Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Adhesive enough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

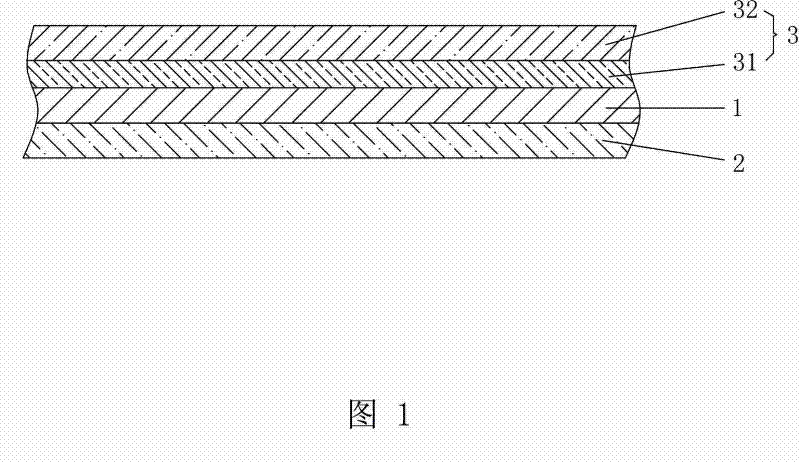

Multi-layer thermal transfer ribbon and manufacturing method thereof

The invention relates to a multi-layer thermal transfer ribbon and a manufacturing method thereof, and the multi-layer thermal transfer ribbon comprises a membranous base band, a heat-resistant printing ink layer and a heat transfer printing ink layer, wherein the heat-resistant printing ink layer is coated on one side of the base band, the heat transfer printing ink layer is coated on the other side of the base band, the heat transfer printing ink layer comprises a stripping printing ink layer and an adhesive printing ink layer, the stripping printing ink layer is directly coated on the surface of the base band, the adhesive printing ink layer is coated on the stripping printing ink layer, printing ink in the striping printing ink layer is hot-melting type printing ink, and the printing ink in the adhesive printing ink layer is the hot-melting type printing ink or solvent type printing ink. The heat transfer printing ink layer of the multi-layer mixed-based ribbon can be easily completely stripped off the base band, and the great adhesive ability is realized on a smooth medium; in addition, the multi-layer thermal transfer ribbon further has the advantages of high resolution, clear printing, anti-friction property, moisture resistance, chemical corrosion resistance, environment friendliness and the like.

Owner:泉州市山水电脑耗材有限公司

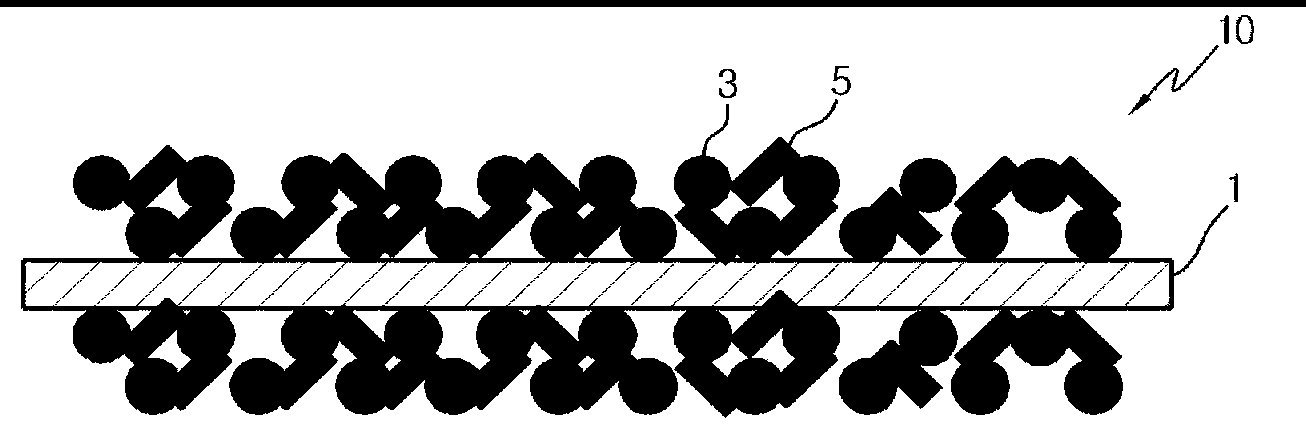

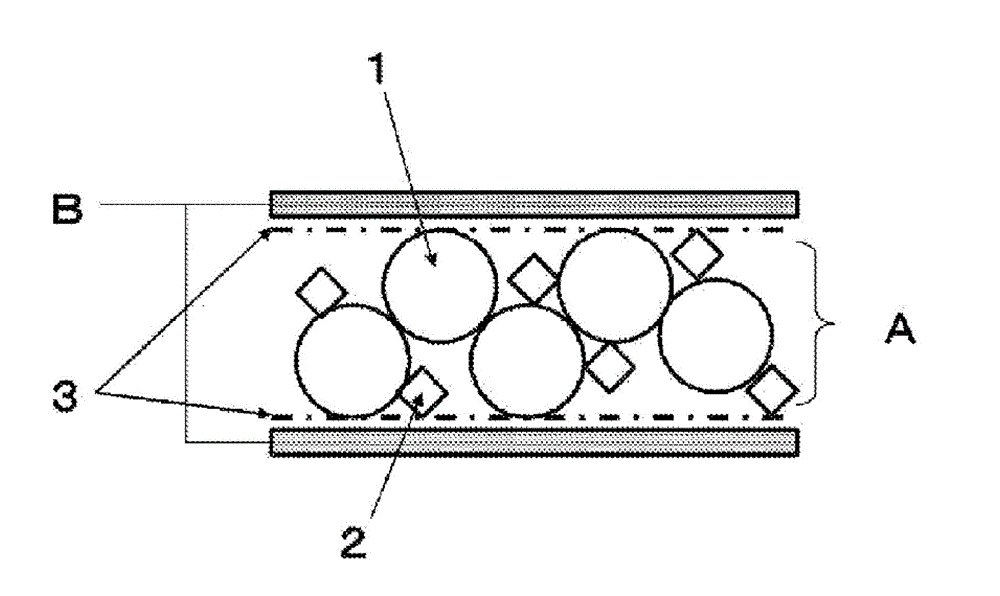

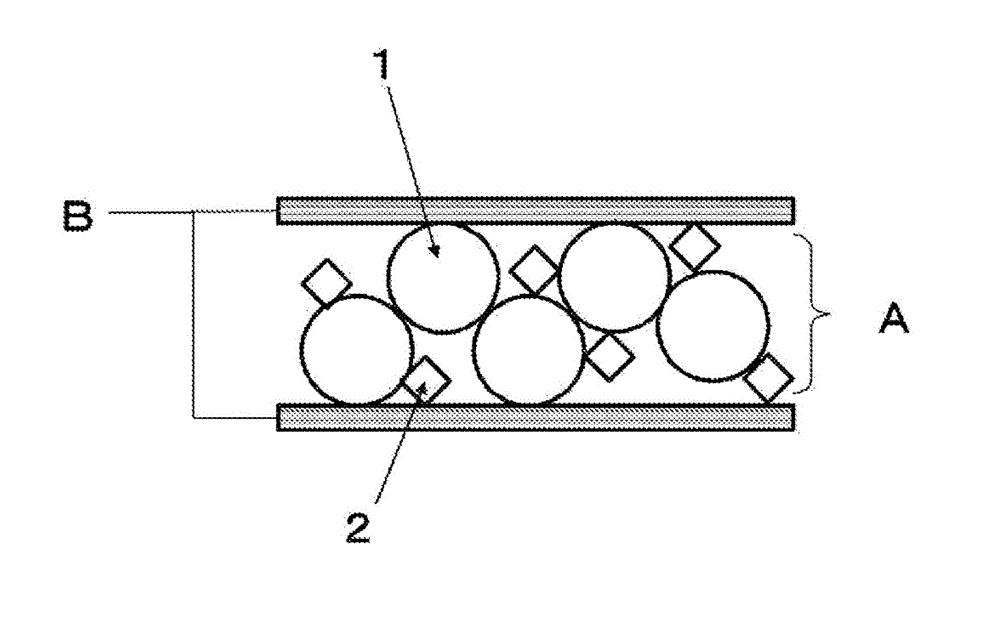

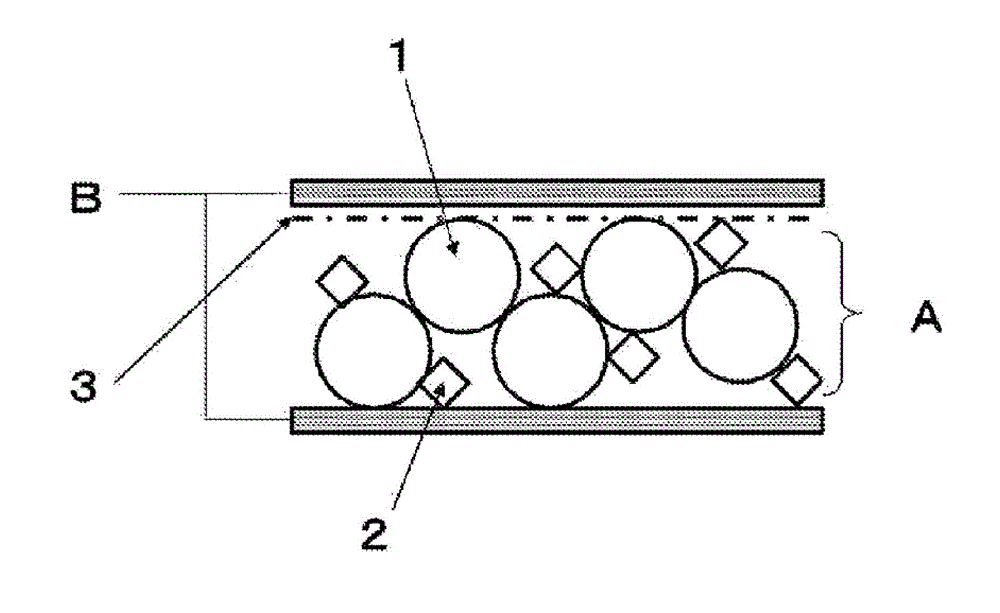

Method for manufacturing separator and electro-chemical device equipped with separator manufactured thereby

ActiveCN103814459AInhibition lossImprove adhesionFinal product manufactureSecondary cells manufacturePorous substratePorous coating

The present invention relates to a method for manufacturing a separator, comprising the following steps: (S1) preparing a planar porous substance having a plurality of pores; (S2) forming a porous coating layer by applying a coating solution in which inorganic particles are scattered and a binder polymer is dissolved in a solvent, onto the porous substance, and drying the porous coating layer; and (S3) forming an adhesive layer by introducing a binder solution to a surface of the dried porous coating layer, wherein the surface energy of the binder solution is larger by as much as 10mN / m when compared to the surface energy of the porous coating layer, and a contact angle of the binder solution with respect to the surface of the porous coating layer is maintained at 80 degrees or more for 30 seconds. The method according to the present invention can easily manufacture the separator capable of minimizing the amount of adhesive to be used for bonding an electrode, ensuring sufficient bonding force to the electrode using a small amount of adhesive, and minimizing the deterioration of battery performance.

Owner:LG ENERGY SOLUTION LTD +1

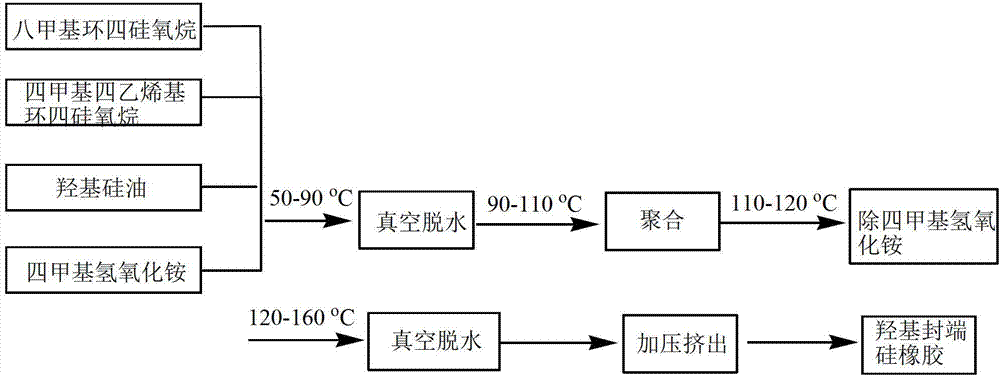

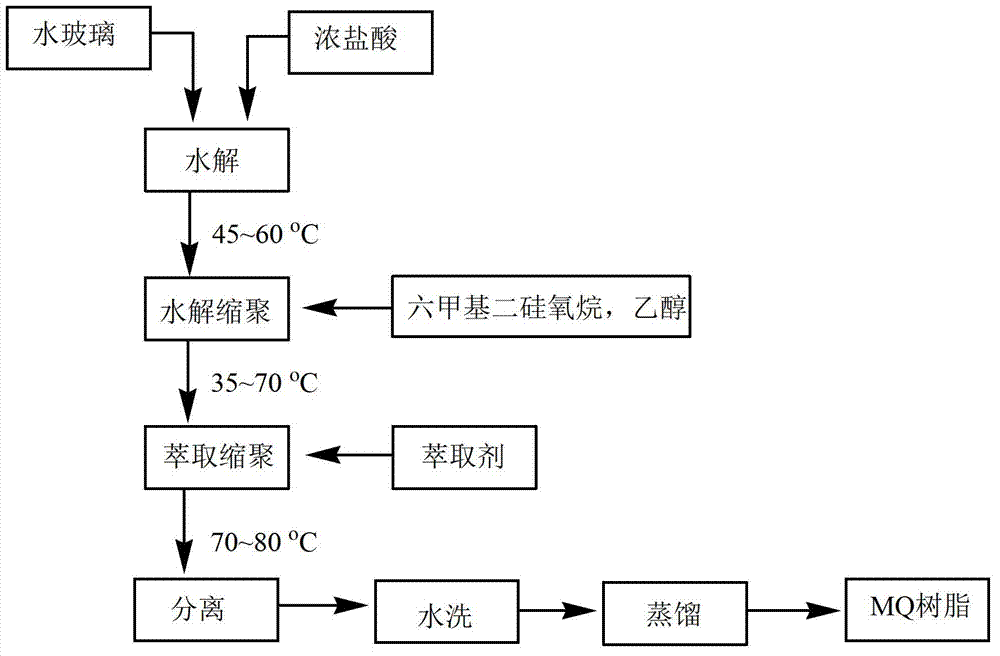

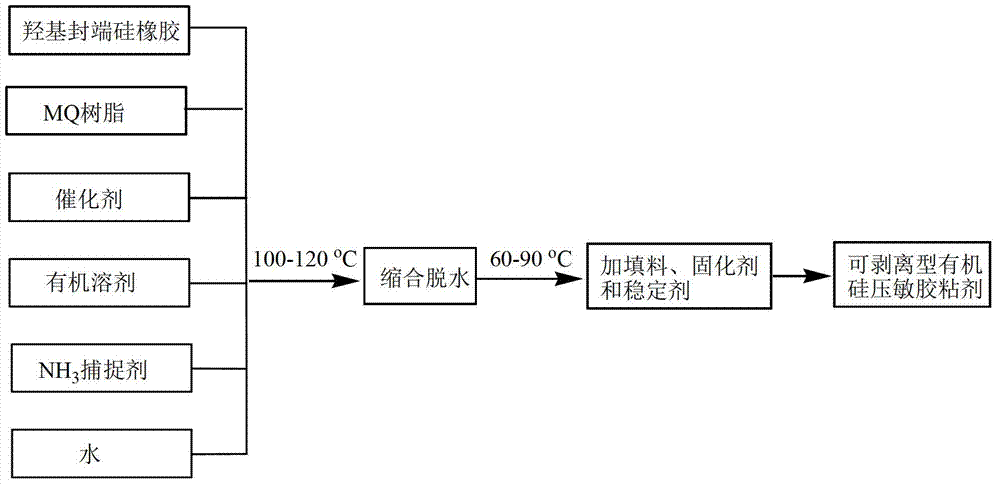

Preparation method of peelable type organosilicon pressure-sensitive adhesive

InactiveCN102876249AStir wellGood storage stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesive cementEndcapping

The invention provides a preparation method of a peelable type organosilicon pressure-sensitive adhesive. The preparation method comprises the following steps: firstly, synthesizing MQ resin by adopting a water glass method; secondly, synthesizing carboxyl-terminated silicone rubber by adopting a direct equilibrium copolymerization method; and finally, mixing the MQ resin, the carboxyl-terminated silicone rubber and an organic solvent in a certain proportion and stirring evenly, adding a certain amount of catalyst, a filling material, a curing agent and a stabilizing agent and stirring evenly, heating for reflux reaction for a certain time, and cooling and vacuumizing to remove the solvent as much as possible, so as to obtain the peelable type organosilicon pressure-sensitive adhesive. The method better solves the difficult problems of high coating fragility, bad peelability, poor durability and weatherability, higher cost and the like of the conventional peelable type organosilicon pressure-sensitive adhesive product. The peelable type organosilicon pressure-sensitive adhesive has excellent storage stability, film forming property, water resistance and peelability, leaves no mark after being peeled off a base material and can be reused without losing adhesiveness.

