Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

304results about How to "Smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepreg applied for multi-layer board of printed electronic circuit

ActiveCN101220160ALow dielectricReduce residual stressSynthetic resin layered productsCircuit susbtrate materialsSolventFilling materials

The invention pertains to the technical field of the copper clad laminate, which more particularly relates to a prepreg applied to a printing circuit multilayer board. The prepreg comprises reinforced materials and resin composite, wherein, the reinforced materials is glass fiber paper, and according to part by weight, the formulation of the resin composite is as follows: 20 to 84 portions of resin, 0 to 35 portions of filling materials, 0.01 to 0.3 portions of curing accelerator and 10 to 45 portions of solvent; the resin composite solvent is soaked in the glass fiber paper for 1 to 5 minutes, and is put in a 140 to 200 DEG C oven for baking for 2 to 10 minutes; after the solvent is removed, the prepreg applied to multilayer PCB processing materials is obtained; white flake and spot problems of base materials during the manufacturing procedures of the multilayer PCB are prevented, problems of de-lamination, shrink resin, holes and crack of the resin and white flake, etc. that come up after the multilayer PCB goes through cold and hot impact are improved, and the prepreg has good reliability and low cost.

Owner:GUANGDONG SHENGYI SCI TECH

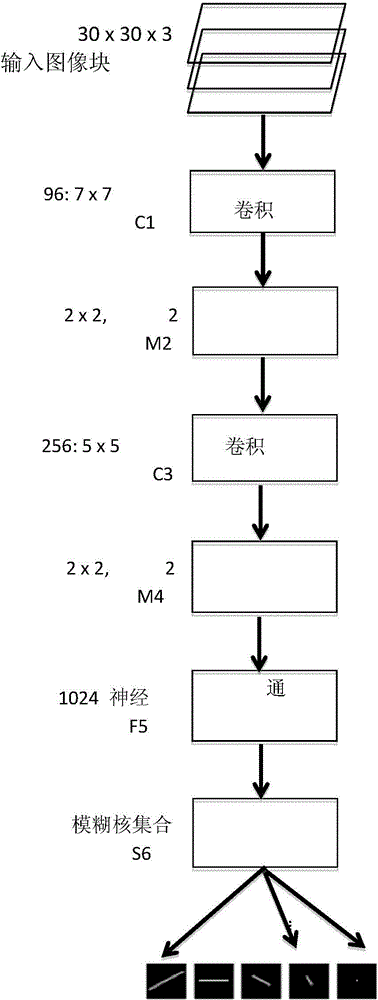

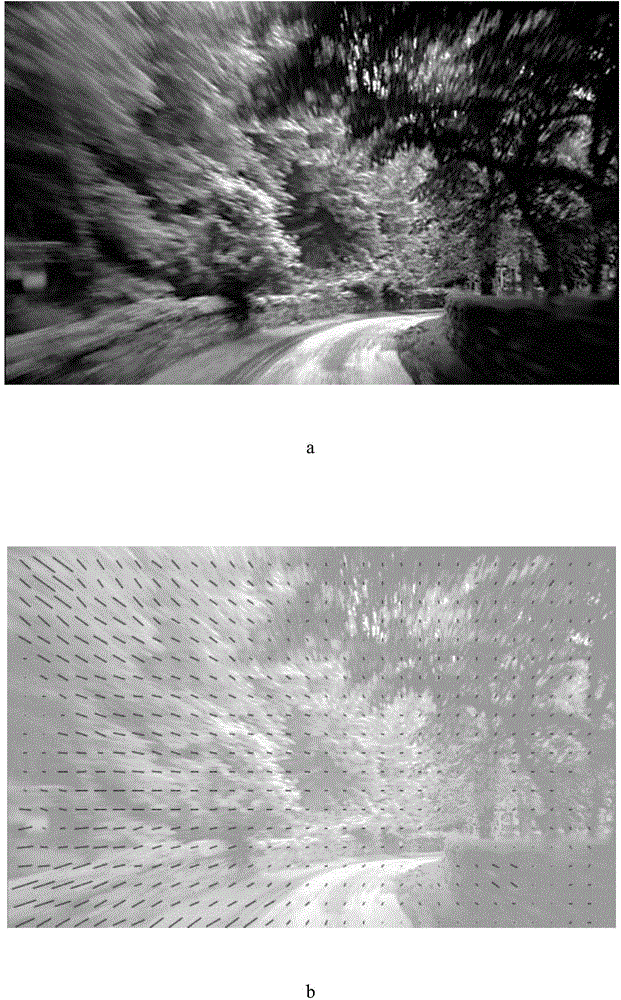

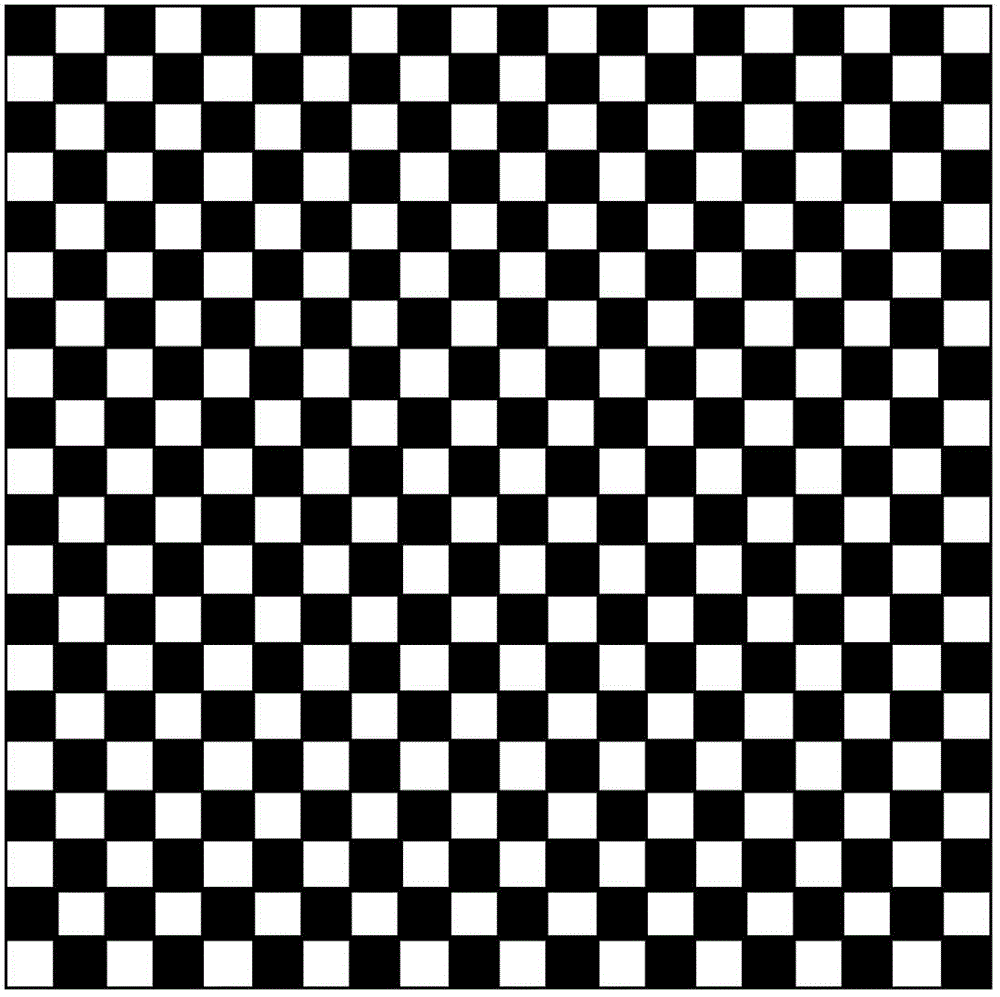

Non-uniform image motion blur removing method based on deep neural network

ActiveCN104680491AAccurate estimateImplement automatic estimationImage enhancementPattern recognitionNetwork structure

The invention discloses a non-uniform image motion blur removing method based on a deep neural network. The non-uniform image motion blur removing method comprises two main steps of training deep neural network parameters, and estimating and removing motion blur by applying a deep network to an image. The deep network structure consists of a convolution network layer and a forward network layer; the network model training process comprises the following steps: generating a blur image block and a blur kernel pair by using a natural image, and training the deep neural network model parameters by using the data; providing a motion blur image, decomposing the image into an image block set with overlapped areas, inputting each image block into motion blur probability distribution corresponding to deep neural network output image blocks, and further acquiring different motion blur kernels per pixel points of the image by optimizing a Markov random field model; finally, acquiring a blur removed image by using a deconvolution algorithm based on the estimated motion blur kernels. Due to good learning capability of the deep neural network, non-uniform motion blur of the image can be precisely estimated, and clear images can be further obtained.

Owner:XI AN JIAOTONG UNIV

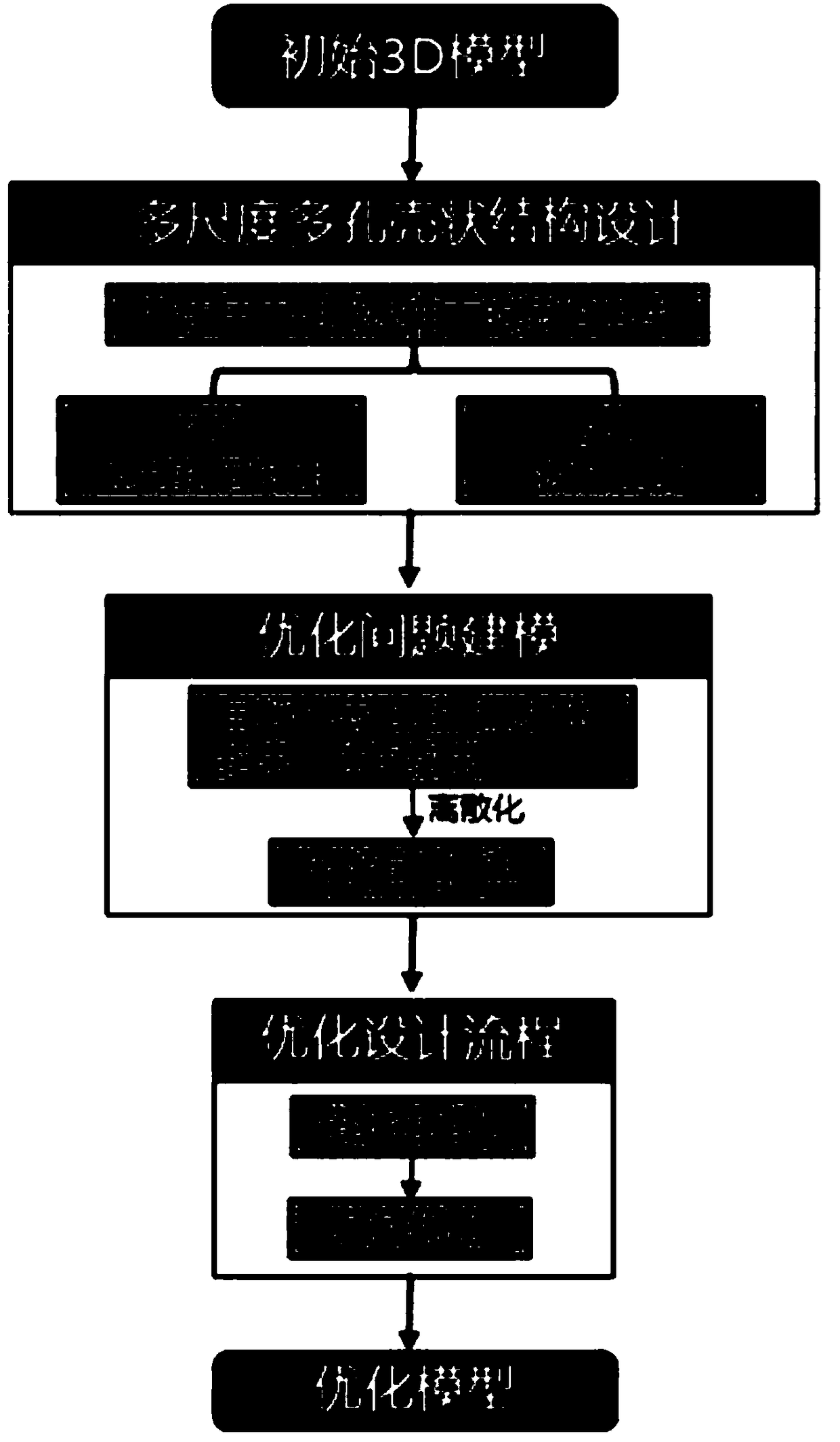

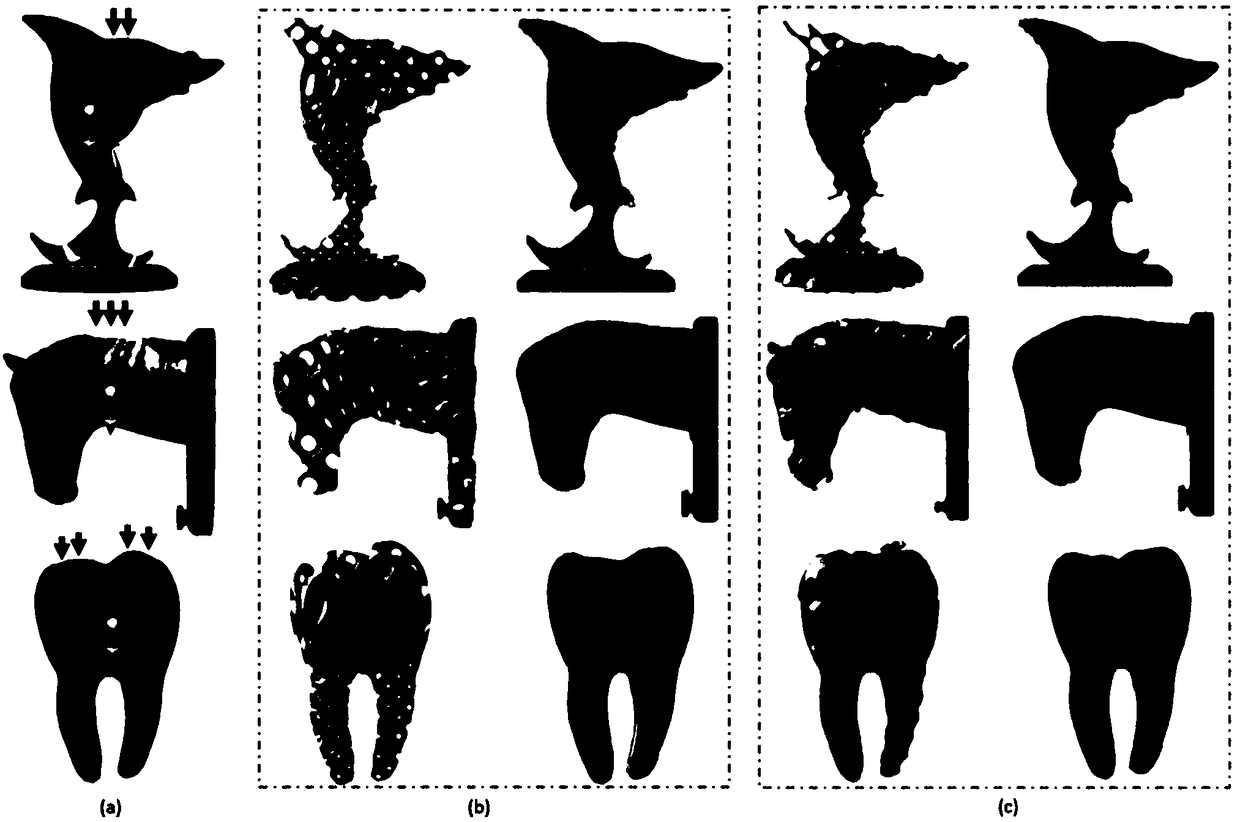

A design and optimization method of porous structure based on three-period minimal surface

ActiveCN109145427AReduce designShorten the overall cycleDesign optimisation/simulationSpecial data processing applicationsComputer Aided DesignEnergy functional

The invention relates to an efficient porous structure design and optimization method based on a three-period minimal surface, belonging to the computer-aided design field. Firstly, the functional representation of porous structure based on three-period minimal curved surface and the corresponding porous structure design method are presented. Then, under the given external constraints, the energyfunction model is constructed to model the porous structure design, and the corresponding discretization form is given. Finally, topology initialization and geometry optimization are carried out to obtain the optimal porous structure under given constraints. The invention greatly shortens the design and optimization period of the cavity structure, and can give the optimal result in theory. The porous structure designed by the invention has the characteristics of smoothness, full connectivity, controllability, quasi-self-support and the like, and is suitable for the common 3D printing manufacturing method, and the internal structure of the printing process does not need additional support, so that the printing time and the printing material can be saved.

Owner:DALIAN UNIV OF TECH

Method for producing real leather intimating polyurethane synthetic leather

InactiveCN101748613AReduce demandSmoothPattern makingSynthetic resin layered productsPolyesterSlurry

The invention discloses a method for producing real leather intimating polyurethane synthetic leather, which comprises the following steps: firstly, preparing a wet synthetic leather semi-finished product; secondly, coating a polyurethane finishing agent on the surface of the wet synthetic leather semi-finished product to perform printing surface treatment; thirdly, sticking a release paper pattern transferred polyurethane film to the surface of the printed wet synthetic leather semi-finished product, wherein raw materials in polyurethane slurry comprise polyester-polyether-polycarbon copolymerized polyurethane resin, cracking resin, dimethyl formamide, down powder, wet wax sensitive toner and solvent pigment; and finally, performing kneading treatment. The polyurethane synthetic leather has frosting effect on the surface, smooth handfeel, color change when pushing the surface by hand and strong third dimension of patterns, has good physical properties such as scratch resistance, cold resistance, hydrolysis resistance and the like, and can replace real leather in many aspects so as to reduce the requirement for furs, protect the nature and keep ecological balance.

Owner:ANHUI ANLI MATERIAL TECH

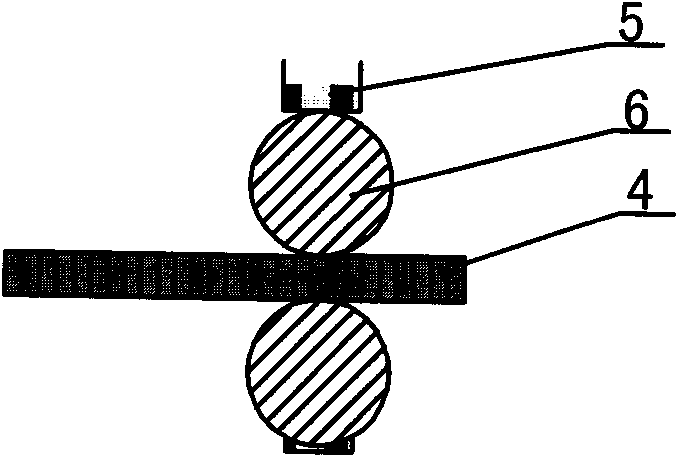

Method for producing foam honeycomb core

InactiveCN101700701AIncrease productivityLow costLamination ancillary operationsLaminationHoneycombFire resistance

The invention relates to a method for producing the foam honeycomb core, mainly comprising the following steps: stretching a honeycomb core; producing foaming material according to the size of the stretched honeycomb core; overlapping the honeycomb core and the foaming material; and putting the honeycomb core and the foaming material in to a plate press. The honeycomb core is a hexagonal, polygonal, corrugated or round tube-type honeycomb core which comprises paper, metal, ceramic and polymer material. The foaming material can be phenolic aldehyde, polyphenyl, polyurethane, etc. The invention has the advantages that the foaming material such as the phenolic aldehyde, the polyphenyl, the polyurethane and the like and the prior honeycomb core are overlapped and then are putted in the plate press to be extruded and combined so that the strength of the sandwich of a foam honeycomb plate is improved and the foam honeycomb plate has the advantages of light weight, high planeness and excellent sound insulation effect, fire resistance and heat insulation properties, in addition, the cost of the material is lowered, the foam honeycomb core has the advantages of good machinability, simple structure, good decorating effect and the like, and moreover, the foam honeycomb plate can be produced with the extremely easier and feasible method.

