Metal shell with ceramic panel and preparation method thereof, and application of metal shell as communication device case

A metal shell and metal shell technology, applied in the field of shell and its preparation, can solve the problems of shell strength and impact resistance reduction, large gaps or steps, and affecting the appearance of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

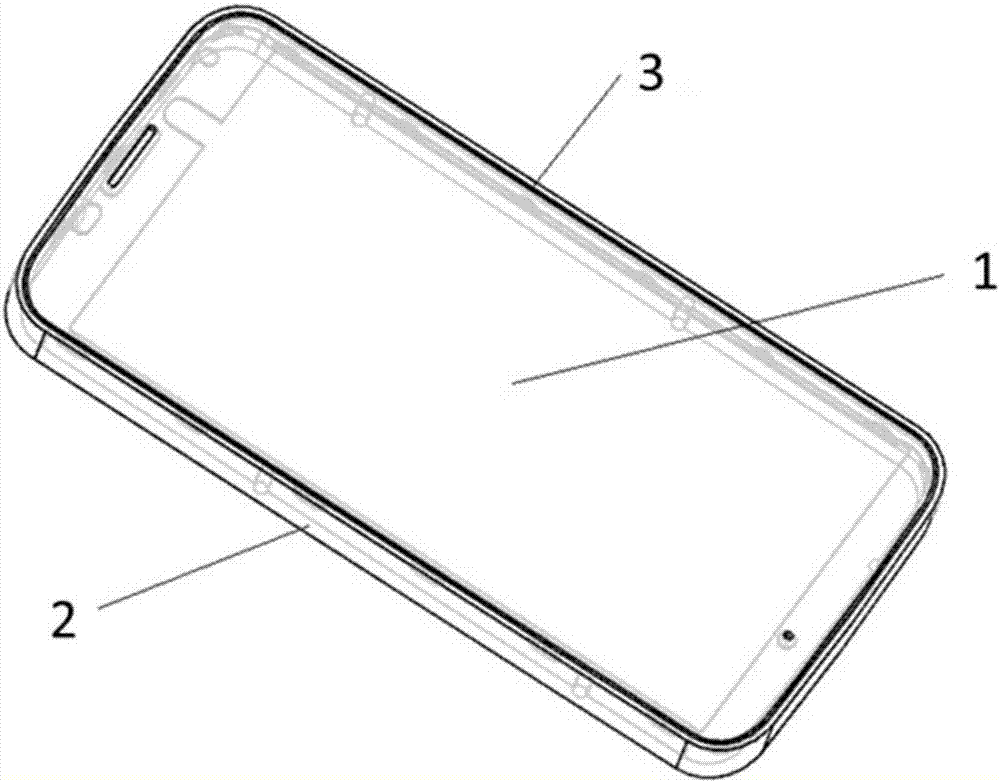

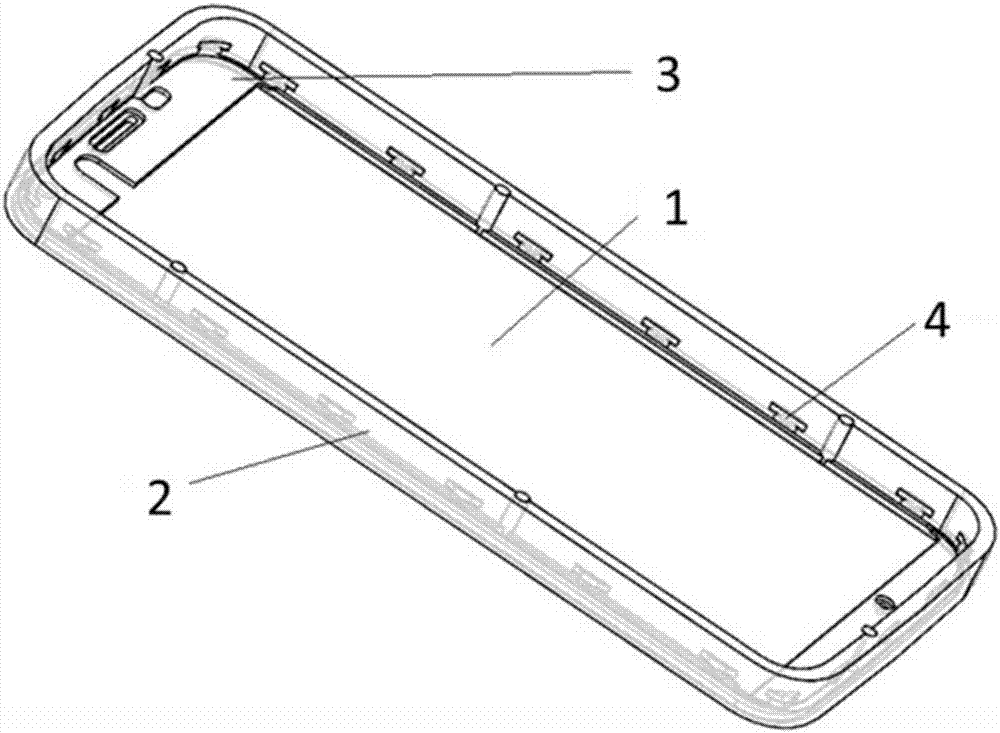

[0053] The present invention also provides a method for preparing a metal shell with a ceramic panel, wherein the method includes the following steps:

[0054] (1) placing the ceramic panel and the metal frame into the injection mold, and making a certain gap between the surroundings of the ceramic panel and the metal frame;

[0055] (2) The plastic layer is formed by injection molding a resin composition.