Owner:杭州材聚科技有限公司

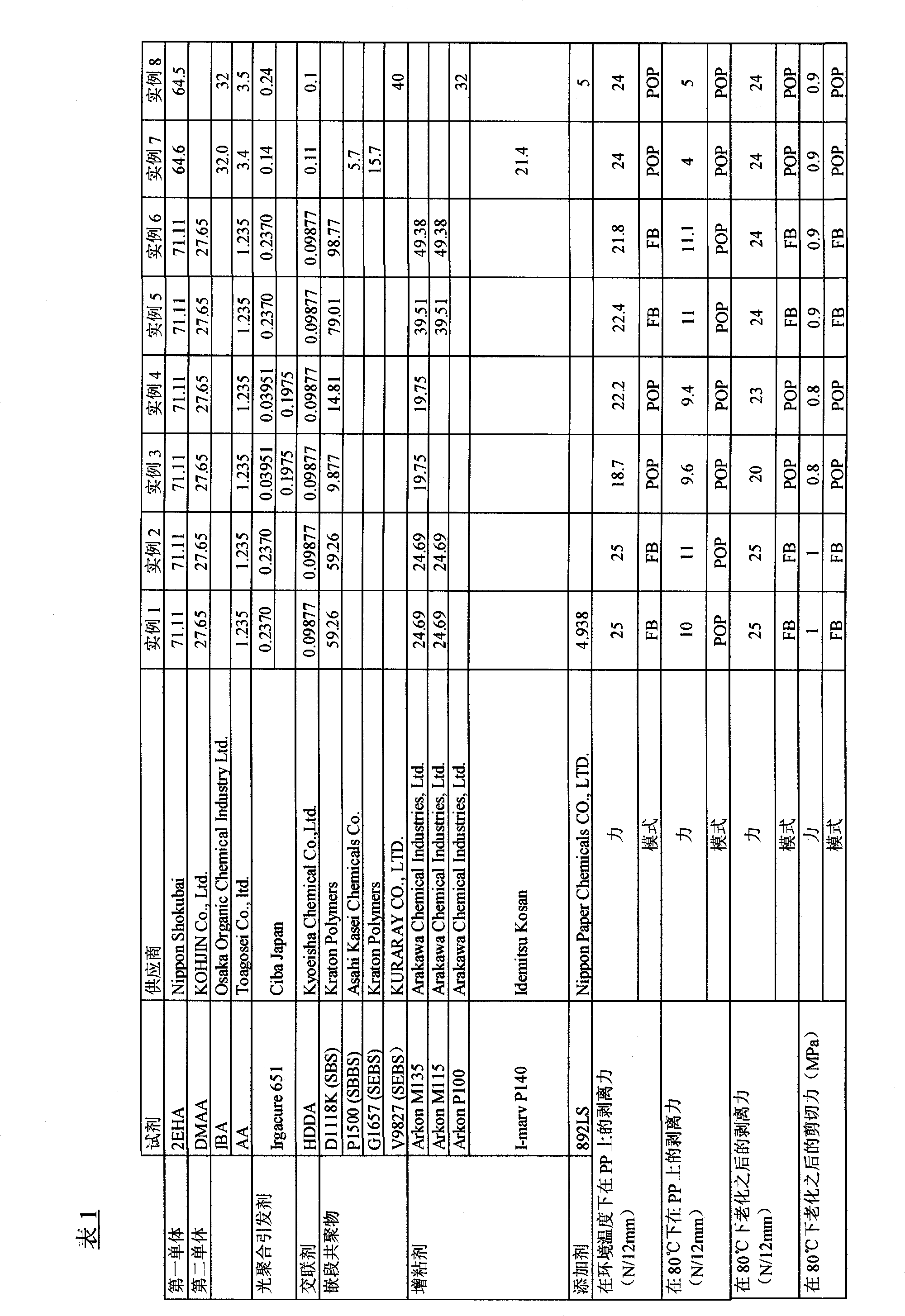

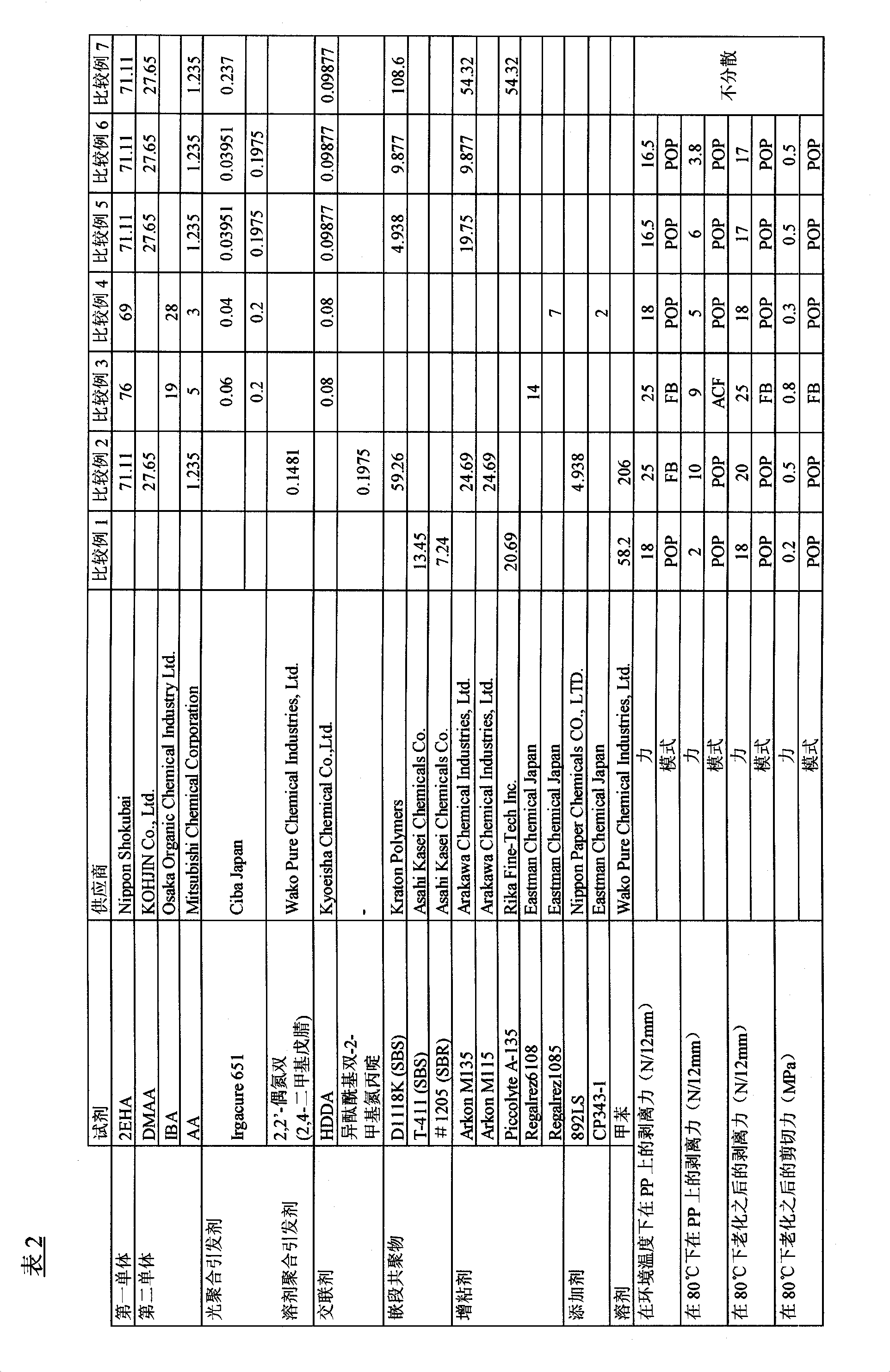

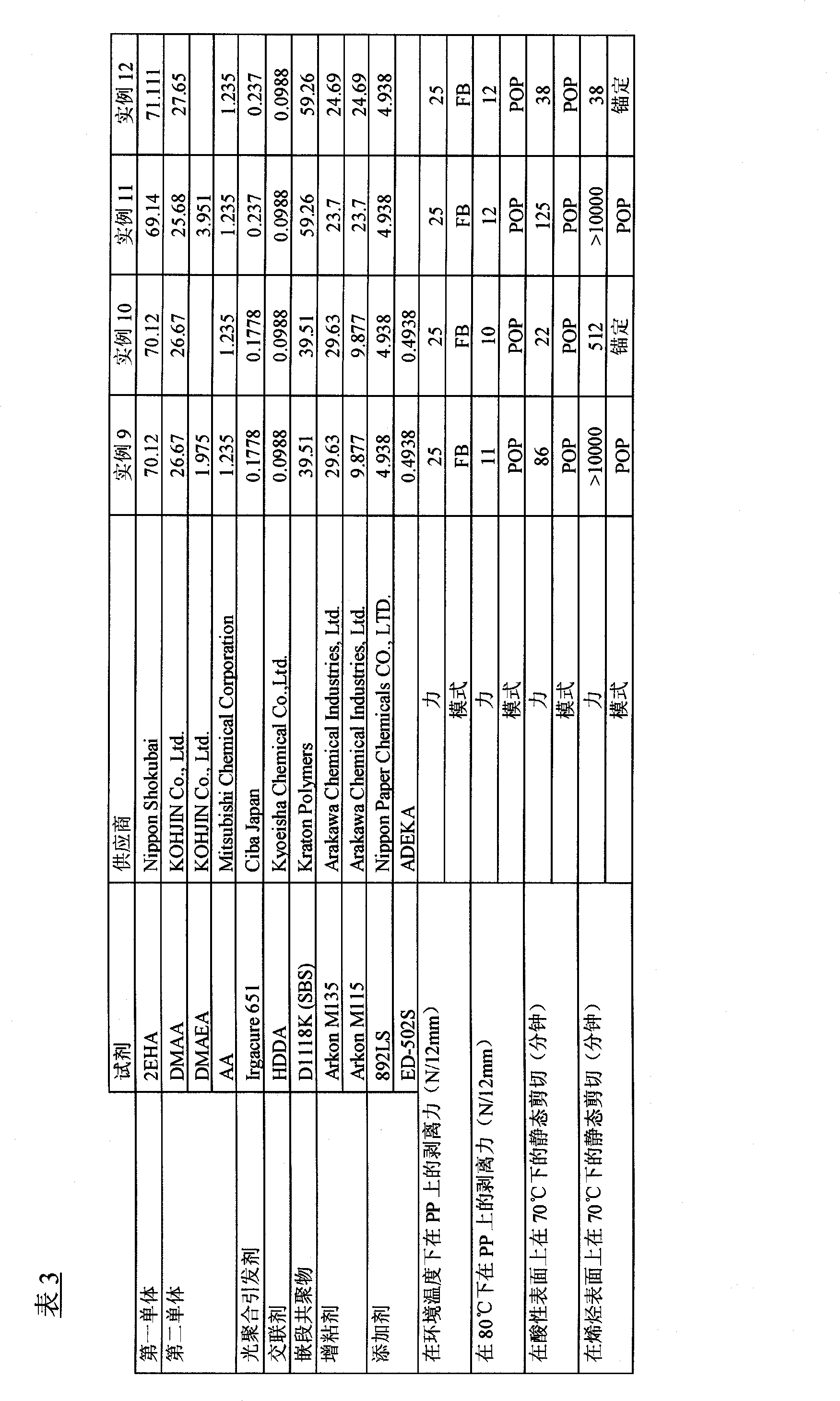

Pressure sensitive adhesive and pressure sensitive adhesive tape

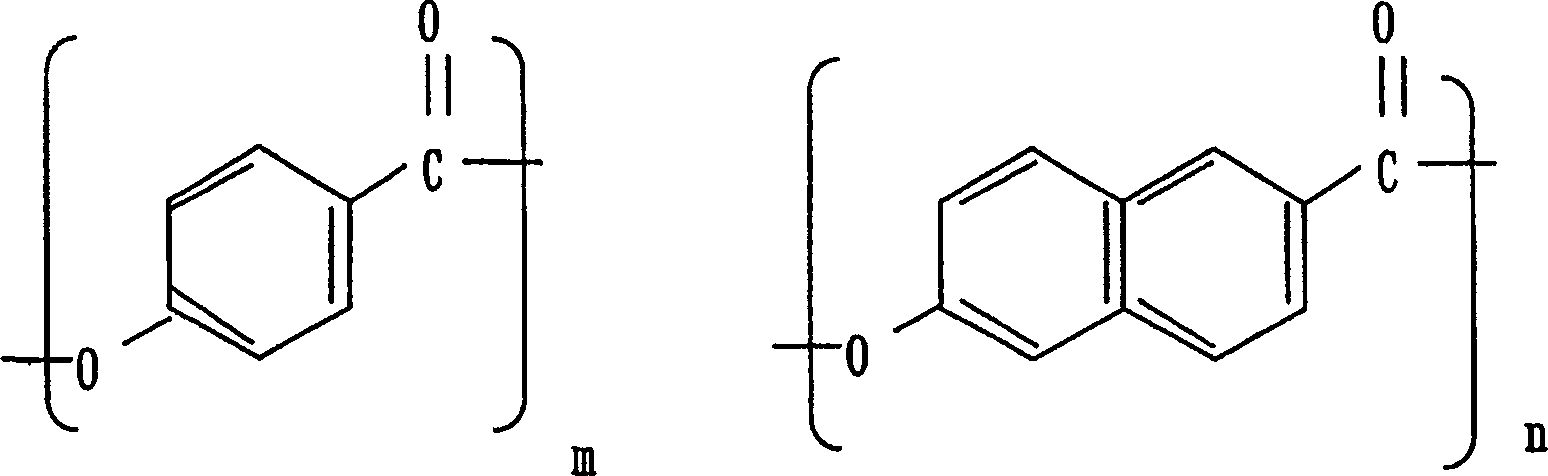

ActiveCN102317393AAdhesive enoughEster polymer adhesivesOrganic non-macromolecular adhesiveCarbon numberStructural formula

A pressure sensitive adhesive is obtained by polymerizing a mixture containing: (1) 100 mass parts of (meth)acrylic monomer comprising 98-50 mass parts of a first monomer selected from an aliphatic (meth)alkyl acrylate having a carbon number of 4-6 and an aliphatic (meth)alkyl acrylate having a carbon number of 7-12, wherein the glass transition temperature of a homo-polymer thereof is -25 degrees C or less; and 2-50 mass parts of a second monomer comprising one or more selected from the group consisting of: an amide group-containing ethylenic unsaturated copolymerizing monomer, a carboxylic group-containing ethylenic unsaturated copolymerizing monomer, an amino group- containing ethylenic unsaturated copolymerizing monomer, a non-tertial alkyl(meth)acrylate wherein the glass transition temperature of a homo-polymer thereof is -25 degrees C or more; and a monomer represented by the chemical structural formula (I) CH2=CR1COO(R2O)nR3 or CH2=CR1COOR4R5 (R1methyl or H; R2 and R4 = linear or branched alkyl having a carbon number of 1-6; R3 =methyl, ethyl, or substituted or non- substituted phenyl; R5=substituted or non-substituted 4-membered or 5-membered ring containing oxygen; n=1-16); (2) 10-100 mass parts of a block copolymer; (3) 20-100 mass parts of hydrogenated tackifier; and (4) 0.05-1.0 mass parts of a photopolymerization initiator.

Owner:3M INNOVATIVE PROPERTIES CO

Adhesive sheet and semiconductor device and process for producing the same

InactiveCN1633487AAdhesive enoughReduce adhesionSolid-state devicesSemiconductor/solid-state device manufacturingPressure sensitiveChemistry

An adhesive sheet comprising a pressure-sensitive adhesive layer and a substrate layer, the adhesive force between the pressure-sensitive adhesive layer and the substrate layer is controlled by irradiation with radiation, and the pressure-sensitive adhesive layer contains the following Components: (a) thermoplastic resin, (b) thermopolymerizable component, and (c) a compound that generates a base by irradiation with radiation. The adhesive sheet of the present invention is to have sufficient adhesive force to prevent semiconductor elements from flying away when cutting, and then control the adhesive force between the above-mentioned pressure-sensitive adhesive layer and the substrate by irradiating radiation, so that when taken out Such an oppositely required adhesive sheet with low adhesion that does not damage the components.

