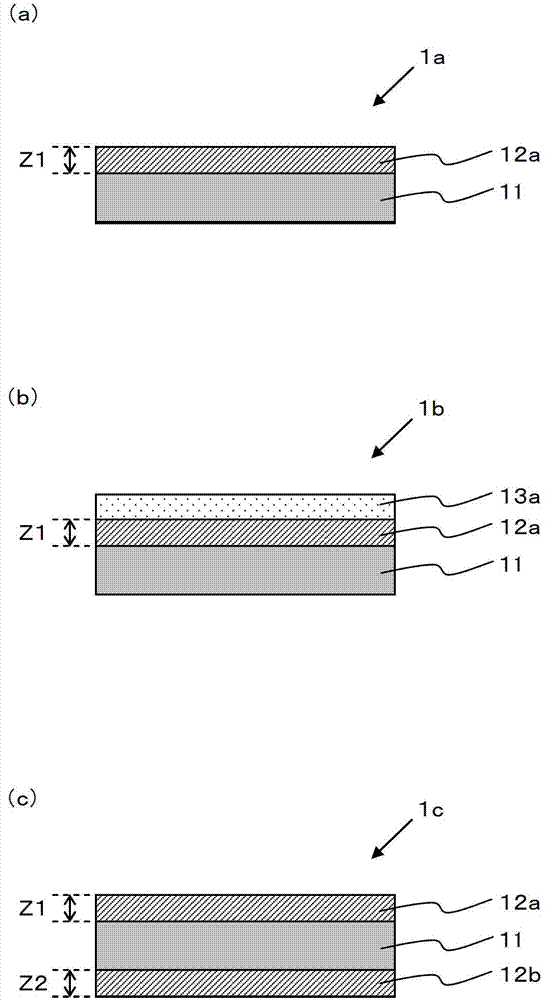

Flame retardant adhering sheet

An adhesive sheet, flame retardant technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as harmful human environment, and achieve excellent flame retardancy and adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

