Flax wet-spun blended yarn and preparation method and spinning frame of flax wet-spun blended yarn

A technique for blending yarn, flax, applied to spinning machines, spinning machines for continuous winding, yarn, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

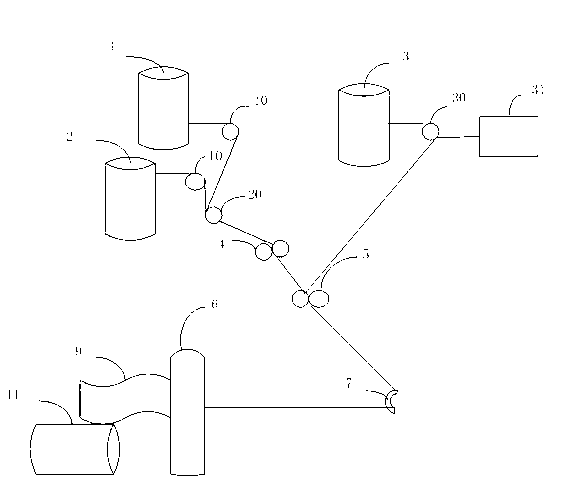

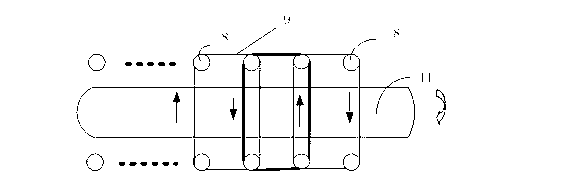

Image

Examples

Embodiment 1

[0032] (1) Selection of raw materials → combing machine → batching → sliver forming → (No. 0 draw frame → 1 draw frame → 2 draw frame → 3 draw frame → final draw frame) total 5-way drawing processing → roving, divide the processed roving into the first flax roving and the second flax roving, and then carry out the following steps respectively;

[0033] (2) Prepare two dyed flax rovings (including color and count) and polyester filaments according to customer requirements. The ratio finally determined by the orthogonal test method of mathematical statistics is: the percentage of the polyester filament weight content accounting for the total weight of the flax wet spinning blended yarn is 2%, and the balance is the first flax roving and the second The difference in count between the second flax roving, the first flax roving and the second flax roving does not exceed 1.2 counts;

[0034] 2. Roving pretreatment, flax semi-degumming and dyeing:

[0035] (1) Roving pretreatment an...

Embodiment 2

[0043] (1) Selection of raw materials → combing machine → batching → sliver forming → (No. 0 draw frame → 1 draw frame → 2 draw frame → 3 draw frame → final draw frame) total 5-step drawing processing → roving processing, divide the processed roving into the first flax roving and the second flax roving, and then carry out the following steps respectively;

[0044] (2) Prepare two dyed flax rovings (including color and count) and polyester filaments according to customer requirements. The ratio finally determined by the orthogonal test method of mathematical statistics is: the weight content of the polyester filament accounts for the percentage of the total weight of the flax wet-spun blended yarn: 2.5%, and the balance is the first flax roving and the second The difference in count between the second flax roving, the first flax roving and the second flax roving does not exceed 1.2 counts;

[0045] 2. Roving pretreatment, flax semi-degumming and dyeing:

[0046] (1) Roving pr...

Embodiment 3

[0054] (1) Selection of raw materials → combing machine → batching → sliver forming → (No. 0 draw frame → 1 draw frame → 2 draw frame → 3 draw frame → final draw frame) total 5-step drawing processing → roving processing, divide the processed roving into the first flax roving and the second flax roving, and then carry out the following steps respectively;

[0055] (2) Prepare two dyed flax rovings (including color and count) and polyester filaments according to customer requirements. The ratio finally determined by the orthogonal test method of mathematical statistics is: the percentage of the weight content of the polyester filament in the total weight of the flax wet spinning blended yarn is 3%, and the balance is the first flax roving and the second The difference in count between the second flax roving, the first flax roving and the second flax roving does not exceed 1.2 counts.

[0056] 2. Roving pretreatment, flax semi-degumming and dyeing:

[0057] (1) Roving pretreat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com