Owner:HITACHI CHEM CO LTD

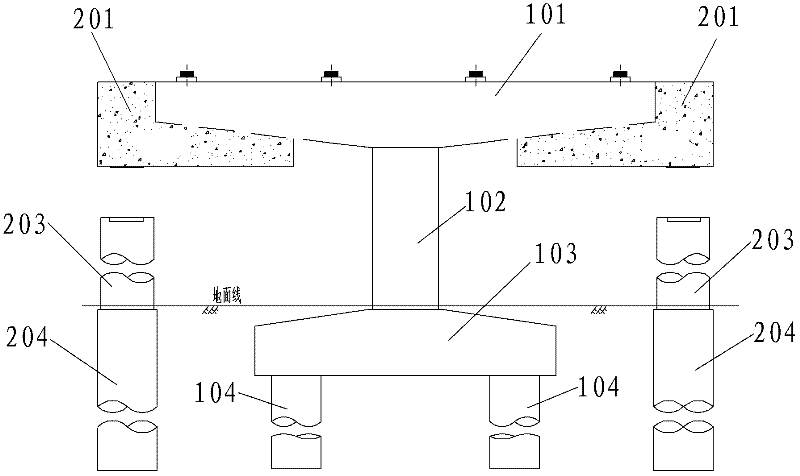

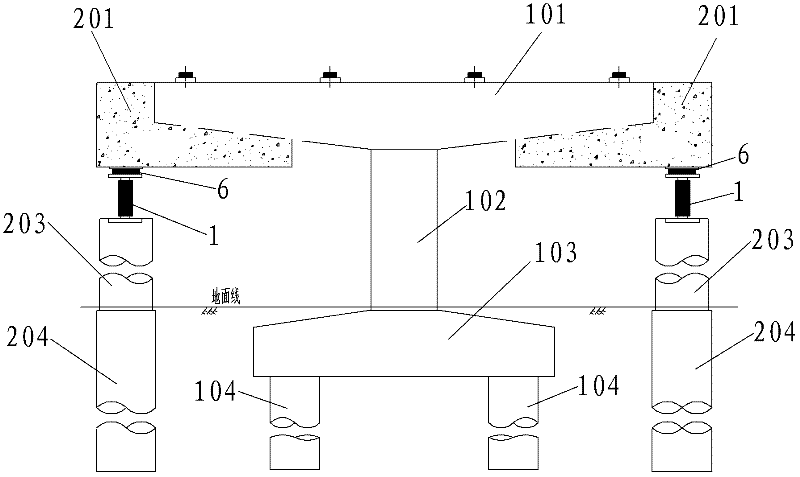

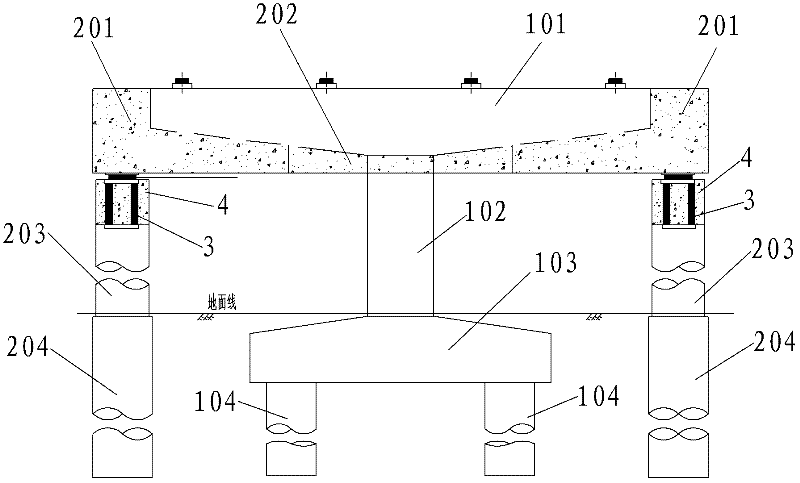

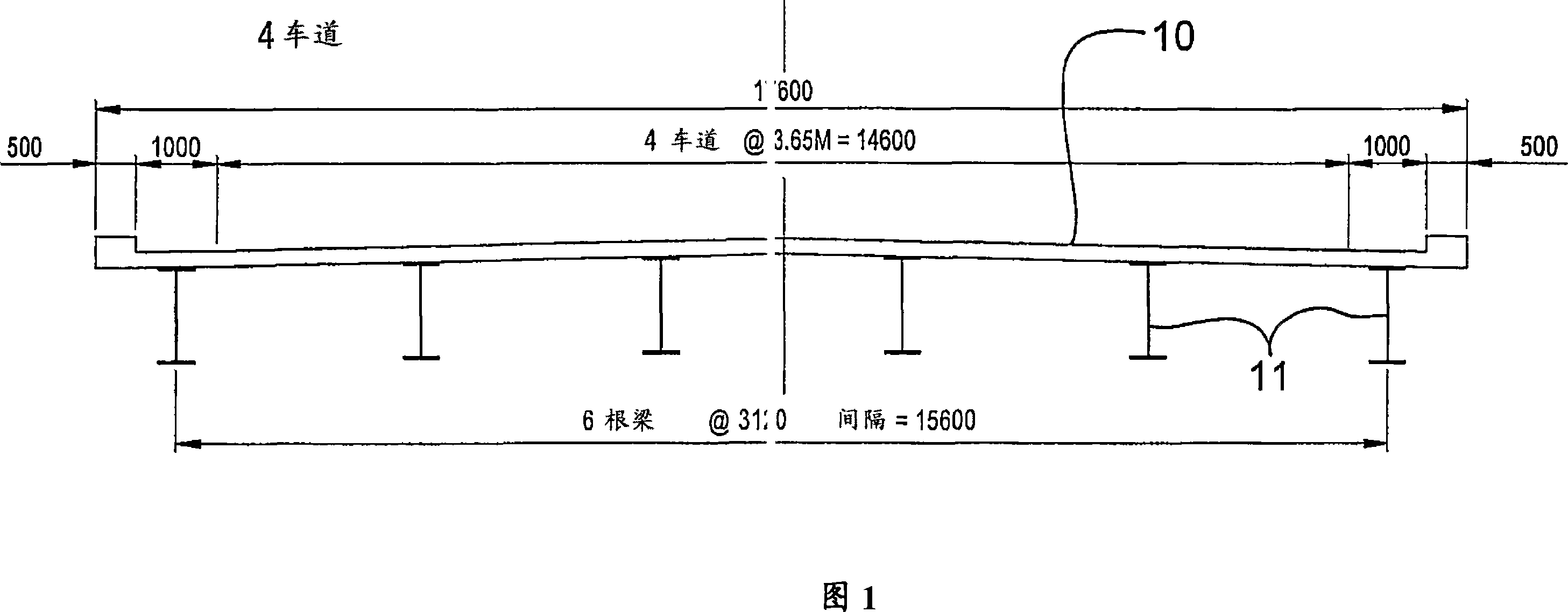

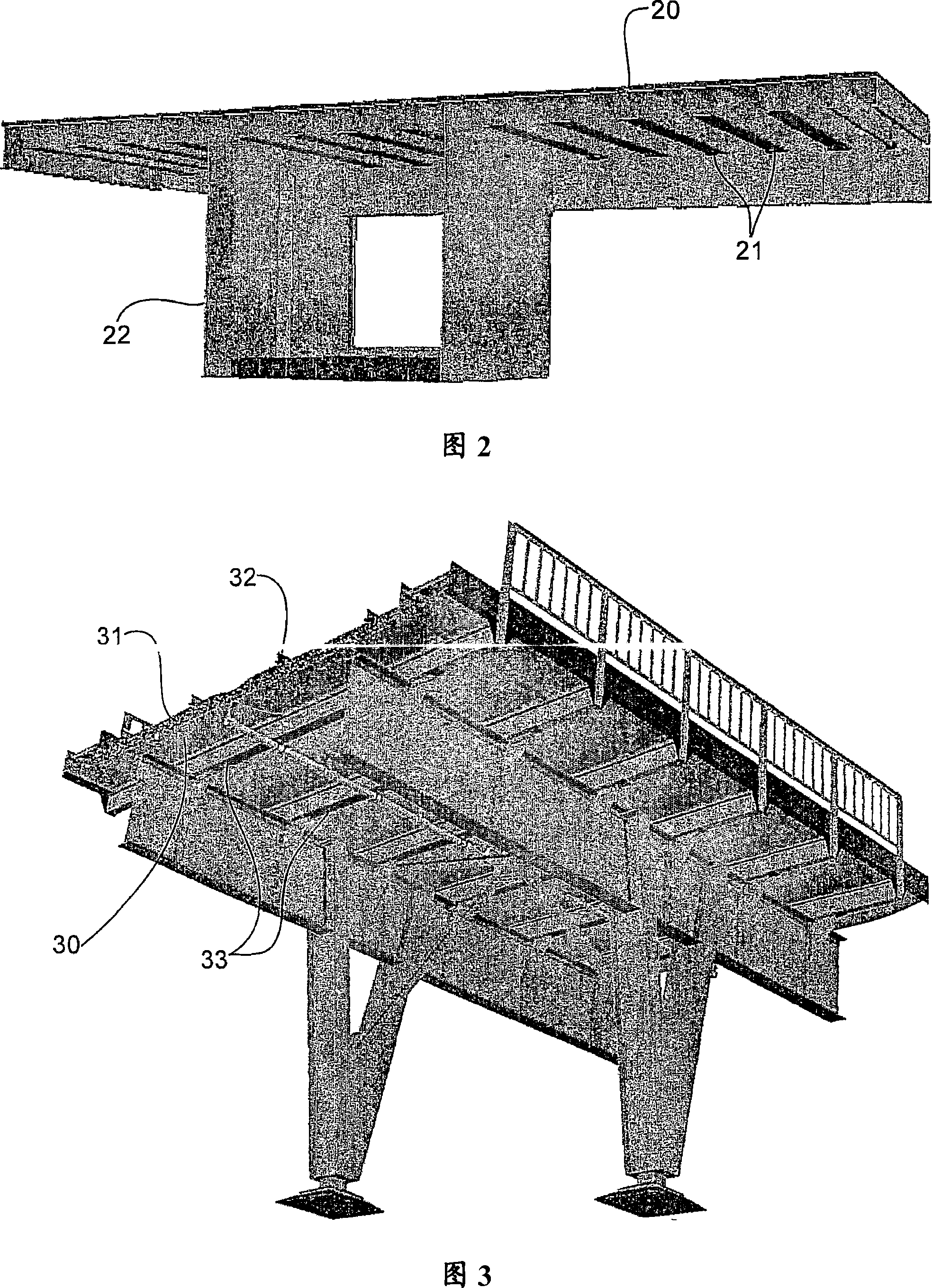

Process for reinforcing adjustable and controllable capping beam of piers

ActiveCN102383379AReduce negative bending momentReduce compressive stressBridge erection/assemblyBridge strengtheningFiberPre stress

The invention discloses a process for reinforcing adjustable and controllable capping beam of piers, comprising the following steps: (1) engraving shearing force grooves on the surface of the original capping beam concrete according to the design, embedding reinforcing steel bars and chiseling; (2) mixing plant fiber and steel fiber with the newly poured capping beam concrete, wherein the plant fiber is mixed in order to prevent the early shrinkage and crack of the concrete, and the steel fiber is mixed in order to prevent the later-stage stressed crack of the concrete; (3) leaving a certain area for secondary pouring in the middle in advance, wherein the area is 1 / 3 the length of the capping beam; (4) jacking capping beams by using two ends of a jack, and adjusting the reasonable load born by the new capping beam and the old capping beam according to a certain proportion by controlling the force and the jacking height of the jack to adjust the internal force of structures according to the design; (5) transferring the internal force of the basic part of the old structure to the basic part of the newly added structure by jacking; and (6) transferring partial or whole load born by the capping beam of the old biers to the new piers and the combined new and old capping beam structure by controlling the number and the position of prestressed steel strands to adjust the proportion of the whole load born by the combined new and old capping beam structure.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

