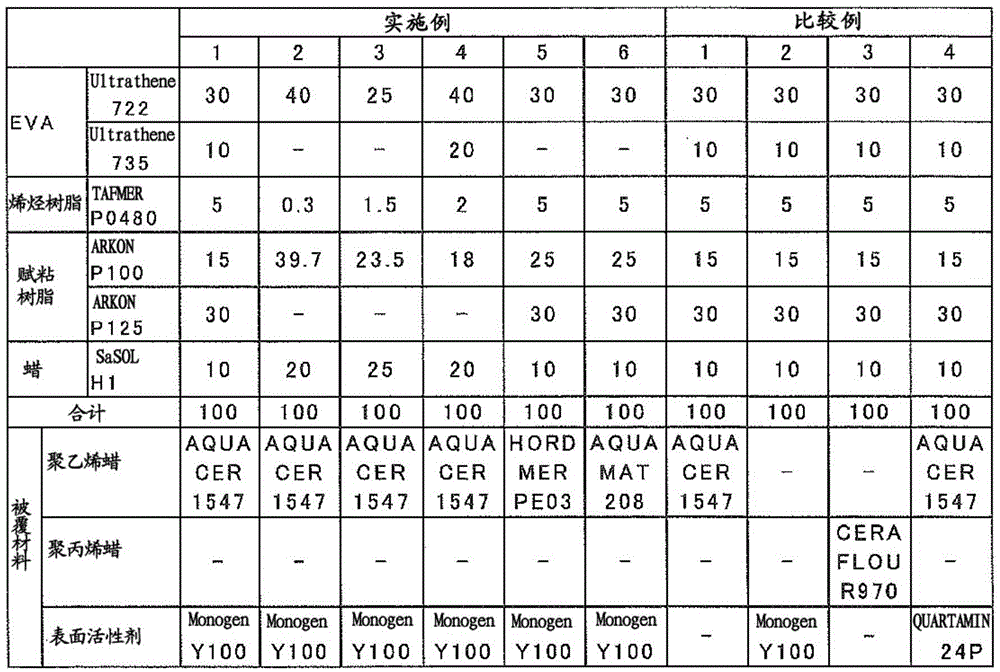

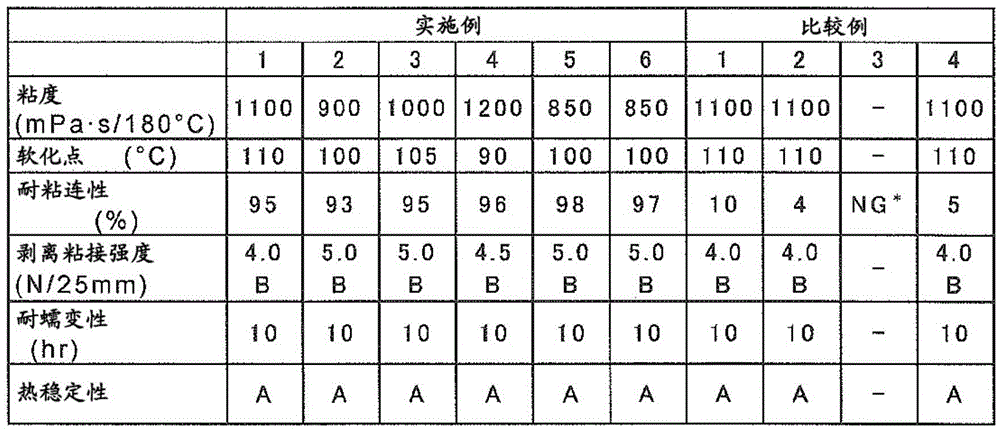

Hot-melt adhesive

InactiveCN105637055AInhibit adhesionExcellent blocking resistanceMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesWaxSURFACTANT BLEND

Owner:RESONAC CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com