Novel PU printing waterproof and anti-crease fabric and preparation method thereof

A new type of printing technology, applied in chemical instruments and methods, dyeing methods, layered products, etc., can solve the problems of large pattern limitations, lack of three-dimensional sense, layered sense, etc., to reduce the phenomenon of depression, feel full and artistic high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

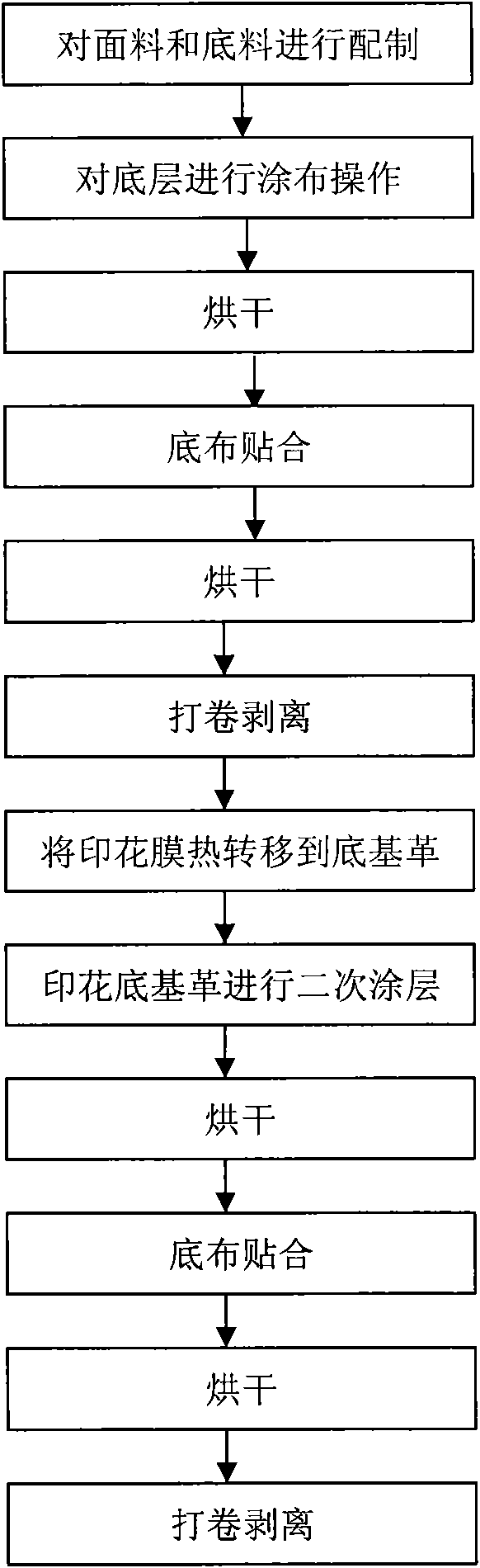

[0036] The method for manufacturing PU printing waterproof, anti-wrinkle novel fabric comprises the following steps:

[0037] (1) The fabric and base material are prepared. The prepared PU slurry contains 100 parts of resin with a modulus of 50, 10 parts of dimethylformamide, 10 parts of butanone, and 60 parts of toluene. The prepared concentration is 3000 cps;

[0038] (2) Put the configured slurry to defoam and filter; then add the static slurry to the release paper, the thickness between the roller and the release paper is 18 wires, and then dry it. The drying temperature is 65 degrees, and the drying time is 20s;

[0039] (3) The knitted cloth is covered on the base material after drying in step 2, and then a 4KG air roller is added on the base cloth;

[0040] (4) Dry the base material covered with knitted cloth again, the drying temperature is 100 degrees, and the drying time is 50s;

[0041] (5) Separate the release paper from the PU leather and roll them separately; ...

Embodiment 2

[0049] The method for manufacturing PU printing waterproof, anti-wrinkle novel fabric comprises the following steps:

[0050] (1) The fabric and base material are prepared. The prepared PU slurry contains 100 parts of resin with a modulus of 50, 10 parts of dimethylformamide, 10 parts of butanone, and 70 parts of toluene, and the prepared concentration is 3000 cps;

[0051] (2) Put the configured slurry to defoam and filter; then add the static slurry to the release paper, the thickness between the roller and the release paper is 18 wires, and then dry it. The drying temperature is 65 degrees, and the drying time is 20s;

[0052] (3) The knitted cloth is covered on the base material after drying in step 2, and then a 4KG air roller is added on the base cloth;

[0053] (4) Dry the base material covered with knitted cloth again, the drying temperature is 110 degrees, and the drying time is 60s;

[0054] (5) Separate the release paper from the PU leather and roll them separately;...

Embodiment 3

[0062] The method for manufacturing PU printing waterproof, anti-wrinkle novel fabric comprises the following steps:

[0063] (1) The fabric and base material are prepared. The prepared PU slurry contains 100 parts of resin with a modulus of 50, 10 parts of dimethylformamide, 10 parts of butanone, and 90 parts of toluene, and the prepared concentration is 3000 cps;

[0064] (2) Put the configured slurry to defoam and filter; then add the static slurry to the release paper, the thickness between the roller and the release paper is 18 wires, and then dry it. The drying temperature is 65 degrees, and the drying time is 20s;

[0065] (3) The knitted cloth is covered on the base material after drying in step 2, and then a 4KG air roller is added on the base cloth;

[0066] (4) Dry the base material covered with knitted cloth again, the drying temperature is 135 degrees, and the drying time is 70s;

[0067] (5) Separate the release paper from the PU leather and roll them separatel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com