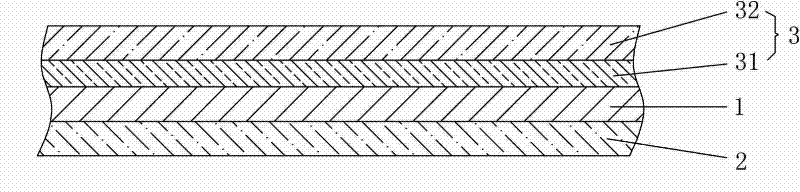

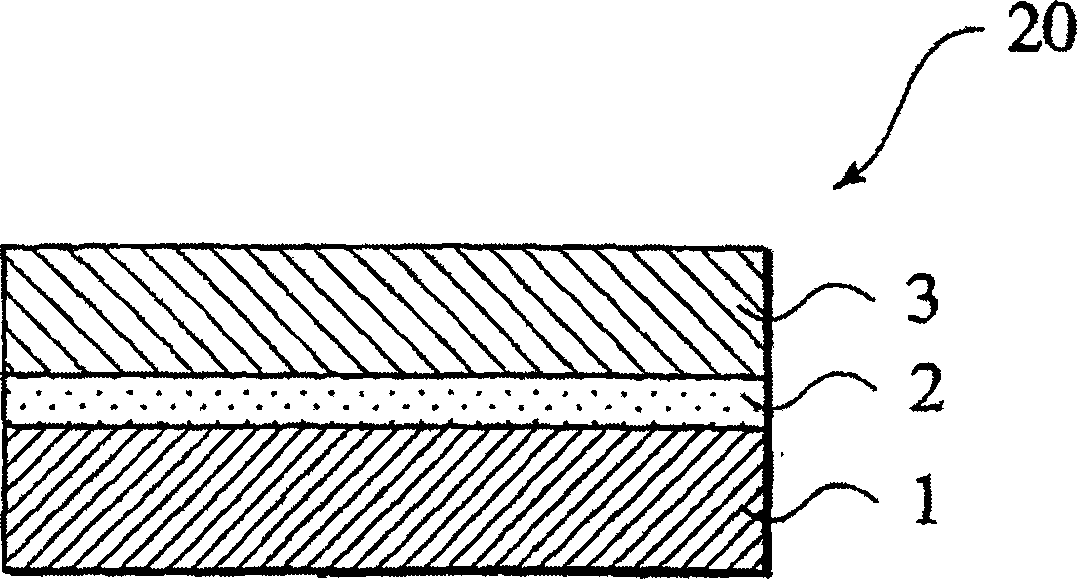

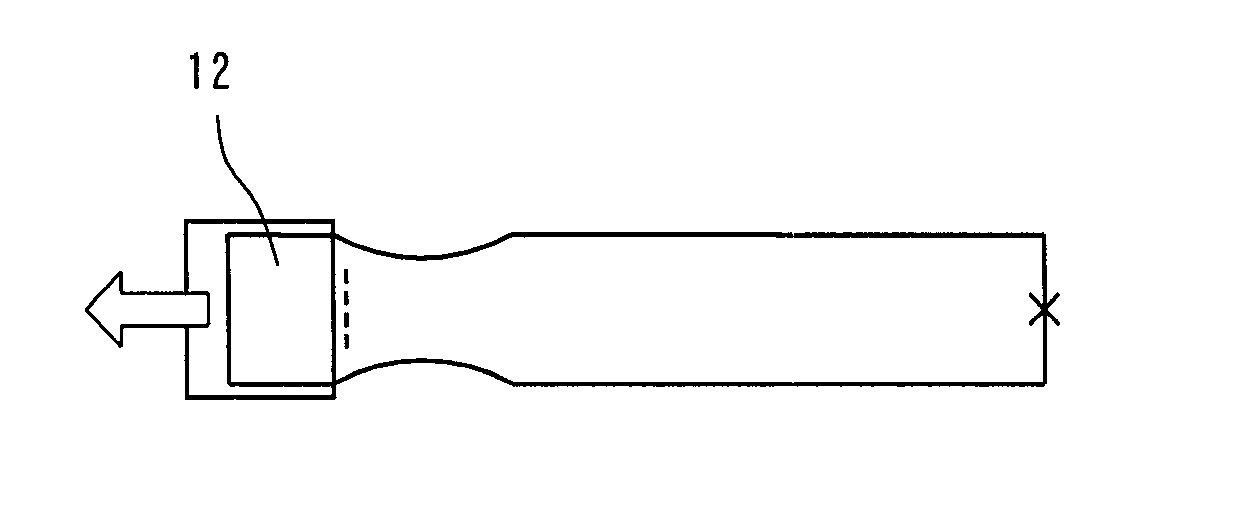

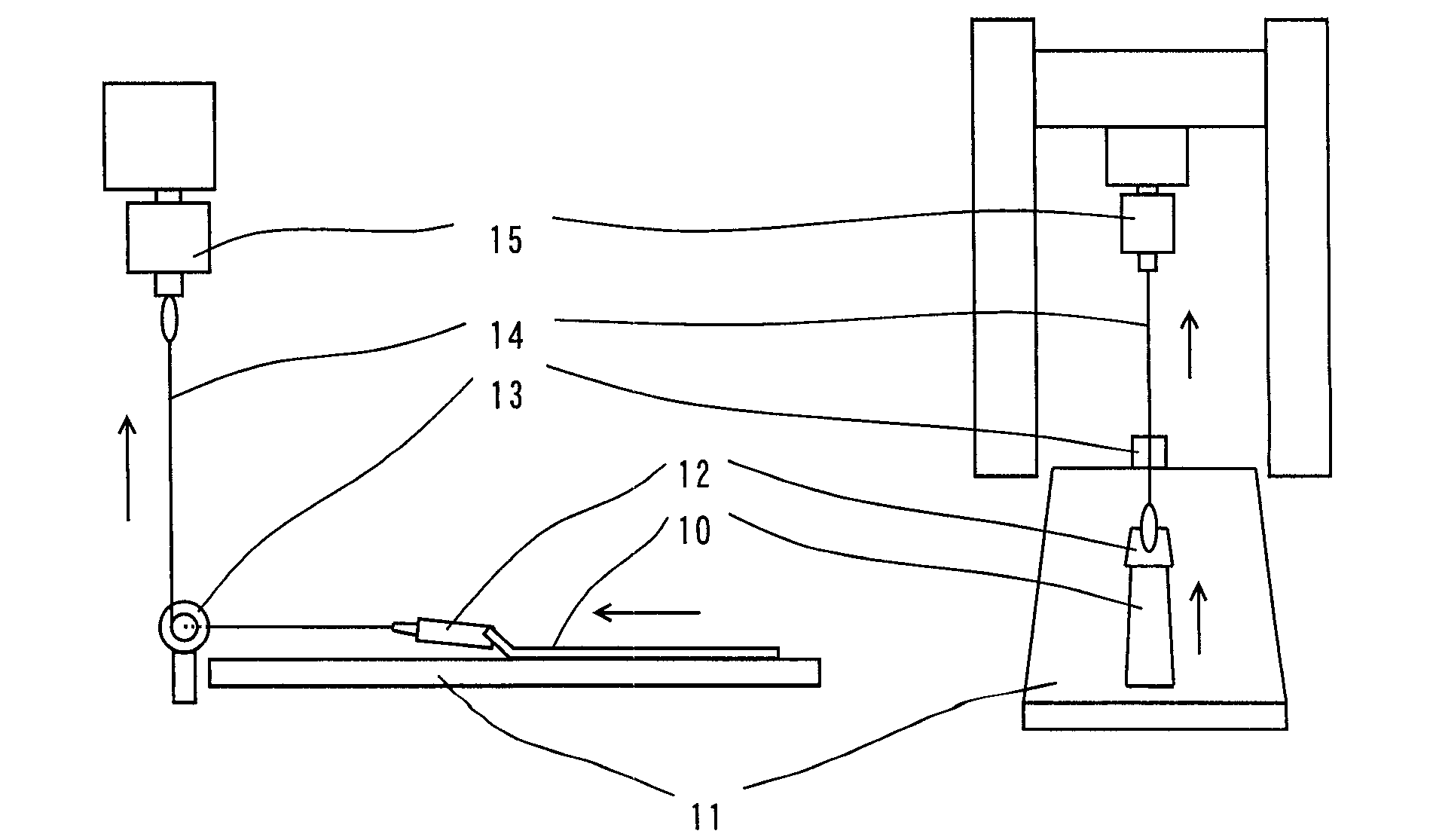

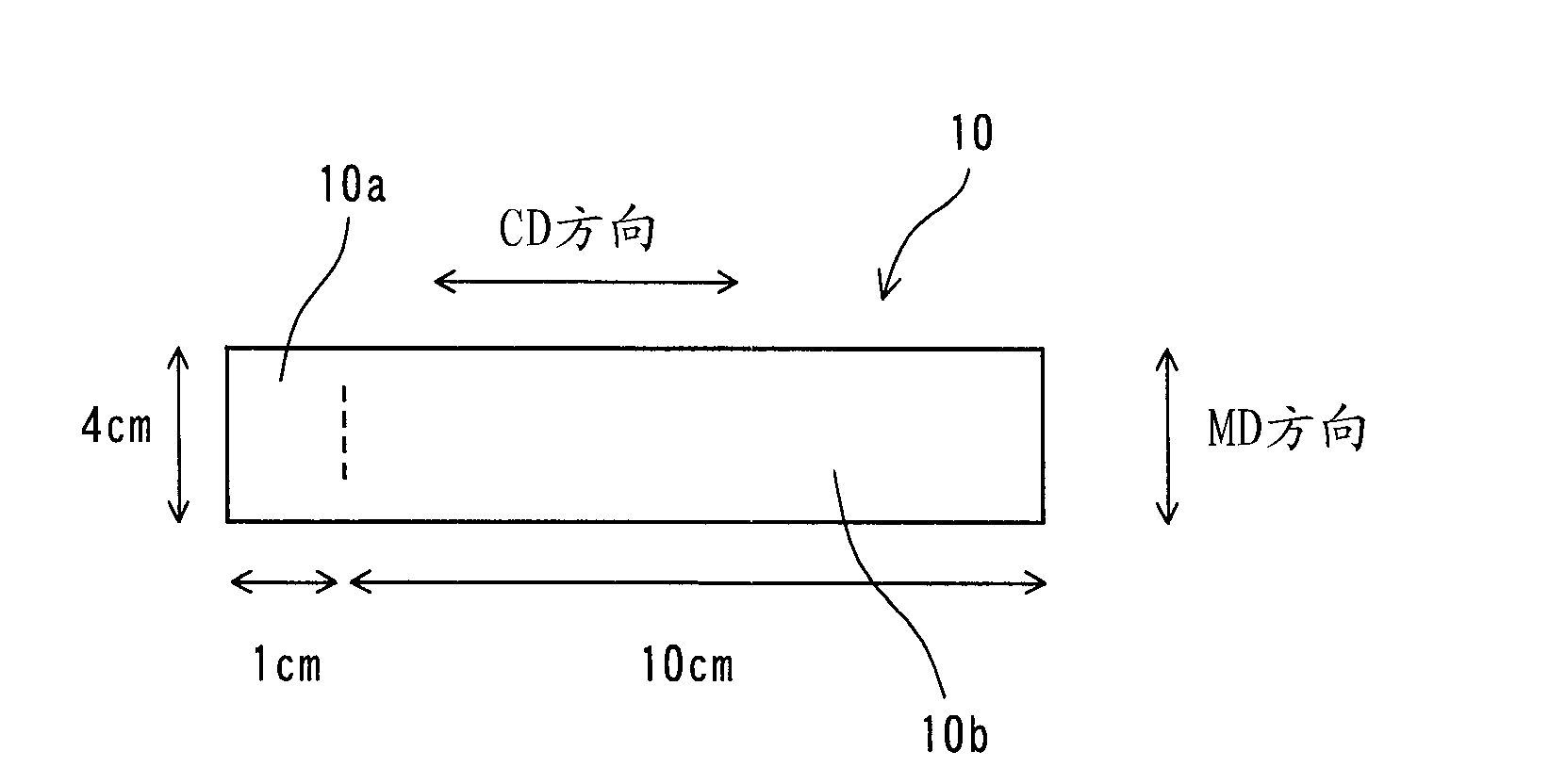

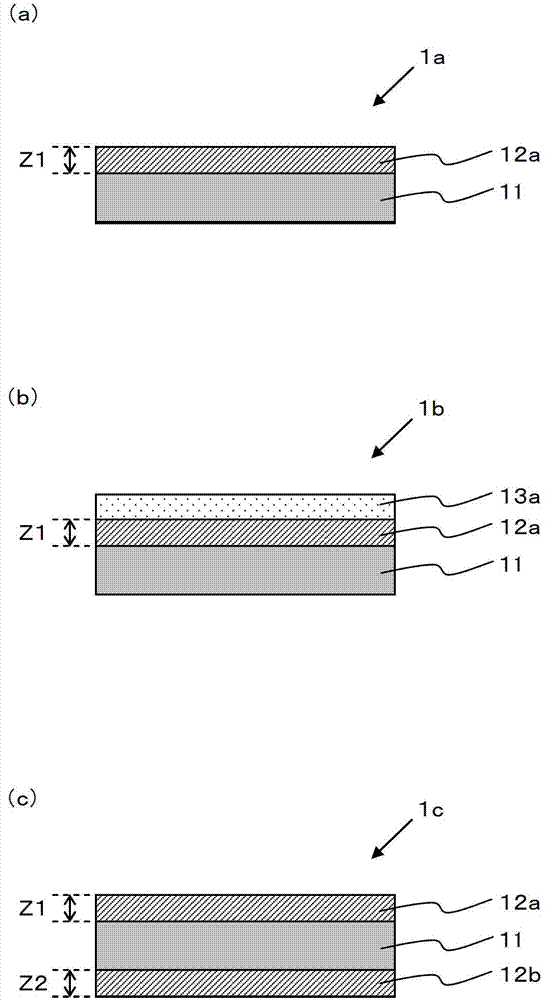

Laminated sheet, and process for production thereof

ActiveCN102482818AImprove adhesionImprove adaptabilityCosmetic preparationsToilet preparationsPolymer scienceSkin contact

A laminated sheet is produced by forming an adhesion layer permeable to a liquid component and contactable with a skin on at least one side of a liquid-retention layer comprising a nonwoven structural member and having an ability to absorb the liquid component. The adhesion layer comprises a nonwoven structural member comprising a fiber having a number-average fiber diameter of not more than 10 [mu]m, and the thickness ratio of the adhesion layer relative to the liquid-retention layer is 1 / 4 to 1 / 100 as a ratio of the adhesion layer / the liquid-retention layer. The fiber of the nonwoven structural member of the adhesion layer may have a standard deviation of fiber diameter of not more than 5. The nonwoven structural member of the liquid-retention layer may comprise a fiber having a fiber diameter larger than that of the fiber of the adhesion layer. The laminated sheet has a liquid retentivity and a liquid releasability in a well-balanced manner, and has an excellent adhesion and an excellent fit to the skin in the state where the sheet is impregnated with a liquid component.

Owner:KURARAY KURAFLEX CO LTD

Acid etching solution used for copper or copper alloy surface and surface treatment method

InactiveCN101230461ASimple processing methodPlay the role of cleaning and degreasingAcid etchingOxidation resistant

The invention relates to an acidic microetching solution used for the surface of copper or copper alloys, is characterized in that the solution contains poly-guanidine. The invention still relates to a method of treating the surface of copper or copper alloys and includes the following steps: firstly, the acidic microetching solution of the invention is used for contacting the surface of copper or copper alloys; and secondly, the surface is covered by an organic coating. Compared with the prior art, the invention has the advantages that the following requirements can be met at the same time, i.e. firstly, the copper surface is provided with a desirable roughness, which can provide enough adhesive power for the combination of the copper surface and the organic coating (a dry film for example); secondly, the treated copper surface is light-colored, friction-resistant and oxidation-resistant; thirdly, the copper surface does not need cleaning in advance, and the microetching and degreasing can be accomplished at the same time; and fourthly, the microetching amount can be as small as possible to meet the lamination requirement of the selective dry film.

Owner:SHANTOU ULTRASONIC PRINTED BOARD NO 2 FACTORY

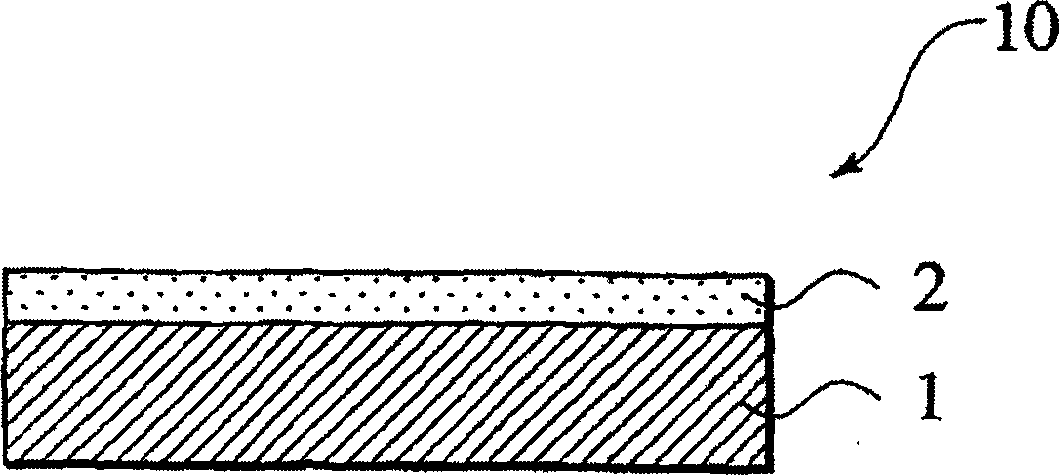

Integrally extrusion-molded object and building member

ActiveCN103209832AGood adhesionAdhesive enoughSynthetic resin layered productsCoatingsPolymer sciencePolyolefin

The present invention provides: an integrally extrusion-molded object having a coating layer which shows sufficient adhesiveness even after long-term storage or use, repetitions of heating and cooling, or contact with water; and a building member. The integrally extrusion-molded object comprises a metallic core (10) and, formed on the outer surface thereof, a coating layer (1) comprising a polyolefin resin and wood flour and an adhesive layer (2) formed between the coating layer and the core, the adhesive layer (2) comprising a copolymer obtained by polymerizing at least an a-olefin and an epoxidized unsaturated monomer. The building member comprises the integrally extrusion-molded object.

Owner:KURASHIKI BOSEKI KK

Method for producing laminate

InactiveCN1798647AImprove adhesionHeat resistance with high adhesionPrinted circuit manufactureFlat articlesLiquid crystallineMetal foil

A method for producing a laminate, wherein a film comprised of a liquid-crystalline polymer film forming an optically anisotropic molten phase and a metal foil are piled and are passed between pressing rolls, to adhere said film to said metal foil by pressing with heating, which comprises using, as at least one roll of said pressing rolls, a coated roll having a metal roll and, provided on the surface thereof, a coating layer of a resin such as a fluororubber or a polyimide having a thickness of 0.02 to 5 mm, or comprises passing the above polymer film and metal foil between metal pressing rolls together with a heat-resistant film piled on the surface contacting with the metal roll of the polymer film or the metal foil. The method allows the production of a laminate of a liquid-crystalline film and a metal foil exhibiting satisfactory adhesion between them and being excellent in heat resistance, with good productivity.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

Flame-retardant deodorizing filter

InactiveCN103068468AWon't dripFull flame retardancyGas treatmentOther chemical processesActivated carbonOzonolysis

To provide an activated carbon sheet excellent in removability of hazardous gas component with ozonolysis function, and in flame retardancy. [Solution] A flame-retardant deodorizing filter containing an activated carbon bed with both surfaces thereof provided with fabric, the flame-retardant deodorizing filter having: the fiber ratio of the fabric that is one kind or more selected from at least cellulose fiber, polyvinyl alcohol fiber, polyacrylonitrile fiber and phenol fiber in 30% or more; the amount of phosphorus-based flame retardant in 10 to 70% by weight relative to the fabric weight; an adhesion layer between the activated carbon bed and the fabric; activated carbon particles adhered by thermoplastic resin binder particles; and the weight per unit area of activated carbon in 50 to 400 g / m2.

Owner:TOYOBO CO LTD

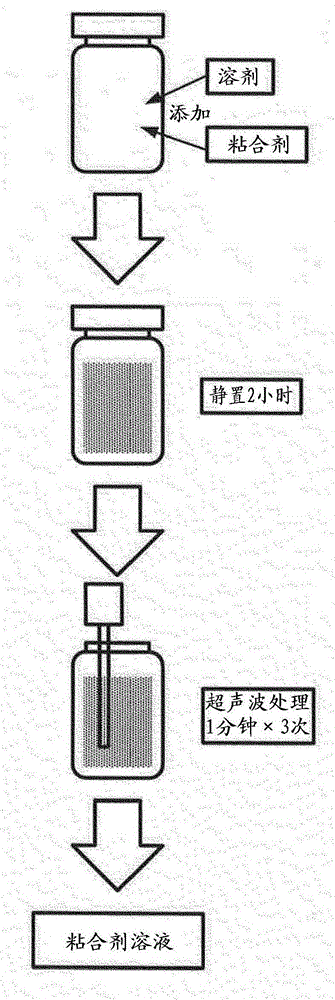

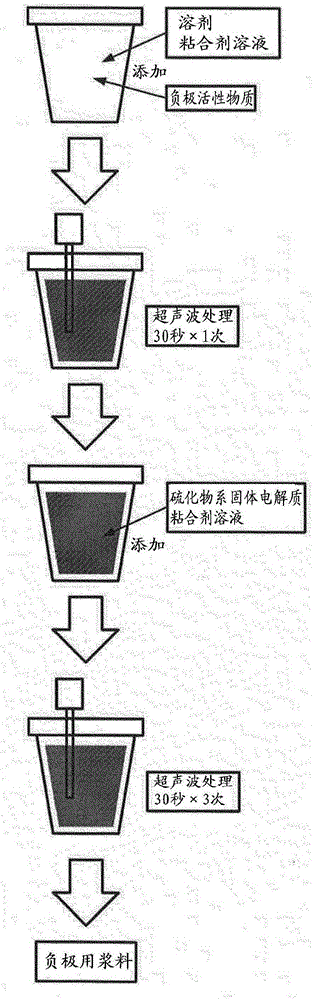

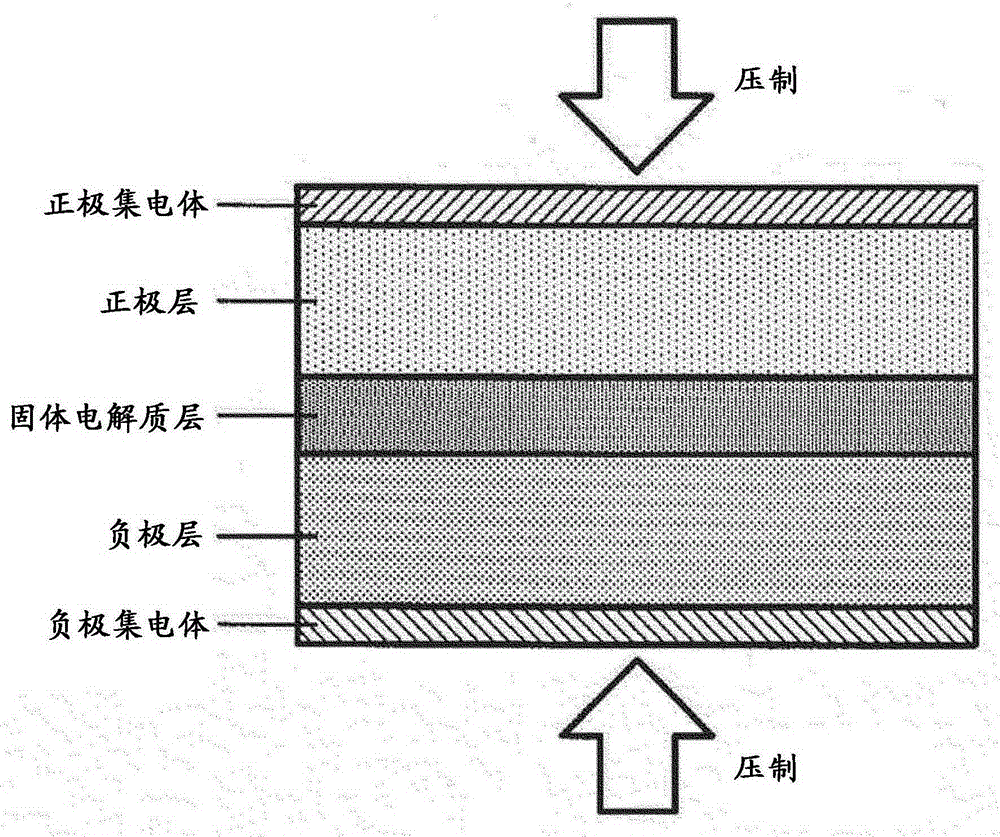

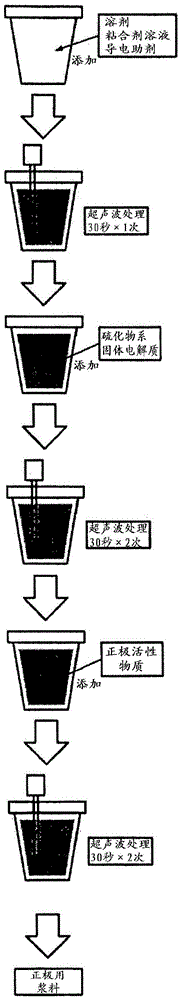

Method of manufacturing negative electrode for solid-state battery, method of manufacturing solid-state battery, and negative electrode slurry

ActiveCN105304904AInhibit deteriorationSuppress capacity deteriorationFinal product manufactureSecondary cellsSolid-state batterySolvent

The invention relates to a method of manufacturing a negative electrode for a solid-state battery, a method of manufacturing a solid-state battery, and negative electrode slurry. Provided is a method of manufacturing a negative electrode for a solid-state battery, the method including: a step of mixing a negative electrode active material, a sulfide solid electrolyte, a binder, and a solvent with each other to prepare a negative electrode slurry; a step of applying the prepared negative electrode slurry to a surface of a solid electrolyte layer of the solid-state battery or a substrate of the negative electrode; and a step of drying the applied negative electrode slurry. In this method, the solvent is butyl butyrate, and the binder is a copolymer containing a vinylidene fluoride (VDF) monomer unit and a hexafluoropropylene (HFP) monomer unit, in which a molar ratio of the HFP monomer unit to a total amount of the VDF monomer unit and the HFP monomer unit is 10% to 25%.

Owner:TOYOTA JIDOSHA KK

Chitosan and polyvinyl alcohol compound cataplasm matrix and preparing method thereof

InactiveCN101229146APositiveImprove physiological activityPharmaceutical non-active ingredientsSheet deliveryAcetic acid solutionPVA - Polyvinyl alcohol

The invention discloses a chitosan or polyvinyl alcohol composite cataplasm matrix. The indigents of the invention and the weight of each indigent are as following: chitosan: 0.25 to 0.75g, polyvinyl alcohol: 0.75 to 1.25g, glutaric dialdehyde with the mass concentration being 2 percent: 0.28 to 0.32g, water: 16 to 20g, propanetriol: twice as much as the sum weight of chitosan and polyvinyl alcohol. The preparation procedure is as following: dissolving the polyvinyl alcohol with water and then adding glacial acetic acid to form acetum which is then added with chitosan until stirring to dissolve; adding propanetriol and glutaric dialdehyde successively, which is statically crosslinked to obtain hydrogel; coating the well-prepared hydrogel on non-woven fabrics evenly and then coating a polyethylene film. The chitosan or polyvinyl alcohol composite cataplasm matrix of the invention does not stimulate skin and has good property.