Owner:钟保元

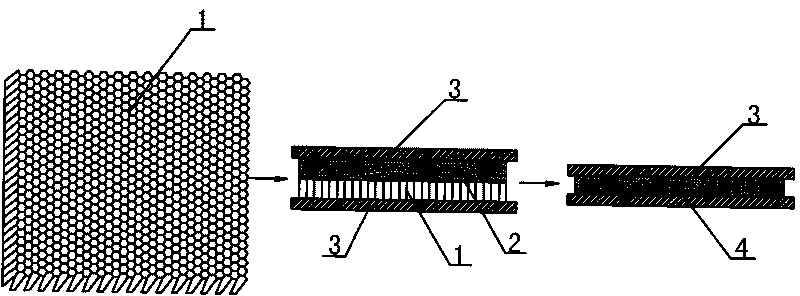

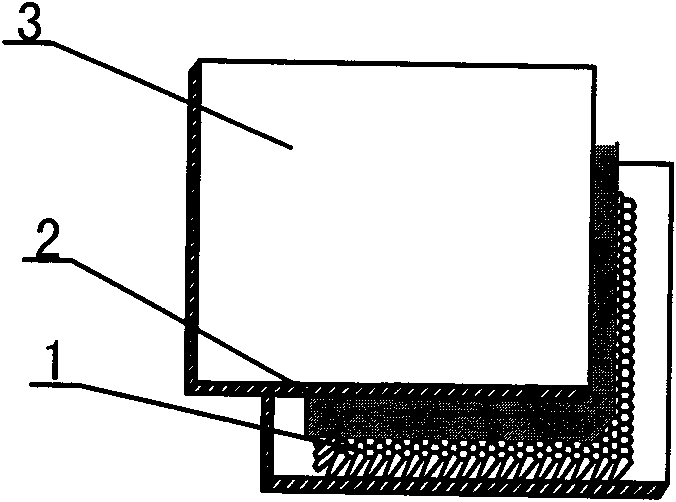

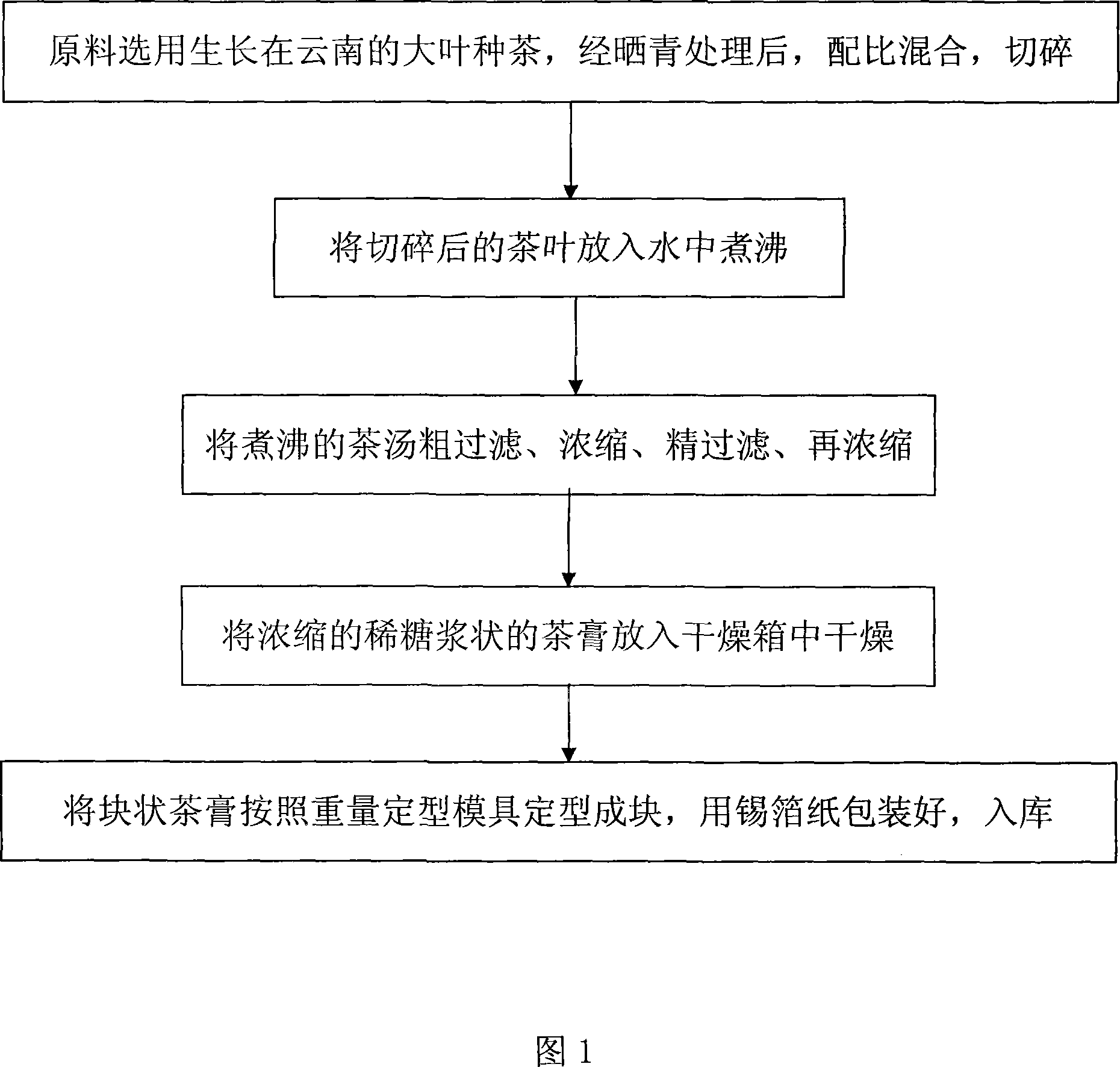

Pu'er tea ointment and the producing technology thereof

The invention relates to a kind of Pu'er tea concrete and the preparing process, which mainly employs fermented tea for one year, two-three year or more than three years as raw material, and comprises processes of boiling, condensing and drying. The raw material employs Yunnan Big Leaf Tree, process employs sun withering, and the weight proportion of tea with different natural fermentation time is as follows: tea with more-than three years fermentation time is not more than 10%, tea with 2-3 years natural fermentation time is not less than 20%, and tea with one year natural fermentation time is not more than 70%. The invention is characterized by the color, brightness, transparency and taste is equivalent to that of Pu'er tea of more than 10 years natural fermentation. The utilization is convenient and widely used for Pu'er tea deep processing.

Owner:老河口牧工商茶叶进出口贸易有限公司

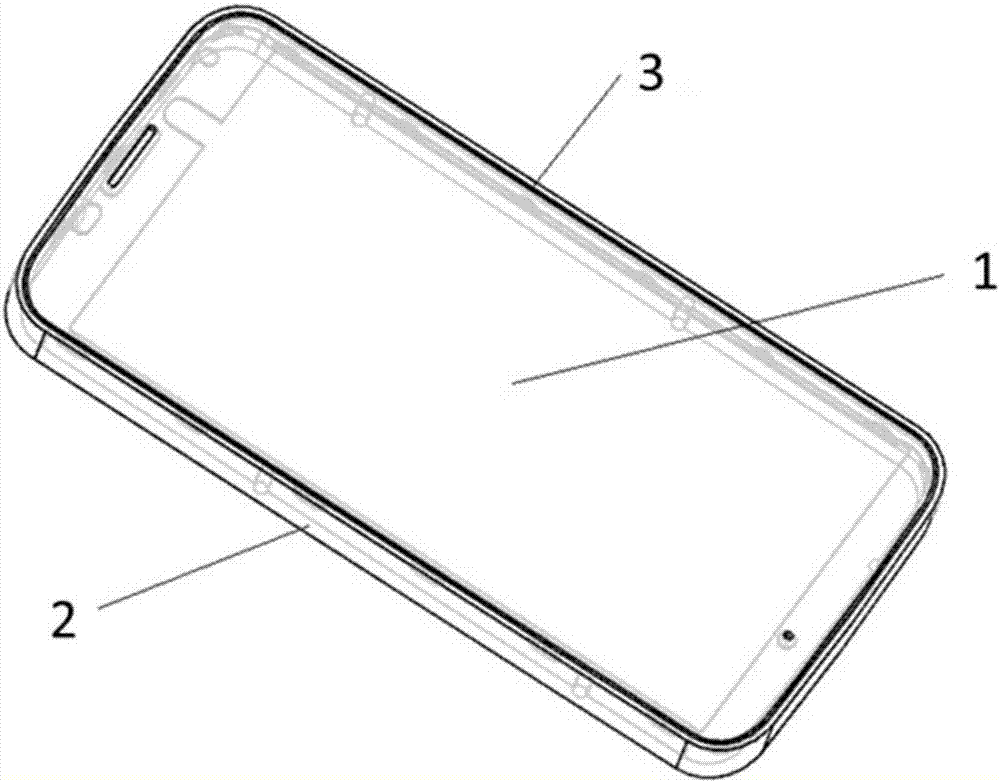

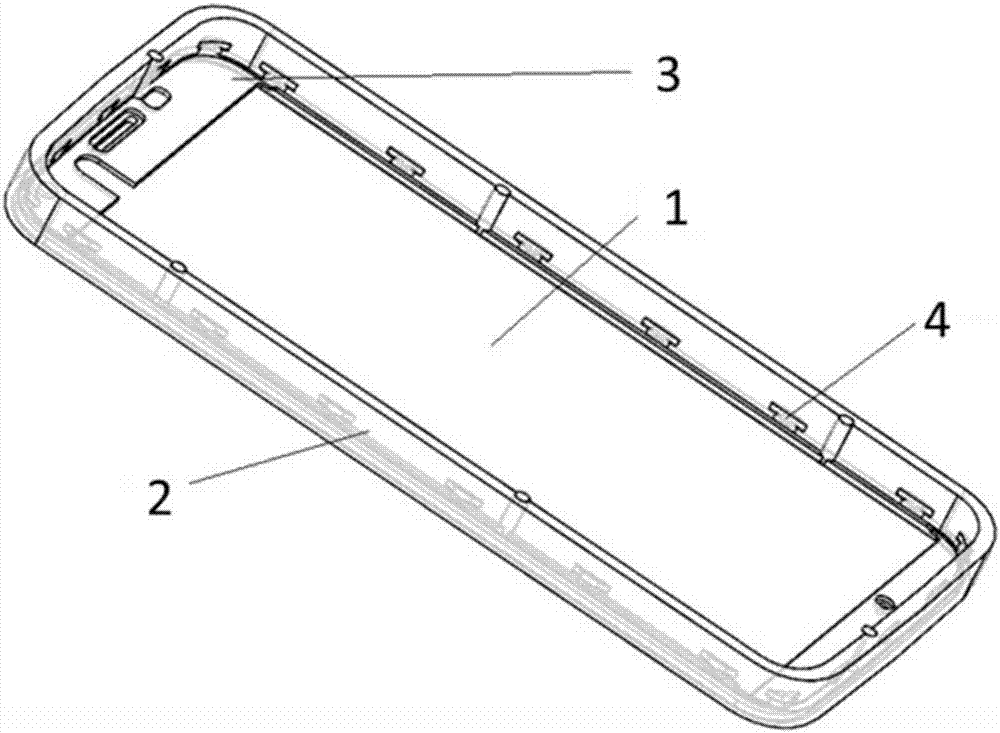

Metal shell with ceramic panel and preparation method thereof, and application of metal shell as communication device case

ActiveCN107295760ASmoothHigh strengthCasings with display/control unitsDomestic articlesUltimate tensile strengthCommunication device

Owner:BYD CO LTD

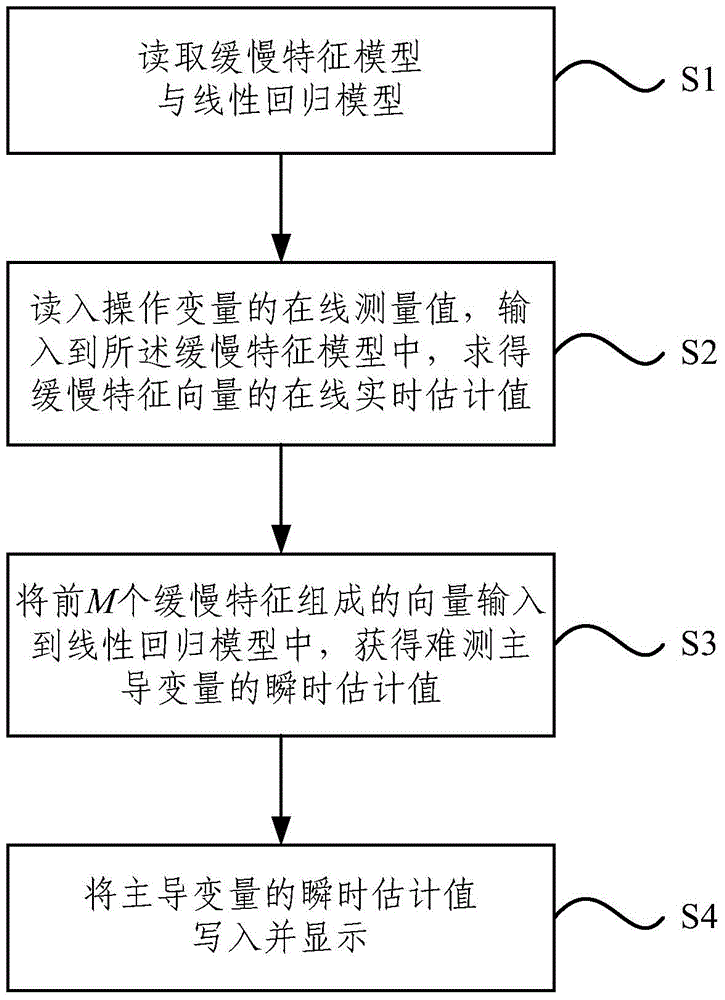

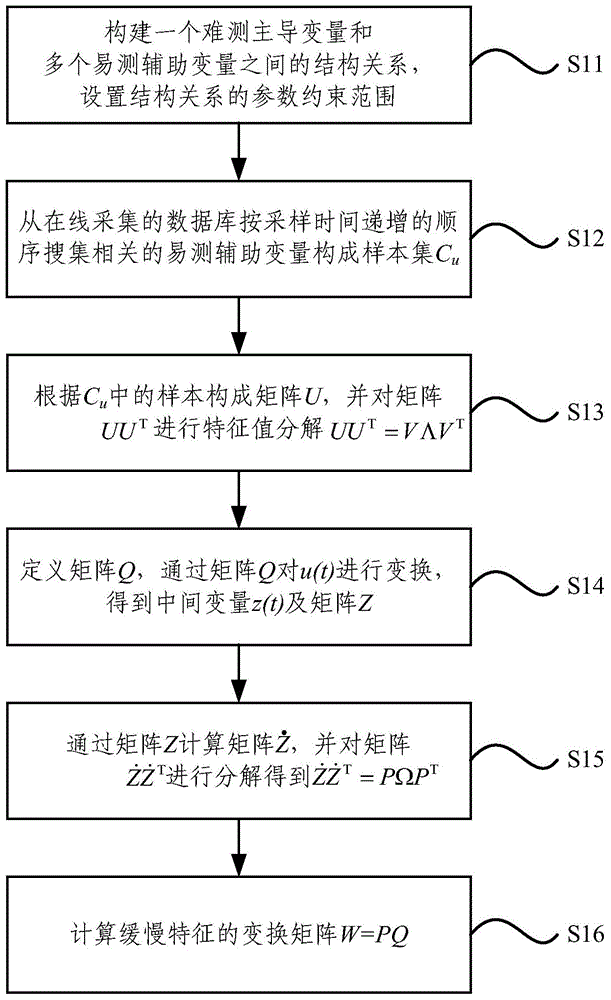

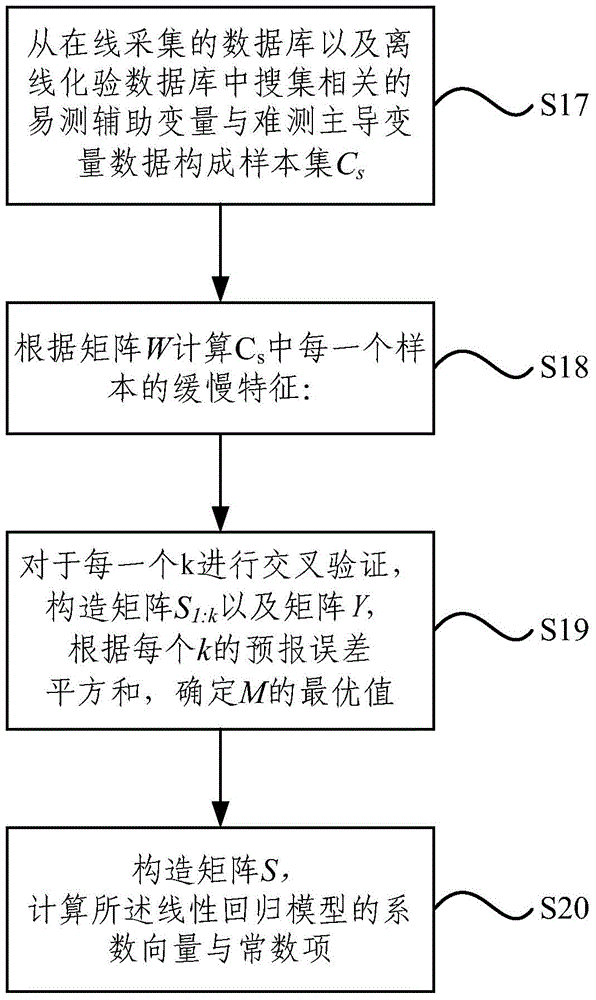

Dynamic soft measurement method and system based on slow characteristic regression

ActiveCN104537260AEfficient miningImprove estimation accuracySpecial data processing applicationsOperating variablesLinear regression

The invention relates to a dynamic soft measurement method and system based on slow characteristic regression. The method includes the steps of reading a slow characteristic model and a linear regression model, reading in online measurement values of operating variables, inputting the online measurement values into the slow characteristic model, and obtaining an online real-time estimated value of a slow characteristic vector s(t); inputting a vector s<1:M>(t) composed of the first M slow characteristics into the linear regression model, and obtaining an instant estimated value (please see the specification) of the leading variable y(t) difficult to measure; writing in and displaying the estimated value (please see the specification) of the y(t). By means of the dynamic soft measurement method and system in the technical scheme, the dynamic characteristics of a process can be effectively mined, the estimation accuracy is higher, the more excellent control performance is achieved when closed-loop feedback control is implemented, the prediction accuracy of a current model can be visually and effectively judged according to the slow change degrees of the hidden characteristics when field implementation is carried out, and the information in large-scale process data can be effectively used.

Owner:TSINGHUA UNIV

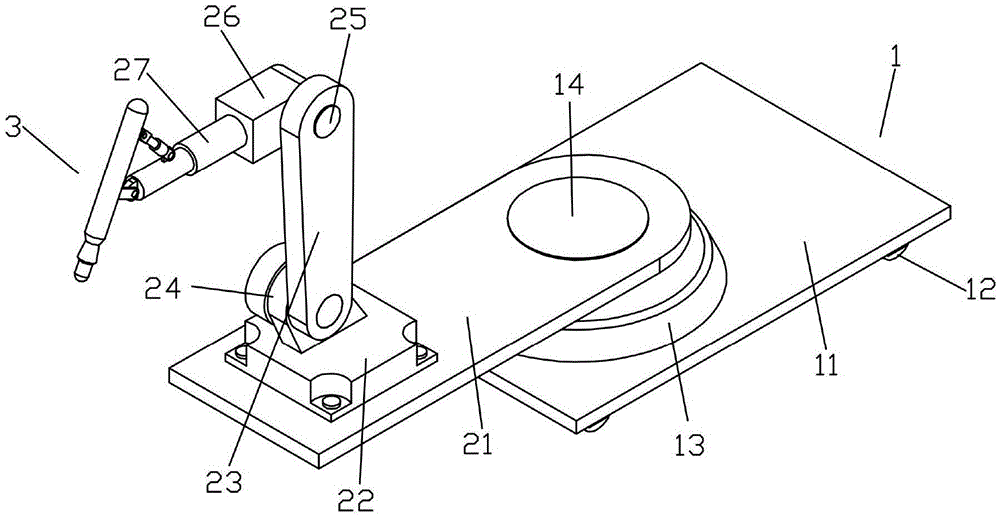

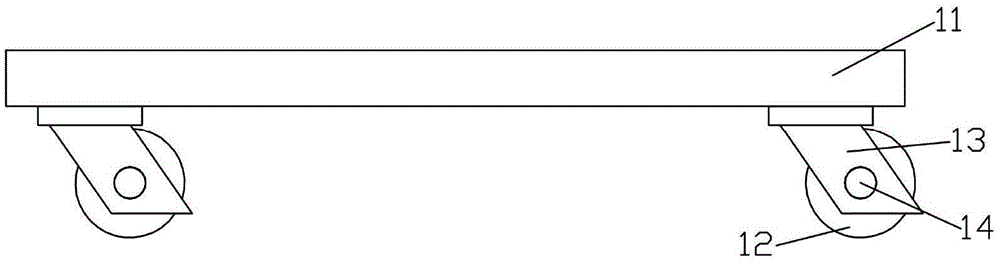

Movable paint spraying machine

InactiveCN105521899AImprove final performanceAvoid manual interventionSpraying apparatusControl systemMechanical engineering

The invention discloses a movable paint spraying machine. The movable paint spraying machine comprises a movable frame, a swinging and rotating unit, a spray gun, a travelling driver, a swinging and rotating driver and a control system. The swinging and rotating unit is connected to the movable frame rotationally. The spray gun is hinged to the swinging and rotating unit. The travelling driver is used for driving the movable frame to move. The swinging and rotating driver is used for controlling the swinging and rotating unit to swing and rotate. The control system is connected with the travelling driver and the swinging and rotating driver electrically to control movement of the movable frame and the swinging and rotating unit. The movable paint spraying machine has the advantages that the movable paint spraying machine has multi-angle multi-direction moving and swinging functions and can spray paint automatically, so that manual work is avoided, and personal injuries are reduced; the spraying speed is high, and paint is smooth and fine in hand feel; the paint is sprayed out in the form of mist, so that the paint can be well sprayed to corners and gaps, and final effect of paint films is good.