[0056] According to the present invention, in step (1), by placing the ceramic panel and the metal frame into the injection mold, keeping a gap of uniform size between the two and keeping the upper surfaces of the two flush in the mold, and then through the step ( 2) Injection molding to form the plastic layer.

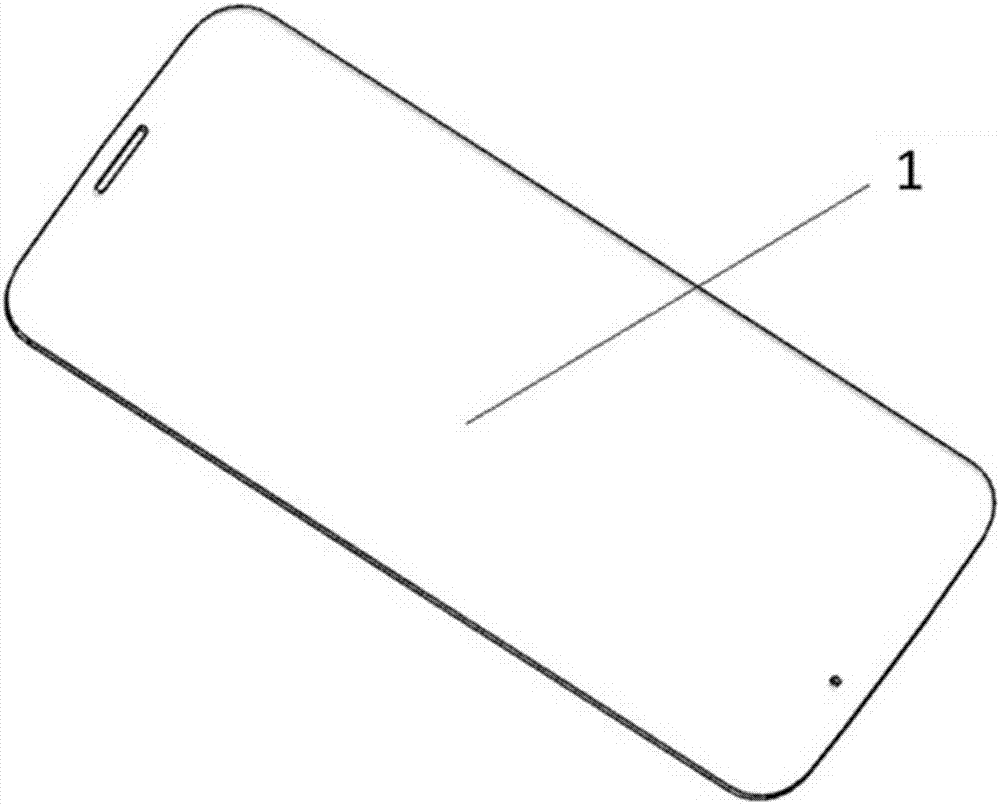

[0057] According to the present invention, the material of the ceramic panel can be conventionally selected ceramics in the field, preferably one or more of zirconia, alumina and silicon oxide. These ceramic panels can be obtained commercially, for example, zirc...

Embodiment 1

[0090] This embodiment is used to illustrate the metal shell with ceramic panels and the preparation method thereof provided by the present invention.

[0091] 1) The metal frame is obtained by CNC machining. The length of the metal frame is 127mm, the width is 65mm, and the thickness is 8.2mm. The material of the metal frame is aluminum alloy, and the thickness of the metal material is 1.5mm;

[0092] 2) The inner surface of the ceramic panel (purchased from Shenzhen Haideji Ceramics Co., Ltd. zirconia ceramic sheet, length 123mm, width 61mm, thickness 0.5mm) is covered with a cured adhesive layer after printing and drying (The adhesive used is purchased from NoriPress SMK adhesive of Baolong Company, Germany, and the thickness after curing is 0.05mm);

[0093] 3) The inner side of the metal frame is processed by CNC to form a rubberized structure (the rubberized structure is an inverted T-shaped dovetail groove structure, and the distance between two adjacent rubberized stru...

Embodiment 2

[0097] This embodiment is used to illustrate the metal shell with ceramic panels and the preparation method thereof provided by the present invention.

[0098] 1) The metal frame is obtained by CNC machining. The length of the metal frame is 127mm, the width is 65mm, and the thickness is 8.2mm. The material of the metal frame is aluminum alloy, and the thickness of the metal material is 1.5mm;

[0099] 2) The inner surface of the ceramic panel (zirconia ceramic sheet purchased from Shenzhen Haideji Ceramics Co., Ltd., with a length of 123.4 mm, a width of 61.4 mm, and a thickness of 0.5 mm) is covered with a layer of cured adhesive after printing and drying Agent layer (the adhesive used is purchased from NoriPress SMK adhesive of Baolong Company, Germany, and the thickness after curing is 0.05mm);

[0100] 3) After dispensing and drying, the inner surface of the metal frame is covered with a cured adhesive layer (the adhesive used is purchased from NoriPress SMK adhesive from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com