Owner:ZHEJIANG UNIV

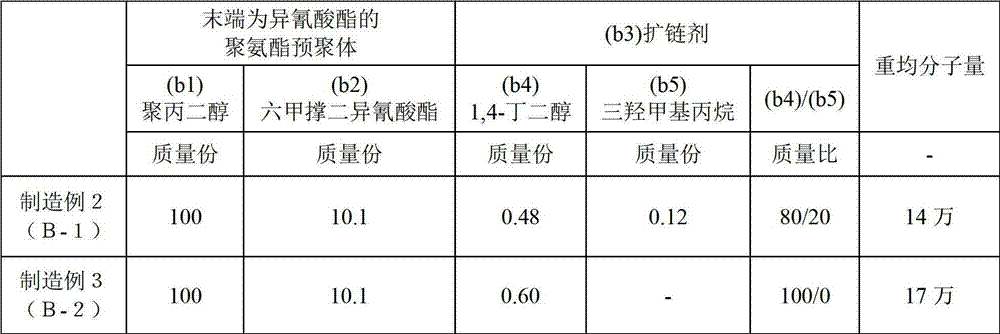

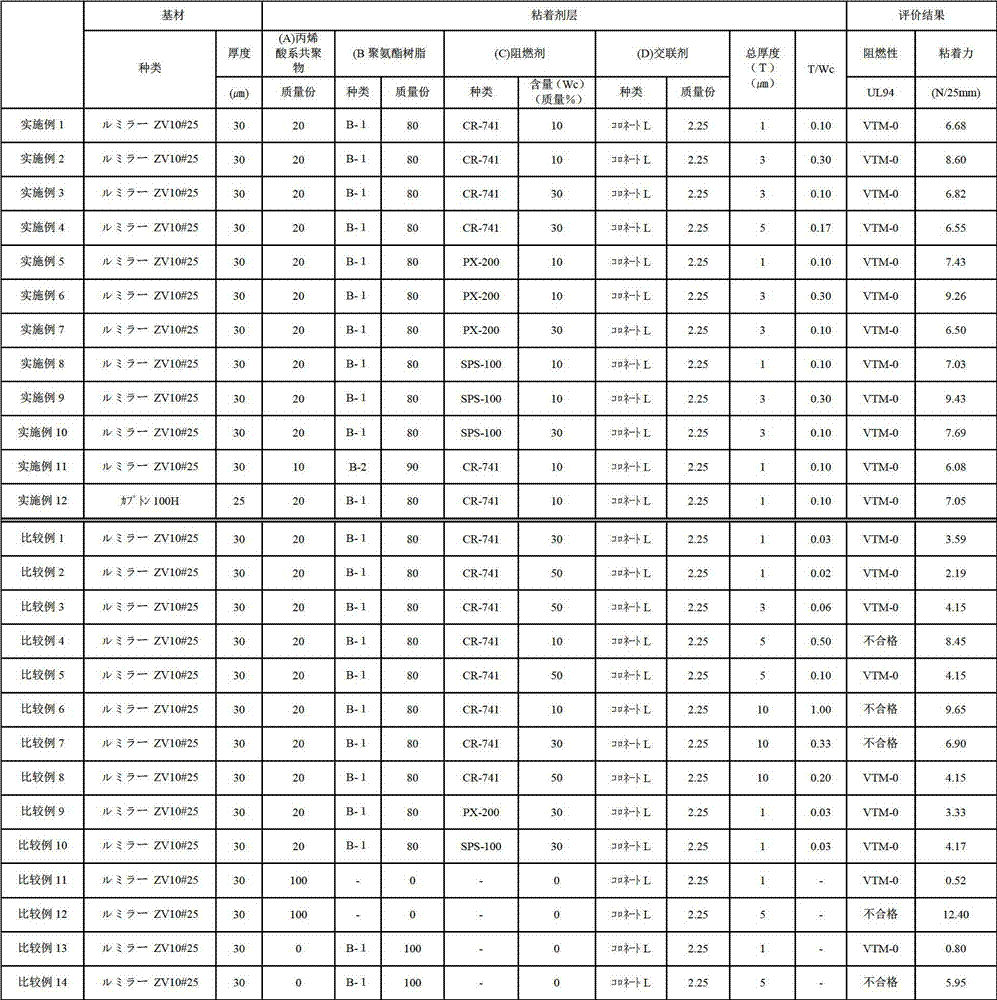

Flame retardant adhering sheet

ActiveCN103131341AImprove flame retardant performanceExcellent adhesionFilm/foil adhesivesPolyureas/polyurethane adhesivesAdhesiveEngineering

The invention provides a thin film type flame retardant adhering sheet which is an adhering sheet characterized in that at least one face of a substrate of the adhering sheet is provided with an adhesive layer, the adhering sheet has enough adhering strength even if in a thin film adhesive layer of which an adhesive contains a flame retardant agent, and the adhering sheet has excellent flame retardant property and adhering strength. The flame retardant sheet is a flame retardant adhering sheet characterized in that at least one face of a substrate of the flame retardant adhering sheet is provided with an adhesive layer, the substrate has flame retardant property which conforms with the VTM-0 in a test based on the UL94 standard, each face of the adhesive layer is more than 0.6 [mu]m in thickness, and the total thickness of the adhesive layer is less than 7.0 [mu]m. An adhesive which the adhesive layer consists of contains a acrylic acid series copolymer A, a polyurethane resin B, and a flame retardant C, wherein the content of the flame retardant C in the adhesive is 0.1 to 40 mass%; when the content of flame retardant C in the adhesive is Wc (mass%) and the total thickness of the adhesive layer is T([mu]m), the value of T / Wc is 0.07 to 0.45.

Owner:LINTEC CORP

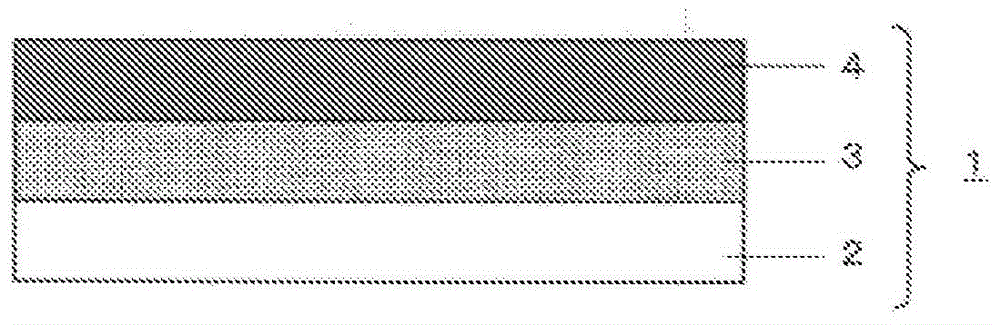

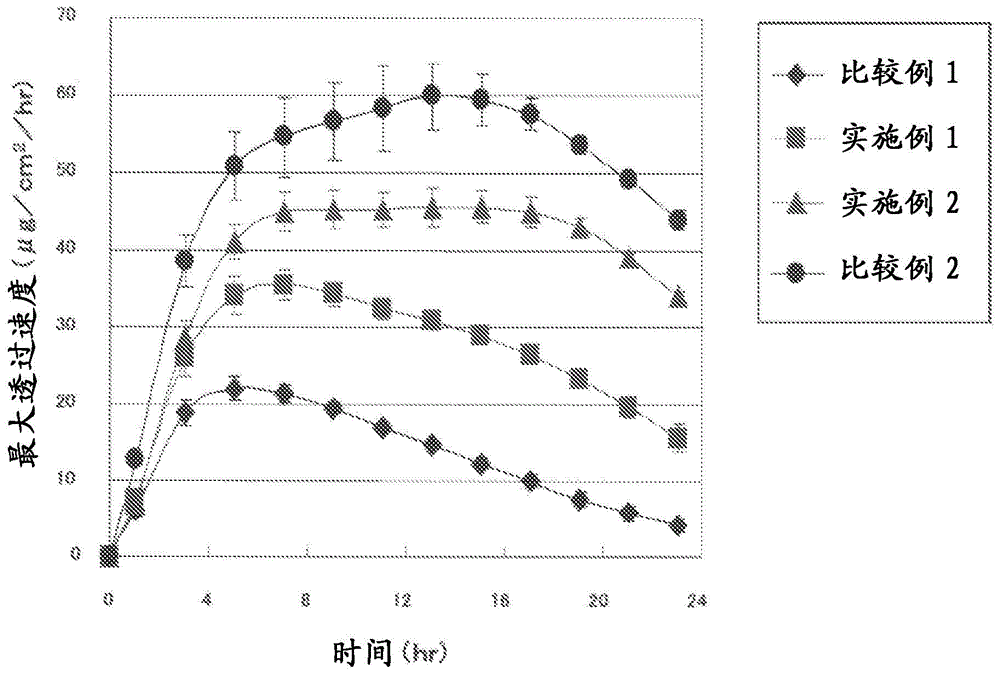

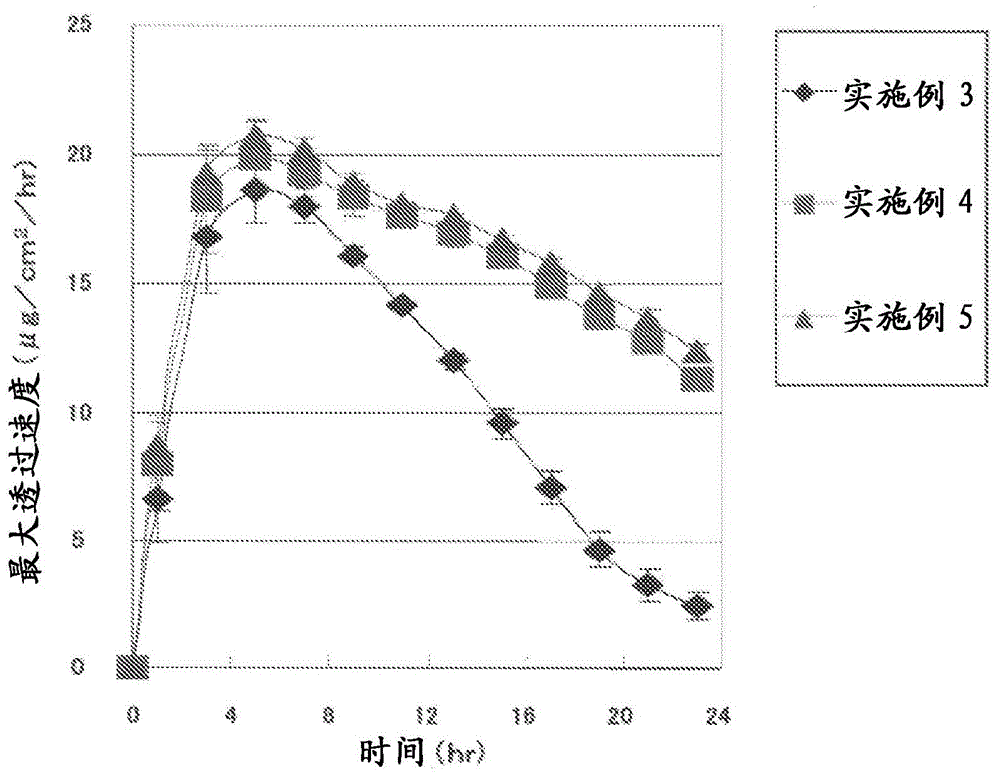

Ropinirole-containing adhesive skin patch and packaged product thereof

InactiveCN103561737AImprove skin permeabilityExcellent stability over timeOrganic active ingredientsNervous disorderSkin patchChemistry

A ropinirole-containing adhesive skin patch comprising an adhesive layer and a support layer, wherein the adhesive layer contains ropinirole and / or a pharmaceutically acceptable salt thereof, and wherein the content of ropinirole and / or the pharmaceutically acceptable salt thereof in terms of free ropinirole content in the adhesive layer fulfills the following two requirements: the content is 5-13.2 mass% relative to the total mass of the adhesive layer; and the content is 0.12-2.7 mg / cm2 per unit area of the adhesive layer.

Owner:HISAMITSU PHARM CO INC

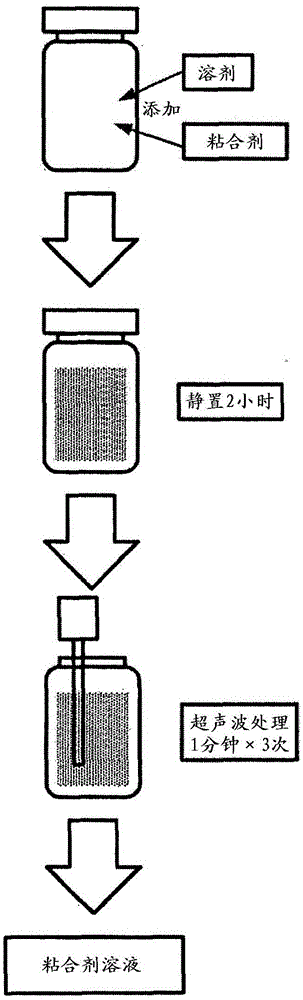

Method of manufacturing positive electrode for solid-state battery, method of manufacturing solid-state battery, and positive electrode slurry

InactiveCN105304863AReduce outputInhibit deteriorationSolid electrolytesFinal product manufactureHexafluoropropyleneSlurry

Owner:TOYOTA JIDOSHA KK

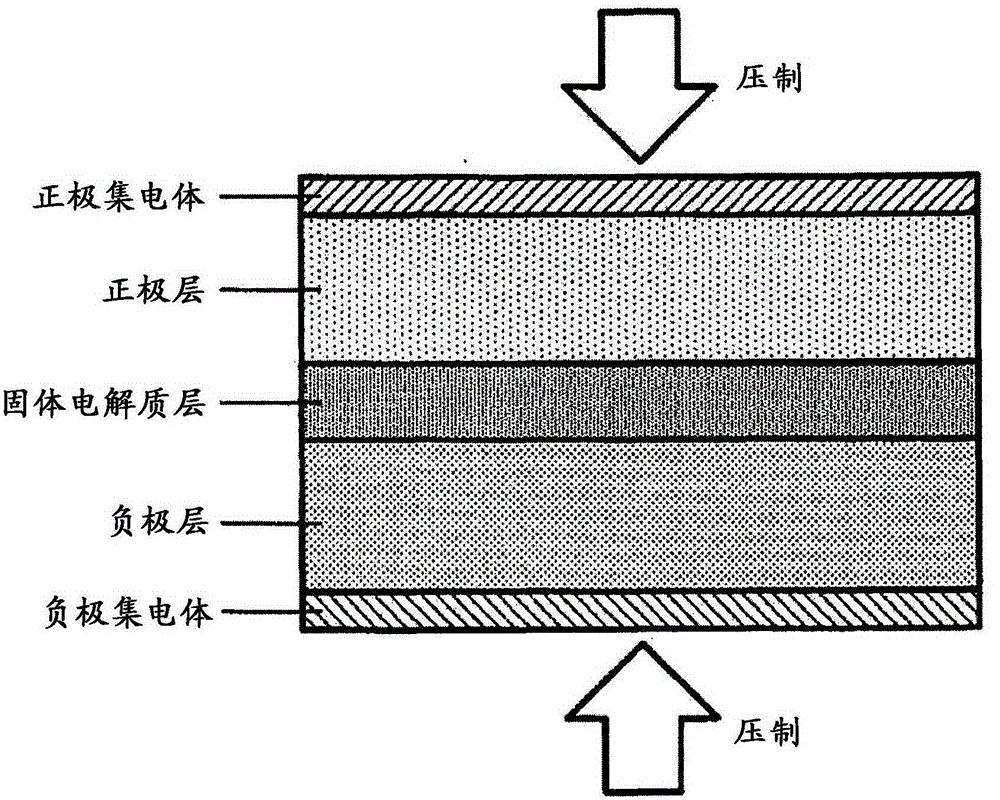

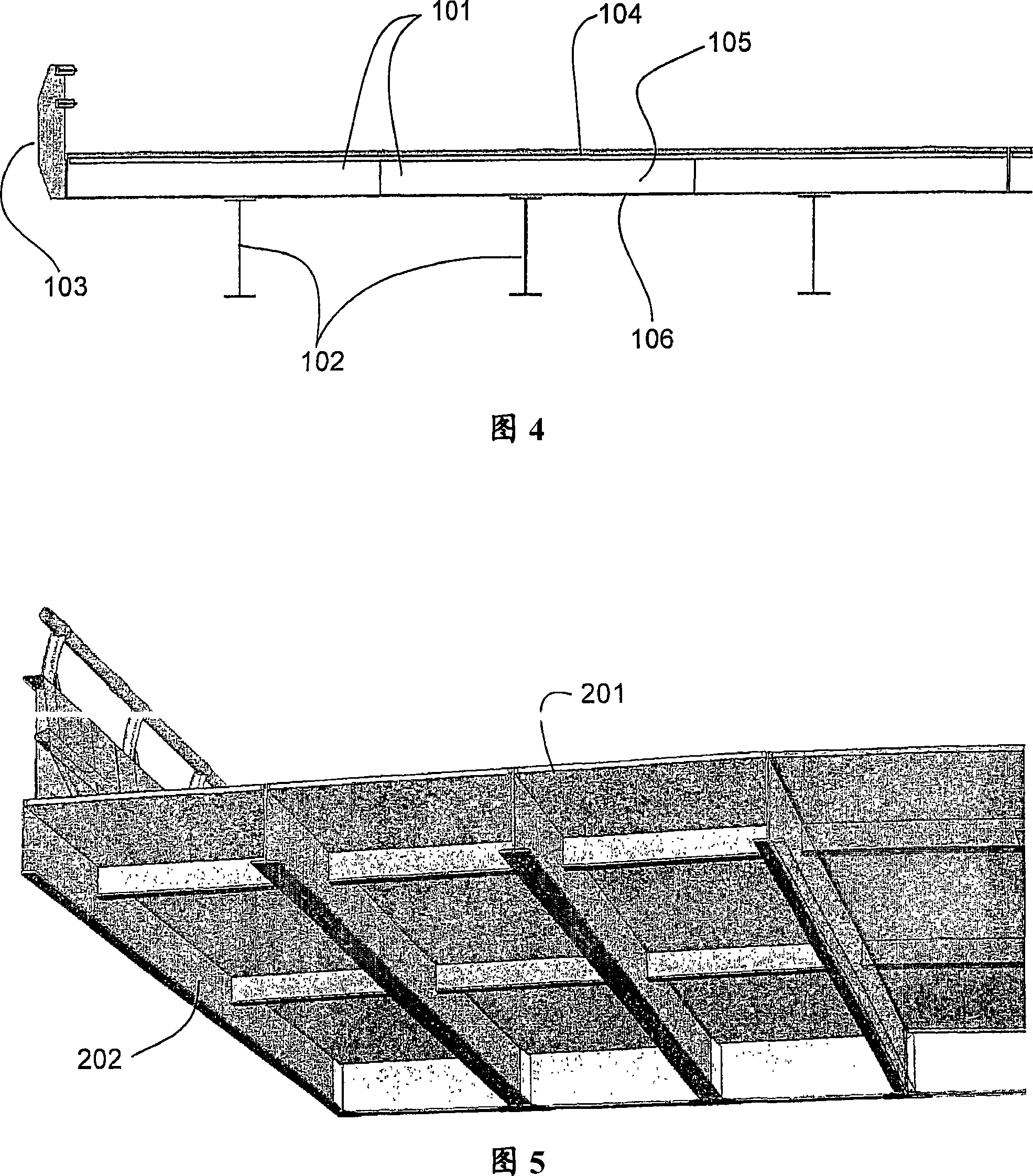

Method of reinforcing a bridge

InactiveCN101091023AImprove load capacityDamage minimizationBridge erection/assemblyBridge strengtheningEngineeringClosed cavity

A method of repairing, reinforcing or reinstating a bridge, comprising fixing a reinforcing plate in a spaced relationship with an existing plate or girder, especially on the underside of the bridge structure, to form a closed cavity, and injecting plastics or polymer material into said cavity in liquid form, whereby said plastics or polymer material sets or cures so as to bond to said reinforcing and existing plates with sufficient strength to transfer shear forces therebetween.

Owner:INTELLIGENT ENG BAHAMAS

Metal gasket material sheet

InactiveCN1617990AExcellent adhesionInhibit sheddingEngine sealsAdhesive processes with surface pretreatmentAdhesiveSilanes

A sheet of metal backing material having a layer of rubber placed on the metal sheet with an adhesive layer, the sheet of metal backing material comprising a silane-based chemical conversion coating formed on the surface between the metal sheet and the adhesive layer, the coating The layers are made of silane coupling agents containing epoxy, mercapto or amino groups as functional groups. The bonding layer is made of phenolic based adhesive and the rubber layer is made of NBR rubber compound. The adhesiveness between the rubber layer and the metal plate is improved by using the adhesive layer, the rubber layer is not easily peeled off from the metal plate, and a chromium-free material plate having no adverse effects on the environment and the human body is provided.