Owner:JIAMA MACHINERY COATING SCI & TECH SUZHOU CO LTD

Thermoplastic polyurethane/fiber composite soft cloth and preparation method thereof

InactiveCN104015444ASmoothSmooth surfaceLamination ancillary operationsSynthetic resin layered productsTextileFiber

The invention relates to a piece of thermoplastic polyurethane / fiber composite soft cloth. An intermediate layer is a piece of continuous fiber cloth, an upper surface layer and a lower surface layer are respectively a thermoplastic polyurethane resin layer, and the intermediate layer is connected with the upper surface layer and the lower surface layer through a hot laminating way. The composite soft cloth adopts TPU and fiber fabrics of different types and colors as raw materials, and TPU is bonded with the fabrics in a hot laminating manner, so that the pollution is avoided, the process is simple, the cost is low, the appearance effect is excellent, and the thermoplastic polyurethane / fiber composite soft cloth can be applied to top-grade appearance parts such as cases and vamps.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

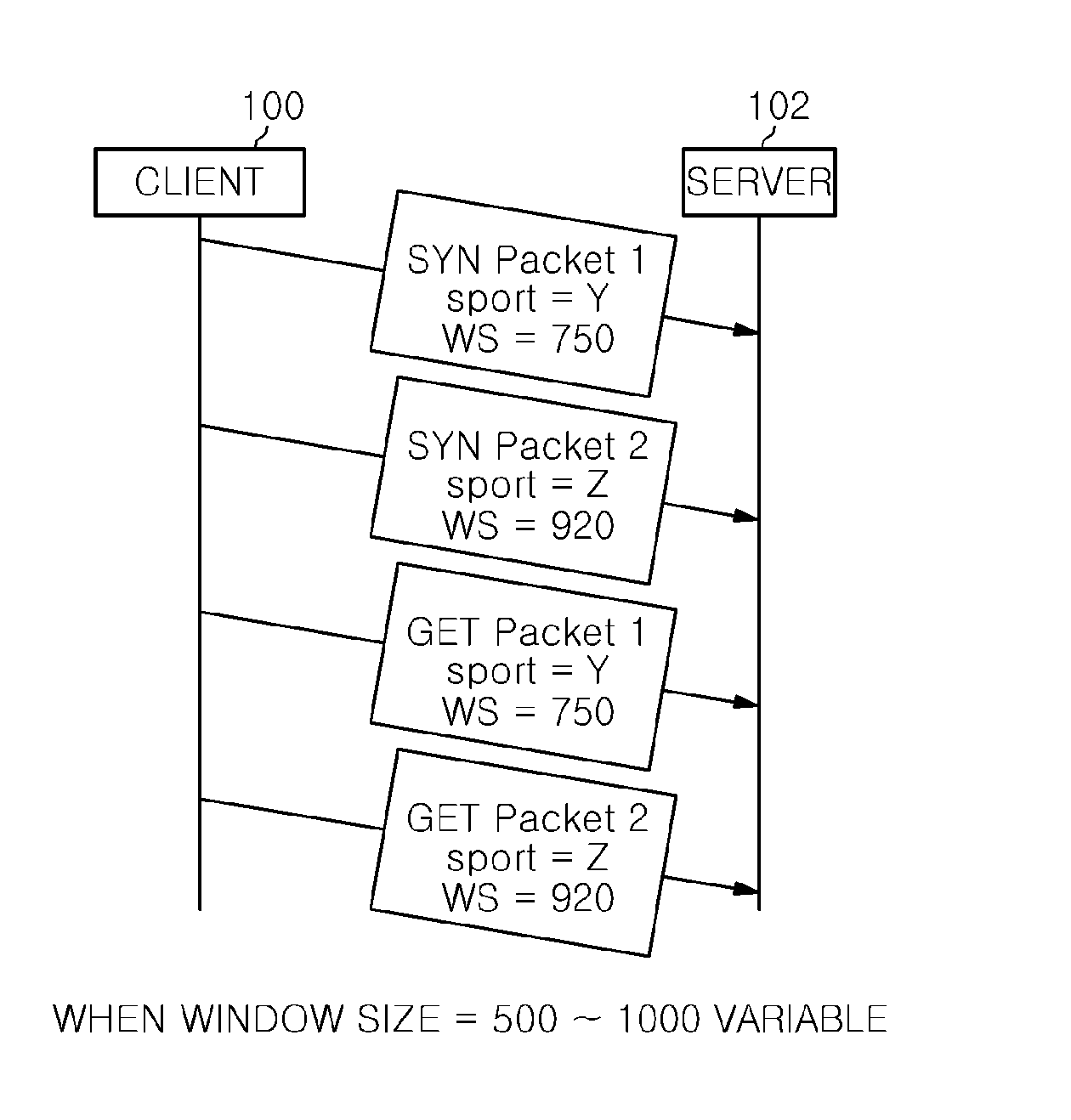

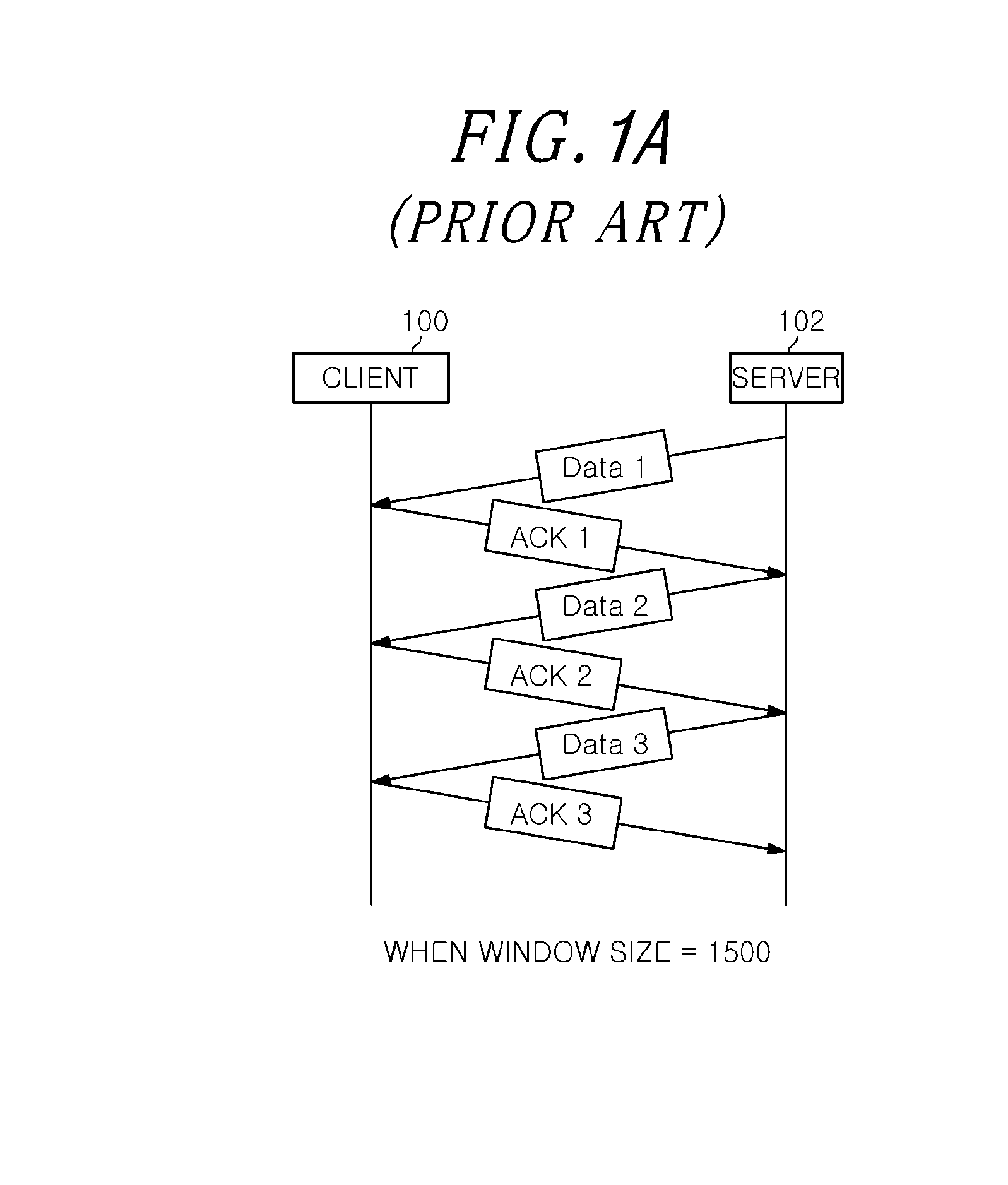

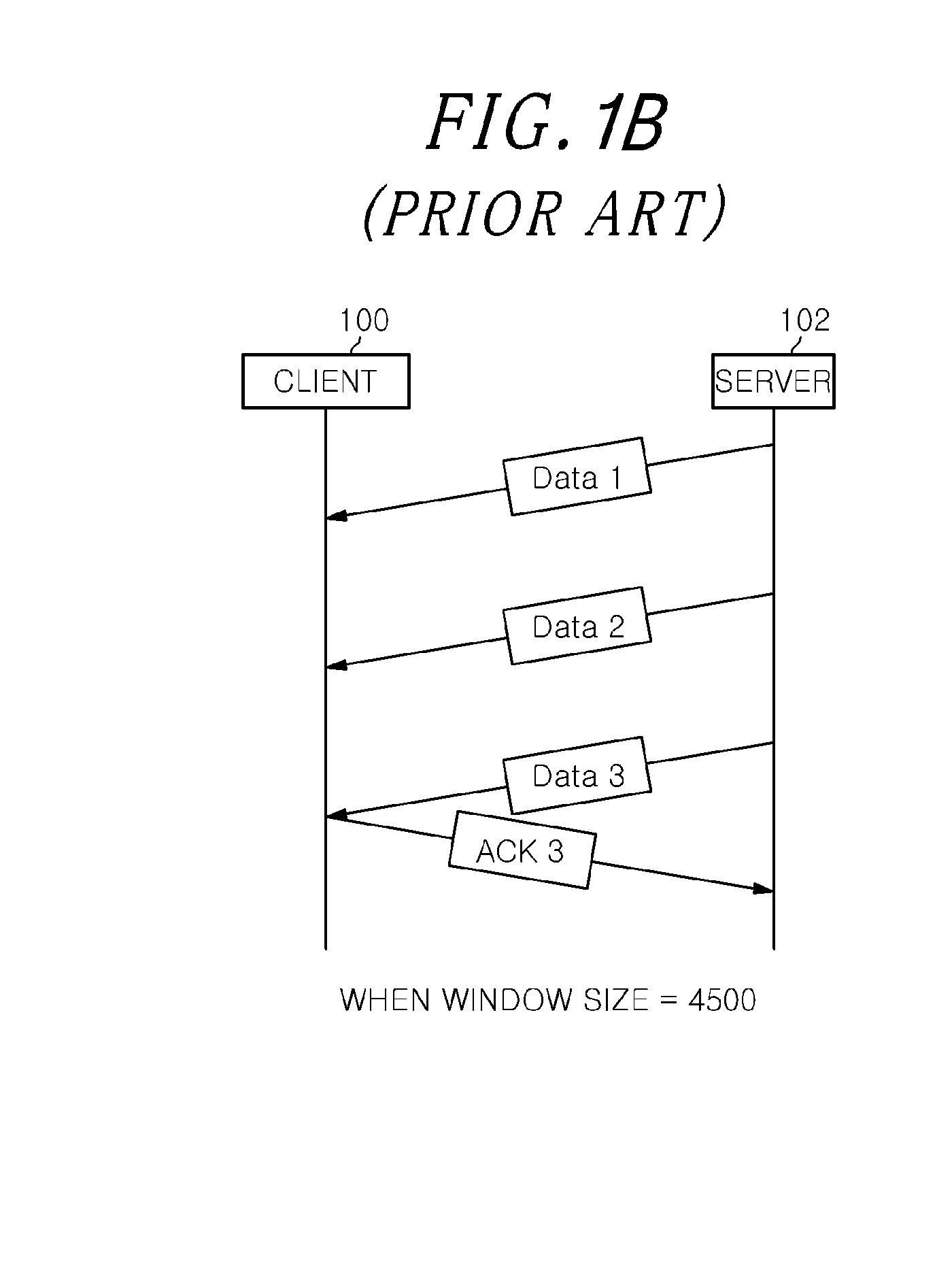

APPARATUS AND METHOD FOR DETECTING SLOW READ DoS ATTACK

InactiveUS20140304817A1SmoothQuick checkMemory loss protectionData taking preventionVirtualizationNetworking protocol

A method for detecting a slow read DoS attack in a virtualized environment, the method comprising: receiving a connection request packet transmitted from a client to a server using a web protocol; checking whether the received packet is a TCP SYN packet or a packet of an HTTP GET request message; when it is checked that the received packet is the packet of the HTTP GET request message, detecting whether the received packet is a packet for the slow read DoS attack by analyzing a window size of the HTTP GET request message.

Owner:ELECTRONICS & TELECOMM RES INST

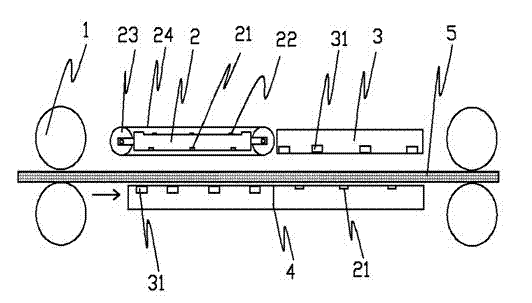

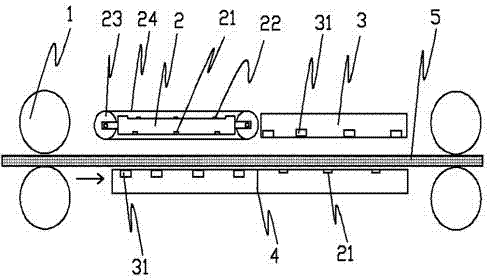

Flannelette ironing machine

The invention provides a flannelette ironing machine, which comprises two distributing and conveying roller pairs on the outlet side and the inlet side of an ironing machine body. The ironing machine body is composed of an upper first iron plate and a lower second iron plate parallel to each other, wherein the upper first iron plate is divided at a perpendicular bisector thereof into a first functional block and a second functional block, a transmission ironing belt is disposed on the first functional block, mist nozzles are evenly distributed on the top of the first functional block, steam spouts are evenly distributed at the bottom of the first functional block, steam collection holes are evenly distributed on part of the second iron plate below the first functional block, steam collection holes are evenly distributed at the bottom of the second functional block, steam spouts are evenly distributed on part of the second iron plate below the second functional block, steam on the first iron plate is high-temperature steam, and the stem on the second iron plate is low-temperature steam. The flannelette ironing machine can be used for well finishing flannelette after washing and dyeing, so that the flannelette is flattened.