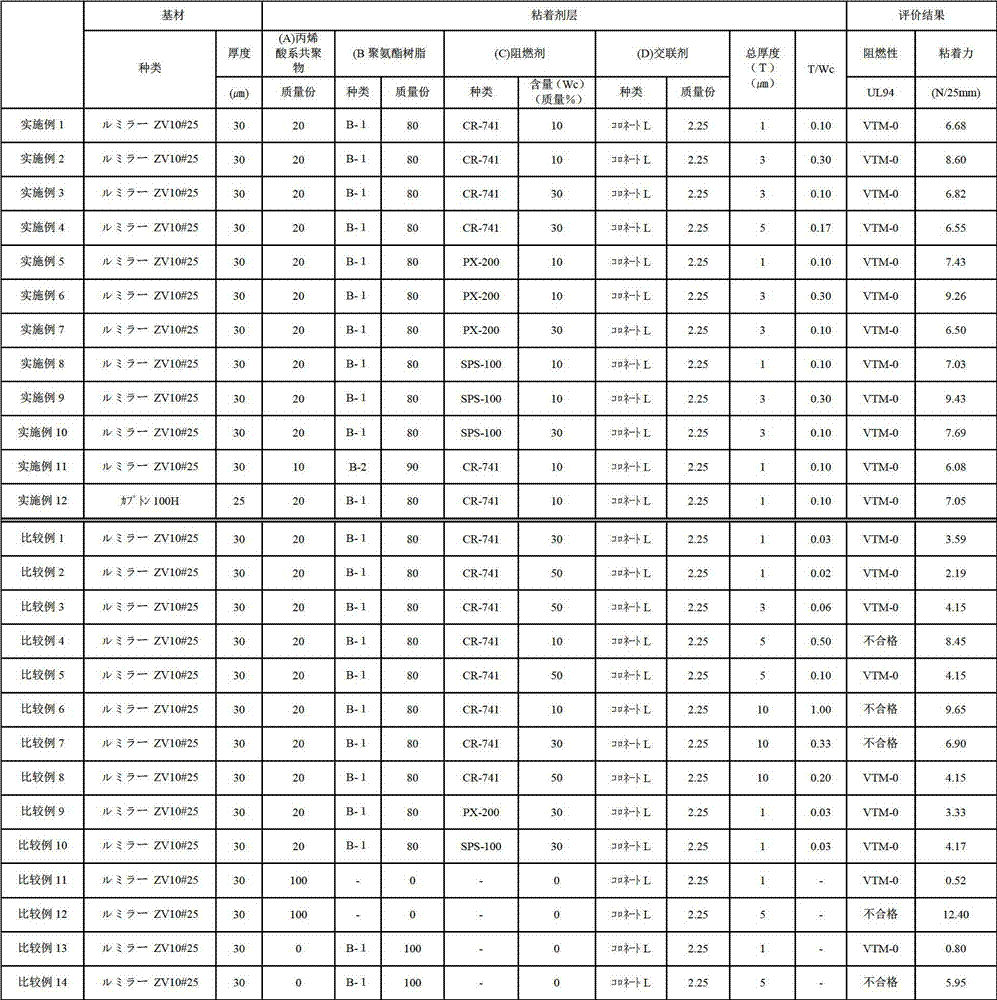

Examples

Embodiment

[0176] The weight average molecular weight (Mw) shown in the description of the following examples is the value calculated|required in standard polystyrene conversion by measuring using Tosoh Corporation "HLC-8020" under the following conditions.

[0177] (measurement conditions)

[0178] Column: "TSK gel GMHXL (×2)" "TSK gel G2000HXL" (both manufactured by Tosoh Corporation)

[0179] Column temperature: 40°C

[0180] Developing solvent: tetrahydrofuran

[0181] Flow rate: 1.0mL / min

[0182] Detector: Differential refractometer

manufacture example 1

[0184] (Preparation of Acrylic Copolymer Solution)

[0185] 90 parts by mass of butyl acrylate and 10 parts by mass of acrylic acid as monomer components, 200 parts by mass of ethyl acetate as a solvent, and 0.2 parts by mass of azobisisobutyronitrile as a polymerization initiator were added to the reactor and mixed. After degassing with nitrogen for 4 hours, gradually raising the temperature to 60° C., and stirring for 24 hours, polymerization reaction was carried out to obtain an ethyl acetate solution (solid content concentration: 33% by mass) containing an acrylic copolymer having a weight average molecular weight of 650,000.

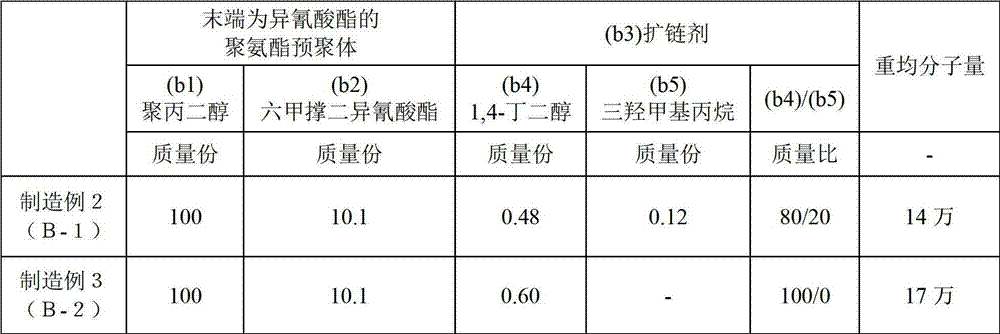

manufacture example 2

[0187] (Preparation of polyurethane resin solution (B-1))

[0188] 100 parts by mass of polypropylene glycol (weight average molecular weight: 2000) as polyol b1, 10.1 parts by mass of hexamethylene diisocyanate (NCO group / OH group (molar ratio) = 1.2) as b2 polyvalent isocyanate compound, dibutyltin dilaurate 0.01 parts by mass were mixed as a catalyst, and the temperature was gradually raised to 85° C., followed by stirring for 2 hours to obtain a polyurethane prepolymer having an isocyanate terminal.

[0189] After adding 110 parts by mass of toluene to the obtained isocyanate-terminated polyurethane prepolymer and cooling to room temperature, 0.48 parts by mass of 1,4-butanediol (b4) and 0.12 parts by mass of trimethylolpropane (b5) were added dropwise As the chain extender b3, after slowly raising the temperature to 70° C., stirring was performed for 2 hours to obtain a toluene solution of a polyurethane resin having a weight average molecular weight of 140,000 (B-1; soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com