Owner:NIPPON LEAKLESS IND CO LTD +1

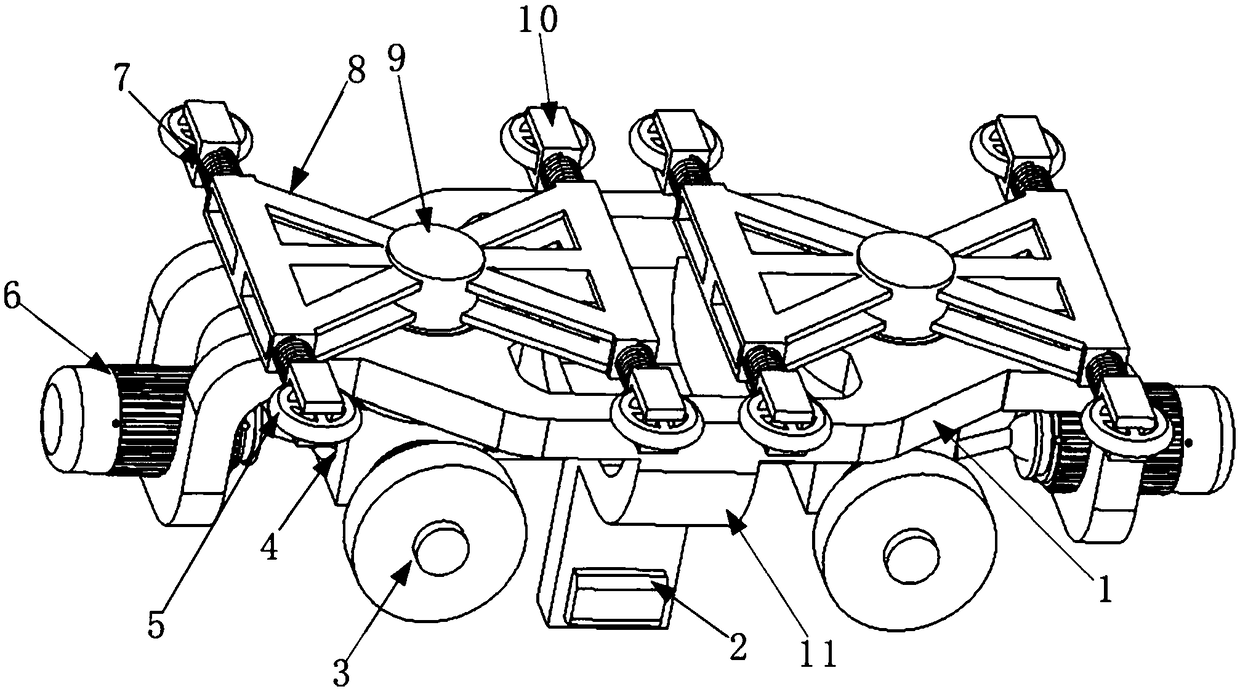

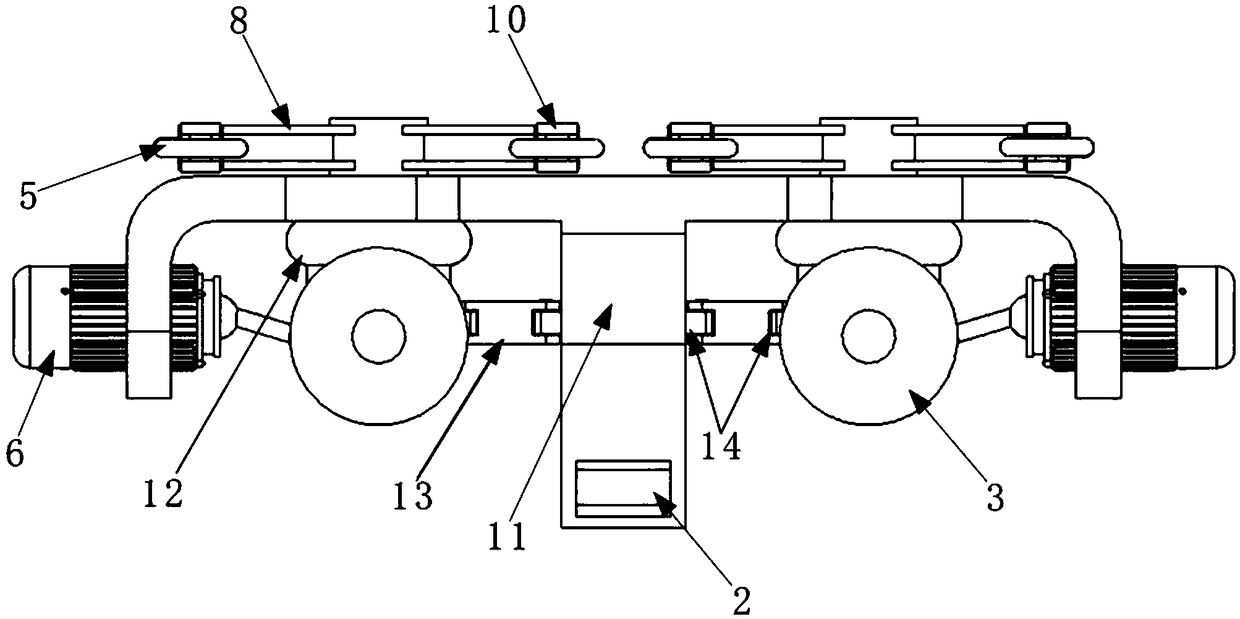

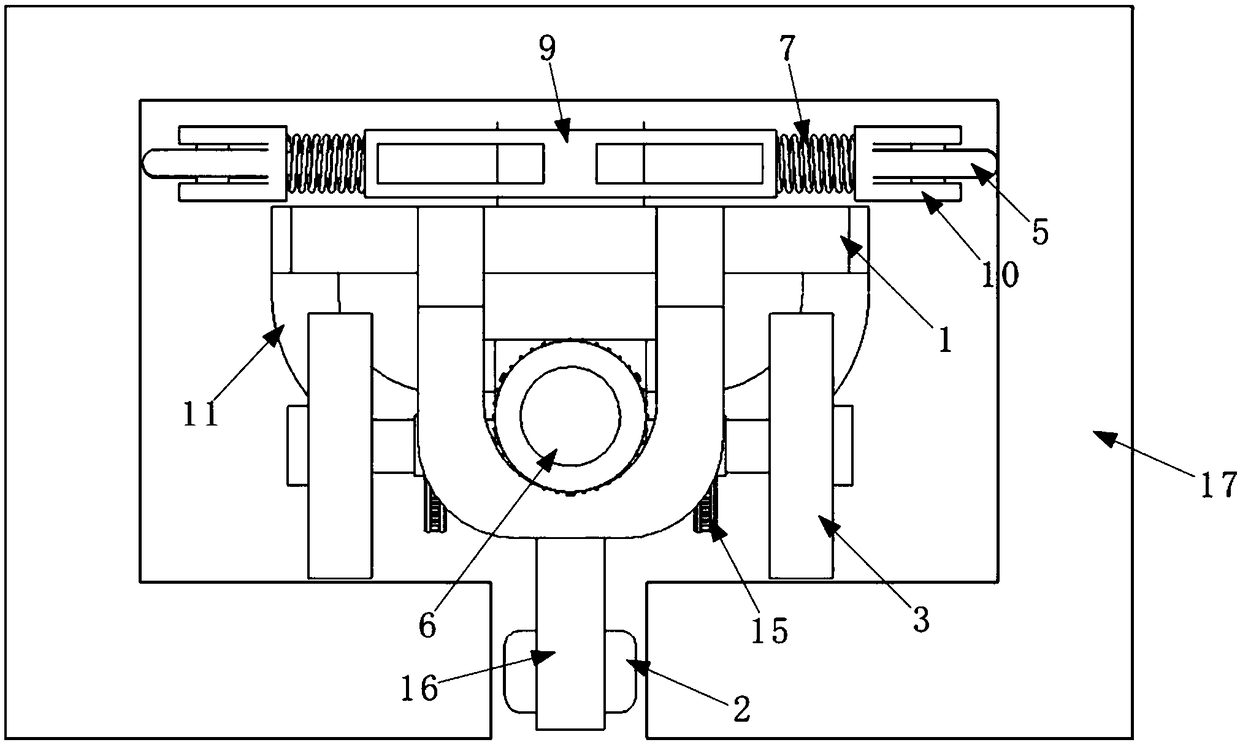

A suspension monorail train radial bogie

PendingCN109159794AReduce lossNo movement interferenceMonorailsRail derailment preventionAdhesion forceBogie

The invention discloses a suspension type monorail train radial bogie, which comprises a supporting frame and a radial guide frame. Two ends of the supporting frame are provided with radial guide frames, and the four vertices of the radial guide frames are movably connected with guide wheels. A pair of running wheels are mounted on both ends of the support frame. The invention effectively reducesthe abrasion between the track and the guide wheel and the running wheel, reduces the power consumption of the locomotive, has small lateral force between the wheels and the rail, is suitable for heavy load and high-speed development; The contradiction between bogie curve passing performance and lateral stability is effectively solved, which can not only ensure the requirement of bogie curve passing performance, but also improve its lateral stability. Moreover, the radial guide frame can ensure that the wheels and the rails are in intimate contact when the train passes through the curve, so asto provide sufficient adhesion force for the train, so that the traction force will not be reduced.

Owner:SOUTHWEST JIAOTONG UNIV

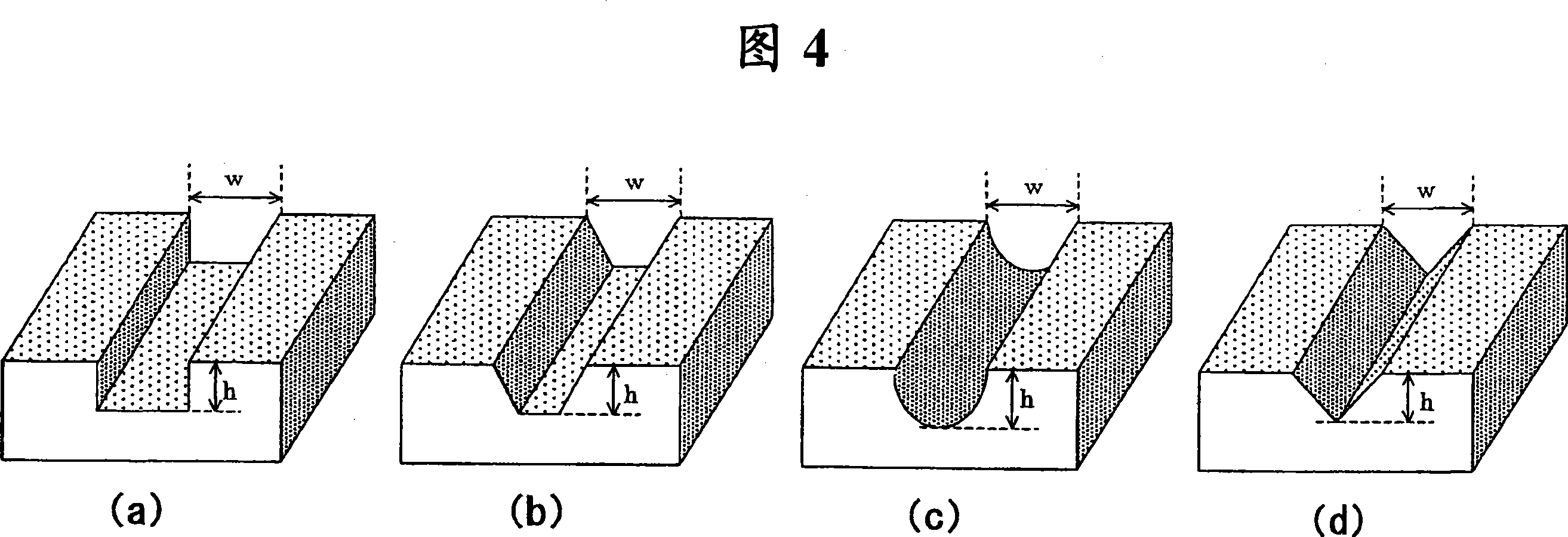

Adhesive sheet and release member

ActiveCN1973011AGood lookingAdhesive enoughThin material handlingPressure sensitive film/foil adhesivesEngineeringSheet material

An adhesive sheet formed by providing an adhesive agent layer on one surface of a resin film, where the resin film shrinks less even the sheet is stored for a long time with a release member attached to it. The adhesive sheet has a resin film and an adhesive agent layer adhered to one surface of the resin film. The adhesive agent layer has one or more grooves in the surface on the other side that adheres to the resin film. The grooves are present only on the inner side of the surface on the other side and do not penetrate up to the side surfaces of the adhesive agent layer. Also provided is a release member for an adhesive sheet, and the surface of the release member is embossed and has excellent smoothness.

Owner:RIKEN TECHNOS CORP

Solidified composition forming as protective membrane, forming method of the membrance and the membrane

InactiveCN1414048AImprove flatnessExcellent surface hardnessSemiconductor/solid-state device detailsEpoxy resin coatingsEpoxyTectorial membrane

The invention provides a curable composition for forming a protective film, the protective film and a method for forming the protective film. This curable composition comprises a copolymer of an unsaturated carboxylic acid and / or an unsaturated carboxylic acid anhydride, an epoxy group-containing unsaturated compound and an olefinically unsaturated compound other than the monomers, an epoxy resin other than the component and a compound capable of producing an acid with heat or radiations. The method for forming the protective film comprises coating the top surface of the resin substrate with the curable composition and then carrying out heat and / or light treatment. The treatment is carried out at a temperature without exceeding 180[deg.]C.