Owner:JIANGSU GUOQIANG TOOLS CO LTD

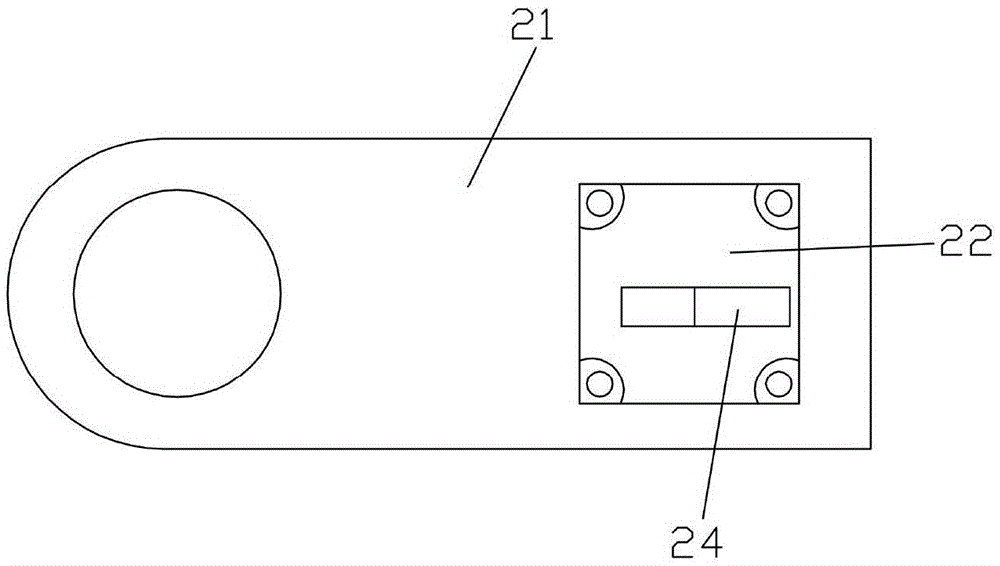

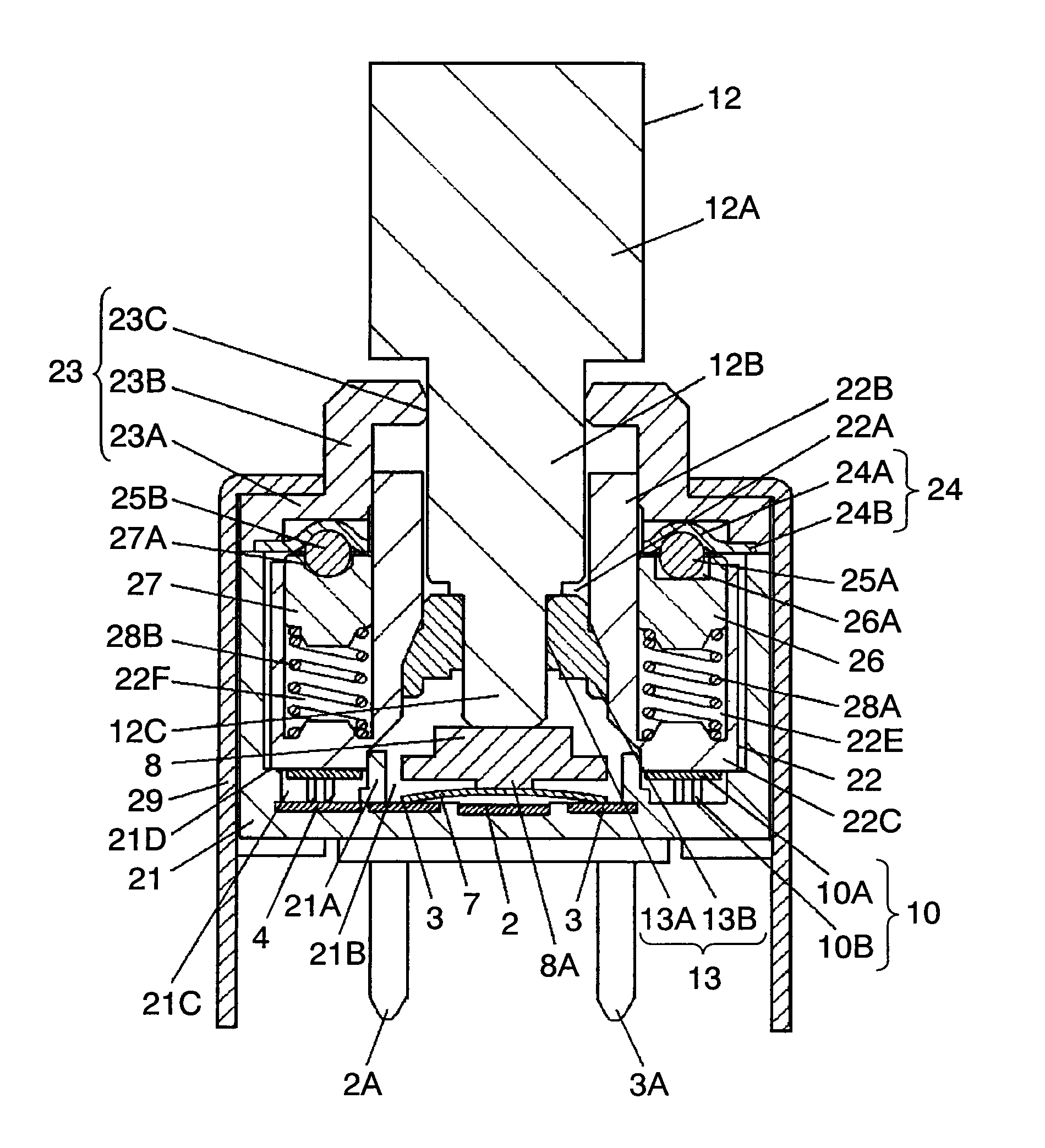

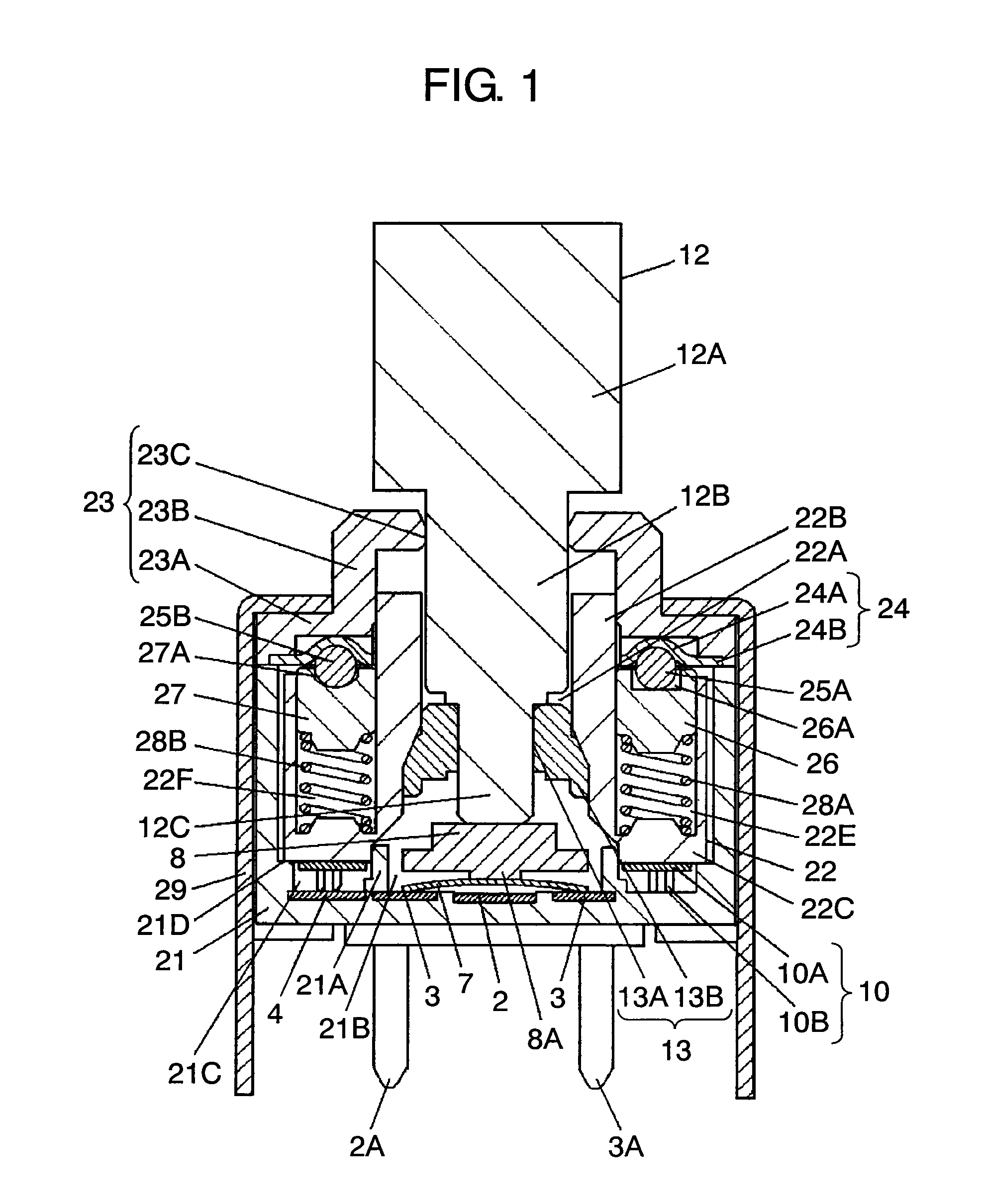

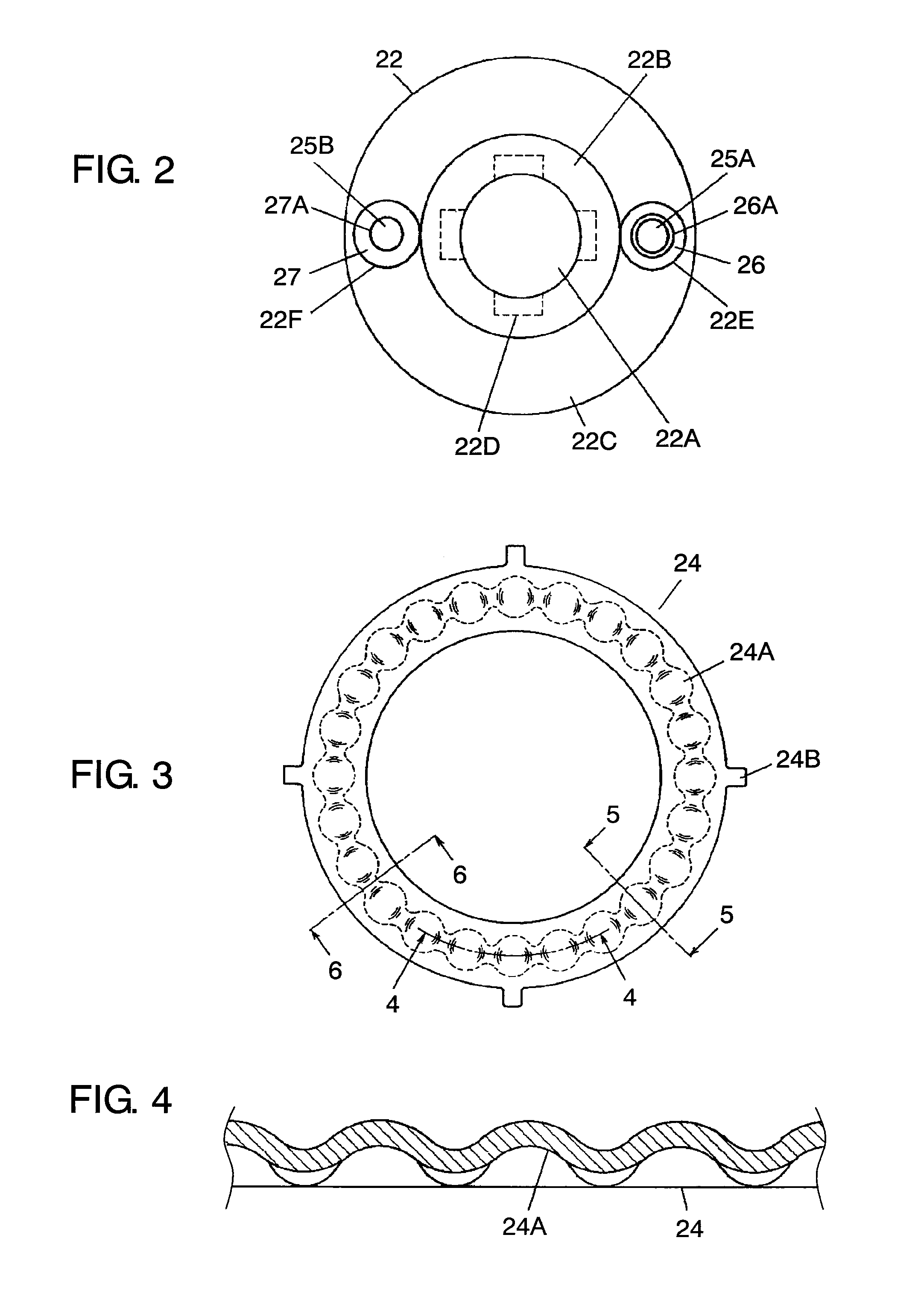

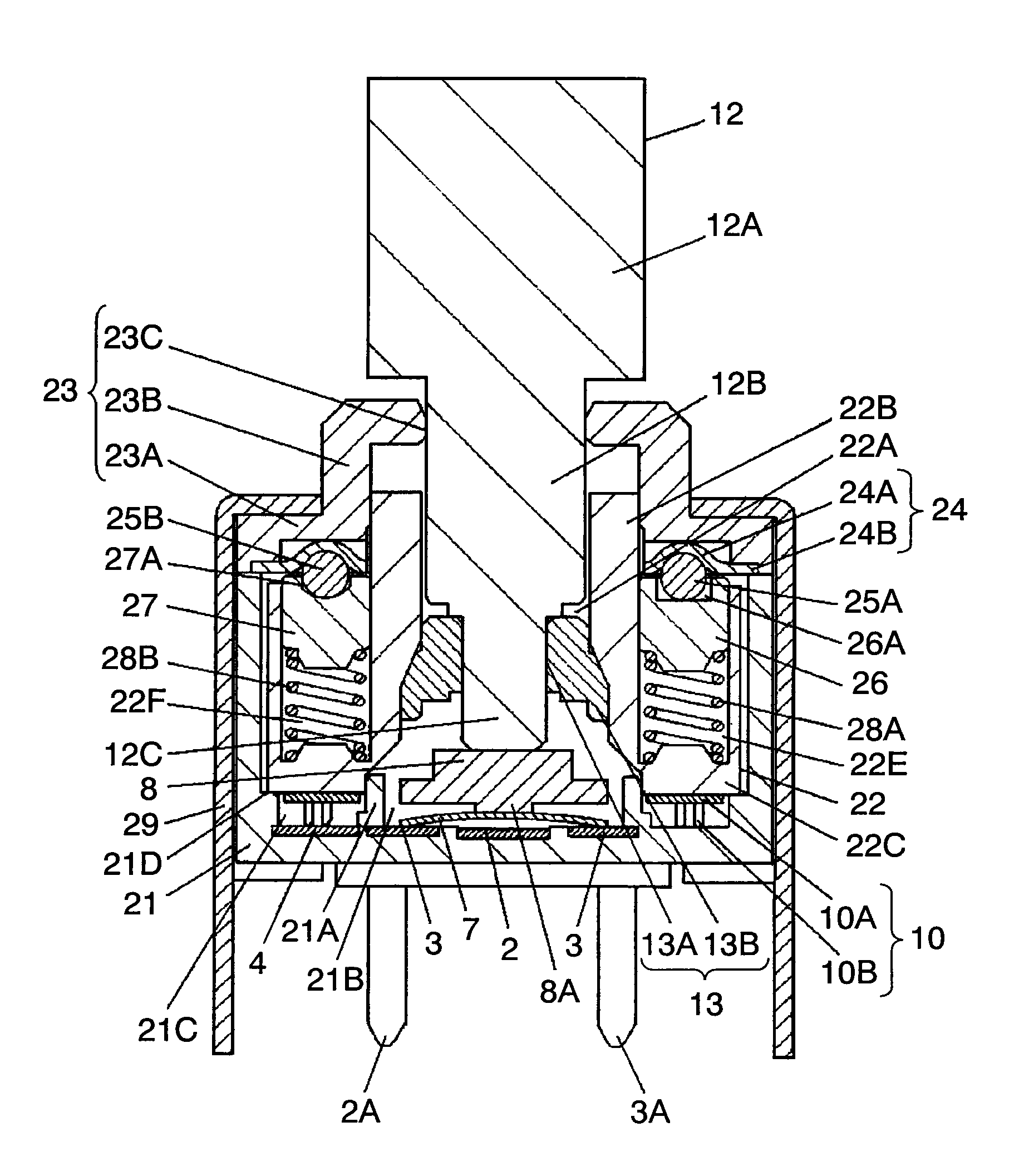

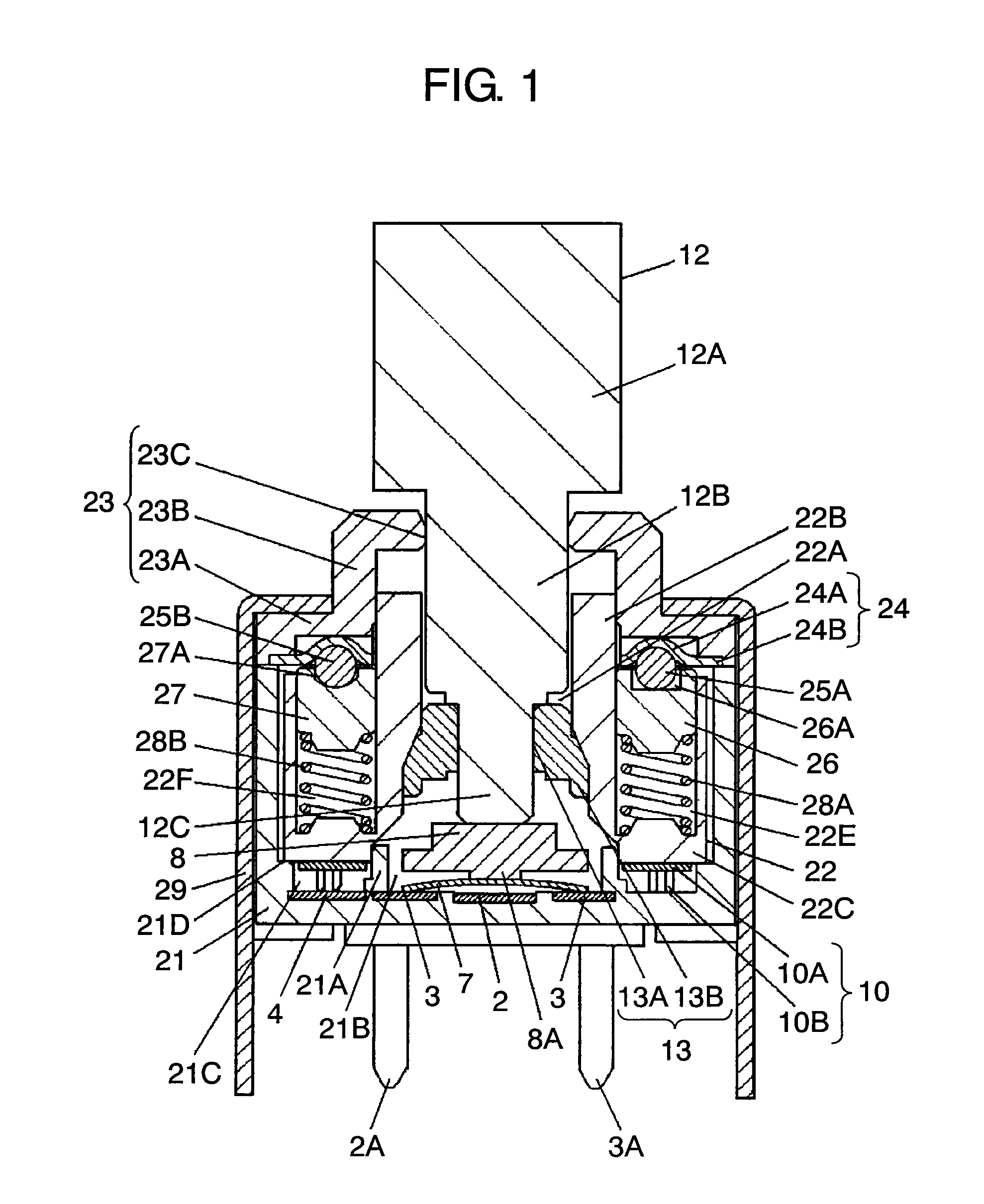

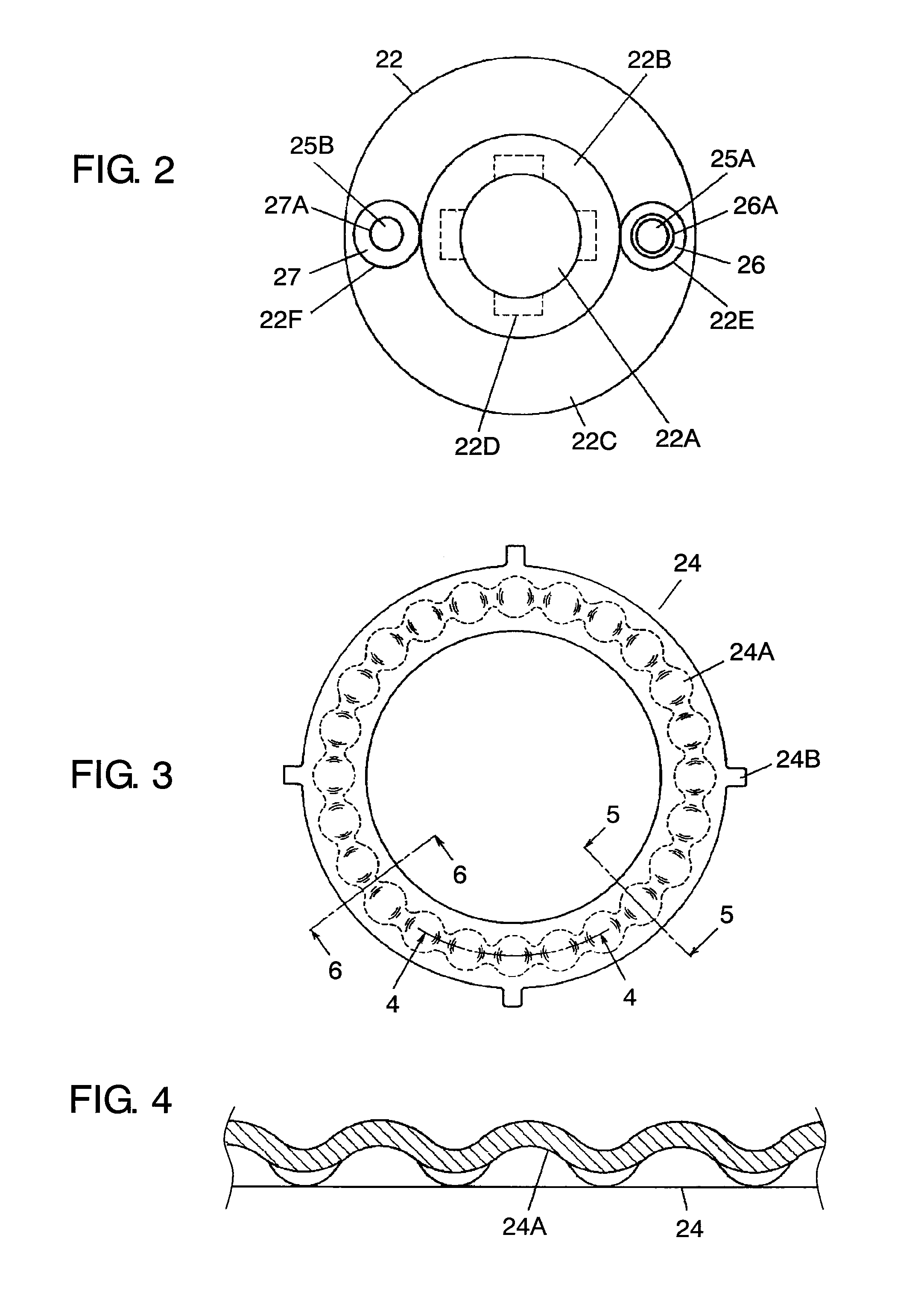

Rotary clicking electronic component

InactiveUS7476822B2SmoothDashboard fitting arrangementsInstrument arrangements/adaptationsCoil springEngineering

Rotary body 22 is provided with storing hole 22E, 22F in two positions point-symmetrical to the rotational center at the upper part of flange 22C, and retainers 26, 27 having steel balls 25A, 25B, steel ball receiving holes 26A, 27A, coil springs 28A, 28B are stored therein from the opening side in order, and steel ball receiving hole 26A of one retainer 26 is provided with a tolerance that enables steel ball 25A to slightly move in the horizontal direction, and click plate 24 on which steel balls 25A, 25B are resiliently contacted is disposed between rotary body 22 and bearing 23, and as a result, it is possible to maintain rhythmical clicking and clicking sound even in case of repeating the rotating operation.

