Pure cotton heavy twist striated fabric and preparation technique thereof

A manufacturing process and fabric technology, which is applied in the field of pure cotton strong-twisted striped fabric and its manufacturing process, can solve the problems of rare fabrics and unseen technical data, achieve smooth hand feeling, bright luster of cloth surface, and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

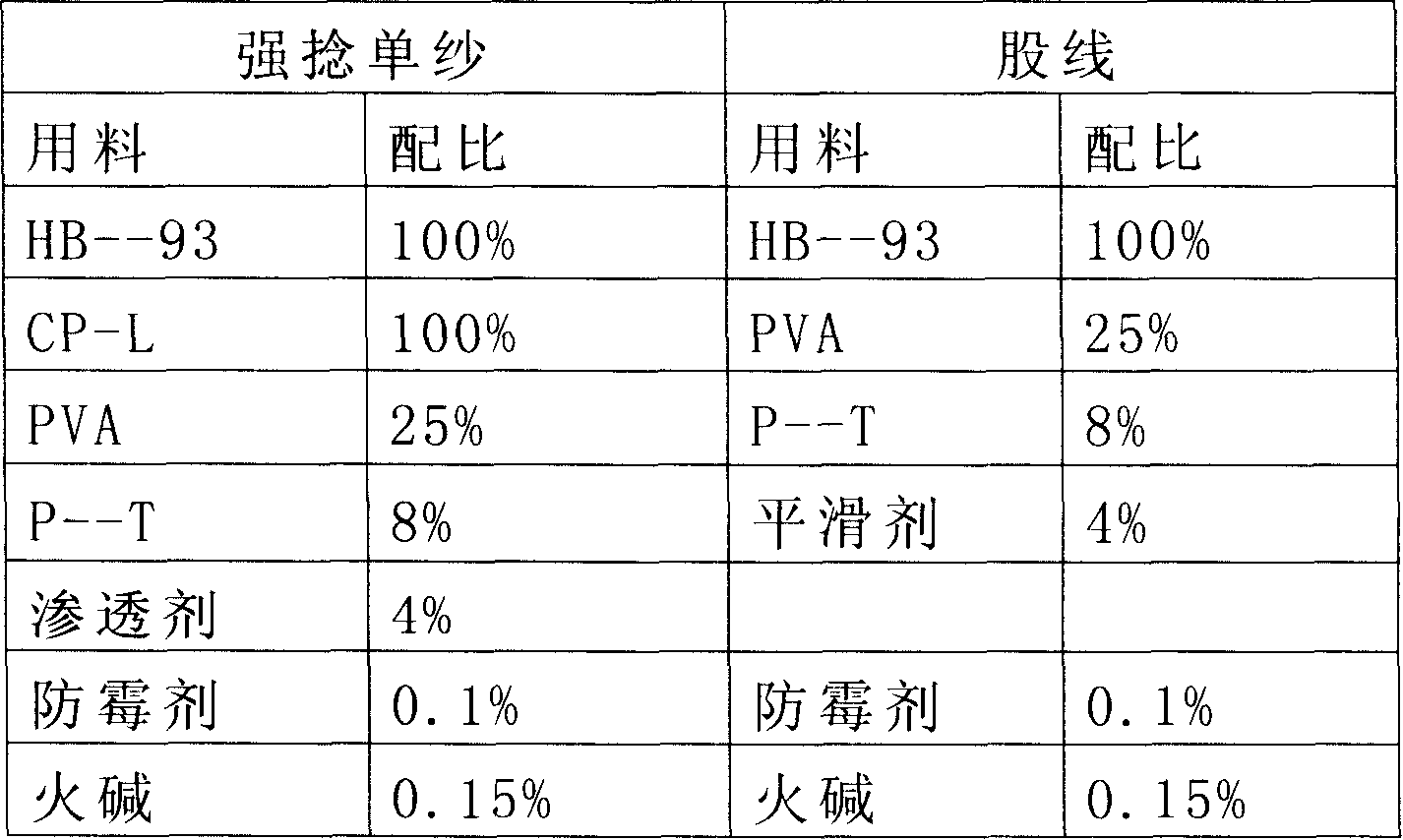

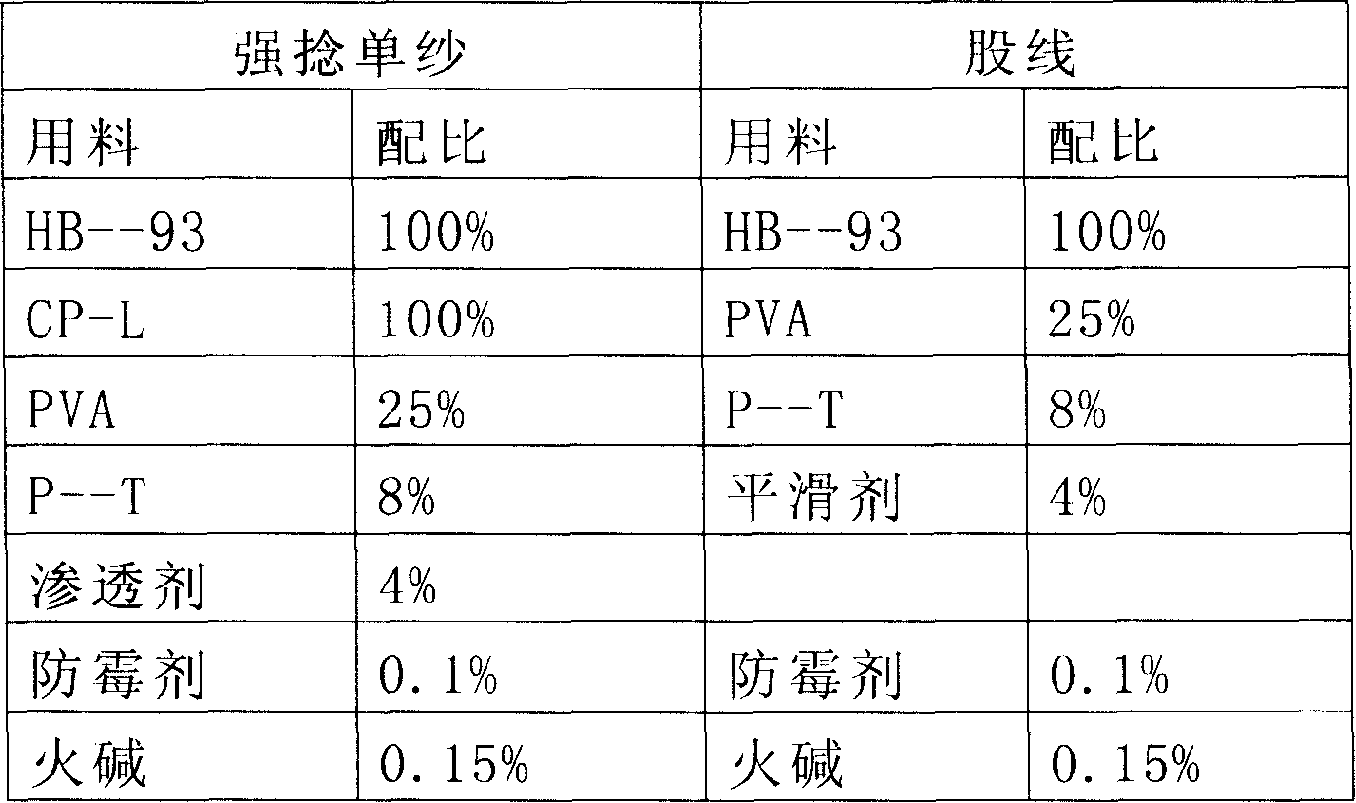

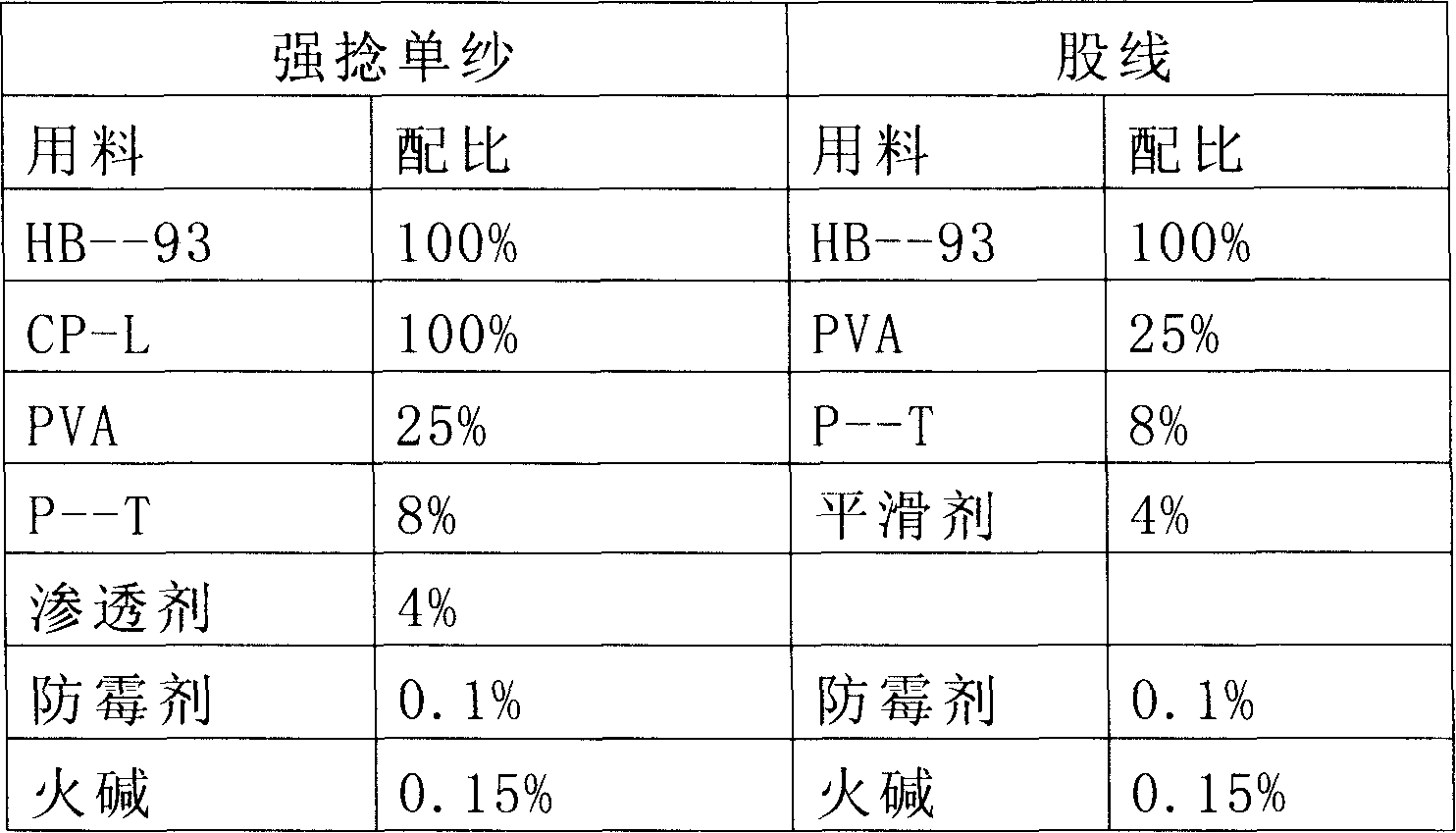

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment.

[0025] 1. Fabric

[0026] 1. Yarn: JC7.3Tex single yarn and JC7.3Tex×2 ply yarn with 210 twists / 10cm are used as warp yarn, arranged in a certain proportion according to the fabric weaving requirements. The weft yarn is JC9.7Tex single yarn with 240 twists / 10cm.

[0027] 2. Fabric: The joint weave of 5 / 2 warp satin + 1 / 1 plain weave is adopted, the warp density is 450.5 threads / 10cm, and the weft density is 301 threads / 10cm. The warp yarn adopts 210 twist / 10cm JC7.3Tex single yarn and JC7.3Tex×2 ply yarn, which are arranged in a certain proportion according to the fabric weave requirements. It presents the effect of thin and dense alternate strips.

[0028] The specific arrangement is: 24 plain weaves: 8 satin weaves: 24 plain weaves: 20 satin weaves: 16 plain weaves: 24 satin weaves: 16 plain weaves: 36 satin weaves: 16 plain weaves: 24 satin weaves: 16 Plain: 20 satin: 24 plain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com