Owner:JSR CORPORATIOON

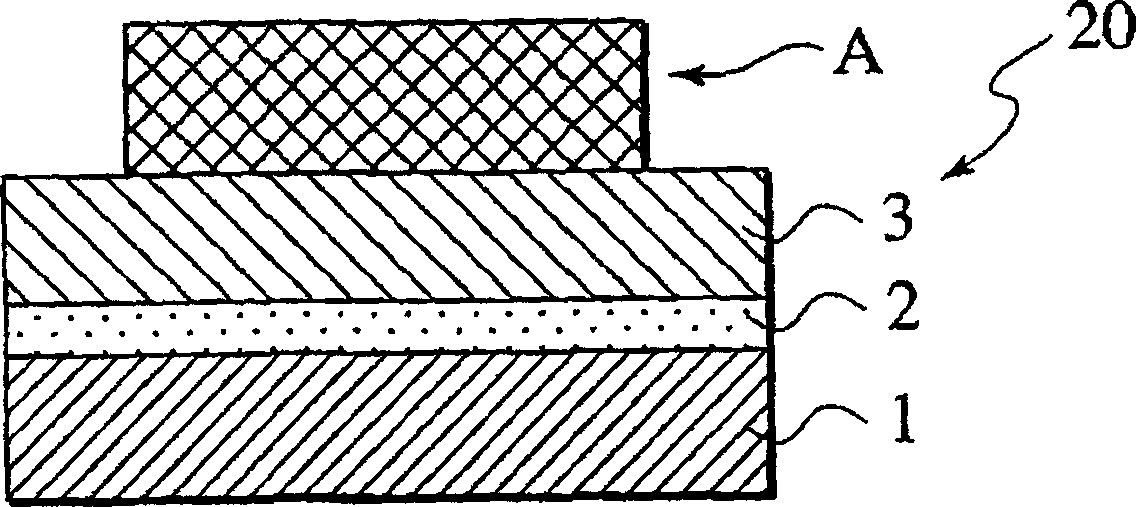

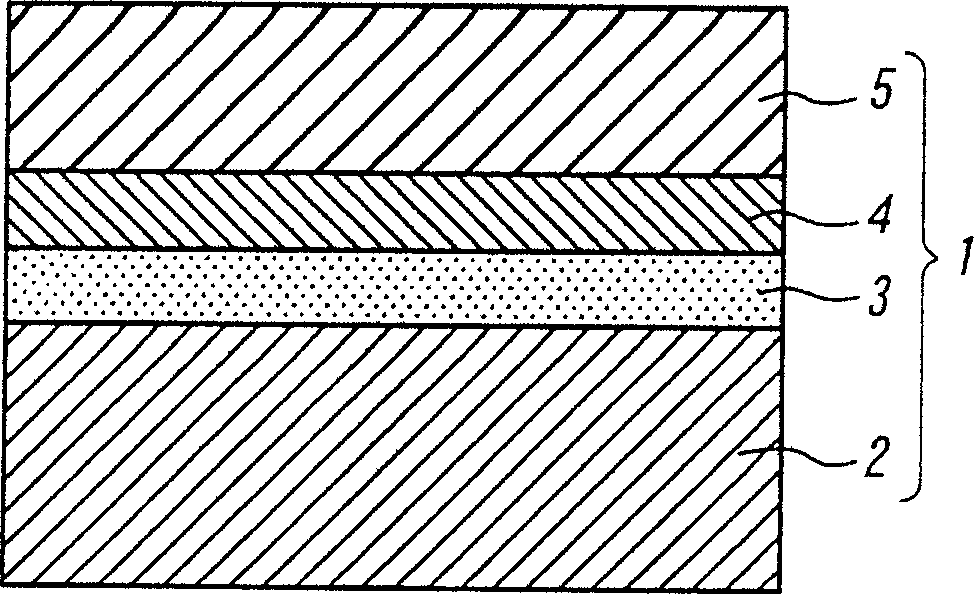

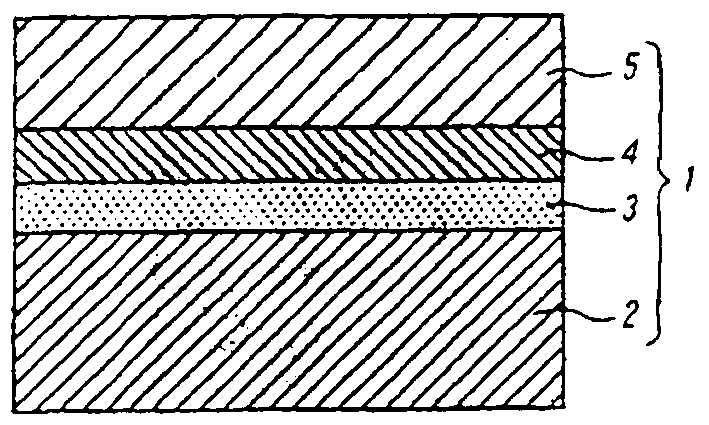

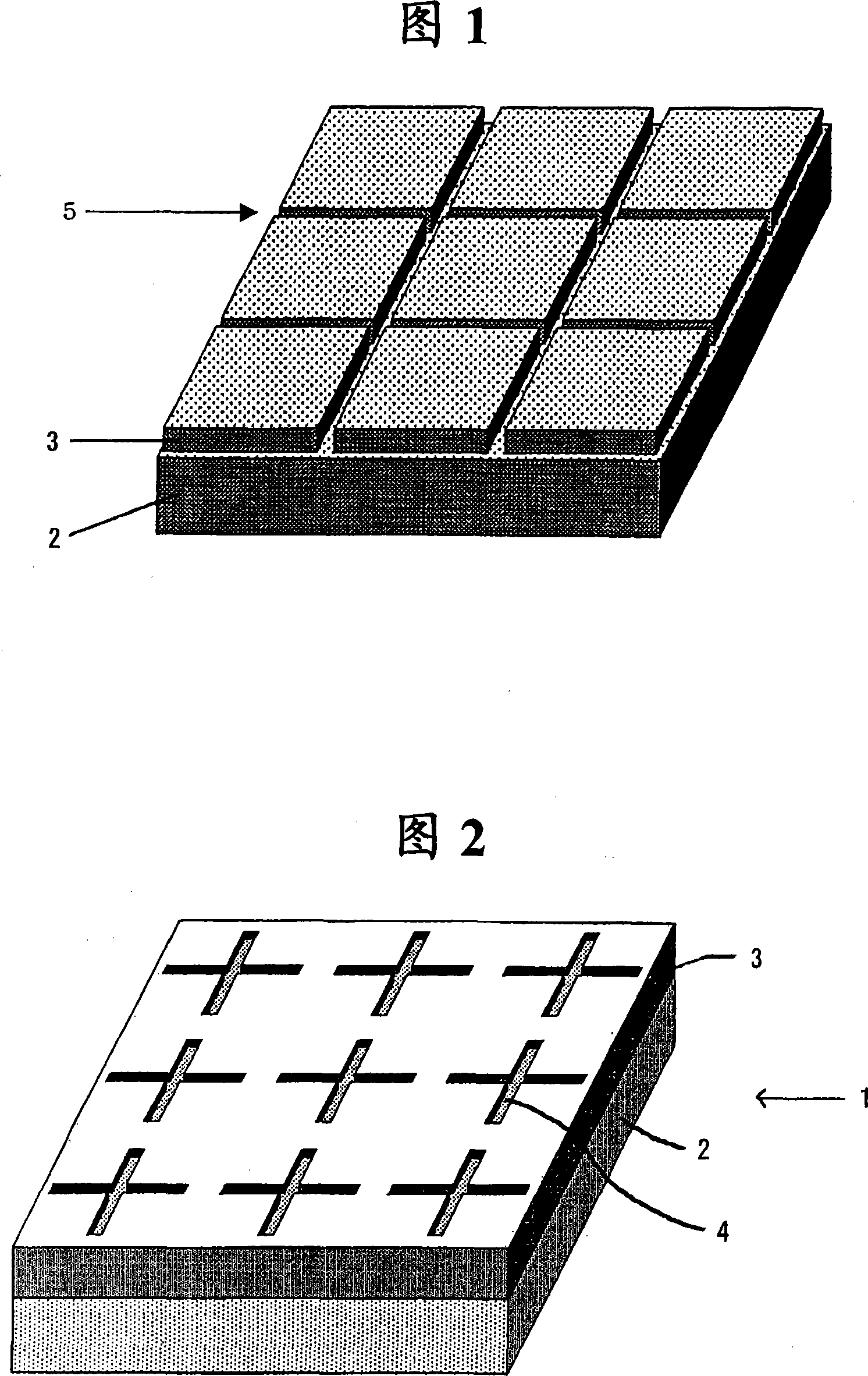

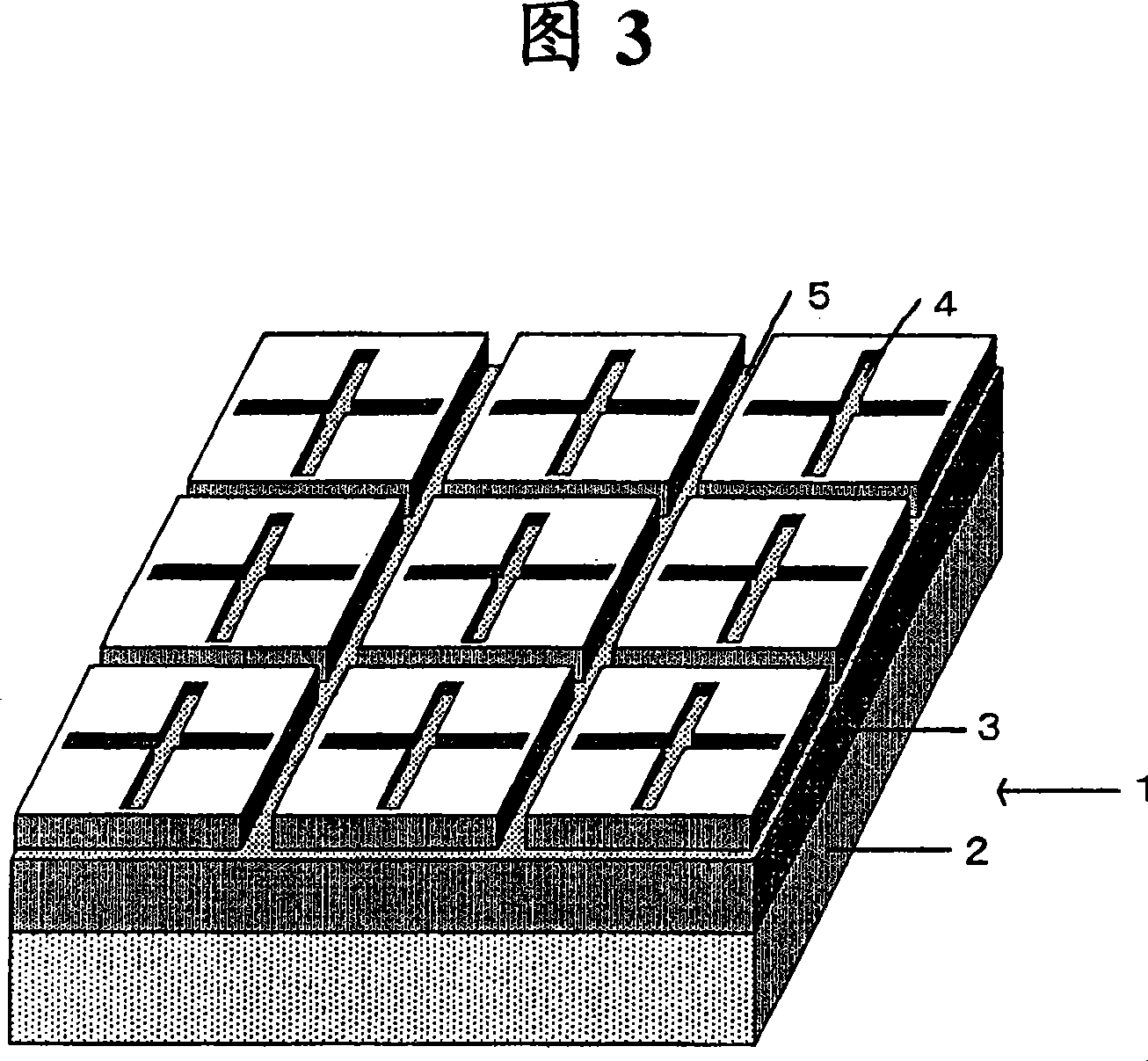

Pressure sensitive adhesive sheet and process for producing the same

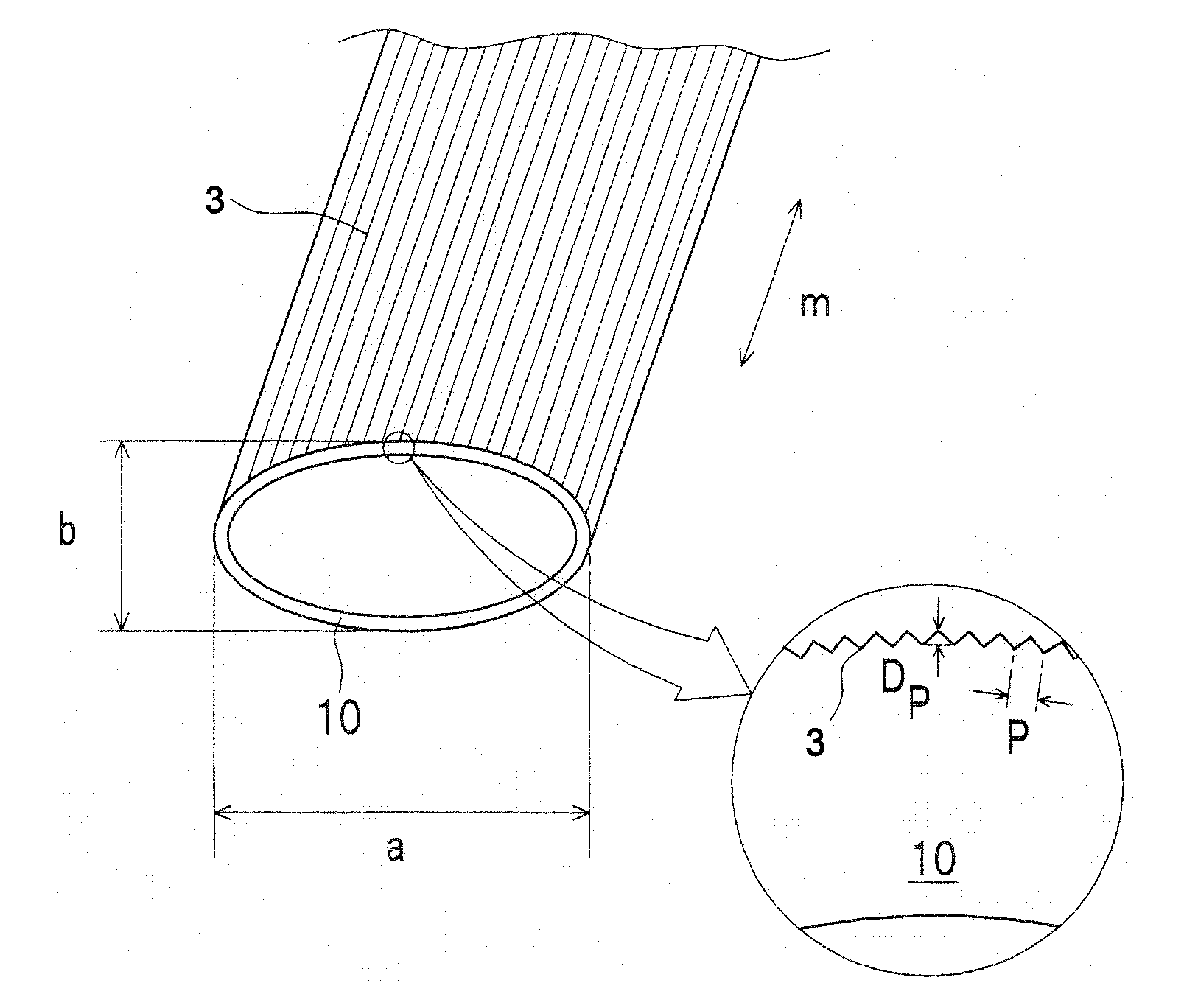

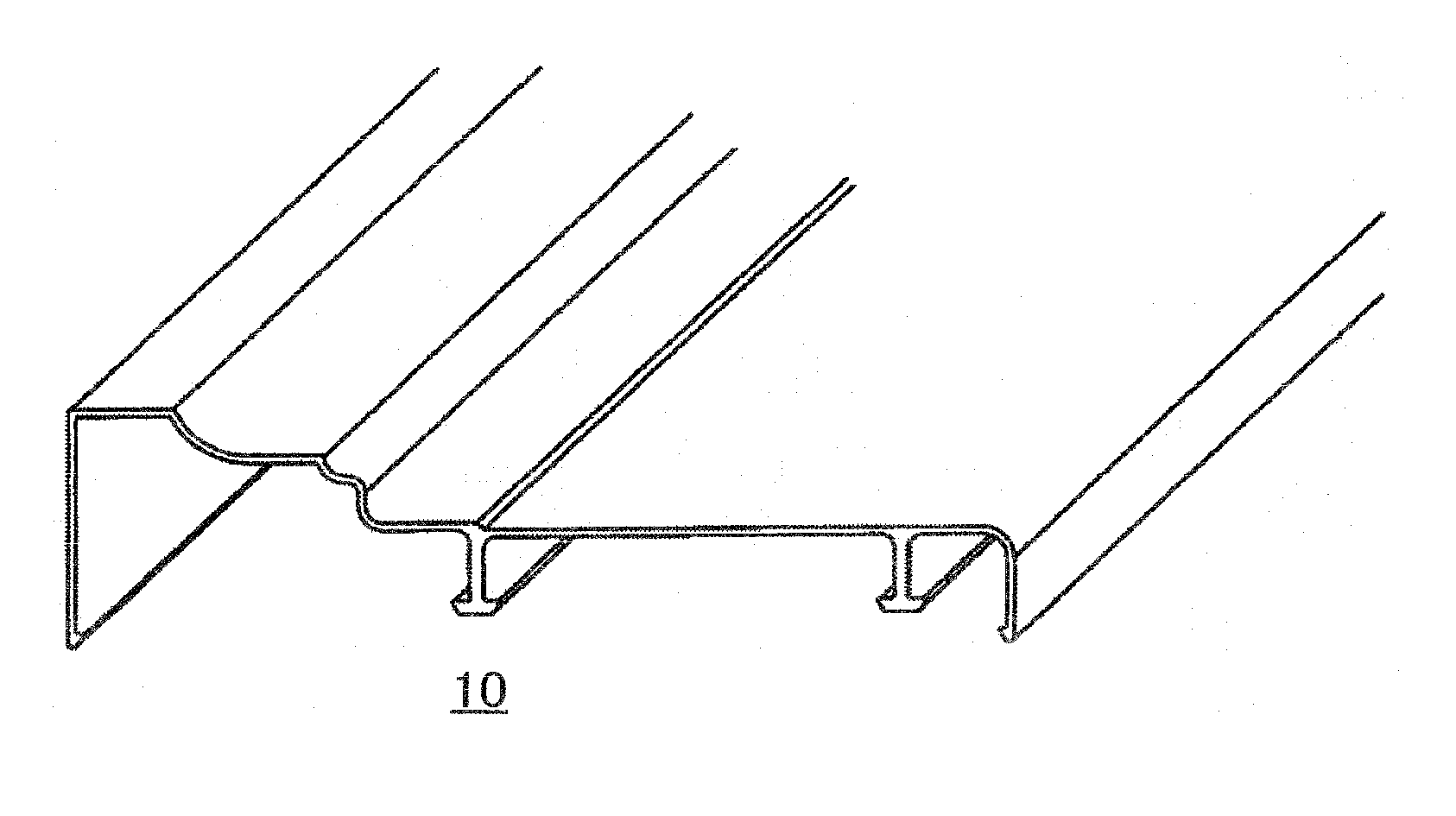

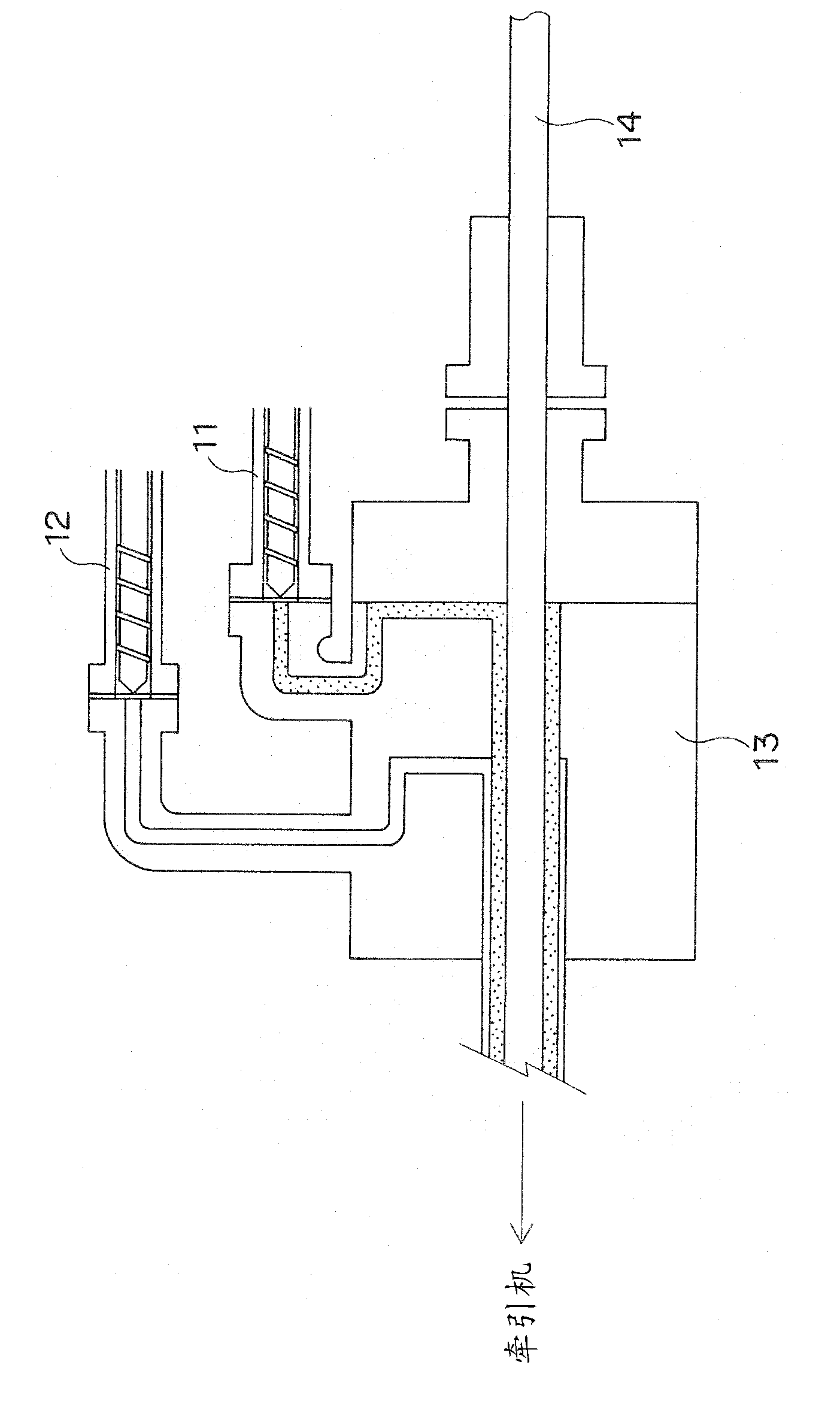

InactiveCN1886478ADoes not damage the appearanceAdhesive enoughAdhesive processes using foamed adhesivesThin material handlingEngineeringPressure sensitive

A substrate 2 having provided in a pressure-sensitive adhesive layer 3 side thereof recesses 21 that continue as far as side edges of the substrate 2, and a pressure-sensitive adhesive layer 3 in which are formed a plurality of penetrating passages 31 that penetrate through the pressure-sensitive adhesive layer 3 in a thickness direction are laminated together such that the recesses 21 in the substrate 2 and the penetrating passages 31 in the pressure-sensitive adhesive layer 3 communicate with one another, thus obtaining a pressure-sensitive adhesive sheet 1. According to this pressure-sensitive adhesive sheet 1, air entrapment and blistering can be prevented or eliminated while securing adequate adhesive strength and with no marring of the appearance of the pressure-sensitive adhesive sheet.