Owner:PANASONIC CORP

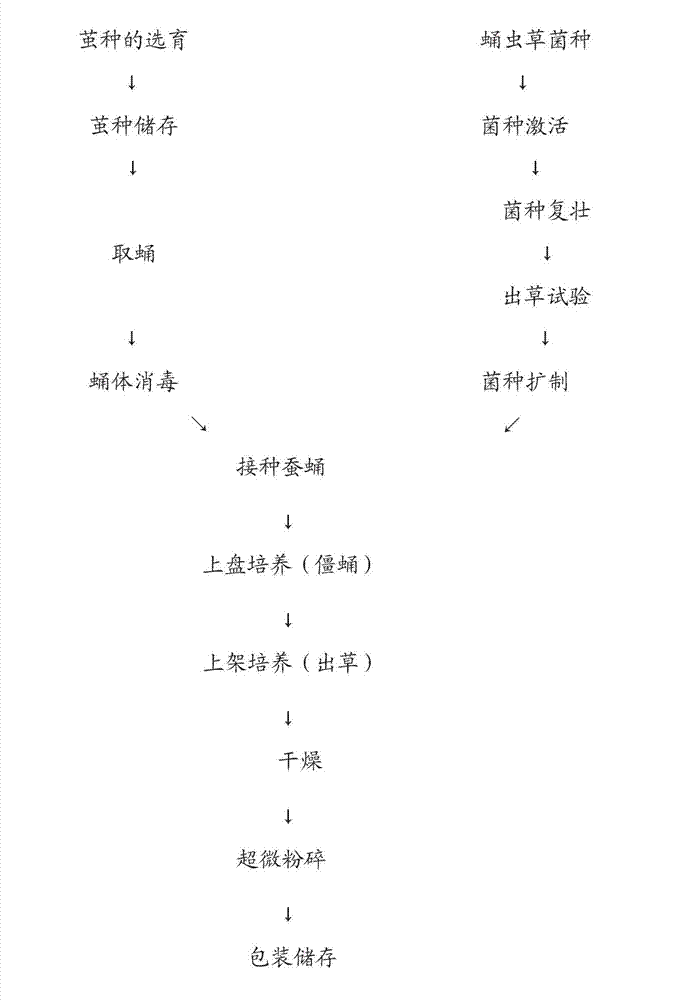

Cordyceps militaris (L) link as well as preparation method and application thereof

The invention provides a cordyceps militaris (L) link as well as a preparation method and an application thereof. The preparation method comprises the following steps of: (1) injecting fugal liquid of cordyceps militaris (L) link into silkworm chrysalis of biological cocoons of tussah, and cultivating the fugal liquid for 7-10 days at a temperature of 16-18 DEG C to obtain stiff cocoons; (2) carrying out no-illumination cultivation on the stiff cocoons for 7-10 days to form fruit body primordium on the surface of cocoon bodies; and (3) carrying out illumination cultivation on the stiff cocoons for 10-15 days with illumination intensity of 800-1000 lux, and then carrying out natural light illumination cultivation on the stiff cocoons at daytime and illumination cultivation on the stiff cocoons at night with illumination intensity of 800-1000 lux until fruit bodies grow out ascocarps. According to the invention, the biological cocoons of tussah and strains of the rejuvenated cordyceps (L) link are selected for cultivating the cordyceps militaris (L) link with high yield and high quality, a superfine grinding technology is adopted to fundamentally improve the dispersibility, dissolubility and absorptivity of the cordyceps militaris (L) link, the original biological activity and nutritional ingredients of the cordyceps militaris (L) link are maintained, and the utilization rate of raw materials is greatly improved.

Owner:吉林省中晟制药有限公司 +1

Softener for thick salix integra and preparation method of softener

ActiveCN103659979AImprove toughnessSmoothReed/straw treatmentWood impregnation detailsEthylenediamineBetaine

A softener for thick salix integra is made from raw materials in parts by weight as follows: 5-7 parts of ethylenediamine, 4-5 parts of tartaric acid, 4-5 parts of coco-betaine, 1-2 parts of decyl polyglucoside, 4-5 parts of ammonium dihydrogen phosphate, 10-12 parts of dandelion, 4-6 parts of chrysanthemum, 10-12 parts of coptis chinensis, 3-4 parts of camphor tree bark, 6-8 parts of povidone iodine,3-4 parts of an assistant and 100 parts of water. According to the softener, the ethylenediamine, the tartaric acid and multiple surfactants are used, so that the softener is high in permeation speed, high in softening speed and even in softening; the salix integra is good in toughness and touches smooth, and the weaving efficiency can be improved; and Chinese herbal medicines such as the camphor tree bark and the like as well as the povidone iodine are used, so that salix integra is smooth in surface, mould-proof and free of worms. The softener is applicable to softening of the thicker salix integra.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

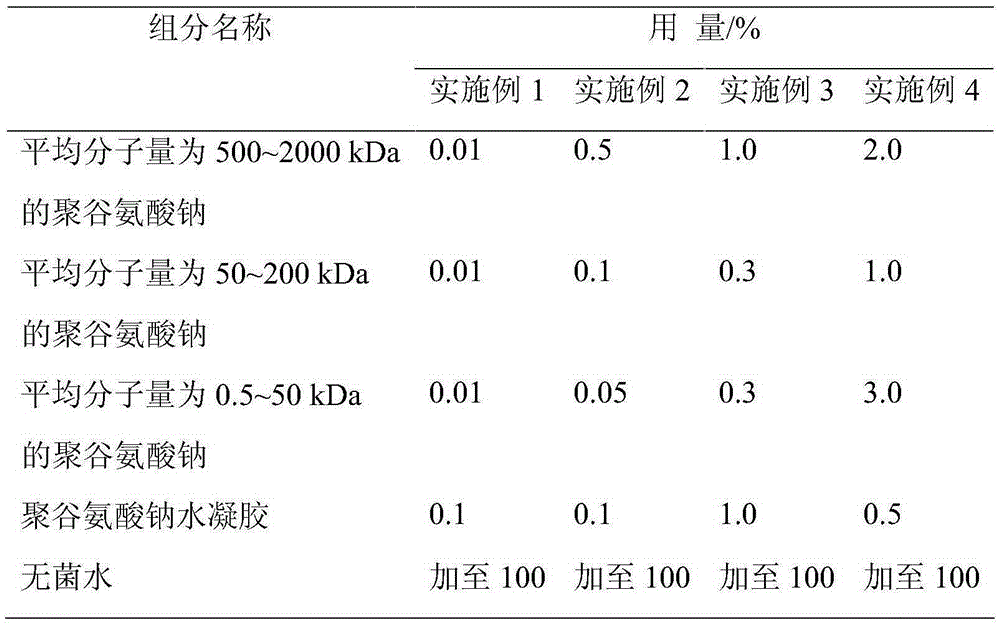

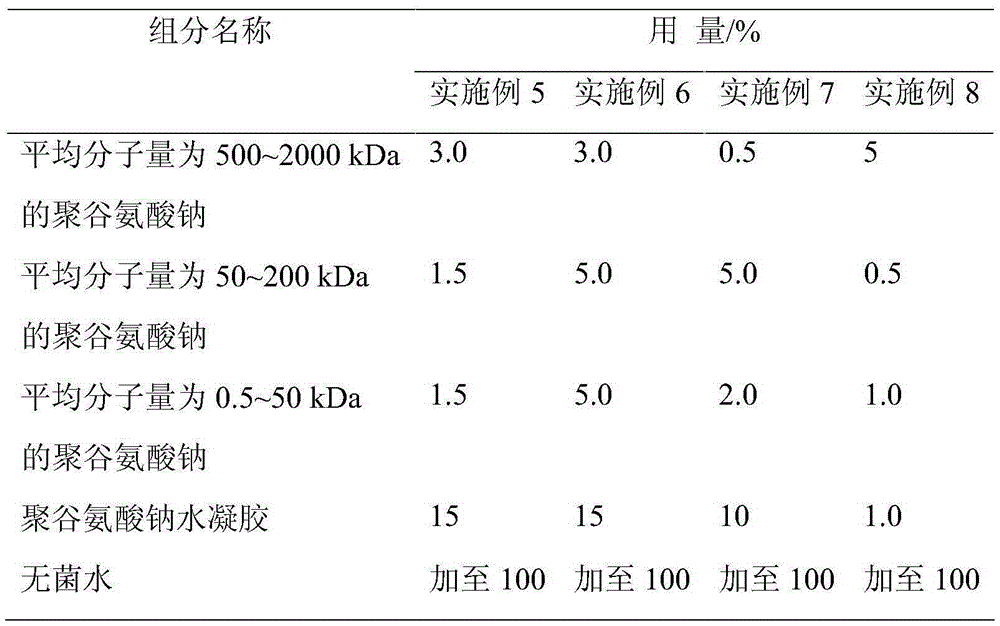

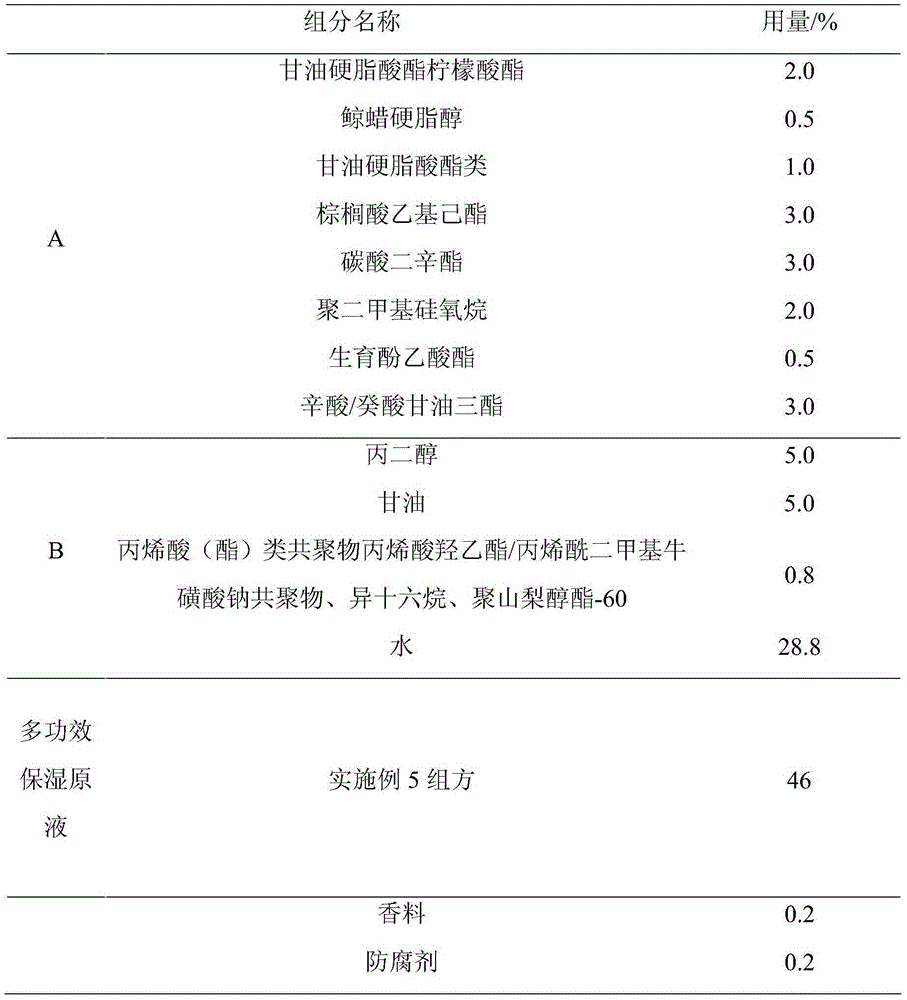

Multi-efficiency compound moisturizing essence and application method thereof

ActiveCN105342882AGive full play to the whitening effectGood biocompatibilityCosmetic preparationsHair cosmeticsEmulsionIrritation

The invention provides multi-efficiency compound moisturizing essence and application thereof. The compound moisturizing essence consists of polyglutamic acid or salt thereof within three molecular weight ranges, and further consists of a polyglutamic acid hydrogel or a polyglutamate hydrogel which is quite strong in water-absorbing capacity and is good in film-forming property. The compound moisturizing essence, in vitro and for human skin, has an excellent moisturizing effect, and the compound moisturizing essence is high in safety of ingredients thereof and free from toxicity and irritation to cells, animals and human bodies. The compound moisturizing essence can be also applied to various cosmetics; and the compound moisturizing essence can be prepared into emulsions, creams, facial masks and the like.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

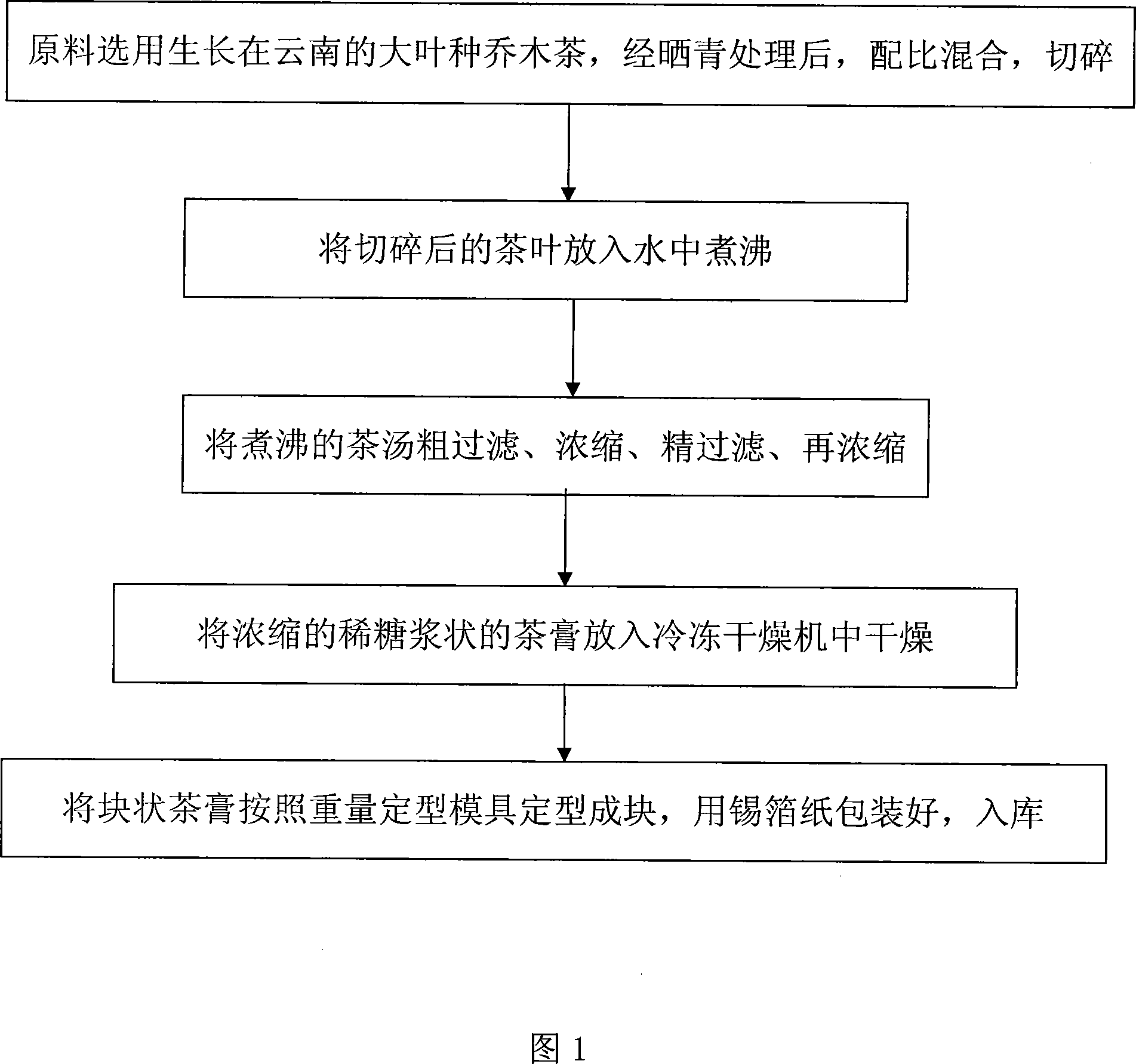

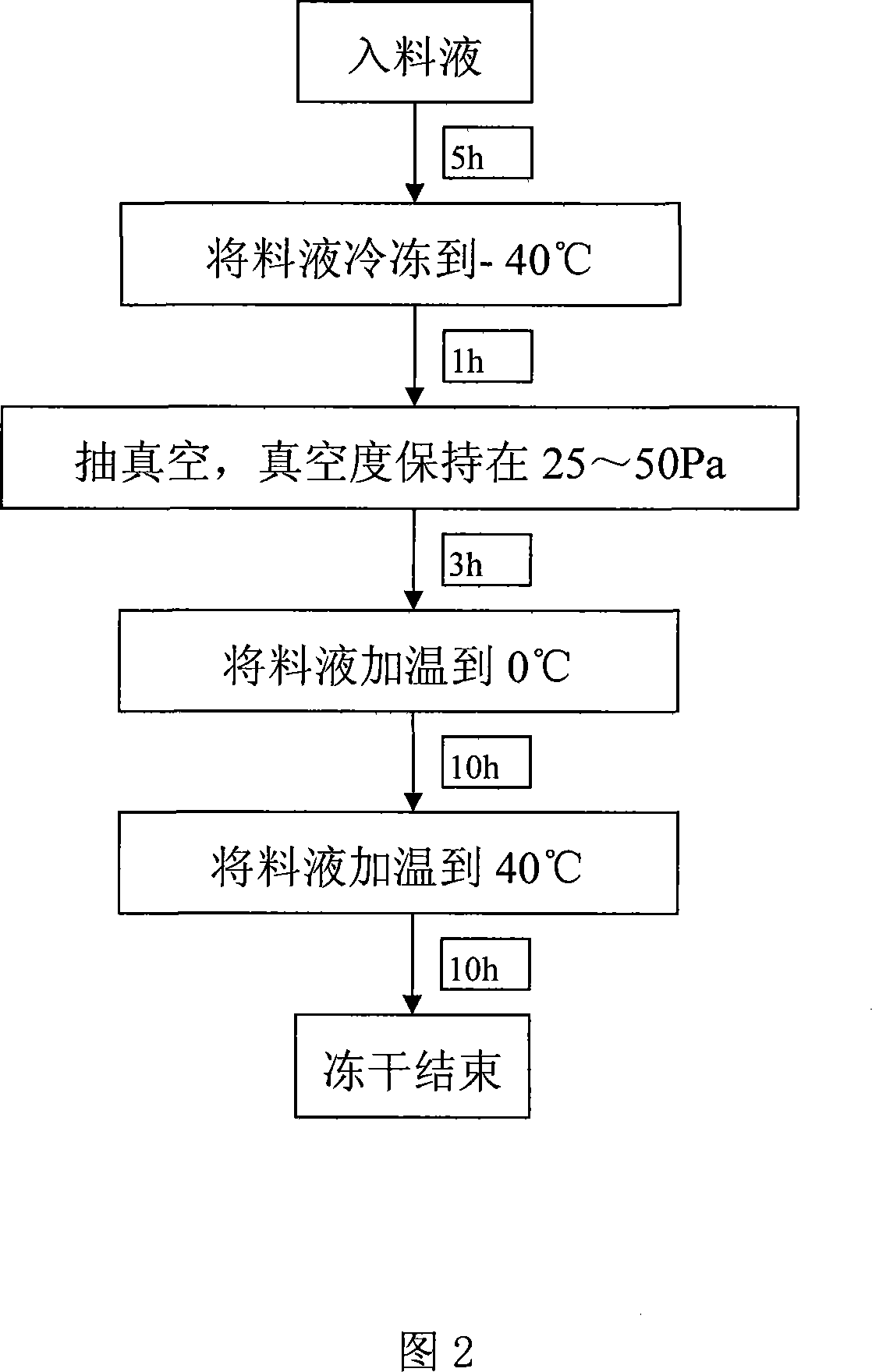

Pure tea cream and its producing technology

The present invention relates to a pu'er tea paste and its production process. Said production process includes the following steps: using naturally-fermented tea leaf as raw material, adding water and boiling, concentrating and freeze-drying so as to obtain the invented pu'er tea paste.

Owner:老河口牧工商茶叶进出口贸易有限公司

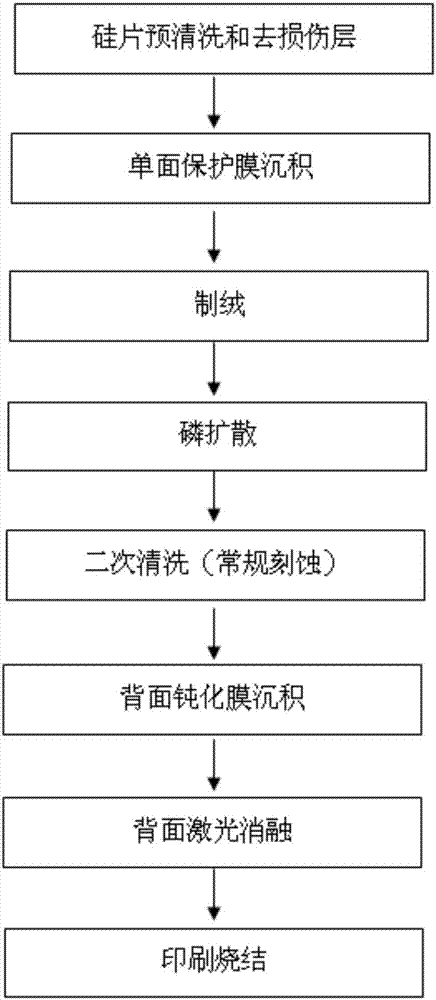

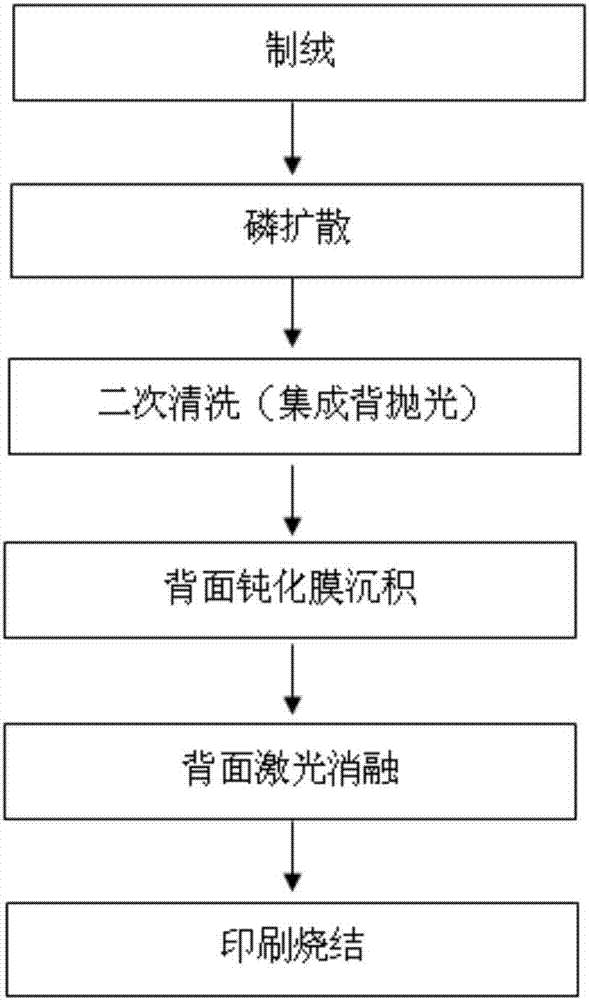

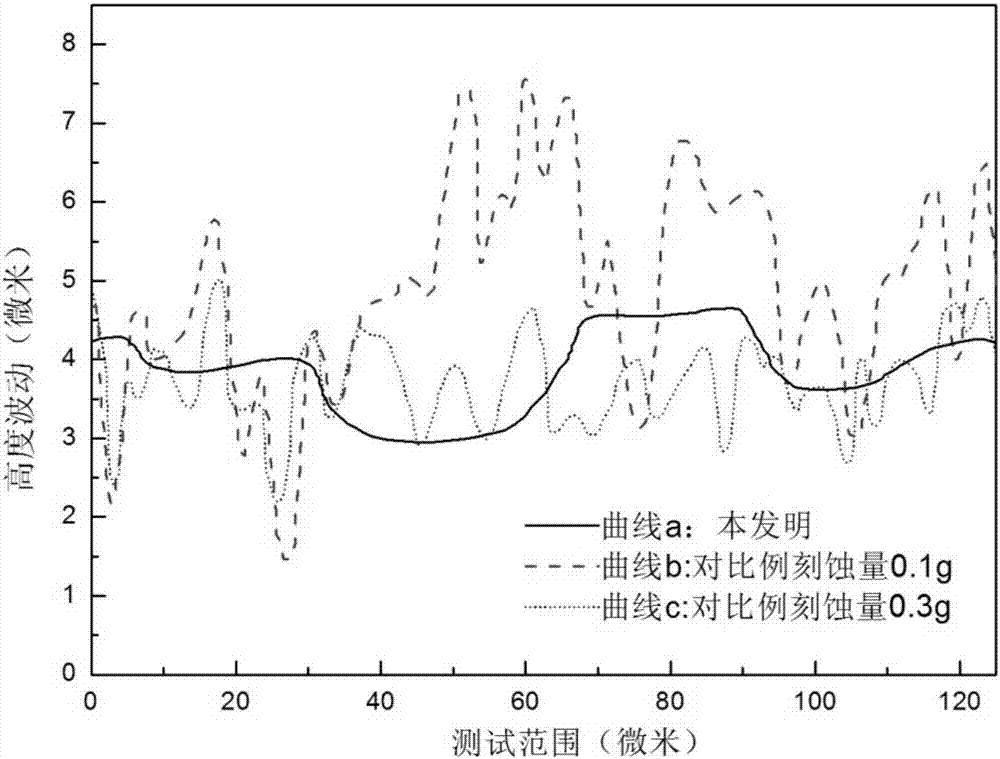

Method for preparing backside-polished PERC battery

InactiveCN107123702ASmall amount of thinningAchieve flatnessFinal product manufacturePhotovoltaic energy generationMicro nanoScreen printing

The invention discloses a method for preparing a backside-polished PERC battery. The method comprises: (1), depositing a single-sided protective film on the backside of a silicon wafer; (2) carrying out texturing on the silicon wafer plated with the single-sided protective film and removing the single-sided protective film of the silicon wafer during a pickling process after texturing; (3), carrying out diffusion on the single-sided-textured silicon wafer; (4), carrying out conventional secondary cleaning; and (5), depositing aluminium oxide / silicon nitride laminated passivation film at the back side, carrying out laser grooving, screen printing and sintering, thereby obtaining a backside-polished PERC battery. According to the method disclosed by the invention, the volume production threshold is low; the operation cost is low; micro-nano flatness is realized; and the photoelectric conversion of the battery is improved.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Rotary clicking electronic component

InactiveUS20080289439A1SmoothDashboard fitting arrangementsInstrument arrangements/adaptationsCoil springSteel ball

Rotary body 22 is provided with storing hole 22E, 22F in two positions point-symmetrical to the rotational center at the upper part of flange 22C, and retainers 26, 27 having steel balls 25A, 25B, steel ball receiving holes 26A, 27A, coil springs 28A, 28B are stored therein from the opening side in order, and steel ball receiving hole 26A of one retainer 26 is provided with a tolerance that enables steel ball 25A to slightly move in the horizontal direction, and click plate 24 on which steel balls 25A, 25B are resiliently contacted is disposed between rotary body 22 and bearing 23, and as a result, it is possible to maintain rhythmical clicking and clicking sound even in case of repeating the rotating operation.

Owner:PANASONIC CORP

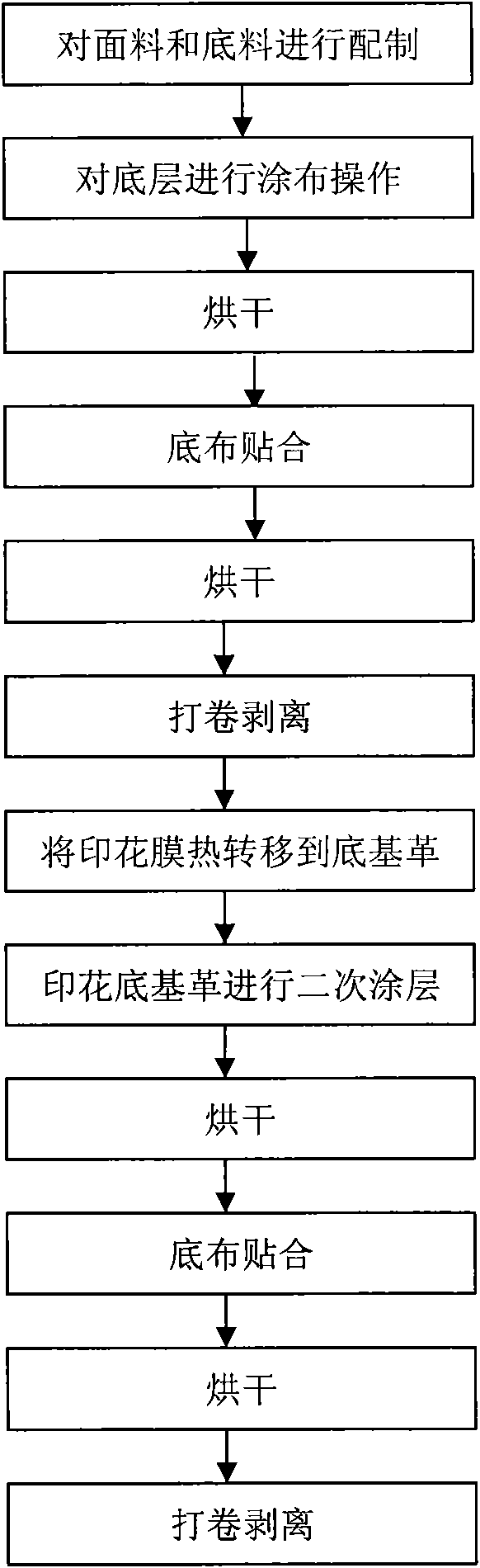

Novel PU printing waterproof and anti-crease fabric and preparation method thereof

InactiveCN101660277AImprove the three-dimensional effectRemove tensionSynthetic resin layered productsDyeing processDisperse dyeAlcohol

The invention discloses a novel PU printing waterproof and anti-crease new fabric, which comprises three layers: the first layer is PU surface layer mainly comprising PU polyurethane; the second layeris printing dyes; the third layer is a PU surface layer mainly comprising PU polyurethane. The printing dyes in the second layer are ink disperse dyes made of disperse dyes and water-soluble carrier,or ink disperse dyes made of the disperse dyes and alcohol-soluble carrier, or ink disperse dyes made of the disperse dyes and oil-soluble resin. The invention also discloses a method for preparing the novel PU printing waterproof and anti-crease fabric, comprising the following steps: firstly, preparing a shell fabric and a backing material; secondly, carrying out coating operation; thirdly, performing the backing lamination; fourthly, drying, rolling and stripping; fifthly, thermally transferring a printing film to base leather; and sixthly, performing the secondary coating on the printingbase leather. The novel PU printing waterproof, anti-crease fabric has advantages of terrific tensile strength and hydrostatic pressure, and is durable in use, fastness to washing, colorfast; and thepreparation method is easy to operate.

Owner:仪征新天地织物面料实业有限公司

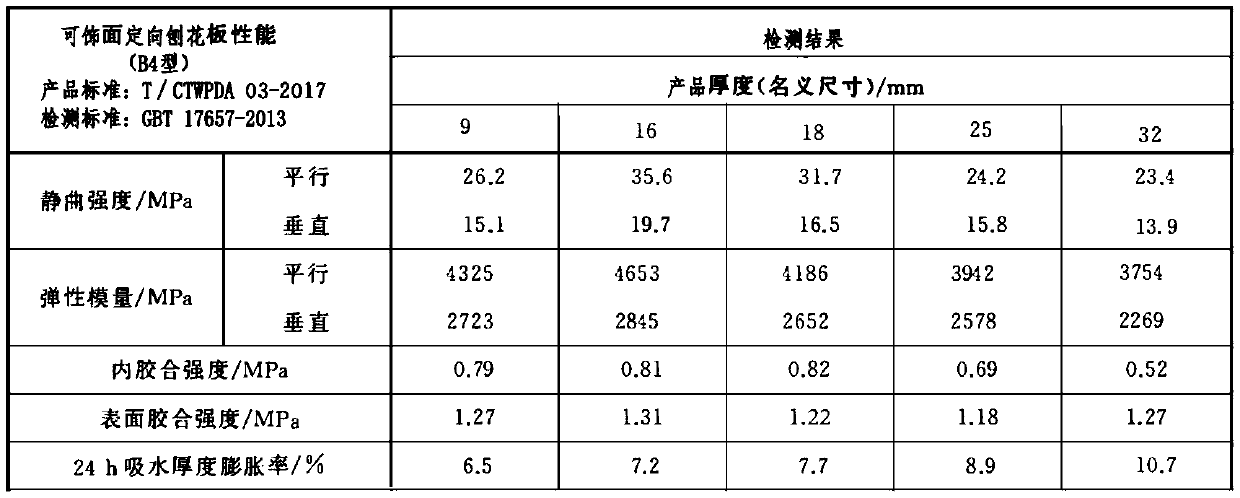

Low-density veneer oriented strand board

InactiveCN110091409AReduce Shrinkage ProblemsReduce breakage rateDomestic articlesFlat articlesWood shavingsSurface layer

The invention relates to a low-density veneer oriented strand board. The low-density veneer oriented strand board comprises a core layer, a sub-surface layer and a surface layer; the core layer is made of slightly larger wood shavings (the wood shaving length is between 50 mm and 80 mm) produced by small-diameter wood and branch wood of poplar through a long wood slicing machine and a two-sectionslicing machine; the sub-surface layer is made of large wood shavings (the wood shaving length is between 80 mm and 120 mm) produced through the long wood slicing machine and the two-section slicing machine; and the surface layer is made of leftover materials, saw dust and wood shavings which are produced in the production process of plywoods, laminated wood boards and strand boards. After the rawmaterials are subjected to drying, screening, gluing, paving, prepressing, edging, steam injection and continuous hot pressing, the low-density veneer oriented strand board is prepared. According tothe low-density veneer oriented strand board, the density is smaller than or equal to 520 kg / m<3>, the static bending strength in the parallel direction can reach 22-38 MPa, and the elasticity moduluscan reach 3,200-4,500 MPa. The low-density veneer oriented strand board is not only limited to the using range of common OSBs, and can be widely applied to directing veneering of furniture, indoor decoration, packaging and floor base materials.