Owner:LINTEC CORP

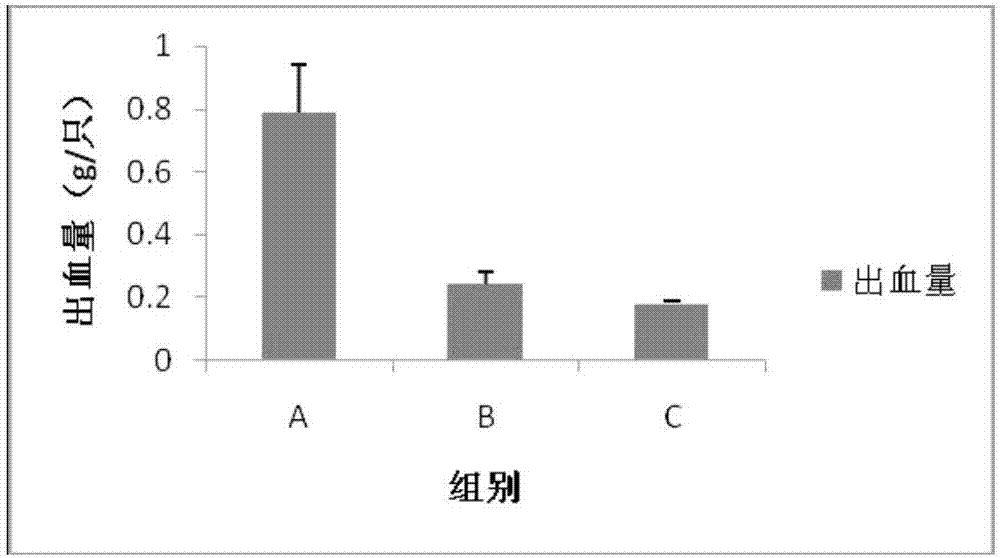

Microfiber collagen hemostatic material and preparation method thereof

ActiveCN107137758ASufficient tensile strengthGood hemostatic effectSurgical adhesivesHeatFibrosisRadiation Sterilization

The invention relates to a microfiber collagen hemostatic material and a preparation method thereof. The preparation method of the material includes the first step of sodium sulfide unhairing, the second step of shredding and fibrosis, the third step of swelling control, the fourth step of drying, the fifth step of depolymerisation and fluffing, and the sixth step of Co60 radiation sterilization, wherein in the fifth step, the obtained fasciculus is treated using a hammer mill to obtain a microfiber collagen product. According to the method, the use concentration of sodium sulphide is reduced, the efficiency of unhairing is improved, and degreasing and impure protein removal are effectively conducted; collagen materials are not oxidized and degenerated, the activity of microfiber collagen is easy to maintain, and the hemostatic effect is improved. Acid is introduced in the treating process, the degreasing and protein removal are more effective, and the adhesion property of the hemostatic material is guaranteed.

Owner:林贵梅

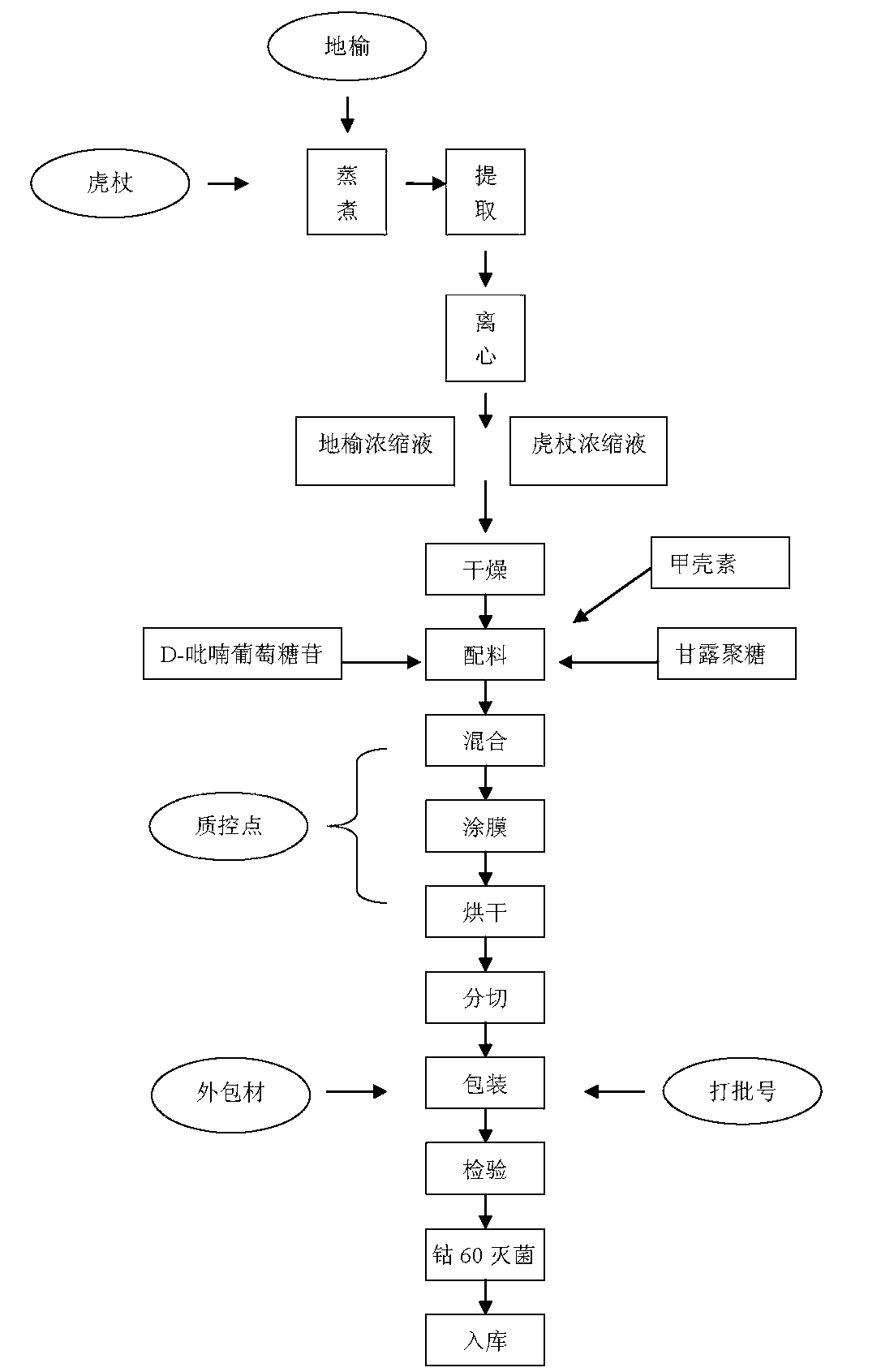

Polymer dressing and dressing patch

ActiveCN103007337ABlood compatibleHistocompatibilityAbsorbent padsBandagesSanguisorba officinalis RootBULK ACTIVE INGREDIENT

The invention relates to a polymer dressing and dressing patch. The dressing patch comprises a base cloth on which glue and the dressing are coated and release paper covering the glue and dressing. The dressing is prepared by mixing the following active ingredients by weight percent: 24-30% of sanguisorba officinalis root extracts, 20-27% of polygonum cuspidatum extracts, 18-25% of chitin, 12-18% of D-glucopyranoside and 10-15% of mannan. The dressing and the dressing patch can stop bleeding quickly, prevent infections, promote wound healing, reduce pains of patients, shorten the rehabilitative periods of patients and avoid pathogen harms and nerve fiber lesions.

Owner:JIAHENG MEDICAL SUPPLY JIANGSU

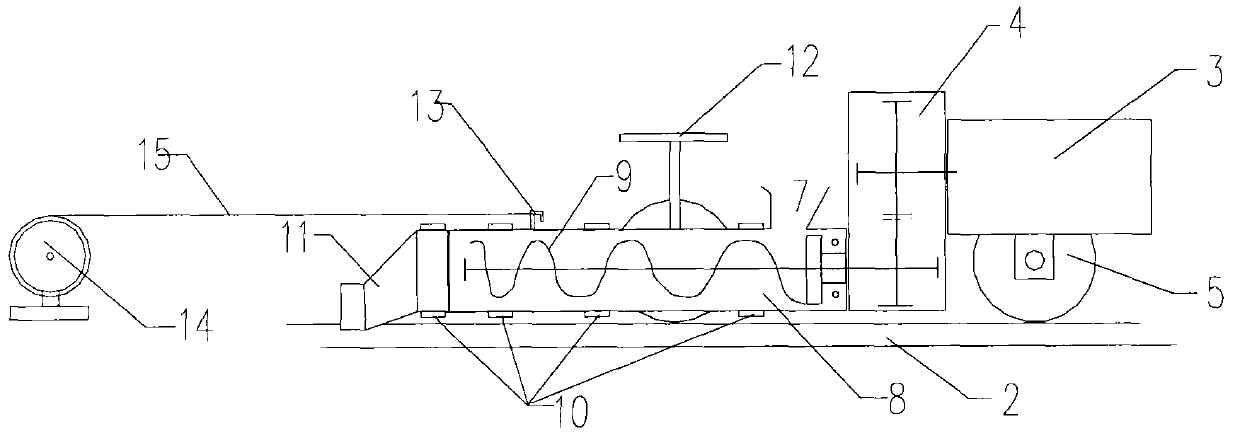

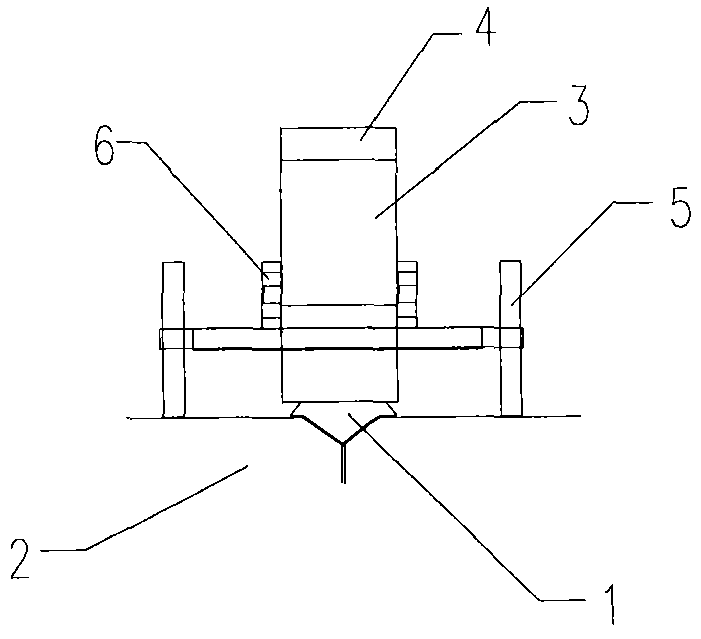

Flexible filler embedder and concrete panel seaming method

InactiveCN101029481AGuaranteed freedom of movementHigh-precision travel across the seamEarth-fill damsRock-fill damsShape controlSpeed regulator

A stuffing machine for filling concrete plate along stone dyke is composed by machine body and two wheels on body's two sides. The body includes a motor, which is connected through a speed regulator to screw extruder in a hopper, at least one heater along the material moving line, a mode head at the hopper outlet for shape control of extruded material.

Owner:张明军

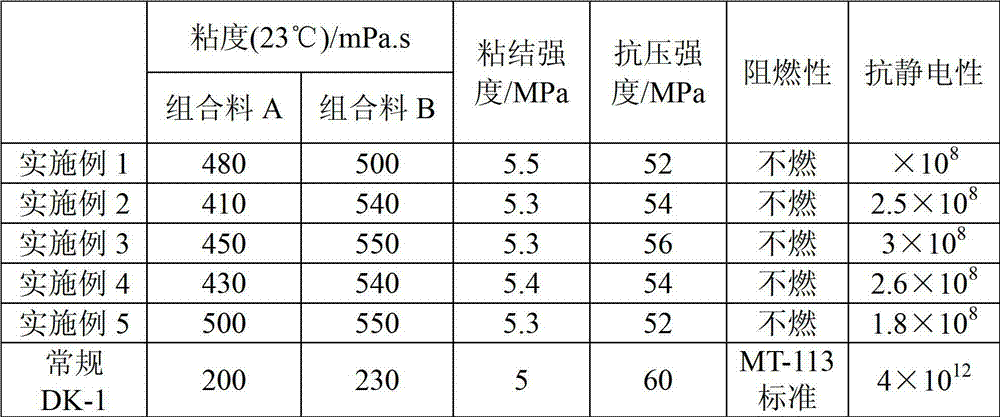

Raw material composition of modified polyurethane material, and preparation method and application thereof

InactiveCN103172815AImprove adhesionAdhesive enoughPolyureas/polyurethane adhesivesDrilling compositionPolymer scienceEthylene oxide

The invention discloses a raw material composition of modified polyurethane material, and a preparation method and application thereof. The raw material composition comprises a component A and a component B, wherein A and B do not exist in the same component; the component A comprises 19-39% of polyoxypropylene polyalcohol, 60-80% of epoxyethane modified silicone polymer and 1% of metal catalyst; and the component B comprises 9.99999-19.99999% of polyether glycol, 80-90% of polyisocyanate and 0.00001% of storage stabilizer. The preparation method comprises the following steps: component A: mixing the polyether glycol, modifier and catalyst, stirring at 15-40 DEG C for 3-4 hours at the rate of 100-120 rpm; and component B: heating the polyether glycol to 80-100 DEG C, stirring, dehydrating and degassing in vacuum until the water content is less than 0.05%, cooling to 10-40 DEG C, adding the polyisocyanate, reacting at 80-85 DEG C for 2-3 hours, cooling to 10-40 DEG C, adding the storage stabilizer, and uniformly stirring. The raw material composition has the advantages of low reaction temperature, incombustibility, high reaction speed, favorable flowability and the like.

Owner:SHANGHAI DONGDA CHEM

Silicone-acrylate low surface energy ocean anti-fouling paint and preparation method thereof

InactiveCN101250378AImprove economyImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesEngineeringSolvent

The invention relates to a silicone-acrylic low surface energy marine anti-fouling paint and the process for preparation, which relates to a marine anti-fouling paint. The invention provides a silicone-acrylic low surface energy marine anti-fouling paint with lower surface energy which can keep environmental protection property, economy and excellent dust-proof effect, can be permanently used, and utilizes a novel multi-component silicone-acrylic block polymer to be base material and the process for preparation. The silicone-acrylic low surface energy marine anti-fouling paint is remixed by base material, pigments, additives and paint solvent, wherein the base material is dimethyl silicone polymer-b-polymethyl methacryate-b-poly butyl methacrylate ternary silicone-acrylic block copolymer, and the additive is methyl silicone oil and di-n-octyl phthalate. Methyl silicone oil and di-n-octyl phthalate are mixed to get coating auxiliary A, dimethyl silicone polymer-b-polymethyl methacryate-b-poly butyl methacrylate ternary silicone-acrylic block copolymer and pigments are mixed to get a mixture B, the coating auxiliary A is added in the mixture B to get a mixture C, and the mixture C is dissolved in solvent solvent to get a mixture D, and products are got after stewing.

Owner:XIAMEN UNIV

Thermosensitive adhesive material

InactiveCN101343519AExcellent blocking resistanceAdhesive enoughNitrile polymer adhesivesEster polymer adhesivesVitrificationAcrylonitrile

An object of the present invention is to provide a thermosensitive adhesive material which is superior in blocking resistance when not active and which has adequate adhesion in a wide temperature range to a target with little smoothness such as corrugated fiberboard. Specifically, the present invention relates to a thermosensitive adhesive material including a support, and a thermosensitive adhesive layer provided on one surface of the support, the thermosensitive adhesive layer containing as essential components a thermoplastic resin and a hot-melt material that melts when heated, wherein the thermoplastic resin contains as a main component a (meth)acrylic copolymer in which acrylonitrile, a monomer component, occupies 5% by mass to 20% by mass of all monomer components, and wherein the glass transition temperature of the copolymer is in the range of -70 DEG C. to -30 DEG C.

Owner:RICOH KK

Adhesive based on non-polar polyolefin resin

ActiveCN106905892ASufficient service lifeImprove adhesionHydrocarbon polymer adhesivesGraft polymer adhesivesElastomerPolyolefin

The invention aims to provide an adhesive which does not contain active ingredients (for example, EVA), and is high in stability, relatively long in service life and relatively great in binding force. The adhesive provided by the invention contains polyolefin-serial resin, a polystyrene-serial compound and acid modified polyethylene; the polyolefin-serial resin comprises more than any one of high density polyethylene, medium density polyethylene, low density polyethylene, linear low density polyethylene, a polyolefin elastomer and polypropylene; and the adhesive does not contain an ethylene-vinyl acetate copolymer. The adhesive provided by the invention has the beneficial effects of preventing use of necessary active ingredients (EVA) in a previous adhesive while keeping a sufficient binding force, so that the adhesive has a good binding property, an enough service life and excellent stability.

Owner:XIAMEN NEIJIA LAKE NEW MATERIAL TECH CO LTD

Photosensitive acrylic AED resin and negative photoresist composition comprising same, and preparation method thereof

InactiveCN103819616AUniform thicknessTightly boundPhotosensitive materials for photomechanical apparatusIonResist

The invention discloses a negative photoresist composition which is prepared by an anodic electrodeposition process. The photoresist composition mainly contains deionized water, (A) a photosensitive acrylic AED (Anodic Electrodeposition) base material, (B) a polyfunctional reactive diluent, (C) antalkali, (D) a photo-initiation body and (E) a water-based colour paste. A photoresist has high degree of automation through an AED method, and a film layer is thin and compact, has uniform thickness, and is tightly combined with the surface of an electrode. The photoresist can have enough and strong adhesive force on a filament during refining, the reliability during development and etching can be increased, and VOC emission is reduced to a great extent. The photoresist material can be applied to the fields of etching-resisting imaging printing ink, color filters of liquid crystal displays and the like.

Owner:JIANGYIN MORE CHEM NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com