Owner:江苏慧典新材有限公司

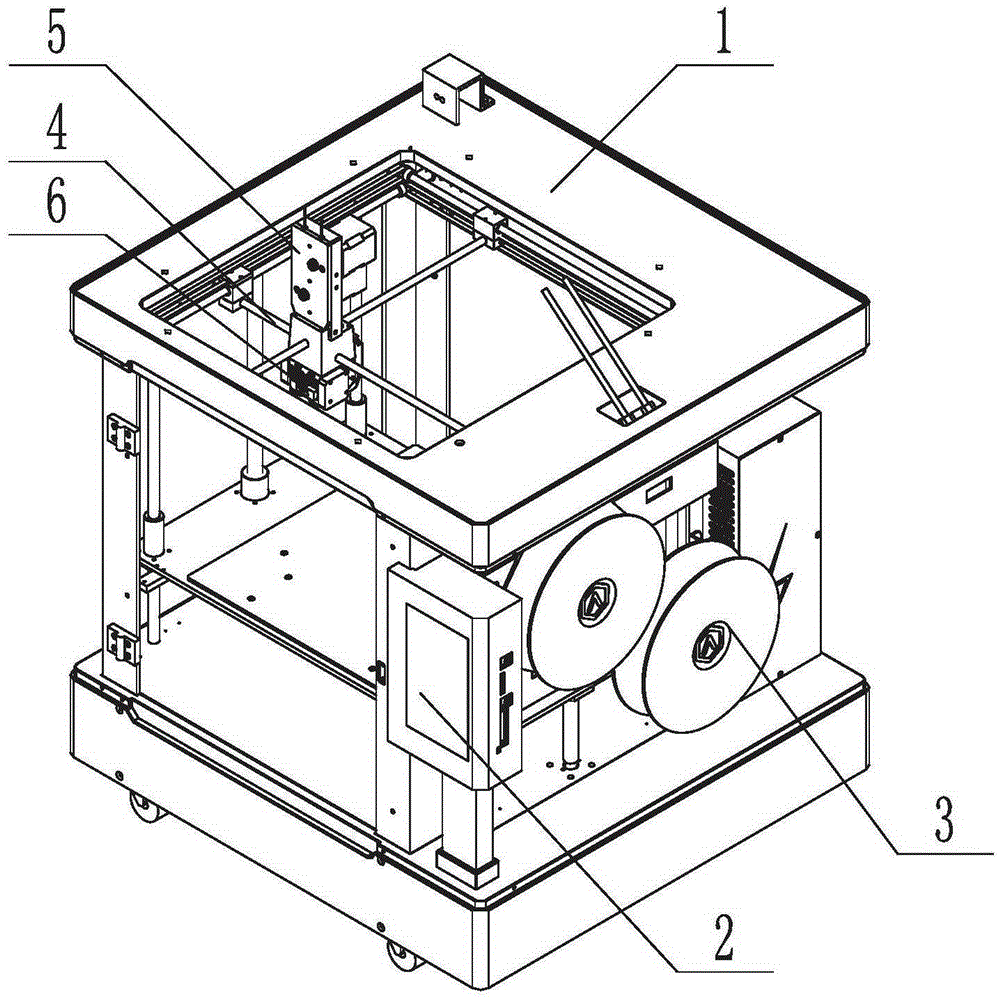

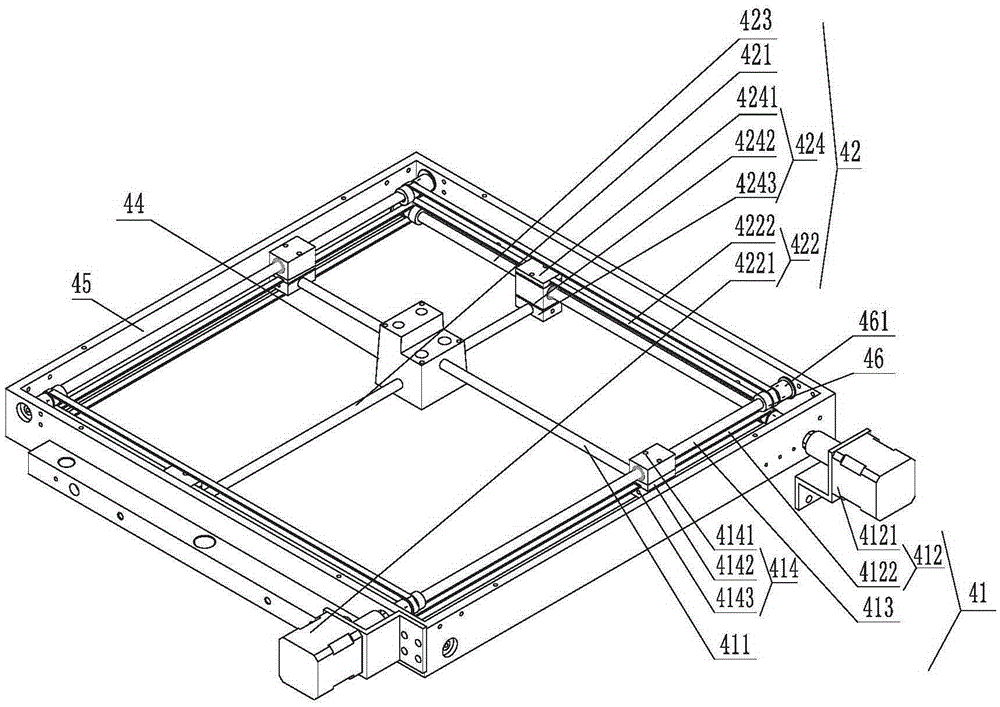

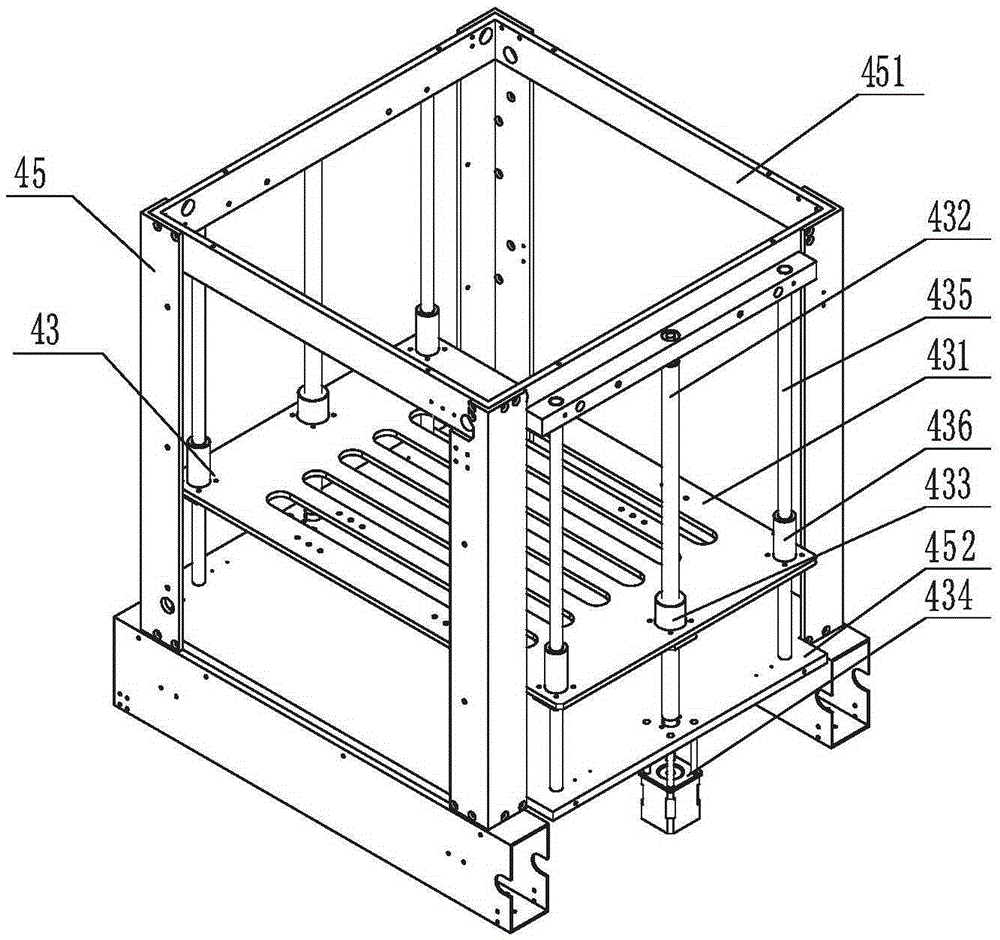

Desktop-level 3D printer

InactiveCN105252776AReasonable structural designHigh precisionAdditive manufacturing apparatusElectricityColor printing

The invention discloses a desktop-level 3D printer. The desktop-level 3D printer comprises a machine frame, a controller, a material conveying device, an X,Y and Z axis movement device, a feeding device and a spraying nozzle device, wherein the material conveying device and the X,Y and Z axis movement device are installed on the machine frame; the feeding device and the spraying nozzle device are installed on the X,Y and Z axis movement device; the material conveying device is connected with the feeding device; the feeding device is connected with the spraying nozzle device; the controller is electrically connected with the material conveying device, the X,Y and Z axis movement device, the feeding device and the spraying nozzle device. The desktop-level 3D printer can realize effective multi-color printing, a printed model is high in accuracy, the printing effect is good, and color switching nearly without errors can be achieved. Meanwhile, the environmental characteristic that materials like acrylonitrile butadiene styrene (ABS) need to be printed at a constant temperature can be realized, so that technical support is provided for clients needing to print the ABS. The products with the biggest effective printing area are included, and requirements of various clients can be met.

Owner:SHANGHAI FUSION TECH CO LTD

Method of manufacturing line of autohesion thread

An object of the present invention is to provide a method of manufacturing autohesion thread such that a smooth surface is offered, the cutting thereof is easy, filaments composing thread are not frayed in cutting, and additionally drainability are superior, and then plural kinds of filaments can be combined. The invention provides a method of manufacturing a line of fusion thread characterized in that plural filaments comprising thermoplastic resin are paralleled, twisted and / or braided if desired, and subsequently drawn under heating at a draw ratio of less than 1.0 to thereby substantially fuse the adjacent filaments to be subsequently drawn under heating at a draw ratio of more than 1.0.

Owner:YOZ AMI

Environment-friendly leather-producing process by using sturgeon skins

InactiveCN103436643AFeel goodFine grainTanning treatmentPre-tanning chemical treatmentSturgeonSolvent degreasing

The invention relates to a leather-producing process, and specifically relates to an environment-friendly leather-producing process by using waste sturgeon skins in a food processing process of artificially cultured sturgeons. The leather-producing process comprises the following steps of 1) group batching the sturgeon skins; 2) washing; 3) soaking; 4) liming; 5) washing; 6) deliming; 7) bating; 8) washing; 9) pickling; 10) neutralizing; 11) oxidation bleaching; 12) reduction bleaching; 13) washing; 14) dealkalizing; 15) washing: washing the dealkalized sturgeon skins with water; 16) repeat pickling; 17) tanning; 18) re-tanning; 19) drying; 20) trimming; 21) buffing; 22) solvent degreasing; 23), spin-drying; 24), drying; 25), rewetting; 26), re-tanning; 27), dyeing; 28) drying; 29) buffing; 30) finishing: spraying a coating agent on the buffed leather to obtain sturgeon leather. The sturgeon leather produced by the process has the advantages of softness, fullness, non-harsh handfeel and fine grains. The process is environment-friendly.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Leather edge coat

InactiveCN105602429AHigh color fastnessSmoothPolyurea/polyurethane coatingsLeather surface finishingWaxHazardous substance

The invention relates to leather edge coat, and belongs to the field of leather coating agents. The leather edge coat is prepared from, by weight, 150-200 parts of polyurethane binder, 30-50 parts of polyurethane brightener, 20-100 parts of extinction filler, 30-100 parts of handfeel wax, 50-100 parts of diluent and 1-3 parts of thickener. The leather edge coat has the advantages of being excellent in color fastness, resistant to bending, low temperature and friction, free of solid powder additives and heavy metal hazardous substances, smooth in hand feeling and capable of well meeting the requirements of leather products for the leather edge coat.

Owner:GUANGZHOU DIFU KALE IMPORT & EXPORT TRADE CO LTD

Wax print cloth wax veins producing prescription and technique

InactiveCN101144251AElasticFlexibleFibre treatmentDyeing processParaffin waxOxidation-Reduction Agent

The present invention discloses a print production prescription and a process of the wax print fabric. The production prescription used adopts rosin, paraffin wax, beeswax, and macromolecule resin as wax material. The process flow is as follows: firstly, an original grey cloth is processed through singeing, desizing, scouring, bleaching, mercerizing, stenter tentering of weft ripe or padding Naphthol liquid Naphthol, the wax liquid melted and mixed under the condition of 50 DEG C to 200 DEG C on a wax printing machine is uniformly printed on the fabric through a rotary screen on the condition of constant temperature, after the air-cooled or water-cooled solidification, the dyeing redox is dyed blue with flora on the indigo machine or the color flora machine is dyed with color through padding the azoic dyestuff, and then a wax swinging machine is pulled over the small circular hole in a rope shape. Under 40 DEG C, and by the machinery outside force, the wax membrane is cracked naturally, and through processing the wax-dyeing by using indigo, insoluble azo dyes, and India blue IBN etc., the wax print fabric with various glaze and different style of wax print can be obtained.

Owner:王化斌

High-denier high-density double-weft cloth and manufacturing technique thereof

The invention relates to a high count high density weft backed fabric and a manufacturing technique thereof, wherein, the fabric adopts weft backed weave structure; end spacing of the fabric is 240 ends per inch and weft density of the fabric is 240 picks per inch; warp threads adopt JC100 purified cotton folded yarns and weft yarns adopt JC80 purified cotton yarns. The manufacturing technique for the fabric is to adopt special technological methods in procedures like warping, slashing, denting, weaving and so on, thereby product quality is guaranteed, and quality and grade of products are obviously improved. By adoption of weft backed structure for weaving the high count high density fabric, the invention has the advantages of double-faced satin displayed on fabrics, bright luster of cloth covers, smooth hand feeling, refined grain and unique style; by adoption of 100 percent long stapled cotton, the invention has the characteristics of high count high density, flat and refined textile surface and good style of fabric covers.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

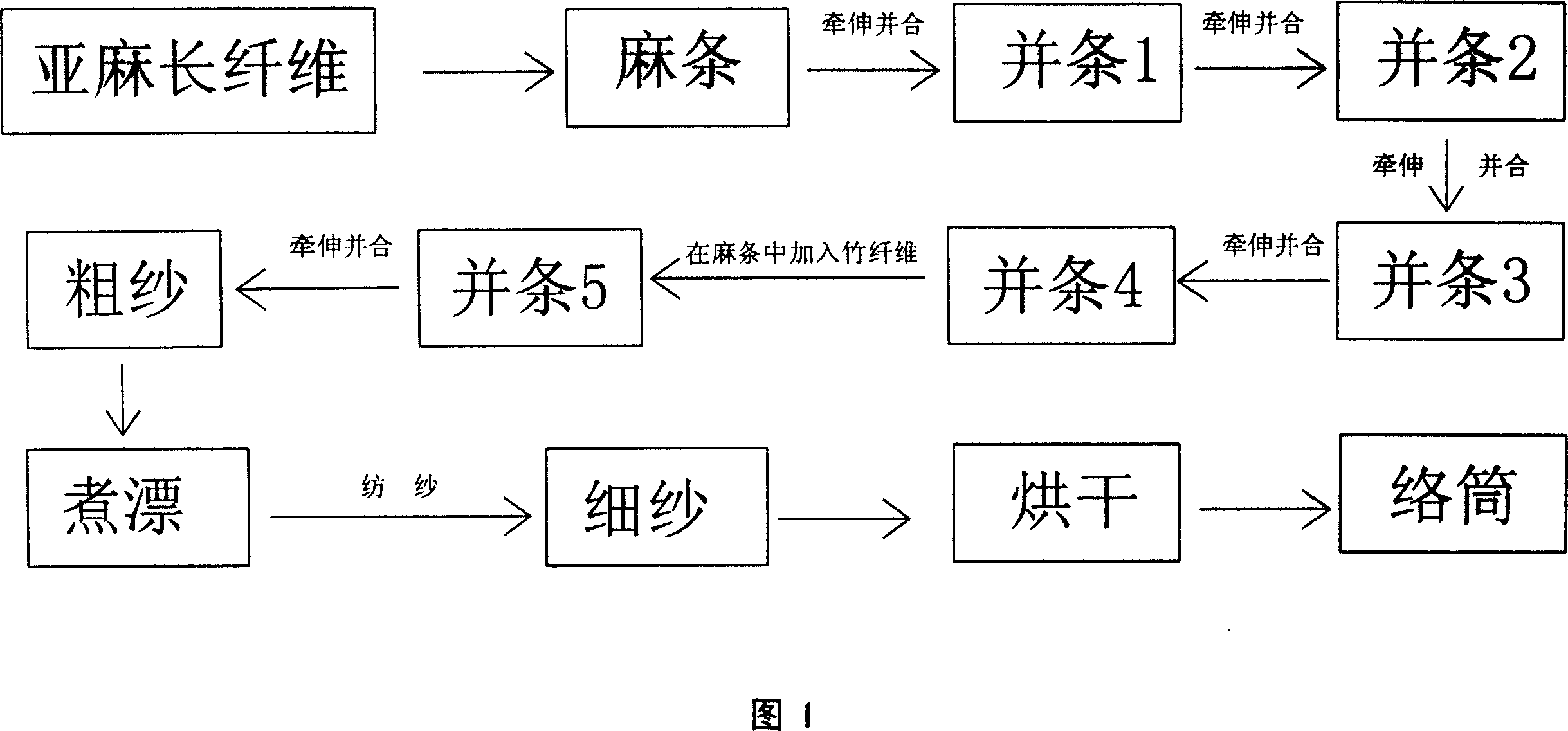

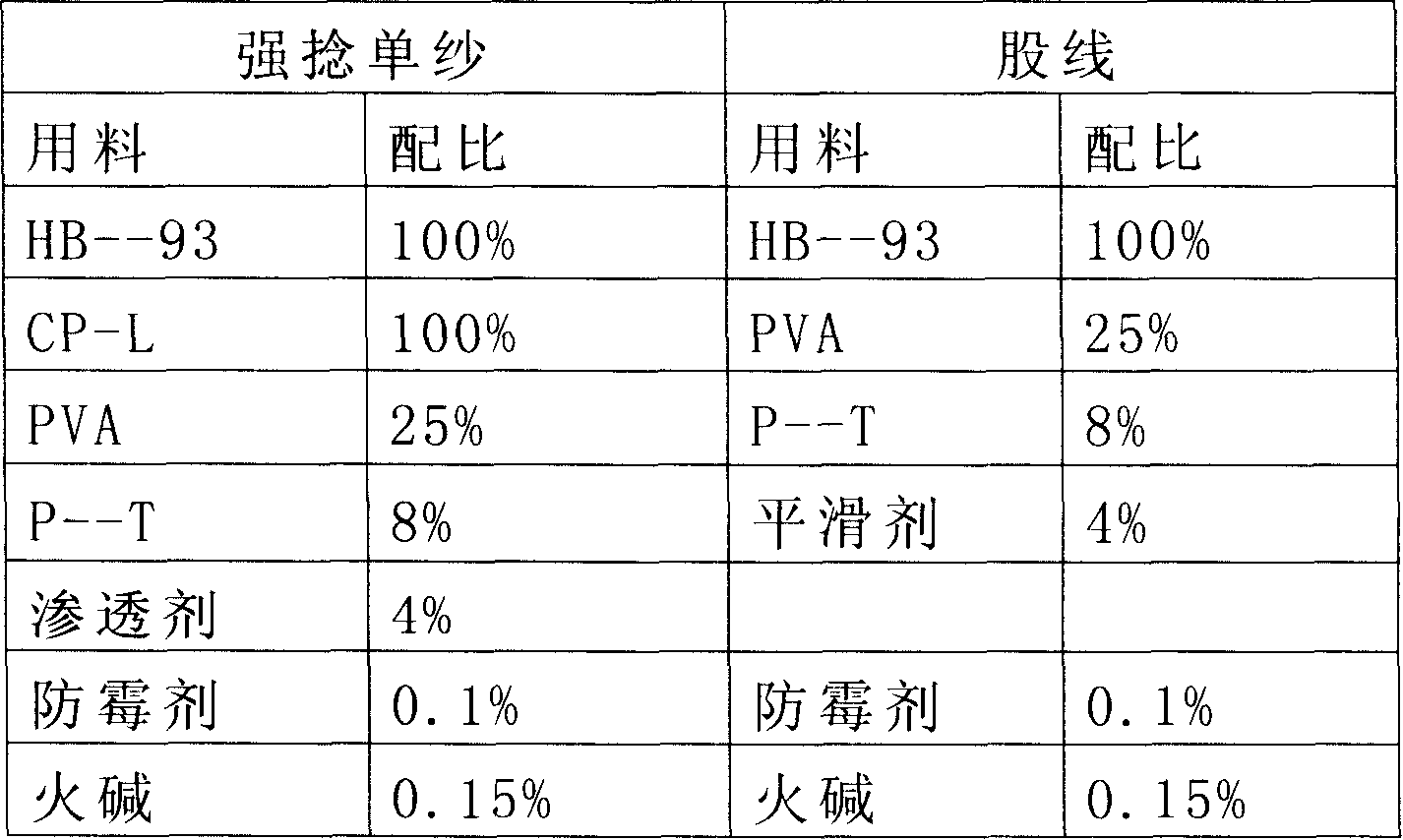

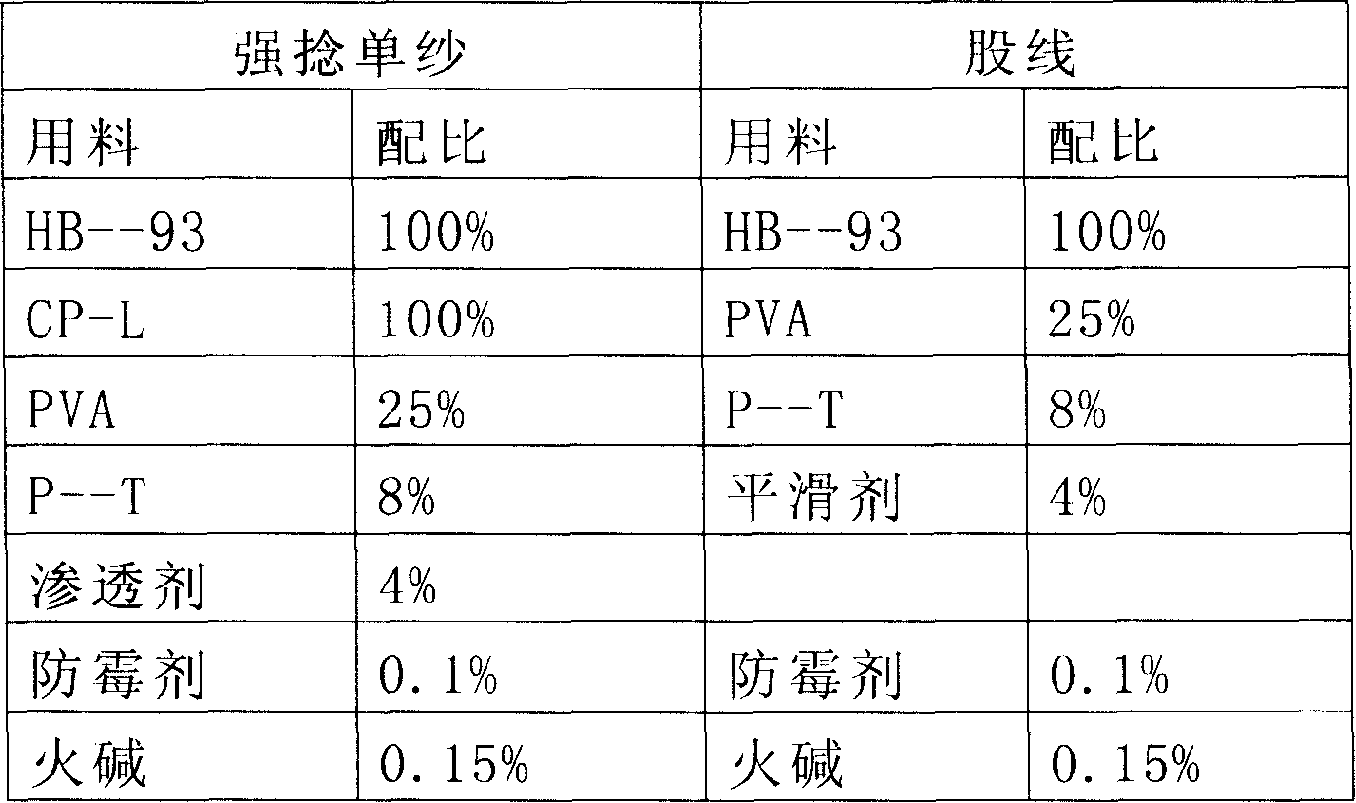

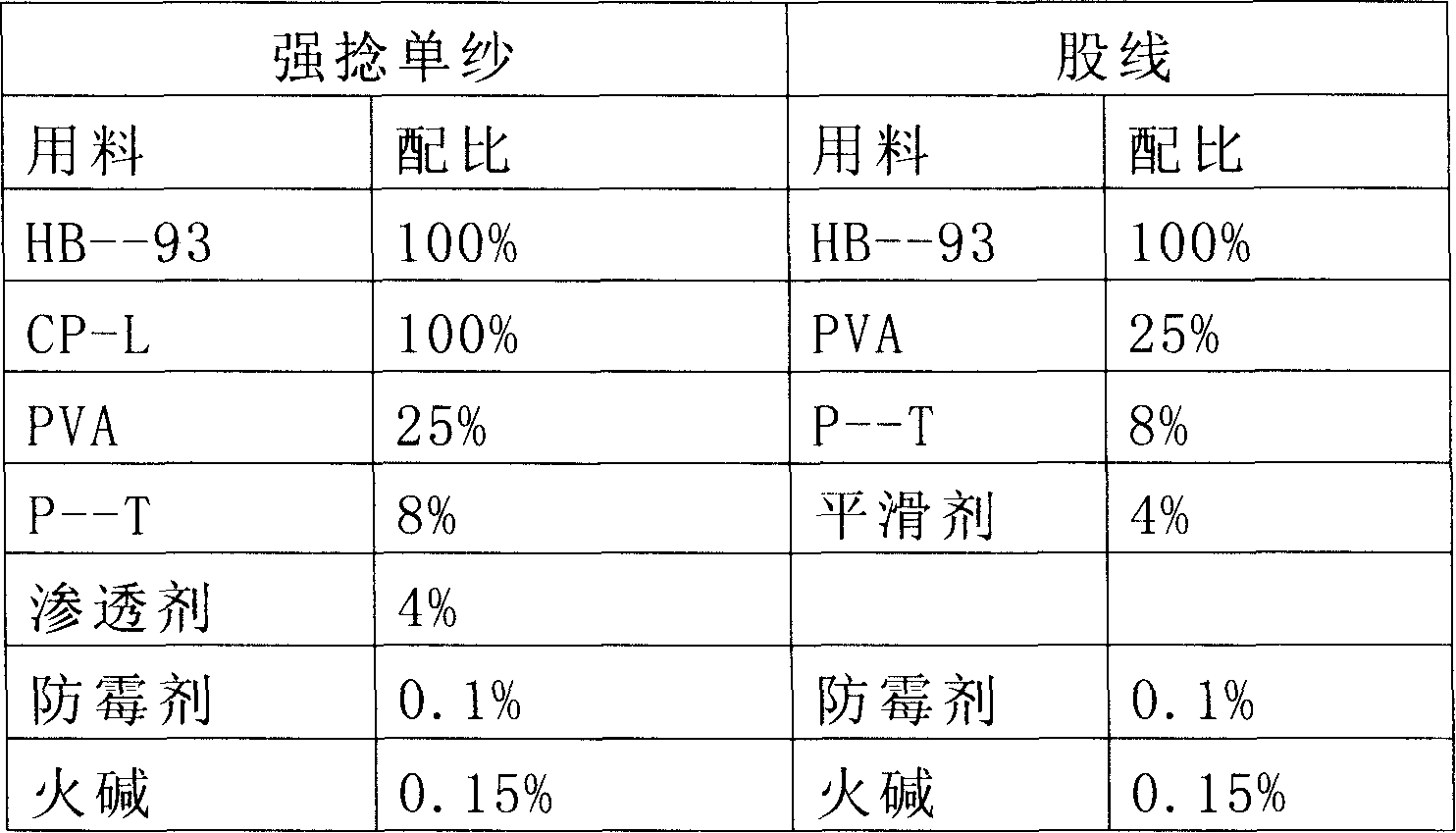

Flax blended spinning preparation process

The invention discloses a method for producing flax blended yarn used in clothes and face fabric, comprising that: preparing flax long fiber into flax bars; combing bars via at least five processes; adding bamboo fibers into combining process, while the bamboo fibers are 8-75mass% of total blended yarn mass; combing them and drawing to prepare rove; boiling and bleaching the rove; spinning into spun yarn; drying, coiling and shaping. The invention has simple process, while the product has uniform bars, beautiful appearance and smooth surface.

Owner:ZHEJIANG JINYUAN FLAX

Pure cotton heavy twist striated fabric and preparation technique thereof

The invention relates to a purified cotton hard twisted stripe and a manufacturing technique thereof, wherein, the stripe adopts combined weave of 5 / 2 kettsatin and 1 / 1 plain weave; end spacing of the stripe is 450.5 ends per ten centimeters and weft density of the stripe is 301 picks per ten centimeters; warp threads adopt JC7.3Tex single yarns with a twist number of 210 twists per ten centimeters and JC7.3Tex x 2 folded yarns; compound yarns are used for closely weaving satin weaves, and hard twisted single yarns are used for weaving plain weaves; fabrics are of thick and thin variable stripe effect; weft yarns adopt JC9.7Tex single yarns with a twist number of 240 twists per ten centimeters. In the aspect of the manufacturing technique, special technological methods are adopted in procedures like warping, slashing, denting, weaving and so on, thereby product quality is guaranteed, and quality and grade of products are obviously improved. Because the stripe adopts the combined weave of the 5 / 2 kettsatin and the 1 / 1 plain weave, the invention has the advantages of bright luster of cloth covers, smooth hand feeling and refined grain; because the compound yarns are used for closely weaving satin weaves and the hard twisted single yarns are used for weaving plain weaves, the fabrics are of thick and thin variable stripe effect and the style is unique.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

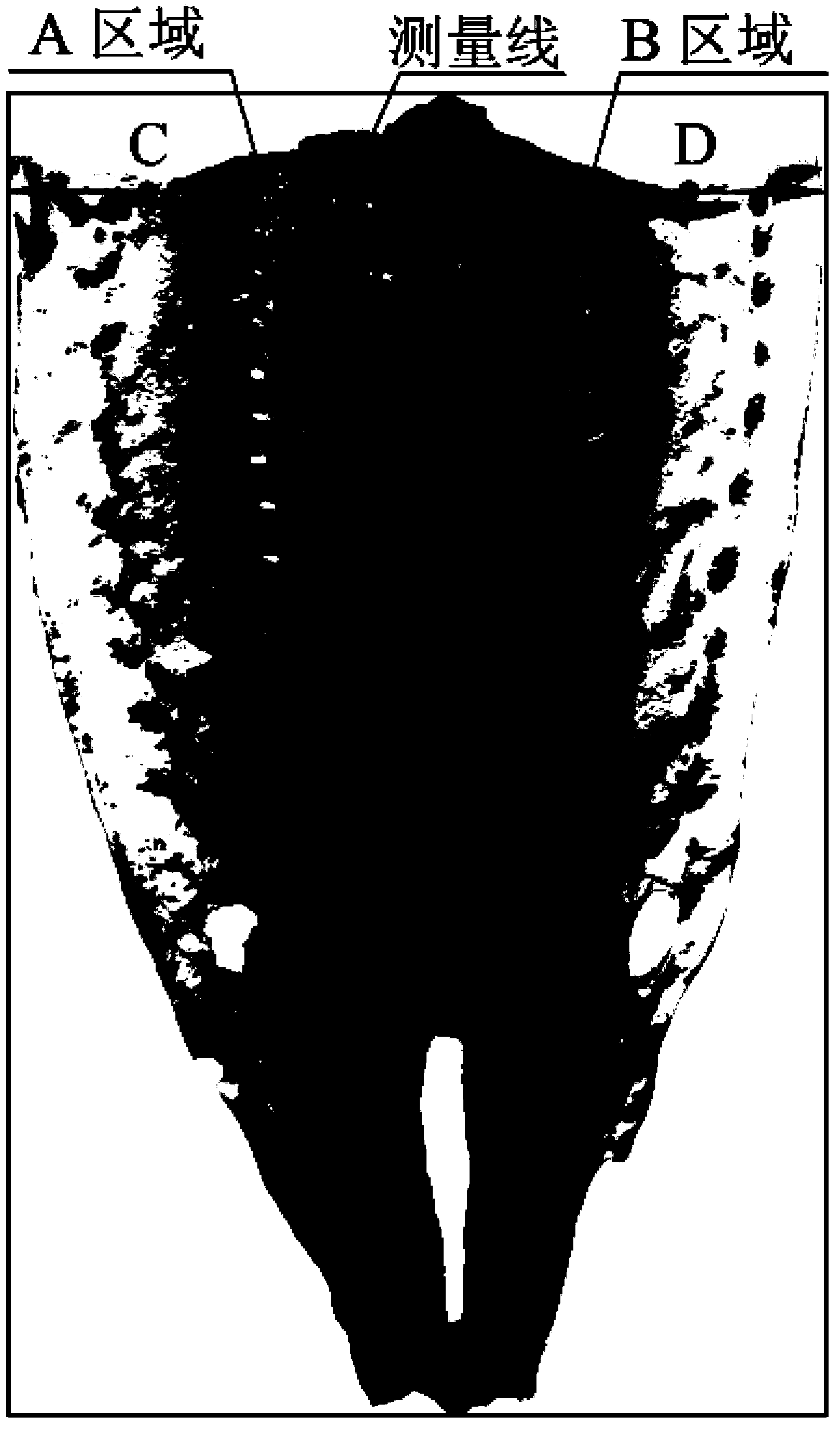

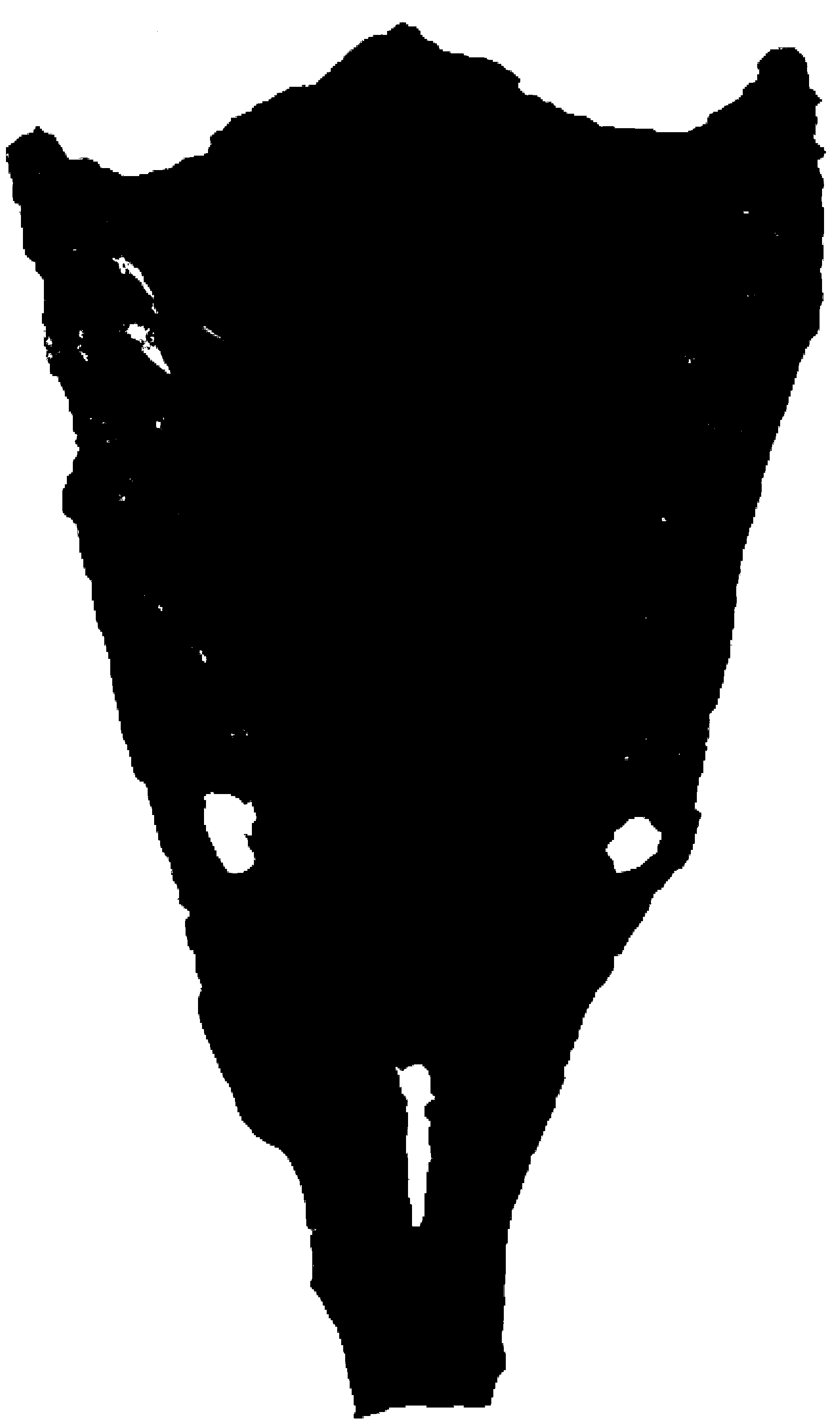

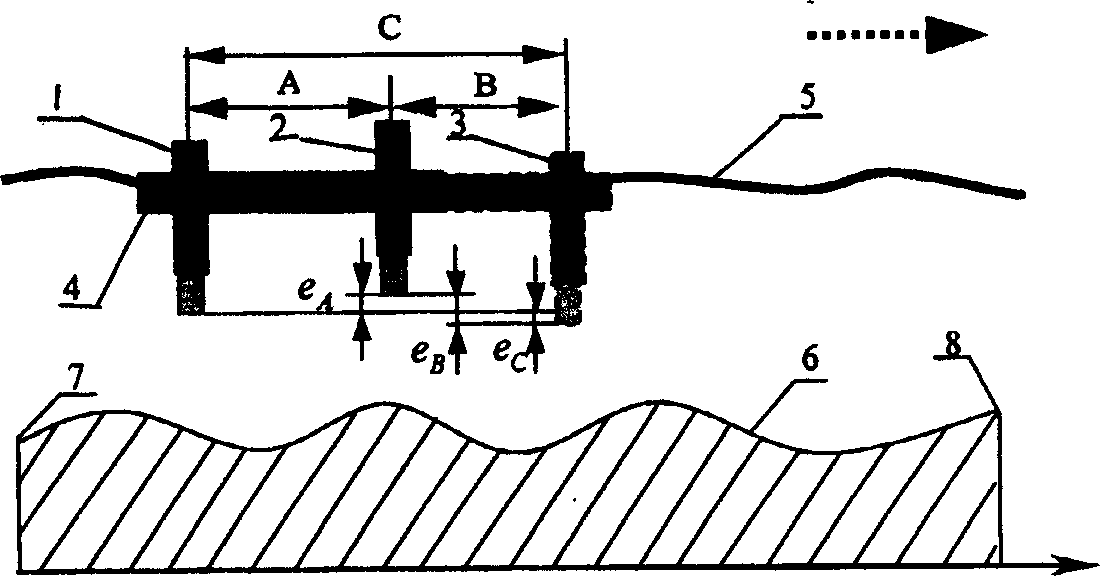

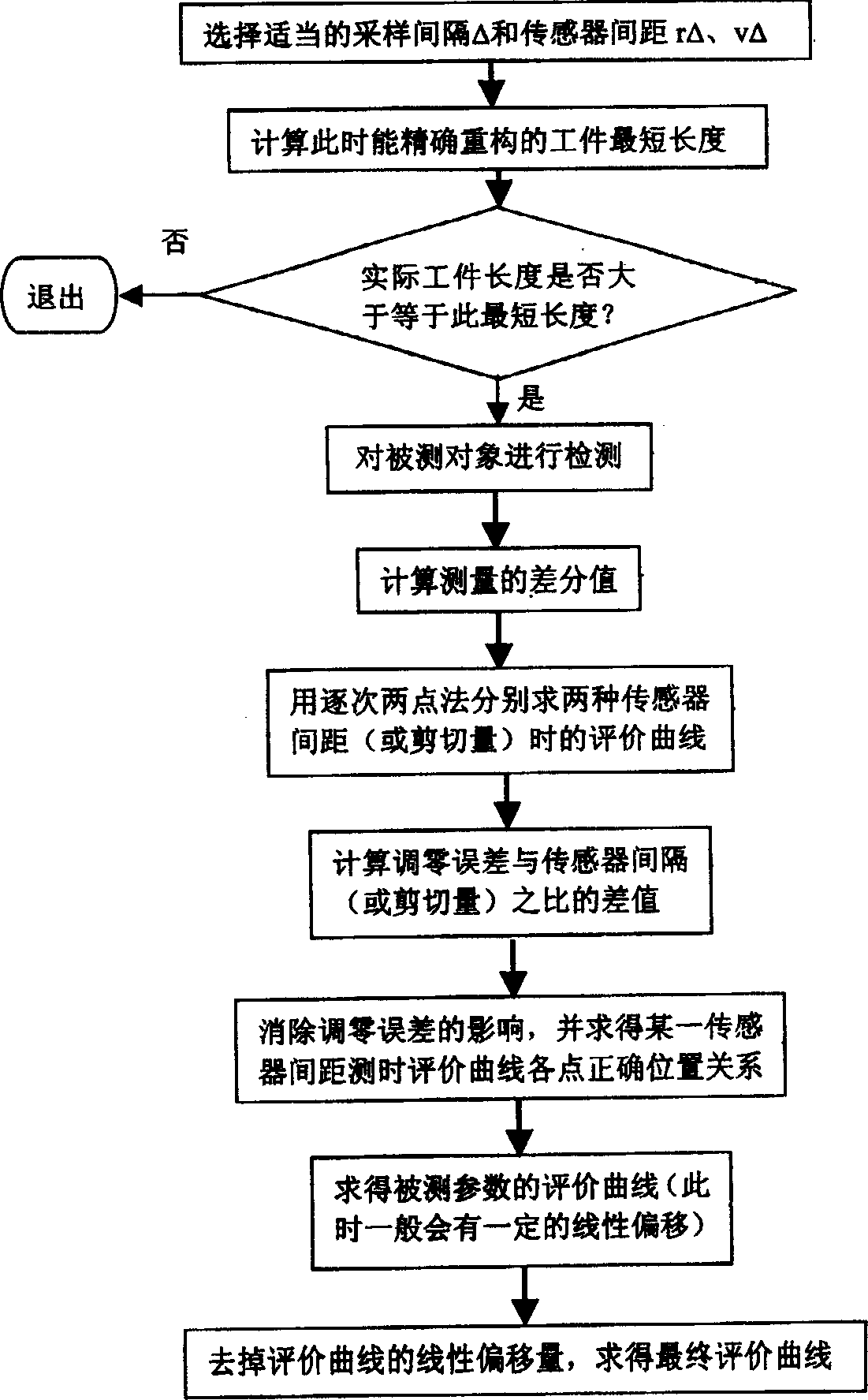

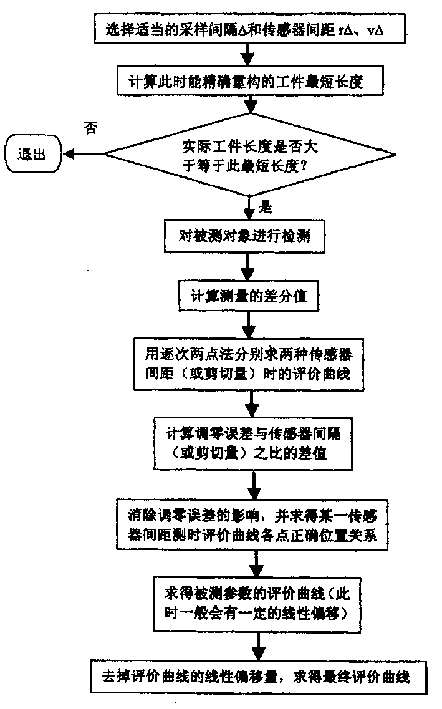

Method for utilizing time domain method to make difference measurement of accurate reconfiguration

InactiveCN1477369ASmoothHas a cycleElectric/magnetic contours/curvatures measurementsUsing optical meansTime domainDifferential measurement

The method for making accurate restructure of difference measurement by using time domain is characterized by that according to the difference value obtained by measuring two different separation distances or shearing quanties of measured object, respectively using successive two-point method to evaluate two groups of different difference values, the number of evaluation curves obtained by every group is the ratio value of correspondent sensor separation distance or shearing quantity and sampling interval, then utilizing the interrelationship between two groups of the curves to calculate the influence of zero modulation error to the evaluation result so as to resolve the interrelationship between every curves in the two groups of curves, finally synthesizing these curves into an evaluation curve.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com